Combustion furnace based on liquid ethanol-natural gas composite fuel and method thereof

A combustion furnace and natural gas technology, which is applied to the combustion of liquid fuel and gaseous fuel, the combustion of block fuel and liquid fuel, the combustion of liquid fuel and powder fuel, etc. Emission, inability to adapt to liquid ethanol fuel, high working temperature and other problems, to achieve the effect of simple structure, uniform heating and sufficient heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

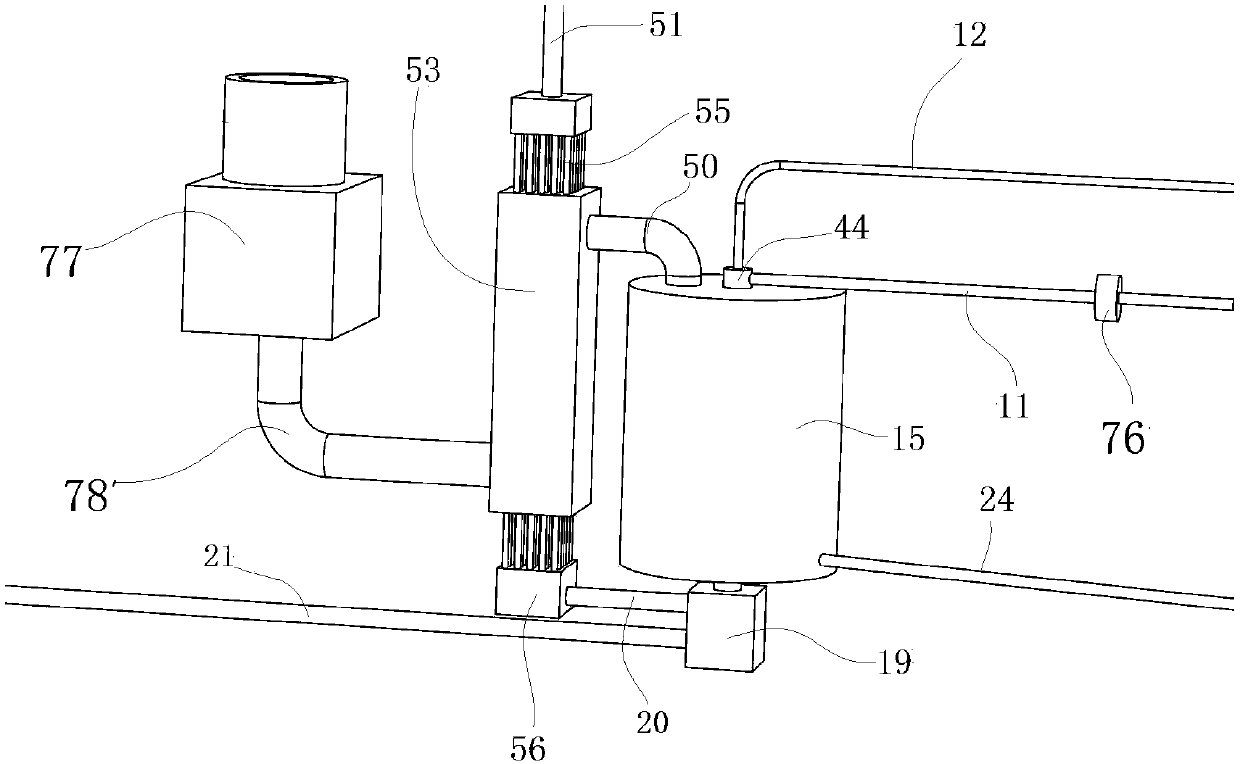

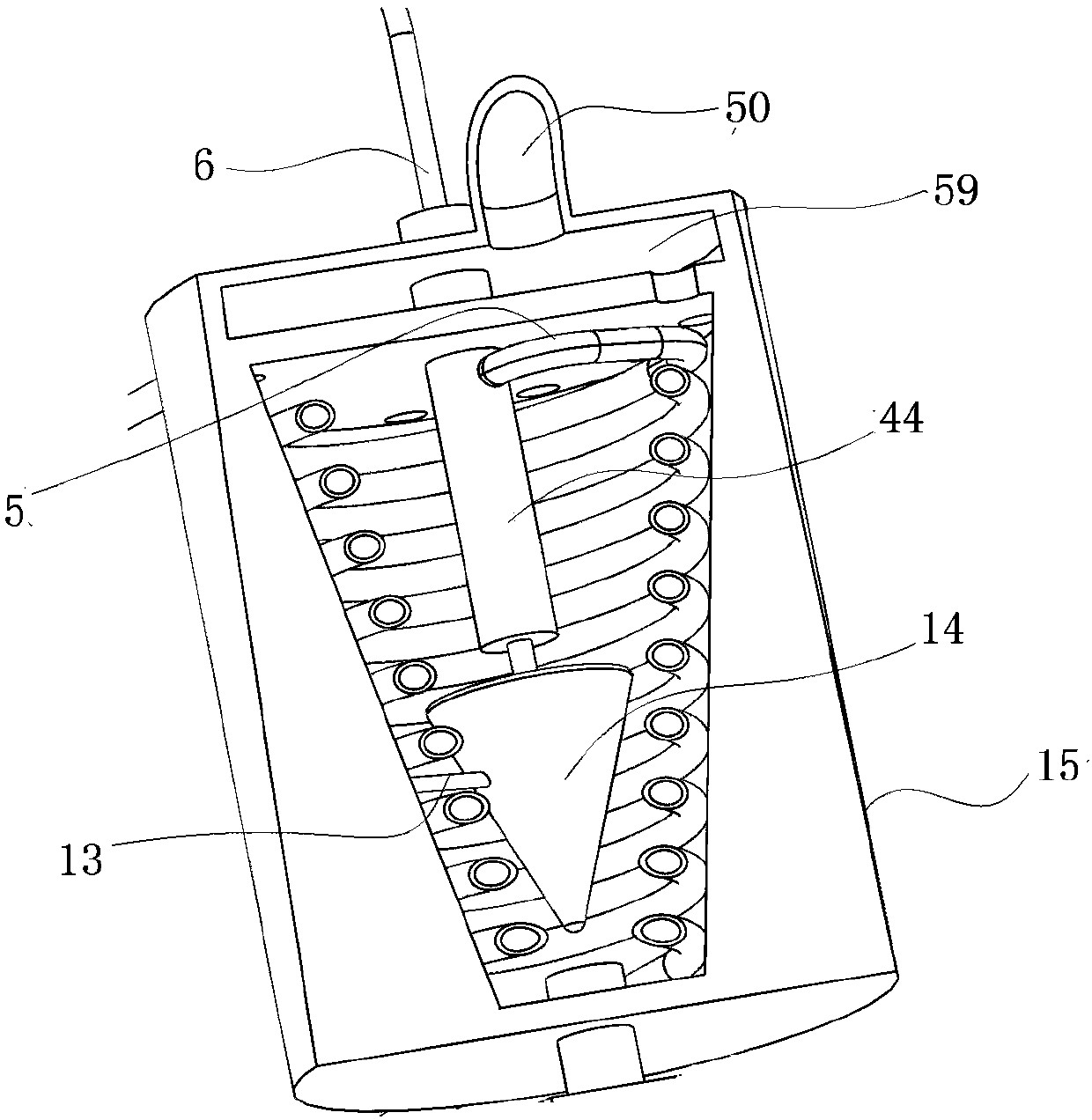

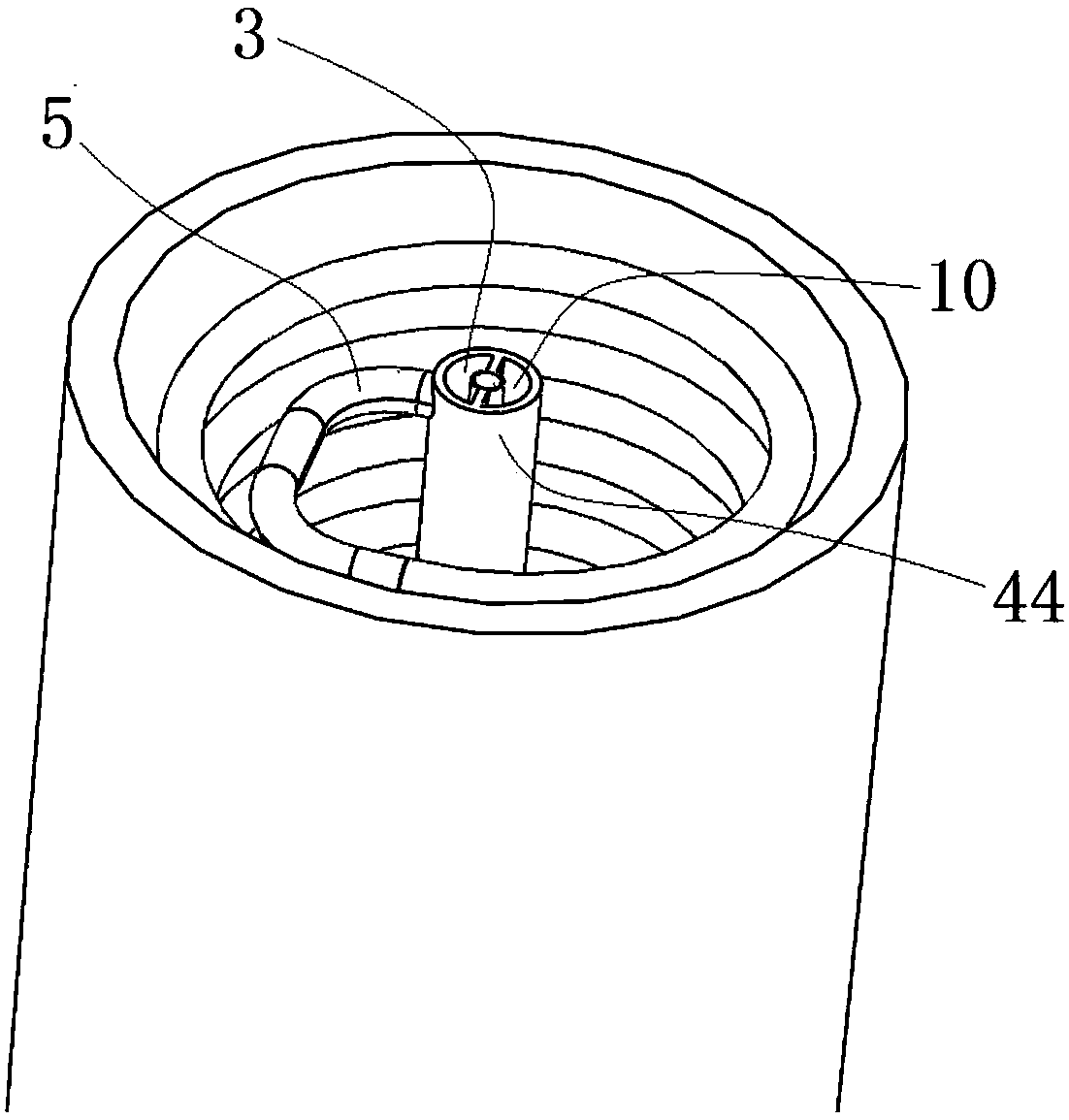

[0031] as attached Figures 1 to 7A kind of combustor based on liquid ethanol-natural gas combined fuel shown comprises a combustor body 15, and the combusted fuel combustor 17 is included in the combustor body 15, and in this embodiment, the combusted fuel combustor 17 has a thin end facing downward The conical circular frustum structure; the lower end of the combined fuel combustion chamber 17 is coaxially provided with a flame nozzle 7, and the flame injection direction of the flame nozzle 7 is vertically upward; the upper end of the combined fuel combustion chamber 17 is a smoke exhaust wall 60, and the A number of smoke outlets 27 are arranged on the smoke exhaust wall 60; the combined fuel combustion chamber 17 also includes an ethanol gasification cone 14; the outer wall of the ethanol gasification cone 14 is a conical structure with the tip facing downward; Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com