Patents

Literature

92 results about "Cerium hydroxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cerium(III) hydroxide is a hydroxide of the rare-earth metal cerium. It is a pale white powder with the chemical formula Ce(OH)3.

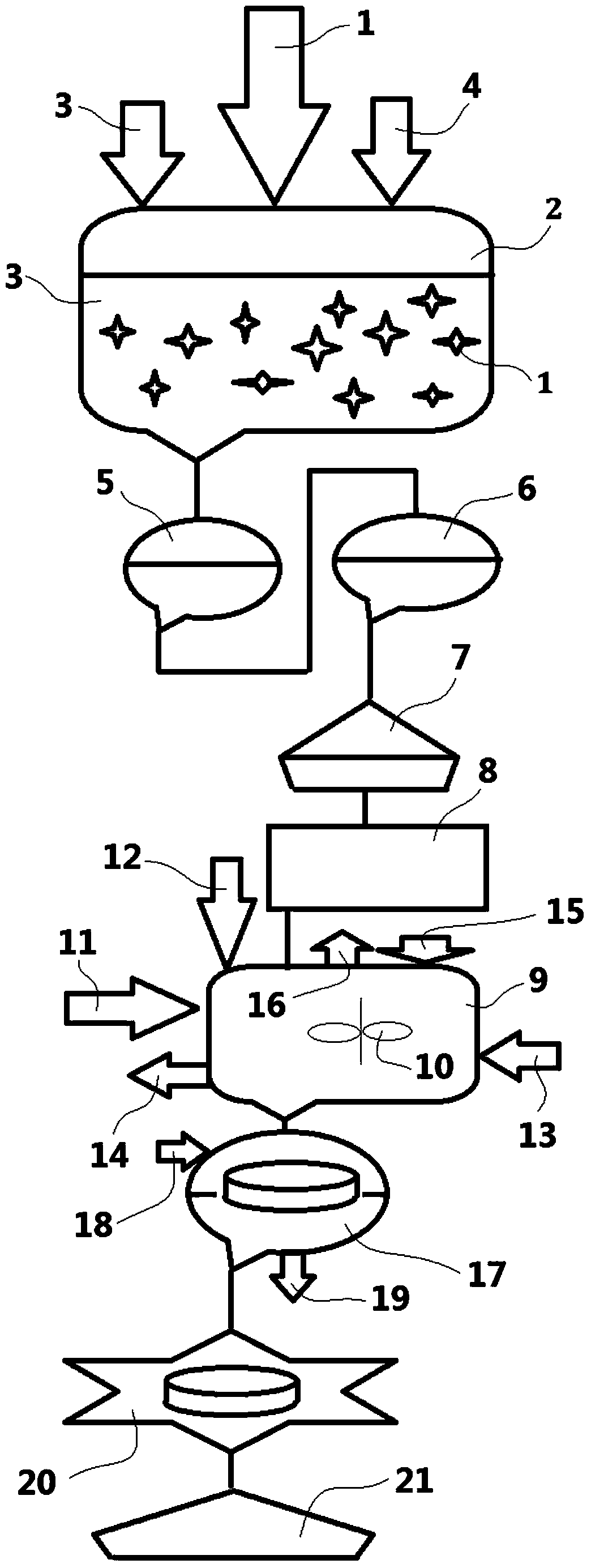

Fuel additive containing lattice engineered cerium dioxide nanoparticles

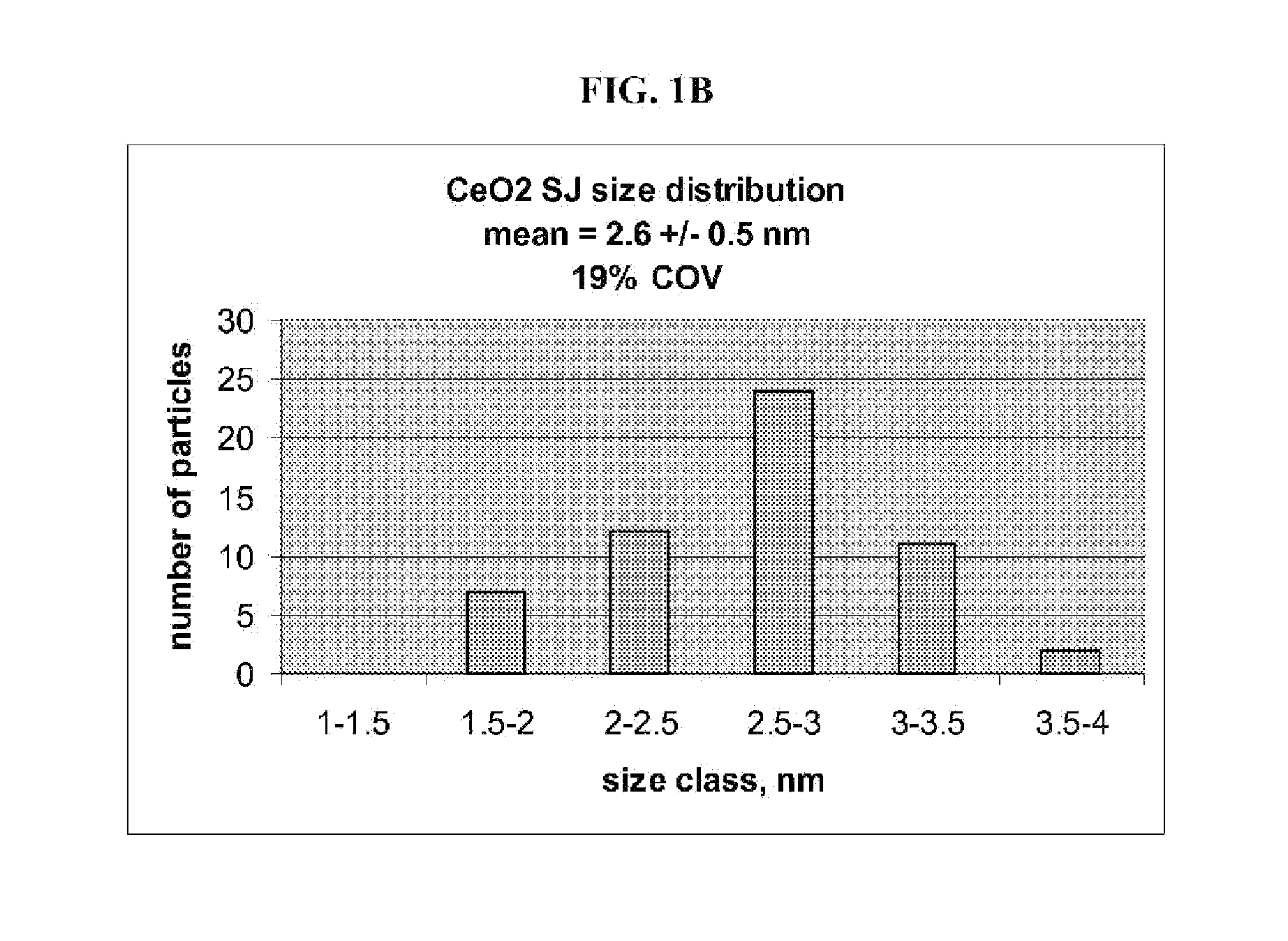

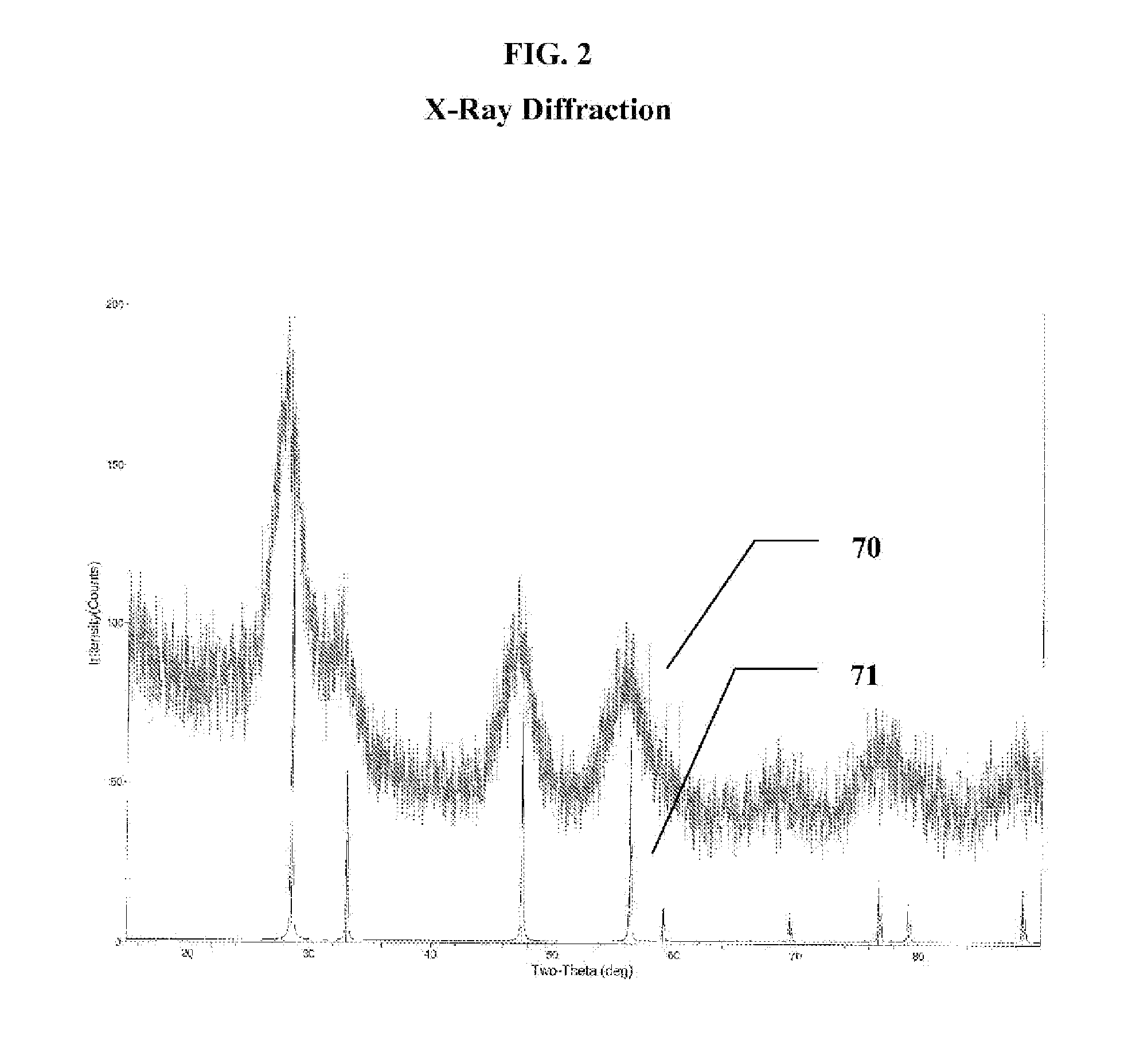

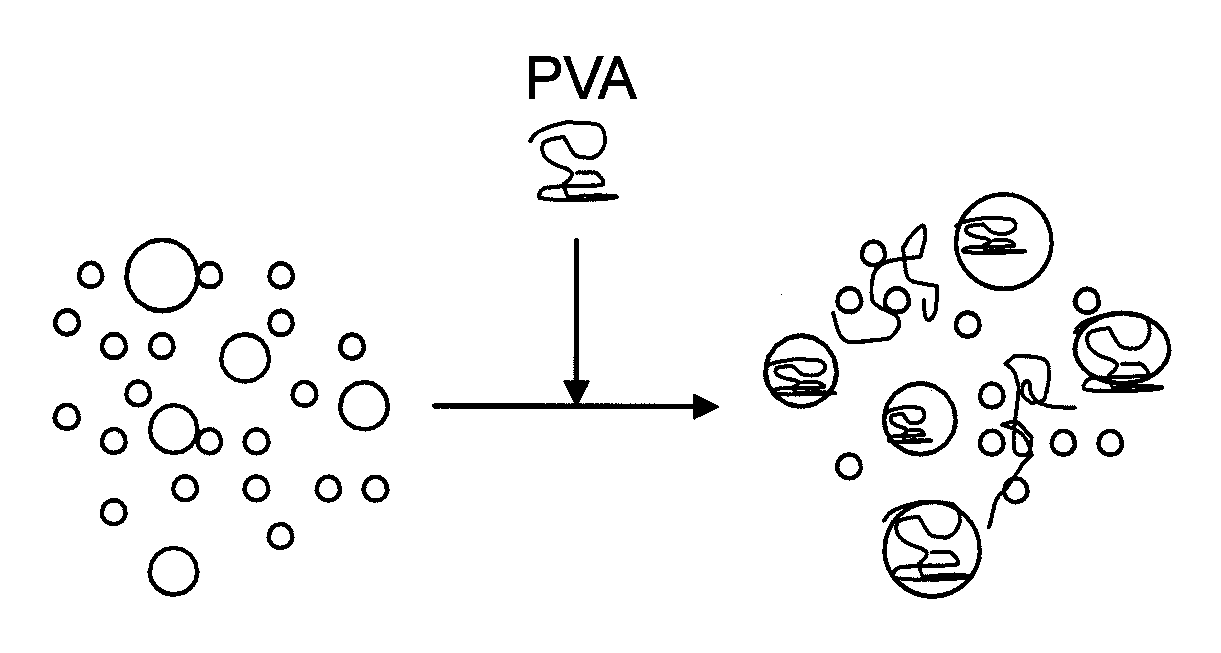

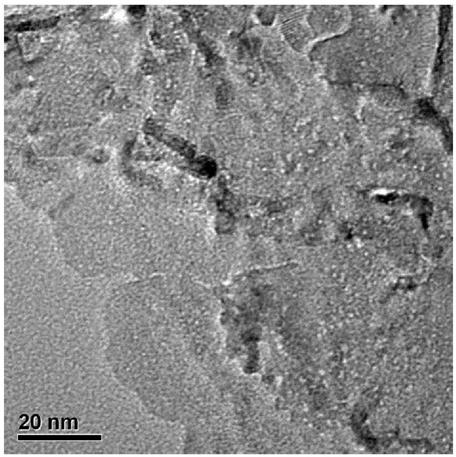

ActiveUS20120124899A1Material nanotechnologyHeterogenous catalyst chemical elementsKinetic diameterNanoparticle

A process for making cerium dioxide nanoparticles containing at least one transition metal (M) utilizes a suspension of cerium hydroxide nanoparticles prepared by mechanical shearing of an aqueous mixture containing an oxidant in an amount effective to enable oxidation of cerous ion to ceric ion, thereby forming a product stream that contains transition metal-containing cerium dioxide nanoparticles, Ce1-xMxO2, wherein “x” has a value from about 0.3 to about 0.8. The nanoparticles thus obtained have a cubic fluorite structure, a mean hydrodynamic diameter in the range of about 1 nm to about 10 nm, and a geometric diameter of less than about 4 nm. The transition metal-containing crystalline cerium dioxide nanoparticles can be used to prepare a dispersion of the particles in a nonpolar medium.

Owner:CERION

Coated pearlescent pigments with SiO2 and cerium oxide

The invention relates to pearlescent pigments comprising a metal oxide-containing, lamellar substrate that is provided with a first and a second protective layer, the metal oxide having a refractive index of more than 1.8. A first protective layer comprising cerium oxide and / or cerium hydroxide as well as a second protective layer which is made of SiO2 and onto which an organic-chemical secondary coating containing at least one silane with at least one functional binding group and at least one silane without a functional binding group is applied, are provided, metal oxide layers that are different from cerium oxide and SiO2 being optionally placed between the first and the second protective layer. The invention also relates to a method for producing the disclosed pigments and the use thereof.

Owner:ECKART GMBH & CO KG

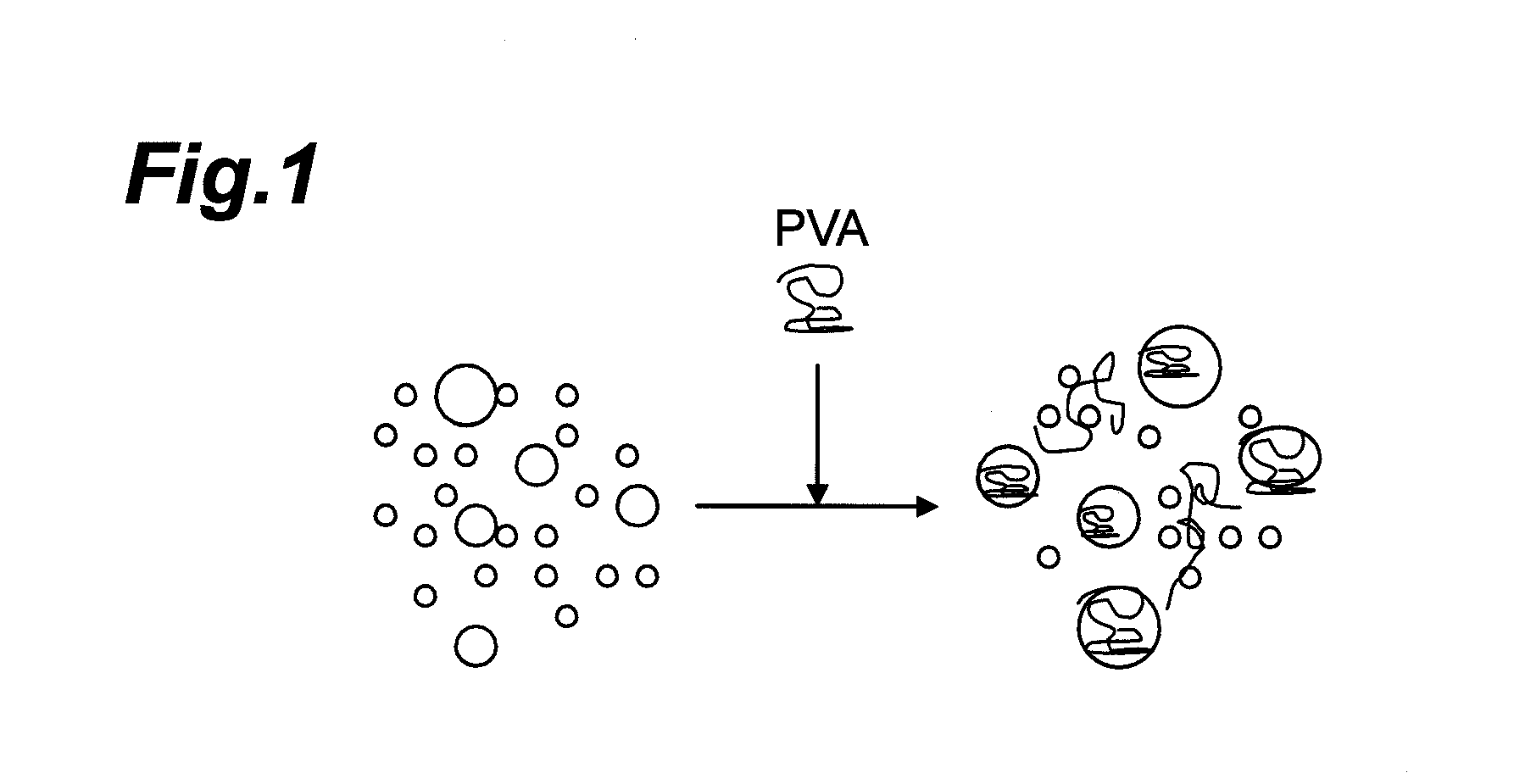

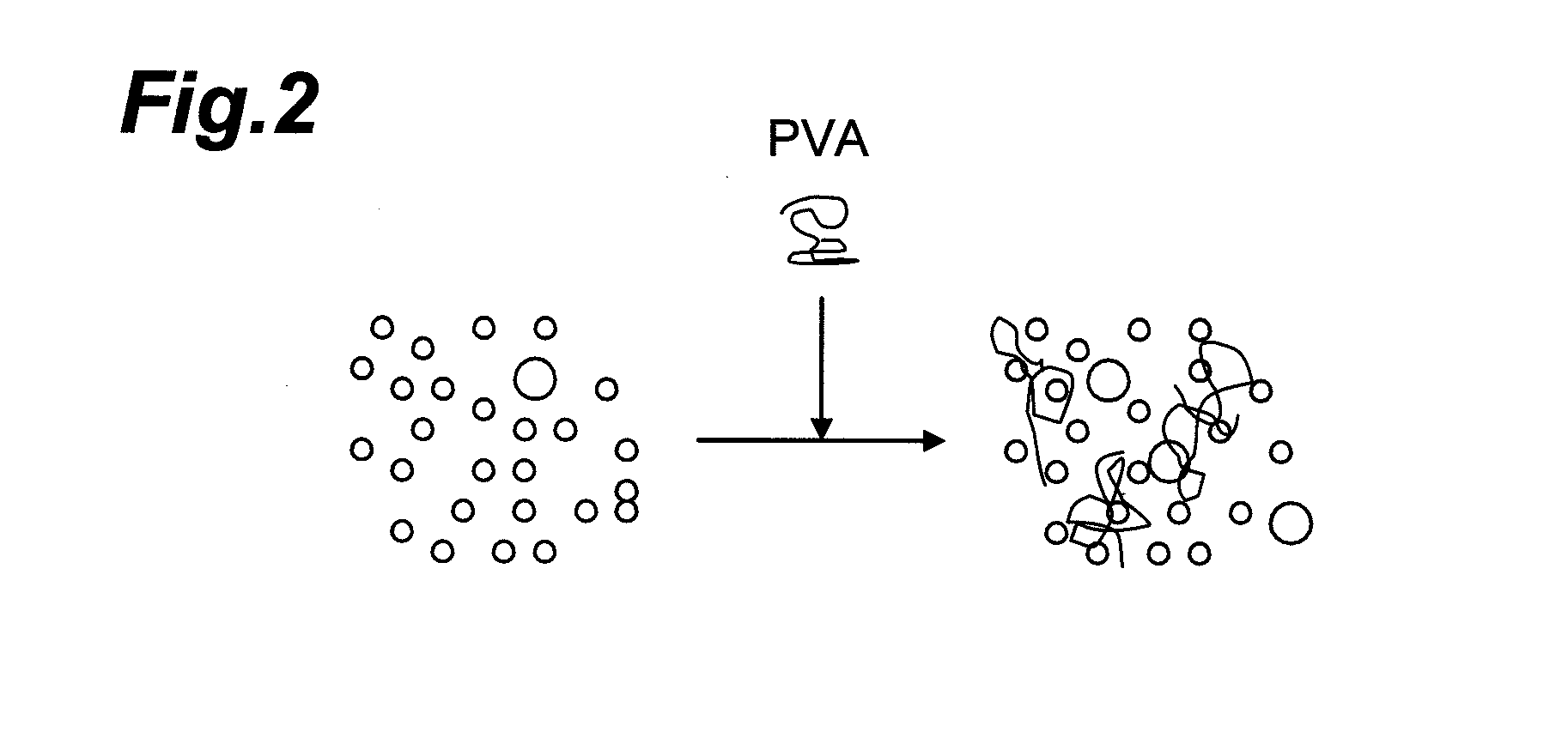

Slurry, polishing fluid set, polishing fluid, and substrate polishing method using same

ActiveUS20120322346A1Increase ratingsAvoid attenuationPigmenting treatmentOther chemical processesTransmittanceSlurry

The slurry of the invention comprises abrasive grains and water, wherein the abrasive grains include tetravalent cerium hydroxide particles and produce light transmittance of at least 50% / cm for light with a wavelength of 500 nm in an aqueous dispersion with the content of the abrasive grains adjusted to 1.0 mass %. The polishing liquid of the invention comprises abrasive grains, an additive and water, wherein the abrasive grains include tetravalent cerium hydroxide particles and produce light transmittance of at least 50% / cm for light with a wavelength of 500 nm in an aqueous dispersion with the content of the abrasive grains adjusted to 1.0 mass %.

Owner:RESONAC CORP

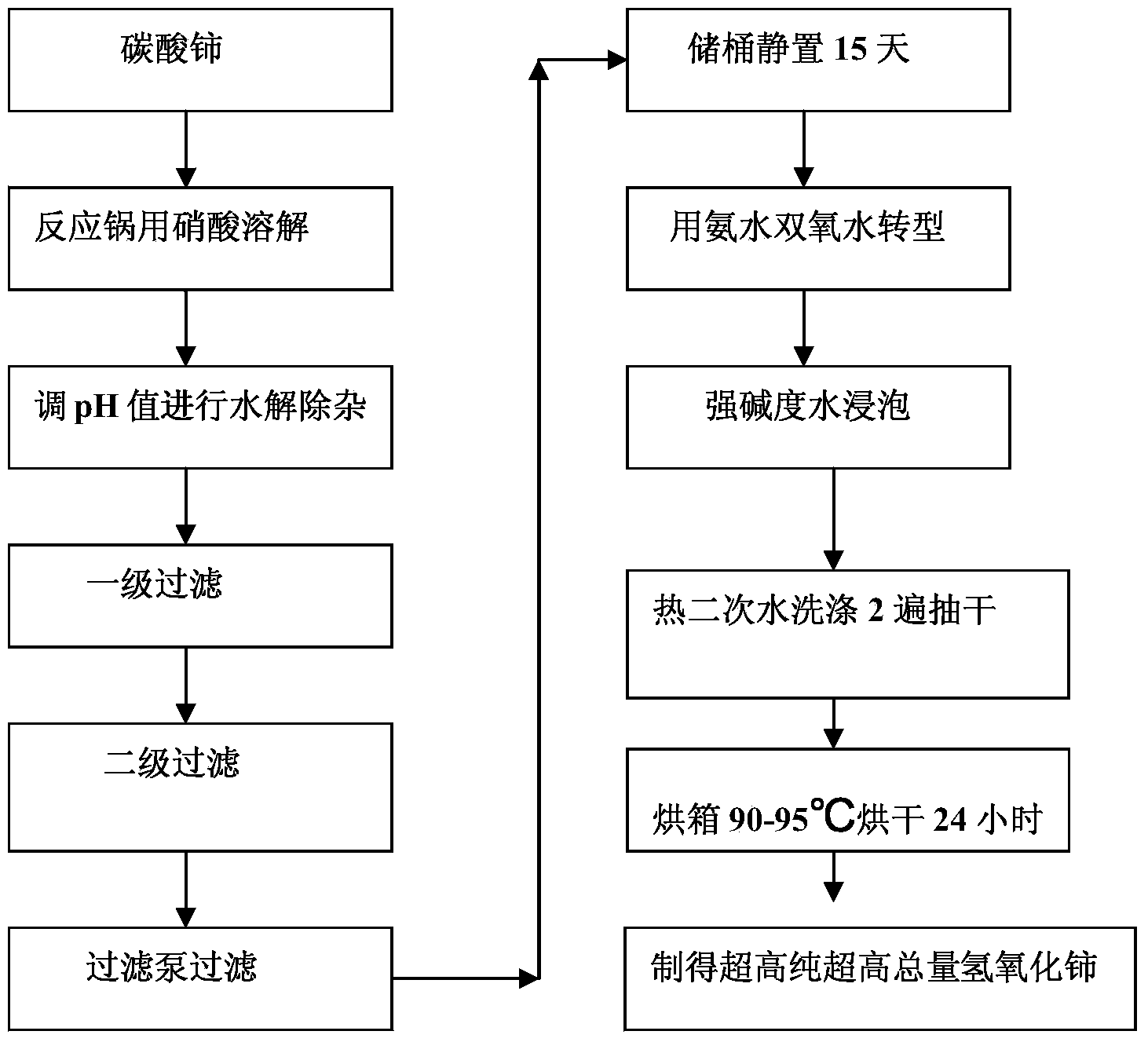

Method and system for preparing cerium hydroxide

ActiveCN103910373AHigh purityLow non-rare earth impuritiesRare earth metal compoundsCerium nitrateRare earth

The invention discloses a method for preparing cerium hydroxide. The method is characterized by comprising the following steps: dissolving cerous carbonate of which the purity is greater than 99.99% as a raw material by using nitric acid to obtain cerium nitrate feed liquid; carrying out hydrolysis to remove impurities in the dissolving process, and filtering for at least two times; filtering the obtained filtrate by using a precision filter, and transferring into a storage container to stand for a plurality of days, wherein the content of general non-rare earth impurities of the obtained cerium nitrate feed liquid is smaller than 5ppm; transforming the purified feed liquid into cerium hydroxide by taking ammonium hydroxide as a transforming agent and hydrogen peroxide as an oxidant; soaking and washing by strong alkalinity liquid to remove nitrate; filtering prepared cerium hydroxide; washing a filter cake by overheated secondary water, and pumping; putting the filtered material into an oven, and baking at 90-95 DEG C for a plurality of times, so as to obtain a cerium hydroxide product with over-high purity and ultra-high gross. According to the cerium hydroxide product prepared by the method, the nitrate content is smaller than 500ppm; the rate-earth purity is greater than 99.99%; the content of general non-rare earth impurities is smaller than 10ppm; the Cl<-> content is smaller than 10ppm; the SO4<2-> content is smaller than 10ppm; the oxidation rate is 98-99.9%; the oxide gross is greater than 90%.

Owner:江西金世纪新材料股份有限公司

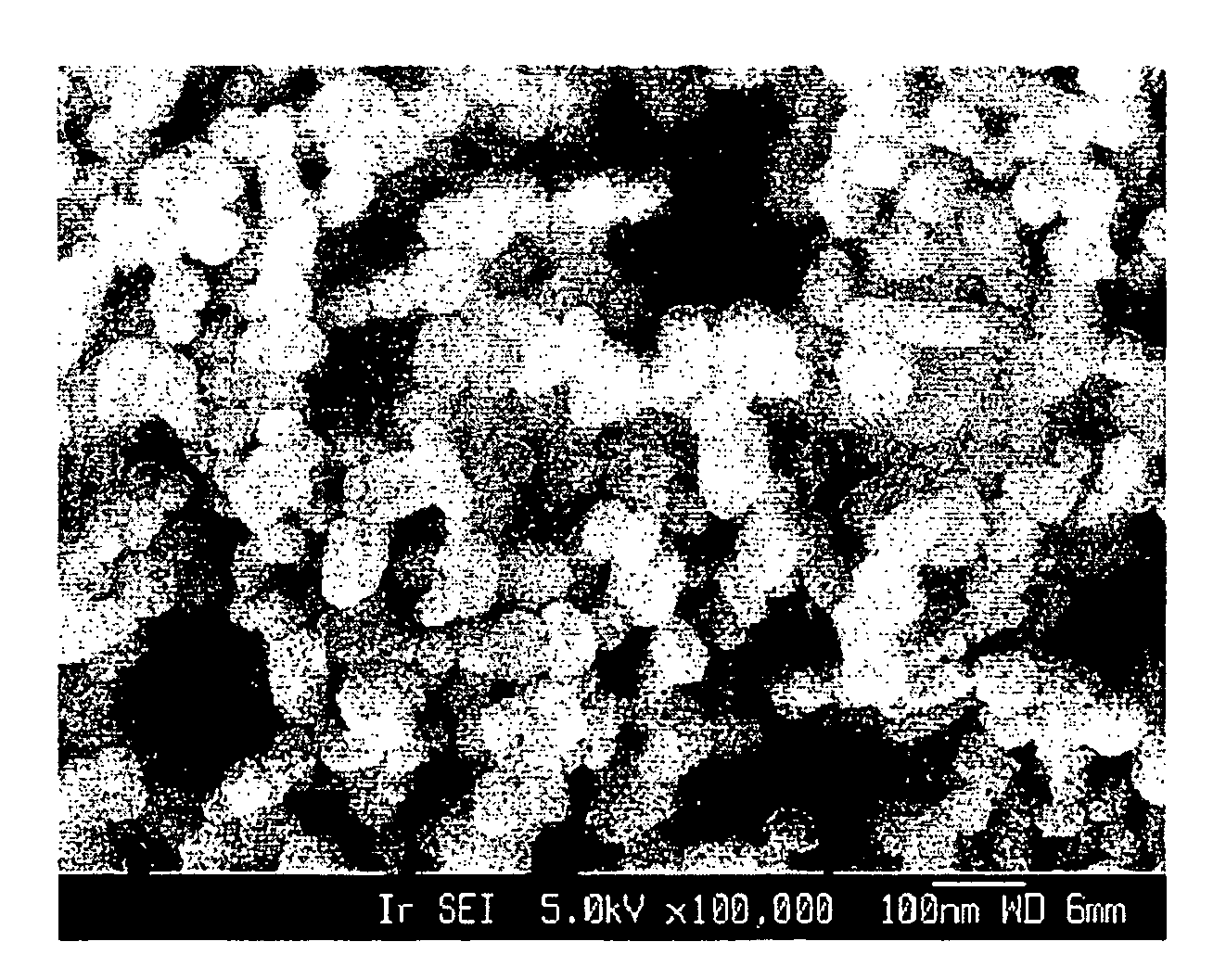

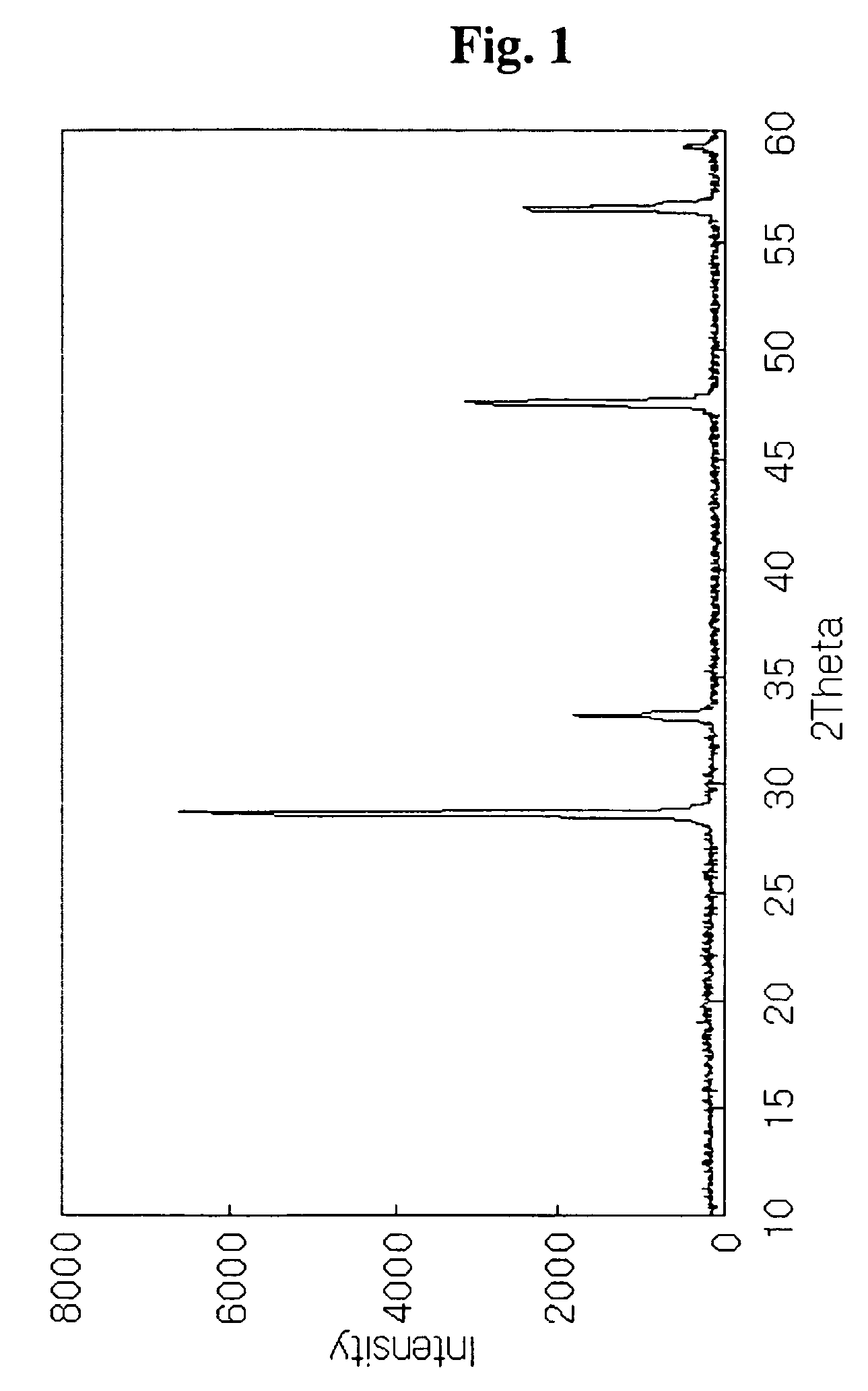

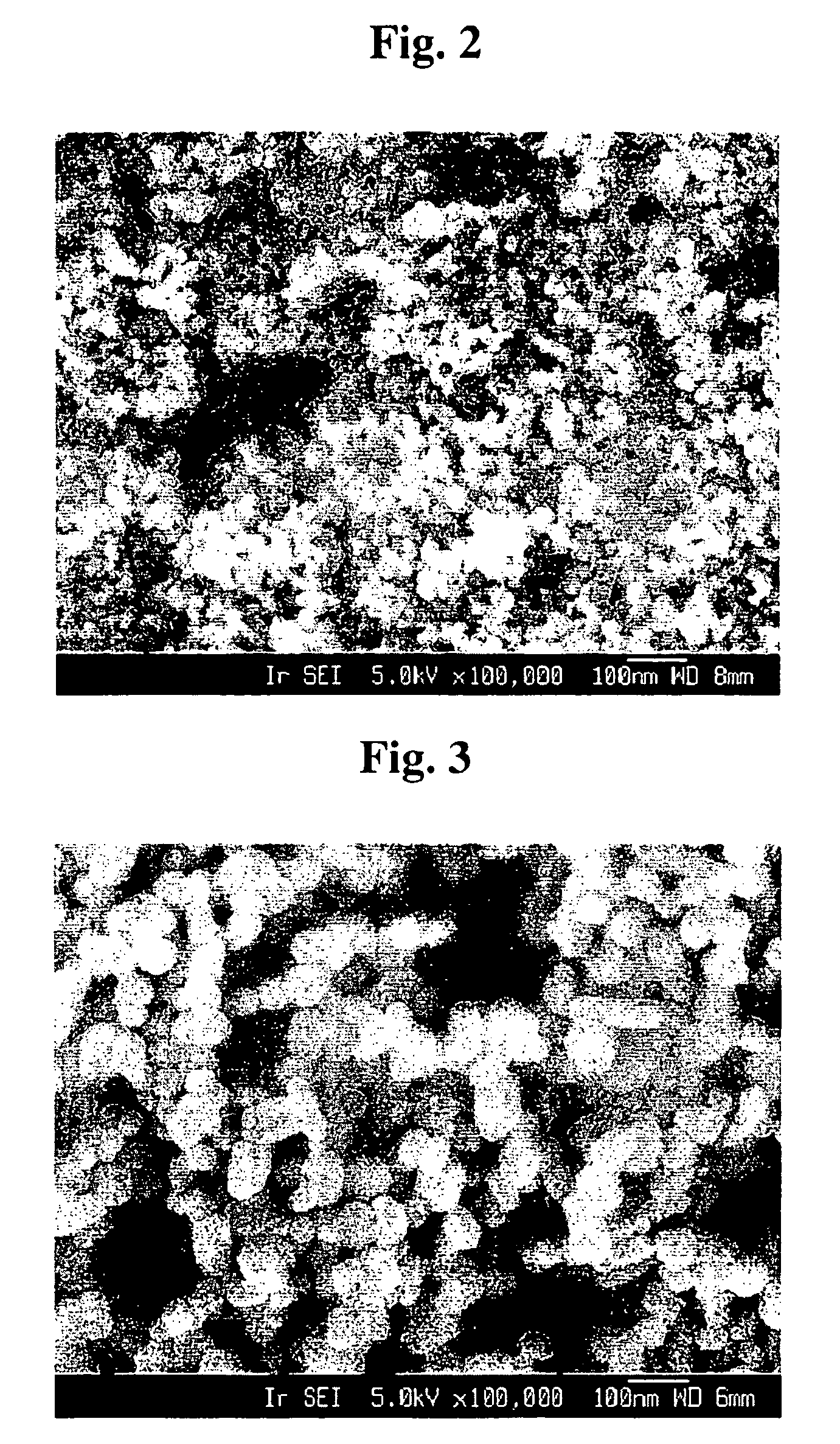

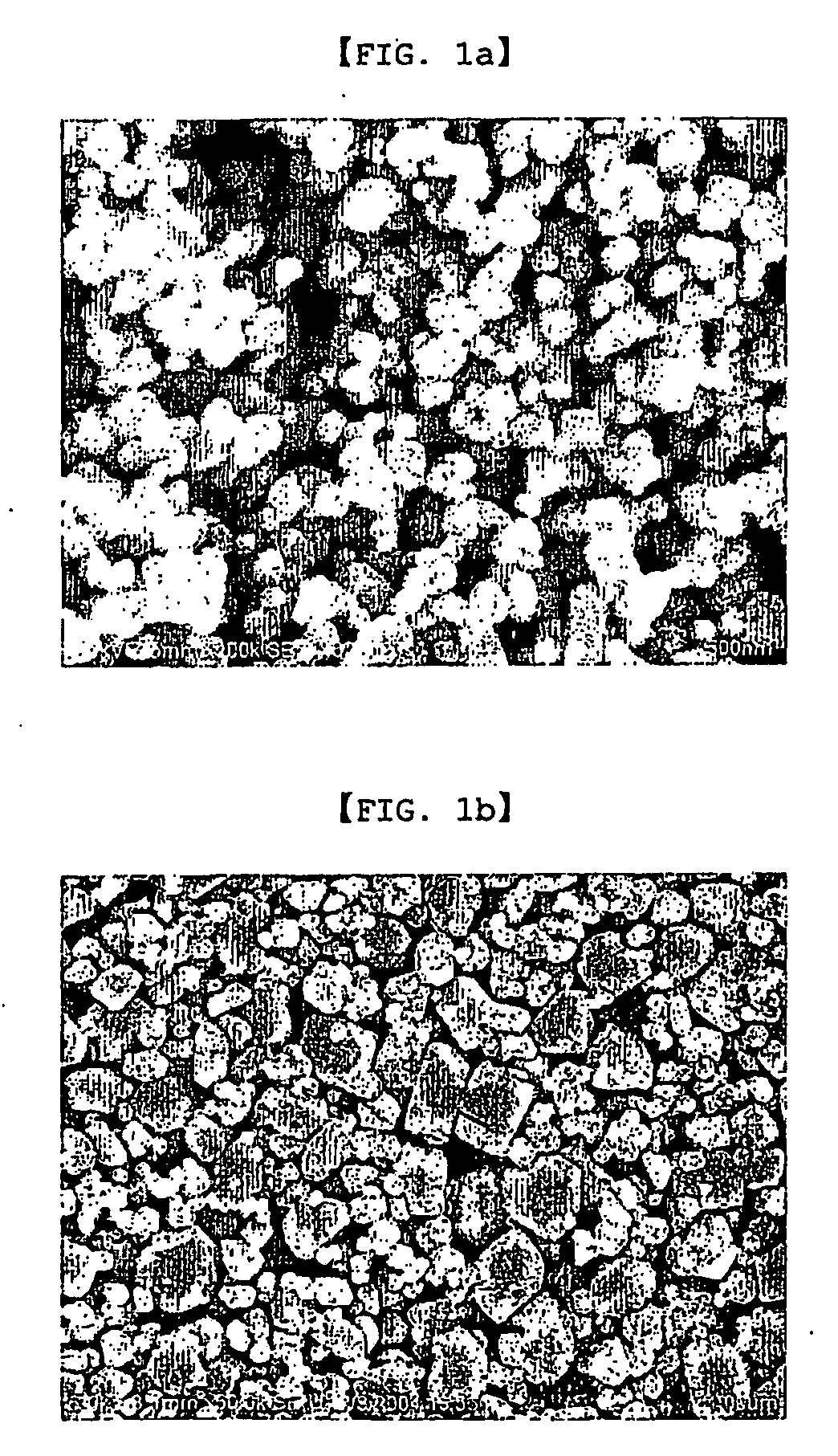

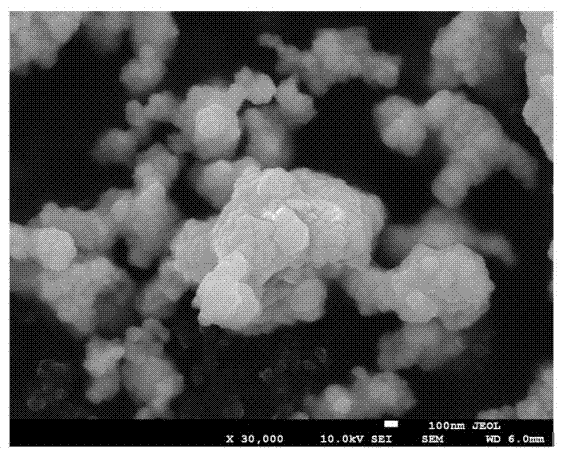

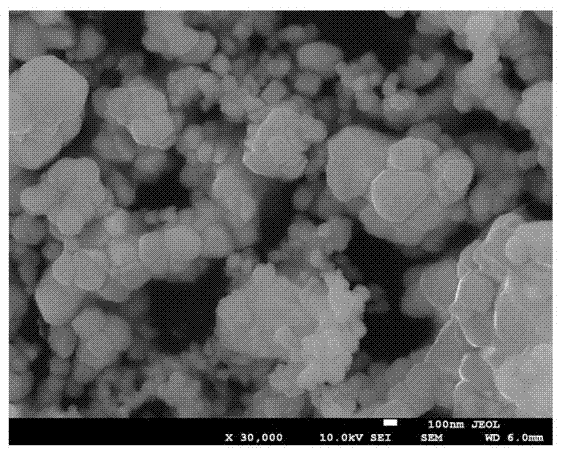

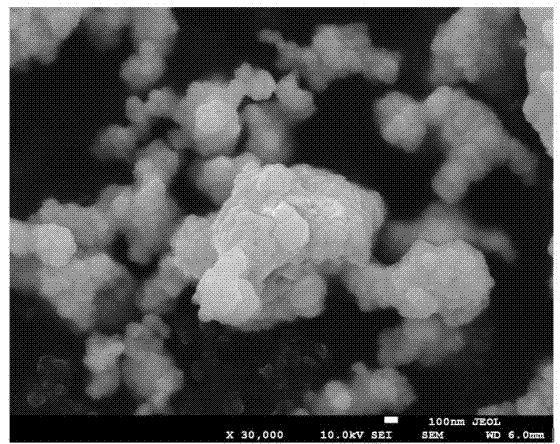

Preparation of single crystalline cerium oxide powder

The present Invention relates to a method for preparing single crystalline cerium oxide nanopowder capable of easily controlling the shape and granularity of particles. The method includes preparing cerium hydroxide by precipitating a cerium salt in the presence of a solvent mixture of organic solvent and water and hydrothermally reacting the prepared cerium hydroxide. The prepared single crystalline cerium oxide has a particle size of not less than about 30 nm and an excellent degree of dispersion.

Owner:LG CHEM LTD

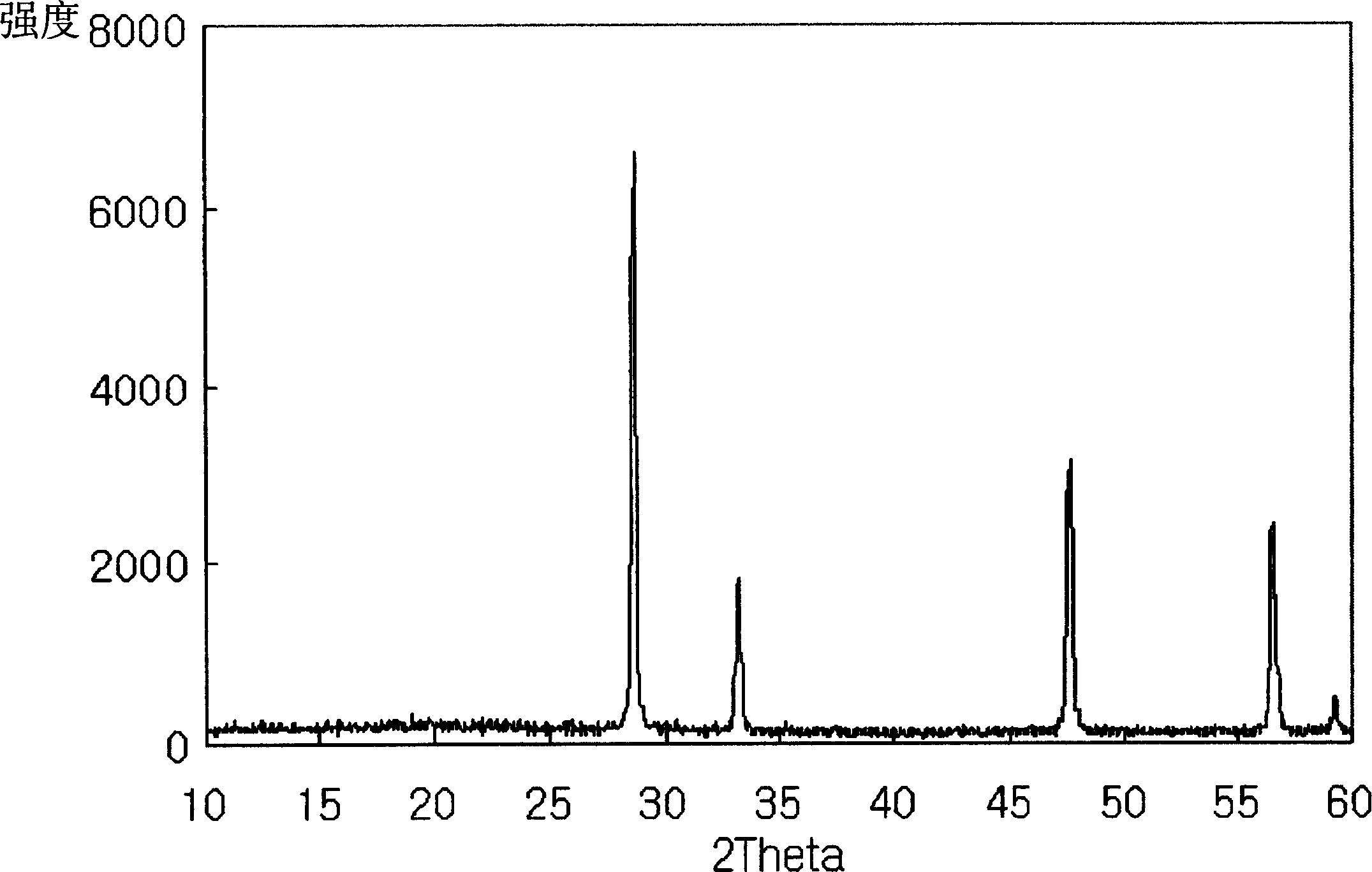

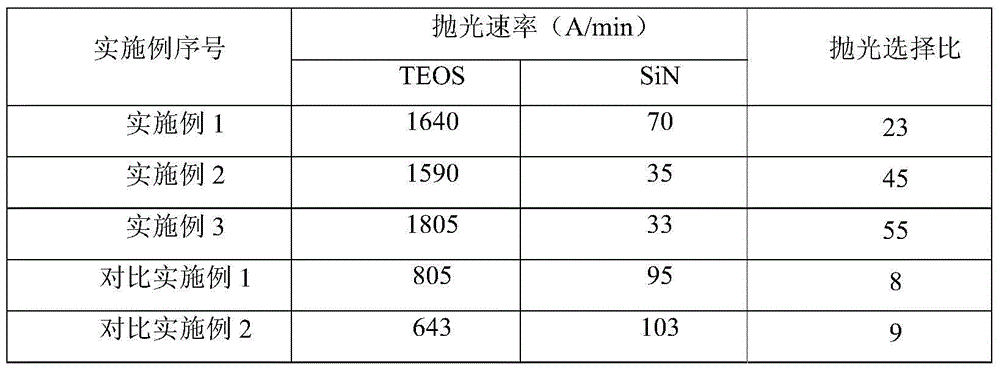

Hydro-thermal preparation method for cerium oxide and application of cerium oxide in chemical-mechanical polishing

The invention discloses a preparation method for cerium oxide. The preparation method comprises the following steps: step 1, mixing a precipitating agent, a cerium source and an oxidizing agent, wherein the precipitating agent is added into a solution of the cerium source while stirring at first, then addition of the precipitating agent is stopped when the pH value of precipitate mixed liquor reaches 7.0 to 10.0, and then adding a solution of the oxidizing agent into the precipitate mixed liquor for precipitation so as to obtain cerium hydroxide; and step 2, subjecting cerium hydroxide to hydro-thermal synthesis reaction so as to prepare cerium oxide particles. The cerium oxide synthesized in the invention does not need other special treatment, has good dispersibility and polishing activity and can be used as an abrasive for STI polishing.

Owner:ANJI MICROELECTRONICS TECH (SHANGHAI) CO LTD

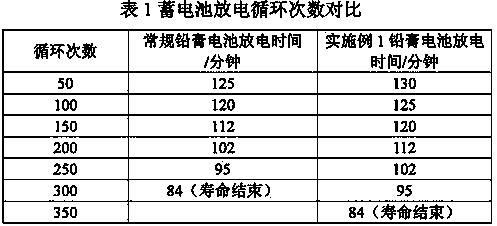

Impregnation liquid special for lead-calcium alloyed grid

InactiveCN102618859AImproves deep cycle performanceImprove electrical propertiesMetallic material coating processesHigh resistanceElectrical battery

The invention discloses an impregnation liquid special for a lead-calcium alloyed grid, which comprises, by weight, 5-10% of phosphoric acid, 10% of antimonous oxide, 7-12% of zinc oxide, 5-15% of aluminum sesquioxide, 5-8% of ammonium bicarbonate, 3-5% of cerium hydroxide, 7-15% of tin oxide, and the balance of water. According to the technical scheme, technical operation is simple, formation of a high-resistance layer (CaSO4 crystal) on an active material interface during use of positive grids can be avoided greatly, deep cycle performance of a lead-calcium alloy battery can be improved, and the defect that early capacity loss of a VRLA (valve regulated lead acid) lead-calcium alloy battery is overcome. The battery made of the lead-calcium alloyed grid has no acid gas leakage, is fine in sealing performance, lower in gassing quantity and lower in self-discharge, and has advantages of both the lead-calsium battery and the lead-antimony-cadmium alloy battery, electrical property of an anode film of the grid is improved to the maximum extent, and deep-cycle durability of the lead-acid battery is improved.

Owner:CHAOWEI POWER CO LTD

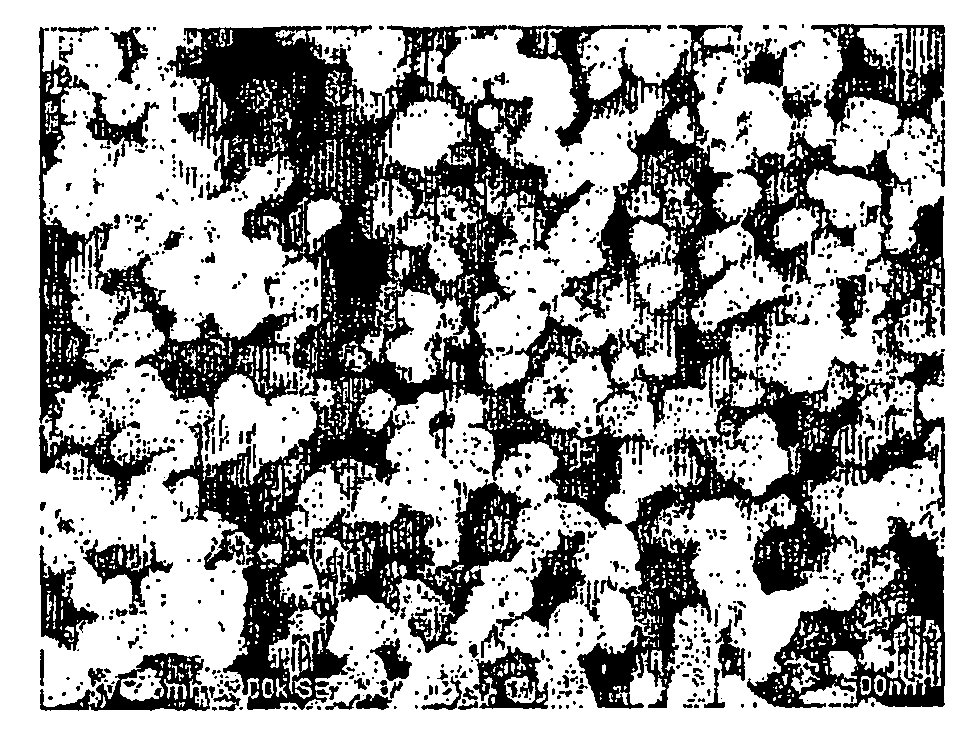

Method for preparing single crystalline cerium oxide powders

ActiveUS7473408B2Great degree of dispersionUniform shapeMaterial nanotechnologyCerium oxides/hydroxidesOrganic solventGranularity

The present invention relates to a method for preparing single crystalline cerium oxide nanopowder capable of easily controlling the shape and granularity of particles. The method includes preparing cerium hydroxide by precipitating a cerium salt in the presence of a solvent mixture of organic solvent and water and hydrothermally reacting the prepared cerium hydroxide. The prepared single crystalline cerium oxide has a particle size of not less than about 30 nm and an excellent degree of dispersion.

Owner:LG CHEM LTD

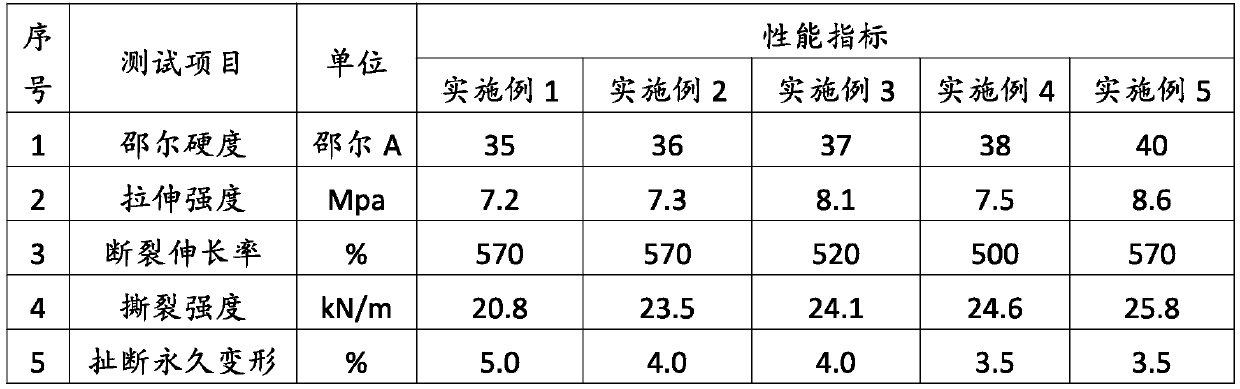

Flame-retardant ceramic silicone rubber and preparation method and application thereof

InactiveCN109762341ALow costConvenient sourceRubber insulatorsEnvironmental resistancePolymer science

The invention discloses flame-retardant ceramic silicone rubber and a preparation method and application thereof. The flame-retardant ceramic silicone rubber is prepared from the raw materials in parts: 85-100 parts of raw rubber with 0.04% vinyl content, 0-15 parts of raw rubber with 3% vinyl content, 5-8 parts of hydroxy silicone oil, 40 parts of fumed silica, 15-25 parts of aluminum hydroxide / magnesium hydroxide, 0.5-0.8 part of a platinum flame retardant, 0-50 parts of mica powder, 0-10 parts of kaolin, 0-10 parts of wollastonite, 0-10 parts of low-melting-point glass powder, 0-2 parts ofzinc borate, 0-1 part of cerium hydroxide, 0-0.8 part of a silane coupling agent, and 2 parts of a vulcanizing agent. The flame-retardant ceramic silicone rubber has high thermal stability, and has the characteristics of excellent weather resistance, excellent electrical insulation properties, non-toxic and tasteless and environmental protection.

Owner:ZHEJIANG JOTEC NEW MATERIAL TECH

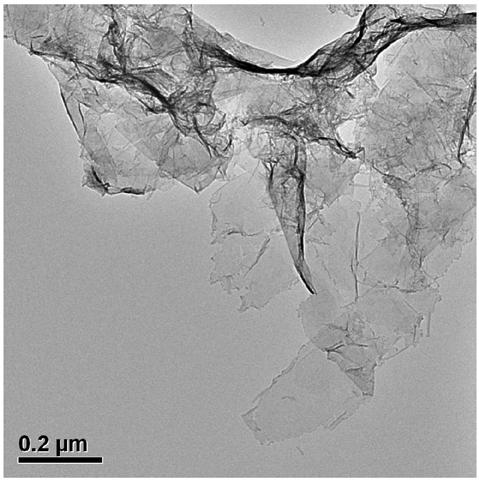

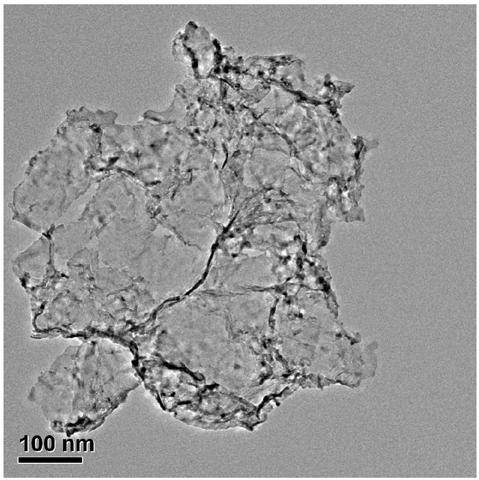

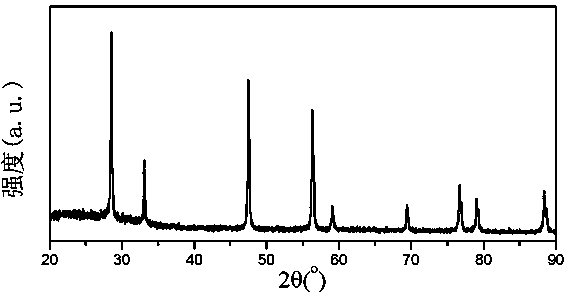

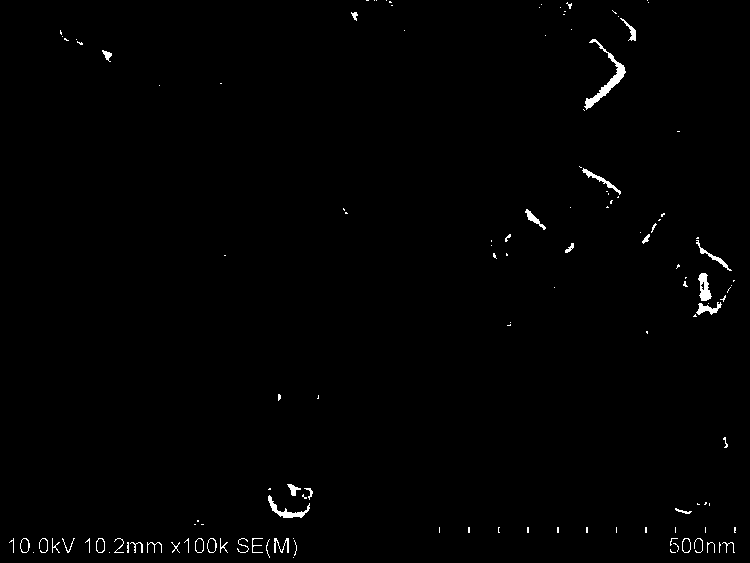

Cerium dioxide nanosheet as well as preparation method and application thereof

ActiveCN109052451AEasy to prepareSimple and fast operationRare earth metal oxides/hydroxidesNanotechnologyCerium(IV) oxidePotassium hydroxide

The invention relates to cerium dioxide nanosheets as well as a preparation method and application thereof. The preparation method comprises the following steps: (1) precipitating a cerous nitrate solution with an alkali solution so as to obtain a cerium hydroxide nanosheet precursor; (2) drying and roasting the cerium hydroxide nanosheet precursor obtained in the step (1), thereby obtaining cerium dioxide nanosheets, wherein the alkali solution of the step (1) comprises a sodium hydroxide solution and / or a potassium hydroxide solution, and the mole ratio of hydroxide ions in the alkali solution to cerous nitrate in the cerous nitrate solution is (8-27):1. The cerium dioxide nanosheets provided by the invention can be used as multiple nano metallic carriers and have very good application prospects in fields of energy, environment protection and catalysis. The cerium dioxide nanosheets has the advantages of being free of high-temperature high-pressure equipment for hydrothermal reactions and the like, free of organic modifier or organic solvent, good in environment protection, gentle in reaction condition, low in cost, and the like, and is beneficial to industrial amplified production.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Preparation method of anhydrous ceric sulfate

InactiveCN101633514AGood water solubilityMeet quality requirementsRare earth metal compoundsSolubilityCeric sulfate

The invention discloses a preparation method of anhydrous ceric sulfate, taking high-purity cerium hydroxide as a raw material, and comprising the following steps: using industrial concentrated sulfuric acid to carry out acid dissolution on cerium hydroxide, controlling the (H<+>) mol / L of spent acid of the acid solution, the Ce<4+> dissolved concentration (g / L) of the acid solution and the dissolving temperature to fully dissolve the cerium hydroxide, then carrying out concentrated crystallization, cooling and filtering to obtain crystallized ceric sulfate which is put into a crucible and dehydrated and dried in a drying box, and then obtaining the product, namely anhydrous ceric sulfate. The anhydrous ceric sulfate prepared by the method has high product purity, good water solubility, short process flow and convenient operation, and is easy for scale production; in addition, the mother liquor can be reused, thereby playing a role of energy saving and emission elimination.

Owner:甘肃稀土新材料股份有限公司

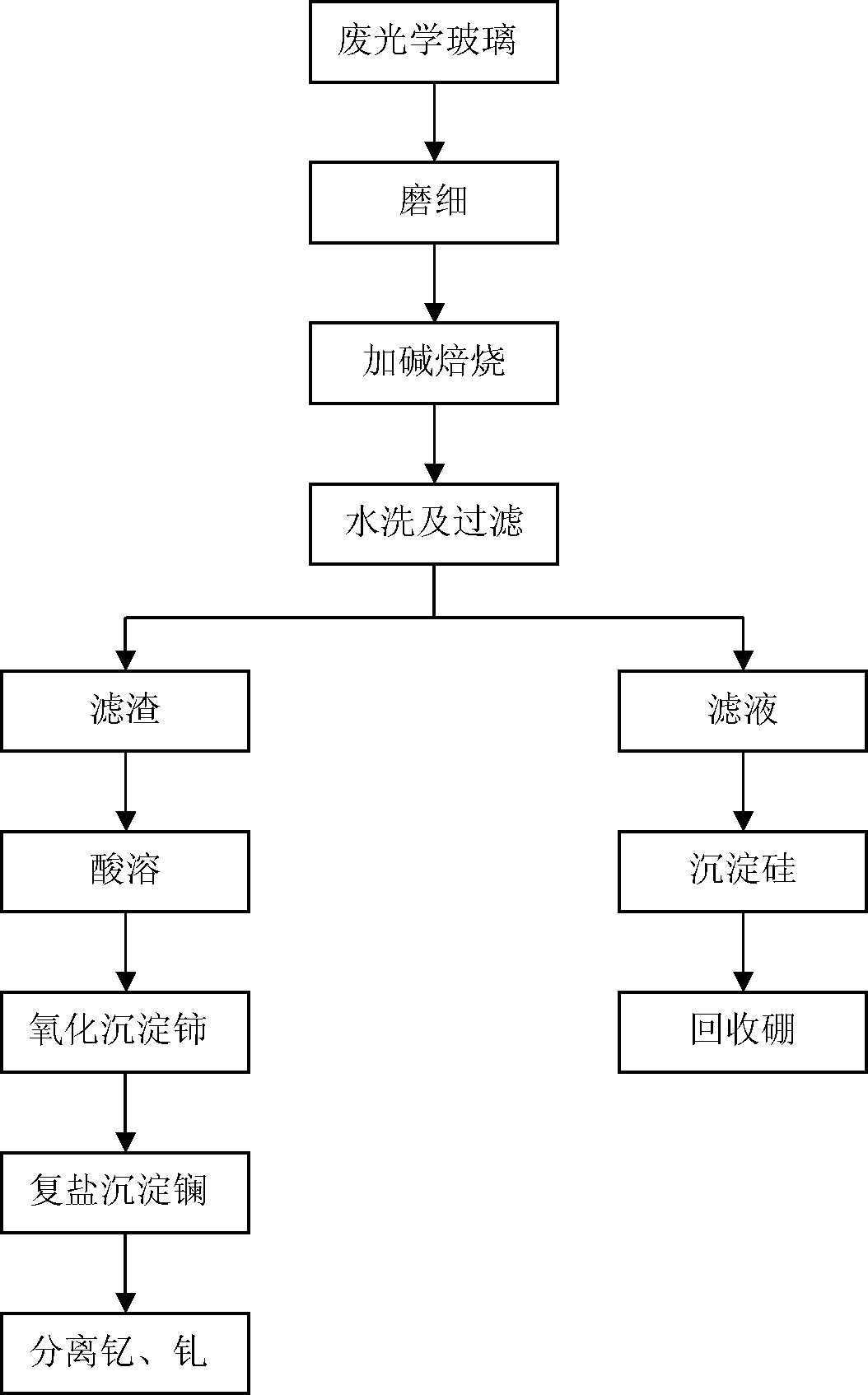

Method recovering rare earth from precise instrument waste glass materials

ActiveCN103131874ATake advantage ofSimple methodProcess efficiency improvementSilicic acidRare earth

The method provides a method recovering rare earth from precise instrument waste glass materials. The method comprises the following steps of levigating waste glass materials, roasting in an alkali method to enable acid oxide to be dissolved in molten alkali, washing and filter to remove soluble salt after roasting, using acid to adjust potential of hydrogen (pH) of filter liquor to enable silicic acid to settle, obtaining boric acid through concentration crystallization to separate silicic acid from the boric acid, acid dissolving, oxidizing and settling filter residue, filtering to obtain tetravalent cerium hydroxide and filter liquor, settling lanthanum through a double-salt sedimentation method, and separating yttrium from gadolinium. The method can conveniently and effectively purify and prepare rare earth products from optical waste glass materials to comprehensively recover silicon dioxide, boric oxide and rare earth.

Owner:荆门格林循环电子废弃物处置有限公司

Cerium Oxide Power and Process for Producing the Same

ActiveUS20080132403A1Small sizeLow costOxide/hydroxide preparationOther chemical processesCeriumSpherical shaped

The present invention relates to cerium oxide powder and a process for producing the same. The cerium oxide powder of the invention, which is produced by mixing a cerium source such as cerium oxide, cerium hydroxide and cerium carbonate with an alkali metal compound, as flux, and performing high temperature treatment, may have a variety particle size while having spherical shape.

Owner:LG CHEM LTD

Method for preparing supported copper oxide catalyst by using cerium oxide as carrier

ActiveCN108927163AIncrease satietySimple structureHydrogen separation using solid contactMetal/metal-oxides/metal-hydroxide catalystsFreeze-dryingCerium(IV) oxide

The invention relates to an ultrasonic assisted method for preparing a supported copper oxide catalyst by using cerium oxide as a carrier. An excess amount of an alkali is added to an aqueous solutionof a copper salt and a cerium salt, and the alkali dissolving process is an exothermic process; the copper salt forms a copper hydroxide precipitate, and is further converted into small copper oxideparticles by using the exothermic process; the cerium salt forms a cerium hydroxide precipitate, and forms cerium oxide having a hole structure in an exothermic environment; the obtained sample is sonicated for a certain period of time to generate local high-temperature and high-pressure "hot spots" in order to promote the copper oxide enter holes of the cerium oxide and form mixed oxides; and centrifugal washing, freeze drying and high temperature calcination are carried out to obtain the final catalyst. The close combination and interaction between copper oxide and the cerium oxide carrier and partial unsaturated coordination of the copper oxide part make defective copper oxide having good redox ability formed, so the complete oxidation of carbon monoxide under hydrogen-rich conditions at a low temperature in a wide window range by the catalyst is achieved.

Owner:ZHEJIANG UNIV

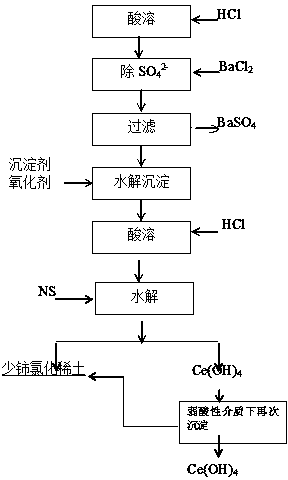

Process of extraction of high-purity soluble cerium hydroxide from fluorine-carbon-cerium mixed rare earth carbonate

ActiveCN103395820AWill not cause secondary pollutionLow priceRare earth metal compoundsRare earthMetal impurities

A process of extraction of high-purity soluble cerium hydroxide from a fluorine-carbon-cerium mixed rare earth carbonate comprises the steps: taking the mixed rare earth carbonate, firstly dissolving by an acid, then removing SO4<2->, next carrying out hydrolytic precipitation of cerium to generate cerium hydroxide, then dissolving cerium hydroxide in the hydrochloric acid medium to form a Ce<4+> solution with the hydrochloric acid weak acidic medium, controlling conditions, precipitating again in the weak acidic medium to make a lot of metal impurities remain in the solution, and thereby obtaining cerium hydroxide which contains the quite low content of non rare earth impurities and can be easily dissolved in a nitric acid medium. Hydrolytic precipitation of the rare earth adopted by the invention is complete, so a large amount of alkali is saved; an oxidant is added to allow cerium to be greatly oxidized into tetravalent cerium, and thus achievement of hydrolytic precipitation is facilitated, so as to realize an effect of high percentage extraction of cerium. The process generates a small amount of waste water, is simple, has low preparation cost, is expected to large-scale industrial production, and has certain economic benefits and quite good social benefits.

Owner:江苏国源稀土新材料有限公司

Production method of ceria powder polishing size

ActiveCN102559066AHigh hardnessAppropriate hardnessPolishing compositions with abrasivesMetallurgyCerium hydroxide

The invention relates to a production method of ceria powder polishing size. The production method comprises the steps that cerium hydroxide and / or cerium carbonate are added to a baking furnace, and the baking furnace is gradually heated up from room temperature to a temperature of 1000 DEG C to bake the cerium hydroxide and / or the cerium carbonate and then thermally-preserved for 2 to 4h; ceriapowder is mixed with acid according to a mass ratio of 1:1 to 3, and the size with a pH (potential of hydrogen) of 3 to 5 is obtained; and after the size is roughly ground for 10 to 20h and fine ground for 0.3 to 3h, the polishing size is obtained. The production method has the advantages that the ceria powder size is produced by adopting a multilevel temperature baking manner, so that the hardness of ceria can be increased, and the hardness and the surface activity of the ceria can simultaneously reach better states; through regulating the pH of the size, ceria particles have low probabilityof agglomeration, the suspension ability and the stability of the size are good, and dispersion agents do not need to be added, so that the influence of the dispersion agents on the stability of the size can be eliminated; the process is simplified; and the cost is reduced.

Owner:HENAN UNION ABRASIVES

Lead plaster composition of positive electrode of internally formalized storage battery

ActiveCN103633320AAvoid generatingImproves deep cycle performanceCell electrodesO-Phosphoric AcidElectrical battery

The invention belongs to the technical field of storage batteries, and specifically relates to a lead plaster composition of a positive electrode of an internally formalized storage battery. The lead plaster composition of the positive electrode of the internally formalized storage battery is prepared from the following raw materials in parts by weight: 990-1010 parts of lead powder, 0.5-1.5 parts of fibers, 0.5-1.0 part of phosphoric acid, 1-2 parts of antimonous oxide, 0.7-1.2 parts of zinc oxide, 0.5-1.5 parts of aluminum oxide, 0.5-0.8 part of ammonium hydrogen carbonate, 0.3-0.5 part of cerium hydroxide, 0.7-1.5 parts of tin monoxide, 110-130 parts of water and 80-90 parts of dilute sulphuric acid. The lead plaster composition of the positive electrode is improved, so that capacity attenuation of the internally formalized battery in the early stage is inhibited, and the service life of deep circular discharge of the battery is prolonged.

Owner:HENAN CHAOWEI POWER SUPPLY

Antibacterial aging-resistant modified fluororubber composite material

InactiveCN105367956AImprove heat resistanceImprove aging resistanceBisphenol AFPolytetrafluoroethylene

The invention discloses an antibacterial aging-resistant modified fluororubber composite material. The antibacterial aging-resistant modified fluororubber composite material comprises fluororubber 2601, fluororubber 2605, epichloro-hydrin rubber, Bisphenol AF, benzyltriphenylphosphonium chloride, light magnesium oxide, accelerant NA-22, calcium hydroxide, cerium hydroxide, barium sulfate, nano-silver, nano-zinc oxide, nano-titanium dioxide, polytetrafluoroethylene, graphite, molybdenum disulfide, palm wax, anti-aging agent MC, anti-aging agent MB, N,N-diethyl aminopropyl methyldimethoxysilane, octamethylcyclotetrasiloxane, 3-chloro-2-hydroxypropyltrimethylammonium chloride, and polyphosphazene. The antibacterial aging-resistant modified fluororubber composite material possesses excellent antibacterial properties, heat resistance, and aging resistance, and long service life.

Owner:ANHUI JINYANG FLUORINE CHEM

Surface treatment method of rear-earth magnesium alloy casting product

ActiveCN103215584ASolubility product is smallMetallic material coating processesTectorial membranePre treatment

The invention relates to a surface treatment method of a rear-earth magnesium alloy casting product. The surface treatment method sequentially comprises the following steps of: immersing the rear-earth magnesium alloy casting product in 0.02mol / L-0.12mol / L of cerium sulfate aqueous solution in an ultrasonic precipitating-crystallizing device after carrying out oil-removing and impurity-removing pre-treatment onto the rear-earth magnesium alloy casting product; adding a magnesium hydroxide solution to regulate the pH value to 8-11; adding hydrogen peroxide to generate cerium hydroxide, wherein the mass percentage concentration of the hydrogen peroxide is 5%-20%, and the weight ratio of the using amount of the hydrogen peroxide to the cerium hydroxide aqueous solution is (1-5):100; generating a precipitated and crystallized compact tetravalent cerium protective film on the surface of the rear-earth magnesium alloy casting product by the cerium hydroxide under the ultrasonic action; and getting out the rear-earth magnesium alloy casting product from the precipitating-crystallizing device, and drying at 120 DEG C to 240 DEG C after water-washing to obtain the rear-earth magnesium alloy casting product coated with cerium dioxide on the surface. The surface treatment method of the rear-earth magnesium alloy casting product can be used for forming a compact tetravalent cerium protective film on the surface of the rear-earth magnesium alloy casting product; moreover, the process is simple and reliable.

Owner:YANGZHOU FENG MING METAL PROD

Preparation method of cubic Nb-CeO2 material as well as product and application thereof

InactiveCN109569570ADecompose fullyEvenly dopedCatalyst carriersCatalyst activation/preparationOxalateSolvent

The invention provides a preparation method of a cubic Nb-CeO2 material. The preparation method comprises the following steps: absorbing niobium oxalate by virtue of cerium hydroxide, directly roasting, dispersing sodium cerium hydroxide prepared in a hydrothermal method in a niobium oxalate solution, completely evaporating the solvent, roasting in a muffle furnace to obtain Nb-CeO2 composite oxide. The prepared material contains 1 to 10 percent of Nb2O5 and 90 to 99 percent of CeO2 and has cubic morphology. By adopting the method disclosed in the invention, the niobium oxide can more sufficiently form the composite oxide with cerium oxide, so that the modification effect for the cerium oxide can be improved, and the preparation method is further applied to various catalytic reactions.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Ceramic, silicone rubber and glass fiber composite insulation rubber

The invention relates to a ceramic silicon rubber glass fiber composite insulating rubber for welding machine transformers and other transformer winding wires. D. 4 , vinyl silicone oil, zinc oxide, sodium bisilicate, quartz powder, muscovite powder, phlogopite powder, melamine, cerium hydroxide, 4# fumed carbon black, superfine calcined clay, hydroxyl silicone oil, surface treatment The base rubber is kneaded at room temperature, and then vulcanized by adding a vulcanizing agent and vulcanized on an open mill. The beneficial effects of the present invention are: 1. Fire resistance, high and low temperature resistance, odorless, non-toxic, non-corrosive, and little negative impact on the environment; 2. High insulation, high resistance to compression deformation and excellent low-temperature elasticity; 3. The production process is simple and safe, the production speed is high and the efficiency is high, and the product is easy to realize.

Owner:广州金象实业集团有限公司

Method for efficiently removing fluorine ions in manganese sulfate solution

InactiveCN108118152AWith physical adsorptionEasy to separateProcess efficiency improvementIon contentSulfate

The invention provides a method for efficiently removing fluorine ions in a manganese sulfate solution. The method is characterized in that a certain quantity of to-be-processed manganese sulfate solution is added into reaction equipment, the content of the fluorine ions in the solution is measured, solid cerium hydroxide with a certain fluorine ion content proportion is added under the conditionsthat the temperature is 30-50 DEG C and the pH value is 2-6, the material is stirred for 8-12 h at the rotational speed of 150-350 r / min, then stirring is stopped, the material is left to stand for 12-18 h and then transferred into filtering equipment for filtration, the filtrate is a fluorine-removed qualified manganese sulfate solution, filter cake is added into reverse osmosis water at a solid-liquid mass ratio of 1:(1-6), stirring and washing are performed for 0.5 h, and filtering is performed to obtain fluorine-containing cerium hydroxide which is then fed into a regeneration procedure.According to the method, lots of residual fluorine ions in a manganese sulfate solution system can be removed, the content of a fluoride in the processed solution can be reduced to 100 ppm or below, and the fluorine removal agent cerium hydroxide can be recycled after being regenerated, so that the production cost is greatly lowered.

Owner:GUANGDONG GUANGHUA SCI TECH

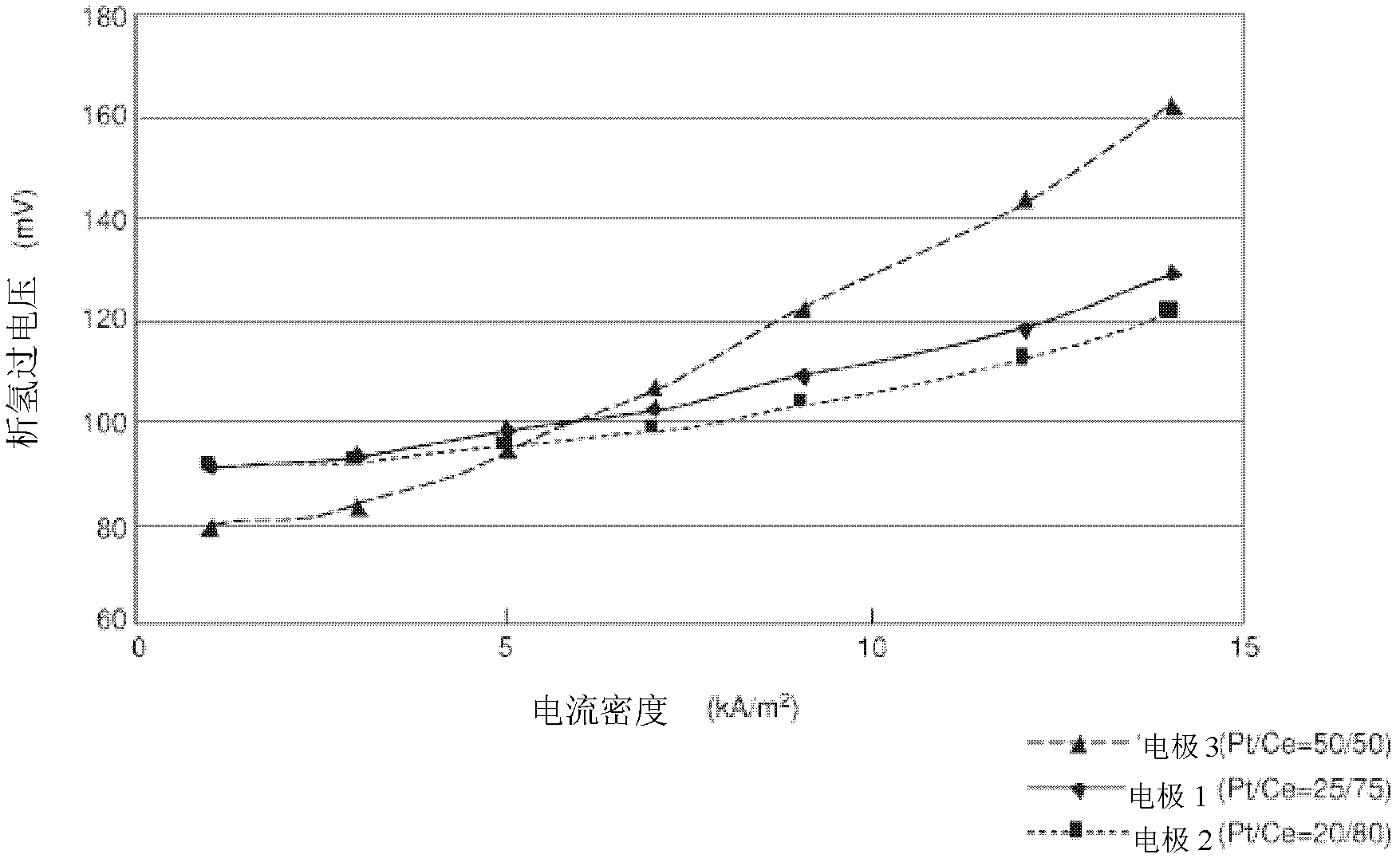

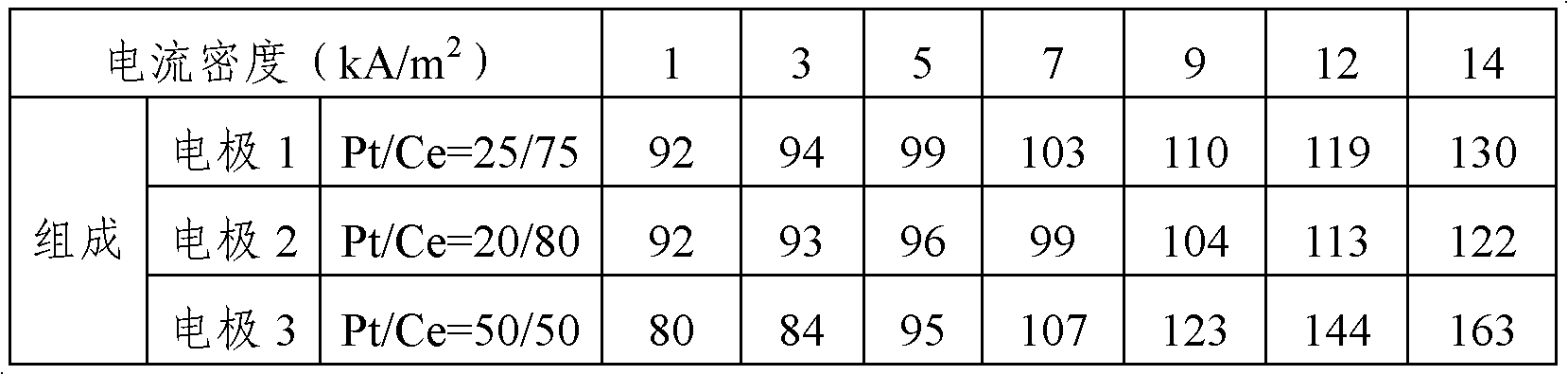

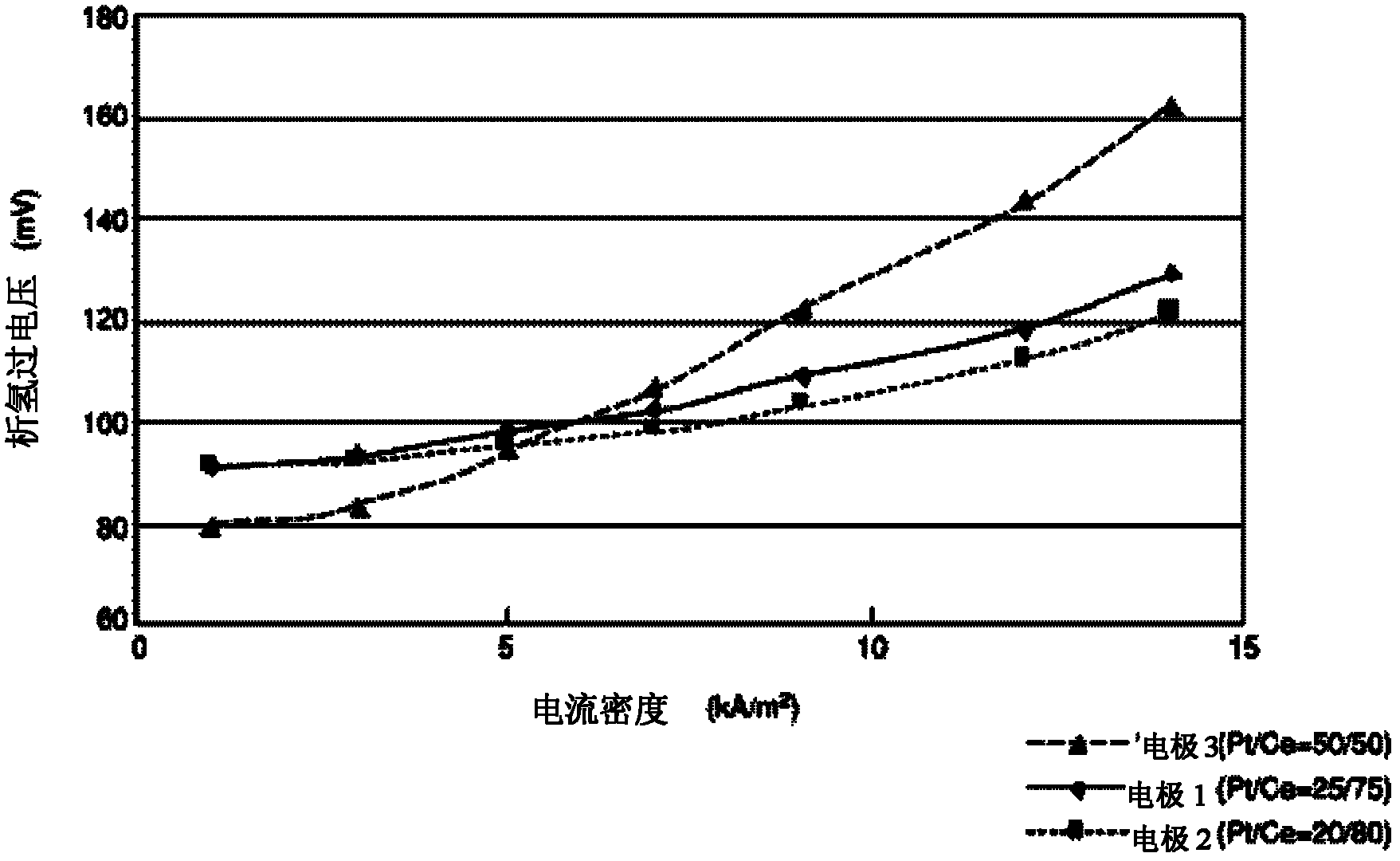

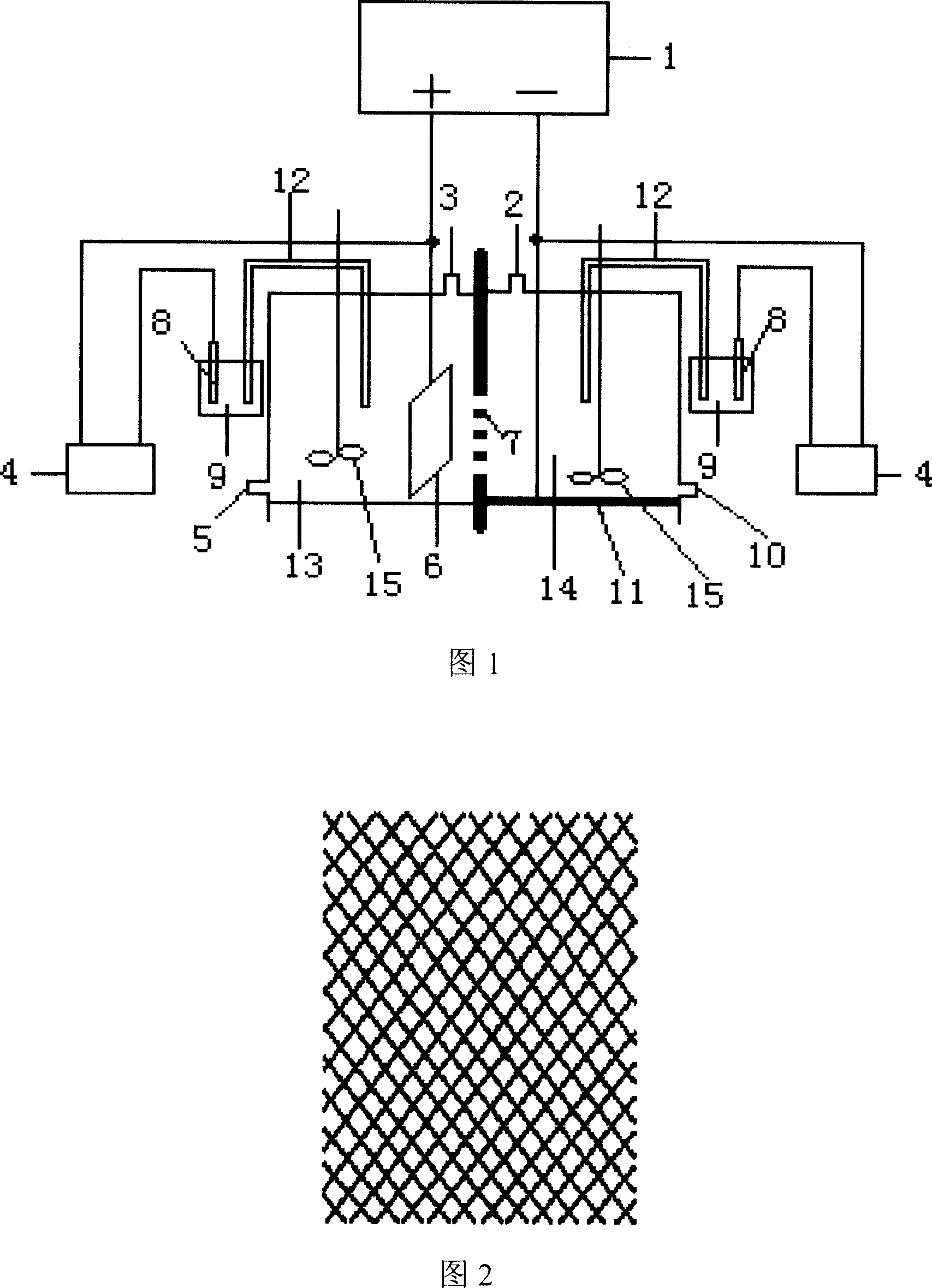

Electrode for generation of hydrogen, and electrolysis method

InactiveCN102471905ALow costReduce hydrogen evolution overvoltageMultiple component coatingsElectrolysisCerium

Disclosed is a cathode for use in an electrolysis process accompanied by the generation of hydrogen, mainly for use in the brine electrolysis in an ion exchange membrane method, in which the increase in an electrolysis voltage can be prevented even when an electrolysis current density is high and the energy cost can be reduced. Specifically disclosed is an electrode for use in the generation of hydrogen, which comprises an electrically conductive metal and an electrode active material that coats the electrically conductive metal and comprises at least one component selected from metal cerium, a cerium oxide and a cerium hydroxide and metal platinum, wherein the electrode active material has such an enormously cerium-rich composition that the molar fractions of platinum and cerium are 15 to 30 mol% and 70 to 85 mol%, respectively, in terms of metal contents.

Owner:DAISO CO LTD

Pearlescent pigments having a secondary coating comprising α-silanes and method for the production thereof

InactiveUS8197591B2Improve weather stabilityEffective protectionPigmenting treatmentLiquid surface applicatorsHydrogen atomSilanes

The invention relates to a pearlescent pigment comprising a metal oxide-containing, platelet-shaped substrate and having a first and a second protective layer, wherein the metal oxide has a refractive index greater than 1.8, and in which the first protective layer comprises cerium oxide and / or hydrated cerium oxide and / or cerium hydroxide, the second protective layer consists substantially, preferably completely, of SiO2, wherein the second protective layer is disposed on top of the first protective layer, and between the first and second protective layers there can be disposed metal oxide layers which differ from cerium oxide and / or hydrated cerium oxide and / or cerium hydroxide and SiO2, wherein the second protective layer has an organochemical aftercoat and the organochemical aftercoat comprises at least one silane bonded to the second protective layer by means of at least one oxygen atom, said α-silane having the formula—O(4-n-m)—Si(—R1)m(—CH2—Y)n (I),in which 1≦n+m≦3; m=0 to 2; n=1 to 3 andR1 is a hydrogen atom or an Si—C-bonded C1-C20-hydrocarbon radical or a C1-C15-hydrocarbonoxy radical, in which in each case one or more methylene units not adjacent to one another can be replaced by the groups —O—, —CO—, —COO—, —OCO—, or —OCOO—, —S—, or —NRx— and in which one or more methine units not adjacent to one another can be replaced by the groups —N═, —N═N—, or —P═, wherein R1 can independently be the same or different, Rx can be a hydrogen atom or a linear, branched and / or cyclic C1-C15-hydrocarbon radical or aryl radical, and Y is a functional binding group reactive with a binder system.

Owner:ECKART GMBH & CO KG

Simultaneous process of electroreducing ytterbium and oxidizing cerium

InactiveCN1986895APrevent volatilizationPrevent dispersalPhotography auxillary processesProcess efficiency improvementCeriumIon-exchange membranes

The present invention is one electrolytic process of reducing Yb, enriching Tu and Lu, and oxidizing Ce simultaneously. The electrolytic process reduces Yb into bivalent Yb ion in the cathode chamber so as to separate out Yb from the enriched Yb, Tu and Lu; oxidizes Ce into four-valent ion so as to separate out Ce. The electrolytic equipment has cathode of metal mercury or amalgam, anode of inert metal, anion exchange membrane to separate the anode chamber from the cathode chamber, cathode solution of sulfuric acid solution of pH 0.1-4.0 with enriched Yb, Tu and Lu, and anode solution of sulfuric acid solution of acidity 0.01-3.0 mol / L with enriched Ce. The present invention has low production cost, best utilization of electrolytic current and other advantages.

Owner:北京方正稀土科技研究所有限公司 +2

Nano silver modified fluororubber composite material

The invention discloses a nano silver modified fluororubber composite material. The nano silver modified fluororubber composite material comprises fluororubber 2601, fluororubber 2605, EPDM, butadiene-acrylonitrile rubber, ethylene-octene copolymer, calcium hydroxide, cerium hydroxide, light magnesium oxide, barium sulfate, nano-silver, nano-zinc oxide, nano-titanium dioxide, 4,4'-(Hexafluoroisopropylidene)diphenol, dibenzoyl peroxide, sulphur, palm wax, accelerant DM, accelerant CZ, anti-aging agent MC, anti-aging agent MB, N-beta-(aminoethyl)-gamma-aminopropyltrimethoxysilane, alpha, omega-dihydroxyl polydimethylsiloxane, and 3-chloro-2-hydroxypropyltrimethylammonium chloride. The nano silver modified fluororubber composite material possesses excellent antibacterial effect, processing performance, heat resistance and low temperature resistance, and long service life.

Owner:ANHUI JINYANG FLUORINE CHEM

Flame-retardant polypropylene material and preparation method thereof

The invention relates to a flame-retardant polypropylene material. The material is prepared from 35 parts of a polypropylene random copolymer, 11 parts of maleic anhydride grafted polypropylene, 8 parts of powdery polyphenylene sulfide, 13 parts of hydroxyl-terminated hyperbranched polyester, 9 parts of a rare earth coupling agent, 18 parts of ammonium polyphosphate, 5 parts of cerium hydroxide, 15 parts of coupling agent modified nano talcum powder and 3 parts of an antioxidant. A preparation method of the material comprises the steps as follows: (1) weighing raw materials in a formula in theweight ratio, putting the raw materials in a high-speed mixer, and stirring the raw materials for 25 min to be uniformly mixed; (2) putting the mixed raw materials in step (1) in a feeding hopper ofa twin-screw extruder, and performing melt extrusion and granulation; the processing technology is as follows: the temperature range of a barrel of the twin-screw extruder is 190 DEG C and the temperature of a die head is controlled at 170 DEG C. The material has the benefits as follows: the material has high mechanical strength, good elasticity and flame-retardant effect and excellent wear resistance and tear resistance.

Owner:GUANGDONG HONGRUI TECH CO LTD

Cerium hydroxide heat stabilizer and preparation method thereof

InactiveCN102775635AImprove heat resistanceGood colorRare earth metal compoundsPolymer scienceRare earth

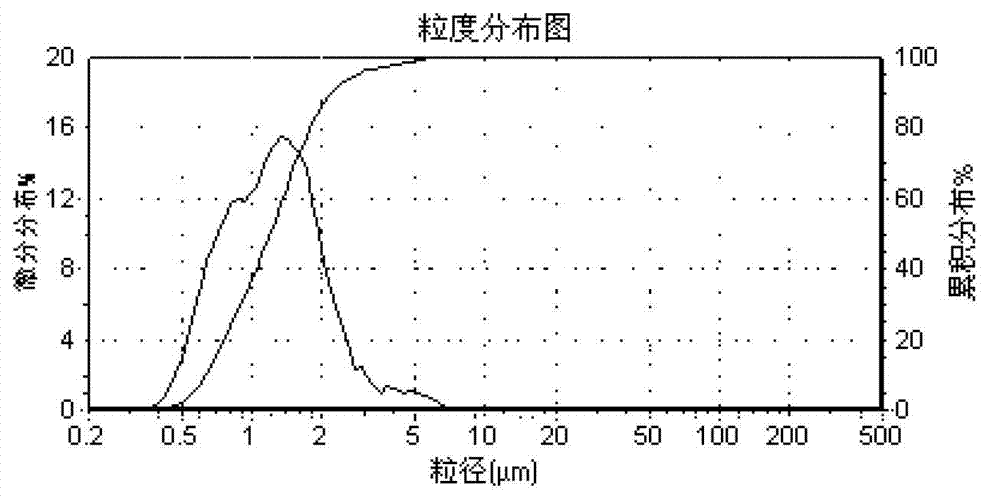

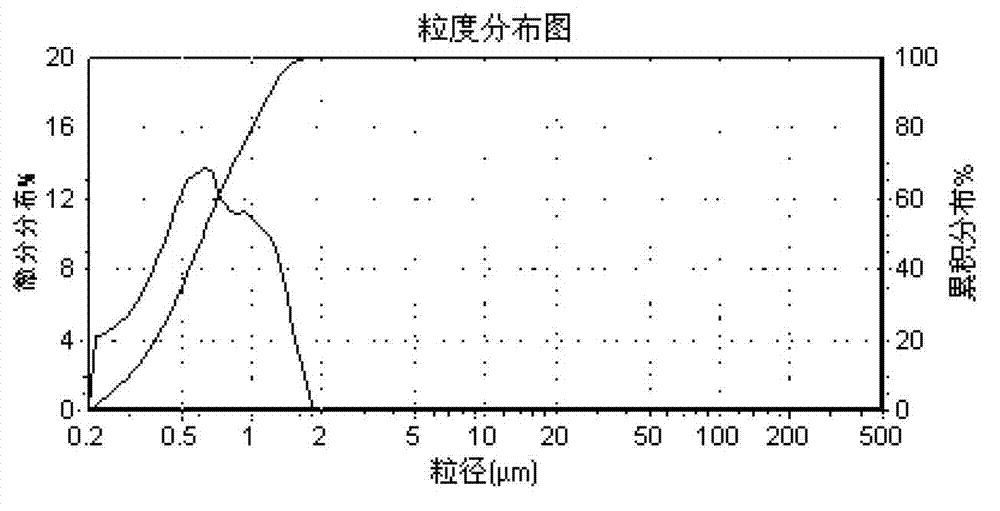

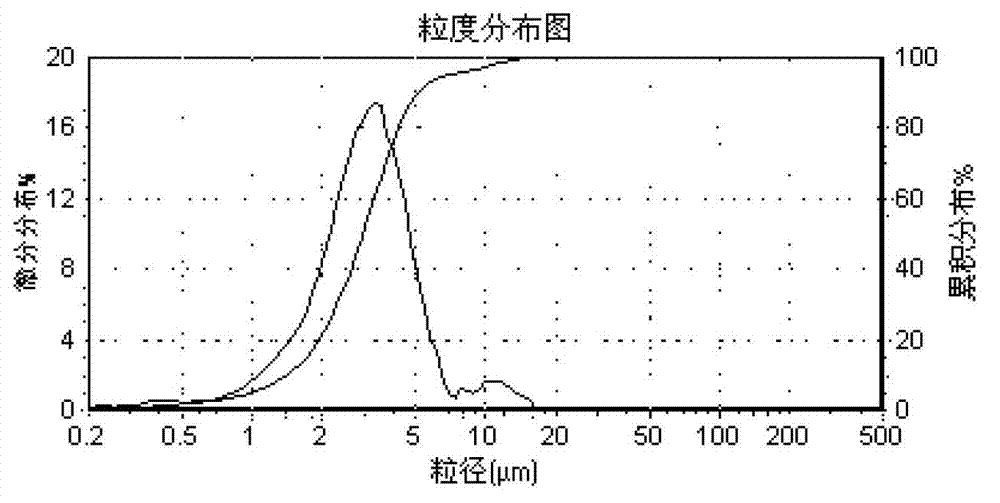

The invention aims to disclose a cerium hydroxide heat stabilizer and a preparation method thereof. The rare earth content of the heat stabilizer is 90-95 percent; the cerium oxide content (CeO2 / TREO) of the heat stabilizer is more than or equal to 99.9 percent; the burning weightlessness amount of heat stabilizer is 5-10 percent; and the average grain diameter D50 of the heat stabilizer is 0.5-3 microns. Compared with the existing product, a silicon rubber product prepared by using the cerium hydroxide heat stabilizer has the advantages of high heat-resistant performance, good product color and the like, so that the aims of the invention are fulfilled.

Owner:上海华明高纳稀土新材料有限公司

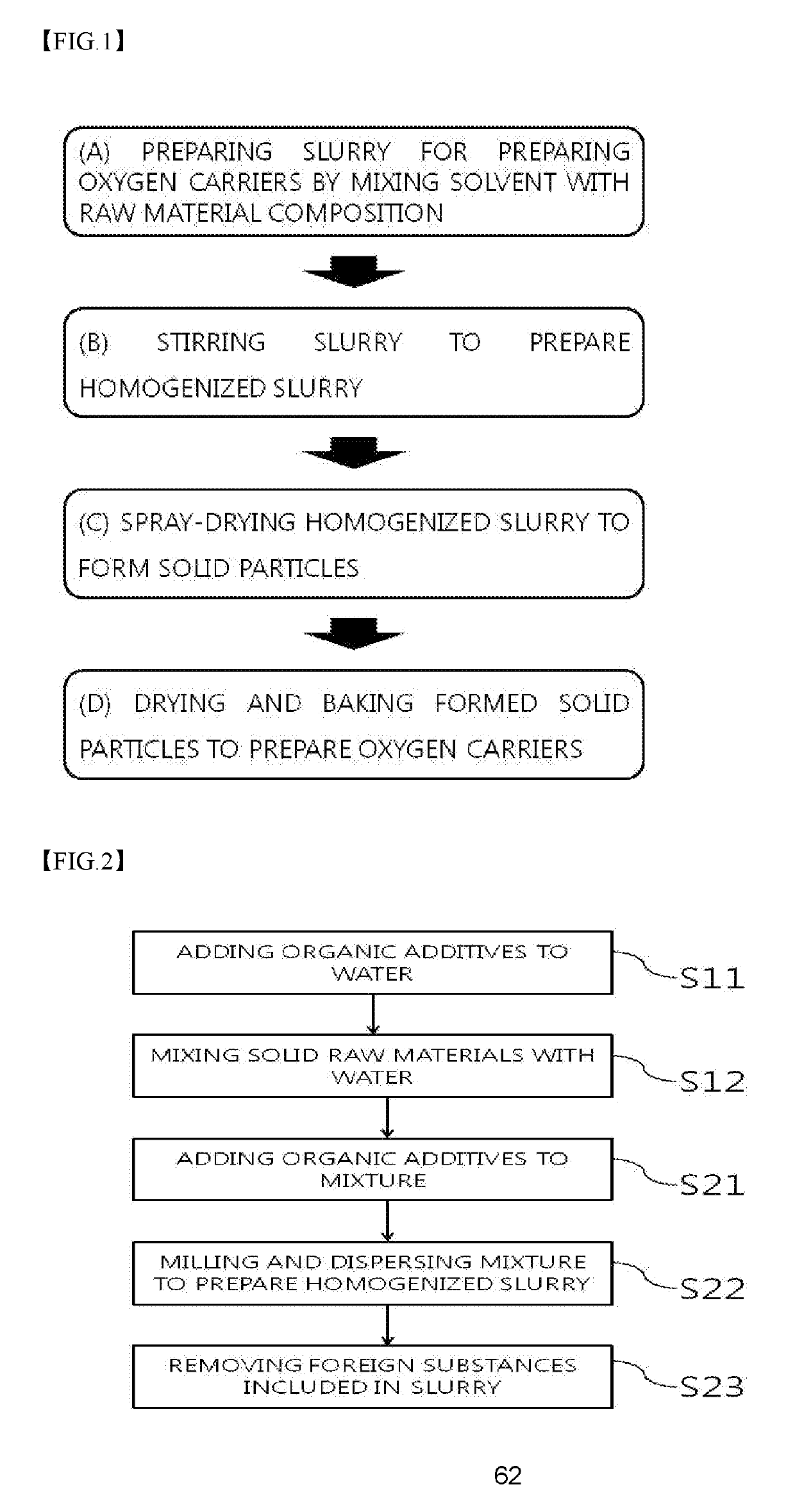

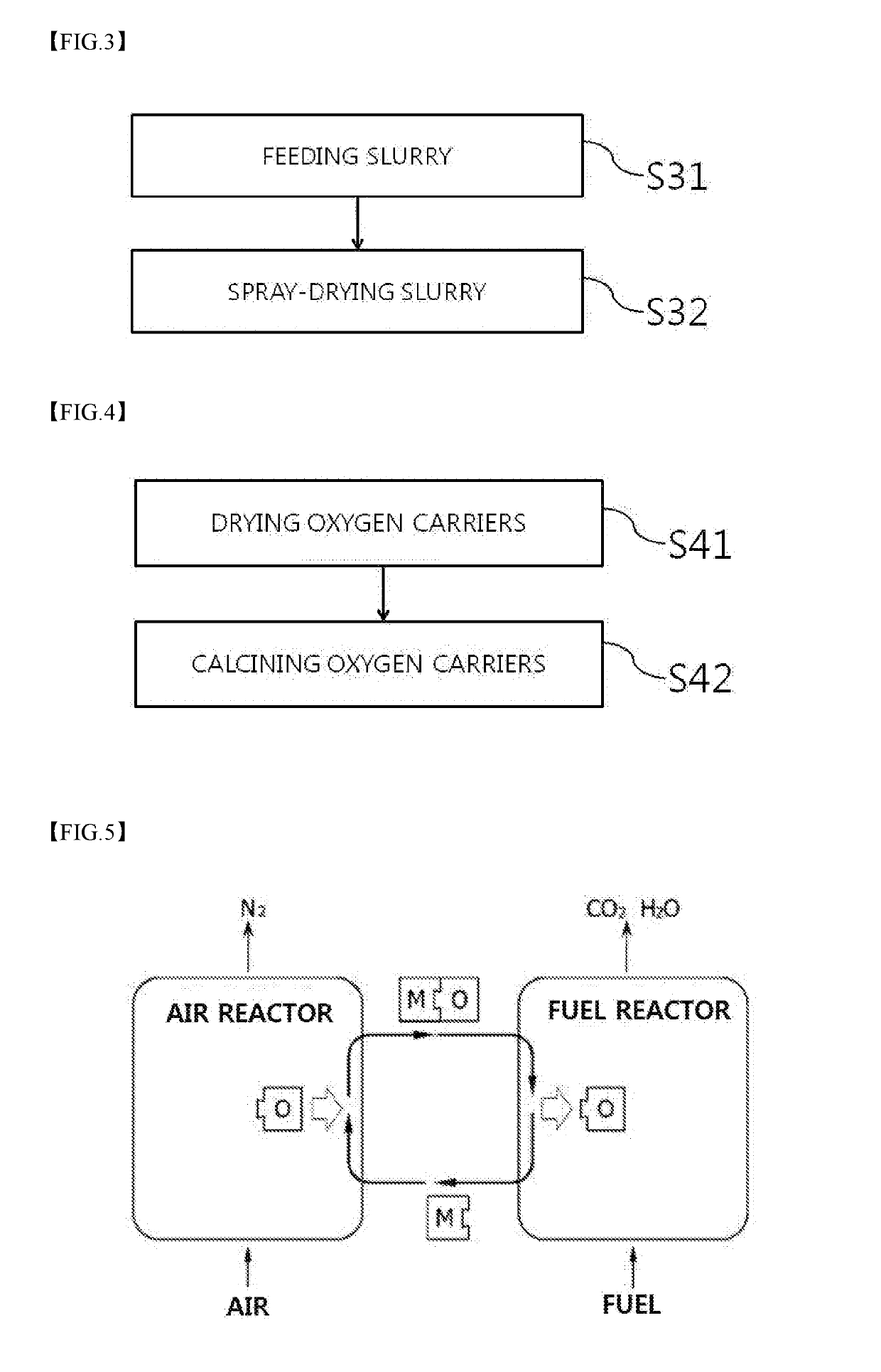

Raw material composition for preparing oxygen carrier particles, oxygen carrier particles prepared by using same, and method for preparing oxygen carrier particles

PendingUS20190170346A1Improved attrition resistanceImprove long-term durabilityHydrogenFluidized bed combustionFluidized bedCerium

A raw material composition for producing oxygen carriers includes a first component which is one or more of nickel oxide and nickel hydroxide and a second component which is one or more of boehmite, cerium oxide, cerium hydroxide, magnesium oxide, magnesium hydroxide, and titanium oxide, wherein, when the first component is nickel oxide, the second component includes cerium hydroxide. Such a raw material composition for producing oxygen carriers of the present invention is formed into oxygen carriers according to an oxygen carrier producing method, which will be described below, by adjusting the composition, formulation of raw materials, and degree of homogenization. Then, it is possible to produce oxygen carriers having physical properties such as a shape, a particle size, and a particle distribution suitable for a fluidized bed process or a high speed fluidized bed process and having improved wear-resistance, long-term durability, and oxygen transfer performance.

Owner:KOREA ELECTRIC POWER CORP

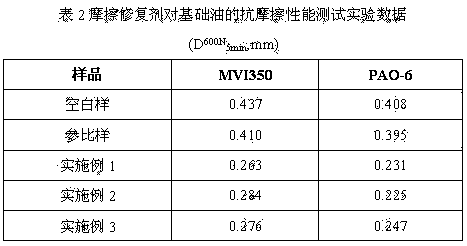

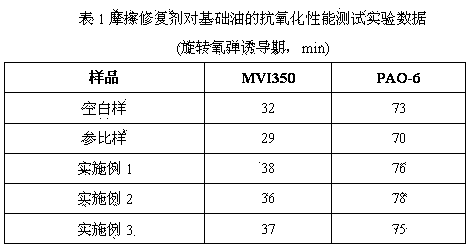

Metal organic friction repair agent and preparation method thereof

ActiveCN104004566AImprove anti-wear performanceRaw materials are easy to getAdditivesOctanoic AcidsDistillation

The invention discloses a metal organic friction repair agent and a preparation method thereof. The preparation method particularly comprises the following steps: adding isocaprylic acid and dimethyl benzene to a reaction kettle; uniformly stirring, then adding copper hydroxide, trihydroxy molybdenum and cerium hydroxide, continuously stirring, adding octyl butyl diphenylamine, heating to 70-150 DEG C for inert-gas protection reaction; and finally adding polyisobutylene succinimide, carrying out reduced pressure distillation, and recovering a solvent. The metal organic friction repair agent obtained through the preparation method disclosed by the invention has good oil solubility in various oil products, does not contain the elements, such as sulfur, phosphorus and halogen which are harmful to the environment, has good repair effect on abrasion marks, can be widely applied to repairing the abrasive surfaces in the fields of compressors, air cylinders, gears, precision machine tools, aerospace and the like and can prolong the service life of rotating equipment, reduce the equipment cost and achieve the purposes of electricity conservation and oil conservation.

Owner:XI'AN PETROLEUM UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com