Flame-retardant ceramic silicone rubber and preparation method and application thereof

A ceramic silicone rubber, flame-retardant technology, applied in the direction of rubber insulators, organic insulators, etc., can solve the problems of poor fire resistance, limited manufacturing length, poor sealing of joints, etc., to improve crack resistance and quality loss rate The effect of small size and stable rubber properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

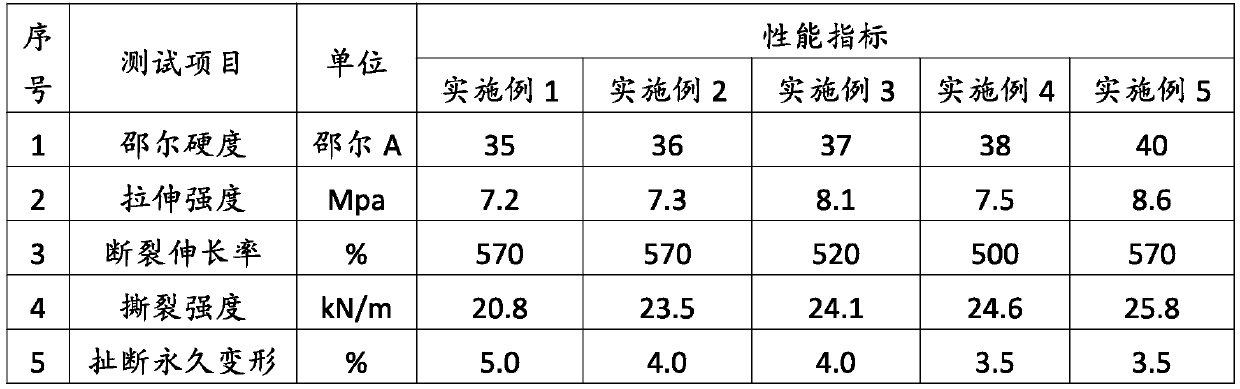

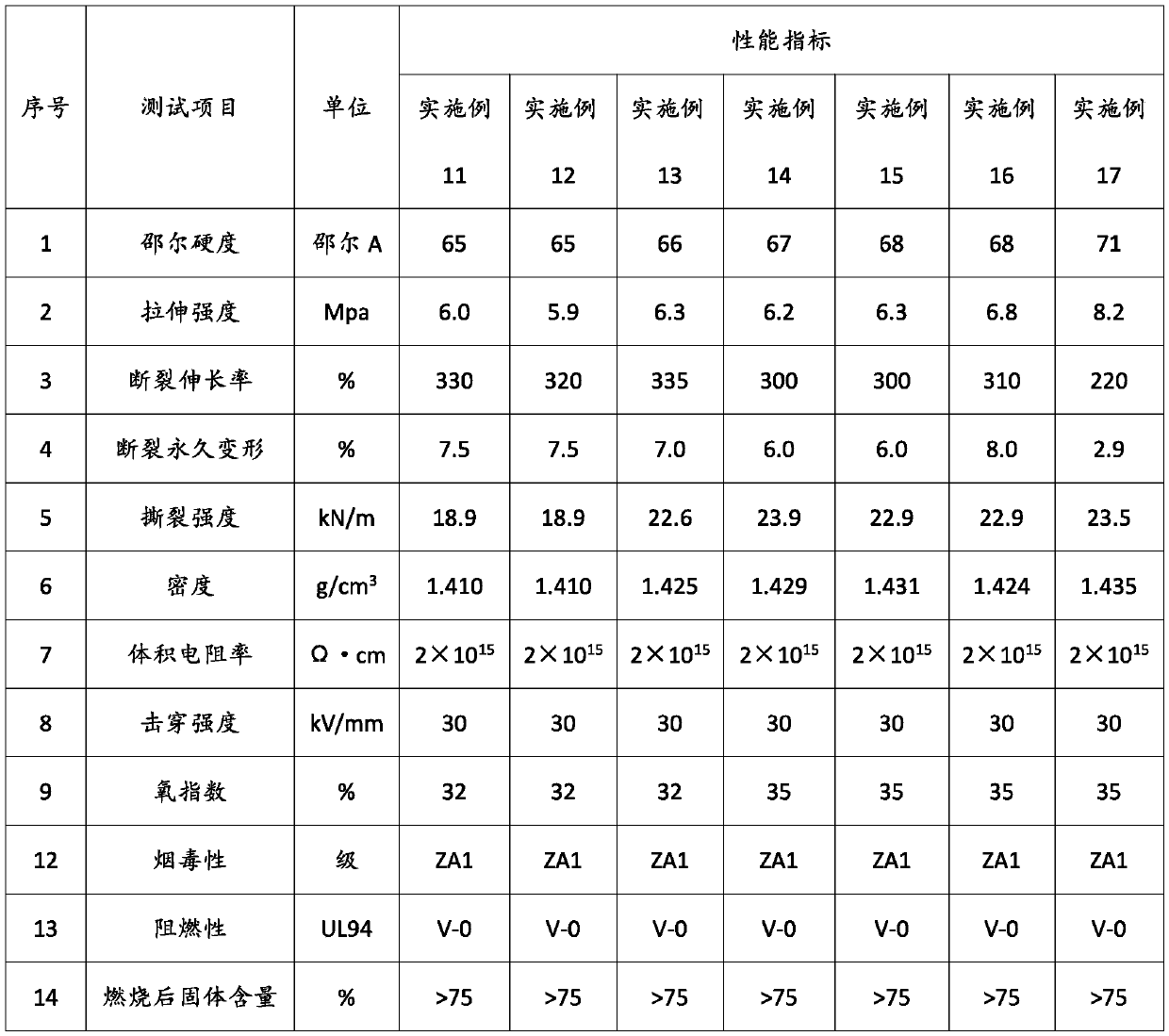

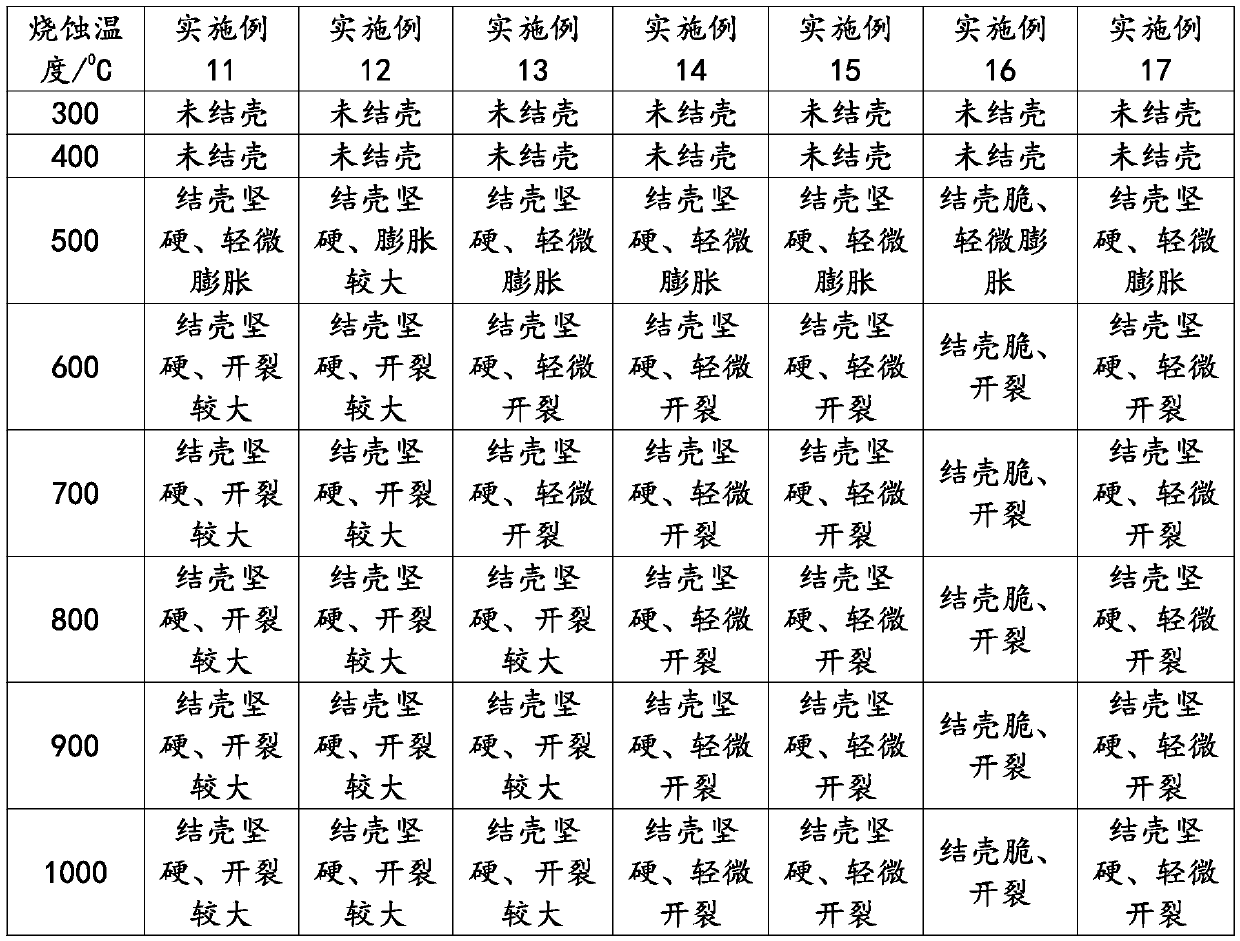

Examples

Embodiment 1

[0040] In the kneader, first add 100 parts of raw rubber with 0.04% vinyl content and 0 parts of raw rubber with 3% vinyl content. Refining evenly, heat up to 150°C after agglomeration, heat treatment for 2 hours, vacuum degree is -0.04~-0.08MPa. Mix the heat-treated rubber with 1% peroxide on a double-roller rubber mixer, put it into a mold of 130mm×130mm×2mm, vulcanize it for 10 minutes under the condition of 125℃×10MPa, and make a test piece after demoulding. piece.

Embodiment 2

[0042] In the kneader, first add 95 parts of raw rubber with 0.04% vinyl content and 5 parts of raw rubber with 3% vinyl content. After turning over the roll to be wrapped, add 35 parts of reinforcing filler white carbon black and 5 parts of hydroxyl silicone oil several times. , mixed evenly, after agglomeration, the temperature was raised to 150°C, heat treated for 2 hours, and the vacuum degree was -0.04~-0.08MPa. Mix the heat-treated rubber with 1% peroxide on a double-roller rubber mixer, put it into a mold of 130mm×130mm×2mm, vulcanize it for 10 minutes under the condition of 125℃×10MPa, and make a test piece after demoulding. piece.

Embodiment 3

[0044]In the kneader, first add 90 parts of raw rubber with 0.04% vinyl content and 10 parts of raw rubber with 3% vinyl content. After turning over the roll to be wrapped, add 35 parts of reinforcing filler white carbon black and 5 parts of hydroxyl silicone oil several times. , mixed evenly, after agglomeration, the temperature was raised to 150°C, heat treated for 2 hours, and the vacuum degree was -0.04~-0.08MPa. Mix the heat-treated rubber with 1% peroxide on a double-roller rubber mixer, put it into a mold of 130mm×130mm×2mm, vulcanize it for 10 minutes under the condition of 125℃×10MPa, and make a test piece after demoulding. piece.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com