Process for producing glass product

A manufacturing method and technology of glass products, applied in the direction of cleaning methods using liquids, manufacturing tools, cleaning methods and utensils, etc., can solve problems such as obtaining cerium oxide abrasive grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0049] Examples of the present invention are specifically described below, but the present invention is not limited to these Examples.

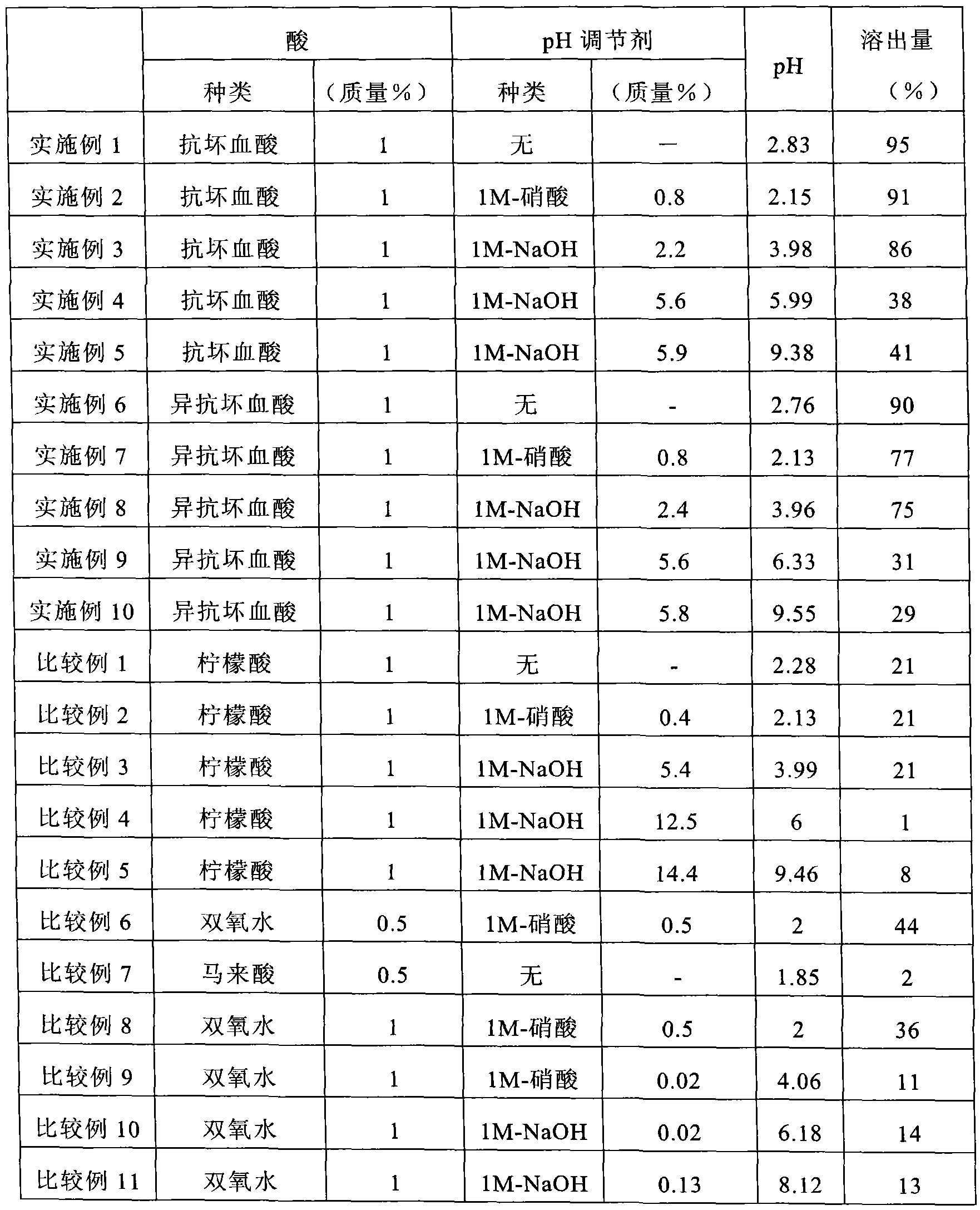

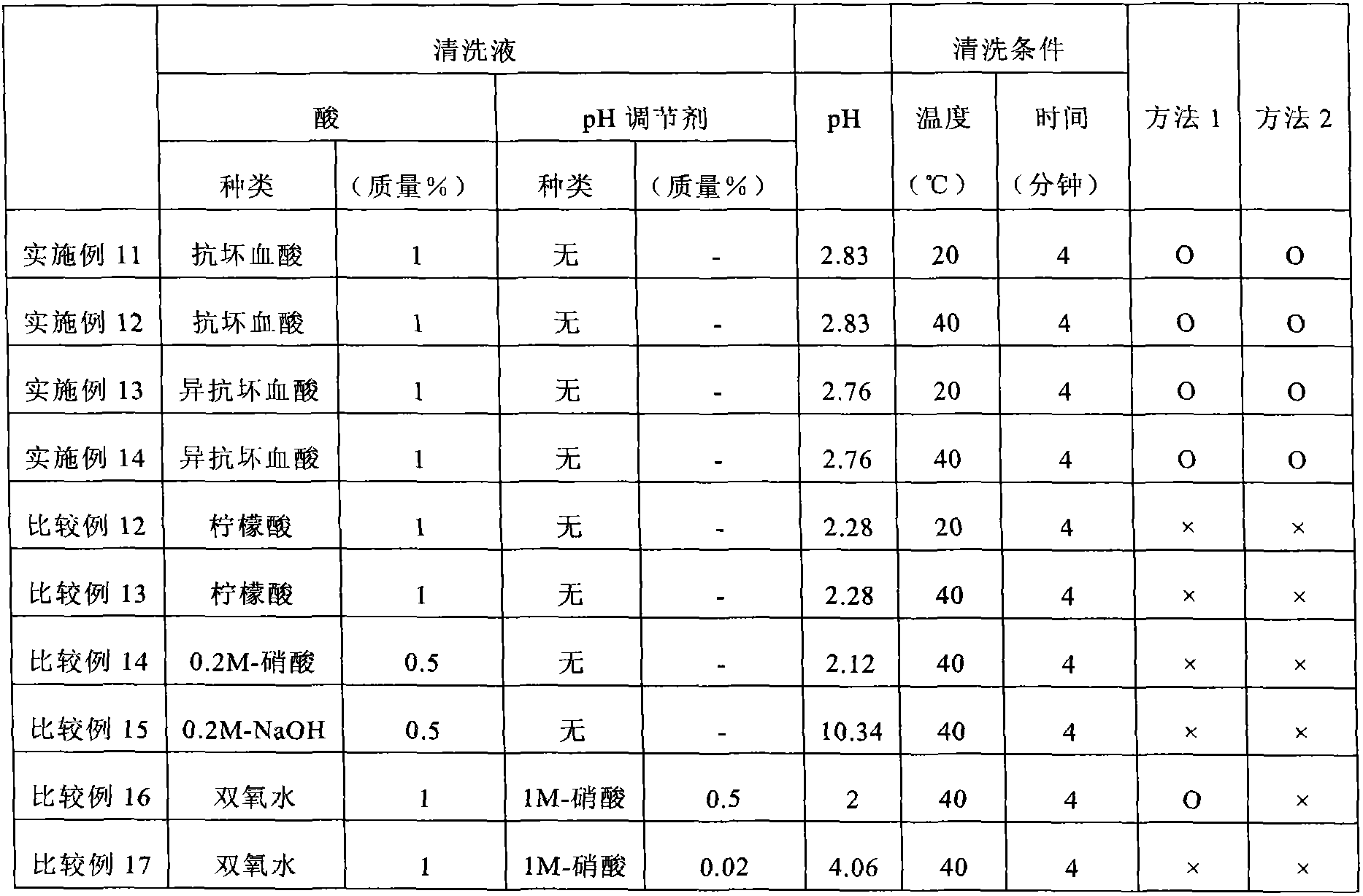

[0050] (1) Study on the solubility of manganese trioxide abrasive grains

[0051] It is considered that an aqueous solution in which dimanganese trioxide abrasive grains are dissolved can be used as a cleaning solution for an abrasive containing dimanganese trioxide abrasive grains. Therefore, as a preliminary study, a dissolution test of dimanganese trioxide abrasive grains (average particle diameter: 1 μmφ) was carried out. The average particle diameter of the dimanganese trioxide abrasive grains was measured with a laser diffraction particle size distribution analyzer (MT3300EX-II manufactured by Nikkiso).

[0052] After adding acid to achieve the composition shown in Table 1, various aqueous solutions with pH adjusted were prepared. 0.04 g of dimanganese trioxide abrasive grains were added to 40 ml of various aqueous solutions, and shak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com