High-temperature phosphorus-bearing cerium-manganese-tin composite denitrification catalyst and preparation method thereof

A denitrification catalyst, cerium-manganese technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of poor catalytic activity, catalyst deactivation, etc., achieve simple preparation methods and reduce production costs , good denitrification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

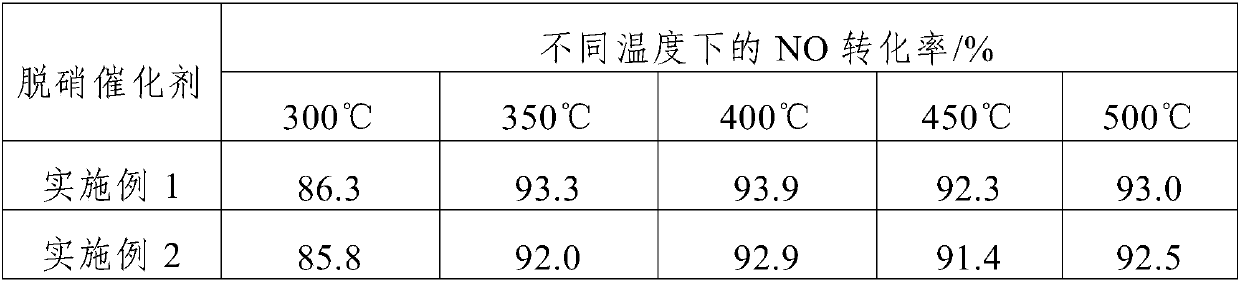

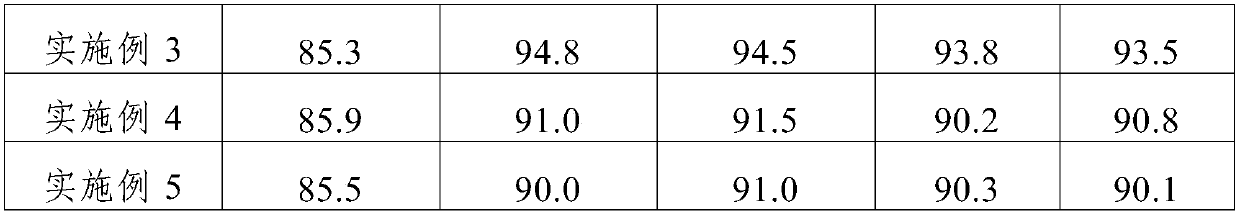

Embodiment 1

[0024] The high-temperature phosphorus-containing cerium-manganese-tin composite denitrification catalyst in this embodiment is made of cerium phosphate, manganese trioxide and tin oxide, and the molar ratio of cerium phosphate, manganese trioxide and tin oxide is 1:0.15:0.02 ; The nitrogen oxide conversion rate of the catalyst is not lower than 85% under the condition of applicable temperature of 300°C to 500°C.

[0025] The preparation method of the high-temperature phosphorus-containing cerium-manganese-tin composite denitration catalyst comprises the following steps:

[0026] Step 1, take by weighing 0.03mol cerous nitrate (13.02g) and be dissolved in 150mL deionized water, be mixed with cerous nitrate solution, 0.015mol pyrophosphoric acid (2.68g) be dissolved in 100mL deionized water, be mixed with pyrophosphoric acid solution; Add the cerous nitrate solution into the pyrophosphoric acid solution, stir to obtain solution A, drop 0.30mol urea (12.00g) into the solution A ...

Embodiment 2

[0030] The high-temperature phosphorus-containing cerium-manganese-tin composite denitrification catalyst of this embodiment is made of cerium phosphate, manganese trioxide and tin oxide, and the molar ratio of cerium phosphate, manganese trioxide and tin oxide is 1:0.15:0.03 ; The nitrogen oxide conversion rate of the catalyst is not lower than 85% under the condition of applicable temperature of 300°C to 500°C.

[0031] The preparation method of the high-temperature phosphorus-containing cerium-manganese-tin composite denitration catalyst comprises the following steps:

[0032] Step 1, take by weighing 0.03mol cerous nitrate (13.02g) and be dissolved in 150mL deionized water, be mixed with cerous nitrate solution, 0.015mol pyrophosphoric acid (2.68g) be dissolved in 100mL deionized water, be mixed with pyrophosphoric acid solution; Add the cerous nitrate solution into the pyrophosphoric acid solution, stir to obtain solution A, drop 0.30mol urea (12.00g) into the solution A ...

Embodiment 3

[0036] The high-temperature phosphorus-containing cerium-manganese-tin composite denitration catalyst of this embodiment is made of cerium phosphate, manganese trioxide and tin oxide, and the molar ratio of cerium phosphate, manganese trioxide and tin oxide is 1:0.15:0.04 ; The nitrogen oxide conversion rate of the catalyst is not lower than 85% under the condition of applicable temperature of 300°C to 500°C.

[0037] The preparation method of the high-temperature phosphorus-containing cerium-manganese-tin composite denitration catalyst comprises the following steps:

[0038] Step 1, take by weighing 0.03mol cerous nitrate (13.02g) and be dissolved in 150mL deionized water, be mixed with cerous nitrate solution, 0.015mol pyrophosphoric acid (2.68g) be dissolved in 100mL deionized water, be mixed with pyrophosphoric acid solution; Add the cerous nitrate solution into the pyrophosphoric acid solution, stir to obtain solution A, drop 0.30mol urea (12.00g) into the solution A at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com