Novel petroleum exploitation auxiliary device

A technology for oil extraction and auxiliary devices, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of high oil extraction concentration, unreachable temperature, and high oil wax content, and achieve uniform heating, guaranteeing The effect of normal conveying and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

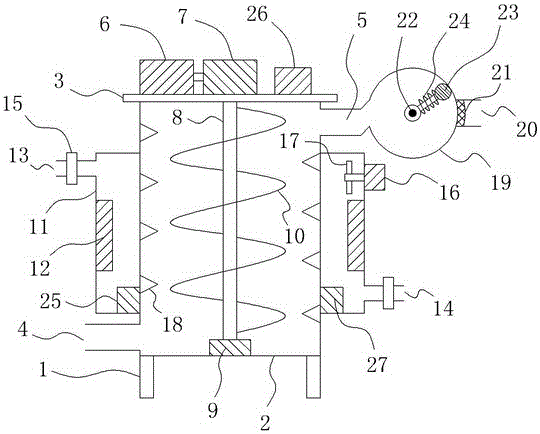

[0013] Such as figure 1 As shown, a new auxiliary device for oil extraction includes a support 1 and a cylinder 2 mounted on the support 1. A cylinder cover 3 is provided at the top of the cylinder 2, and an oil inlet is provided at the left bottom of the cylinder 2. port 4, an oil outlet 5 is provided on the top right side of the cylinder body 2, and a first motor 6 and a reducer 7 connected to the output shaft end of the first motor 6 are respectively provided on the cylinder cover 3. The output shaft end of 7 is also connected with a rotating shaft 8 through a coupling, and the rotating shaft 8 is arranged vertically downward and extends to the inside of the cylinder 2, and a bearing 9 is also provided at the inner bottom of the cylinder 2, and the rotating shaft 8 The bottom end is fixedly connected to the inner ring of the bearing 9, and a helical blade 10 is also provided on the rotating shaft 8, and a plurality of blade holes (not shown in the figure) are evenly distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com