Patents

Literature

121 results about "Manganese(III) oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manganese(III) oxide is a chemical compound with the formula Mn₂O₃.

Refractory far infrared radiation ceramics coating

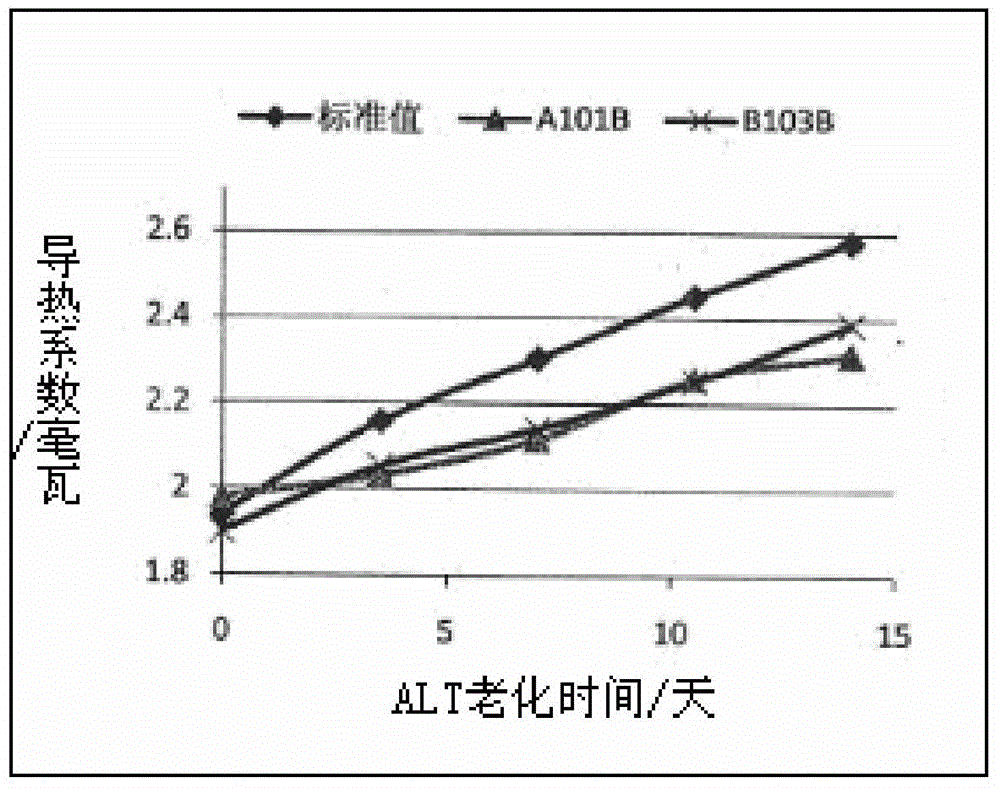

The invention provides a high temperature resistance infrared radiation pottery dope, which belongs to the thermal engineering field. The dope is a mixture of the following materials in mass share: 200 mesh zirconium dioxide 10, 200 mesh zircon quartz sand 20, 300 mesh feldspar 10, 300 mesh cerium oxide 7, 300 mesh manganese sesquioxide 15, 300 mesh manganic oxide 3, 600 mesh titanium dioxide 2, 200 mesh alumina 10, 400 mesh graphite 10, 400 mesh boron nitride 3 and 200 mesh carborundum 10. The graphite and boron nitride in the dope are of lubricating and anti-bonding functions, the carborundum is of wear resistance function, the manganic oxide, titanium dioxide and alumina are of strong infrared ray emission and the dope mad of zirconium dioxide, zircon quartz, feldspar and cerium oxide has good compact structure and strong fire-proof and the manganese sesquioxide can catalyze C, S and N for conversion. Therefore, the invention is applicable for use in dynamic furnaces such as coal dust furnace, boiling furnace and fluidized bed furnace.

Owner:颐珑达绝热材料技术(北京)有限公司

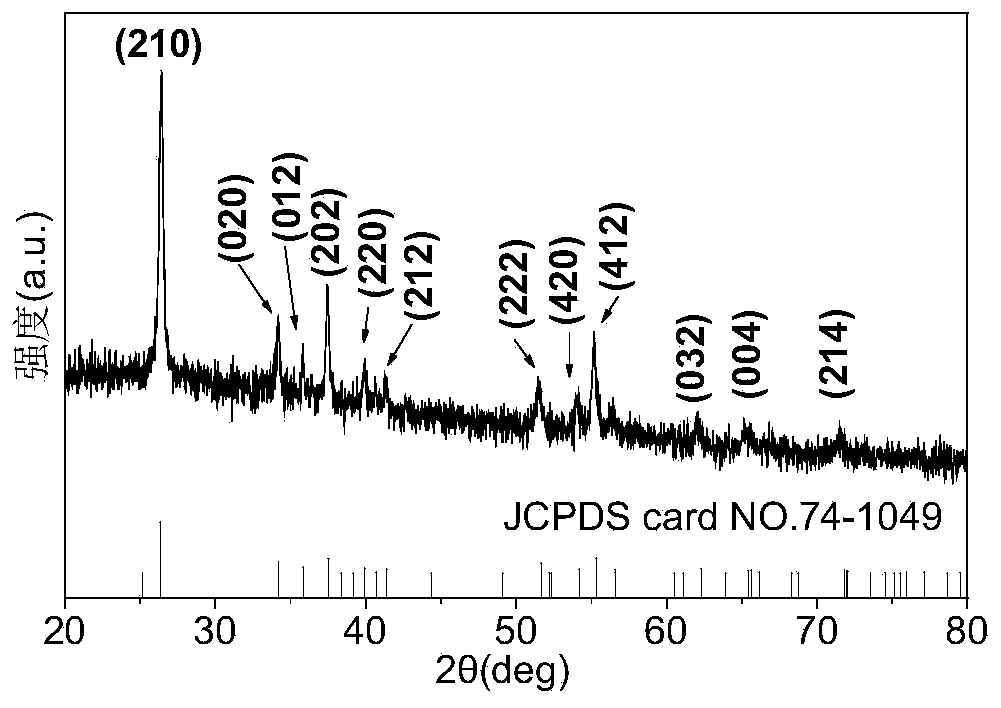

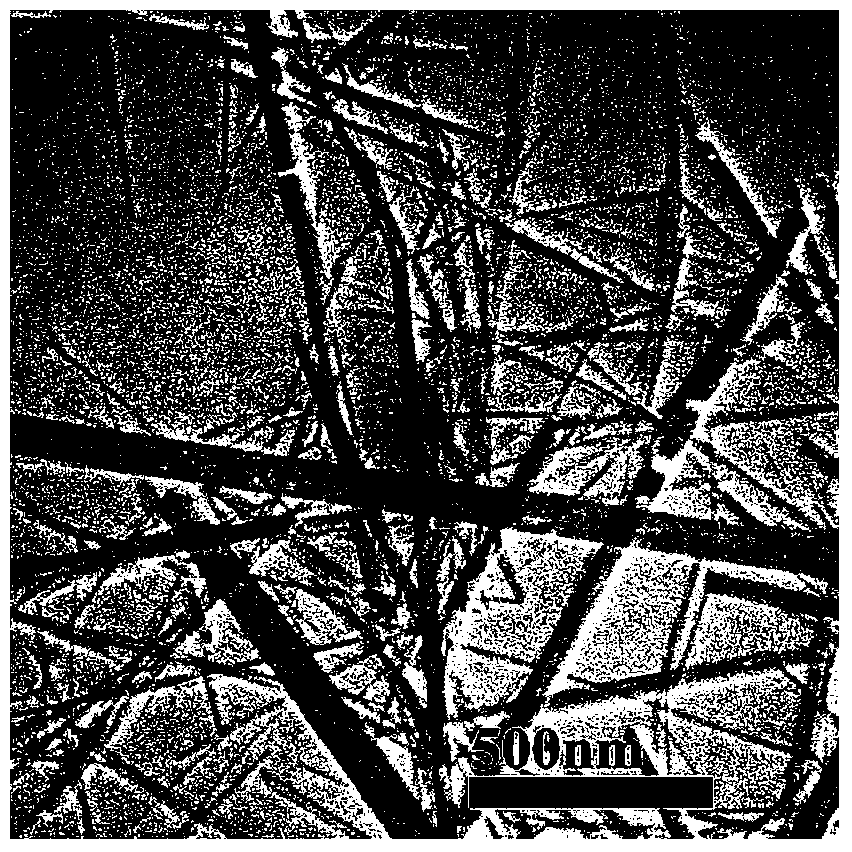

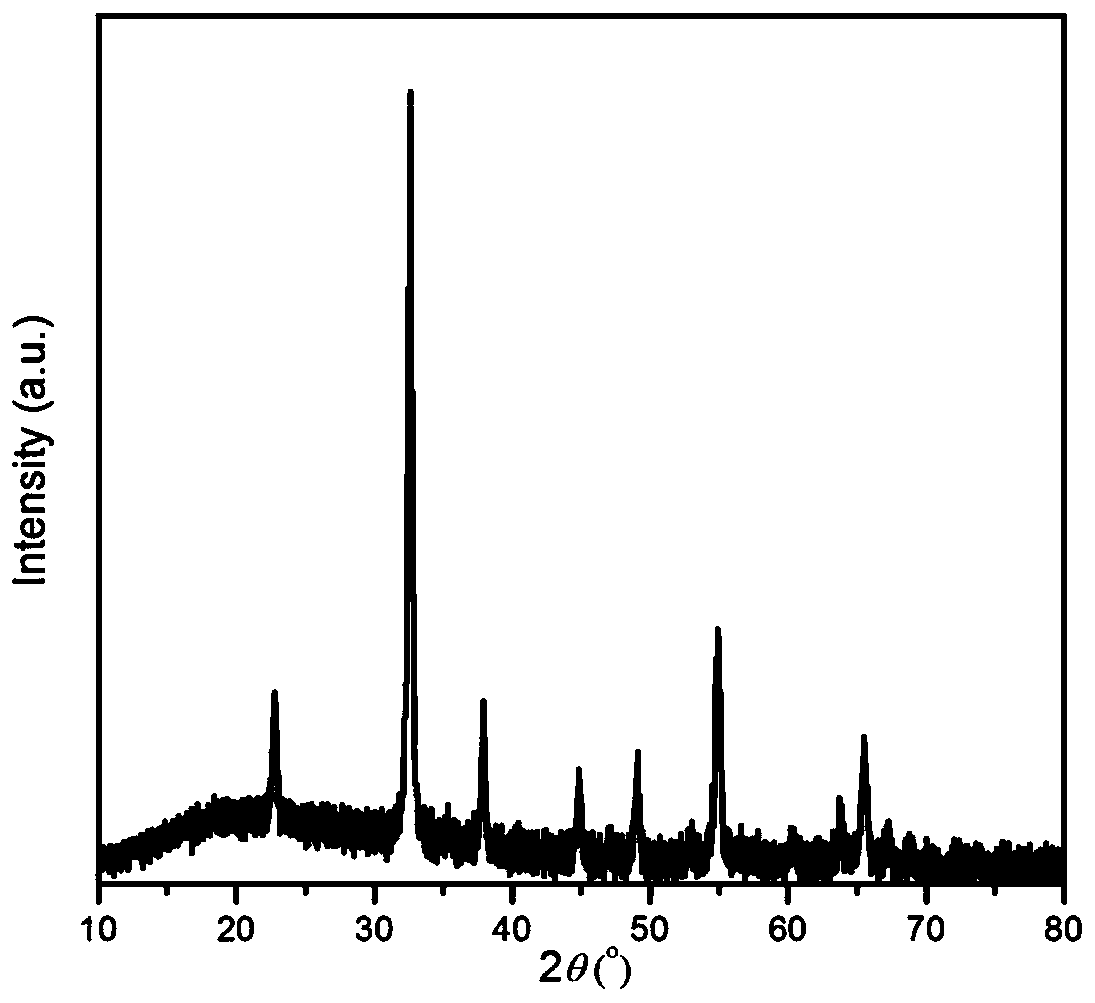

Preparation method for manganese oxide nano rods

InactiveCN104211123ASmall diameterUniform size distributionMaterial nanotechnologyManganese oxides/hydroxidesSesquioxideReaction temperature

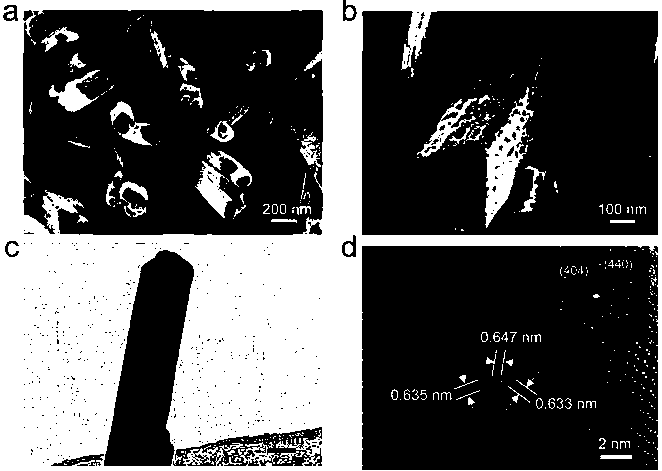

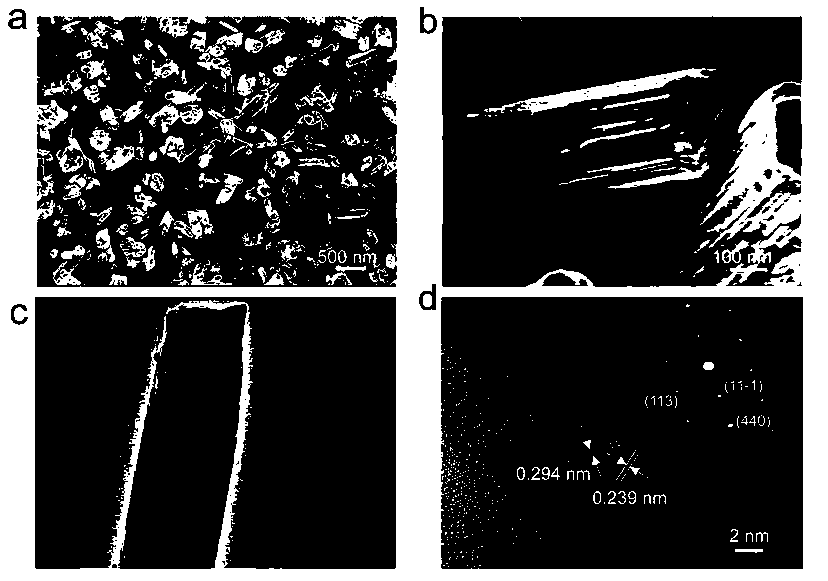

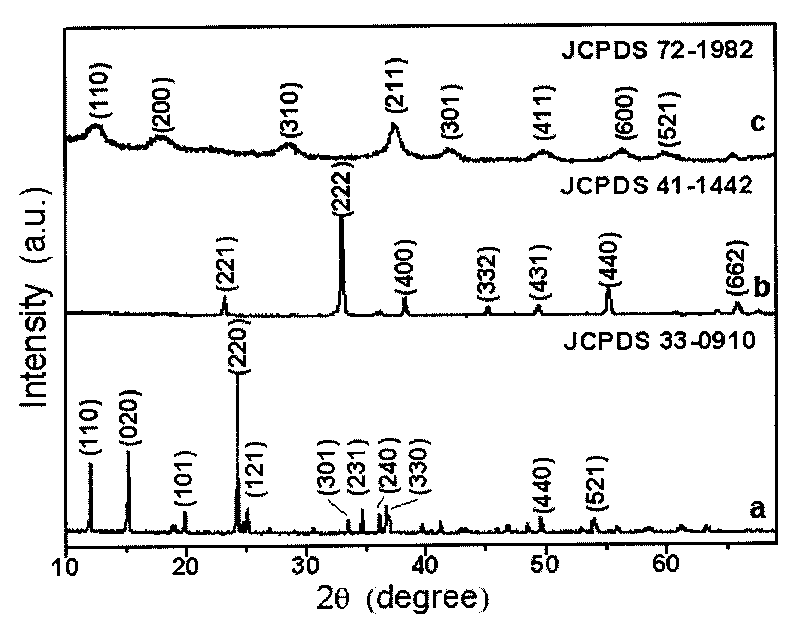

The invention relates to a preparation method for manganese oxide nano rods, belonging to the field of nano function materials. According to the preparation method, rod-shaped alkaline manganese oxide can be prepared by using hypermanganate and ethylene glycol under a hydrothermal condition, wherein the longest length of the alkaline manganese oxide can be up to six microns and the diameter size is 10nm-130nm; alkaline manganese oxide precursors are calcined under different calcining conditions to obtain the manganese oxide nano rods with different valence states and different sizes, namely manganese dioxide nano rods, manganese sesquioxide nano rods and trimanganese tetraoxide nano rods. By adopting the preparation method, the problems of an existing solvothermal method that the reaction time is long and the reaction temperature is high when the alkaline manganese oxide nano rods are synthesized and the diameters of the products are great and the products are not uniformly distributed are solved; and the preparation method has the advantages of simplicity in operation and many product varieties.

Owner:JILIN UNIV

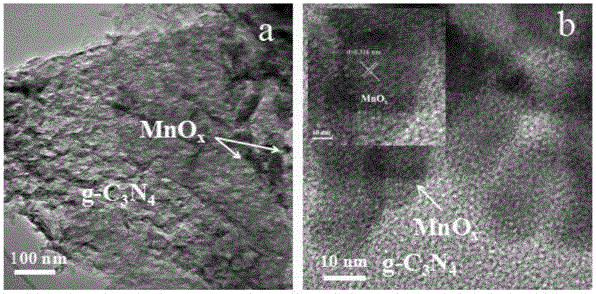

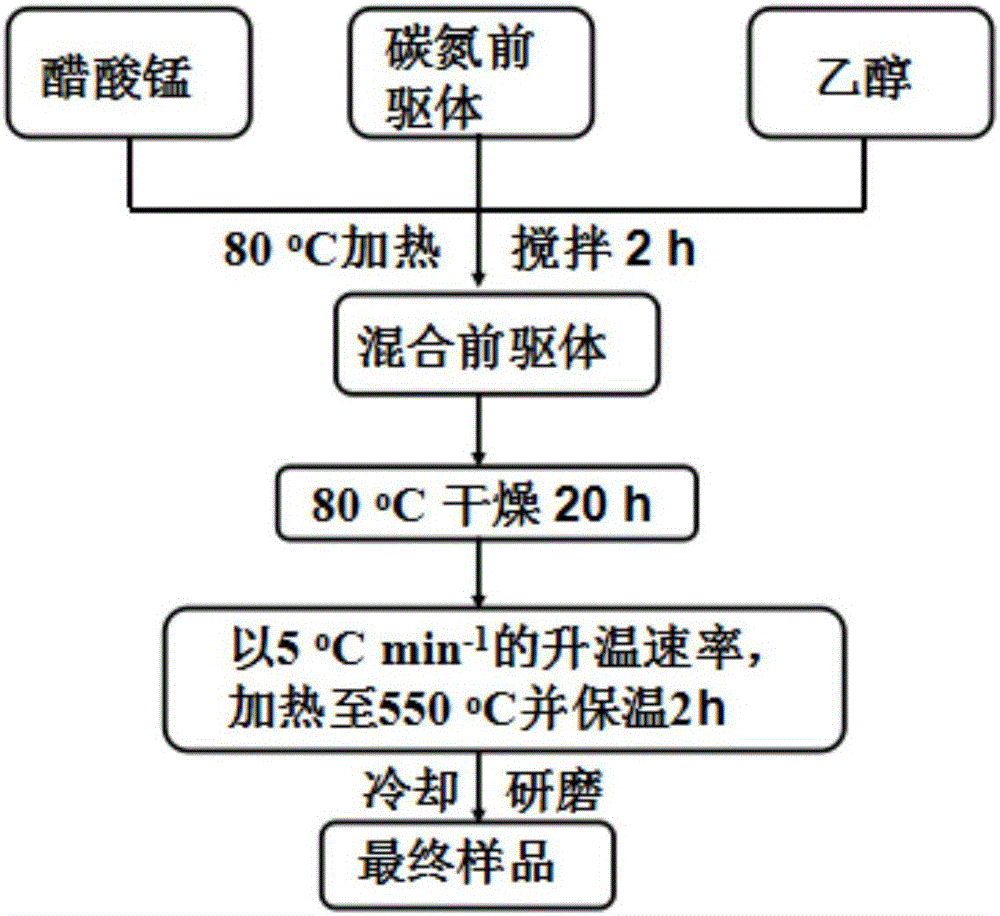

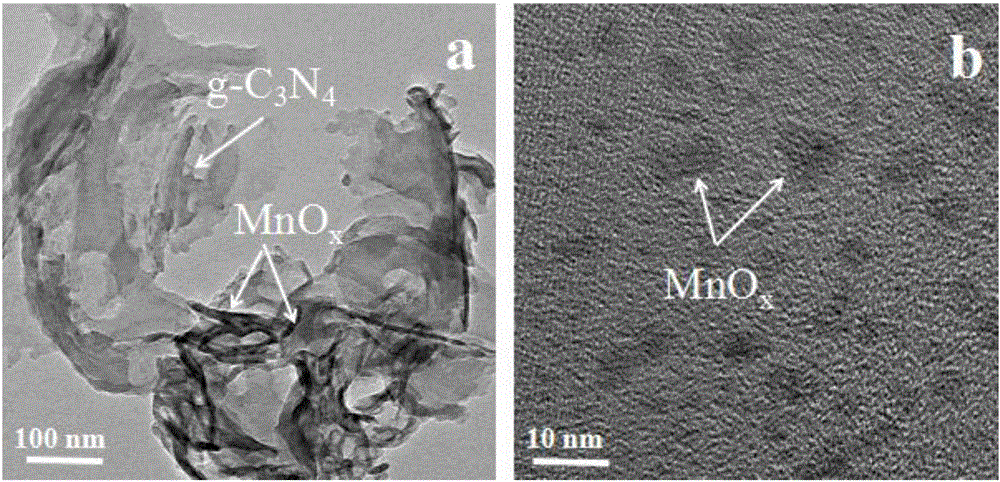

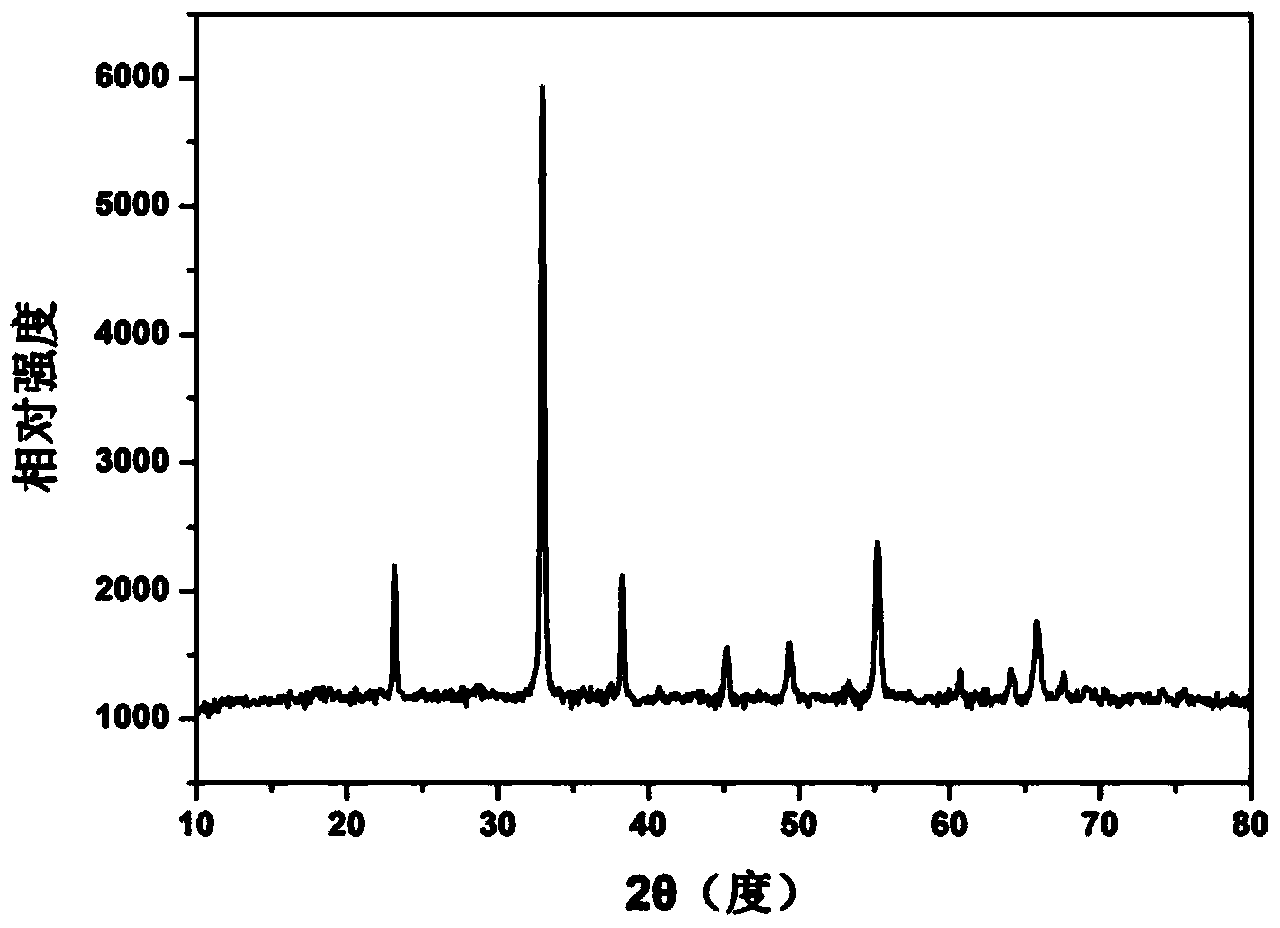

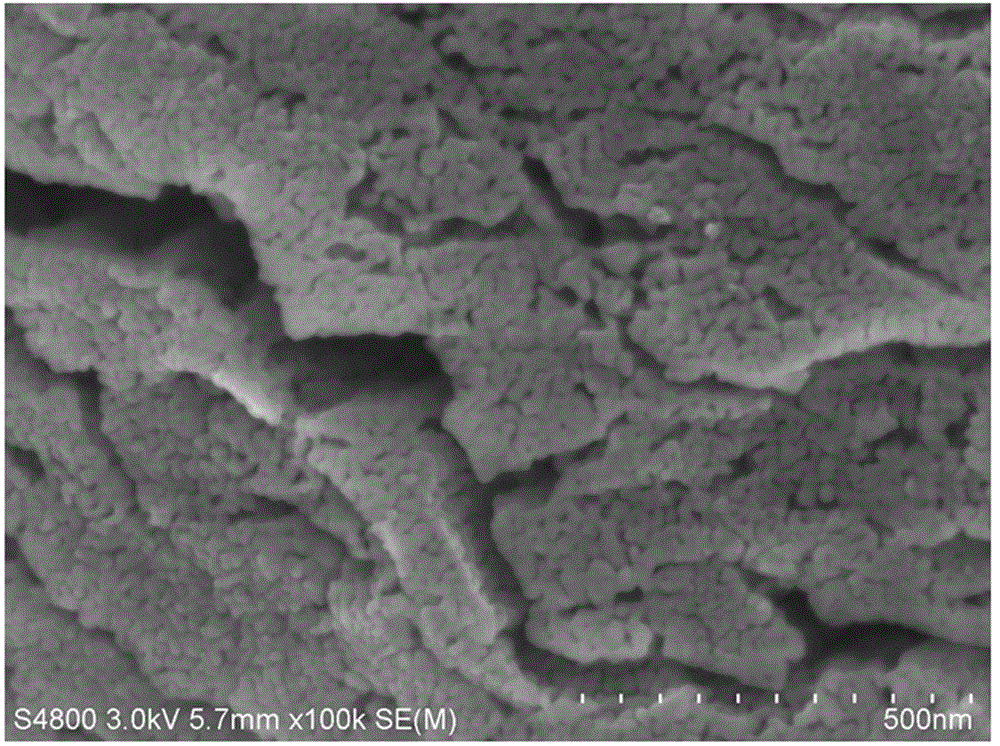

Manganese oxide-graphite phase carbon nitride composite photocatalytic material and preparation method thereof

InactiveCN105817255AImprove thermal stabilityGood chemical stabilityPhysical/chemical process catalystsEnergy inputManganese oxideElectrochemistry

The invention relates to a manganese oxide-graphite phase carbon nitride composite photocatalytic material and a preparation method thereof. The manganese oxide-graphite phase carbon nitride composite photocatalytic material is prepared by depositing manganese oxide nanoparticles on the surface of layered graphite phase carbon nitride, and the manganese element loading capacity of manganese oxide in the composite photocatalytic material is 0.3-1.2 mol%; manganese dioxide or trimanganese tetroxide or dimanganese trioxide or a mixed oxide of manganese dioxide, trimanganese tetroxide and dimanganese trioxide is adopted as manganese oxide. Manganese oxide in the composite photocatalytic material is uniformly loaded on graphite phase carbon nitride, the loading capacity is controllable, the good catalytic capacity is achieved, a manganese oxide cocatalyst is closely combined with graphite phase carbon nitride, therefore, the defects that a single photocatalyst is high in photoproduced electron hole pair composite ratio and low in photocatalytic efficiency are effectively overcome, the solar utilization efficiency is greatly improved, and the excellent catalytic activity is achieved when the composite photocatalytic material is used for photocatalytic hydrogen production. The composite photocatalytic material has the wide application prospect in the fields of photocatalysis, electrochemistry, energy, environments and the like.

Owner:WUHAN UNIV OF TECH

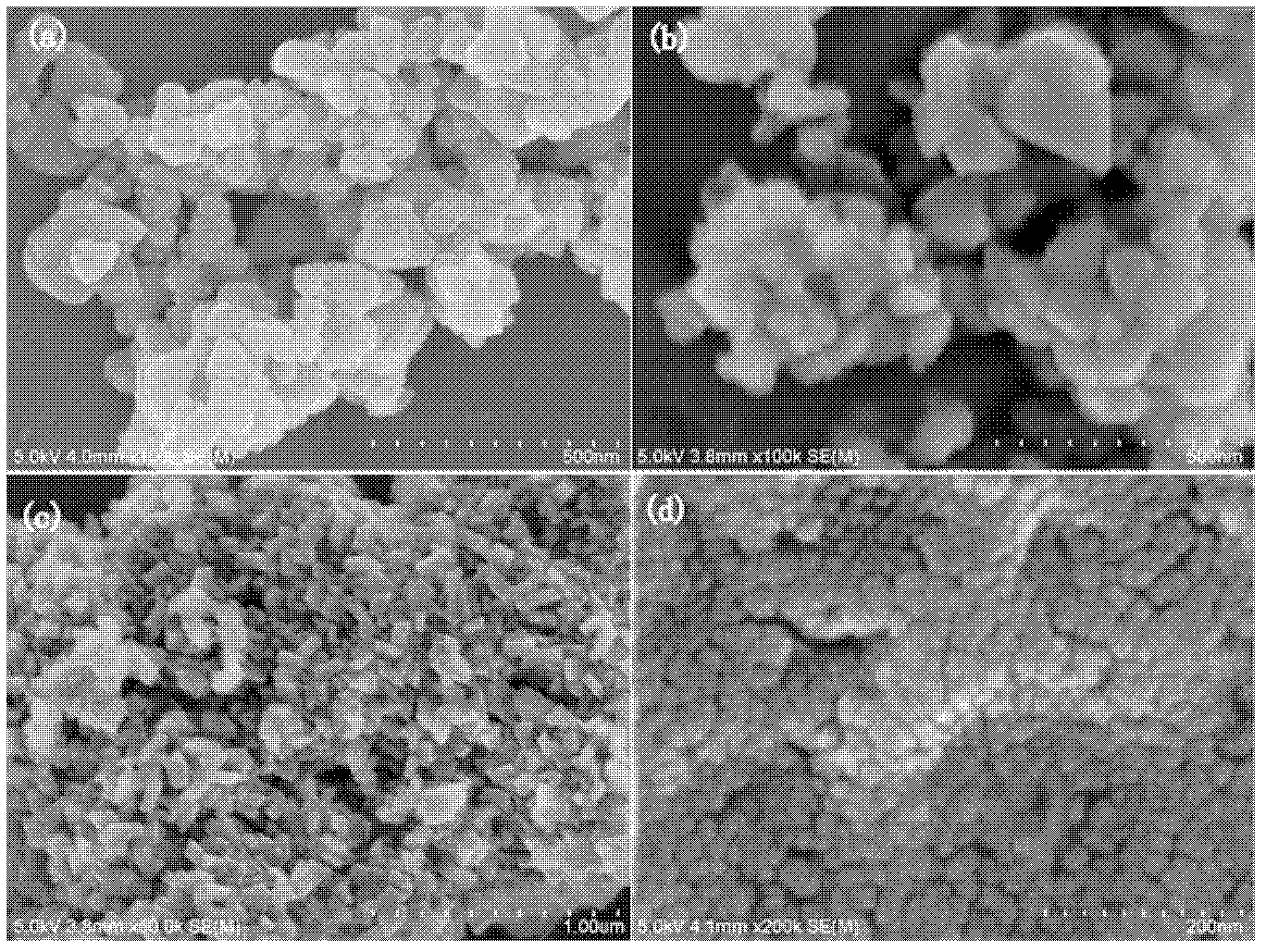

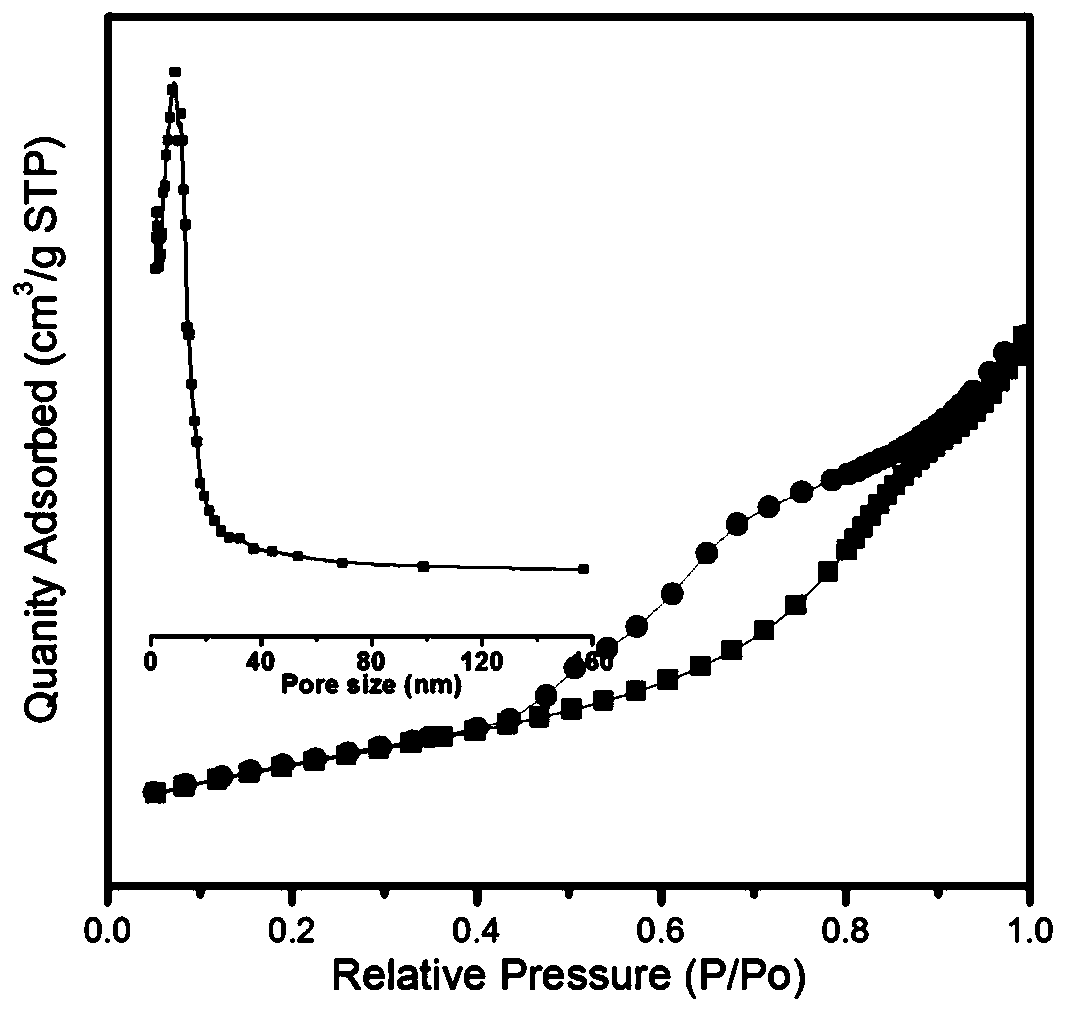

Mesoporous manganese oxide nano granule and preparation method thereof

InactiveCN101597085AImprove protectionSimple preparation processManganese oxides/hydroxidesMANGANESE ACETATESesquioxide

The invention relates to a mesoporous manganese oxide nano material and a preparation method thereof. In the invention, a uniformly distributed mesopore with the aperture of 2 to 10 nanometers and a mixture of oxyhydrogen manganese oxide and manganic manganous oxide or a mangano-manganic octoxide monocrystal granule or a manganese sesquioxide monocrystal granule with the granule particle diameter controlled within the range of 20 to 80 nanometers are prepared by the hydrothermal function of manganese metal, manganese acetate and ammonia and the subsequent calcination control, and the uniformly distributed mesoporous, the mixture of oxyhydrogen manganese oxide and manganic manganous oxide, the mangano-manganic octoxide monocrystal granule and the manganese sesquioxide monocrystal granule play a catalytic action to a toluene combustion reaction. The invention has simple preparation method, loose synthesizing condition, easy repetition and cheap raw materials and can carry out large-scale production.

Owner:HEBEI UNIV OF TECH

Porous manganic oxide cube as well as preparation method and application thereof

InactiveCN103979610ANo pollution in the processReduce energy consumptionManganese oxides/hydroxidesAir atmosphereLithium-ion battery

The invention discloses a porous manganic oxide cube as well as a preparation method and application thereof. The size of the porous manganic oxide cube is 0.4-2 microns, a porous structure comprises macropores and micropores, aperture of each macropore is 25-48nm, and the aperture of each micropore is 5-8nm. The preparation method of the porous manganic oxide cube comprises the following steps: uniformly mixing potassium permanganate, an organic solvent and a carbonate aqueous solution in a certain proportion, carrying out condensation and reflux on the mixed solution for 5-24 hours at the constant temperature of 60-100 DEG C, carrying out reduction reaction on potassium permanganate, so that manganese carbonate grey white precipitate is obtained, placing the manganese carbonate grey white precipitate in an air atmosphere, and calcining for 2-20 hours at the temperature of 520-620 DEG C, so that the porous manganic oxide cube is obtained. The porous manganic oxide cube is prepared by carrying out a constant temperature liquid phase reaction, the related raw materials are common and non-toxic, a technology is simple and practicable, yield is high, and the obtained porous manganic oxide cube has great application value in the field of battery electrodes of lithium ion batteries.

Owner:WUHAN UNIV OF TECH

Manganese oxide catalyst used for toluene liquid phase catalytic oxidation, its preparation method and application

InactiveCN1824383AHigh activityGood choiceOrganic compound preparationCarboxylic compound preparationBenzoic acidBenzaldehyde

The present invention relates to a manganic oxide catalyst for toluene liquid-phase catalytic oxidation to prepare benzoic acid and benzaldehyde, its preparation method and application. The described manganic oxide can be manganese dioxide, manganese sesquioxide, trimanganese tetraoxide and manganese monoxide and other mixed valence manganic oxide, and said catalyst can be prepared by means of thermolysis method, hydropyrolysis process or precipitation process. Said catalyst has higher activity, selectivity and stability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

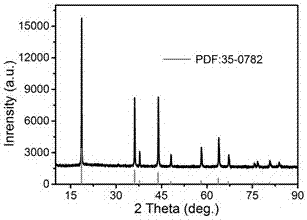

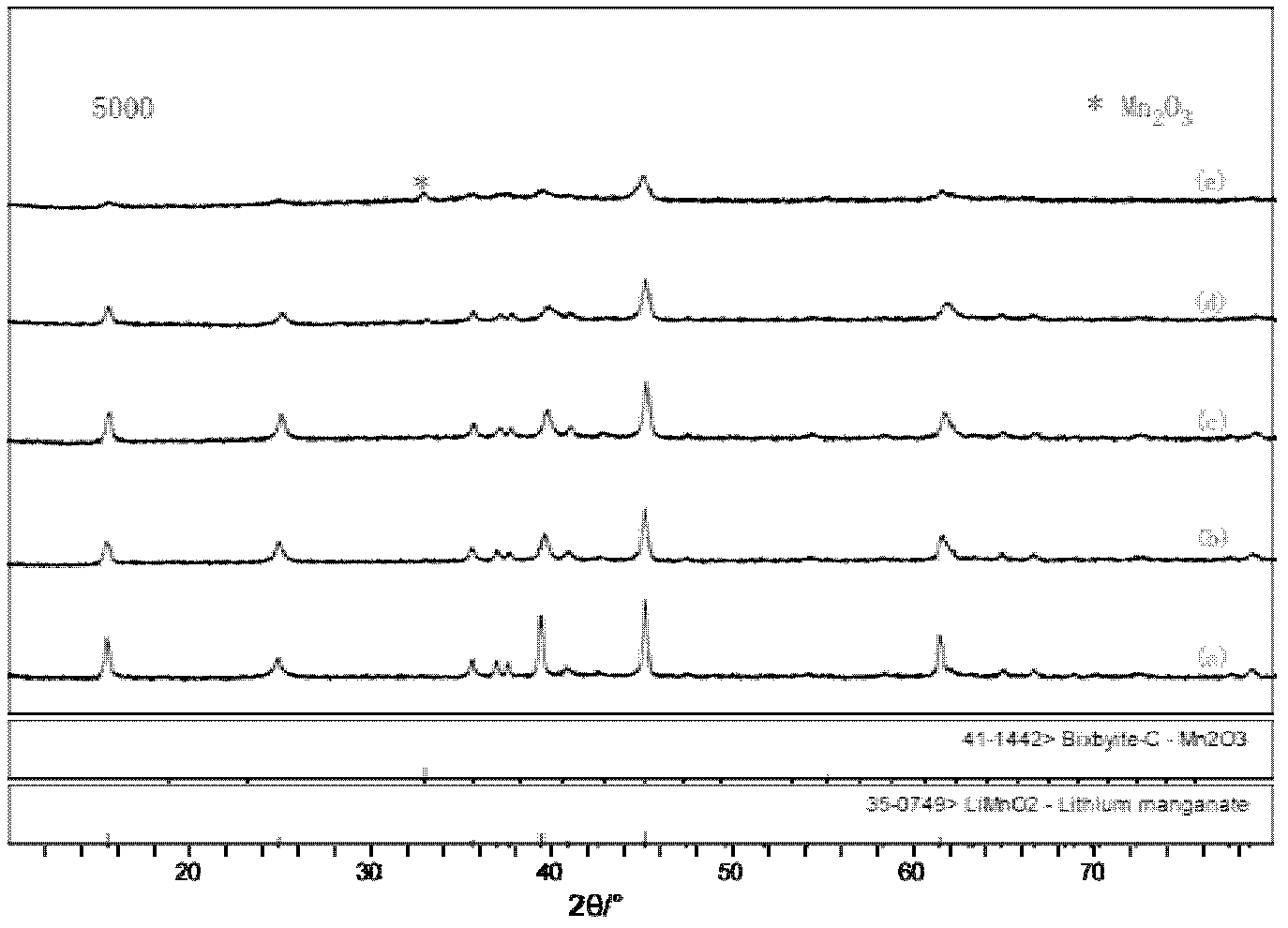

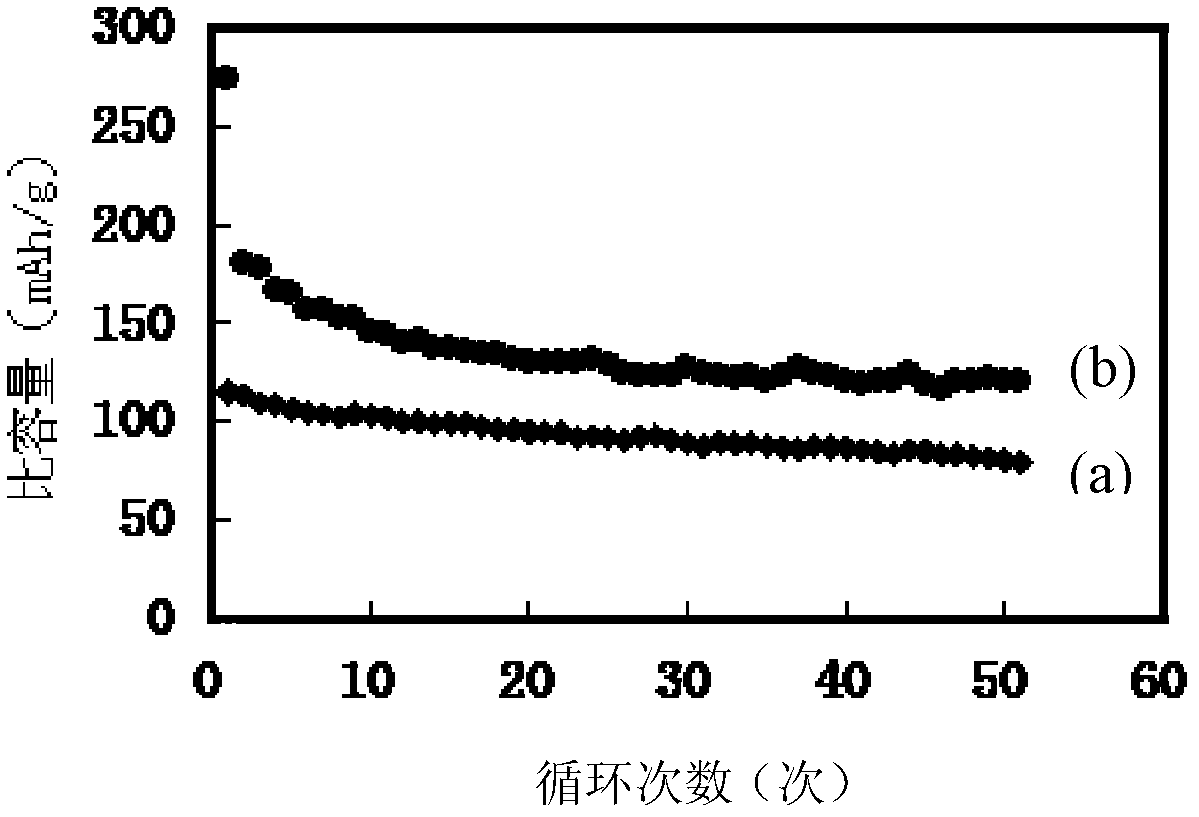

Homologous manganese oxide and spinel-type lithium manganate lithium ion battery and preparation method thereof

InactiveCN104078672AHigh specific capacityReduce the use effectCell electrodesElectrolyte accumulators manufactureSesquioxideActive agent

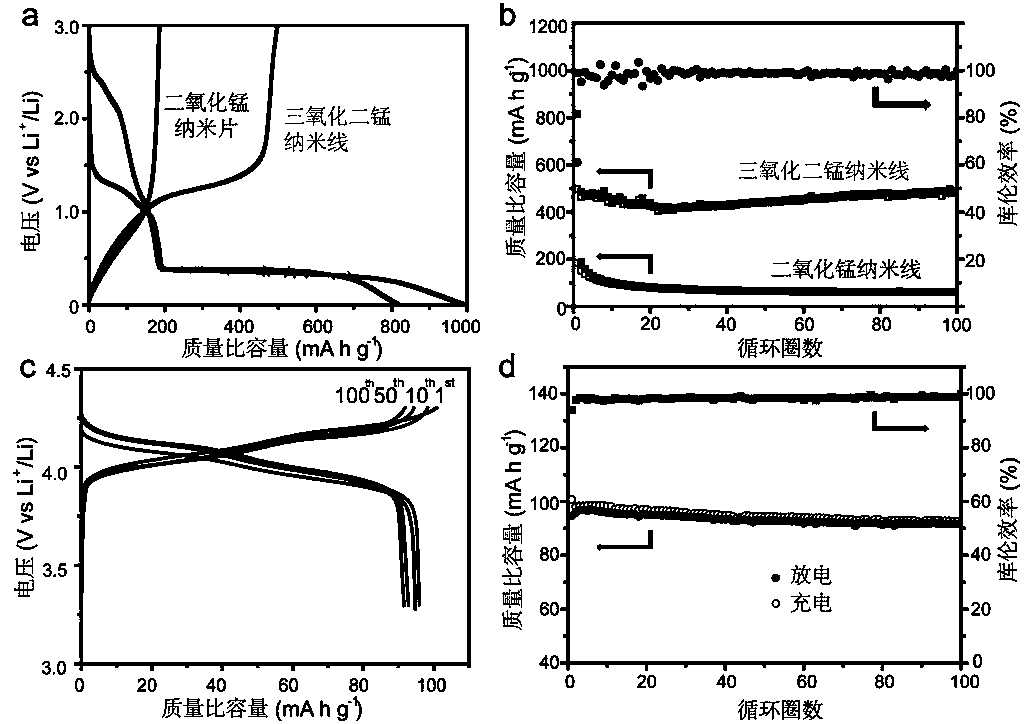

The invention belongs to the technical field of a lithium ion battery, and particularly relates to a homologous manganese oxide and lithium manganate lithium ion battery on the basis of a nanowire structure. By adopting a two-step hydrothermal method and a high-temperature solid-phase method, a reducing agent and a surface active agent are added into a hydrothermal system, so that the transformation between a manganese oxide nano-sheet array and a nanowire array can be realized. By adding a lithium source in the high-temperature solid reaction process, the preparation of the homologous manganese oxide and spinel-type lithium manganate nanowire can be realized. The homologouos manganese oxide and the spinel-type lithium manganate nanowire can be assembled to form a lithium ion full battery of a nanowire structure. The preparation method comprises the following steps: 1, facilitating the hydrothermal growth of manganese dioxide nano-sheet array; 2, in-situ transforming a hydroxyl manganese oxide nanowire array; 3, preparing manganese sesquioxide and spinel-type lithium manganate nanowire; 4, assembling the full battery. Compared with the lithium ion battery, the source of the raw materials is wide, the preparation process of an anode-cathode material can be simplified, and the anode-cathode material and the lithium ion full battery are both high in specific capacity and good in cycling property.

Owner:FUDAN UNIV

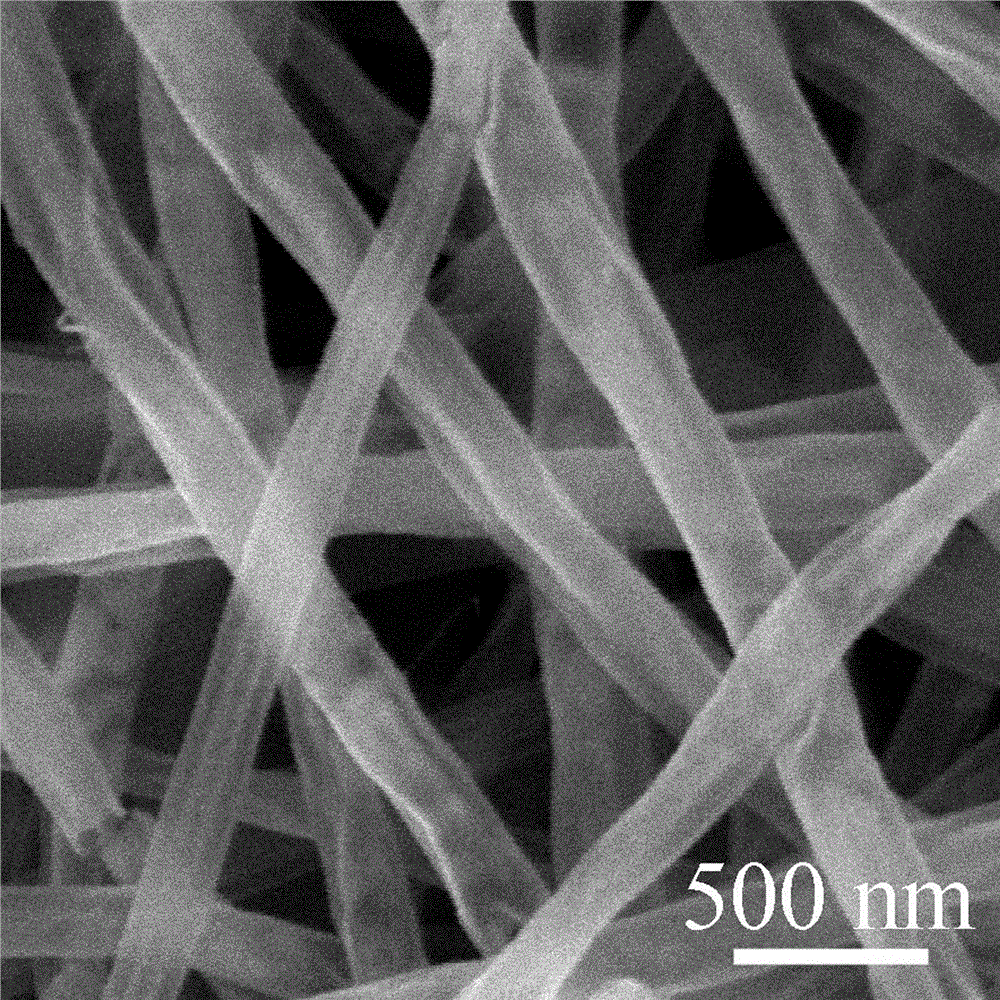

Porous manganese dioxide of nanofibre texture and preparation method thereof

The invention discloses a porous manganese dioxide of nanofibre texture and a preparation method thereof. Hydro-thermal reaction is carried out on an aqueous solution containing Mn 2+ and an aqueous solution containing tartrate ion to firstly prepare micron-sized stripe-shaped manganese tartrate crystal; then, manganese tartrate is calcined under the controlled process condition to obtain porous manganese sesquioxide; and finally, oxidizing reaction is carried out on the manganese sesquioxide with a low-temperature hydrothermal method to synthetize porous manganese dioxide with nanofibre texture. The porous manganese dioxide of the invention is weaved by even nanofibre texture, which not only ensures larger specific surface area but also provides smooth high-porosity path for the chemical process to transfer mass. The composite method of the invention is different from the oxidizing atmosphere calcination synthesis method at high temperature; and products are synthetized at low temperature so as to totally avoid the disadvantage that manganese oxide is easy to sinter at high temperature, so that the products can keep the feature of a precursor and can realize the porous structure of the nanofibre texture.

Owner:ZHEJIANG UNIV

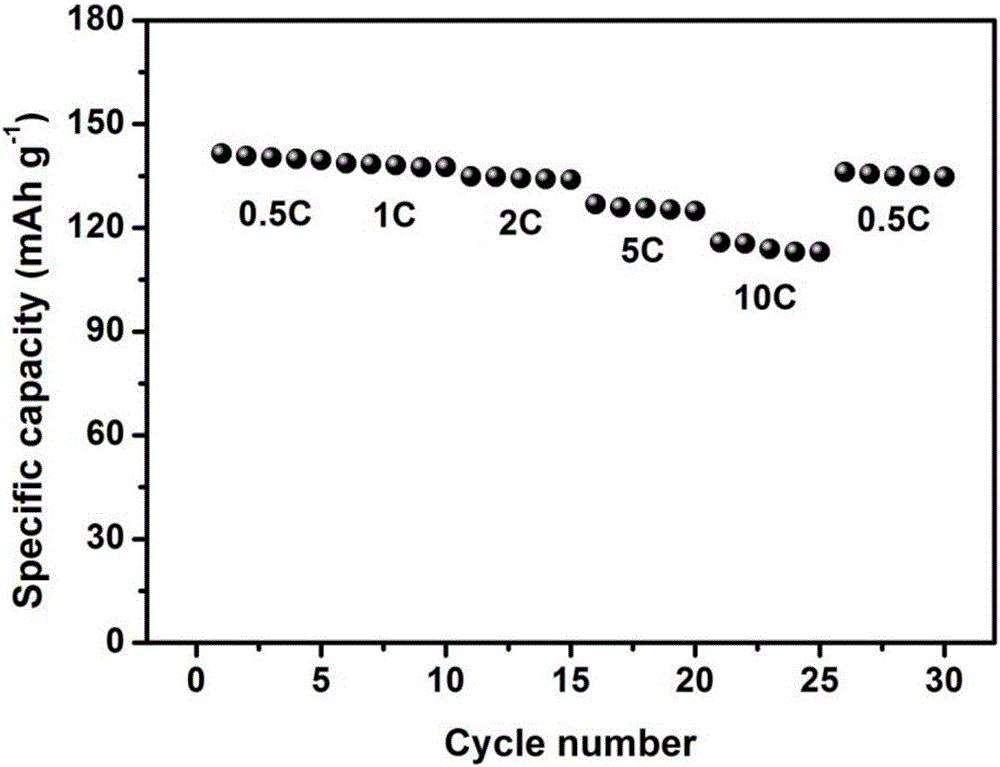

Graphene combined multilayered perforated spheroidic lithium manganese oxide electrode material and lithium ion battery prepared therefrom

ActiveCN107331853AIncrease storage spaceShorten the transmission pathSecondary cellsPositive electrodesHigh energyLithium metal

The invention discloses a graphene combined multilayered perforated spheroidic lithium manganese oxide electrode material capable for charging and discharging lithium ions and a high-voltage rechargeable lithium ion battery containing the material. The multilayered perforated spheroidic lithium manganese oxide is prepared from manganic oxide which is used as a precursor with a solid phase method, manganese oxide has multiaperture, layered and open-ended morphology, and graphene laminated structures of the combined material are uniformly dispersed around the prepared lithium manganese oxide particles. The high-voltage rechargeable lithium ion battery employs graphene combined multilayered perforated spheroidic lithium manganese oxide as an anode, lithium metal or embeddable delithiated active material as a cathode, and a soluble lithium salt organic solution as electrolyte. The graphene combined multilayered perforated spheroidic lithium manganese oxide is used as the lithium ion battery electrode material, and the material has the advantages of low cost, rich raw materials, high voltage, good multiplying power, and good cycling stability. The rechargeable lithium ion battery containing the material has high energy density and high power density, and wide market application prospect.

Owner:ZHENGZHOU UNIV

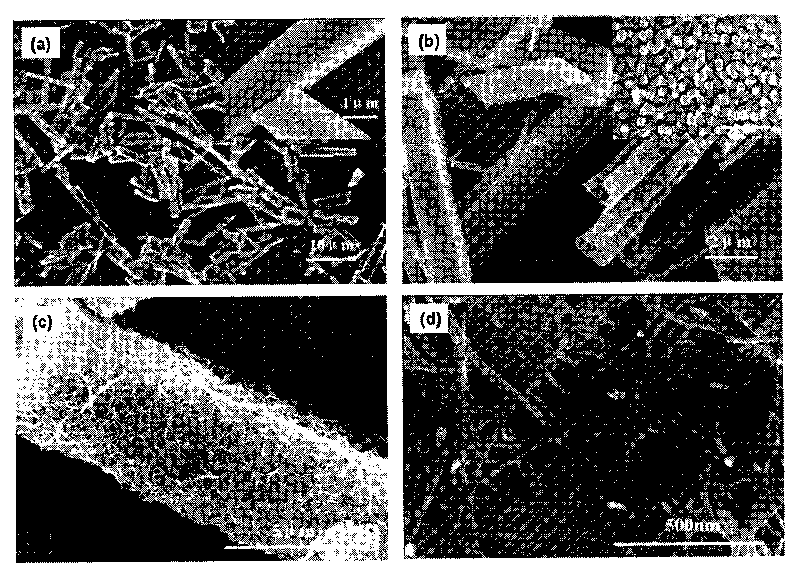

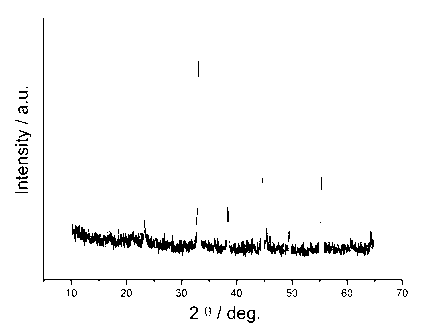

Method for preparing manganese sesquioxide one dimension nano material

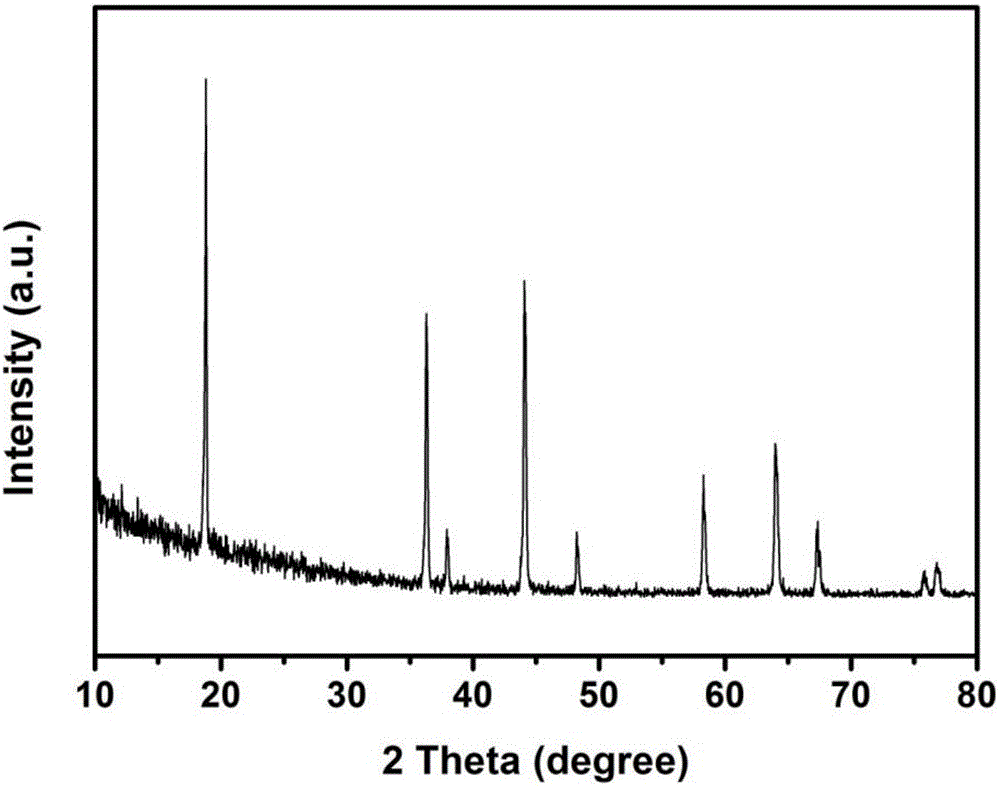

InactiveCN101525155AImprove distributionEvenly distributedManganese oxides/hydroxidesSesquioxideManganese(III) oxide

The invention relates to a method for preparing manganese sesquioxide one dimension nano material, comprising the process: organic complex aqueous solution with the mass concentration of 1-6% is prepared; metal salt containing manganese element and the organic complex aqueous solution are evenly mixed with each other according to the mass ratio of 1:5-5:1; a base plate is dipped into the mixed solution and tiled at the bottom of the solution; the mixed solution with the base plate is put into a baking oven and heated up to 120-150 DEG C at the speed of 5-20 DEG C / min and then the temperature is maintained for 0.5-3h; the manufactured sample is transferred into a box-type resistance furnace and heated up to 290-310 DEG C at the speed of 5-20 DEG C / min, then the temperature is maintained for 0.5-1h; the temperature is risen to 530-560 DEG C at the speed of 5-20 DEG C / min, and temperature is maintained for 0.5-3h; finally, the manganese sesquioxide one dimension nano material is formed on the base plate. The technique provided by the invention can be used for preparing the nano material with smaller and more uniform size; the method is also further simplified, and the optional scope of the raw materials is wider, thus further reducing the manufacturing cost.

Owner:TIANJIN UNIV

Lithium ion battery cathode material and preparation method for lithium ion battery cathode material

InactiveCN102593459AReduce area resistivityImprove electrochemical performanceCell electrodesSecondary cellsLithium hydroxideLithium-ion battery

The invention provides a lithium ion battery cathode material. The chemical formula of the lithium ion battery cathode material is LiMnxAl1-xO2, wherein x is not less than 0.7 but is less than 1. The preparation method for the lithium ion battery cathode material comprises the following steps of: dissolving manganic oxide into lithium hydroxide aqueous solution to obtain mixed solution; adding aluminum oxide into the mixed solution to obtain a mixture, wherein the molar ratio of lithium to manganese is (10:1)-(20:1); performing a hydro-thermal reaction on the mixture at the temperature of 110-200 DEG C to generate the LiMnxAl1-xO2, wherein x is not less than 0.7 but is less than 1. According to the preparation method for the lithium ion battery cathode material, Al<3+> is introduced into layered LiMnO2 so as to restrain the Jahn-Teller effect of Mn<3+> and stabilize the structure of the layered LiMnO2; relative to the layered LiMnO2, the area impedance rate of the material can be effectively lowered by the LiMnxAl1-xO2, and meanwhile, the plug-in potential and the energy density of Li<+> can also be increased, and thereby, the electrochemical performance of the material is optimized to a certain degree. The preparation method is simple and convenient in operation and is low in cost and can be used for mass production.

Owner:BEIJING NORMAL UNIVERSITY +1

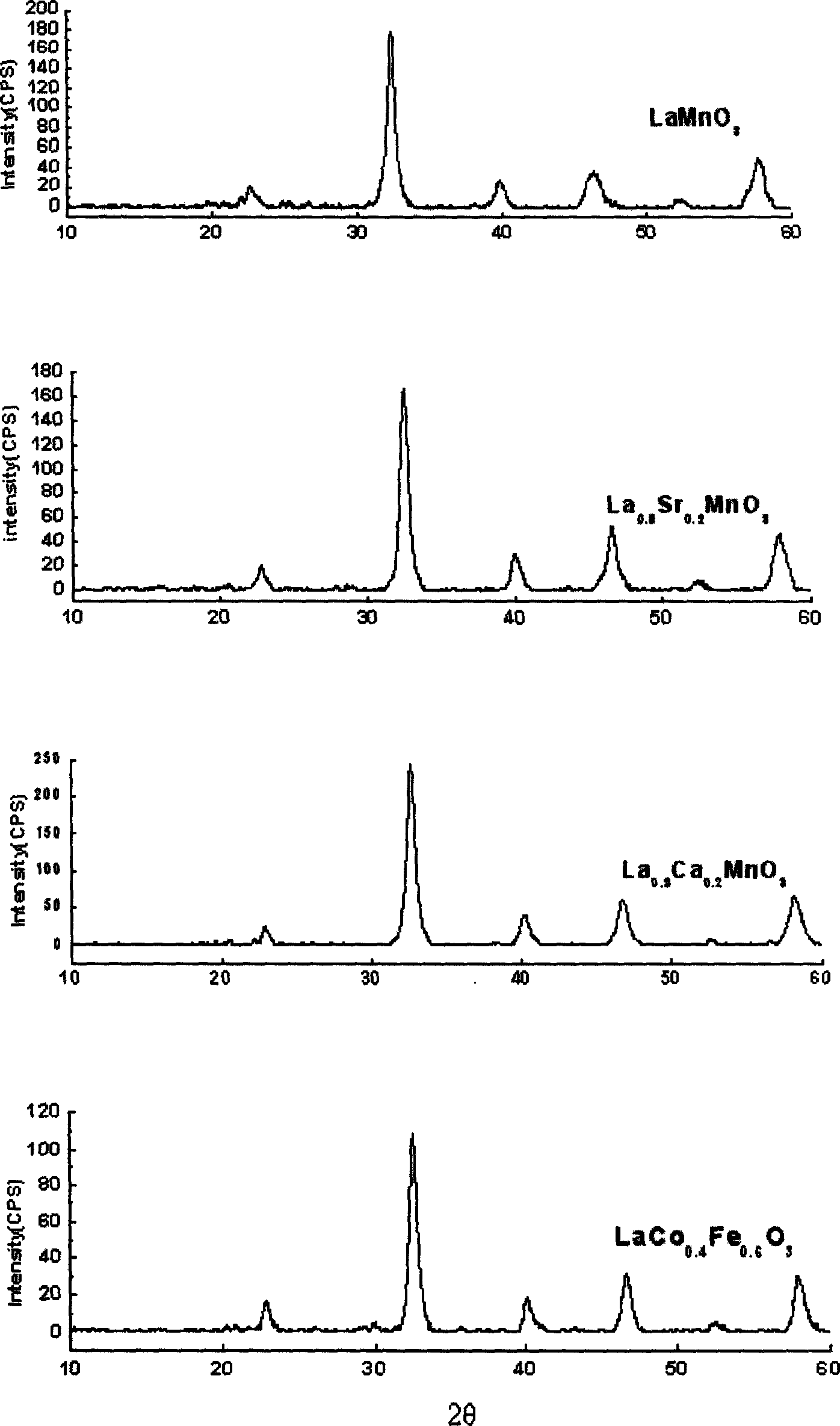

Reduced catalyst of mono fluorin, and preparation method and usage

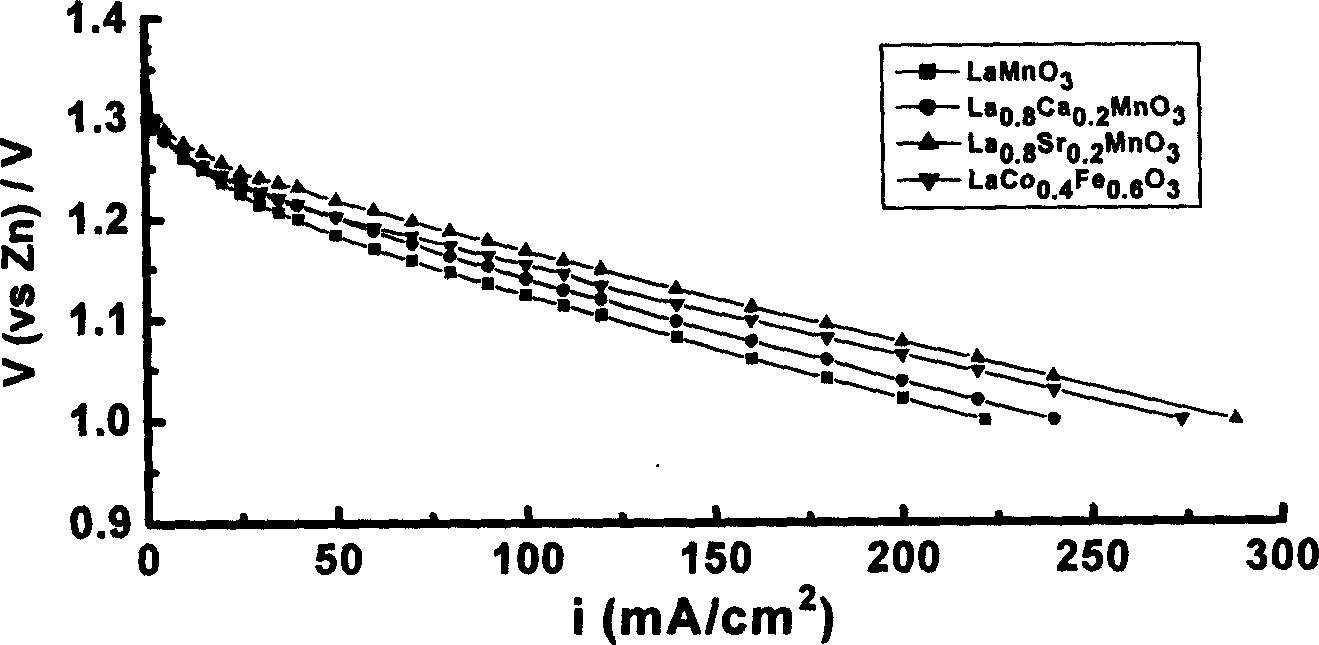

InactiveCN1872414AImprove performanceThe characteristic diffraction peaks are obviousMetal/metal-oxides/metal-hydroxide catalystsStrontium oxideCerium oxide

An oxygen reducing catalyst is prepared from lanthanum oxide, praseodymium oxide, strontium oxide, calcium oxide, MnO2, Mn2O3, Fe2O3, Co3O4, nickel oxide and chromium oxide through swinging-vibrating type ball grinding while reaction for 0.5-12 hr. Its chemical formula is ABO3 or A1-xMxB1-yO3. It can be used to prepare air electrode with high oxygen reducing power in air and high stability in alkaline medium.

Owner:WUHAN HONGYUAN WEILI NEW ENERGY TECH

Ferrous-manganese combined metal oxide magnetic nanofiber with pipe-in-pipe structure and preparation method of ferrous-manganese combined metal oxide magnetic nanofiber

InactiveCN104928800AMagneticControl shapeInorganic material artificial filamentsFilament/thread formingFiberSpinning

The invention relates to a ferrous-manganese combined metal oxide magnetic nanofiber with a pipe-in-pipe structure and a preparation method of the ferrous-manganese combined metal oxide magnetic nanofiber. The nanofiber comprises manganous ferrite and manganese sesquioxide. The preparation method comprises the following steps: at first, preparing a spinning solution from polyvinylpyrrolidone (PVP), ferric salt, manganous salt and N,N-dimethylformamide (DMF), then preparing a composite fiber through an electrostatic spinning technology, and at last, calcining segment by segment to obtain the combined metal oxide magnetic nanofiber with the pipe-in-pipe structure. According to the combined metal oxide magnetic nanofiber and the preparation method, the technical route is simple, the operation is easy, the preparation process can be controlled relatively simply and conveniently, the raw materials are low in price, and wide in source, and the suitability for large-scale production is realized; through the adoption of a technology of calcining segment by segment, a nanofiber product, of which the appearance and the size are uniform, with the pipe-in-pipe structure can be obtained, the sample has certain magnetism, and can be independently applied to or compounded with other materials to be applied to the fields of sewage treatment and catalysis.

Owner:UNIV OF JINAN

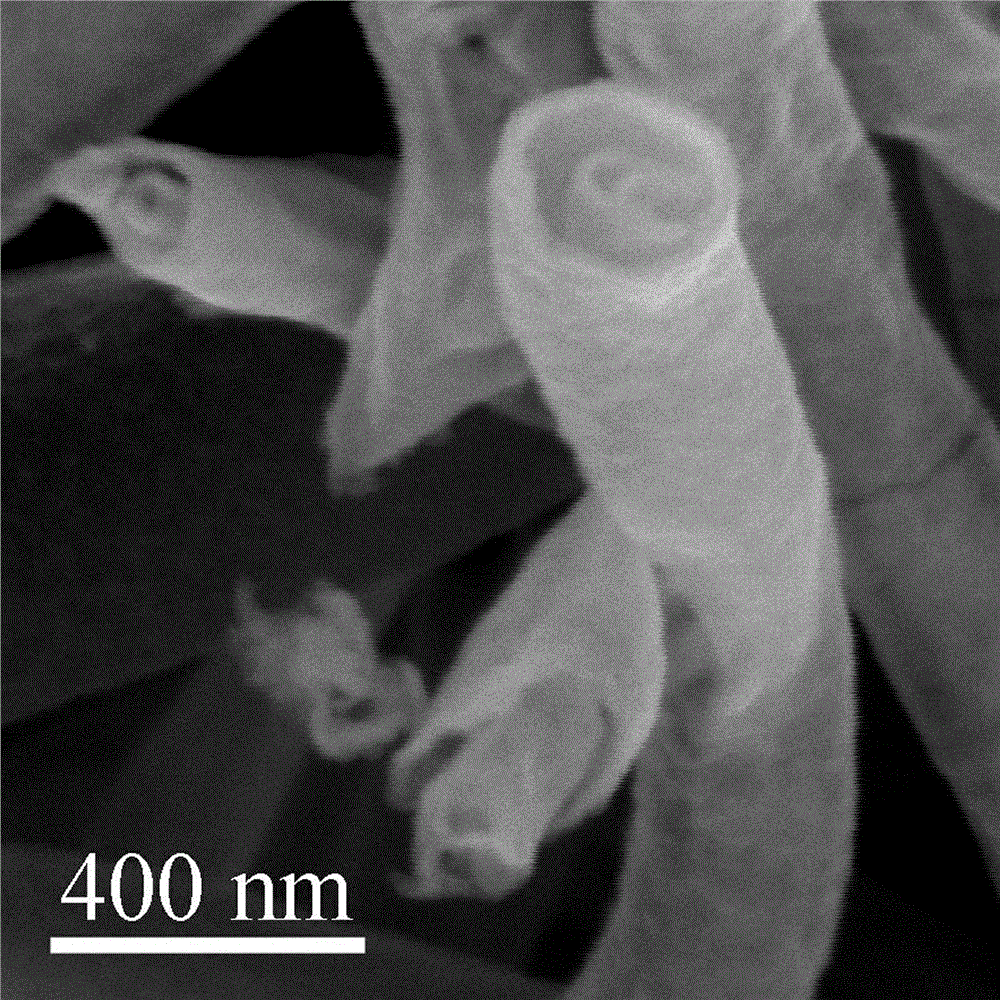

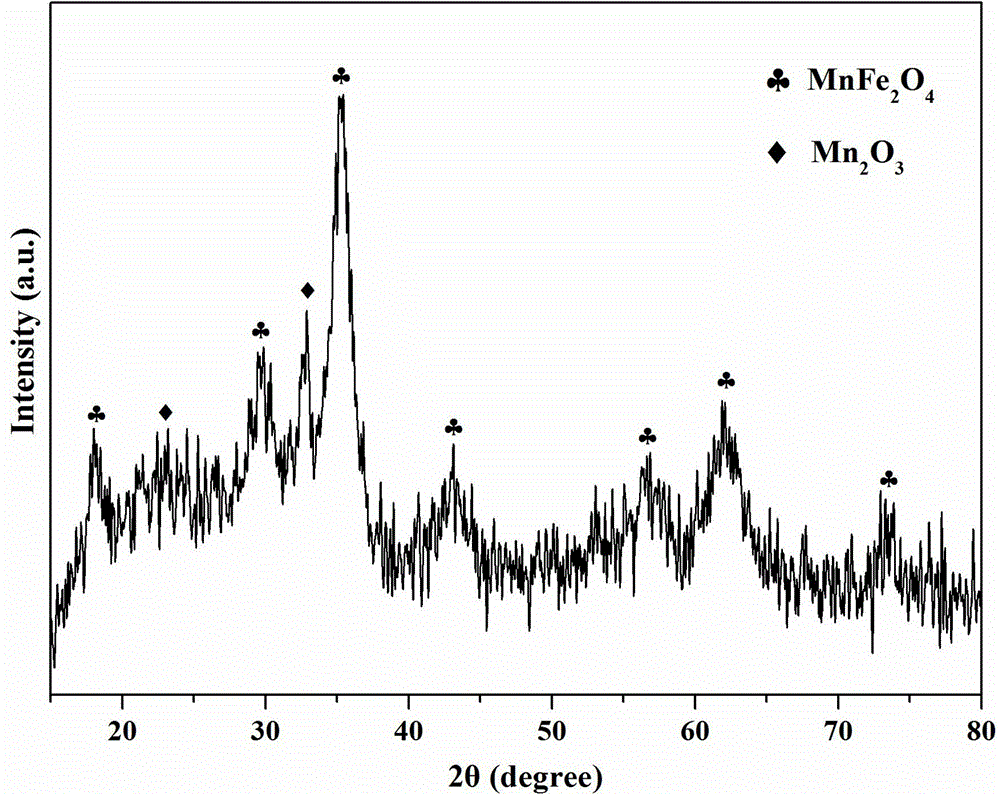

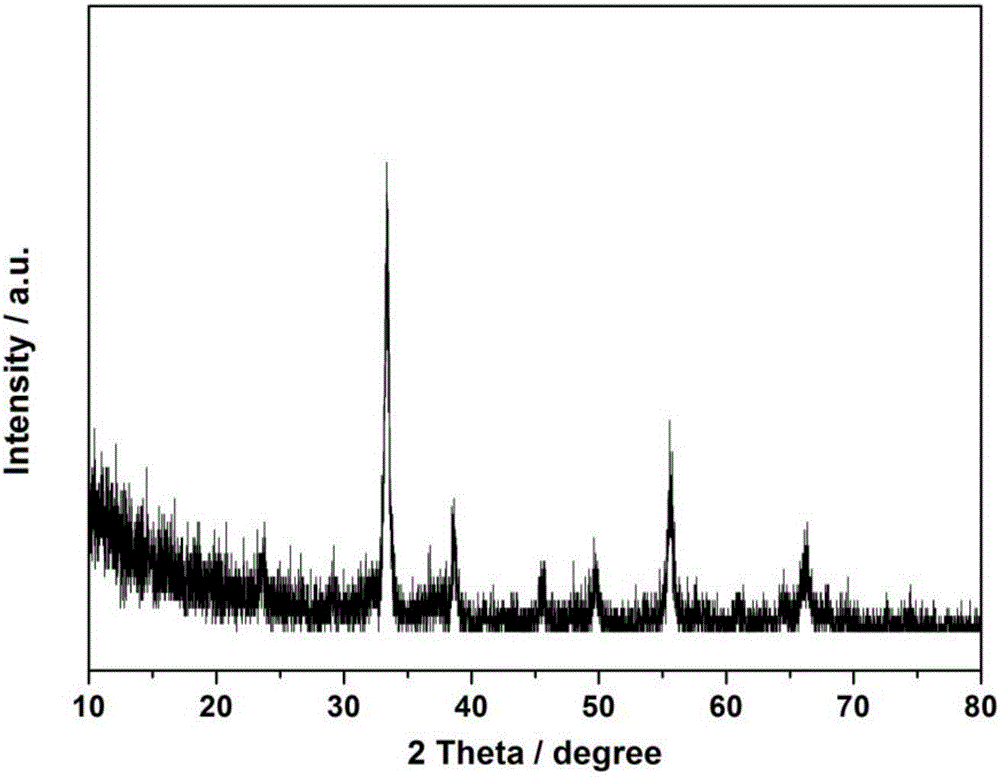

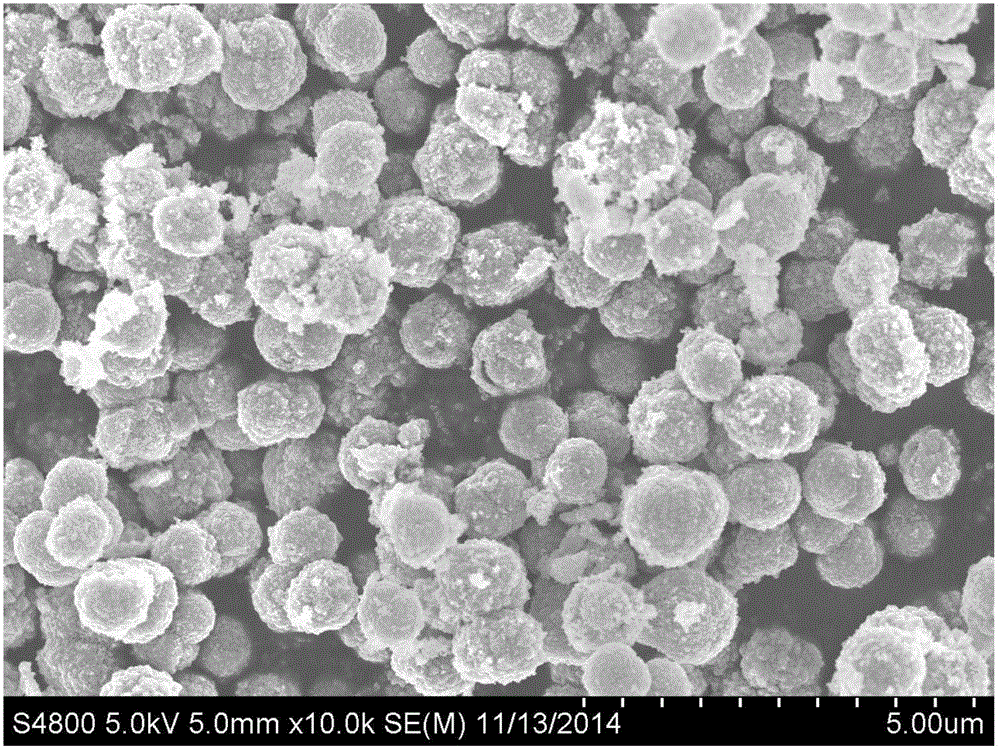

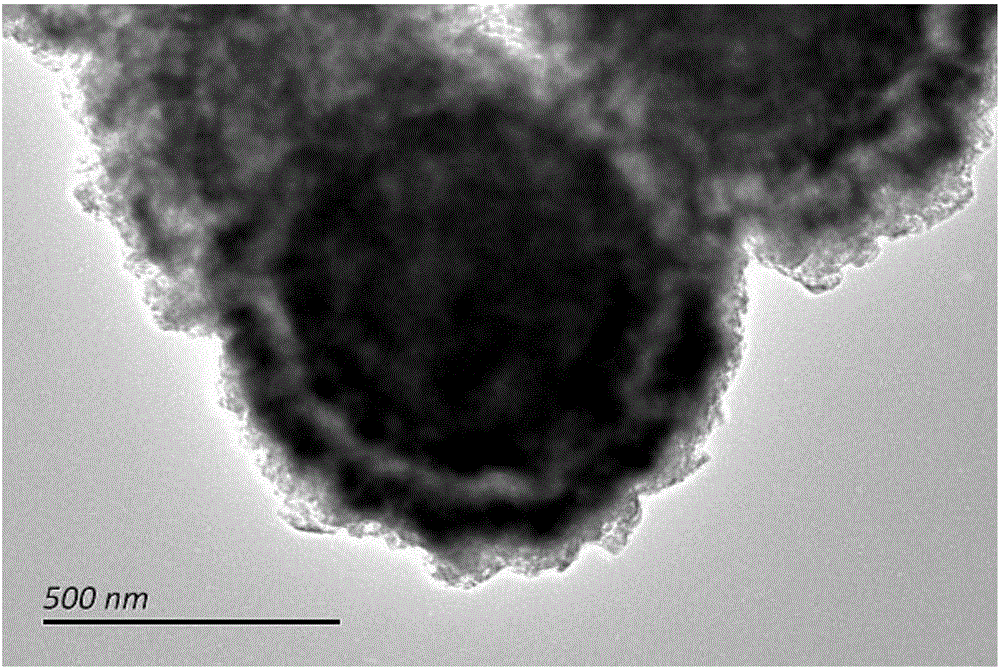

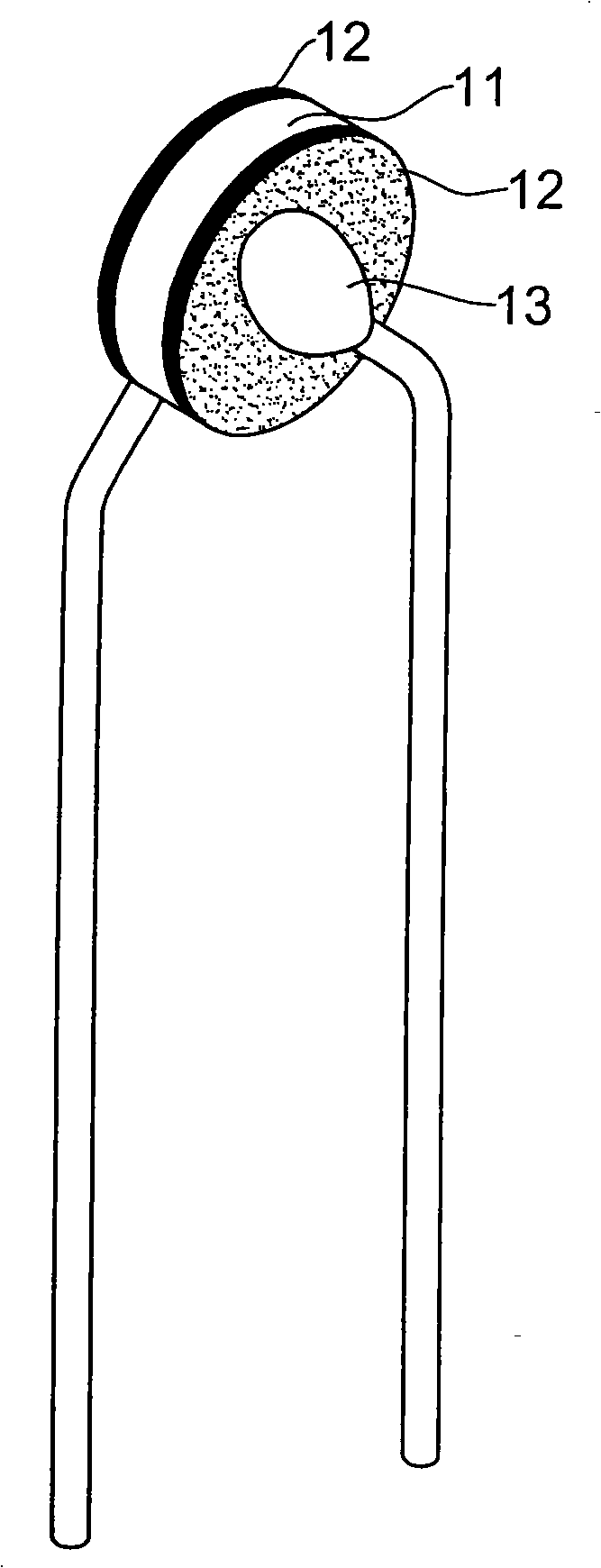

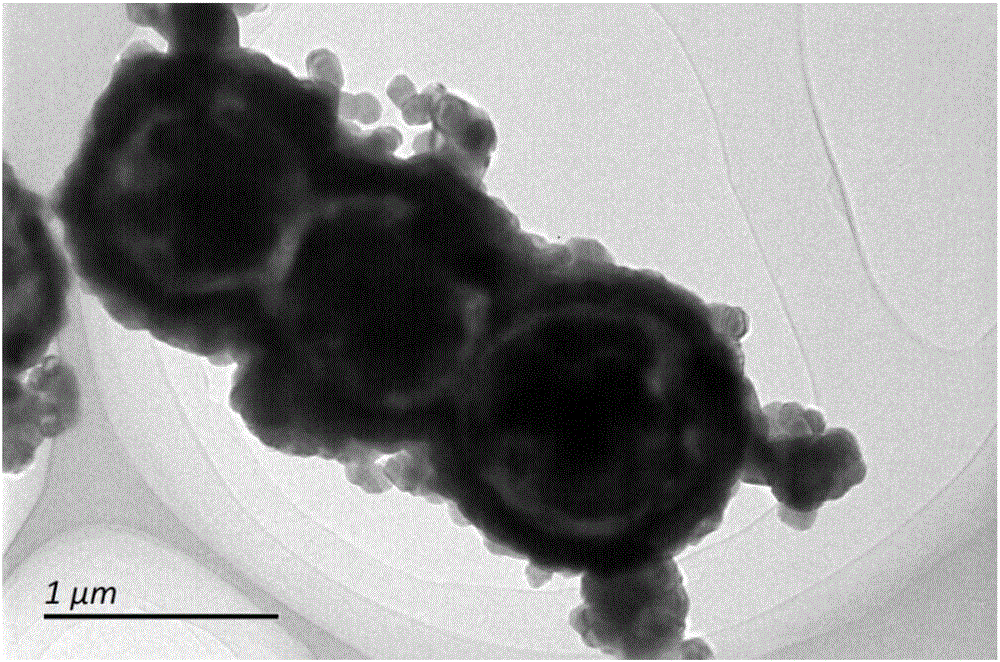

Preparation method of Mn2O3 having yolk-eggshell structure

The invention relates to a preparation method of Mn2O3 having a yolk-eggshell structure. The method mainly includes the steps of: respectively preparing a manganese salt solution and an alkaline reagent solution, and after complete dissolution, adding the solutions into a reaction container according to the molar ratio of manganese ion to alkaline reagent being 1:(1-8), stirring the solutions, and performing reflux condensation under a microwave-stimulated heating condition, naturally cooling the mixture to room temperature and centrifugally separating the mixture to obtain a manganese carbonate precursor; thermally-treating the manganese carbonate precursor in a high-temperature furnace at 200-700 DEG C for 1-10 h, and cooling the product in the furnace to room temperature to prepare the Mn2O3 having a yolk-eggshell structure. The preparation method is simple, is easy to carry out, is low in cost, allows controllable preparation and mass synthesis, and is beneficial to industrial mass production.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Porous nano manganese oxide catalyst, preparation and application thereof

InactiveCN110404530ALow ignition temperatureLarge specific surface areaIncinerator apparatusMetal/metal-oxides/metal-hydroxide catalystsManganese oxideSolvent

The invention belongs to the technical field of environmental catalytic materials, and more particularly relates to a porous nano manganese oxide catalyst and preparation and application thereof. Manganese salt and amino acid are mixed and dissolved in a solvent, then the temperature is raised to reach the ignition point of the amino acid, a combustion reaction occurs, a product is washed after the reaction is completed, and the porous nano manganese oxide catalyst is obtained after solid-liquid separation. When manganic oxide prepared by the method is applied to catalytic combustion of volatile organic compounds, the manganic oxide has the advantages of higher specific surface area, uniform pore size distribution, high catalytic activity, strong stability, excellent water resistance and the like. The porous nano manganese oxide catalyst has high combustion product selectivity, no secondary pollution, environmental friendliness, low cost and easy industrial production.

Owner:HUAZHONG UNIV OF SCI & TECH

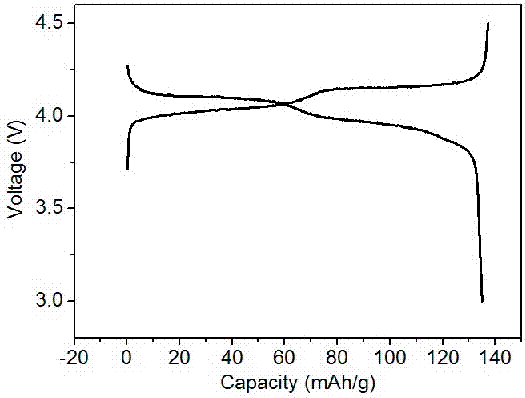

Manufacturing method for layered lithium manganate cathode material for lithium ion battery

InactiveCN102249341AImprove the first discharge capacityImprove cycle performanceManganates/permanganatesElectrolysisSesquioxide

The invention relates to a manufacturing method for a layered lithium manganate cathode material for a lithium ion battery, which adopts electrolytic manganese dioxide as a raw material, and comprises the following steps: performing high-temperature calcination to obtain manganese sesquioxide; mixing the manganese sesquioxide and anhydrous sodium carbonate according to a molar ratio of 1:1, performing sintering to obtain NaMnO2; weighing a lithium source and NaMnO2 according to a molar ratio of 6-10:1, filtering the mixed solution, washing the precipitates, drying to obtain the layered lithium manganate. The layered lithium manganate of a lithium ion battery cathode manufactured by the invention has a charge capacity of above 200 mAh / g, and a discharge capacity of above 180 mAh / g, and has a high first discharge capacity, and good cycle performance.

Owner:耿世达

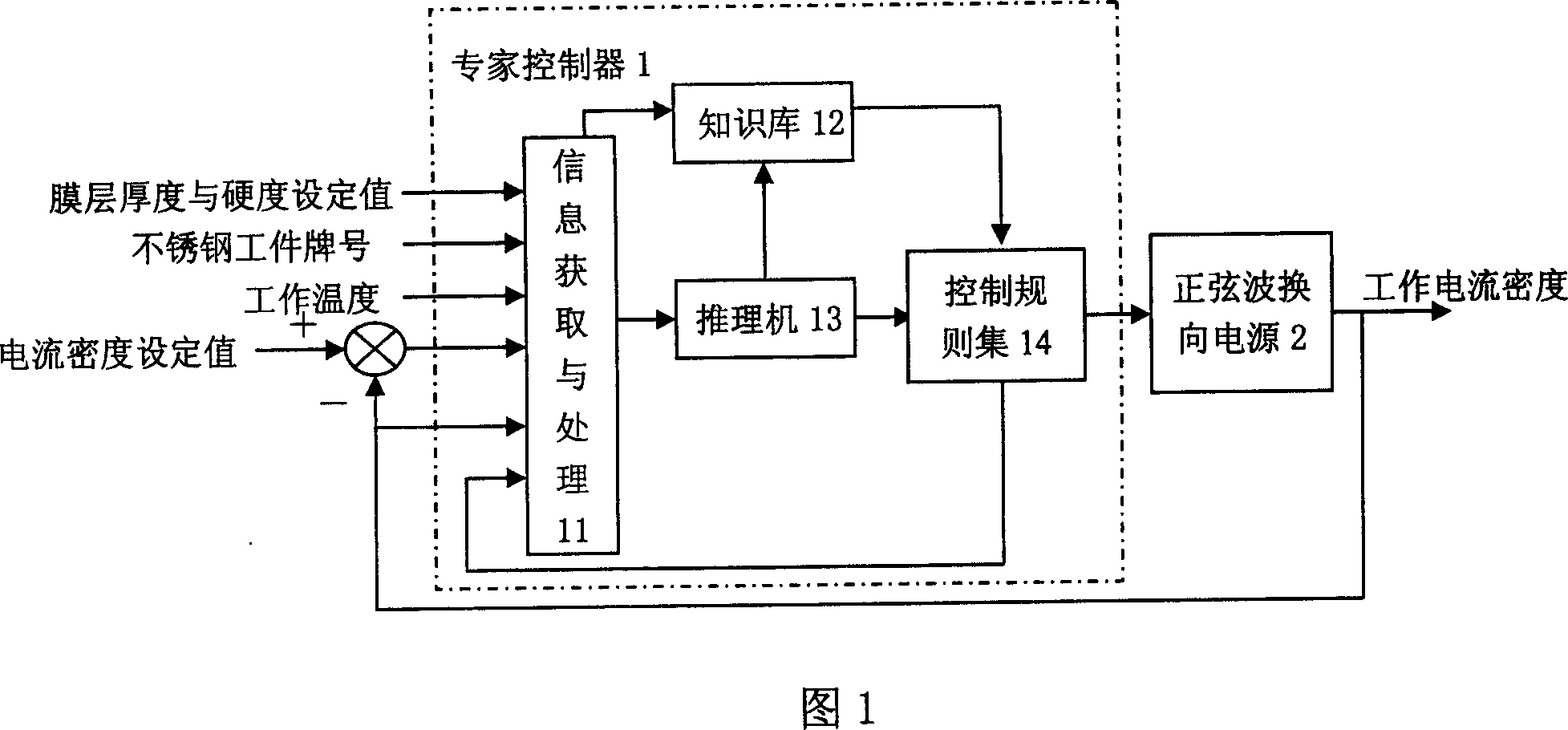

Manufacturing method of stainless non-stick pan and apparatus thereof

InactiveCN1919118ASolve wear resistanceAvoid harmCooking-vessel materialsMicro arc oxidationMetallurgy

The invention discloses a preparing method of stainless steel non-stick pan, which comprises the following steps: placing stainless steel material in the mould to punch and mould, polishing inner surface of non-stick pan mechanically, removing oil, cleaning, placing the non-stick pan in the differential arc oxidized grinded polished electrolytic solution, connecting sine wave switching powder with specialist controller, generating differential arc discharge on the inner surface of non-stick pan.

Owner:JIANGMEN FUSITE METAL PROCESSING ART

Shielding braided sheath for anti-electromagnetic cable used in spaceflight and aviation, and preparation method thereof

InactiveCN107163457AImprove shielding effectExtended service lifeInsulated cablesCable/conductor manufactureAviationTG - Triglyceride

The invention discloses a shielding braided sheath for an anti-electromagnetic cable used in spaceflight and aviation, and a preparation method thereof. The sheath is prepared by braiding a plurality of intertwisted wire jackets. The wire jackets are prepared through the following steps: 1) subjecting polytetrafluoroethylene resin, styrene butadiene rubber, butadiene rubber, ethyl acetate, toluene, dibutyl phthalate and styrene to primary kneading so as to obtain a mixture M1; 2) adding nanometer titanium oxide, manganic oxide, molybdenum sulfide, pentlandite, brass powder, aluminum powder, talcum powder, carbon black, inositol hexaphosphate, epoxidized triglyceride, citrate and a sulfuration promoter TMTD into the mixture M1 and carrying out secondary kneading so as to obtain a mixture M2; and 3) and subjecting the mixture M2 to extrusion granulation and processing and carrying out braiding so as to obtain the shielding braided sheath for the anti-electromagnetic cable used in spaceflight and aviation. The sheath prepared in the invention has better shielding properties, so the service life of the cable used in the field of aviation and spaceflight can be substantially prolonged.

Owner:WUHU HANGTIAN SPECIAL CABLE FACTORY

Metal cream composing substance for capacitor

InactiveCN101329942ALow costImprove the problem of poor electrical propertiesFixed capacitor electrodesMetal/alloy conductorsAdhesiveSesquioxide

The invention discloses a metal cream component applied to producing a capacitor, which serves as a terminal electrode of a capacitor. The metal cream component of the capacitor consists of metal powder, an organic adhesive, glass powder and a metal oxide such as bismuth oxide (Bi2O3), nickel oxide (NiO), zinc oxide (ZnO), boron oxide (B2O3), cuprous oxide (Cu2O), tin oxide (SnO2), manganese oxide (Mn2O3), MnO2 (manganese dioxide), aluminum sesquioxide (Al2O3), silicon dioxide (SiO2), zirconium dioxide (ZrO2) and copper oxide (CuO). The metal cream component of the capacitor of the invention is used for coating the two sides of a capacitor medium to form a thickness; after an appropriate producing process, the capacitor aiming at reducing cost, modifying electric property and protecting environment is produced.

Owner:WALSIN TECHNOLOGY CORPORATION

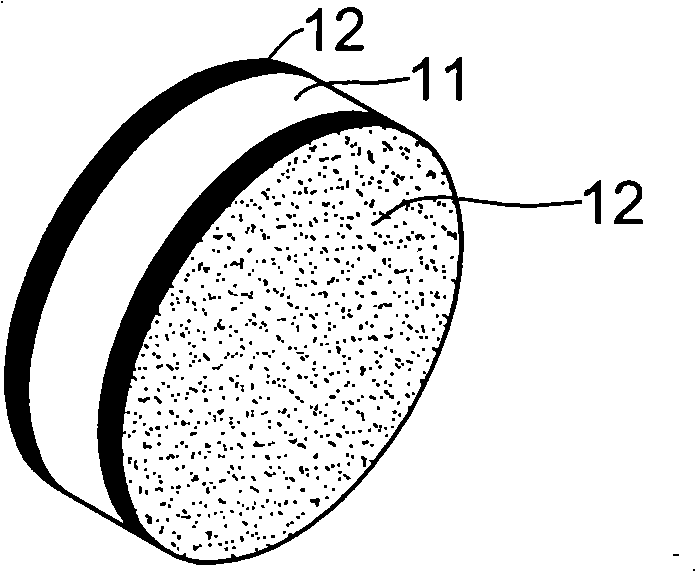

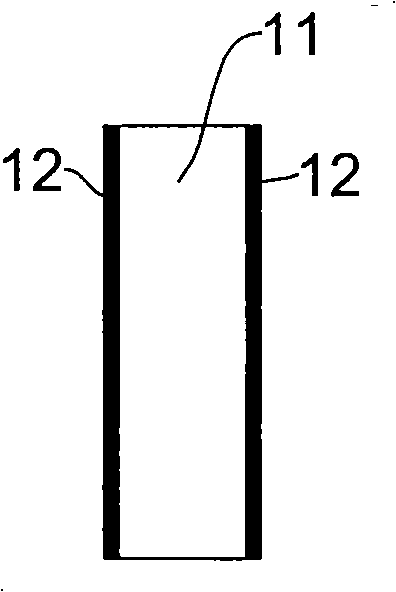

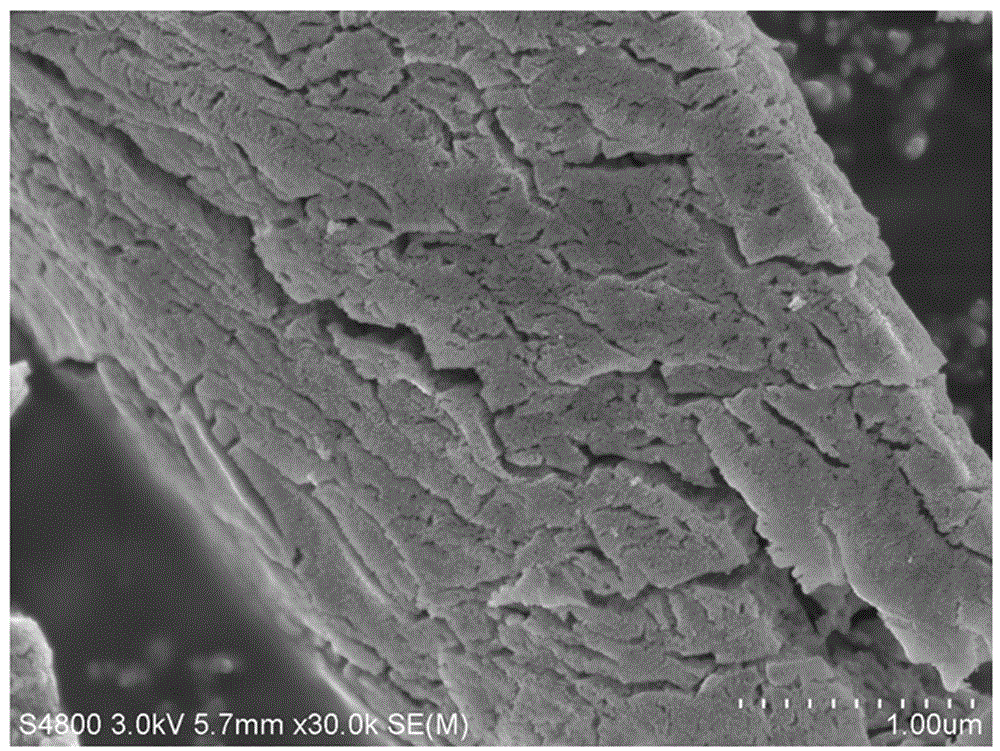

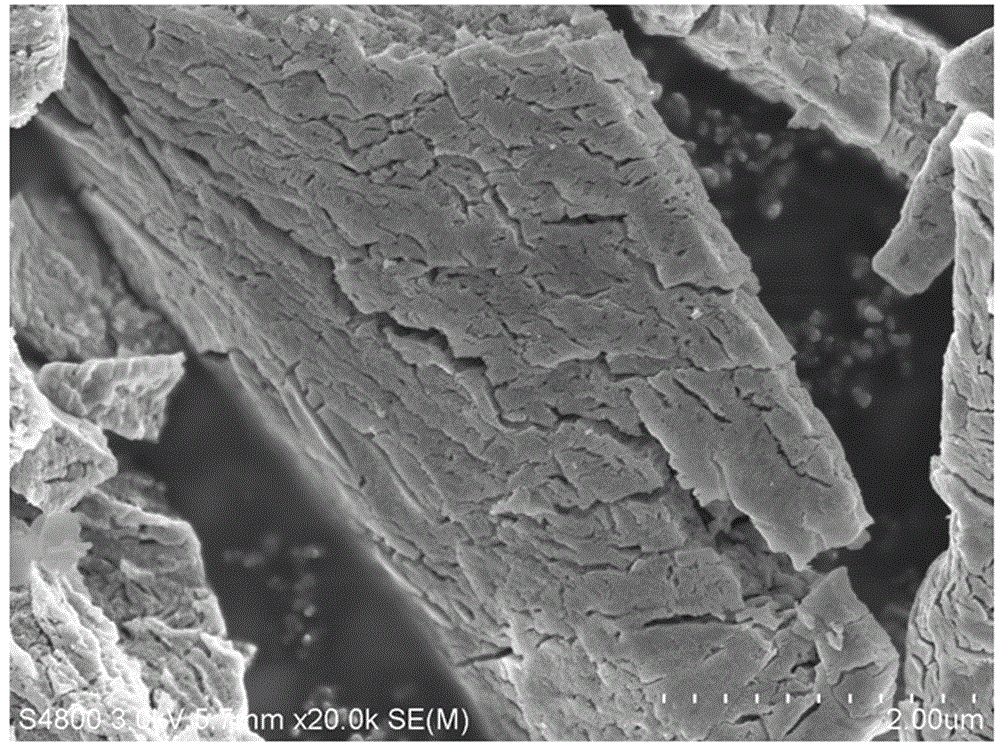

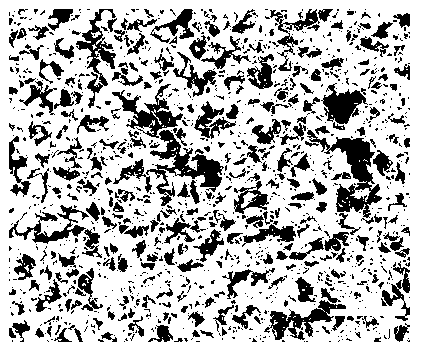

Preparation method of manganese sesquioxide hierarchical-structure material

InactiveCN105883924ALarge specific surface areaMany gapsMaterial nanotechnologyHybrid capacitor electrodesCapacitanceSesquioxide

The invention belongs to the technical field of functional material preparation and relates to a preparation method of a manganese sesquioxide hierarchical-structure material. The method comprises the following steps: dropwise adding a soluble manganese salt aqueous solution into an oxalic acid aqueous solution; reacting at constant temperature under a stirring condition until precursor precipitate is generated; and after the reaction is over, filtering, washing, drying and calcining to obtain the manganese sesquioxide hierarchical-structure material. The product is a flaky hierarchical-structure material formed by assembling a large quantity of manganese oxide nano particles. The flake size is 10-20mu m, and the size of the manganese oxide nano particles is 20-30nm. With low preparation cost and easiness in operation control, the technology has relatively high production efficiency and can realize industrial mass production. The manganese sesquioxide hierarchical-structure material prepared by the preparation method is used as an electrode material and has relatively high specific capacitance and good cycle performance.

Owner:BOHAI UNIV

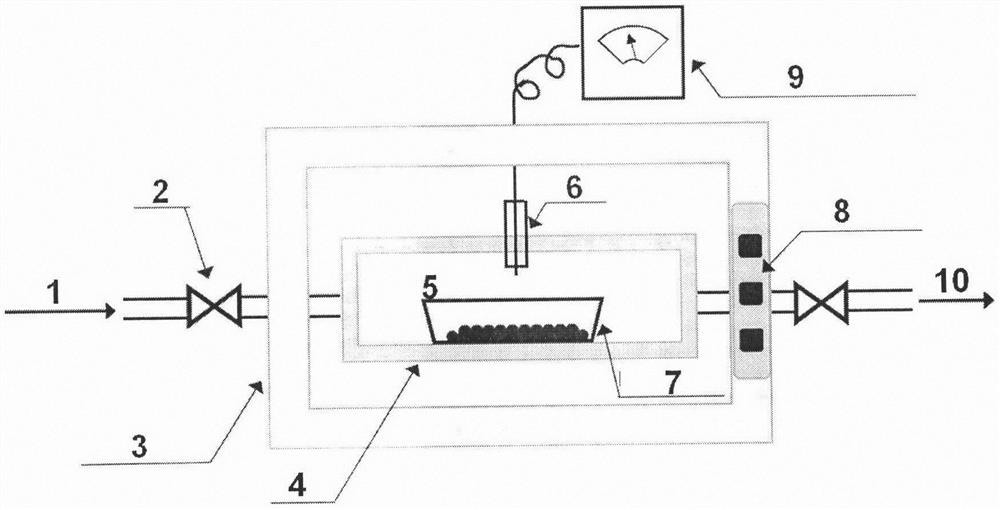

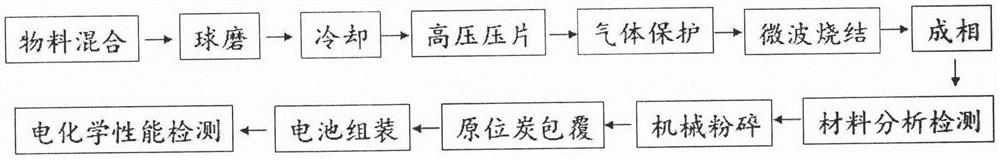

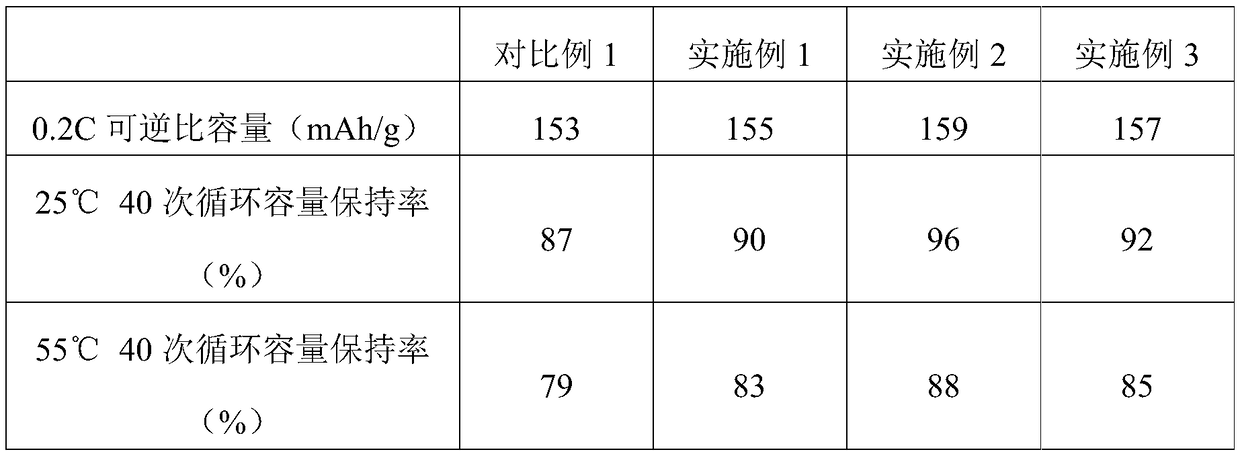

Controllable regulation and control method of Na2/3Mn1/2Fe1/4Co1/4O2 positive electrode material of sodium-ion battery meeting high-rate discharge cycle performance

ActiveCN111933942AHigh specific capacityImprove electrochemical performanceSecondary cellsPositive electrodesElectrical batteryPhysical chemistry

The invention relates to a controllable regulation and control method of a Na2 / 3Mn1 / 2Fe1 / 4Co1 / 4O2 positive electrode material of a sodium-ion battery meeting high-rate discharge cycle performance. Themethod comprises the steps of taking sodium carbonate (with a molecular formula of Na2CO3), manganese sesquioxide (with a molecular formula of Mn2O3), ferric oxide (with a molecular formula of Fe2O3)and cobalt carbonate (with a molecular formula of CoCO3) as raw materials, weighing according to a stoichiometric ratio, and fully mixing to prepare a precursor compact sheet; synthesizing the Na2 / 3Mn1 / 2Fe1 / 4Co1 / 4O2 positive electrode material of the sodium ion battery by adopting a microwave sintering technology. The technical route has the characteristics of simple process, high reaction speed,controllable product morphology, low cost and the like, and is suitable for rapid controllable preparation of sodium ion battery positive electrode materials and related materials; the synthesized pure-phase Na2 / 3Mn1 / 2Fe1 / 4Co1 / 4O2 material has high specific capacity, good cycling stability and high rate capability, and provides a valuable basis for improving the comprehensive electrochemical performance of the sodium ion battery.

Owner:苏州聚云新能源科技有限公司

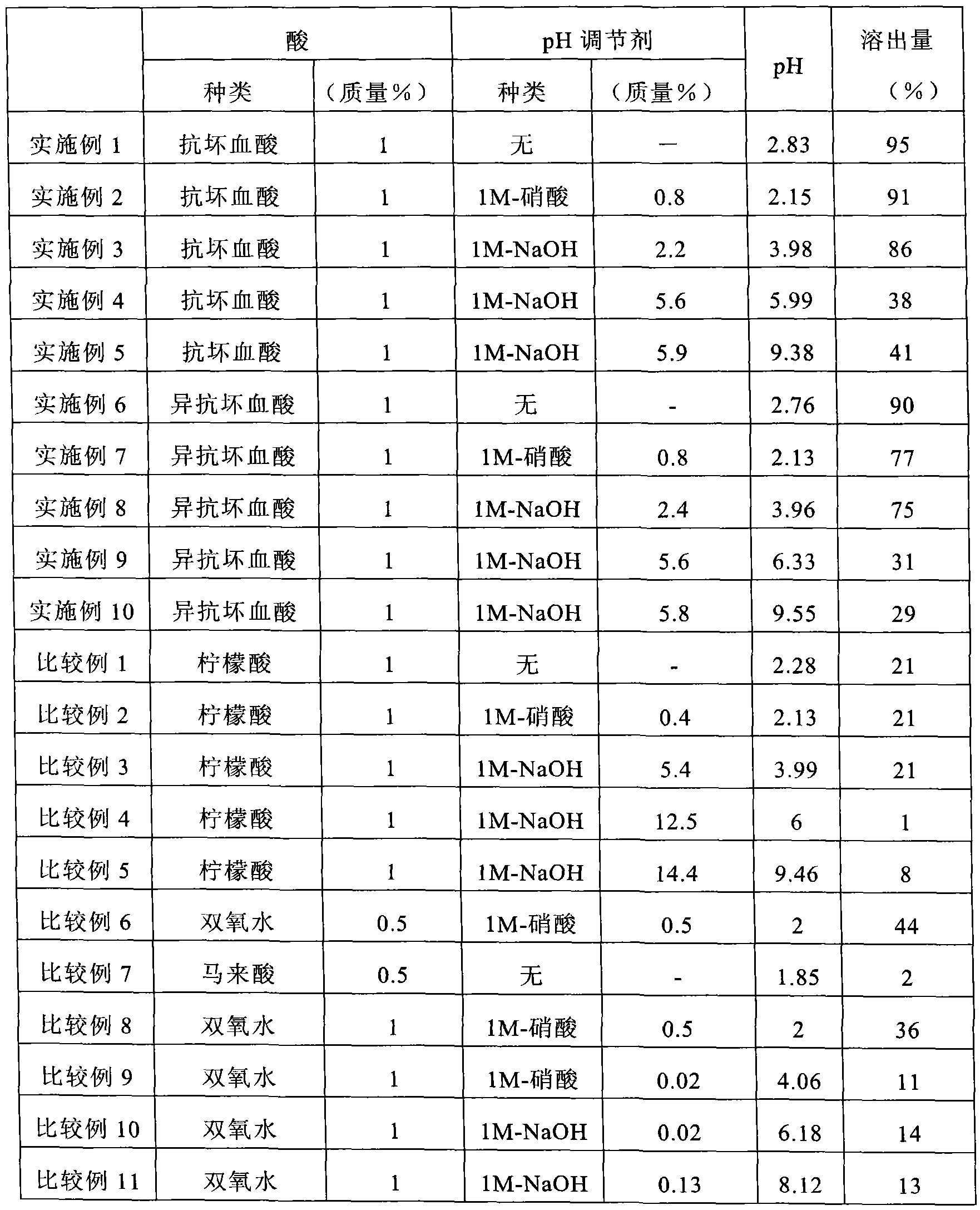

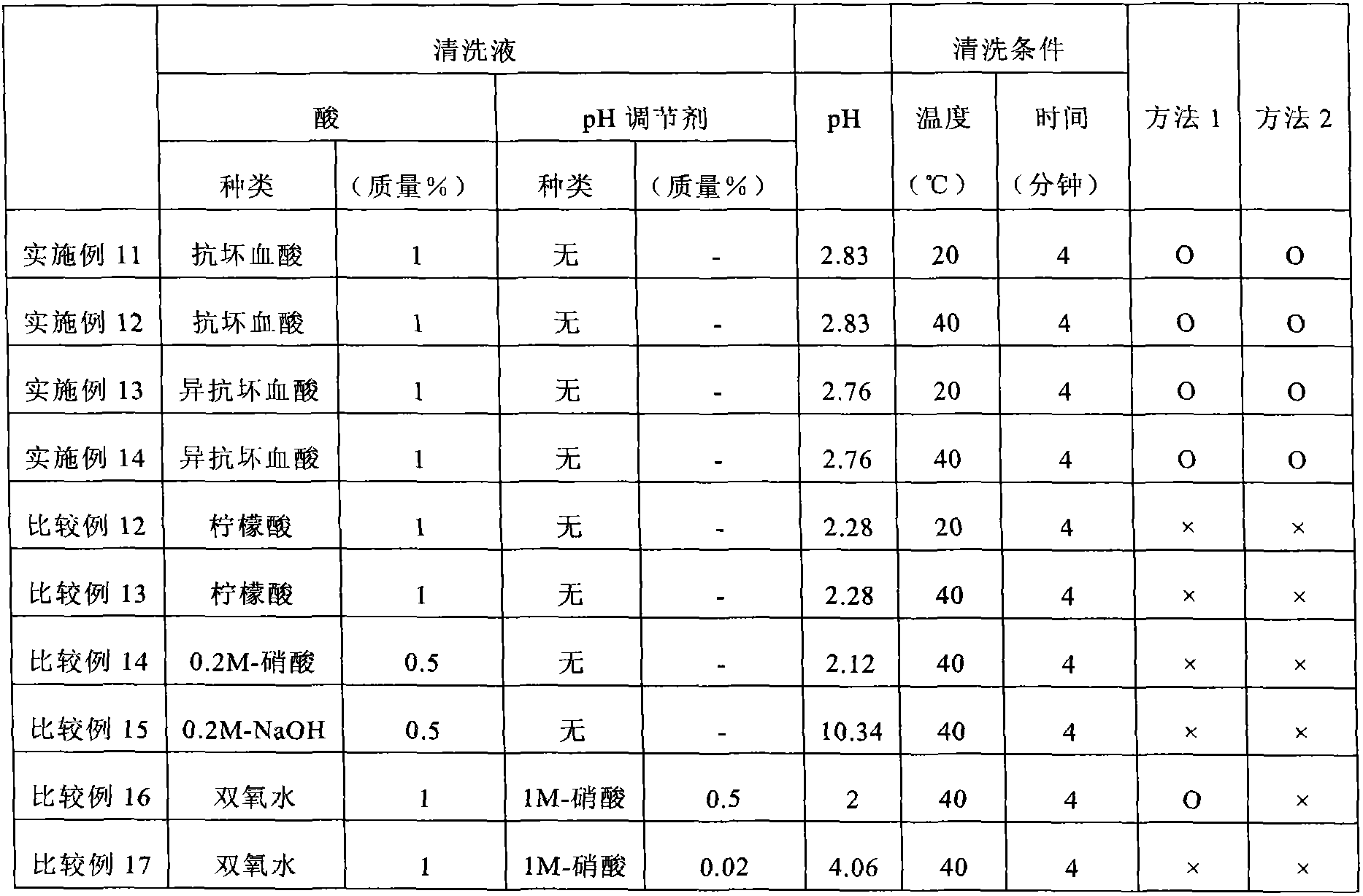

Process for producing glass product

InactiveCN103747917AEasy to cleanOther chemical processesLapping machinesMetallurgyManganese(III) oxide

The purpose of the present invention is to provide a process for glass product production which includes, after the step of polishing a glass using a polishing agent that contains dimanganese trioxide abrasive grains, the step of effectively removing the polishing agent which contains dimanganese trioxide abrasive grains and has adhered to the glass. The process for producing a glass product comprises a polishing step in which a glass is polished using a polishing agent that contains dimanganese trioxide abrasive grains and a cleaning step in which the glass is thereafter cleaned using a cleaning fluid, wherein the cleaning fluid is a cleaning fluid containing ascorbic acid and / or erythorbic acid.

Owner:ASAHI GLASS CO LTD

Preparation method of nanometer manganese sesquioxide with a hollow cone shape

ActiveCN103121725ANovel structureImprove responseNanotechnologyManganese oxides/hydroxidesCarbon compositesNano structuring

The invention discloses a manganese sesquioxide nano-structure with a hollow cone shape and a preparation method thereof. The cavity of a hollow cone has the diameter being 60-100nm and the wall thickness being 20-30nm. The preparation method comprises the following steps of: with a tri-block copolymer PEO-PPO-PEO (P123) as a structure-directing agent, dissolving the structure-directing agent in an aqueous solution, then adding co-reducer carbon powder and manganese nitrate, dispersing and mixing, adding potassium permanganate, stirring for a period of time, carrying out hydro-thermal treatment at a certain temperature, washing to obtain manganese dioxide hollow cone / carbon composite material; and baking the manganese dioxide hollow cone / carbon composite material for a period of time in 550 DEG C-air to obtain a manganese sesquioxide hollow nanometer cone with high purity. The preparation method disclosed by the invention is simple in a reaction process and easy to control. The manganese sesquioxide structure is novel in structure and has good application prospect in fields of energy storage, catalysis and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for producing metal compound by waste zinc-manganese dioxide dry cell

InactiveCN1530180ASolve unhandled problemsSolid waste disposalZinc compoundsCadmium sulfateElectrolysis

Owner:于之涛

Method for separating calcium and magnesium from oxides of manganese

InactiveCN101234787AReaction conditions are easy to controlLow costManganese oxides/hydroxidesSesquioxideSlurry

The invention belongs to a hydrometallurgy field, which discloses a method for separating calcium and magnesium from manganese oxide. Crude (or elementary) manganic manganous oxide or manganese sesquioxide prepared by oxygen or air sulfur oxide acid manganese liquor or manganese hydroxide have high calcium and magnesium impurity of which contents are higher than national or industry standards. In the manganese oxide, the calcium and magnesium can exist in the forms such as sulfate and hydroxide. The method utilizes processes such as partial disliquor, morphological change of the oxide and rearrangement of crystal structure component, etc. of the manganese oxide in acid medium to cause the calcium and magnesium composition mixed with the manganese oxide to be exposed and dissolved to achieve the aim of separating the calcium and magnesium. Manganese mixed oxide is obtained after calcium and magnesium separated slurry is filtered, washed and parched; the manganic manganous oxide is obtained by thermally treating the mixture. The method for separating the calcium and magnesium from the manganese oxide has the advantages of easy control of reaction condition, good effect of removing the calcium and magnesium and low cost.

Owner:UNIV OF SCI & TECH BEIJING

Ruthenium dioxide coated spinel lithium-rich lithium manganate and preparation method thereof

ActiveCN109037613ARandom combinationSmall and uniform particle sizeCell electrodesSecondary cellsHigh temperature storagePotassium

The invention discloses a ruthenium dioxide coated spinel lithium-rich manganate lithium and a preparation method thereof. The preparation method comprises the following steps: adding an aqueous solution of sodium hydroxide and manganese trioxide to 160 to 200 DEG C for microwave hydrothermal reaction to obtain a precursor; carrying out molten salt reaction of lithium nitrate, potassium chloride and the precursor at 450 to 500 DEG C to obtain spinel lithium manganate rich in lithium; dispersing spinel lithium-rich lithium manganate in an aqueous solution of ruthenium chloride and then adding the aqueous solution of sodium hydroxide, and making th obtained solid to react at 150 to 180 DEG C. The prepared ruthenium dioxide coated spinel lithium-rich manganate is coated with a layer of ruthenium dioxide on the surface of the lithium-rich manganate, on the one hand, RuO2 can increase the conduction of Li + and electrons on the surface; and on the other hand, RuO2 can avoid the direct contact between Li-rich lithium manganate and an electrolyte, thereby improving the stability of a crystal structure, and further improving the high-temperature storage and cycle performance of Li-rich lithium manganate.

Owner:SHANGHAI ELECTRICGROUP CORP

Getter for vacuum insulation board and vacuum insulation board

ActiveCN105435732AImprove inhalation effectReduce operational riskThermal insulationOther chemical processesSesquioxideCerium

The invention provides a getter for a vacuum insulation board. The getter comprises an external packaging bag and powder therein, wherein the powder comprises first powder which is an oxide mixture or a compound oxide, and the oxide mixture or the compound oxide is formed by at least two of manganese dioxide, manganese sesquioxide, manganous-manganic oxide, copper oxide, cerium dioxide, cobaltosic oxide, cobalt sesquioxide, aluminium sesquioxide, zinc dioxide and silver oxide; and a drier which comprises one or more of alkaline-earth metal oxides, soda lime, phosphorus pentoxide, chlorides and bromides. The getter is relatively good in gettering action, free of an activation process and safe and convenient to use and operate. The invention further provides the vacuum insulation board which comprises the getter. The vacuum insulation board not only has an excellent vacuum insulation effect, but also is safe and convenient to use and operate, and is low in cost.

Owner:三河市华臻新材料有限公司

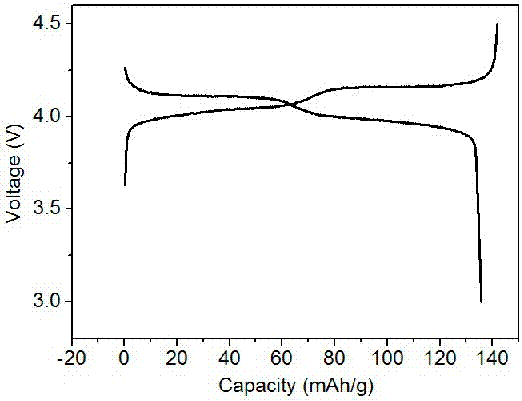

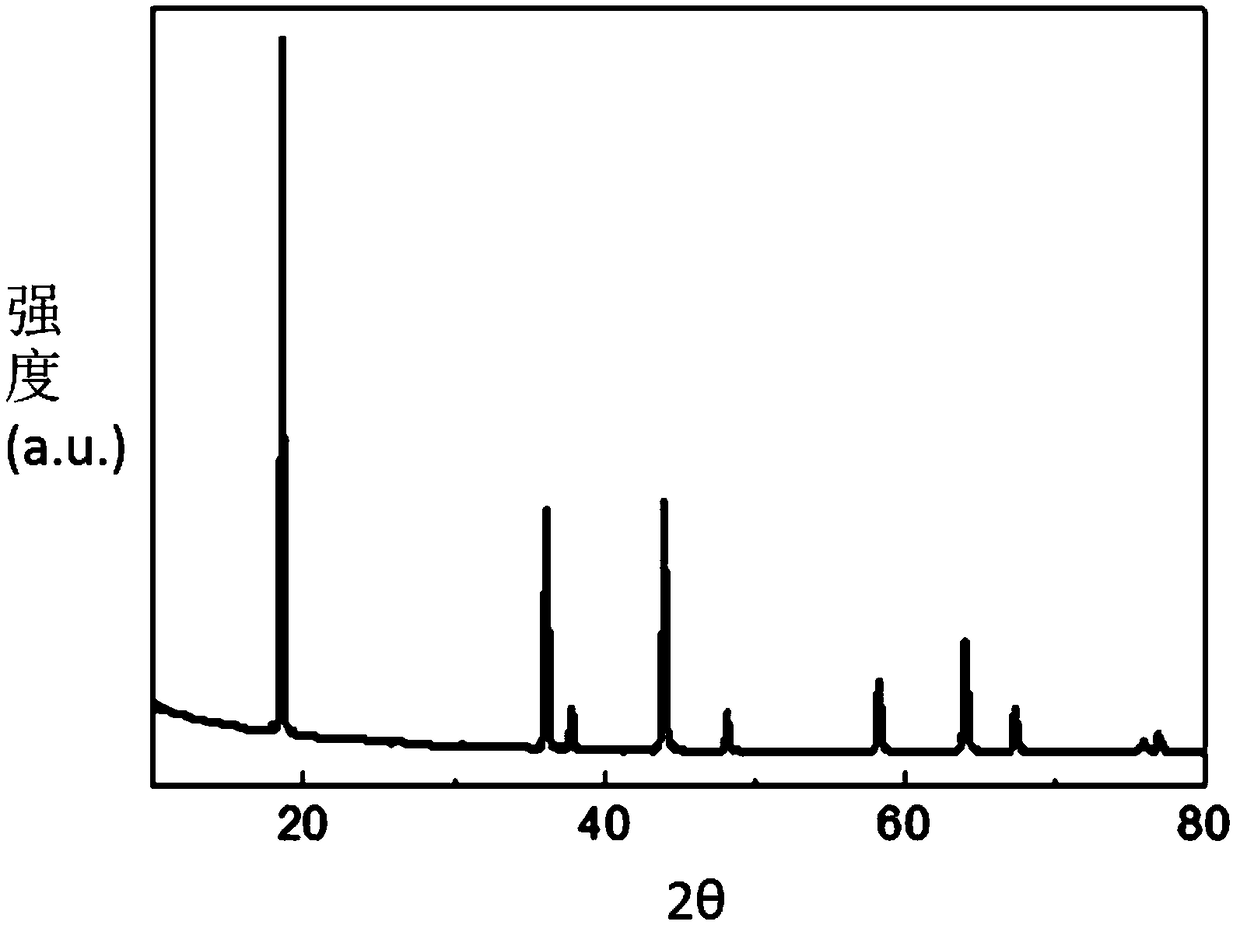

Preparation method for lithium ion battery manganese-based cathode materials of egg yolk-egg shell structure

The invention relates to a universal preparation method for a lithium ion battery manganese-based cathode material of an egg yolk-egg shell structure. The preparation method mainly comprises the following steps of preparing manganese salt solution and alkaline reagent solution respectively, adding the manganese salt solution and the alkaline reagent solution together to a reaction vessel according to the molar ratio of the manganese ions to the alkaline reagent of 1:(1-8) after the manganese salt solution and the alkaline reagent solution are sufficiently dissolved, stirring, and conducting reflux condensation under the condition of microwave excitation heating; after the mixed solution is cooled naturally to room temperature, conducting centrifugal separation to obtain a manganese carbonate precursor; placing the manganese carbonate precursor in a high temperature furnace for heating at 200-700 DEG C for 1-10 hours, and obtaining manganese sesquioxide of the egg yolk-egg shell structure; then obtaining the manganese-based cathode material LiMn2O4, LiNi0.5Mn1.5O4, LiNixCoyMn1-x-yO2(90<x+y<1), xLi2MnO3.(1<=x)LiNi1 / 3Co1 / 3Mn1 / 3O2(0<x<1),xLi2MnO3.(1<=x)LiNi0.5Mn0.5O2(0<x<1)of the egg yolk-egg shell structure through a simple high temperature solid state method. The preparation method is simple in process, easy to operate and low in cost, has the advantages of controllable preparation, large-scale synthesis and the like, and is beneficial to industrialized mass production.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method for producing waste water treating agent using waste battery as raw material

InactiveCN1458077ASolve the pollution of the environmentLow costSolid waste disposalWater/sewage treatment by flocculation/precipitationChlorideManganese(III) oxide

The waste water treating agent includes T flocculant liquid and N coagulant aid liquid. The waste water treating agent is prepared through the process of: crushing and separating waste battery, heating, pressurizing and acid treating MnO2 and MnO3 to produce soluble matter A; heating and pressurizing ammonium chloride, zinc chloride, paste and paper and acid and alkali treatment to produce soluble matter B; heating and pressurizing Cu, Fe, Zn, Ni and Al separately and acid treatment to obtain metal salt C; polymerizing A, B and C inside a polymerizing apparatus through heating, pressurizing and adding catalyst to obtain polymers D1, D2 and D3; mixing D1 and D3 to obtain T flocculant liquid and D2 is the N coagulant aid liquid. The preparation process has no secondary pollution.

Owner:严铁柱 +1

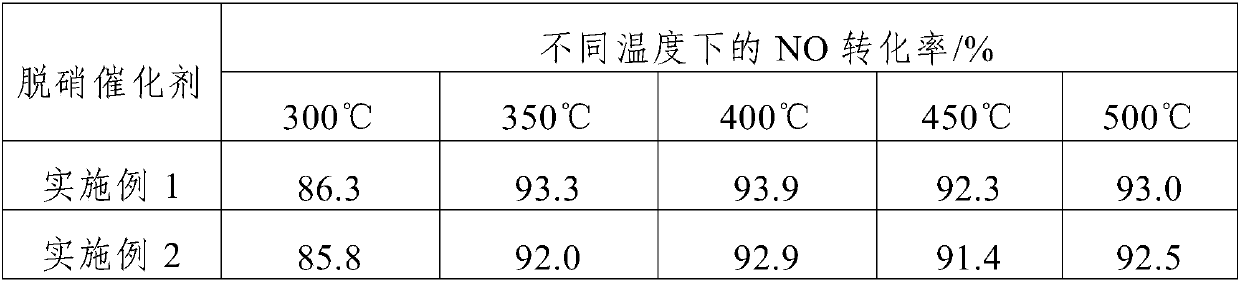

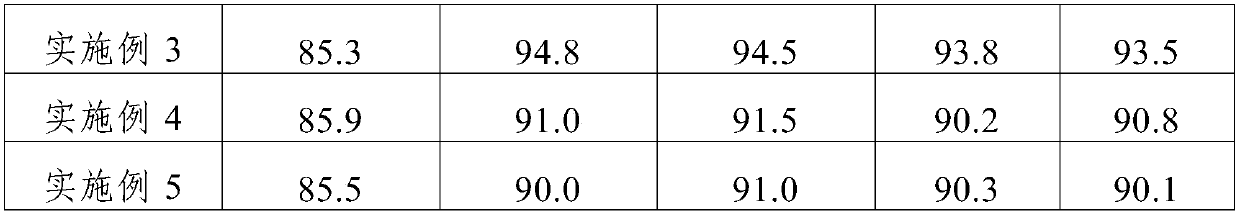

High-temperature phosphorus-bearing cerium-manganese-tin composite denitrification catalyst and preparation method thereof

ActiveCN108031482AEasy to prepareReduce manufacturing costDispersed particle separationCatalyst activation/preparationRare-earth elementPhosphate

The invention discloses a high-temperature phosphorus-bearing cerium-manganese-tin composite denitrification catalyst, made by combining cerous phosphate, manganese(III) oxide and tin oxide in a molarratio of 1:0.15:(0.02-0.06); nitrogen oxide conversion rate of the catalyst at the suitable temperature of 300-500 DEG C is not lower than 85%. The invention also discloses a preparation method of the high-temperature phosphorus-bearing cerium-manganese-tin composite denitrification catalyst, comprising: preparing cerous phosphate, and supporting manganese(III) oxide and tin oxide onto the cerousphosphate. The high-temperature phosphorus-bearing cerium-manganese-tin composite denitrification catalyst uses rare-earth elements, cerium, tin and manganese, as active ingredients having low cost;the preparation method is simple; the high-temperature phosphorus-bearing cerium-manganese-tin composite denitrification catalyst has no volatile vanadium. The high-temperature phosphorus-bearing cerium-manganese-tin composite denitrification catalyst has high removal rate of nitrogen oxides at the high temperature zone of 300-500 DEG C and also has good water resistance.

Owner:THE NORTHWEST RES INST OF CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com