Cooking device

A technology for cooking equipment and cooking chambers, which is applied to kitchen utensils, household utensils, roasters/barbecue grids, etc., and can solve problems such as obstructing air flow and energy waste, and achieve the degree of increased flow speed, fast flow speed, and cooked food uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

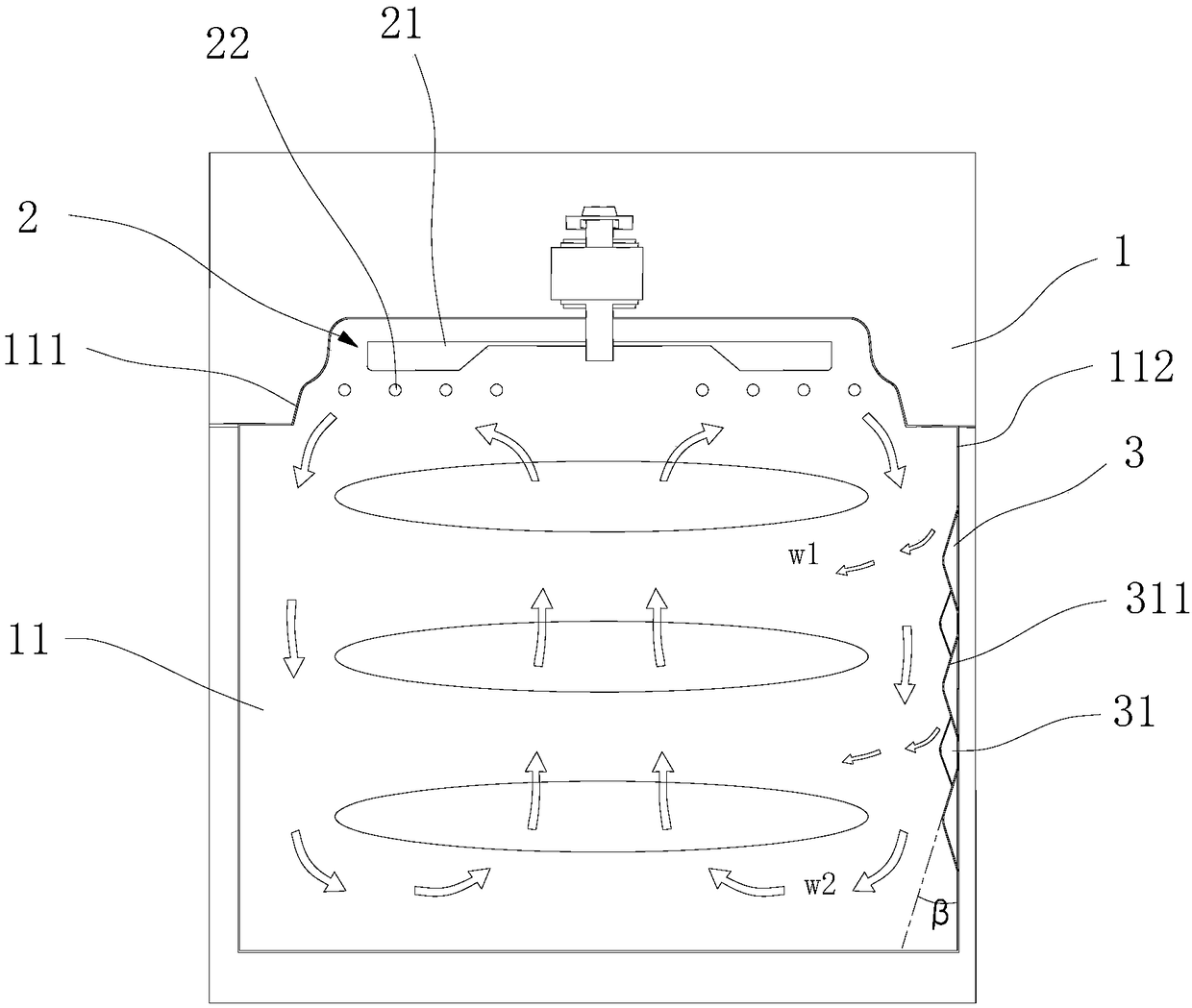

[0046] This embodiment provides a cooking device, such as figure 1 As shown, it includes a housing 1, a hot air flow generating device 2 and an air flow guiding device 3.

[0047] Wherein, a food cooking chamber 11 is provided inside the housing 1, and a hot air flow generating device 2 is provided inside the top of the food cooking chamber 11, and specifically includes a blowing device 21 and a heating device 22, wherein the blowing device 21 is used to generate flow The heating device 22 heats the airflow generated by the blowing device 21 to form a heating airflow. The food cooking chamber 11 has an air blowing hood 111, which is completely covered on the upper and outer sides of the air blowing device 21 and the heating device 22, wherein the heating airflow rotates and flows downward along the inside of the air blowing hood.

[0048] The food cooking chamber 11 has side walls 112, and one of the side walls 112 is provided with an airflow guide device 3 to force a portion (a sm...

Embodiment 2

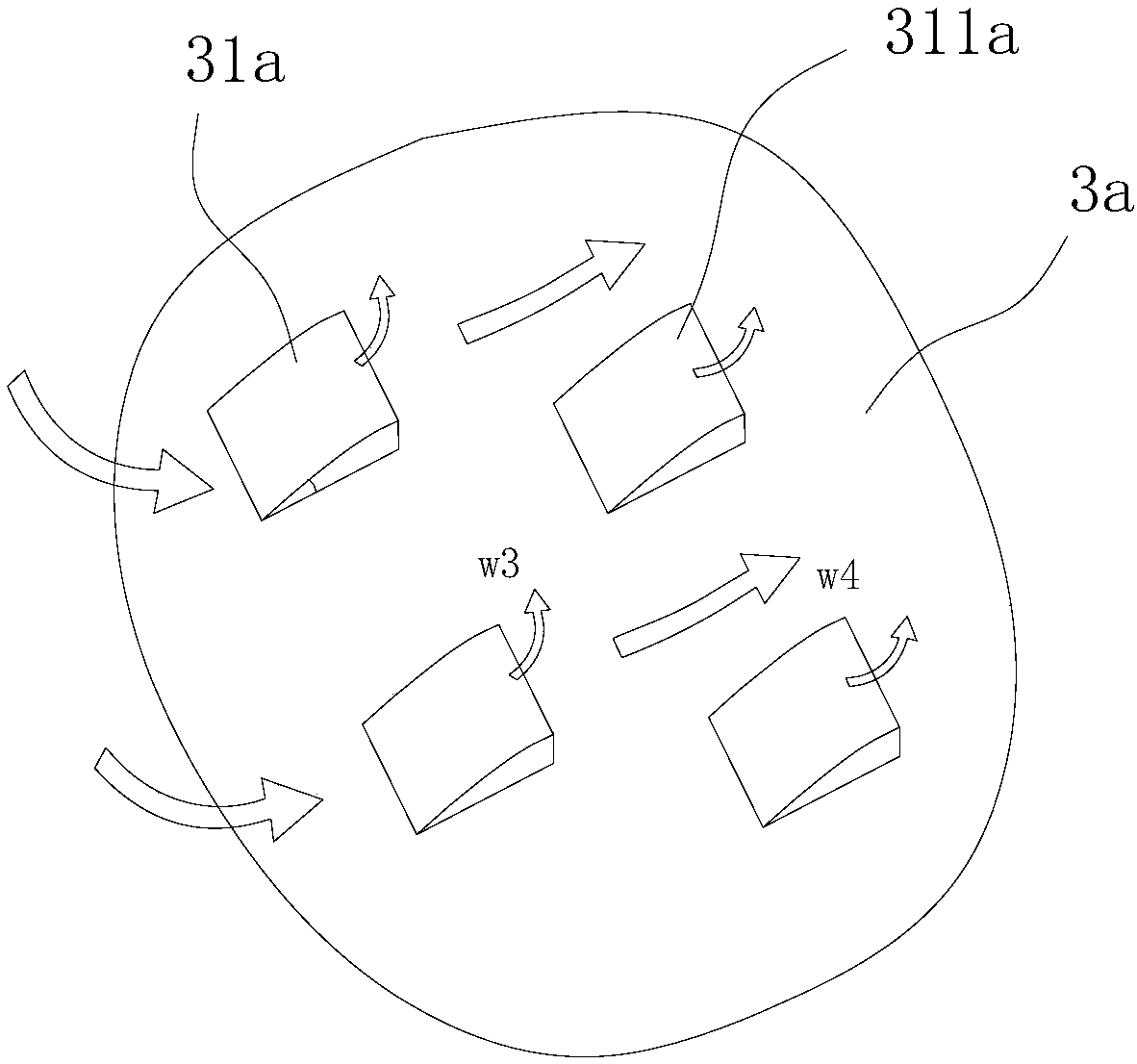

[0050] The difference between this embodiment and embodiment 1 lies in figure 2 As shown, the air guide device 3a in this embodiment has a plurality of guide portions 31a, the guide portion 31a has a guide surface 311a along the heating airflow into the guide portion 31a, the guide surface 311a is a curved surface, and a part (a small amount) of the heating airflow passes through After the guide surface, it rebounds along the guide surface 311a to form an auxiliary heating air flow w3 directly to the food surface, and part of the (main) heating air flow w4 continues to circulate along the original direction.

Embodiment 3

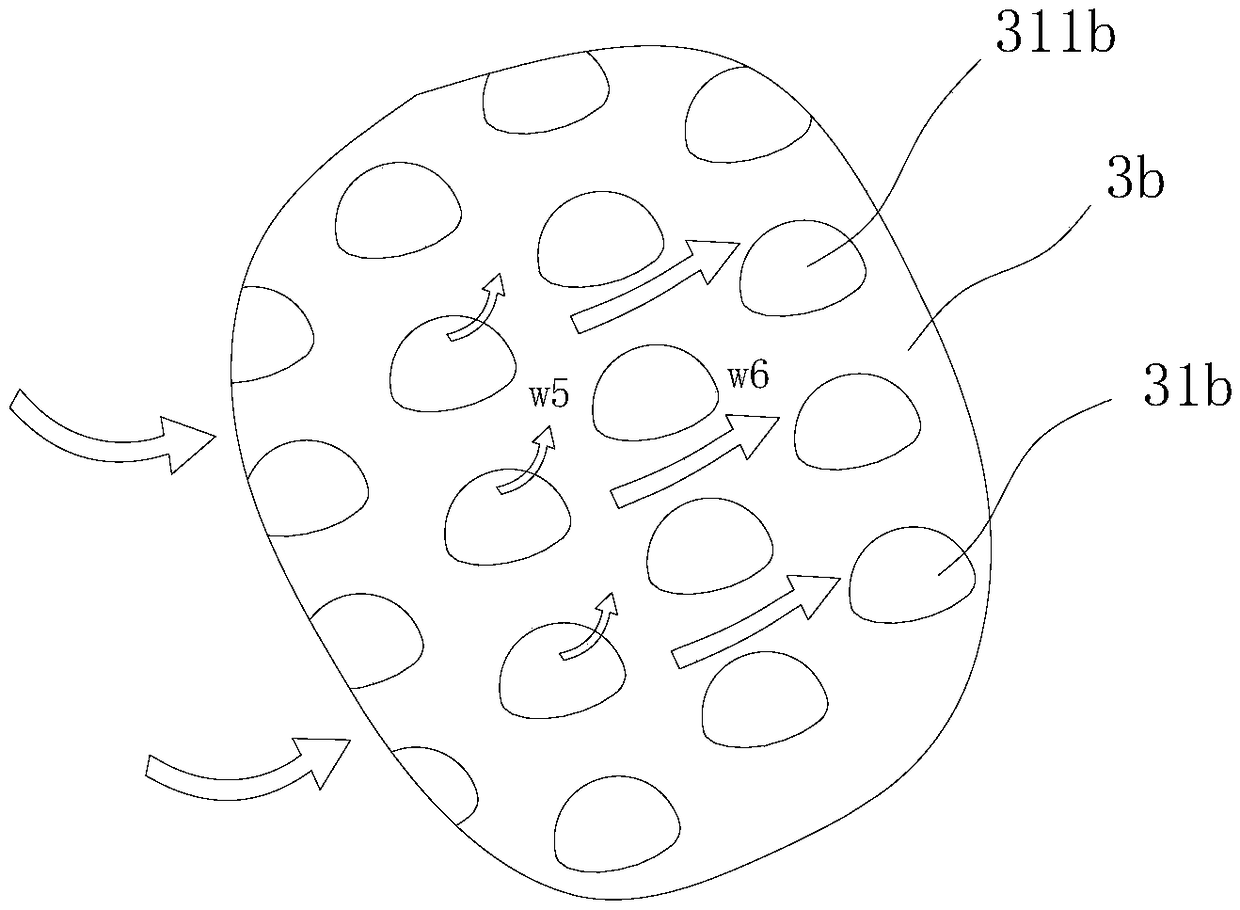

[0052] The difference between this embodiment and embodiment 1 lies in image 3 As shown, the airflow guide device 3b in this embodiment includes a plurality of spherical guide portions 31b. The guide surface 311b of the guide portion 31b is a spherical surface structure protruding along the inner side wall of the food cooking chamber, and partially (a small amount) is heated After the air flow passes through the guide surface 311b, it bounces back along the guide surface 311b to form an auxiliary heating air flow w5 directly to the food surface, and part of the (main) heating air flow w6 continues to circulate along the original direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com