Polymer emulsion interfacial agent for treating building wall and preparation method of polymer emulsion interfacial agent

A polymer emulsion and building technology, applied in polyester coatings, biocide-containing paints, coatings, etc., can solve problems such as poor sealing, poor adhesion, and unusable substrates with smooth surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0289] The present invention is described in detail below in conjunction with embodiment

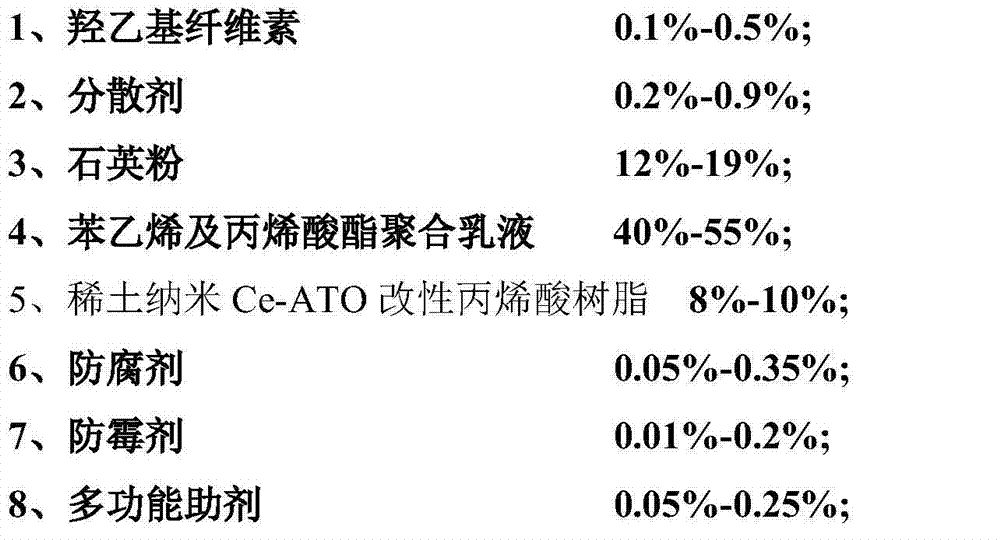

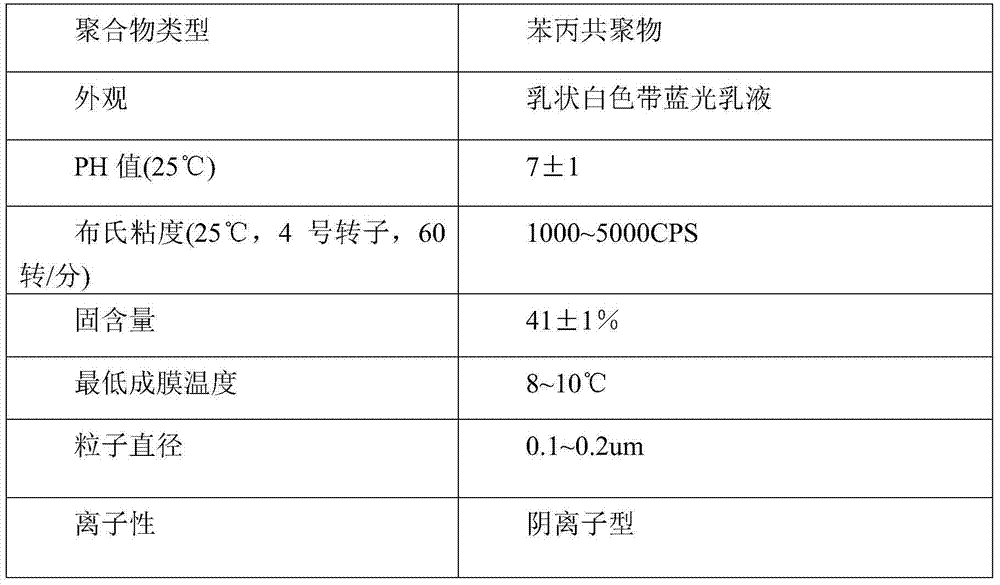

[0290] (1) The specific components and weight percentages of component A are as follows:

[0291]

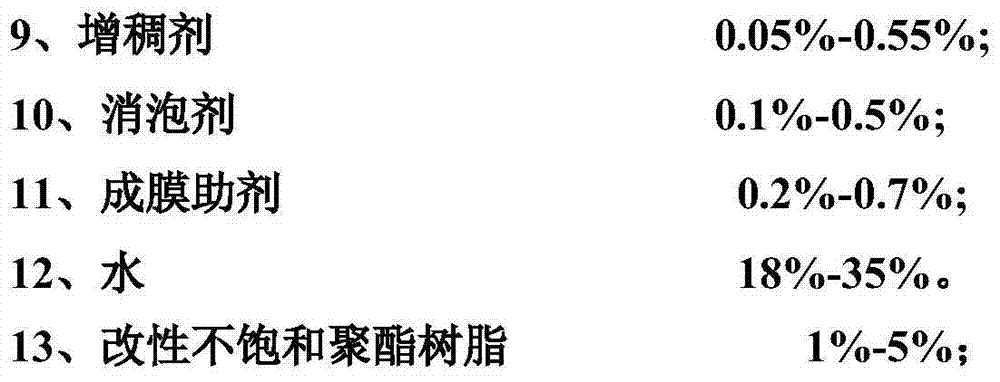

[0292]

[0293] The modified unsaturated polyester resin is prepared by the following method: 1) maleic anhydride is hydrolyzed to generate maleic acid; 2) dicyclopentadiene is mixed with maleic acid at 110-140°C Addition reaction occurs at the carboxyl group to generate dicyclopentadiene-maleic acid monoester; 3) dicyclopentadiene-maleic acid monoester is esterified as monobasic unsaturated acid and propylene glycol under esterification catalyst Polycondensation reaction to obtain dicyclopentadiene-terminated polyester; 4) dicyclopentadiene-terminated polyester, diluted with methyl methacrylate, to obtain dicyclopentadiene-modified unsaturated polyester resin;

[0294] Wherein step 3) dicyclopentadiene is used as a monobasic unsaturated acid and propylene glycol under the methanesu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com