Patents

Literature

46 results about "Cerium phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Application of metal oxide modified CePO4 catalyst to collaborative denitration and demercuration

InactiveCN104888602AEasy to operateRaw materials are readily availablePhysical/chemical process catalystsDispersed particle separationCerium phosphateManganese

The invention discloses application of a metal oxide modified CePO4 catalyst to collaborative denitration and demercuration. The application includes introducing medium-high temperature flue gas containing elemental mercury and nitrogen oxide into a catalyst loaded catalytic apparatus. Specifically, the main component of the catalyst is cerium phosphate, and the modification component is at least one of cobalt, manganese, copper, iron, vanadium, cerium, molybdenum and tin metal oxides. The temperature of the medium-high temperature flue gas is 250-420DEG C. According to the application of the metal oxide modified CePO4 catalyst to collaborative denitration and demercuration, the oxidation efficiency to null valence mercury in high temperature flue gas is high, the NO is the flue gas can promote and enhance the catalytic efficiency of the catalyst, and the practicability is strong. In addition, the catalyst has good medium-high temperature SCR activity and anti-sulfur and waterproof performance.

Owner:ZHEJIANG UNIV

Luminophore and core-shell luminophore precursors

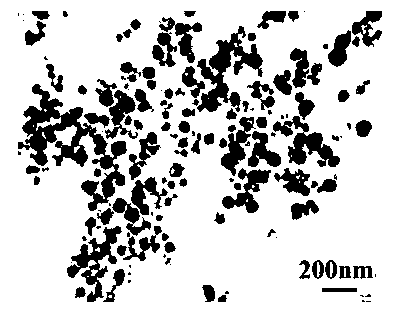

InactiveCN101490211ASmall particlesLess quantityLamp incadescent bodiesLuminescent compositionsMean diameterCerium phosphate

The present invention relates to a new type of green luminophore composed of mixed rare-earth phosphates, and a method of preparation of these new luminophores from precursors comprising particles having a mean diameter of between 1.5 and 15 microns, these particles comprising an inorganic core and a shell composed of a mixed lanthanum and / or cerium phosphate, optionally doped with terbium, evenly covering the inorganic core with a thickness greater than or equal to 300 nm.

Owner:RHODIA OPERATIONS SAS

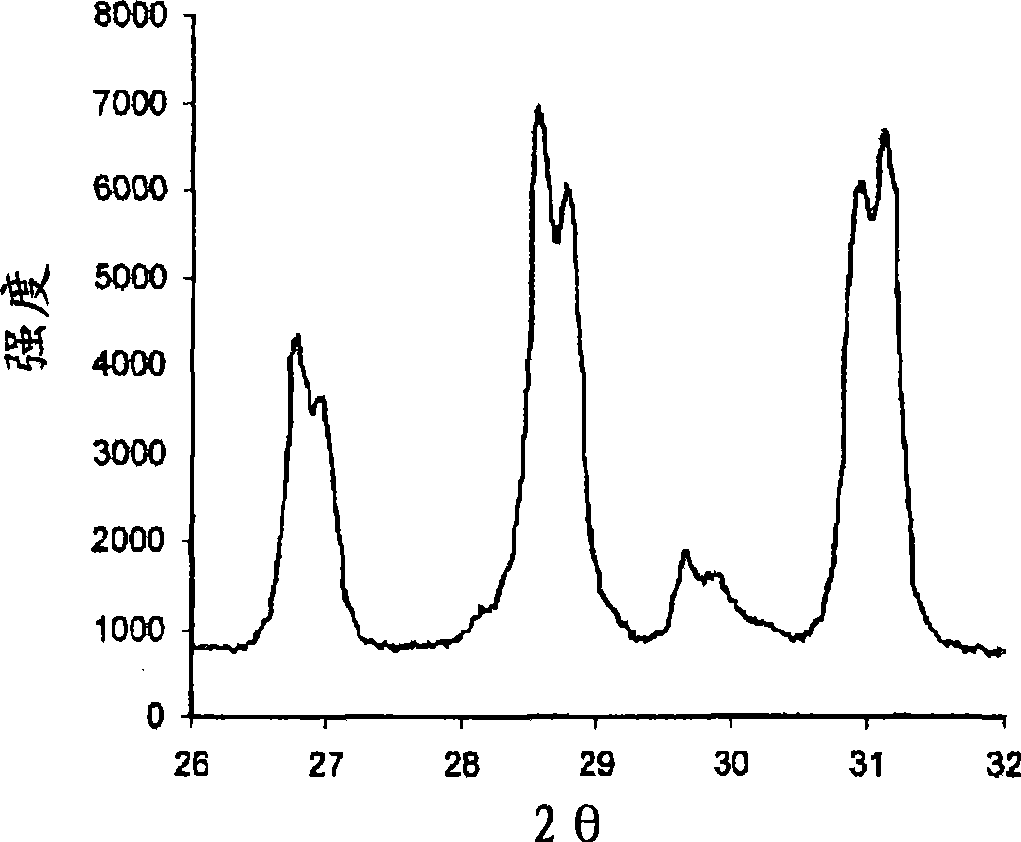

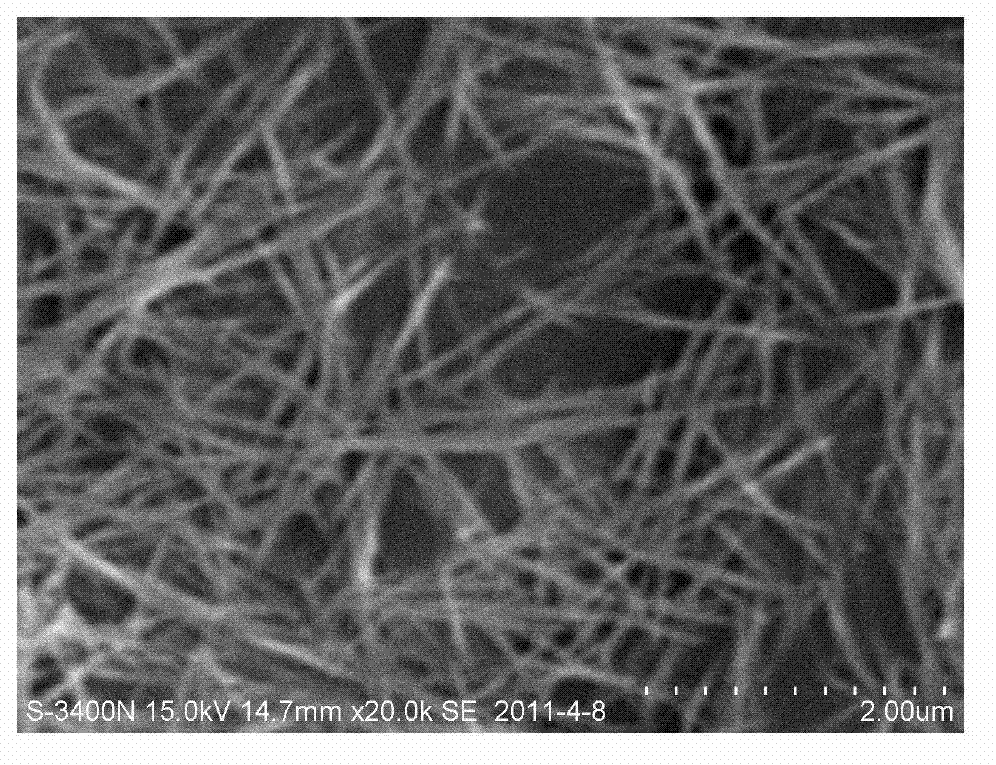

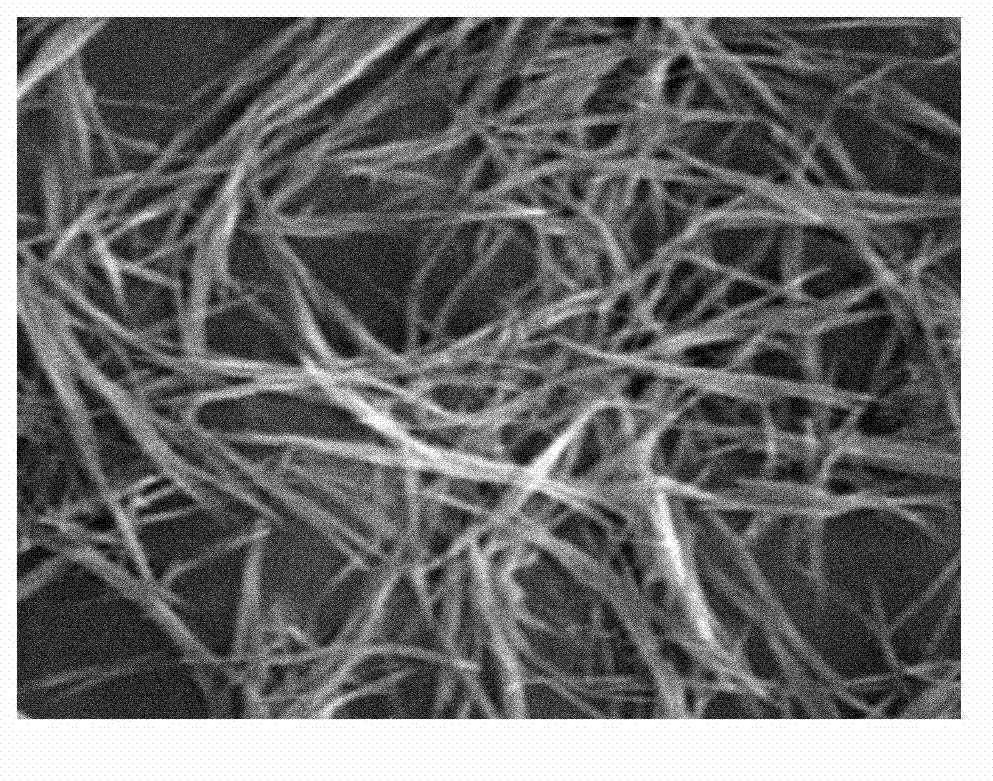

Preparation method of cerium phosphate nano-wires

InactiveCN102849706AMild preparation conditionsEnvironmentally friendlyMaterial nanotechnologyPhosphorus compoundsCerium phosphateSalt solution

The invention provides a preparation method of cerium phosphate nano-wires. The preparation method comprises the following steps: respectively preparing a Ce<3+> salt solution and a PO4<3-> salt solution; adding the PO4<3-> salt solution to the Ce<3+> salt solution under continuous stirring to obtain a mixed solution I; stirring the mixed solution I, and adjusting the pH value of the mixed solution I to 0.5-10.0 to obtain a mixed solution II; and ageing the mixed solution II at 4-89DEG C under an environmental pressure for above 1h to obtain the cerium phosphate nano-wires. The preparation method can be implemented through adopting simple and cheap equipment under the environmental pressure, so it is convenient for realizing the industrialized production; and there is no need to add a template in the preparation process, so the environmental influence possibly brought by a waste liquid is avoided.

Owner:SHENZHEN UNIV

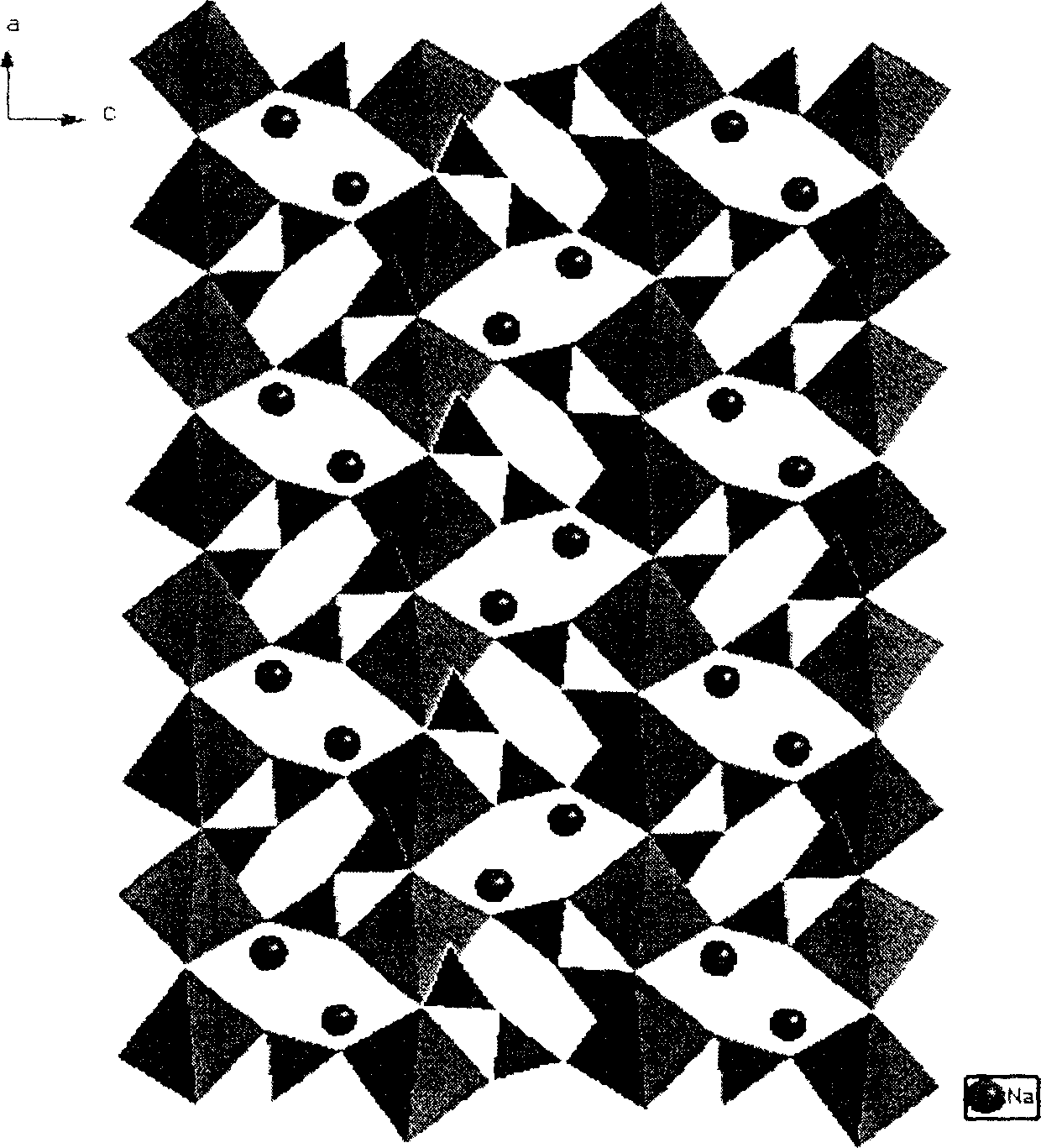

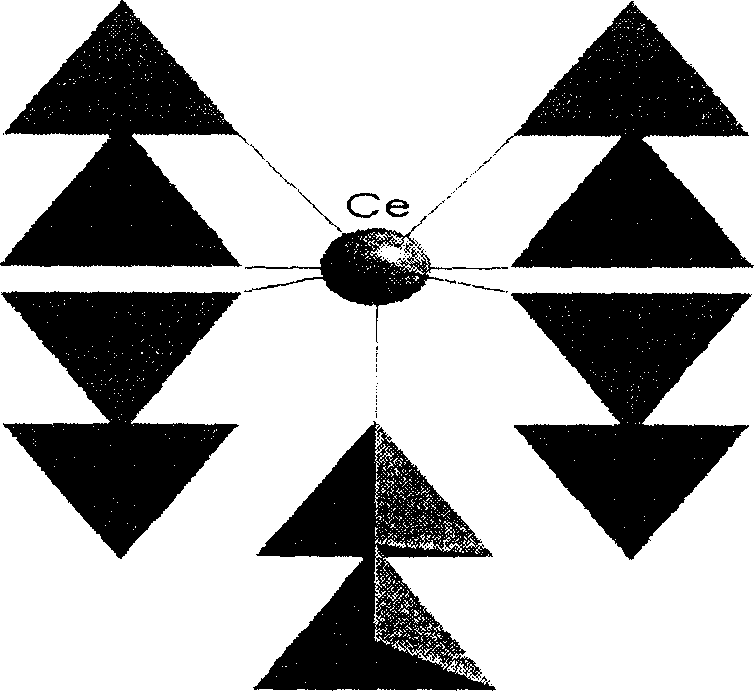

Cerium sodium phosphate crystal material capable of transmitting light of ultraviolet radiation

InactiveCN1916108AAchieving UV emissionSimple preparation processLuminescent compositionsCerium phosphateSodium phosphates

This invention discloses a UV-luminescent sodium cerium phosphate crystal material, which has the crystal form of orthorhombic system, and the space group of Pnma; a = 8.6202, b = 5.2907, c = 12.6800, alpha = beta = gamma = 90degree, and V = 578.305. The crystal is synthesized by: completely grinding the raw materials, mixing uniformly in a Pt crucible, placing in a carbinet furnace, heating for synthesis, keeping temperature at the highest point, and cooling slowly to room temperature to obtain sodium cerium phosphate monocrystal. The crystal material can be used in small-scale and high-power solid lasers.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

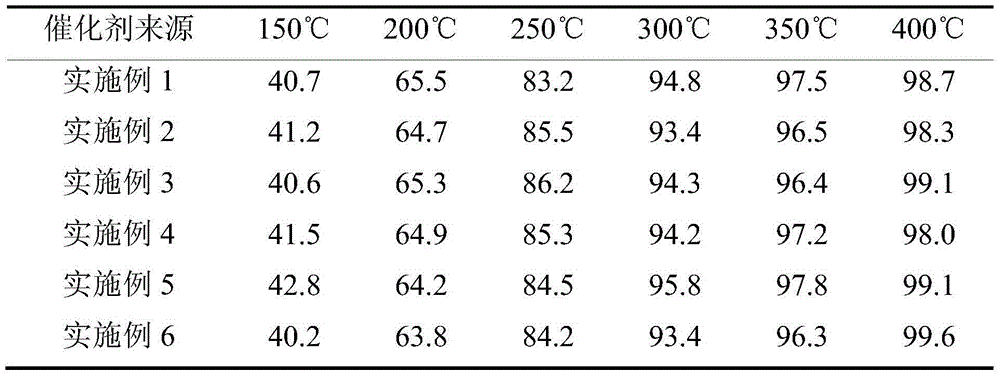

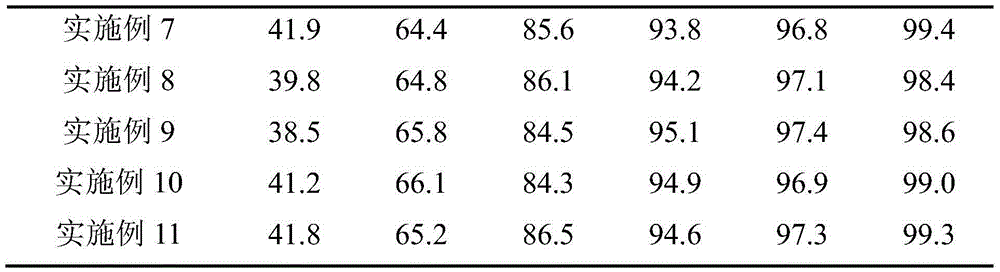

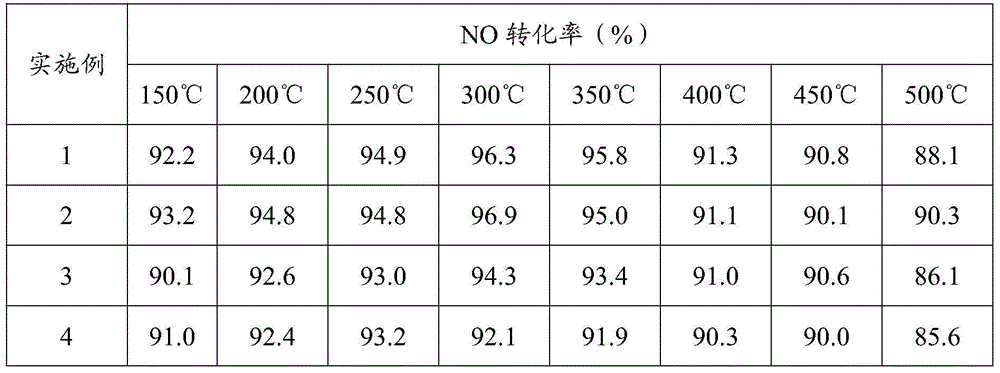

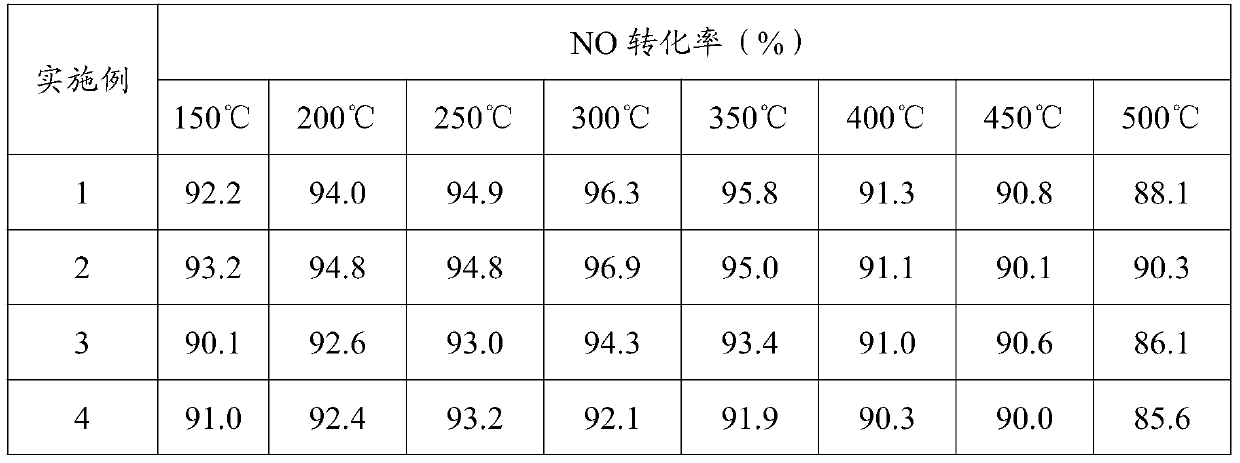

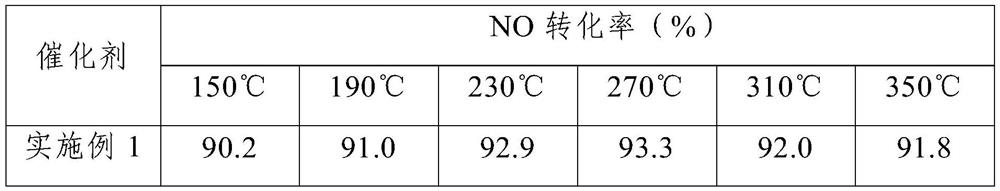

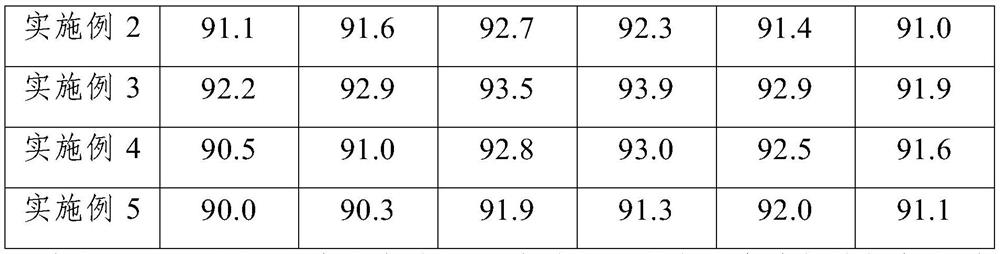

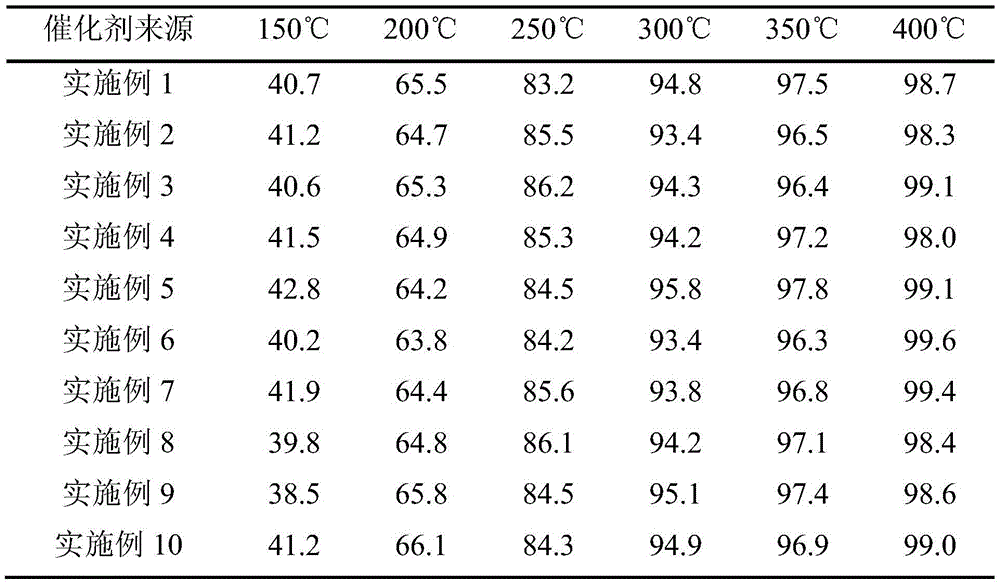

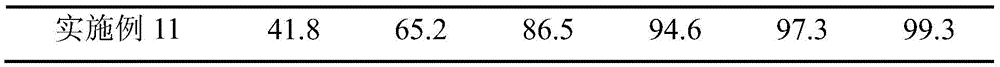

Wide temperature range type phosphorus-containing cerium-based denitration catalyst and preparation method thereof

ActiveCN105214698ALarge temperature rangeImprove escape ratePhysical/chemical process catalystsDispersed particle separationCerium phosphateNitrogen oxide

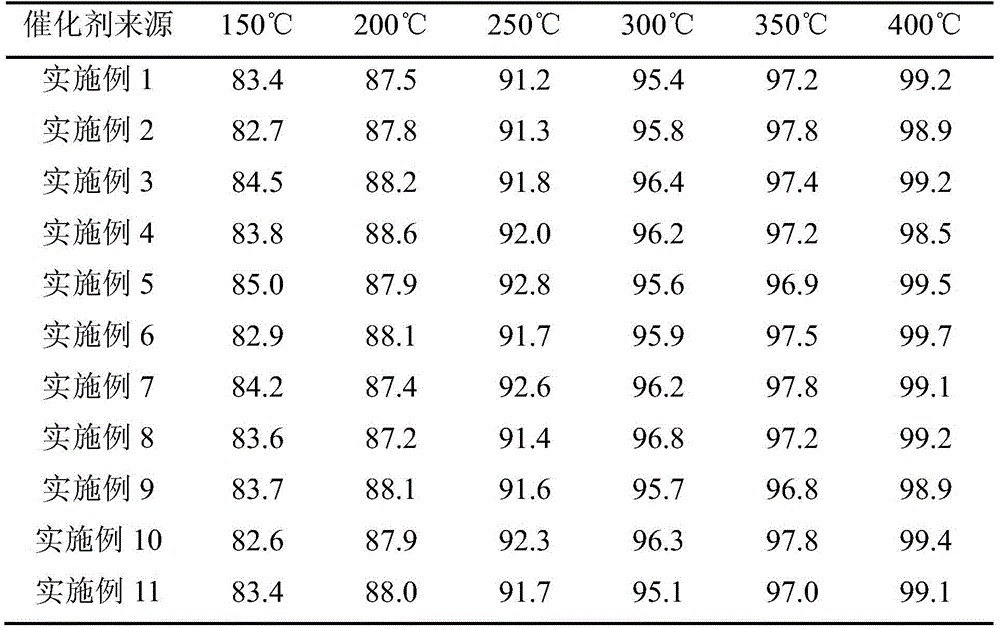

The invention relates to a wide temperature range type phosphorus-containing cerium-based denitration catalyst and a preparation method thereof. The catalyst is mainly prepared from cerium phosphate (CePO4) and manganese oxide Mn2O3 according to the molar ratio of 1:0.5-3. The wide temperature range type phosphorus-containing cerium-based denitration catalyst has the nitrogen oxide removal temperature interval of 150-500 DEG C and has high denitration stability and N2 selectivity. In particular, the nitrogen oxide removal effects of the phosphorus-containing cerium-based denitration catalyst in low-medium temperature intervals (150-350 DEG C) are good, and the nitrogen oxide conversion rates are both above 90%.

Owner:THE NORTHWEST RES INST OF CHEM IND

Preparation method of rare-earth doped nanometer spherical CePo4 material

InactiveCN102807867ASimple manufacturing methodLow priceMaterial nanotechnologyLuminescent compositionsCerium phosphateO-Phosphoric Acid

Owner:BEIJING UNIV OF CHEM TECH

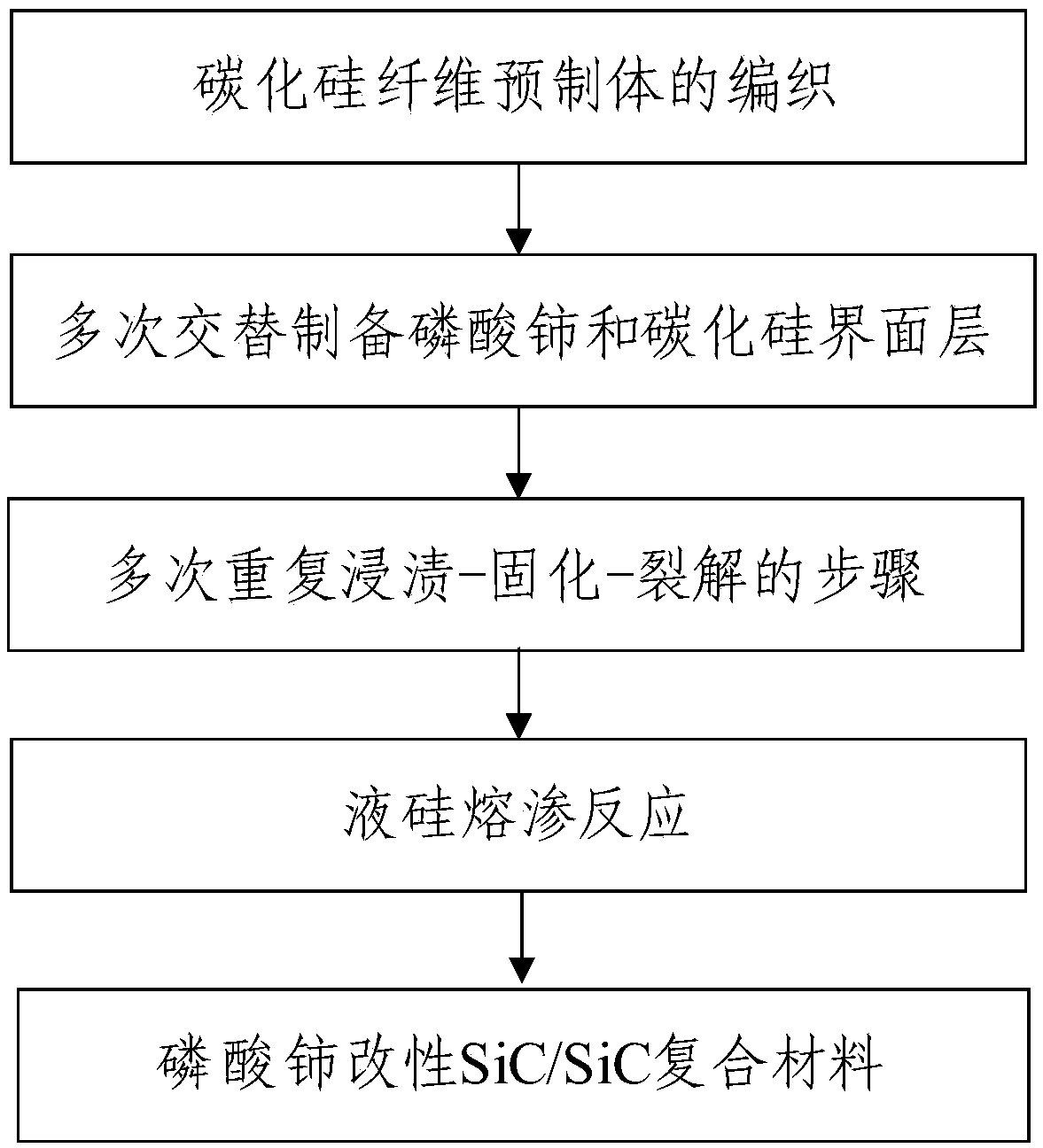

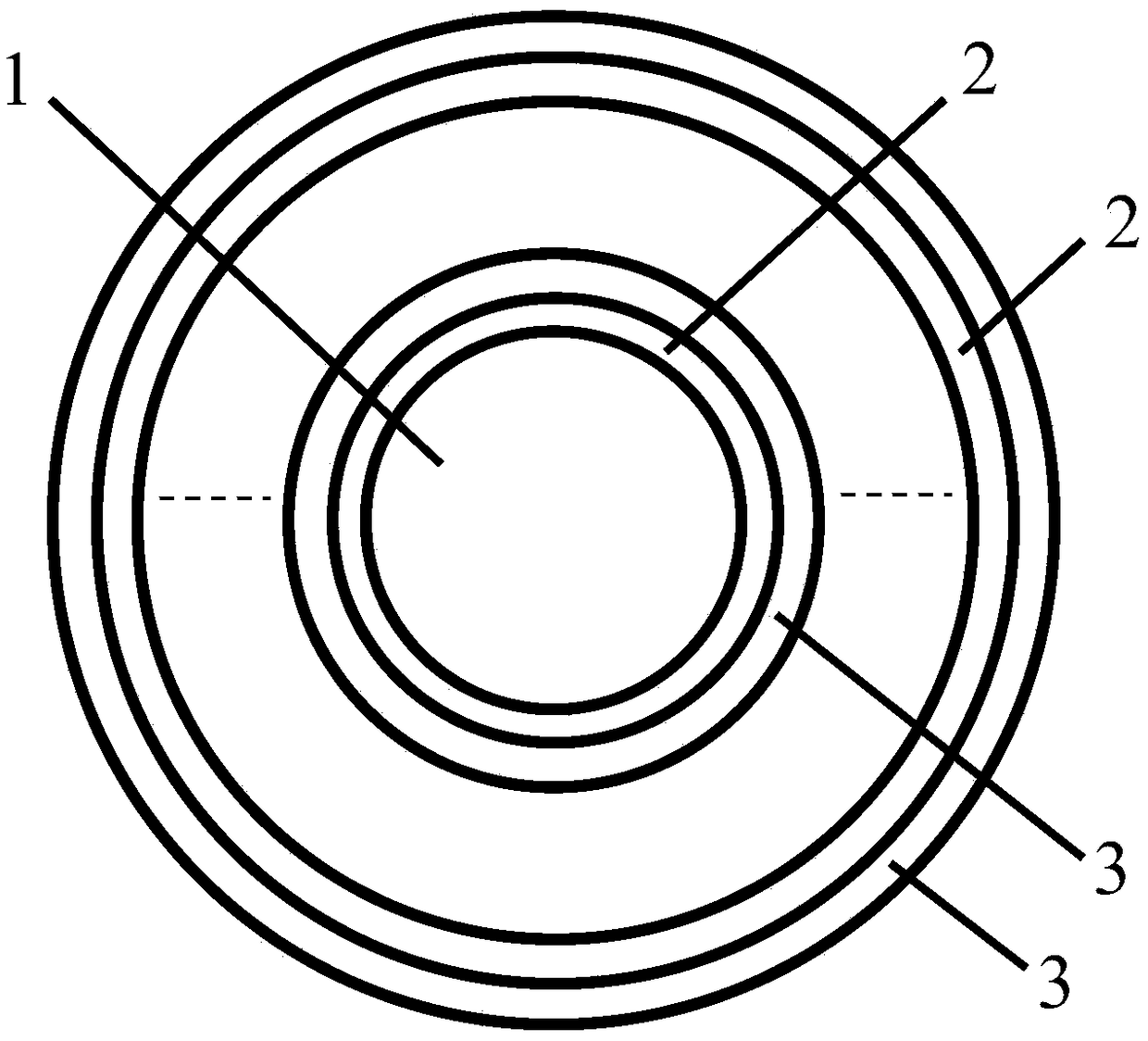

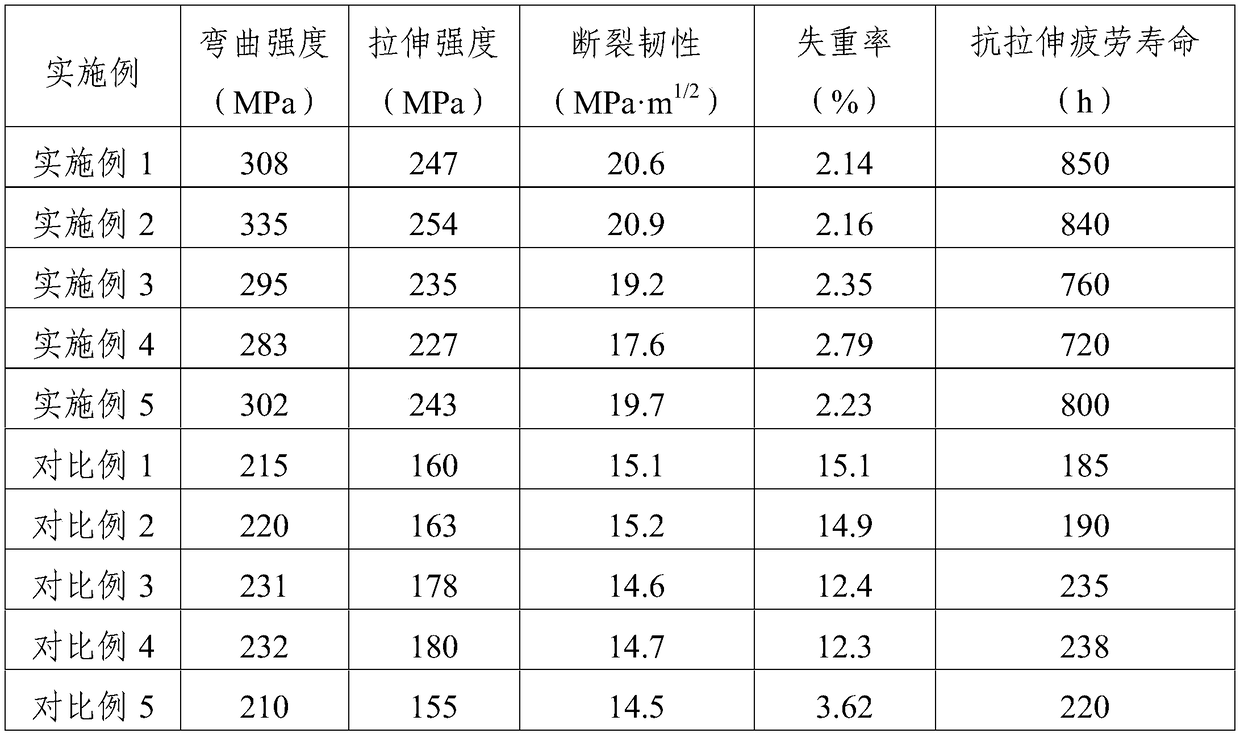

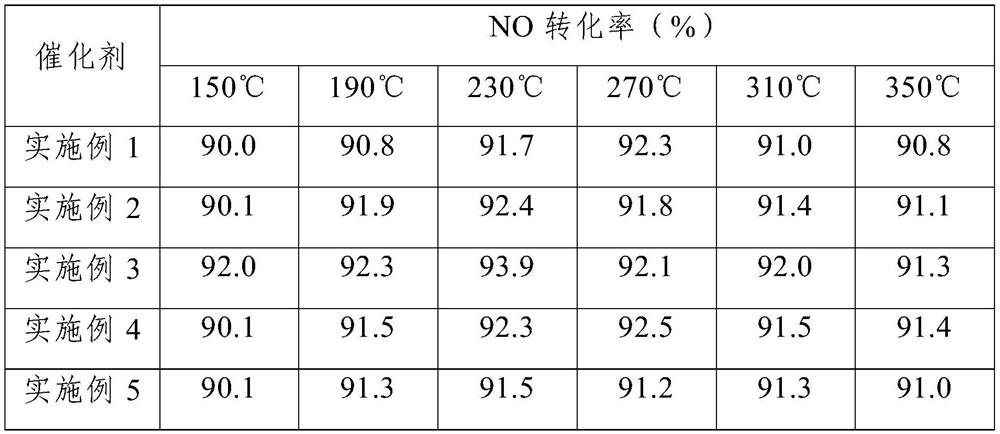

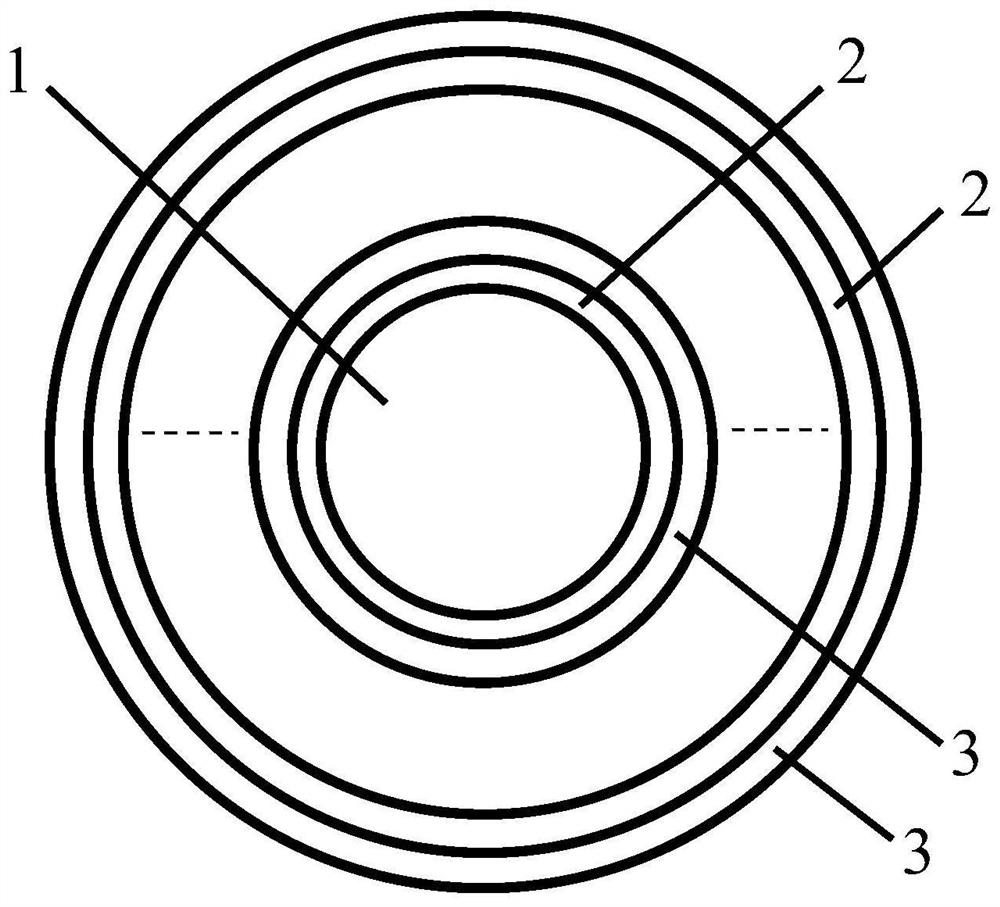

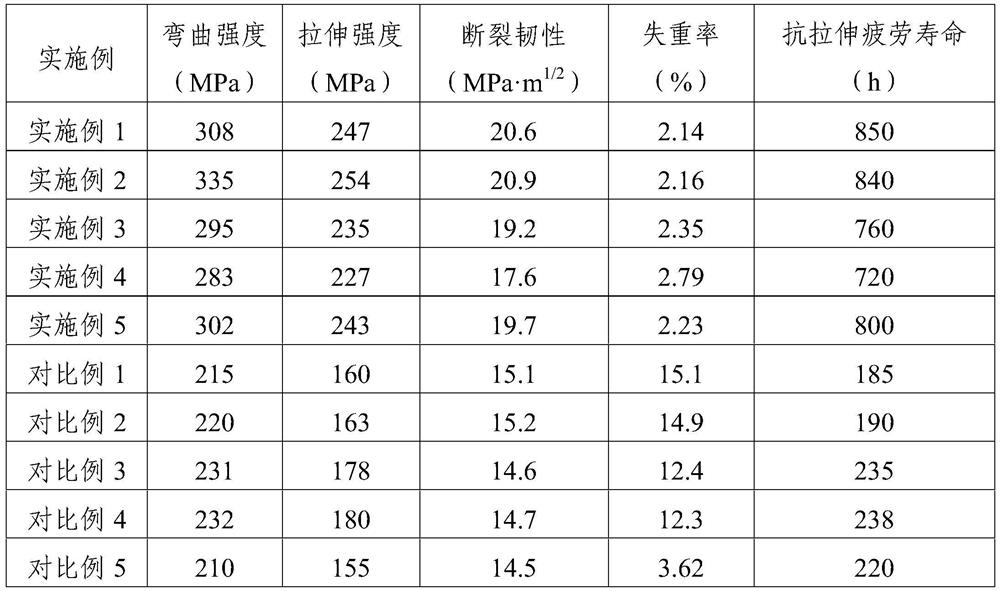

Cerium phosphate modified silicon carbide fiber reinforced silicon carbide composite material and preparation method thereof

ActiveCN109293367AHigh melting pointHigh temperature resistance and oxidation resistanceCeramicwareCerium phosphateInterface layer

The invention relates to a cerium phosphate modified silicon carbide fiber reinforced silicon carbide composite material and a preparation method thereof. The method comprises the steps: (1) alternatively preparing a cerium phosphate interface layer and a silicon carbide interface layer on the surface of silicon carbide fiber preforms until the predetermined thickness or the predetermined number of layers is reached, and thus preparing modified silicon carbide fiber preforms; (2) impregnating the modified silicon carbide fiber preforms with a carbon precursor solution, and then solidifying andsplitting the impregnated modified silicon carbide fiber preforms in turn; (3) repeating the step (2) at least once, and thus preparing porous silicon carbide fiber preforms; and (4) carrying out liquid silicon melt-infiltration reaction of the prepared porous silicon carbide fiber preforms, and thus preparing the cerium phosphate modified silicon carbide fiber reinforced silicon carbide composite material. The prepared cerium phosphate modified silicon carbide fiber reinforced silicon carbide composite material has the advantages of excellent oxidation resistance, temperature resistance andthermal shock resistance, excellent comprehensive performance at high temperature and long service life.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

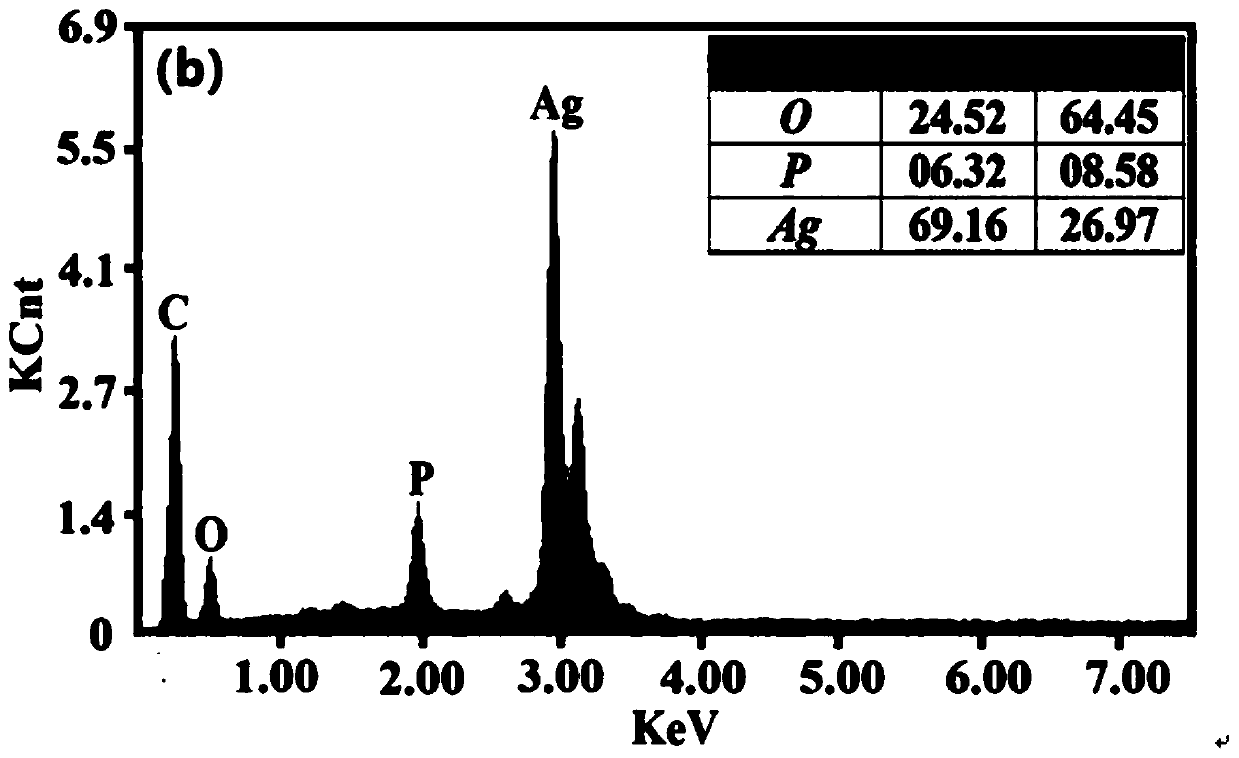

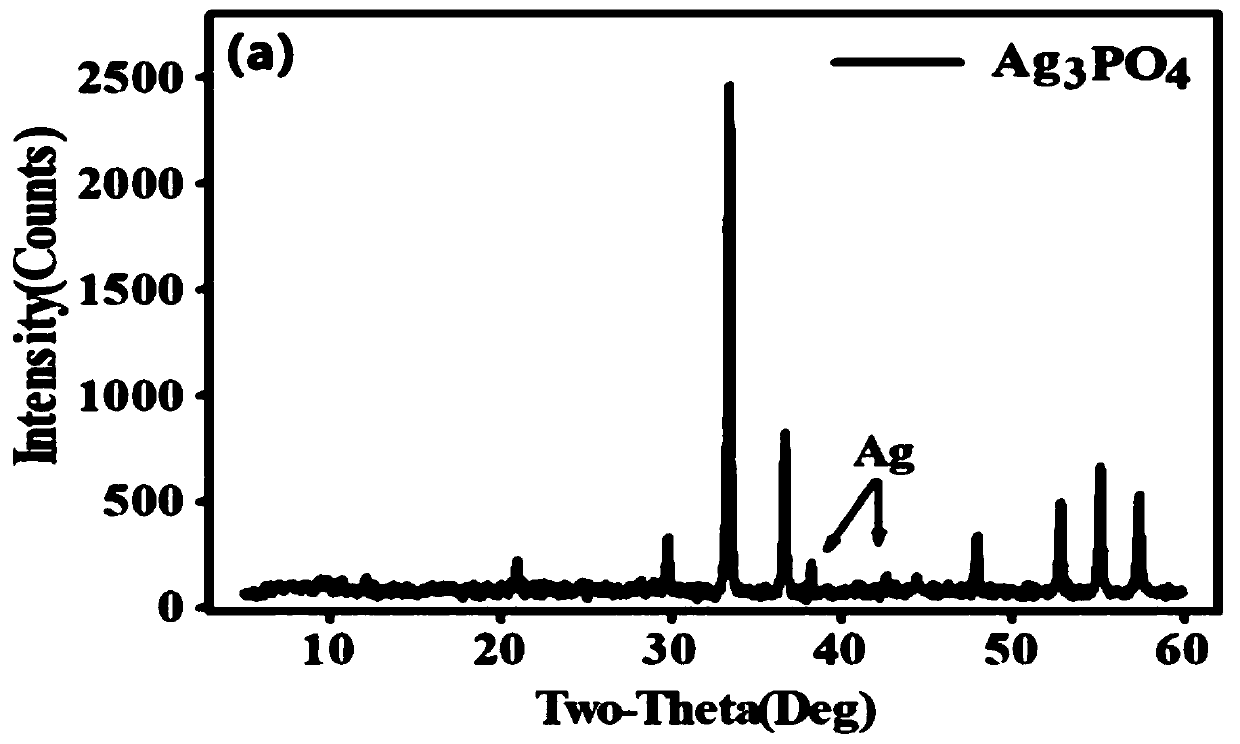

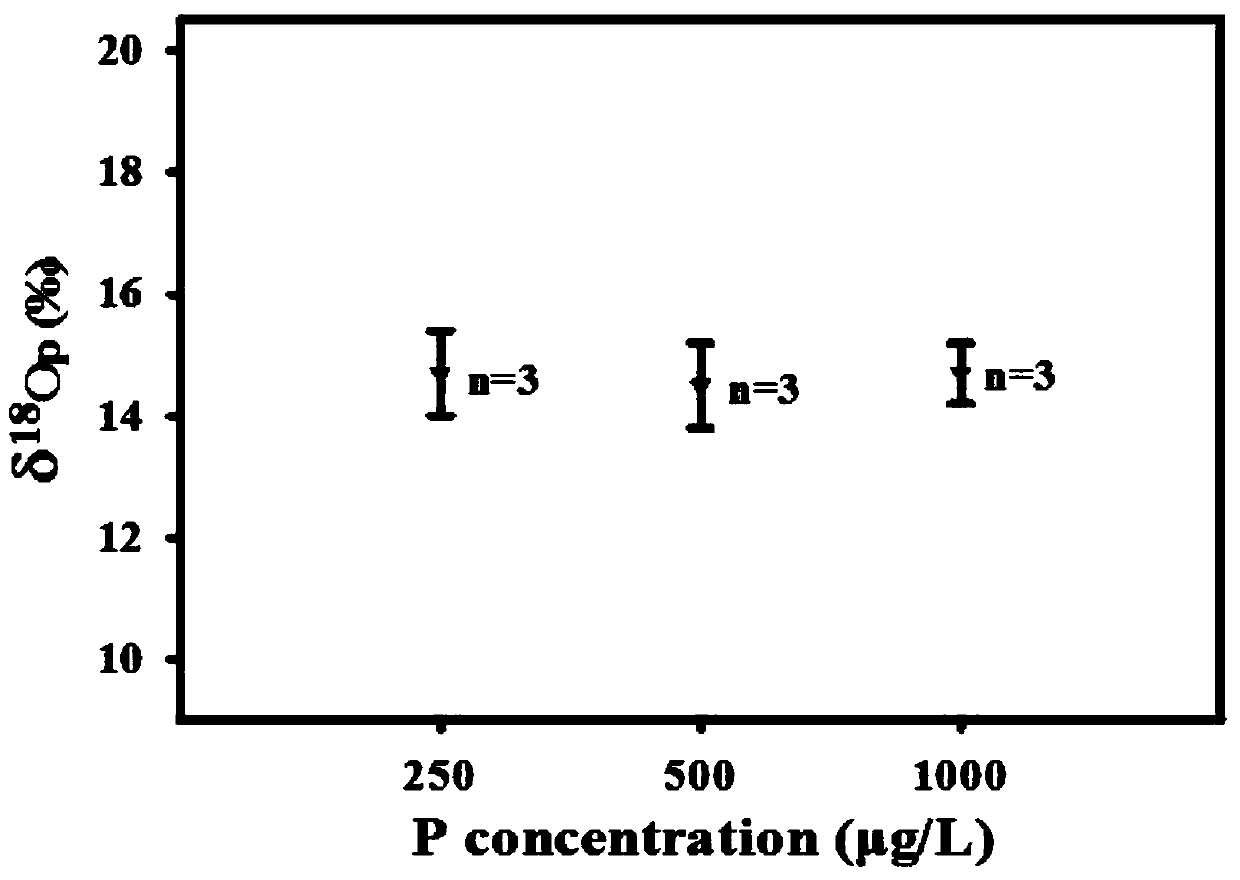

Method for preparing water body phosphate oxygen isotope sample through in-situ enrichment

PendingCN110793838AAvoid bulk samplingReduce or simplify difficultyPreparing sample for investigationCerium phosphateFiltration

The invention, which belongs to the environment-friendly monitoring method field, relates to a method for preparing a water body phosphate oxygen isotope sample through in-situ enrichment. The methodcomprises the following steps: immersing a Zr-Oxide gel film into a water body, fishing out the Zr-Oxide gel film after a period of time, putting the Zr-Oxide gel film into a sodium hydroxide solution, carryin gout oscillating for 24 hours, and carrying out filtering to obtain a phosphorus-containing eluent; adjusting the pH value of the eluent to 5.8 and adding a cerous nitrate solution to adjustthe pH value to 5.5; adding nitric acid into a cerium phosphate precipitate, adding cation exchange resin after dissolving of the cerium phosphate precipitate, and carrying out oscillation for 12h; filtering the solution after cation exchange resin processing into a black centrifuge tube, adjusting the pH value to 8.5 by using ammonia water, adding a silver nitrate solution, carrying out centrifuging to obtain a silver phosphate precipitate; washing the silver phosphate precipitate with pure water, adding hydrogen peroxide to react for more than 3 hours, carrying out centrifuging to retain the precipitate, washing the centrifugal precipitate with pure water, and carrying out freezing and drying. Therefore, large-volume sampling can be avoided effectively; and the difficulty or steps of filtration and impurity removal can be reduced or simplified obviously. The method is a novel method for preparing a water body phosphate oxygen isotope sample.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

Surface treatment technology of special titanium dioxide for papermaking

InactiveCN110669359AGood light fastnessExtended service lifeCoatings with pigmentsInorganic pigment treatmentCerium phosphatePapermaking

The invention belongs to the technical field of titanium dioxide production, and particularly relates to a surface treatment technology of special titanium dioxide for papermaking. The technology comprises the following steps: adding a dispersant into a sanded titanium dioxide slurry, performing stirring for dispersing, sieving to obtain a slurry with the TiO2 content of 200-400 g / L, coating the surfaces of titanium dioxide particles with cerium phosphate, silicon dioxide and phosphorus pentoxide, finally coating the surfaces of the titanium dioxide particles with aluminum oxide by parallel flow of alkaline aluminum and acidic aluminum, carrying out solid-liquid separation, and processing the obtained solid to obtain the finished product. The cerium salt and silicate are used for coating the titanium dioxide particles at the same time, so that the sun-proof property of titanium dioxide in a papermaking system is greatly enhanced, and the service life of titanium dioxide is prolonged; and the alkaline aluminum and acidic aluminum parallel flow coating of the aluminum oxide greatly saves the space of a coating tank, so the coating amount of titanium dioxide by one coating tank is increased, the yield is increased within the same time, and the economic benefit can be well improved.

Owner:CHONGQING TITANIUM IND OF PANGANG GROUP

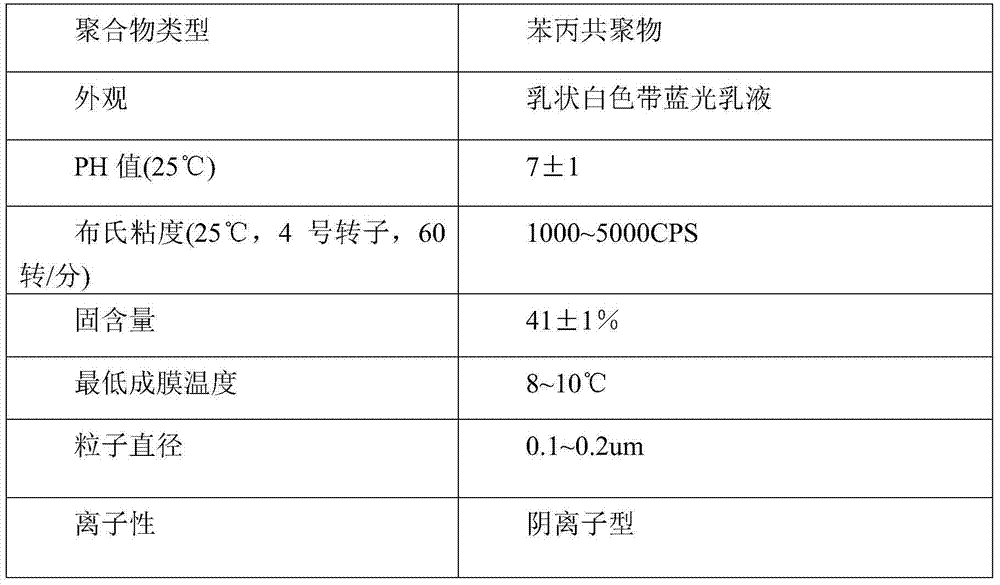

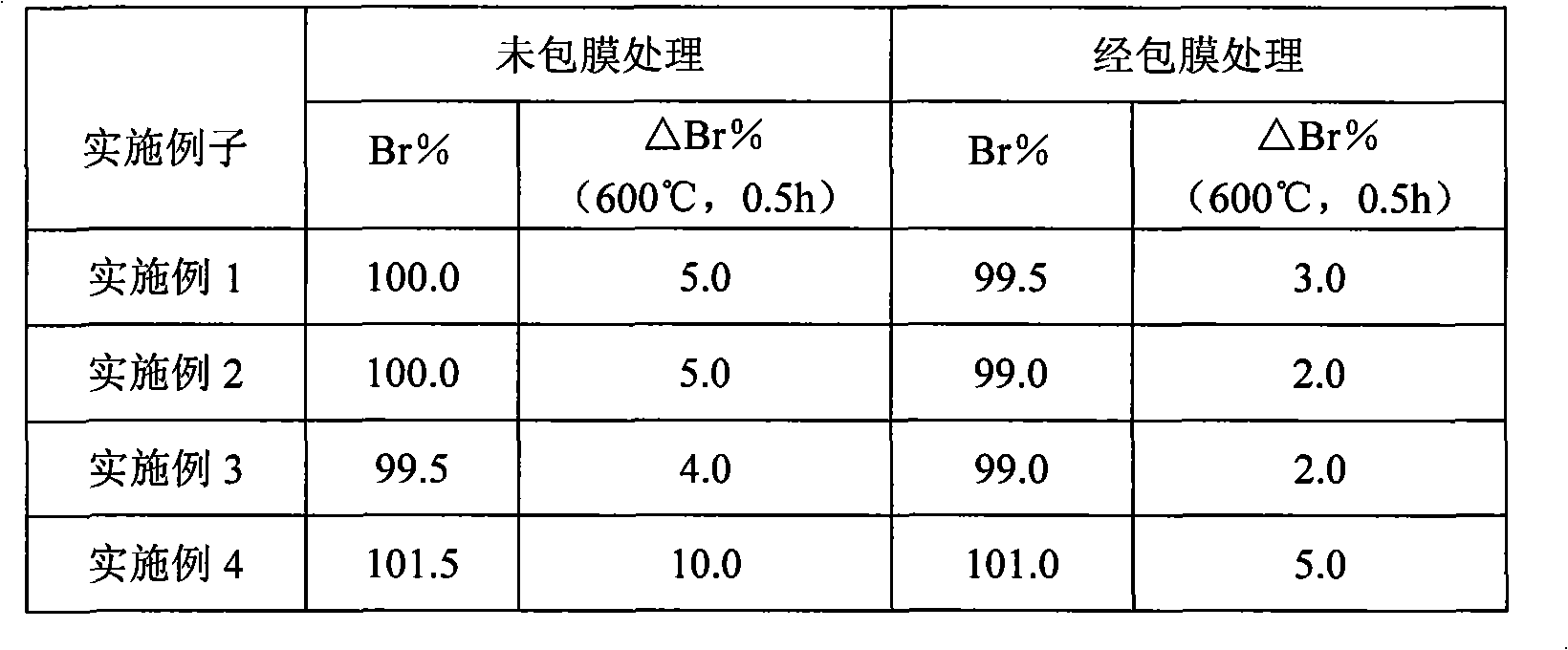

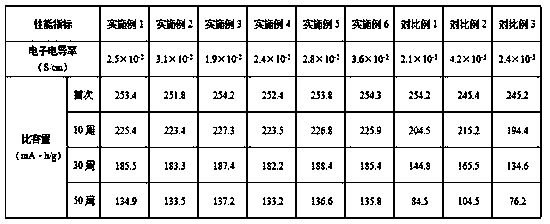

Cerium phosphate coated ternary cathode material, preparation method thereof and lithium ion battery

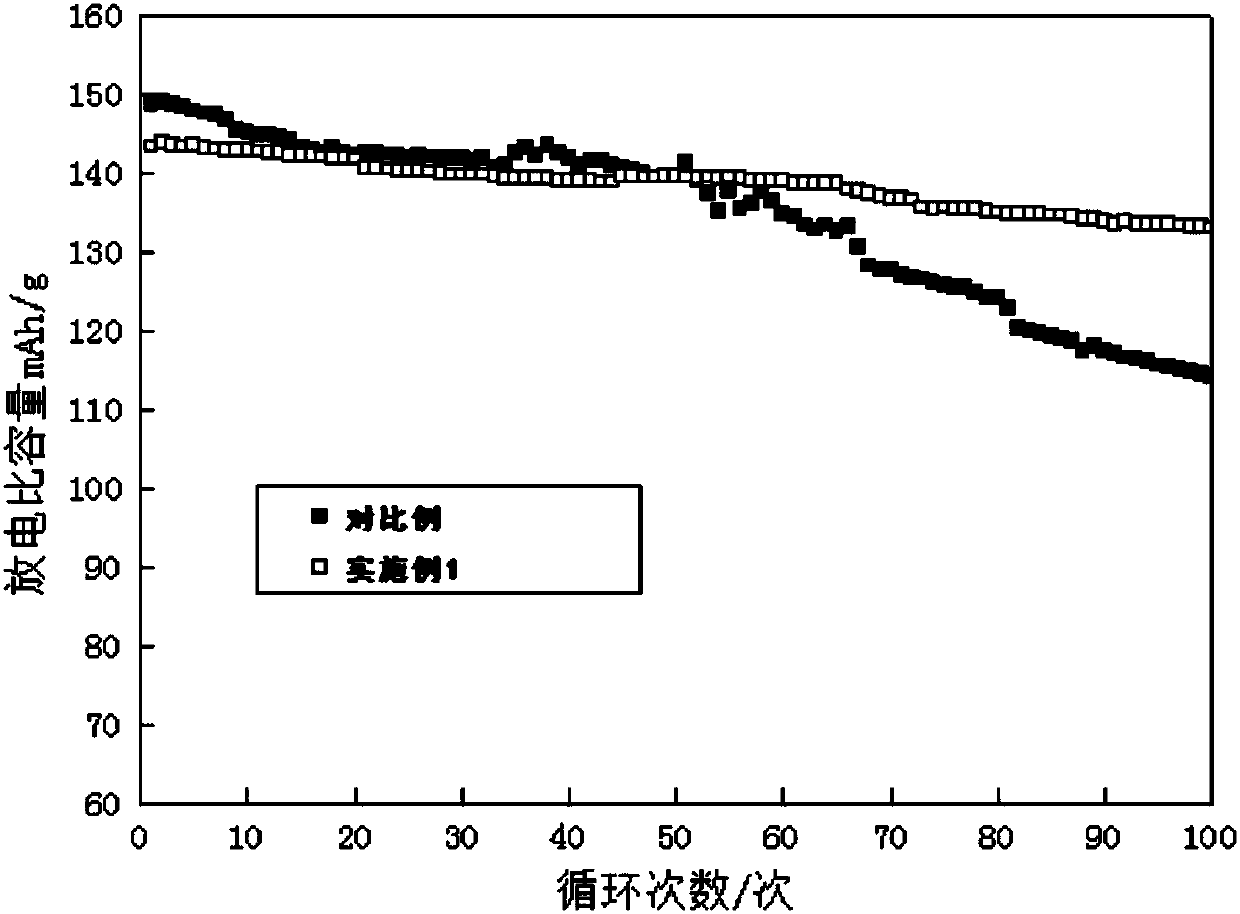

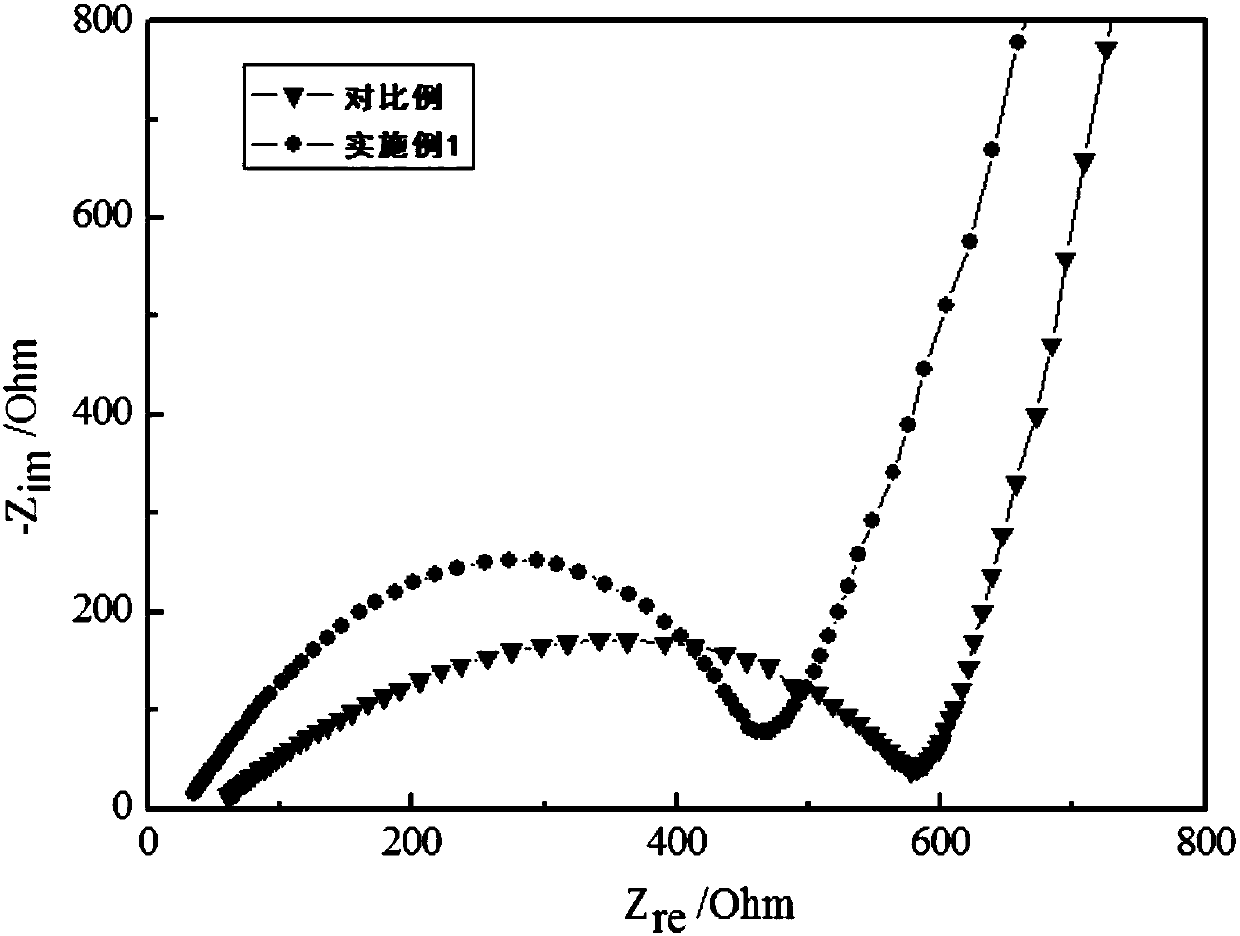

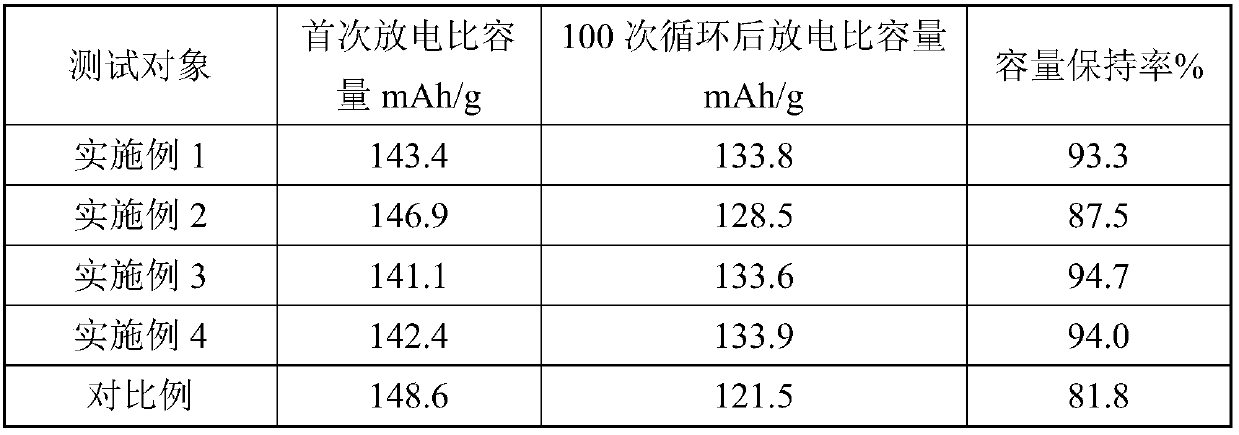

InactiveCN109904449AImproved magnification performanceCell electrodesSecondary cellsCerium phosphateManganate

The invention relates to a cerium phosphate coated ternary cathode material, a preparation method thereof and a lithium ion battery, and belongs to the technical field of cathode active substances forlithium ion batteries. The cerium phosphate coated ternary cathode material comprises a cathode material inner core and a cerium phosphate layer, wherein the surface of the cathode material inner core is coated with the cerium phosphate layer; the cathode material is a nickel cobalt lithium manganate ternary material; and the mass percentage of cerium phosphate accounts for 0.1-5% of the mass percentage of the cerium phosphate coated ternary cathode material. According to the cerium phosphate coated ternary cathode material, the surface of the nickel cobalt lithium manganate ternary cathode material is coated with the cerium phosphate layer, the cerium phosphate has the good lithium ion migration ability and the electron transfer ability, through physical coating, diffusion impedance andohmic impedance can be reduced, contact between the cathode material and an electrolyte can also be isolated, a side reaction between the material and the electrolyte is reduced, the crystal structureof the material is stabilized, the cycling performance and the rate performance of the material are improved, and the cycling life of the nickel-cobalt-manganese ternary cathode material is prolonged.

Owner:PINGGAO GRP +1

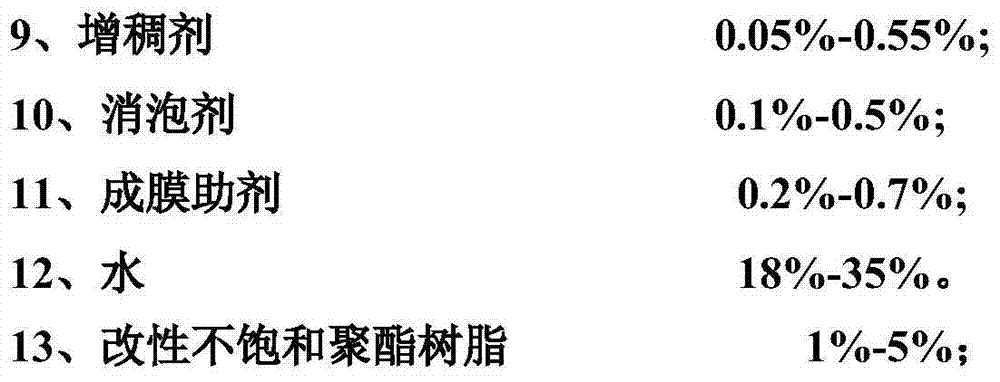

Polymer emulsion interfacial agent for treating building wall and preparation method of polymer emulsion interfacial agent

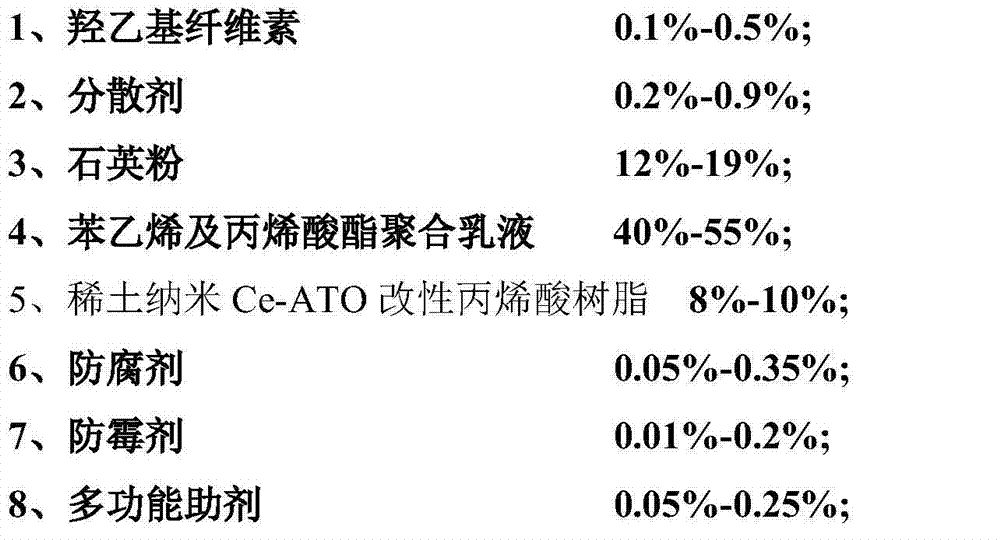

InactiveCN104745012AAvoid pollutionAvoid discardingAntifouling/underwater paintsPaints with biocidesCerium phosphatePolymer science

The invention discloses a polymer emulsion interfacial agent for treating a building wall and a preparation method of the polymer emulsion interfacial agent. The polymer emulsion interfacial agent comprises a component A and a component B, which are mixed at the weight ratio of 1:1 during use, wherein the component A comprises the concrete components as follows: hydroxyethyl cellulose, a dispersing agent, quartz powder, a styrene-acrylate polymer emulsion, rare-earth nanometer Ce-ATO modified acrylic resin, an anticorrosive agent, a mildewproof agent, a multifunctional additive, a thickening agent, a defoaming agent and a coalescing agent, water and unsaturated polyester resin; and the component B comprises the following components: wollastonite powder, quartz powder, quartz sand, cerium phosphate, a titanate coupling agent, cobalt naphthenate and methyl ethyl ketone peroxide. The polymer emulsion interfacial agent has the characteristics of simple preparation process, high adhesive force, wear resistance, good sealing property and the like and can be well used on a smooth-surface substrate.

Owner:FUJIAN LIUJIAN GRP

Coating material applied to improve thermostability of lanthanum-cerium-terbium phosphate green emitting phosphor and method of producing the same

InactiveCN101402854AImprove thermal stabilityLow brightness attenuationLuminescent compositionsCerium phosphateOptical communication

The invention discloses a coating material applied for improving the thermal stability of green fluorescent powder of (La1-x-yCexTby) PO4 and a preparation method thereof. The invention includes the following steps: 1. lanthanum chloride and diammonium phosphate are prepared into a dilute solution with equal volume and equal concentration by secondary de-ionized water and heated for maintaining the temperature between 60 and 90 DEG C; 2. lanthanum phosphate, cerium phosphate and terbium phosphate are co-settled in a container, added with the secondary de-ionized water, heated for maintaining the temperature between 60 and 90 DEG C and stirred at a constant speed of 20 to 50 r / min; 3. the two liquids are slowly dripped into a suspension liquid in step 2 at an equal speed and stirred at a constant speed; after the dropping is finished, stirring is stopped and diluted acid or weak base is used for regulating the pH value of the suspension liquid to be between 4.0 and 6.0; then the suspension liquid stands for 2 to 3h; 4. the suspension liquid in step 3 is filtered and dried; a fluxing agent is added and uniformly mixed with the suspension liquid; and high temperature iglossing is carried out in a weak reduction atmosphere; and 5. a sinter is cooled to the room temperature in the reduction atmosphere, cracked to the needed granularity and washed by pure hot water, thus obtaining the green fluorescent powder of (La1-x-yCexTby) PO4 with good thermal stability; the thermal stability of the green fluorescent powder of (La1-x-yCexTby) PO4 obtained by the preparation method is good; the brightness attenuation after a technique procedure of tube baking is small; the initial optical communication of the green fluorescent powder after being prepared into a light is high; moreover, the light decay is less and the service life is long; and the invention is an excellent green fluorescent material in the backlight cold cathode lamp of an LCD.

Owner:JIANGMEN KANHOO IND +1

Bismuth phosphate/cerium phosphate composite lithium battery positive electrode material and preparation method

ActiveCN109638268AGood effectLower the activation energy of the reactionCell electrodesSecondary cellsCerium phosphateCerium nitrate hexahydrate

The invention relates to the technical field of lithium battery positive electrode materials, and provides a bismuth phosphate / cerium phosphate composite lithium battery positive electrode material and a preparation method. According to the method, a hydrophobic graphene aerogel is firstly prepared through a reduction method; then, bismuth nitrate pentahydrate and cerium nitrate hexahydrate are added to a graphene aerogel dispersion, precipitates produced by bismuth salt and cerium salt hydrolysis are adsorbed in micropores of the graphene aerogel, a diammonium hydrogen phosphate solution is then added and a hydrothermal reaction is carried out, and a graphene aerogel-loaded bismuth phosphate / cerium phosphate composite material is prepared. According to the preparation method provided in the invention, the cycle performance of the bismuth phosphate positive electrode material is improved through doping of cerium phosphate, and through load of the graphene aerogel, the conductivity of the bismuth phosphate positive electrode material is improved.

Owner:泰州新滨江智慧科技服务有限公司

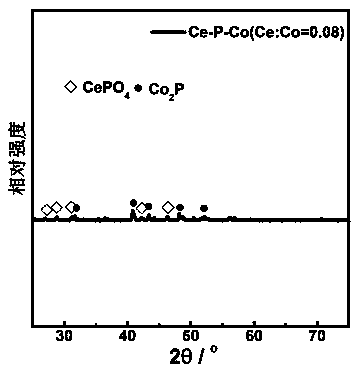

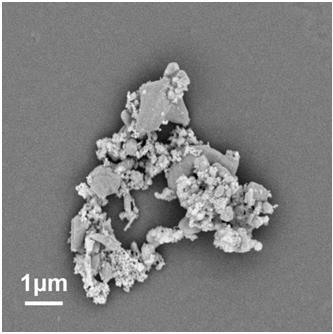

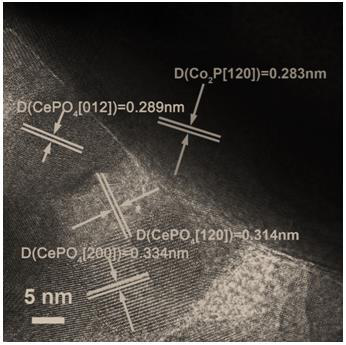

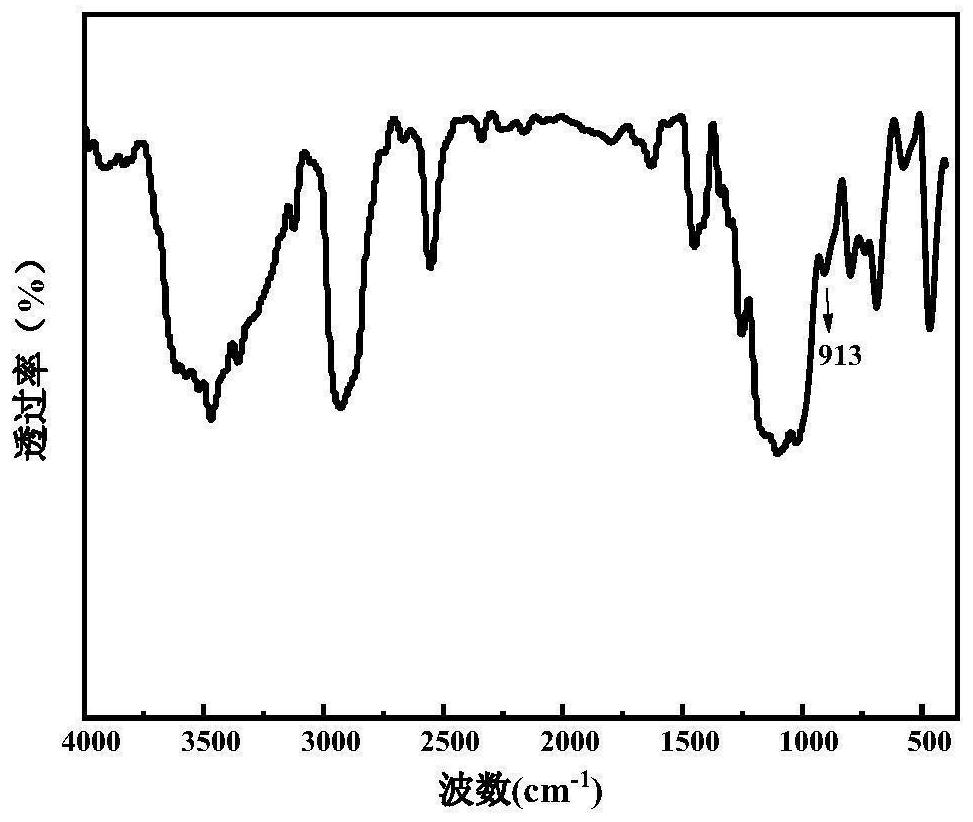

Acid-resistant Ce-P-Co catalyst and preparation method thereof, and application for acid-resistant Ce-P-Co catalyst in synthesis of gamma-valerolactone

InactiveCN109701569AHigh yieldRecyclableOrganic chemistryPhysical/chemical process catalystsCerium phosphateHydrogen atmosphere

The invention provides an acid-resistant Ce-P-Co catalyst and a preparation method thereof, and an application for the acid-resistant Ce-P-Co catalyst in synthesis of gamma-valerolactone. The catalystis a composite material composed of two components namely cerium phosphate and dicobalt phosphide in a molar ratio of 0.02 to 0.50. The preparation method comprises the following steps: preparing a mixed solution of cobalt salt and cerium salt, placing the mixed solution into a stirrer until the mixed solution is uniformly mixed, dropping a prepared monohydrogen phosphate solution B into the mixed solution, continuing stirring for 1 h, then transferring an obtained mixed solution into a polytetrafluoroethylene hydrothermal reaction kettle, and carrying out a reaction at 200 DEG C for 24 h; and after the reaction is completed, carrying out centrifuging so as to filter out a solid matter, carrying out washing, then carrying out drying at 75 DEG C, and carrying out high-temperature programmed treatment for 3 h in a hydrogen atmosphere at 800 DEG C. The acid-resistant Ce-P-Co catalyst provided by the invention has the advantages of low cost, simple synthetic method, environmentally-friendly process, and convenience in scale preparation and application. According to the invention, levulinic acid is converted into the gamma-valerolactone by hydrogenation, so the rate catalysis is rapid;conditions are relatively mild; the yield of the gamma-valerolactone can be up to 98%; and the catalyst is acid-resistant and can be recycled and stably used.

Owner:NANCHANG UNIV

High-elasticity flame-retarding wood-plastic packaging material and preparation method thereof

The invention discloses a preparation method of a high-elasticity flame-retarding wood-plastic packaging material. The preparation method comprises the following steps: crushing plant fibers and carbon fibers into powder, and carrying out surface organic modification; mixing aluminum silicate, polyvinyl chloride, polypropylene, polybutylene succinate and tributyl phosphate, adding into a blending machine and stirring and reacting for 20min to 40min; extruding an obtained mixture through an extruder, and granulating in a granulating machine; adding cerium phosphate, linalool and polyphenylene sulfide fibers, and carrying out ultrasonic reaction for 30min to 40min; filtering and drying to obtain grains; putting the grains into a mold, and carrying out film pressing and molding to obtain the high-elasticity flame-retarding wood-plastic packaging material.

Owner:苏州卫刚木包装制品有限公司

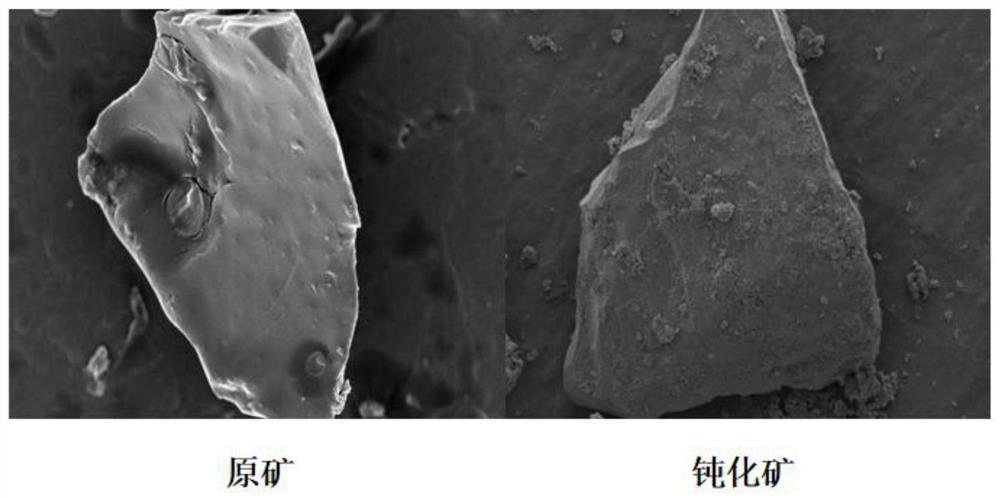

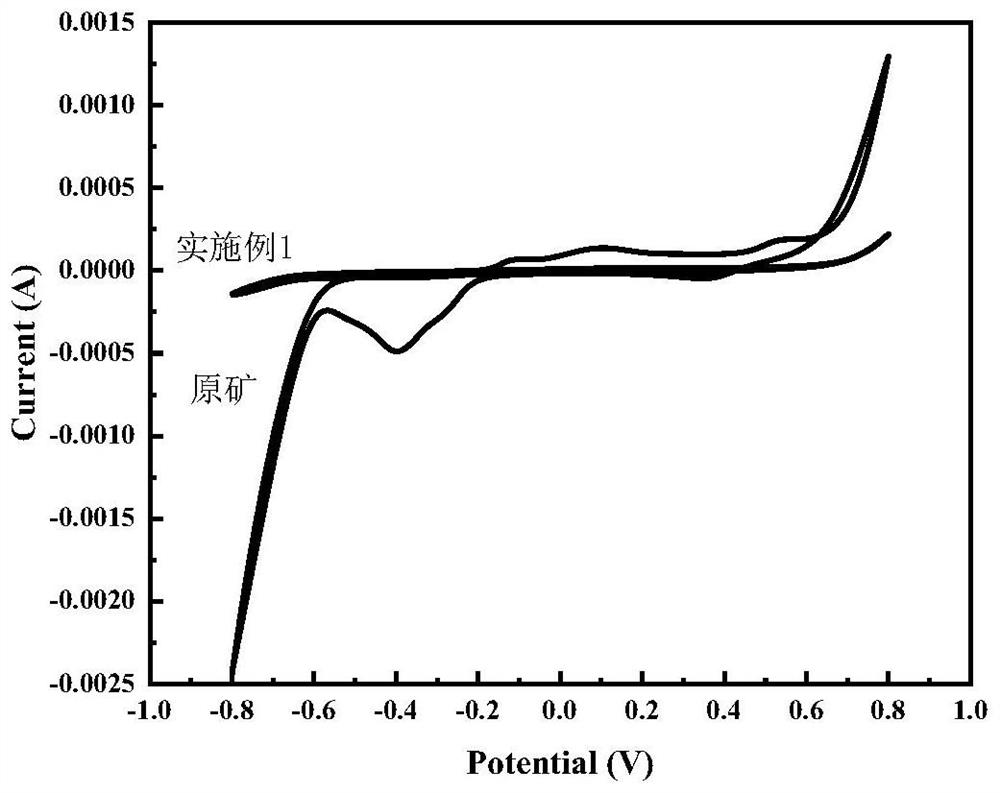

Long-acting tailing passivator capable of being cured at normal temperature as well as preparation method and application of long-acting tailing passivator

ActiveCN114504759AAchieve room temperature curingAvoid traditional high temperature curing processChemical protectionCerium phosphateChemical reaction

The invention discloses a long-acting tailing passivator capable of being cured at normal temperature as well as a preparation method and application of the long-acting tailing passivator. According to the invention, epoxy silane is taken as a main body, aliphatic polyamine is taken as a curing agent, organic cerous phosphate is taken as a repairing agent, the surface of pyrite is coated and passivated through an impregnation method, curing is carried out at normal temperature, and a passive film can inhibit tailing oxidation for a long time. Normal-temperature curing of the passive film is achieved through chemical reaction curing, and the operation and cost problems caused by high-temperature curing in the industry are avoided; the repairing agent with a simple preparation process can repair a locally damaged passivation film under the stimulation of acid and alkali, endows the passivation film with a self-repairing function, improves the effect, reduces the cost, enhances the long-acting passivation performance, and reduces the application frequency of the passivator. The tailing passivator disclosed by the invention has the characteristics of good passivation performance, good long-term effect and the like, avoids the defects of complex preparation, high-temperature curing and the like, is convenient for large-scale industrial production and application of tailing pollution treatment, and can be applied to the field of metal mine tailing passivation.

Owner:SOUTH CHINA UNIV OF TECH

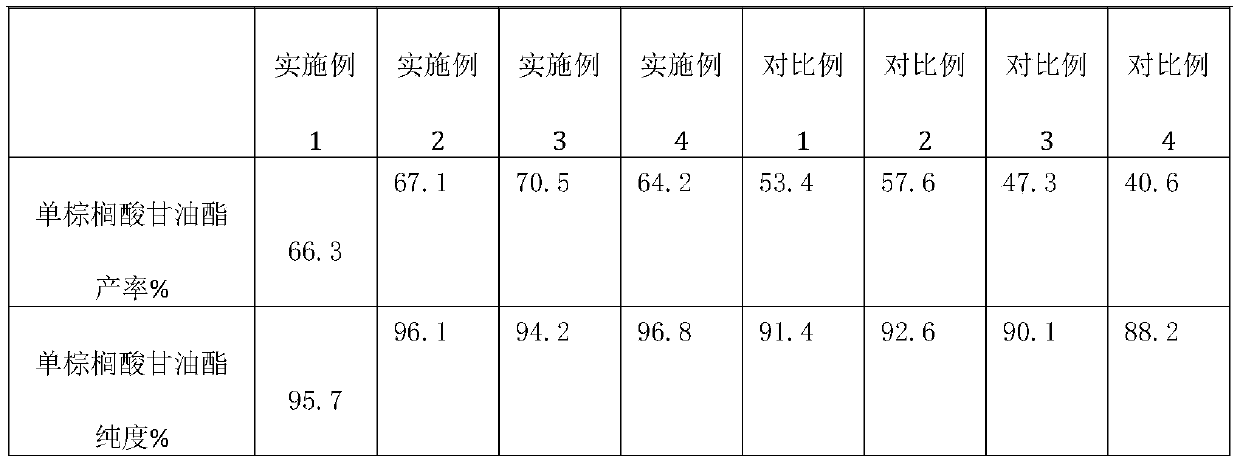

Method for synthesizing monopalmitoyl glyceride

InactiveCN109896954AHigh reaction conversion rateHigh purityOrganic compound preparationCarboxylic acid esters preparationCerium phosphateGLYCERYL PALMITATE

The invention discloses a method for synthesizing monopalmitoyl glyceride. The method comprises the following steps: 1) adding palm oil and glycerol into a first reactor, fully and uniformly stirring,and preheating to the temperature of 100-120 DEG C to obtain a first mixture; 2) adding a catalyst and a phase transfer agent, heating to the temperature of 200-220 DEG C, and stirring and reacting to obtain a second mixture; 3) adjusting the pH value of the second mixture, cooling, and centrifuging and layering to obtain an upper-layer monopalmitoyl glyceride crude product; and 4) distilling themonopalmitoyl glyceride crude product to obtain the monopalmitoyl glyceride. According to the method for synthesizing the monopalmitoyl glyceride, cerium phosphate and antimony trioxide cooperativelyserve as the catalyst, tetrabutylammonium bromide and cyclodextrin are used as the phase transfer agent, the reaction conversion rate of the prepared monopalmitoyl glyceride is remarkably improved, the product purity is high, the product purity reaches 94.2% or above, the conversion rate reaches 64.2% or above, and the method has a good industrial application prospect.

Owner:佳力士添加剂(海安)有限公司

Magnesium-calcium material and preparation method thereof

The invention relates to a magnesium-calcium material and a preparation method thereof. The preparation method comprises the following steps: mixing 60-70 wt% of magnesia-calcia particles, 20-30 wt% of magnesia-calcia fine powder, 2-5 wt% of cerium phosphate and 3-6 wt% of phosphotitanate, uniformly stirring, carrying out compression molding, and naturally drying for 20-30 h; and drying for 8-16 hat the temperature of 110 DEG C, firing for 2-5 h at the temperature of 1500-1700 DEG C, and cooling to obtain the magnesium-calcium material, wherein the MgO content of the magnesia-calcia is greater than or equal to 40 wt%, the particle size of magnesia-calcia particles is 0.2-11 mm, and the particle size of the magnesia-calcia fine powder is 3-200 [mu]m; the particle size of the cerium phosphate is 3-200 [mu]m; and the content of P2O5 in the phosphotitanateis greater than or equal to 1wt%, and the content of TiO2 in the phosphotitanate is greater than or equal to 1 wt%. The method is simple in process, low in cost and environmentally friendly, and the prepared magnesium-calcium material is excellent in hydration resistance, remarkable in metal melt purification effect and suitable forpurifying refractory materials for smelting.

Owner:WUHAN UNIV OF SCI & TECH

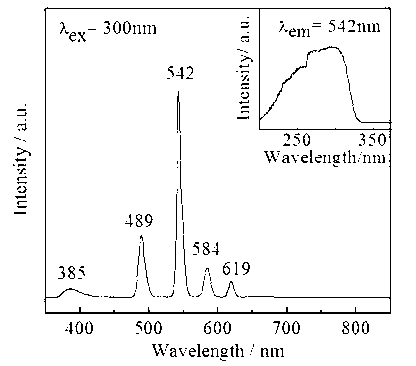

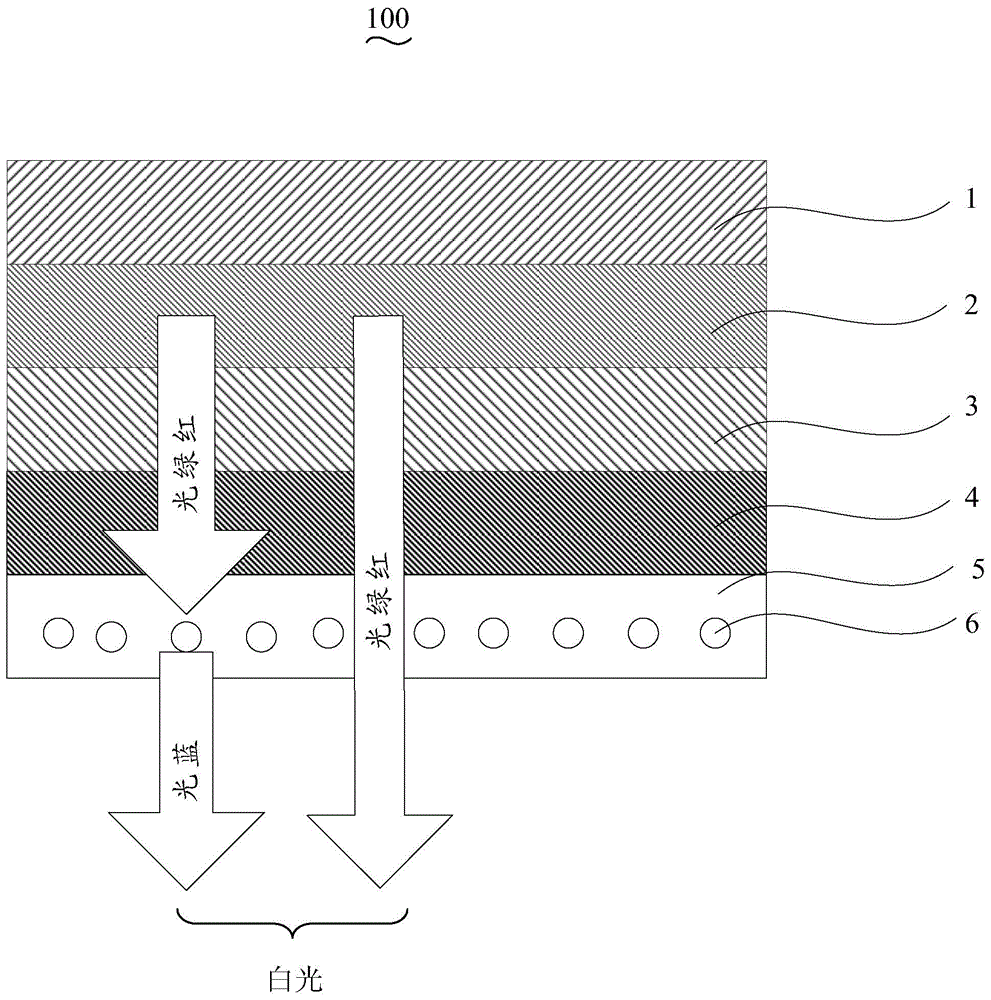

Praseodymium-doped cerium phosphate up-conversion luminescent material, and preparation method and application thereof

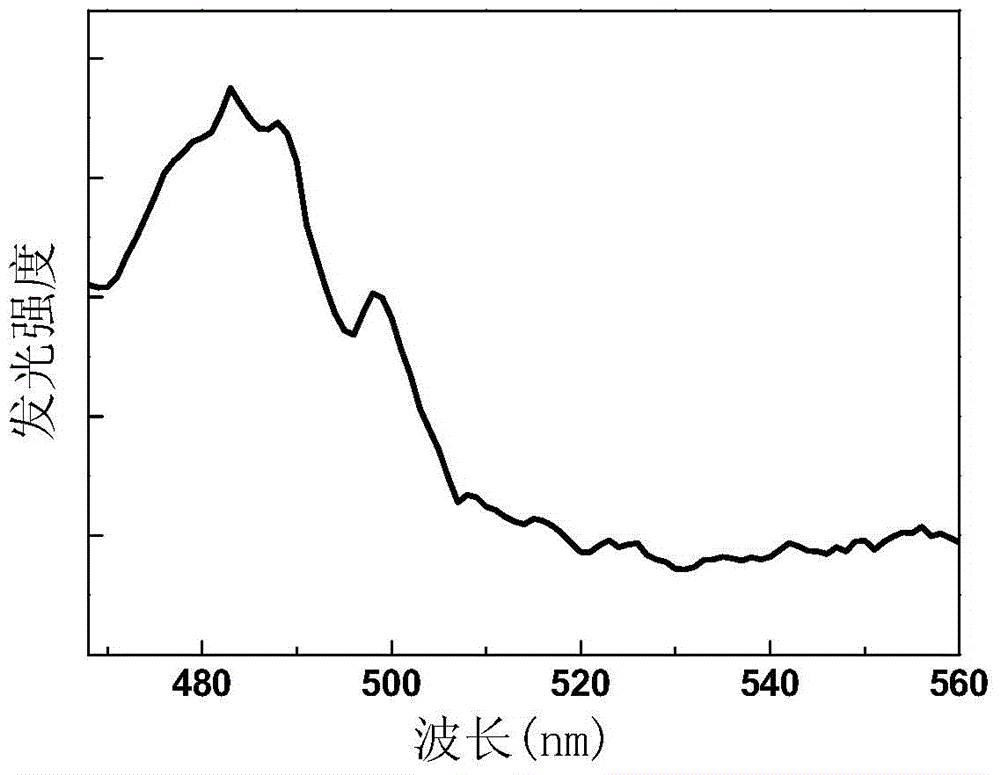

InactiveCN104650910ASolid-state devicesSemiconductor/solid-state device manufacturingCerium phosphatePhotoluminescence

The invention provides a praseodymium-doped cerium phosphate up-conversion luminescent material. The material has the chemical formula of Ce1-xPO4: xPr<3+>, wherein x is in a range of 0.002 to 0.03. According to the photoluminescence spectrum of the praseodymium-doped cerium phosphate up-conversion luminescent material, the excitation wavelength of the material is 578 nm, transition radiation of Pr3+ ions from 3P0 to 3H4 in the region of 483-nm wavelength leads to formation of luminescent peaks, so the material can be used as a blue-light emitting material. The invention also provides a preparation method for the praseodymium-doped cerium phosphate up-conversion luminescent material and an organic light emitting diode using the praseodymium-doped cerium phosphate up-conversion luminescent material.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Flame-retardant material

The invention discloses a fire-resistant flame retardant material, which comprises the following raw materials in parts by weight: 20-30 parts of silicon dioxide, 5-7 parts of silicon carbide, 10-20 parts of carbon nanotubes, and 15-25 parts of alumina 10-20 parts of rock wool, 6-10 parts of copper oxide, 1-3 parts of silicon micropowder, 4-6 parts of cerium hypophosphite, 10-12 parts of quartz sand, 10-20 parts of high alumina cement, 10 parts of high alumina micropowder ‑12 parts and 1‑3 parts of penetrating agent maintain the thermal stability of the composite material and increase the carbonation of the material in the high temperature area.

Owner:王建明

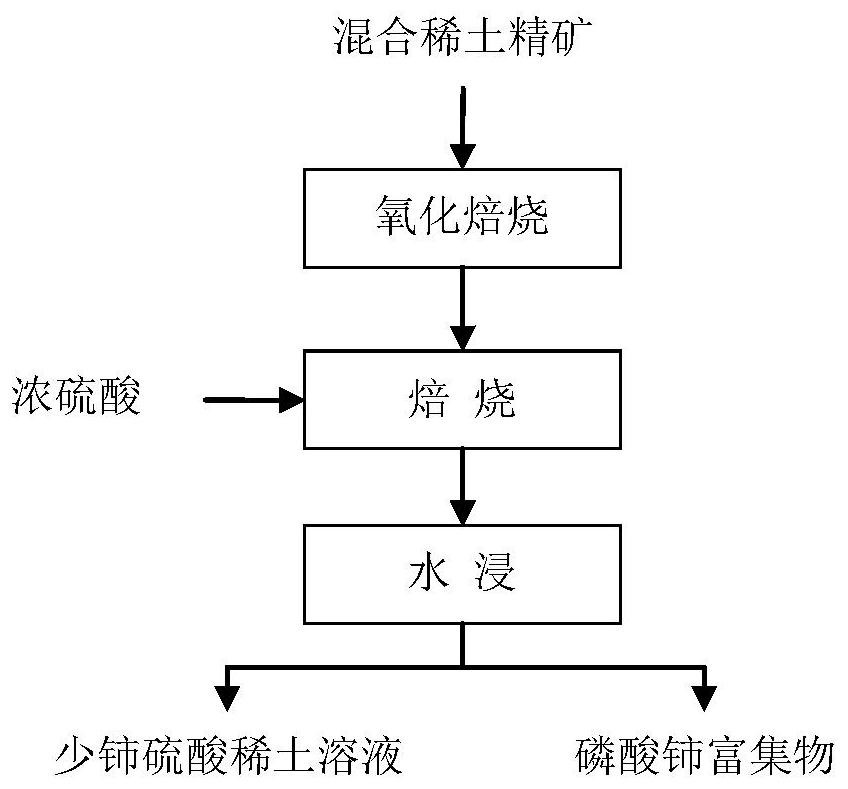

Method for selectively extracting non-cerium rare earth in mixed rare earth concentrate

ActiveCN109161702BHighly selective developmentProcess efficiency improvementCerium phosphateO-Phosphoric Acid

The invention discloses a method for selectively extracting non-cerium rare earth from mixed rare earth ore concentrate. The method comprises the following steps: performing air oxidation roasting onmixed rare earth ore concentrate containing bastnaesite and monazite at 400-650 DEG C for 1-3 h to generate thermal oxidation roasted ore; oxidizing trivalent cerium in the mixed rare earth ore concentrate into tetravalent cerium; uniformly mixing the thermal oxidation roasted ore and concentrated sulfuric acid and roasting the mixture at the low temperature of 150-800 DEG C for 0.5-2 h, and dissolving the oxidation roasted ore in concentrated sulfuric acid to form cerium phosphate and trivalent rare earth sulfate; performing water soaking and size mixing on cerium phosphate and trivalent rareearth sulfate, and performing solid-liquid separation to obtain a little-cerium rare earth sulfate solution and a cerium phosphate enriched product. Technical advantages that high-valent cerium is formed from bastnaesite by oxidation roasting and phosphoric acid is formed from monazite by sulfuric acid decomposition are fully combined, and fixation of cerium and phosphorus resources and selectiveexploitation of non-cerium rare earth are realized by high-stability cerium phosphate.

Owner:BAOTOU RES INST OF RARE EARTHS +1

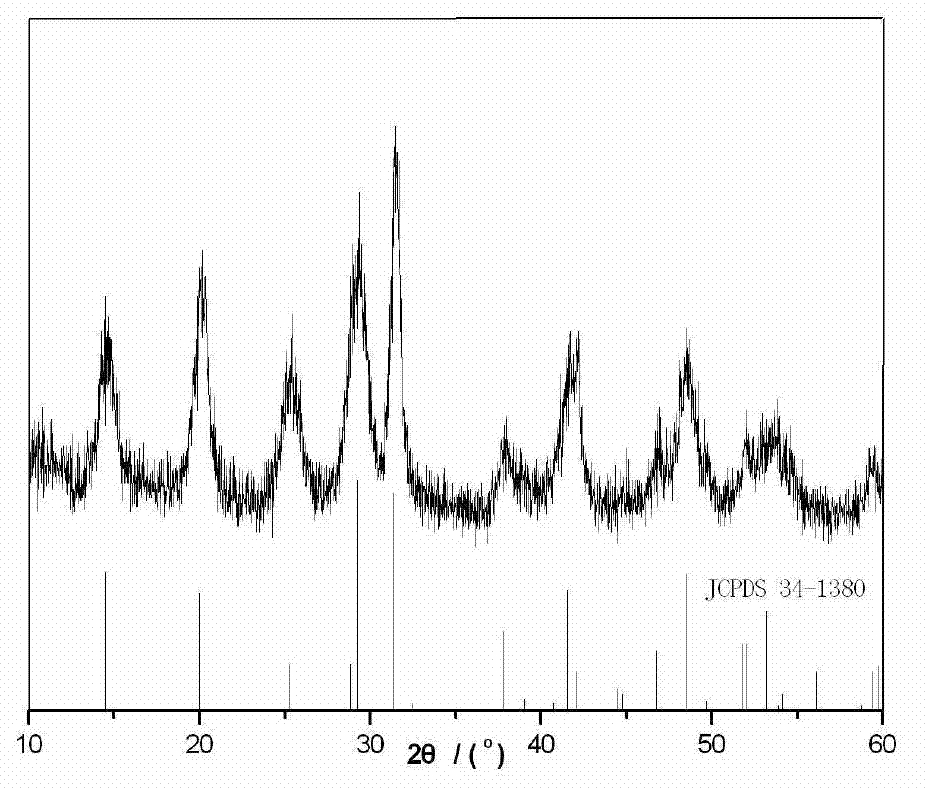

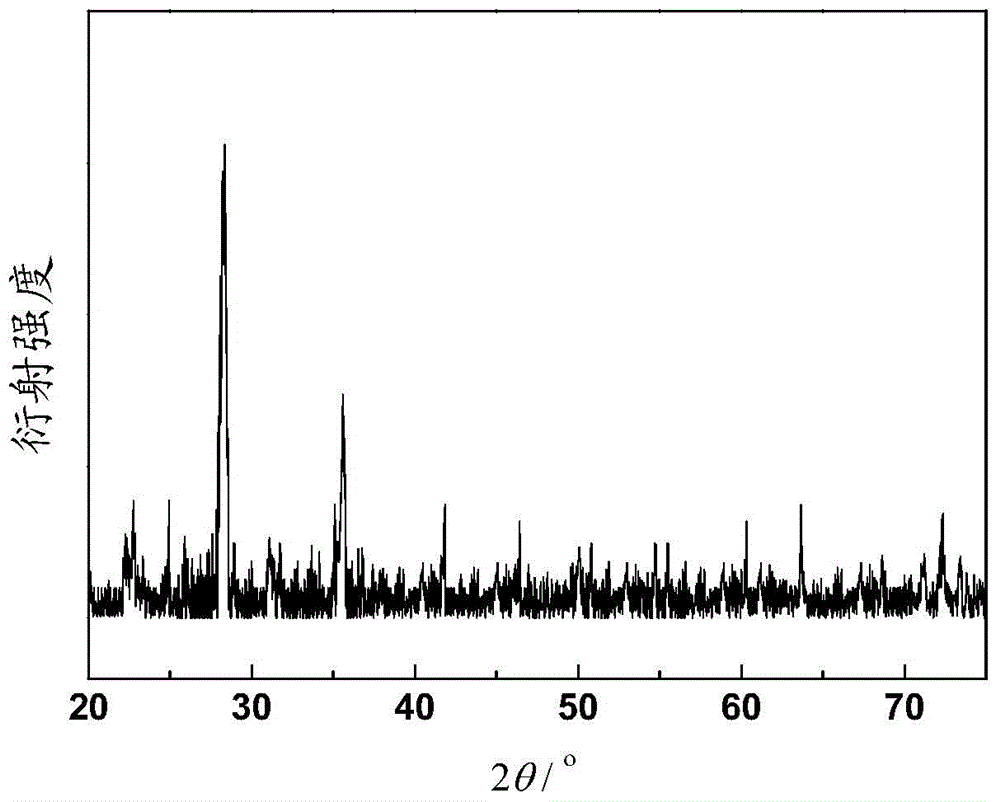

A wide temperature type phosphorus-containing cerium-based denitrification catalyst and preparation method thereof

InactiveCN105214698BLarge temperature rangeImprove escape ratePhysical/chemical process catalystsDispersed particle separationCerium phosphateNitrogen oxides

The invention relates to a wide temperature phosphorus-containing cerium-based denitration catalyst and a preparation method thereof. The catalyst is mainly composed of cerium phosphate (CePO4) and manganese oxide Mn2O3 in a molar ratio of 1:0.5-3. The wide temperature phosphorus-containing cerium-based denitration catalyst of the present invention has a temperature range of 150-500° C. for removing nitrogen oxides, and the denitration stability and N2 selectivity are high, especially the phosphorus-containing cerium-based denitration catalyst of the present invention has The removal effect of nitrogen oxides in the low temperature region (150-350℃) is good, and the conversion rate of nitrogen oxides all reach more than 90%.

Owner:THE NORTHWEST RES INST OF CHEM IND

Preparation method of high-temperature-resistant fireproof bushing for cable

Owner:ANHUI HAOTIAN NEW MATERIALS CO LTD

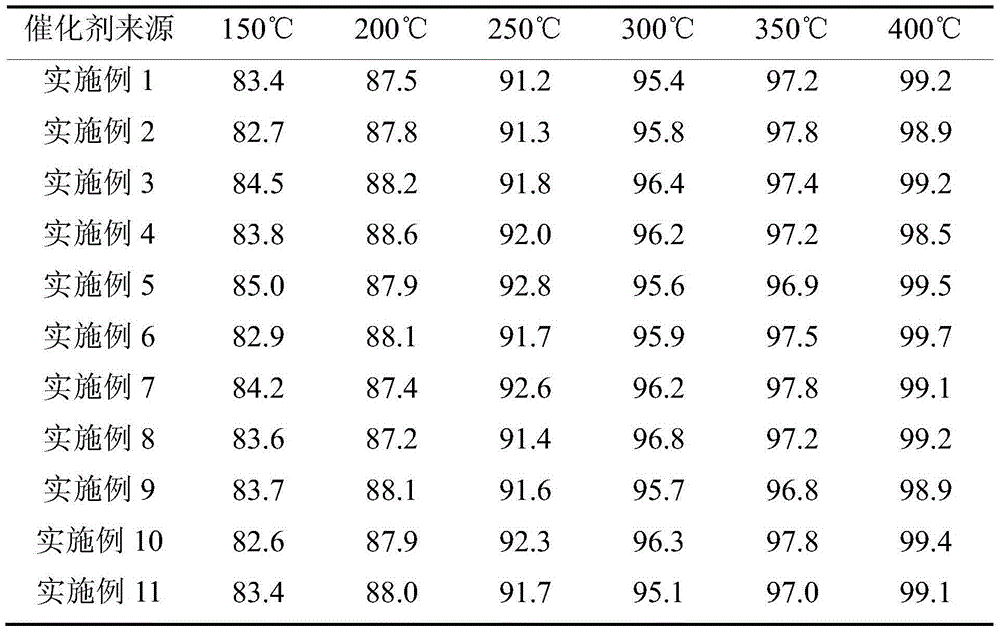

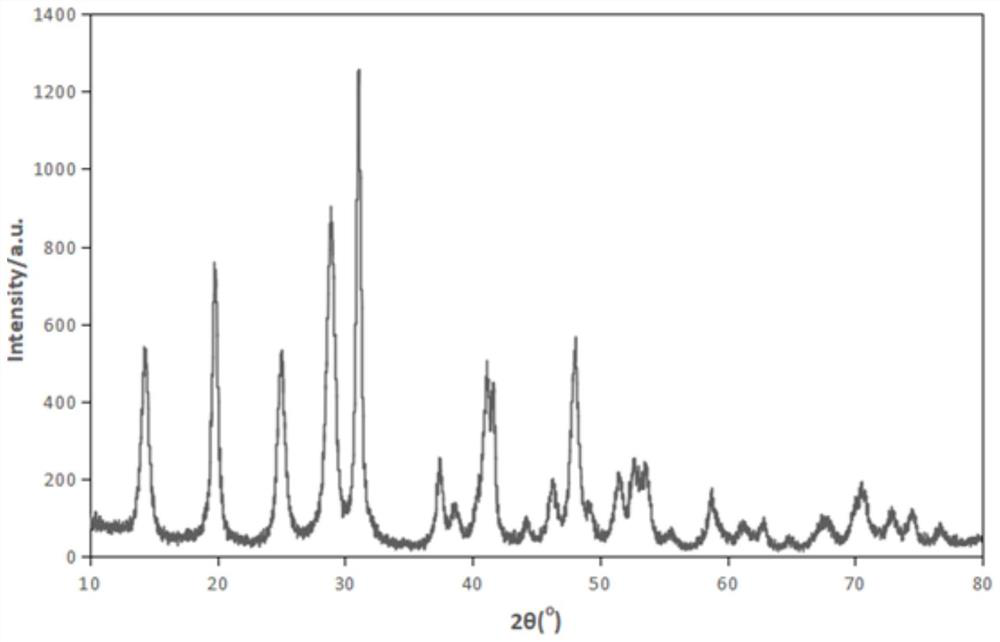

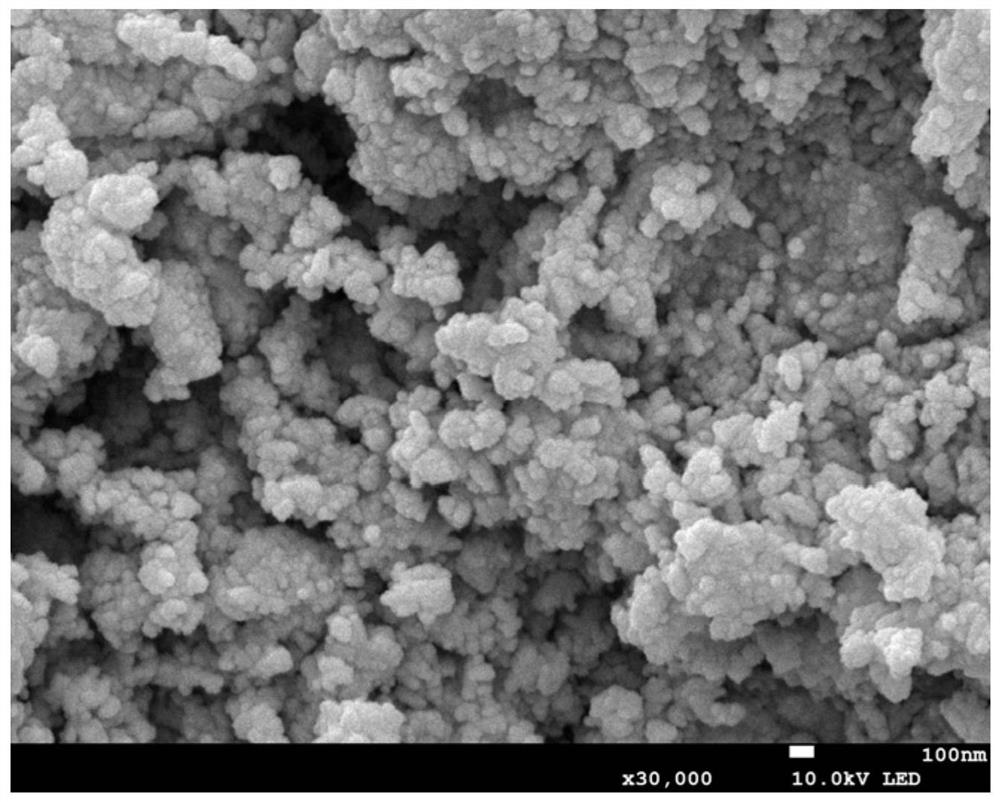

Preparation method of high-purity nano cerium phosphate powder

ActiveCN112551499AProcess Green CycleSimple production processMaterial nanotechnologyPhosphorus compoundsCerium phosphateO-Phosphoric Acid

The invention relates to a preparation method of high-purity nano cerium phosphate powder, which comprises the following steps: (1) taking cerium carbonate, basic cerium carbonate or cerium hydroxide,adding into deionized water or deionized water containing a dispersing agent, and stirring to obtain a cerium-containing suspension, (2) preparing a phosphoric acid solution, adding nitric acid or hydrochloric acid into the phosphoric acid solution, and adding hydrogen peroxide or ascorbic acid to obtain a phosphoric acid solution containing hydrogen peroxide or ascorbic acid, and (3) adding thecerium-containing suspension into a phosphoric acid solution containing hydrogen peroxide or ascorbic acid for reaction, and after the reaction is finished, filtering, washing and drying precipitatesto obtain cerium phosphate powder. The purity of the high-purity nano cerium phosphate prepared by the method is greater than 99.995%, the dispersity is good, and the primary particle size of the high-purity nano cerium phosphate is spherical-like powder of 100nm-500nm.

Owner:YIYANG HONGYUAN RARE EARTH

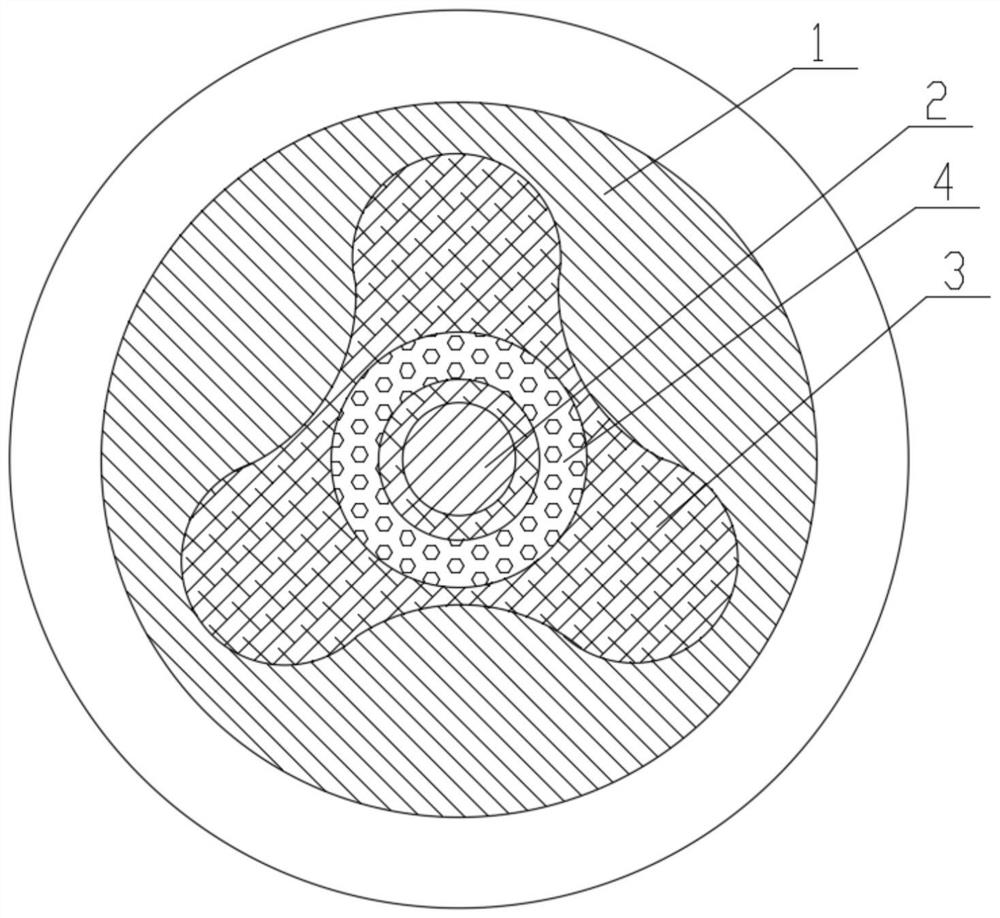

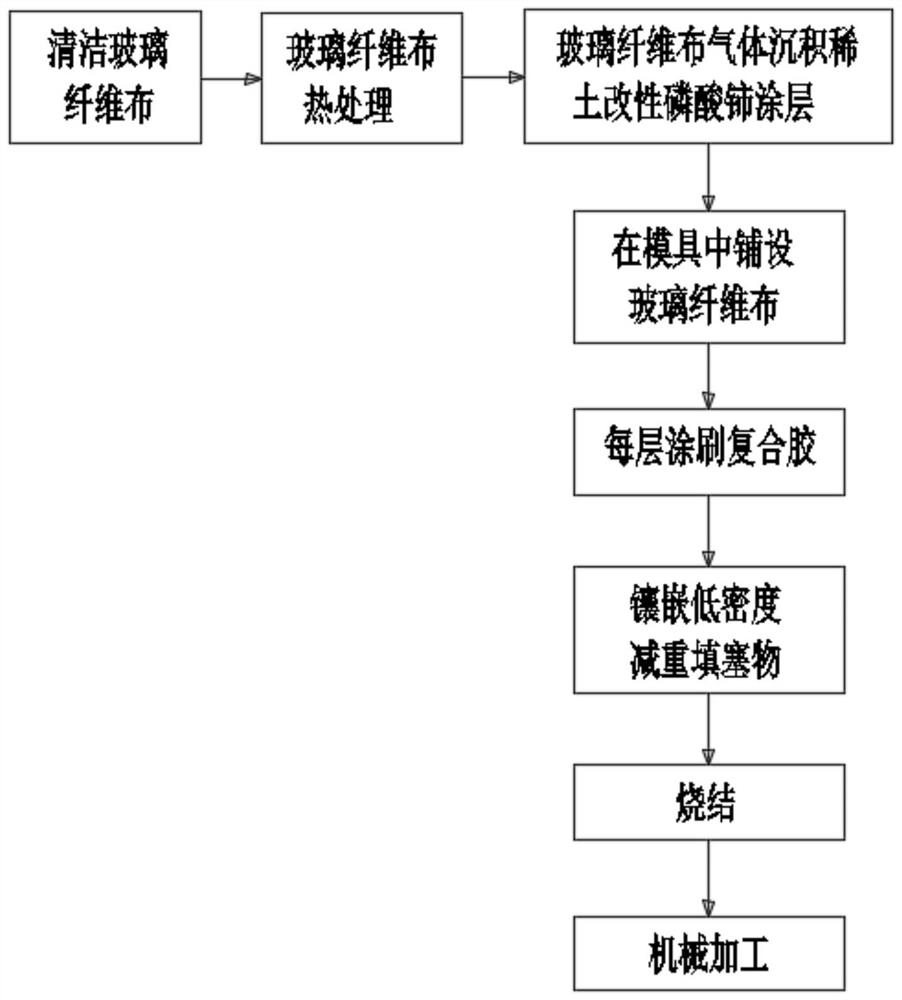

Method for preparing ceramic rotor by taking rare earth oxide as sintering aid

PendingCN114716253AImprove toughnessOptimizing Process ParametersPump componentsPumpsCerium phosphateGlass fiber

The invention relates to the technical field of composite material preparation, in particular to a method for preparing a ceramic rotor by taking rare earth oxide as a sintering aid, which is characterized by specifically comprising the following steps of: laying a plurality of layers of glass fiber cloth which reacts and deposits a rare earth modified cerous phosphate coating in advance in a ceramic rotor mold; embedding low-density weight-reducing stuffing among the layers, coating composite glue for fixing, and sintering to obtain a ceramic rotor blank; the composite adhesive is prepared by uniformly mixing unsaturated polyester resin and ceramic powder; the rare earth modified cerous phosphate coating is obtained on the surface of the glass fiber cloth by adopting a chemical vapor deposition method and then is subjected to high-temperature carbonization treatment; and the low-density weight-reducing stuffing is filled in a hole groove formed by a plurality of layers of glass fiber cloth. Compared with the prior art, the invention has the following beneficial effects: the bending strength of the ceramic rotor is greater than or equal to 15Mpa, the acid resistance is greater than or equal to 98%, the alkali resistance is greater than or equal to 99%, and the thermal expansion coefficient is lt; and 5.46 * 10 <-6 > / K.

Owner:UNIV OF SCI & TECH LIAONING

Low-temperature, sulfur-resistant phosphorus-containing cerium-iron-tin composite denitrification catalyst and preparation method thereof

ActiveCN109248698BIncrease the areaHigh low temperature activityPhysical/chemical process catalystsDispersed particle separationCerium phosphatePtru catalyst

Owner:THE NORTHWEST RES INST OF CHEM IND

A kind of cerium phosphate modified silicon carbide fiber reinforced silicon carbide composite material and preparation method thereof

ActiveCN109293367BHigh melting pointHigh temperature resistance and oxidation resistanceCeramicwareCerium phosphateCarbide silicon

The invention relates to a cerium phosphate modified silicon carbide fiber reinforced silicon carbide composite material and a preparation method thereof. The method: (1) alternately prepare cerium phosphate interface layers and silicon carbide interface layers on the surface of the silicon carbide fiber preform until reaching a predetermined thickness or predetermined number of layers to obtain a modified silicon carbide fiber preform; (2) use carbon The precursor solution is impregnated with the modified silicon carbide fiber preform, and then the impregnated modified silicon carbide fiber preform is sequentially subjected to a curing step and a cracking step; (3) repeating step (2) at least once to prepare a porous silicon carbide fiber preform and (4) subjecting the prepared porous silicon carbide fiber preform to liquid silicon infiltration reaction to obtain a cerium phosphate modified silicon carbide fiber reinforced silicon carbide composite material. The cerium phosphate modified silicon carbide fiber-reinforced silicon carbide composite material prepared by the invention has excellent oxidation resistance, temperature resistance, thermal shock resistance, etc., excellent comprehensive performance at high temperature, and long service life.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Cerium phosphate-based catalyst for zero-valent mercury oxidation, preparation method and application

ActiveCN104399499BRaw materials are readily availableEasy to operatePhysical/chemical process catalystsDispersed particle separationCerium phosphateManganese

The invention discloses a cerous phosphate based catalyst for zero-valent mercury oxidation. The catalyst is mainly composed of cerous phosphate, and comprises modification components; wherein the modification components are composed of at least one oxide of cobalt, manganese, copper, iron, vanadium, cerium, molybdenum, tin, and the like. The invention also discloses a preparation method and applications of the catalyst. The preparation process is simple, and the operation is convenient. Compared to the prior art, the catalyst has the following advantages: (1) the active components of the catalyst are all common metal oxides, the common metal phosphate is taken as the carrier, the raw materials are simple and easily available, and the operation is convenient; (2) the catalyst has a very good sulfur-resistant performance; (3) the CePO4 catalyst, which has been modified by metal oxides, is well adapt to the flue gas. The provided catalyst can fully utilizes the NO in flue gas to greatly promote the oxidation of zero-valent mercury. The great dependence on HCl of conventional catalysts is gotten rid of.

Owner:ZHEJIANG UNIV

a lapo 4 : CE coated calcium strontium aluminum europium composite luminescent material and its preparation method and application

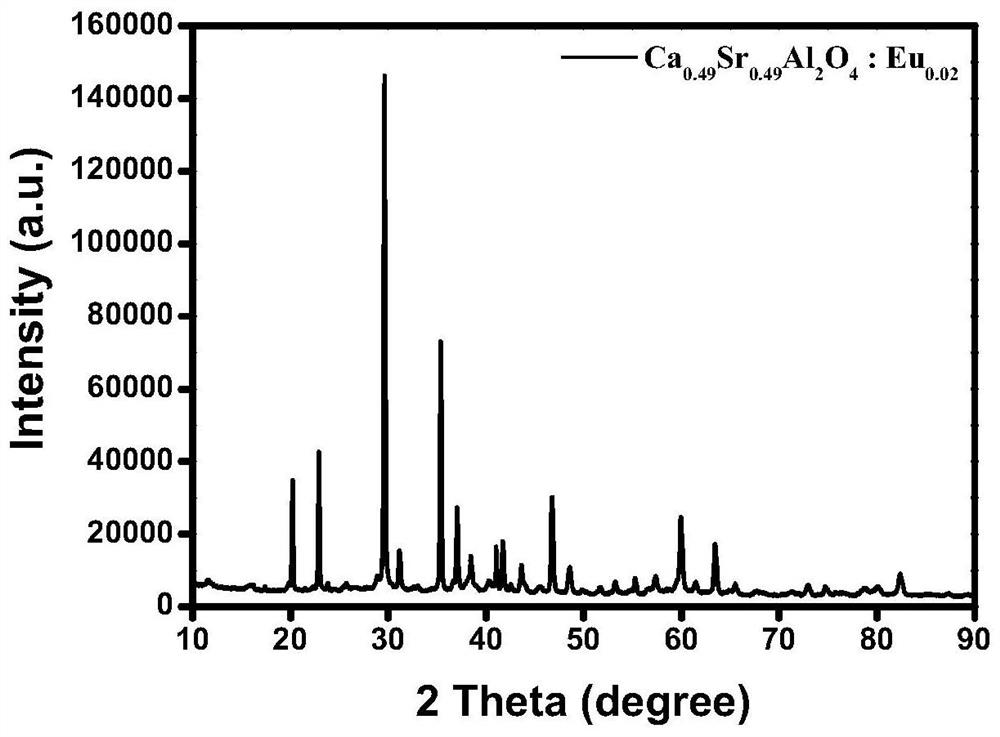

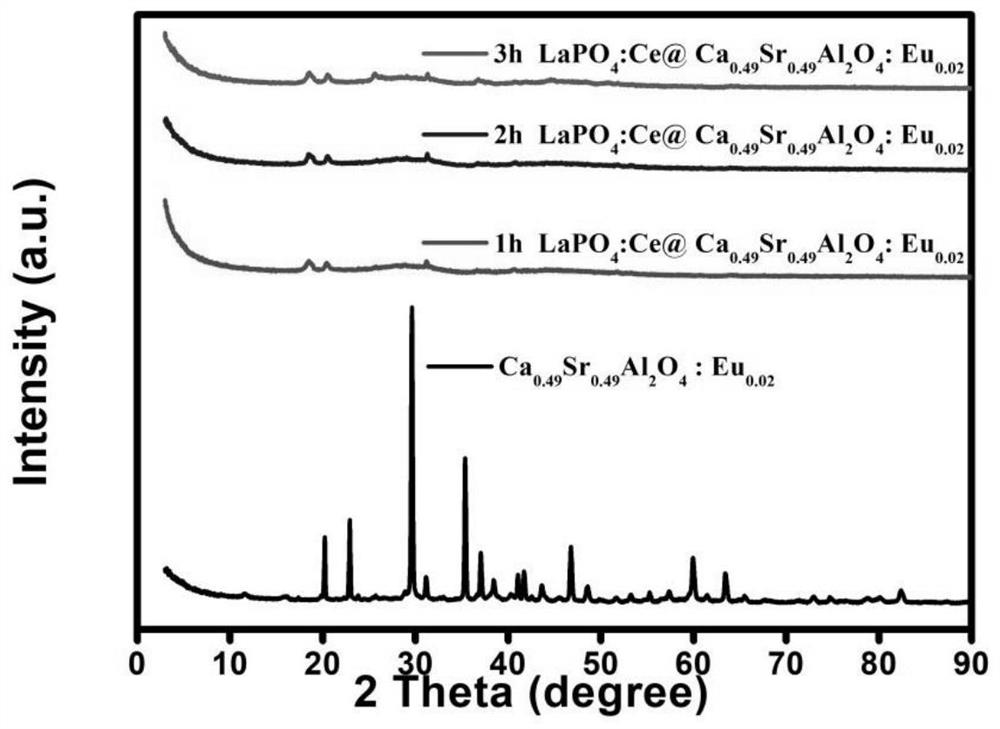

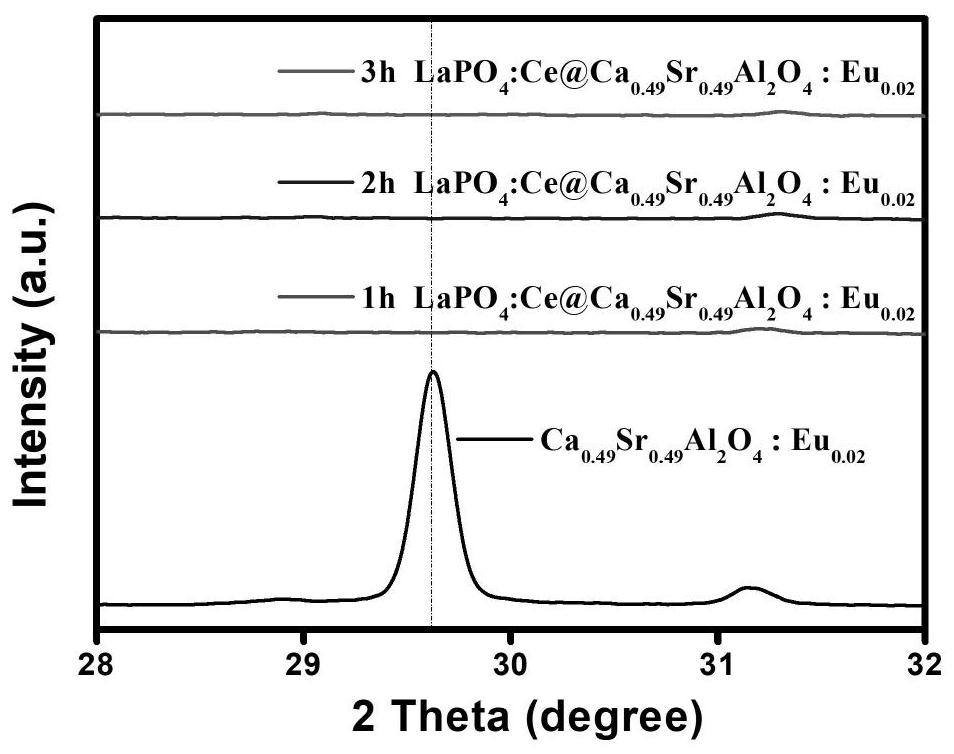

ActiveCN112646580BAchieving controllable equipmentEasy to operateLuminescent compositionsCerium phosphatePhosphoric acid

The invention provides a LaPO 4 The invention relates to a Ce-coated calcium strontium aluminum europium composite luminescent material and a preparation method and application thereof, belonging to the technical field of luminescent materials. LaPO of the present invention 4 :Ce coated calcium strontium aluminum europium composite luminescent material including Ca 0.49 Sr 0.49 Al 2 o 4 :Eu 0.02 and coated on the Ca 0.49 Sr 0.49 Al 2 o 4 :Eu 0.02 Lanthanum cerium phosphate complexes on the surface. The present invention uses lanthanum cerium phosphate complex to coat Ca 0.49 Sr 0.49 Al 2 o 4 :Eu 0.02 , LaPO 4 : The composite material after Ce doping can absorb ultraviolet light, and can 0.49 Sr 0.49 Al 2 o 4 :Eu 0.02 The corresponding spectrum is emitted in the absorption spectrum range, so as to achieve the effect of spectrum adjustment.

Owner:北斗兄弟天津科技股份有限公司

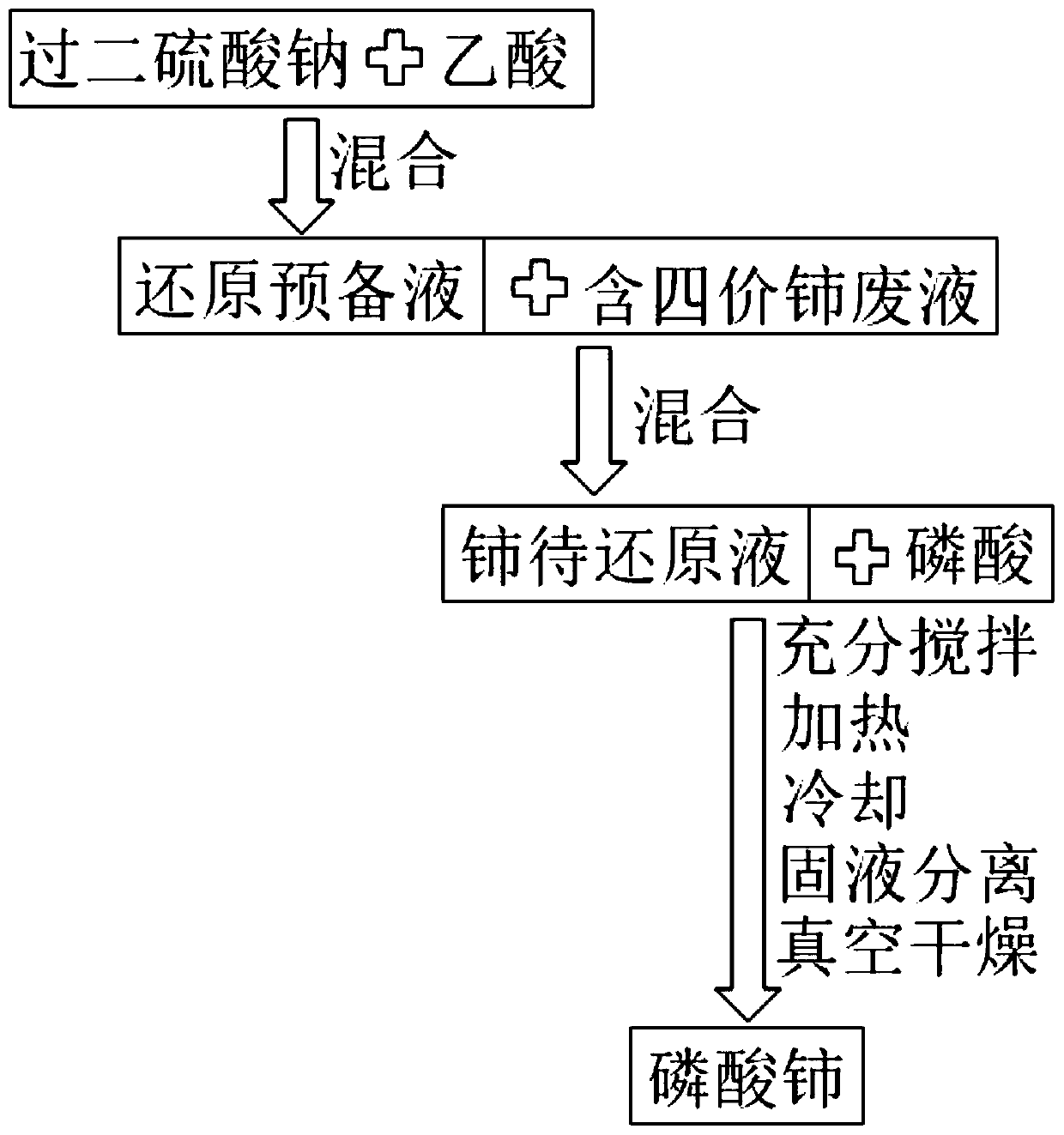

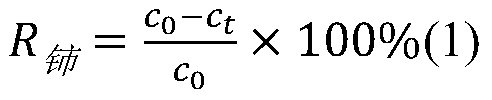

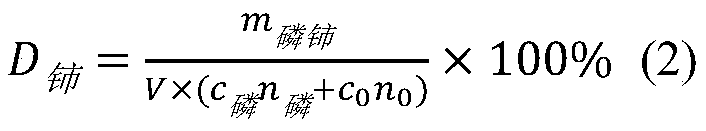

Method for preparing cerium phosphate by utilizing tetravalent cerium-containing waste liquid

ActiveCN111204727ANo effect on reduction efficiencyImprove reduction efficiencyPhosphorus compoundsCerium phosphateO-Phosphoric Acid

The invention discloses a method for preparing cerium phosphate by using tetravalent cerium-containing waste liquid, which comprises the following steps: 1) respectively weighing sodium persulfate andacetic acid, mixing, and stirring until the sodium persulfate is completely dissolved to obtain a reduction preparation solution; 2) mixing the tetravalent cerium-containing waste liquid with the reduction preparation liquid to obtain a cerium to-be-reduced liquid; and 3) adding phosphoric acid into the cerium to-be-reduced solution, fully stirring, heating, cooling, carrying out solid-liquid separation, and carrying out vacuum drying to obtain cerium phosphate. According to the method, the tetravalent cerium-containing waste liquid can be efficiently treated, the cerium recovery rate is as high as 99%, and the cerium phosphate yield is as high as 98%. Meanwhile, cerium phosphate is obtained in the process of treating the tetravalent cerium-containing waste liquid by applying the method,the generated waste liquid only contains sodium sulfate and sodium carbonate, the environmental friendliness is obvious, and secondary treatment is not needed.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com