Technique for embedding stainless steel tube in large-size aluminum alloy casting blank

A stainless steel and aluminum alloy technology, which is applied in the field of aluminum alloy casting, can solve the problems of high cost, large stress deformation, and poor sand mold strength of copper pipes, and achieve the effects of reasonable layout of water pipes, improved performance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

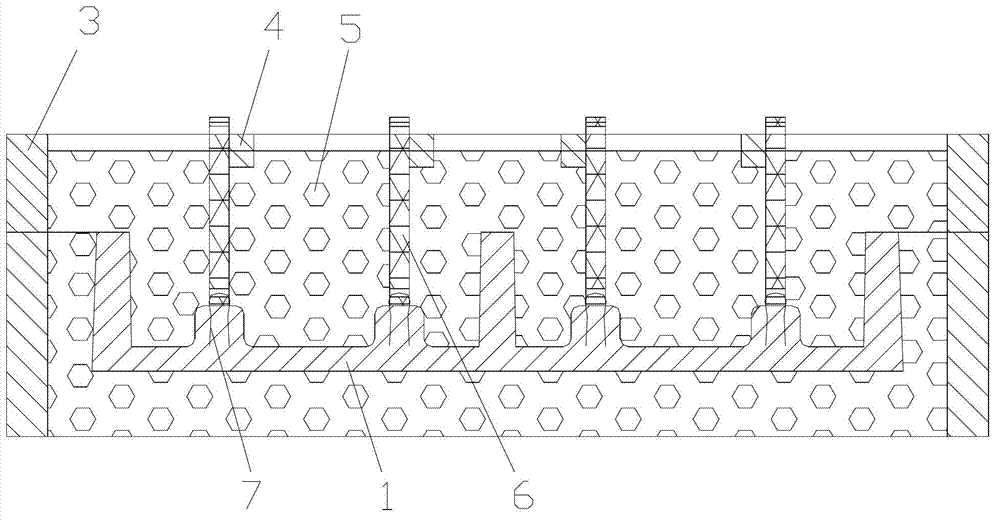

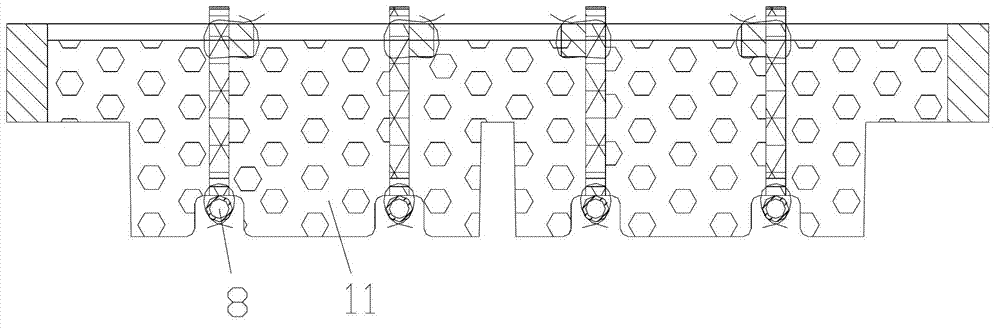

[0022] Such as Figure 1-5 As shown, a large aluminum alloy type slab cast slab is manufactured by embedded stainless steel pipe technology, and the specific implementation method is as follows:

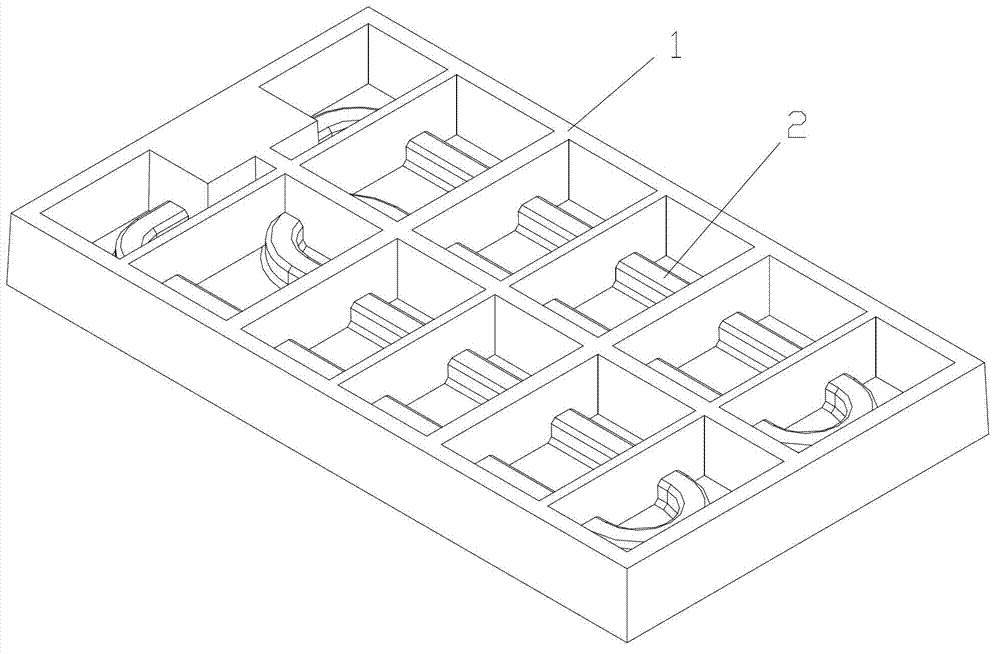

[0023] ①According to the drawings and casting process requirements, make a wooden mold 1, and make a pipe groove 2 in the wooden mold 1, so as to locate and place the water pipe;

[0024] ② Put the wooden mold 1 in the sand box 3, divide and mark the pipe groove 2 according to the distance of 250mm, and then put the lower end of the connecting rod 6 with the binding wire 7 on the upper part of the pipe groove 2, and the connecting rod The upper end of the upper end should be slightly higher than the sand box rib 4, so as to ensure that the connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com