household automatic oil press

An oil press, automatic technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems that the oil press is difficult to clean, the degree of automation is not high, and it is difficult to clean.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

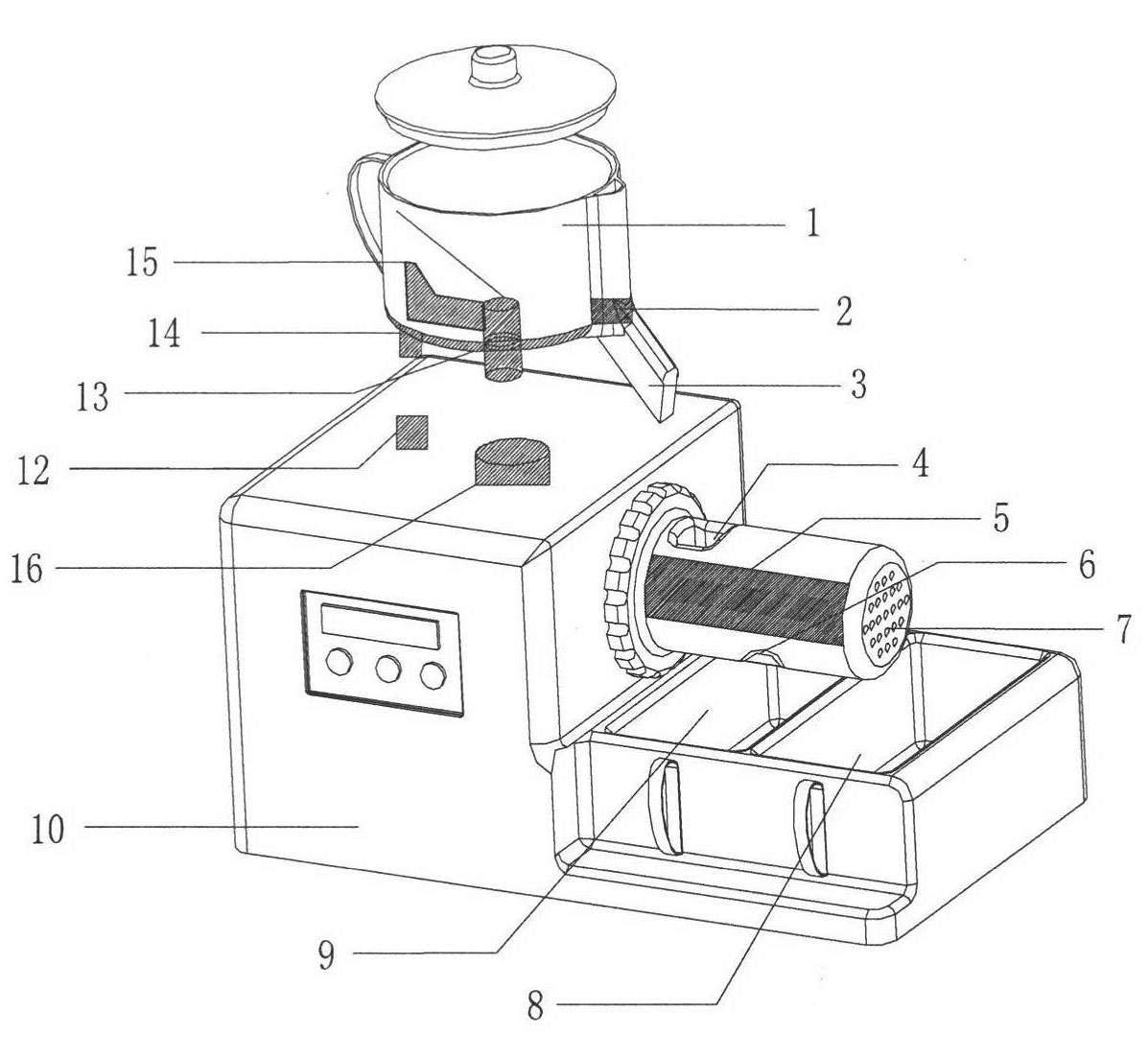

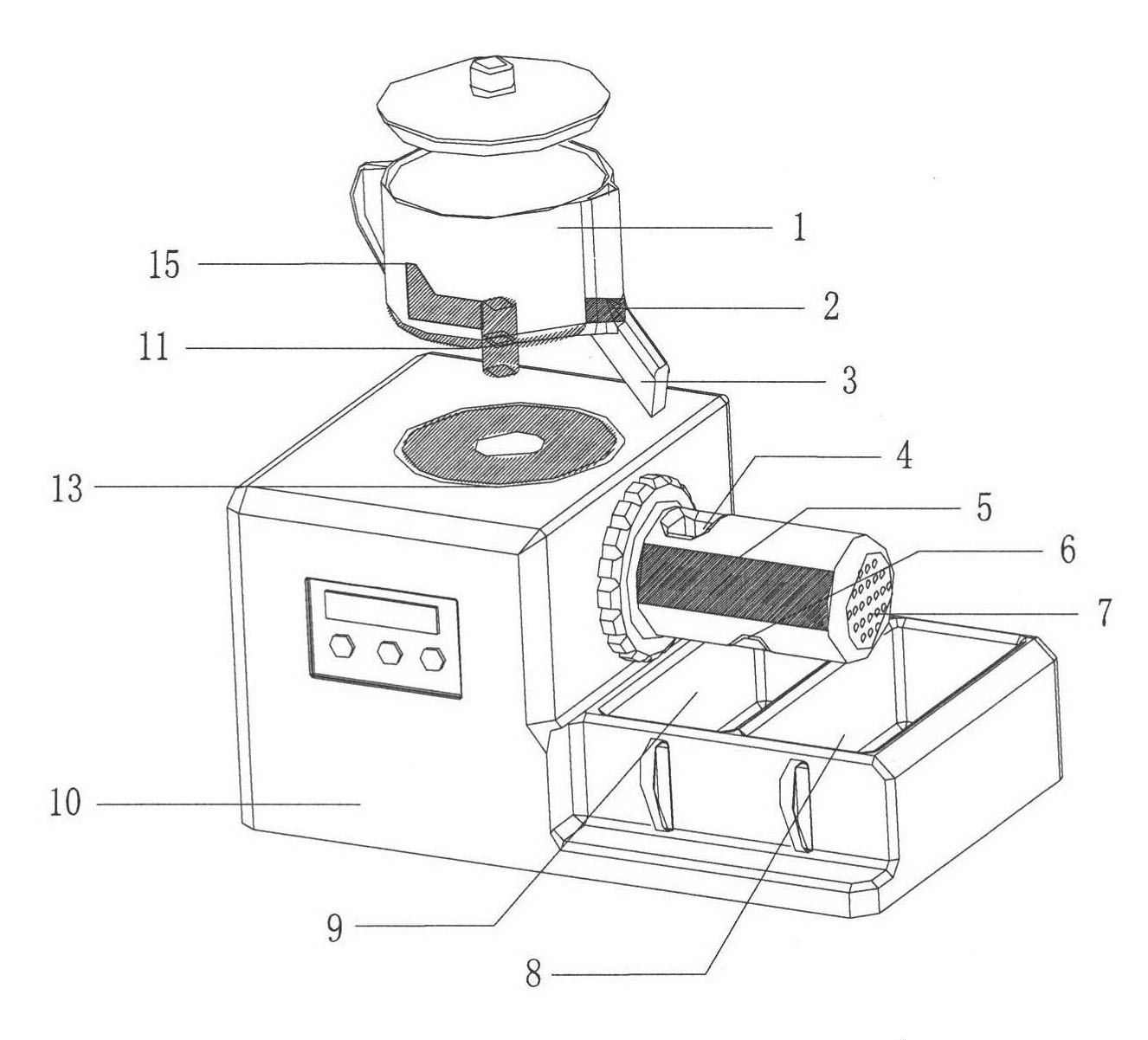

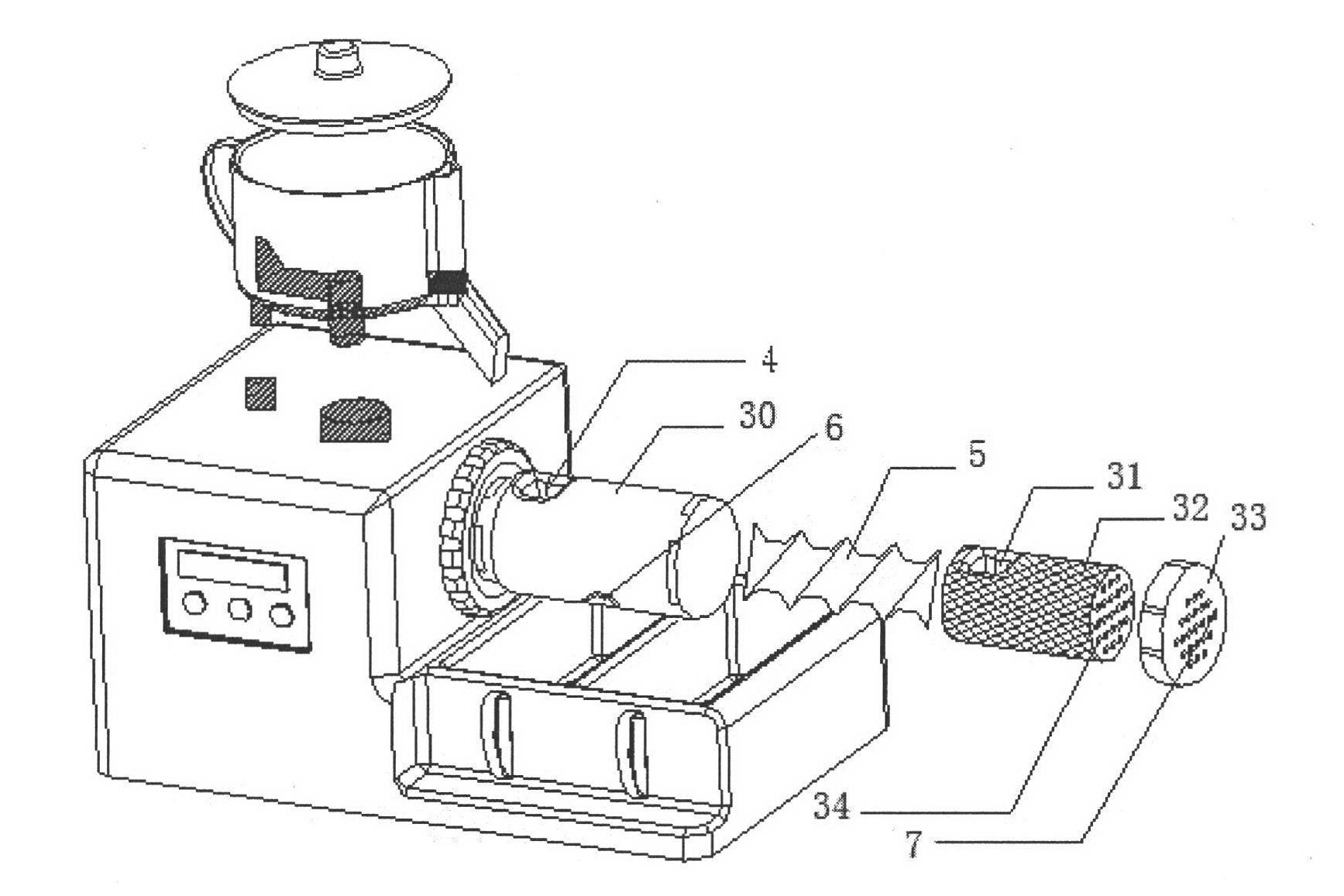

[0021] Examples of household automatic oil presses are figure 1 , including a machine base 10, a heating element, a feeding cup 1, an oil pressing assembly and a collection tank; the feeding cup 1 and the machine base 10 have a detachable joint structure, and there is an electric heating plate 13 at the bottom of the feeding cup 1; there is a plug 14 on the electric heating plate 13, There is a socket 12 on the machine base 10. When the feeding cup 1 is connected with the machine base 10, the plug 14 is combined with the socket 12; the feeding cup 1 is also provided with a stirring knife 15 on its inner base, and the central axis of the stirring knife 15 extends to the feeding Outside the cup 1, the motor 16 that drives the mixing knife 15 is placed on the machine base 10. When the feeding cup 1 is connected to the machine base 10, the central axis of the mixing knife 15 is connected to the motor 16; there is a discharge port 3 at the bottom of the feeding cup 1. There is a so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com