Patents

Literature

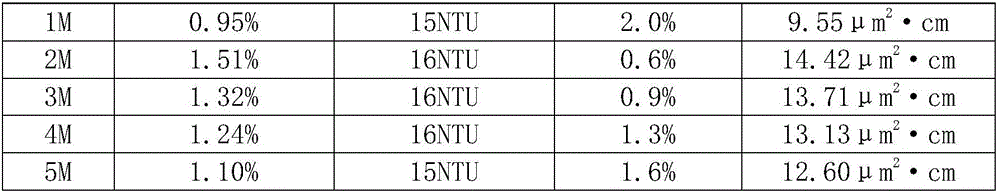

243results about How to "Improves breakage resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cladded quartz sand fracturing support agent for oil production

ActiveCN1640981AWith strengthReduce breakage rateFluid removalPigment treatment with macromolecular organic compoundsBreaking strengthOil production

The present invention relates to one kind of fracturing proppant for petroleum production and its production process. The proppant comprises quartzite grains and hardened thermoset resin film coating the surface of the quartzite grains. The proppant of the present invention has high breaking strength and low cost, and may be used to replace expensive haydite sand.

Owner:BEIJING RECHSAND SCI & TECH GRP

Functional resin tectorial membrane proppant and preparation method thereof

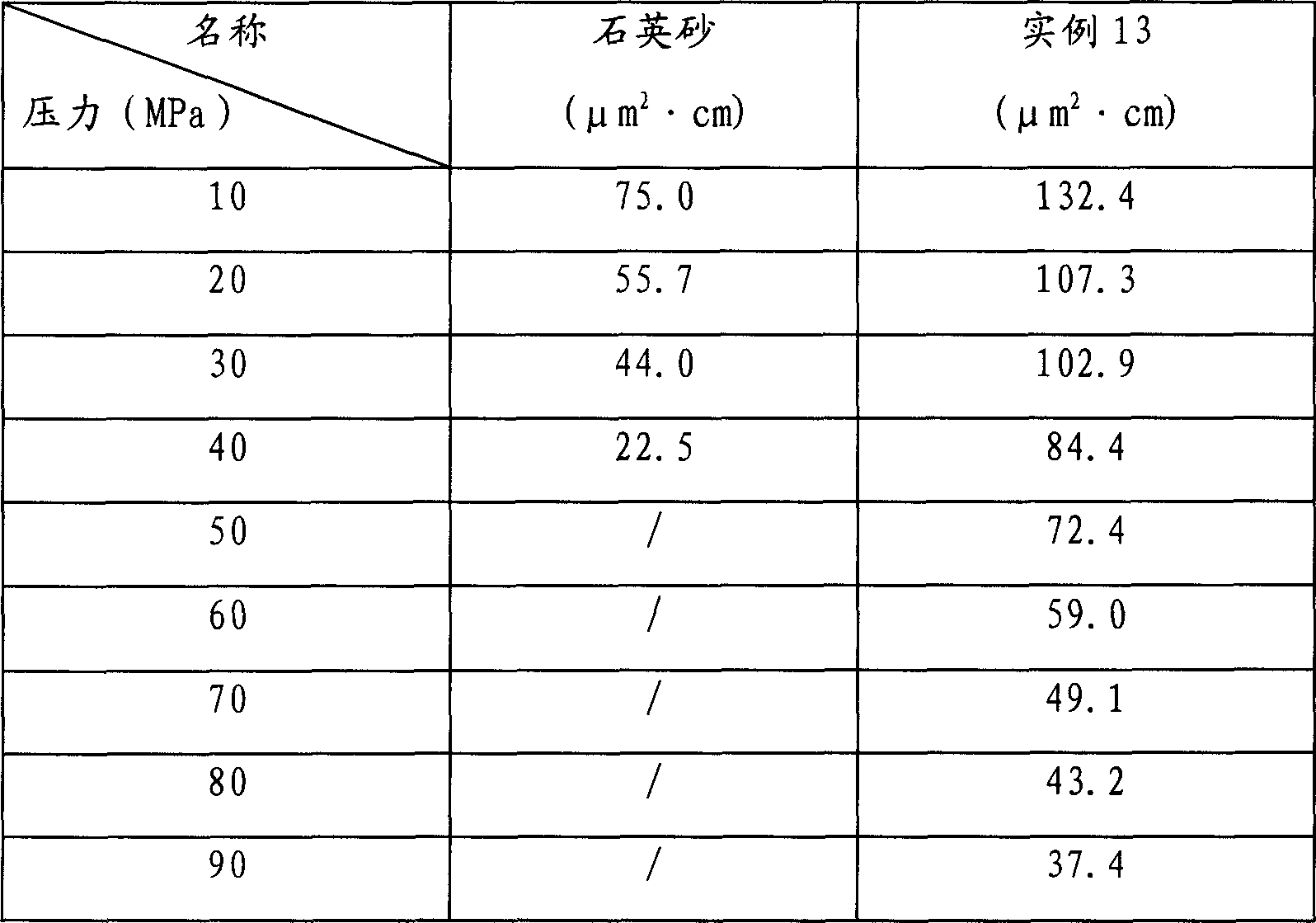

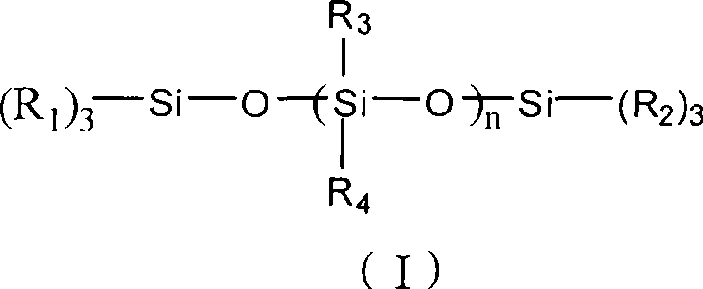

ActiveCN101531893AThrough highPrevent passageFluid removalDrilling compositionTectorial membraneSide chain

The invention relates to a functional resin tectorial membrane proppant and a preparation method thereof, and belongs to the technical field of oil-gas field development. The functional resin tectorial membrane proppant comprises aggregate and a resin film coated on the aggregate. Said resin film comprises organic silicon compounds of one or more active groups of amino, hydroxyl, carboxyl, alkoxyl and hydrosulphonyl. The side chain of the organic silicon compound is a hydrophobic group. The cured resin film has different wetting qualities for oil and water. The functional resin tectorial membrane proppant of the invention has a function of allowing the smooth permeation of oil gas and preventing water from penetrating through the proppant. Such a function improves the separation effect ofoil gas and water and reduces the oil production cost. The excellent hydrophobicity of the resin film facilitates the proppant to have excellent water resisting property and improves the crushing resistance of the proppant, so that the stream guidance effect is good for a long time.

Owner:围场满族蒙古族自治县津通铸造材料有限公司

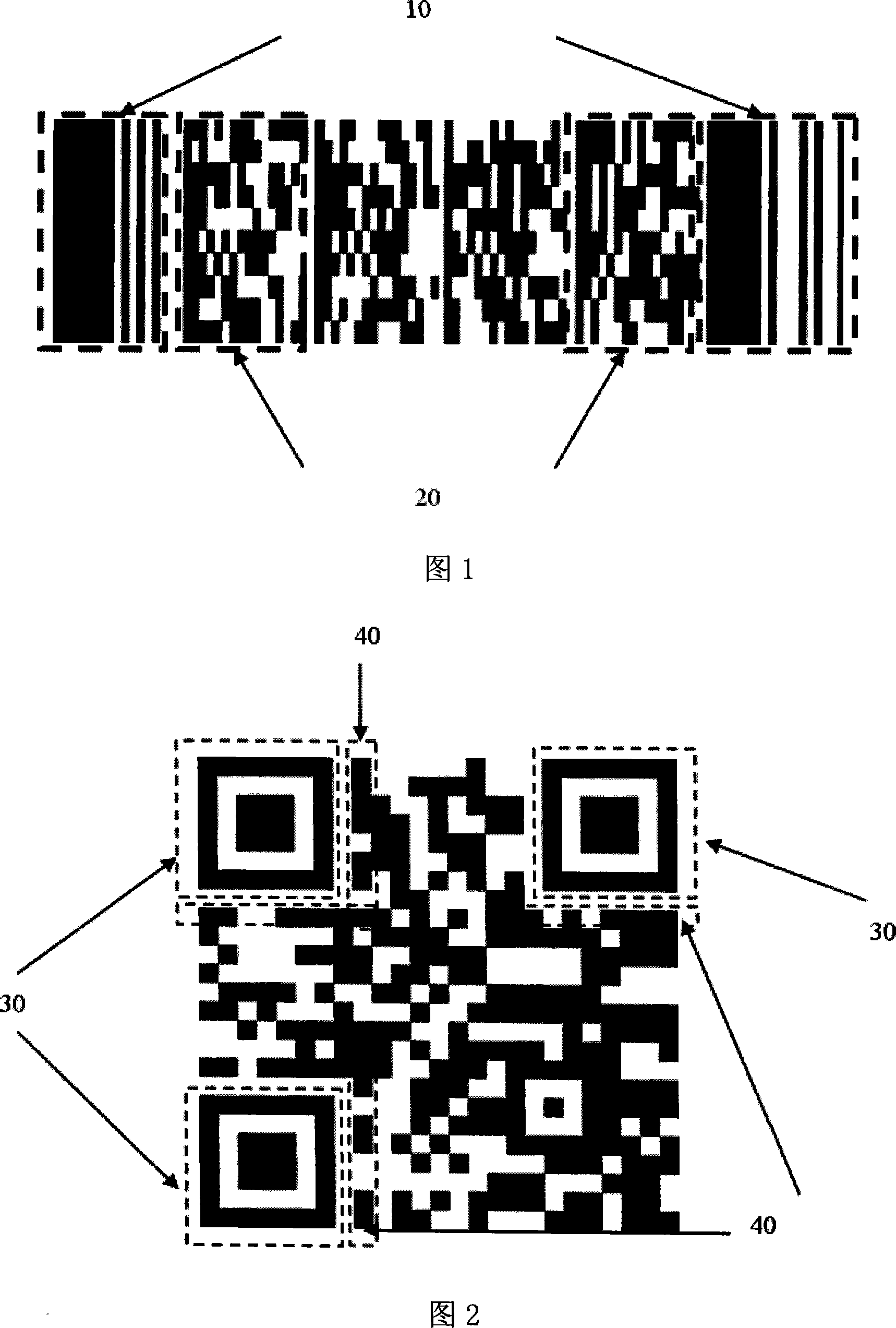

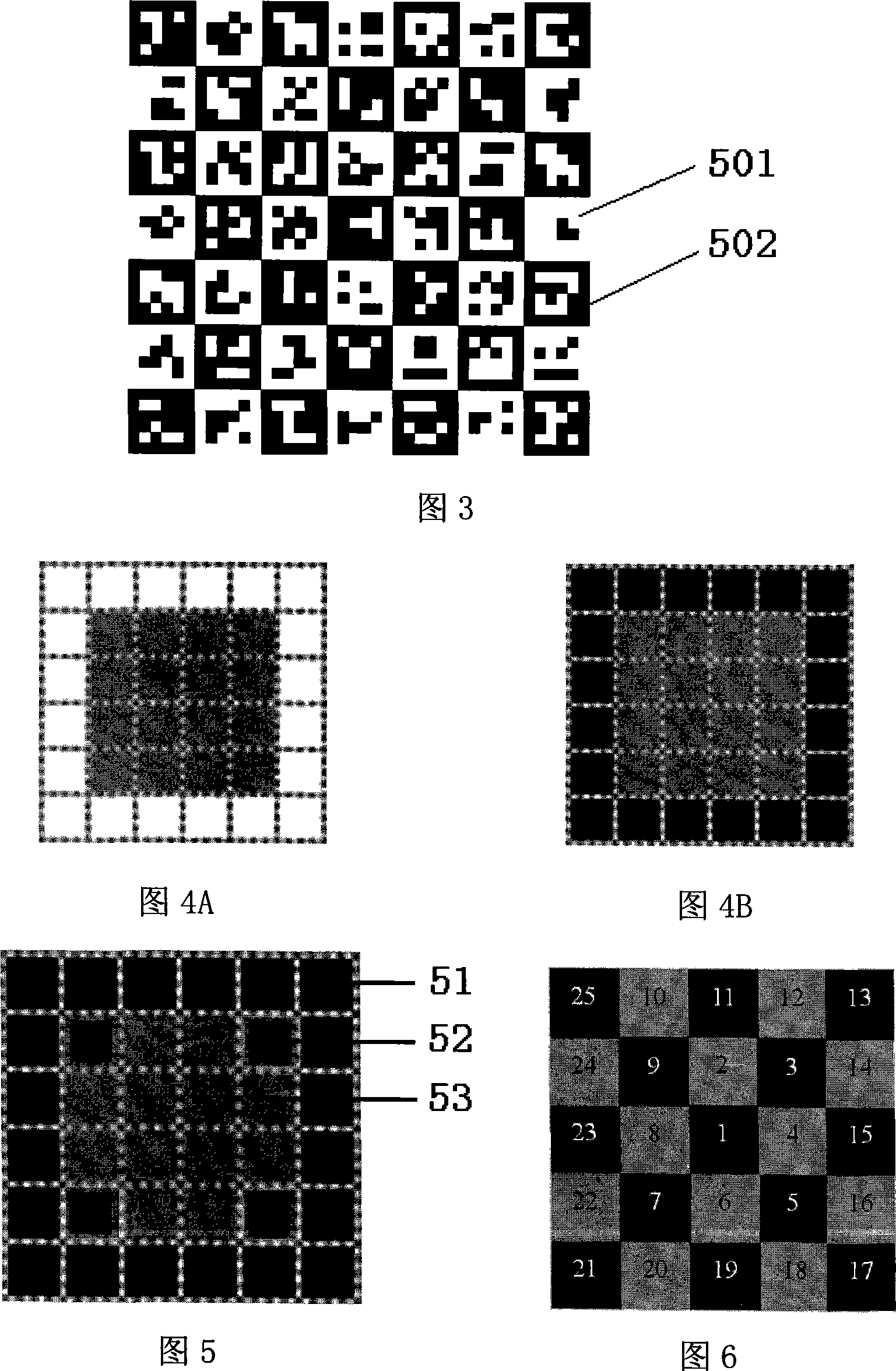

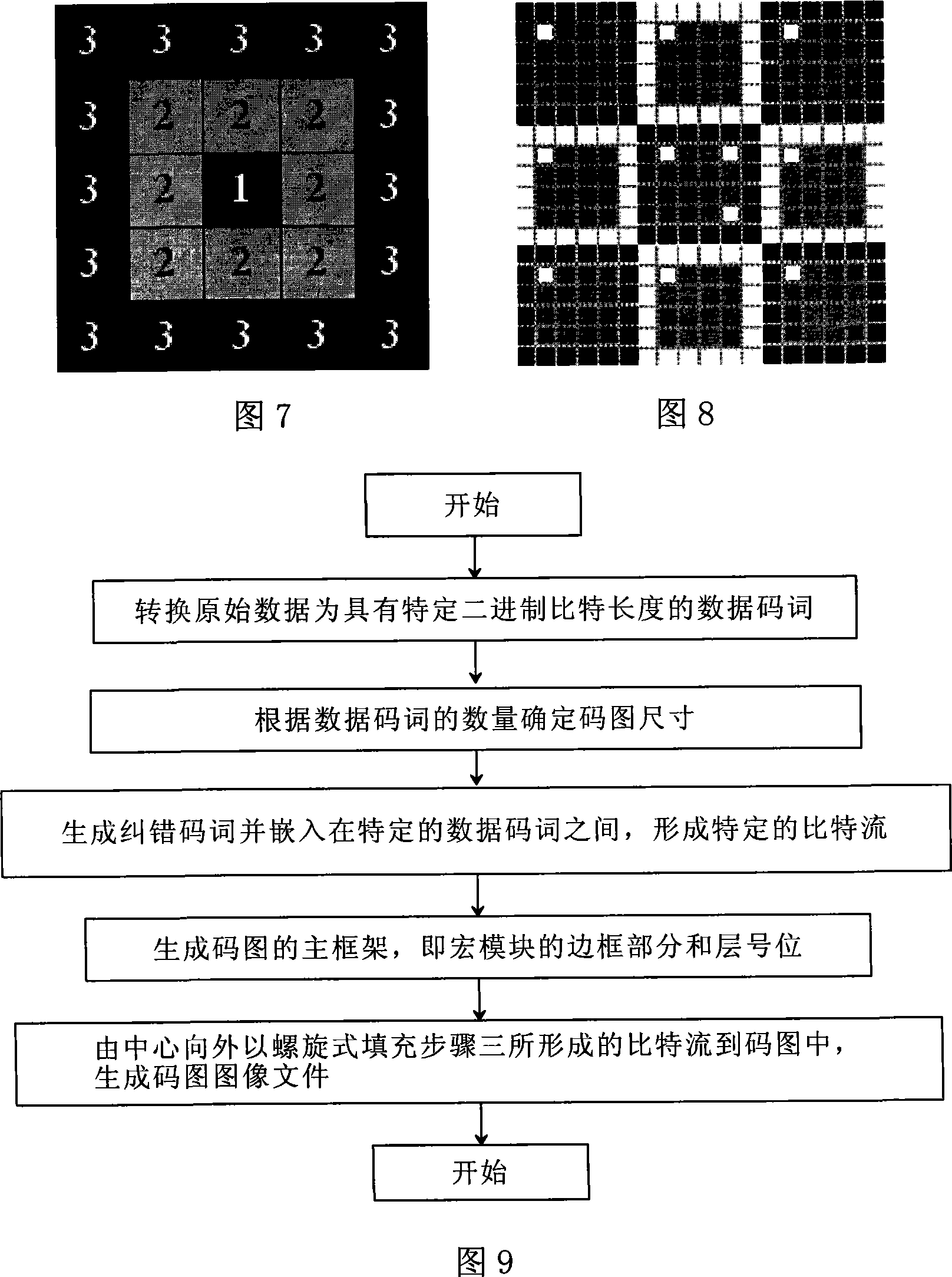

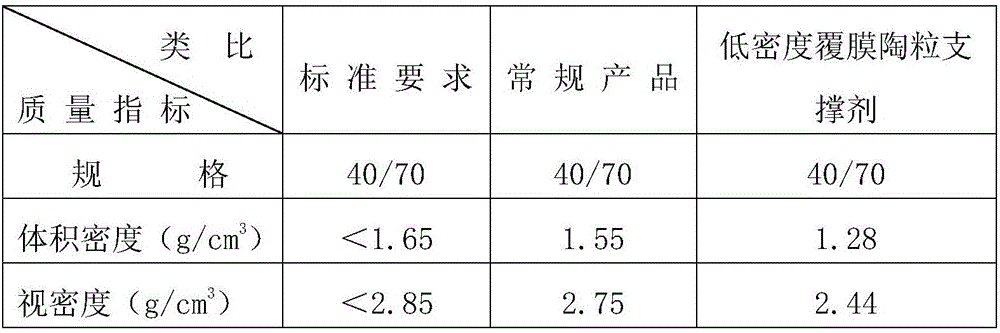

Two-dimension bar code and its coding and decoding method

InactiveCN101197004ADirection is easy to determineSmooth decodingRecord carriers used with machinesSensing by electromagnetic radiationProgramming languageError correcting

The present invention discloses a method for coding and decoding two-dimensional bar codes. The coding method comprises a data code word generating step, an error-correcting code word generating step, a main code pattern frame generating step and a code pattern image forming step through code word filling. The decoding method is that: a gray scale image of a code pattern is acquired through a digital photography mode; the gray value distribution of different pixels in the gray scale image is counted; a threshold value is determined; the gray scale image is converted into a binary image and an edge image is acquired; the four-corner coordinate of each macro block in the code pattern and the center coordinate of each unit module inside the macro blocks are calculated; the bit value stored by each unit module is determined so as to acquire a data code word matrix corresponding to the decoded code pattern; the data code word is read according to a correct center macro block and the code pattern direction; RS error-correcting algorithm is used to correct the errors in the code word according to a preset error-correcting grade; the data code word is output and recovered as a binary number.

Owner:SHENZHEN SYSCAN TECHC CO LTD

Pre-coated film propping agent, preparation method of the pre-coated film propping agent and sand prevention method adopting the pre-coated film propping agent

ActiveCN102660245AImproves breakage resistanceEasy to divertFluid removalDrilling compositionBisphenol FPolyamine

The invention relates to a pre-coated film propping agent, a preparation method of the pre-coated film propping agent and a sand prevention method adopting the pre-coated film propping agent. The pre-coated film propping agent comprises propping agents, one or more pre-coated resins, one or more pre-coating curing agents, a coupling agent and a lubricating agent. The one or more pre-coated resins comprise bisphenol-A epoxy resin, bisphenol-F epoxy resin and / or novolac epoxy resin. The one or more pre-coating curing agents are selected from alicyclic polyamines, aromatic polyamines, modified alicyclic polyamines and / or modified aromatic polyamines. The coupling agent is an organosilane coupling agent.

Owner:BEIJING QISINTAL SCI & TECH +1

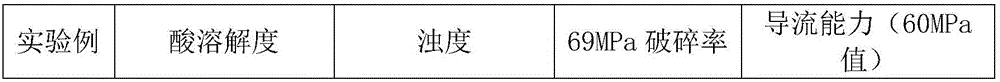

Low-density coated ceramsite proppant and preparation method thereof

ActiveCN106281299AImprove the finishImproves breakage resistanceDrilling compositionPetroleumMaterials science

The invention relates to a low-density coated ceramsite proppant and a preparation method thereof, and belongs to the field of petroleum proppants. A ceramsite base material and mixed resin coating the surface of the ceramsite base material are adopted, so that compared with the traditional proppant, the breaking-resistant capacity is greatly improved, the breaking rate is much lower under the condition of the same consumption of resin, and the low-density coated ceramsite proppant can be suitable for deeper well fracturing. Compared with the traditional proppant, the production cost is lower, the chemical inertness is better, the fracturing effective period can be prolonged, and the low-density coated ceramsite proppant is suitable for the fracturing construction under various complicated stratum environment conditions and is higher in flow conductivity.

Owner:CHONGQING CHANGJIANG RIVER MOLDING MATERIAL GRP

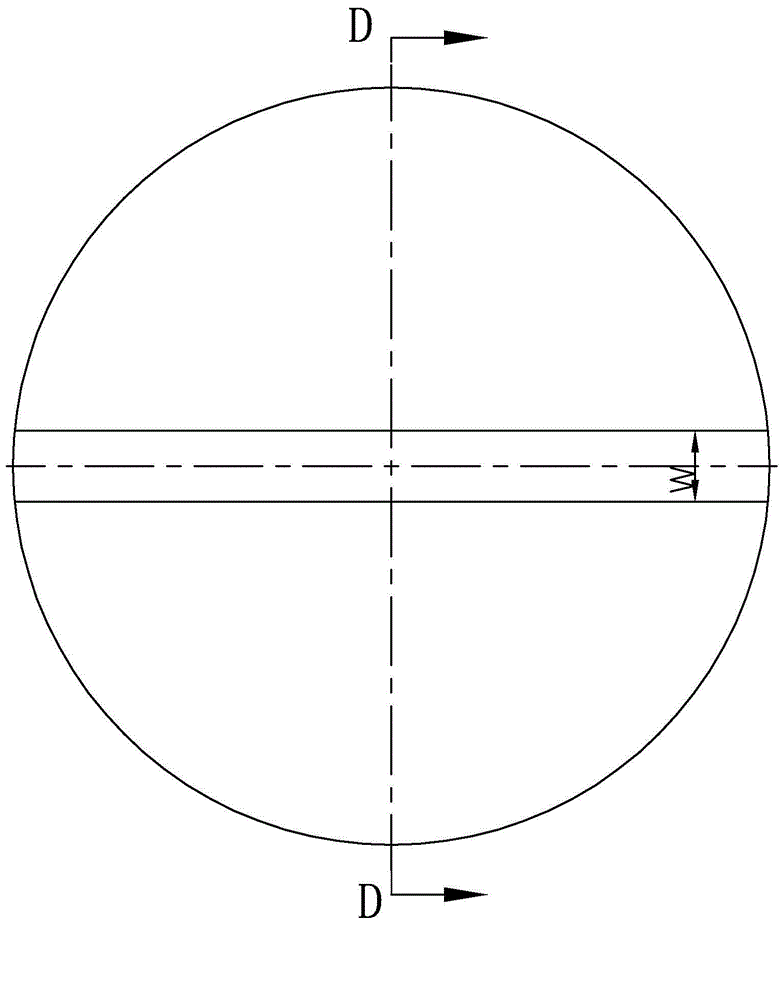

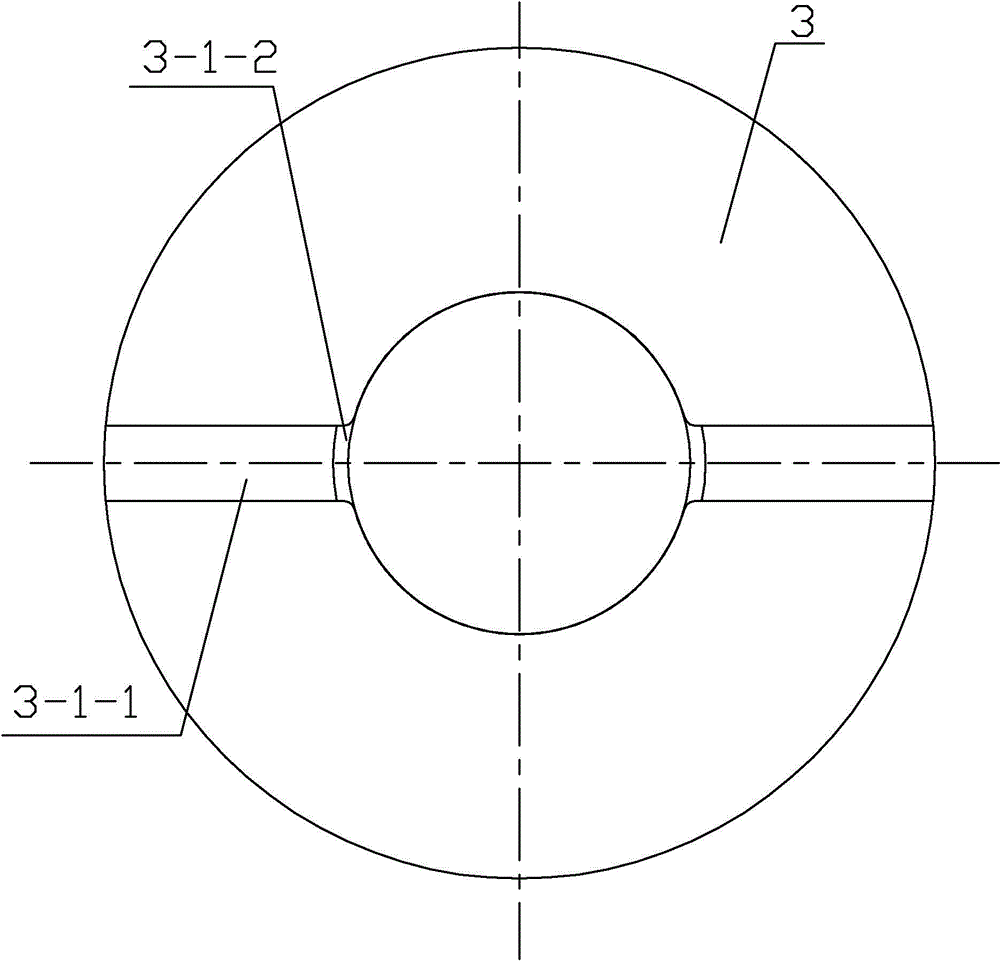

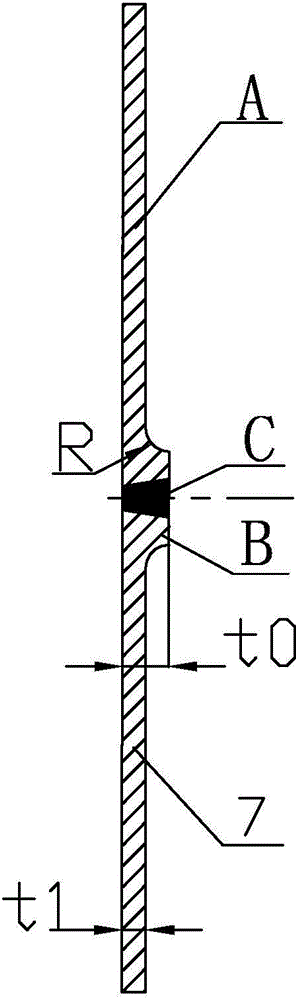

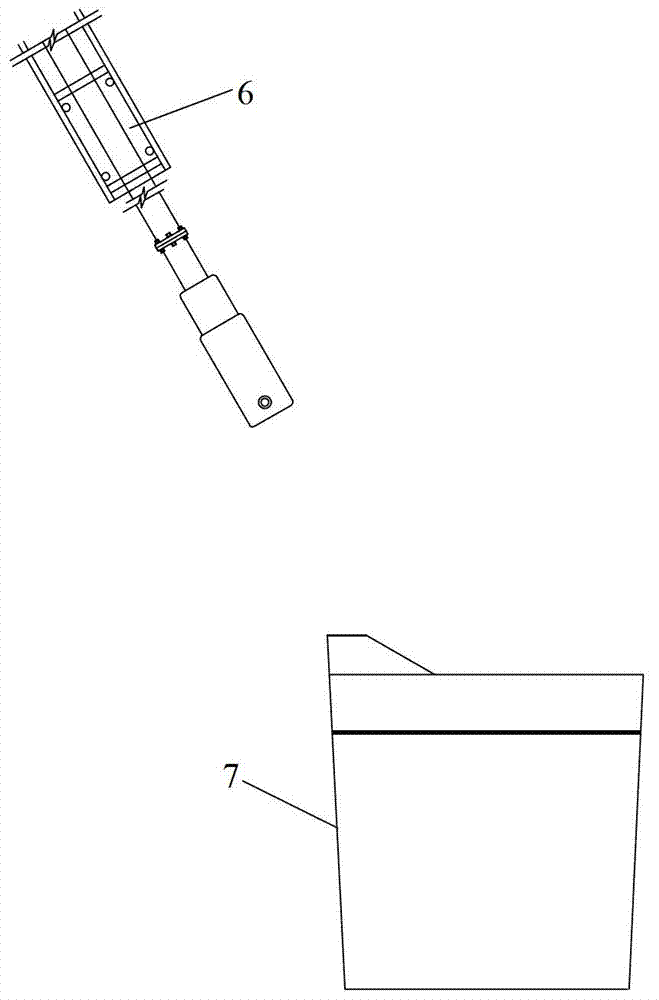

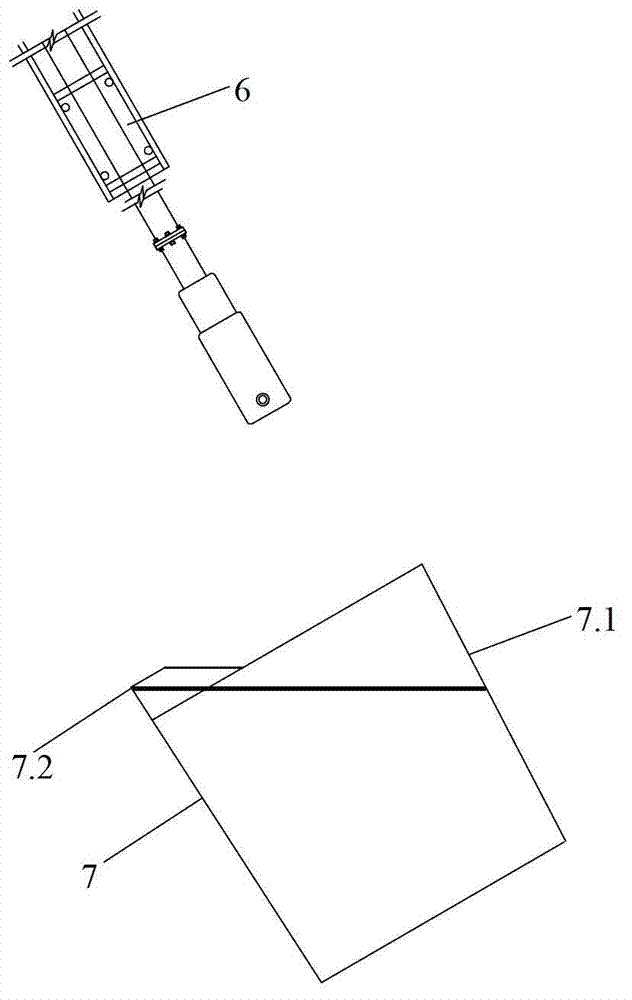

Tailor welded blank integral drawing forming device and method for large-scale curved surface part

The invention discloses a tailor welded blank integral drawing forming device and a method for a large-scale curved surface part, relates to the tailor welded blank integral forming device and method, and the problem that in the prior art, fractures exist in tailor welded blank integral forming is solved. The tailor welded blank integral drawing forming device comprises a male die, a blank holder, a female die and a liquid filling chamber; the portion between the blank holder and the female die is used for containing an unequal thickness tailor welded blank; the profile of the male die is provided with a male die groove which is consistent with the shape of a thick wall area where a sheet metal weld joint is located, blank holder grooves which are consistent with the shape of the thick wall area where the sheet metal weld joint is located are formed in an inner hole of the blank holder and the lower surface of the blank holder simultaneously, and the male die groove and the blank holder grooves are used for preventing the portion, perpendicular to the direction of the weld joint, of the thick wall area from deforming; or female die grooves which are consistent with the shape of the thick wall area where the sheet metal weld joint is located are formed in the upper surface of the female die and an inner hole of the female die and used for preventing the portion, perpendicular to the direction of the weld joint, of the thick wall area from deforming. The invention further provides a tailor welded blank integral drawing forming method of the large-scale curved surface part through using the tailor welded blank integral drawing forming device. The tailor welded blank integral drawing forming device and the method for the large-scale curved surface part are used for filling liquid, drawing and forming for the unequal thickness and symmetrical tailor welded blank through adopting uniform strength bearing design.

Owner:HARBIN INST OF TECH

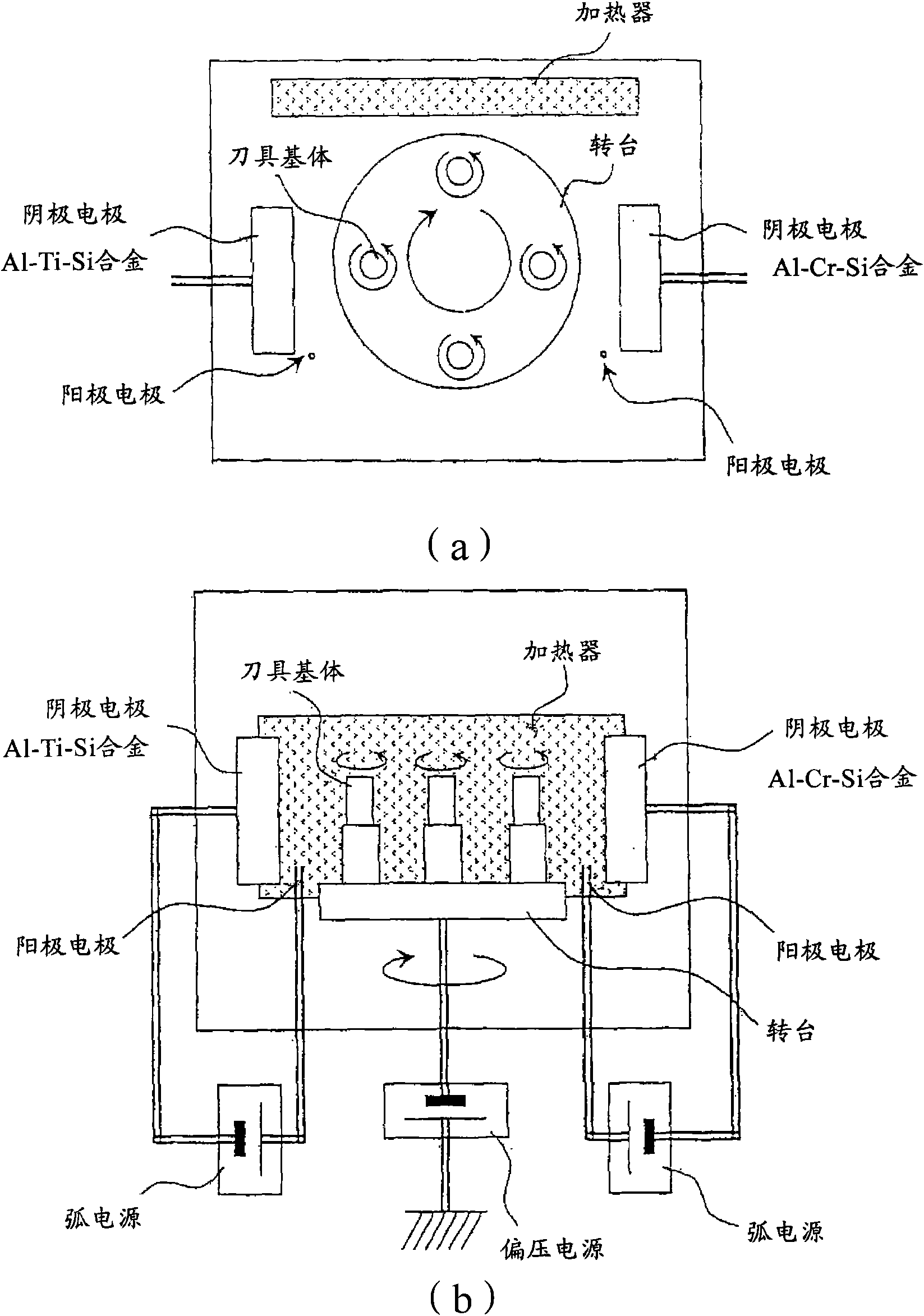

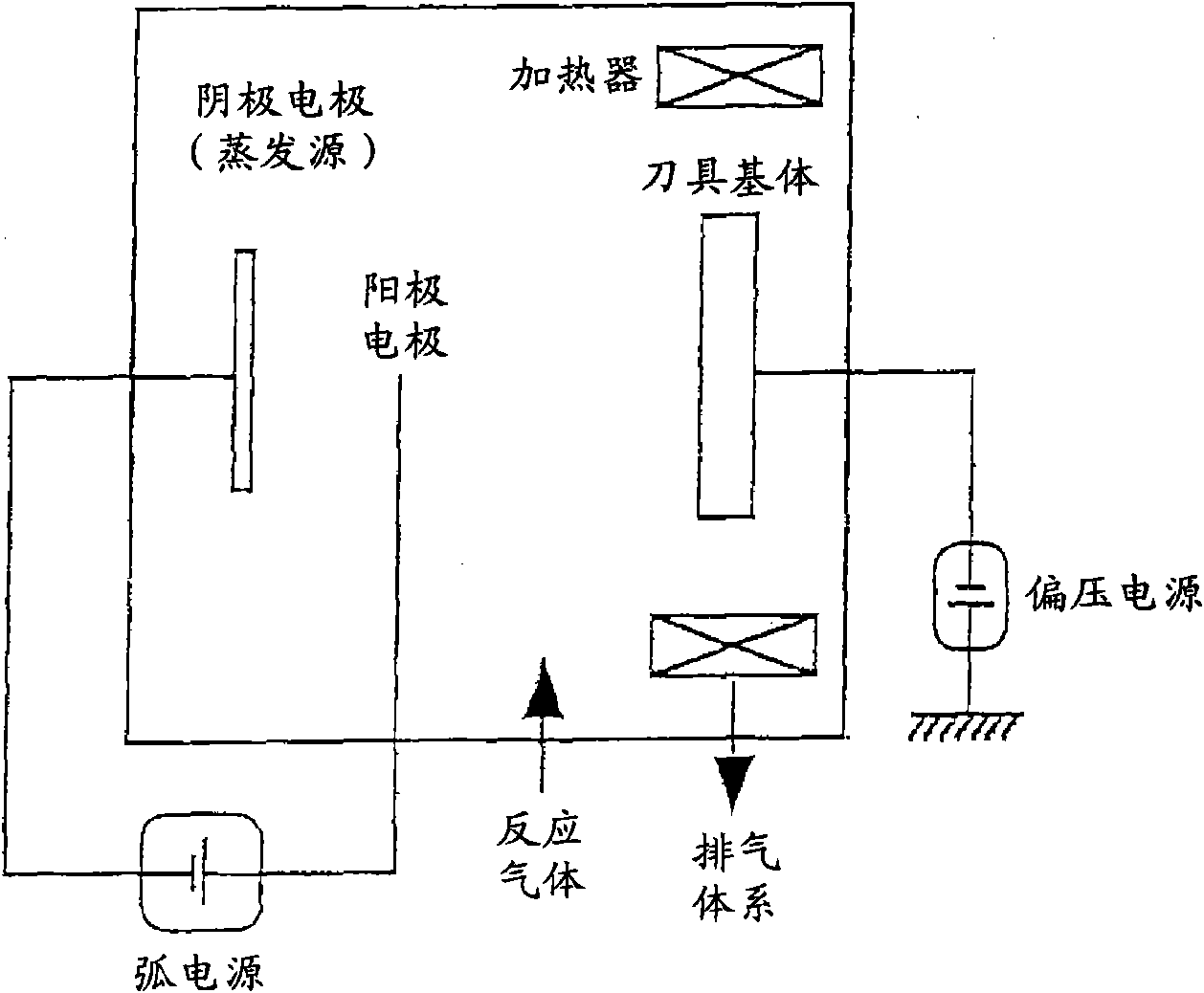

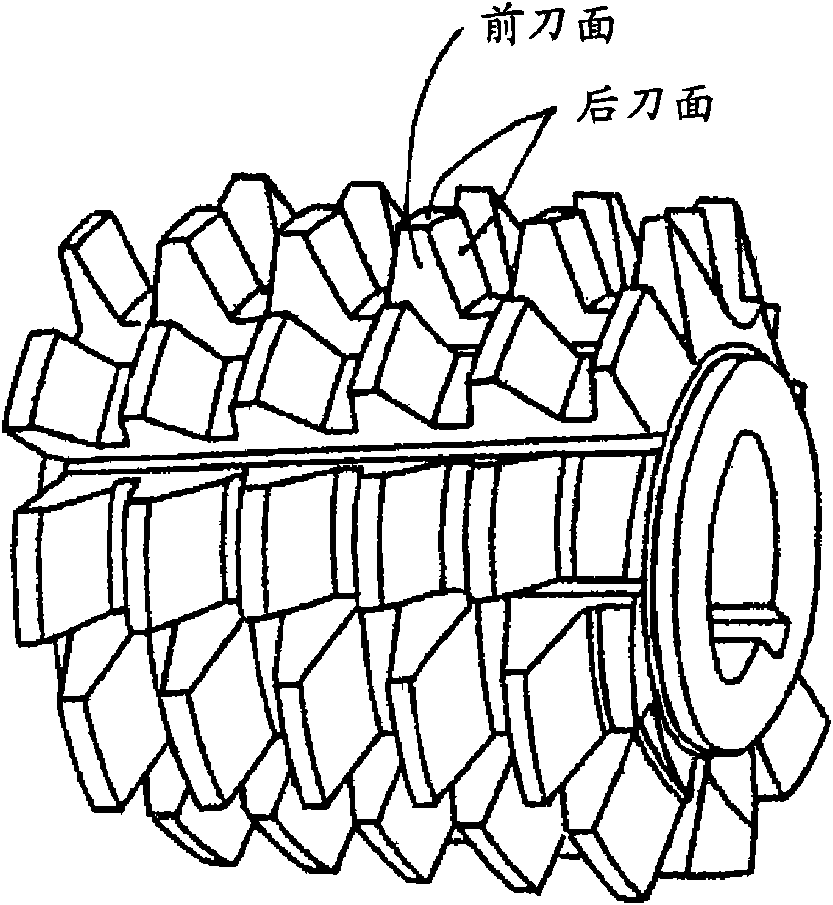

Surface-coated cutting tool

ActiveCN101678467AExcellent high temperature hardnessExcellent high temperature toughnessMilling cuttersVacuum evaporation coatingThin layerCemented carbide

A surface-coated cutting tool which has excellent chipping resistance and wearing resistance in high-speed cutting processing such as high-speed gear cutting processing, high-speed milling processing,and high-speed drilling processing. The surface-coated cutting tool comprises a tool base, e.g., a cemented carbide base, cermet base, or high-speed tool steel base, and at least a hard coating layerformed on a surface of the tool base and having a multilayer structure composed of a thin layer (A) and a thin layer (B) alternating therewith. The thin layer (A) is constituted of an (Al,Cr,Si)N layer satisfying the empirical formula ¢AlXCrYSiZ!N (wherein 0.2 <= X <= 0.45, 0.4 <= Y <= 0.75, 0.01 <=Z <= 0.2, and X+Y+Z=1 in terms of atomic ratio), and the thin layer (B) is constituted of an (Al,Ti,Si)N layer satisfying the empirical formula ¢AlUTiVSiW!N (wherein 0.05 <= U <= 0.75, 0.15 <= V <= 0.94, 0.01 <= W <= 0.1, and U+V+W=1 in terms of atomic ratio).

Owner:MITSUBISHI MATERIALS CORP

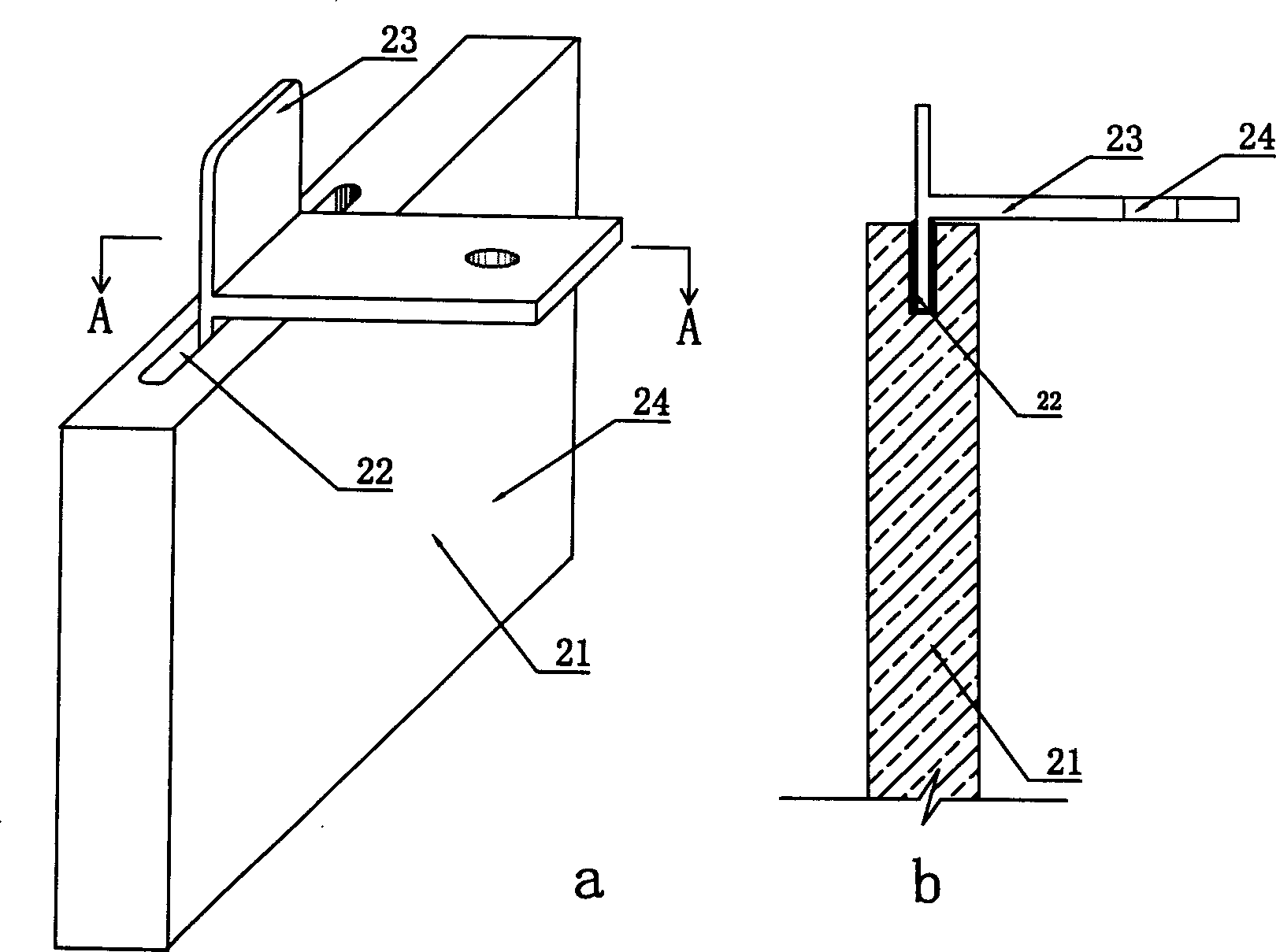

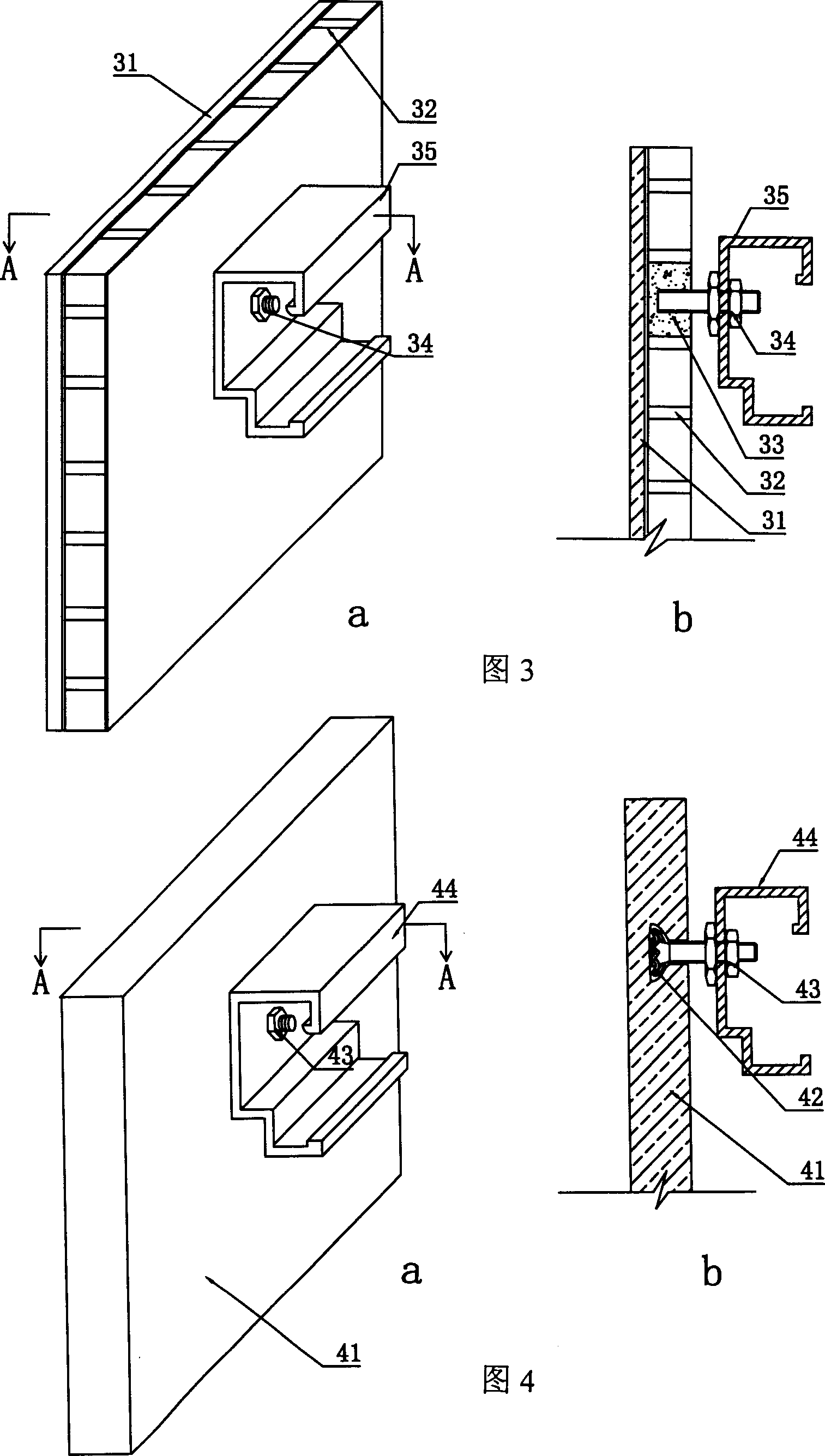

Hanger embedded decorative panel of stone material and its making method

An embedded hanger type decorative stone slab is composed of surfacial stone layer, embedded hangers in the slot on the back of said surficial stone layer, and insulating layer on the back of said surficial layer. It is possible to attach a reinforcing layer to it. Its advantages are less consumption of stone, low cost, and high stress performance.

Owner:ARCHITECTURAL DESIGN & RES INST OF TSINGHUA UNIV +1

Water-based intercoating composition and method of forming multilayered coating film

InactiveCN1918251AEasy to cleanImproves breakage resistanceLiquid surface applicatorsPolyurea/polyurethane coatingsWater basedAdditive ingredient

A water-based intercoating composition which comprises an aqueous dispersion type polyurethane composition obtained from a polyisocyanate ingredient comprising a diisocyanate as an essential component, a polyol ingredient comprising a polycarbonate diol having an average molecular weight of 500 to 5,000 and a carboxylated diol as essential components, an amine ingredient comprising a monoamine compound as an essential component, a carboxy-neutralizing ingredient, and water. A coating film made up of three layers is formed respectively from the water-based intercoating composition, a water-based base coating composition, and a clear coating composition by the wet-on-wet technique on an object to be coated which has an electrodeposited coating film formed thereon. The three layers are simultaneously baked and cured to form a multilayered coating film.

Owner:NIPPON PAINT GUANGZHOU

Torpedo tank lining gunning repairing material, preparation method and applications thereof

The invention discloses a torpedo tank lining gunning repairing material, a preparation method and applications thereof, wherein the torpedo tank lining gunning repairing material comprises, by weight, 60-67 parts of a Al2O3-containing fireproof material after-using regenerating material, 3-7 parts of fireproof clay, 2-5 parts of flaky graphite, 3-7 parts of silicon carbide, 10-15 parts of an alumina homogeneous material, 3-6 parts of kyanite, 2-5 parts of alpha-Al2O3 micro-powder, 3-11 parts of a binder, and 1.2-3.4 parts of an admixture. According to the present invention, the torpedo tank lining gunning repairing material has characteristics of low raw material cost, wide regeneration material source, convenient cold-hot state gunning repairing, excellent thermal shock stability, strong repairing layer interface bonding strength, strong slag iron corrosion resistance, high torpedo tank operation rate, long service life, and the like.

Owner:武汉钢铁有限公司

Method for producing green silicon carbide FEPA F P

InactiveCN101705076AImproves breakage resistanceStable water pressureOther chemical processesVortex flow apparatusMicro cracksSilicon carbide

The invention provides a method for producing green silicon carbide FEPA F P, comprising the following steps in turn: sifting raw materials, grinding, classifying by air flow, cleaning by water, classifying by water conservancy and coating surface, filtering by pressure, drying, calcining, sieving, packaging and warehousing. The invention uses a Raymond grinder for grinding and an air flow classification device for multiple classification, and classifies into products in different levels by water conservatory classification; in water conservatory classification, cladding materials are used asdispersant; in classification, water pressure is stable, multi-level precision is improved by siphon overflow classification, impurities in the crack of the micro powder grains are fully evaporated by calcination and tempering in the later period of production, and the cracks can be healed by high-temperature calcination. The production method in the invention greatly enhances product purity, increases crushing resistance of the grains in grinding and polishing, the grain fineness distribution is even with no large grain and with excellent shape and good affinity to grinding liquid. The invention can produce various green silicon carbide FEPA F P with grain size being less than 100mm.

Owner:HUNAN JINCHENG NEW MATERIAL TECH

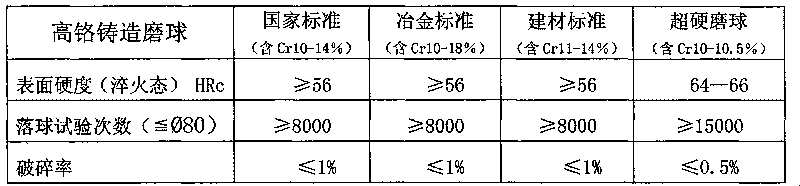

Production method of ultrahard high-chromium cast grinding ball

ActiveCN101705435ALow running costReduce wearHeat treatment process controlQuenching agentsTemperingManganese

The invention relates to a production method of an ultrahard high-chromium cast grinding ball. The ultrahard high-chromium cast grinding ball comprises the following chemical components: 1.8-3.2 percent of carbon (C), 0.3-1.0 percent of silicon (Si), 0.2-0.9 percent of manganese (Mn), 10.0-10.5 percent of chromium (Cr), 0.02-0.1 percent of phosphorus (P), 0.02-0.1 percent of sulphur (S), 0.02-0.1 percent of copper (Cu), 0.02-0.1 percent of molybdenum (Mo), 0.02-0.1 percent of nickel (Ni), 0.02-0.1 percent of wolfram (W), 0.1-0.2 percent of rare-earth yttrium (Y-Re) and 80.1-83.7 percent of iron (Fe). In the invention, the rare-earth yttrium is adopted to carry out modification treatment so as to change the shapes and the distribution of carbides, thereby breaking nets; meanwhile, crystal particles are refined, tissues are thickened, and the toughness is improved. An oil-medium quenching and tempering heat treatment process is adopted to obtain a eutectic carbide of a martensite and a broken net, the hardness of the high-chromium grinding ball achieves HRc64 to 66, and the toughness and the abrasive resistance of the high-chromium grinding ball are obviously improved. The grinding ball is tried in ball grinders of various factories in cement industry, the abrasion is reduced by 20-32 percent on year-on-year basis, and the running cost of the ball grinder is obviously reduced.

Owner:安徽省凤形新材料科技有限公司

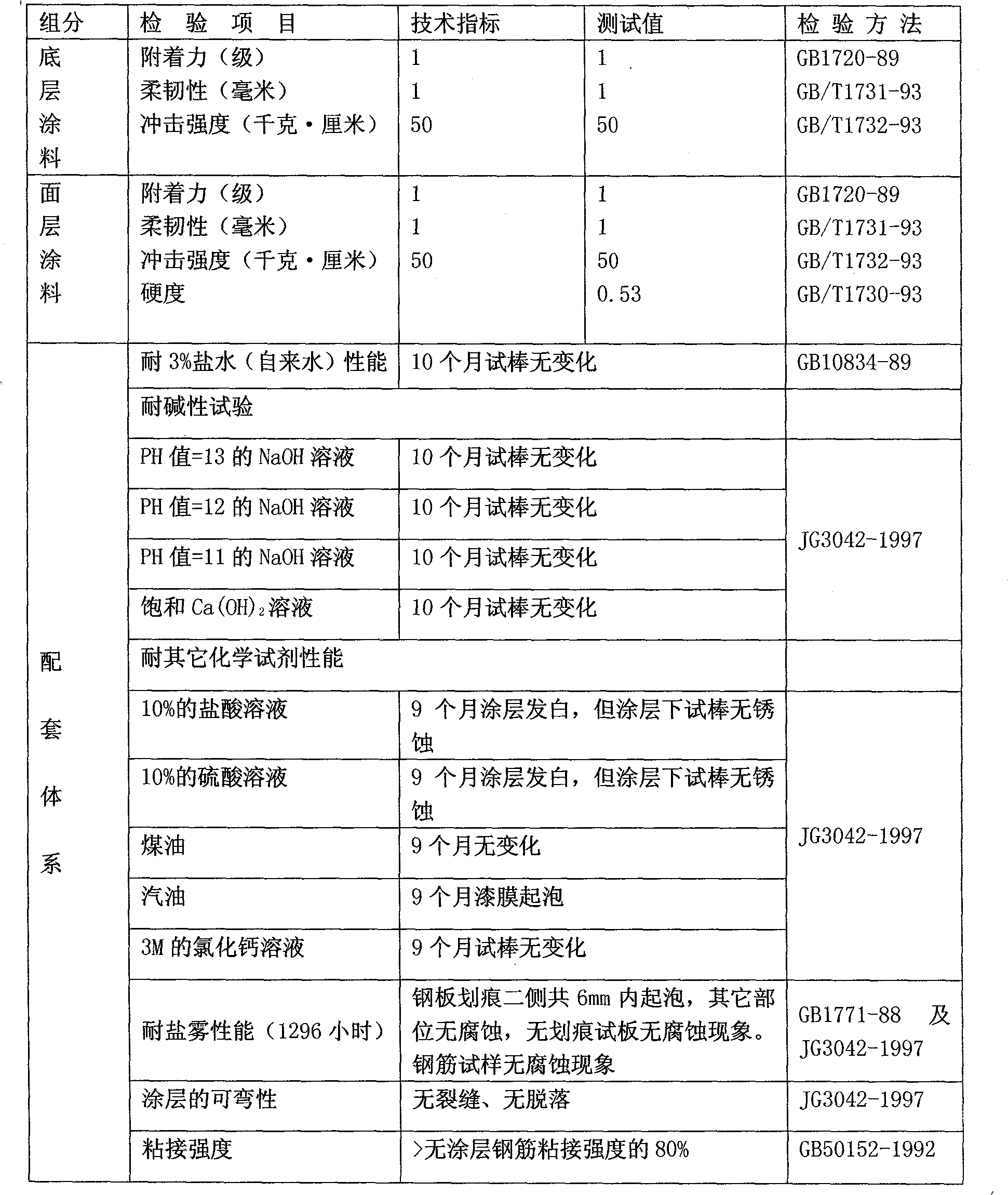

Anticorrosive coating for concrete structure reinforcing bars and preparation method thereof

InactiveCN101671515AImprove adhesionGood flexibilityAnti-corrosive paintsPolyamide coatingsEpoxyCoating system

The invention relates to an anticorrosive coating cured at the room temperature and used for concrete structure reinforcing bars and a preparation method thereof. The coating system comprises a priming paint and a finish paint, wherein the priming paint and the finish paint respectively comprise a component A and a component B which are used in a mixed manner; the component A in the priming paintcomprises the following components in parts by weight: 1:10-30 parts of epoxy resin by weight, 2:5-15 parts of epoxy resin by weight, 30-55 parts of pigment and filler by weight, 0.5-1 part of additive by weight and 20-40 parts of solvent by weight; the component A in the finish paint comprises the following components in parts by weight: 1:10-30 parts of epoxy resin, 2:5-10 parts of epoxy resin,10-30 parts of pigment and filler by weight, 10-30 parts of glass flakes by weight, 0.2-1 part of additive by weight and 20-40 parts of solvent by weight; and the component B of the priming paint andthe component B of the finish paint are the same and are at least one of fatty amine, aromatic amine and polyamide. The coating can be cured at the room temperature, the cured coating has good adhesion, impermeability, alkali resistance, saltfog resistance and wear resistance, can effectively prevent the reinforcing bars in concrete from rusting and further prolongs the service life of the reinforcing bars.

Owner:REAR SERVICE TECH EQUIP INST NAVY PLA

Porous petroleum fracturing propping agent and preparation method thereof

ActiveCN105038758AGood lookingImprove water absorptionFluid removalDrilling compositionManganeseFracturing fluid

The invention provides a porous petroleum fracturing propping agent and a preparation method thereof, and belongs to the technical field of oil-gas well fracturing in oil exploitation. The porous petroleum fracturing propping agent is prepared from bauxite fine powder, bentonite, manganese powder, silicon carbide fine powder, kyanite fine powder and activated alumina fine powder. Compared with an existing medium-density petroleum fracturing propping agent, the porous petroleum fracturing propping agent has the advantages that particles of the roasted propping agent have more opening pores by adopting silicon carbide as a pore forming agent, more scale inhibitors can be accommodated in the propping agent since the porous structure is capable of providing a space structure to portability of the scale inhibitors, and generation of well scale is prevented or reduced by means of slow release of the scale inhibitors after the propping agent and fracturing fluid are pumped into the well by high pressure. Furthermore, the porous petroleum propping agent has a rather low volume density, and the low-density propping agent can be used for overcoming the defect that the fracturing fluid and the propping agent are blocked to flow deep to the rock crack since a high-density propping agent easily forms moundy accumulation at the port of the rock crack, so that the yield of an oil-gas field can be increased.

Owner:洛阳赛罗帕陶瓷科技有限公司 +1

Super-hard middle-chrome cast grinding ball and production process thereof

InactiveCN103060667ARefined grain sizeReduce in quantityFurnace typesQuenching agentsRare earthManganese

The invention discloses a super-hard middle-chrome cast grinding ball which consists of the following chemical ingredients: 1.8-3.0% of carbon, 0.3-1.5% of silicon, 0.2-1.5% of manganese, 7.0-10.0% of chrome, 0.02-0.1% of phosphorus, 0.02-0.1% of sulfur, 0.02-0.1% of copper, 0.02-0.1% of molybdenum, 0.02-0.1% of nickel, 0.02-0.1% of tungsten, 0.1-0.2% of rare earth yttrium and 80.1-87.2% of iron. The rare earth yttrium is adopted for evolution inoculation treatment, so that a carbide is changed in shape and distribution, furthermore a net is broken, and meanwhile crystal grains are refined, the texture is compact and the flexibility is improved. By adopting an oil medium annealing and tempering thermal treatment process, eutectic carbide with martensite with the broken net is obtained, the hardness of the middle-chrome grinding ball is HRC60-69, and the toughness and the abrasion resistance of a high-chrome grinding ball are remarkably improved. On premise that the abrasion resistance and the crushing resistance of the grinding ball are further improved, the content of the noble metal chrome is reduced, and relatively the manufacturing cost of the grinding ball is lowered, and significant social benefits are achieved.

Owner:NINGGUO ZHONGYI WEAR RESISTANT MATERIALS

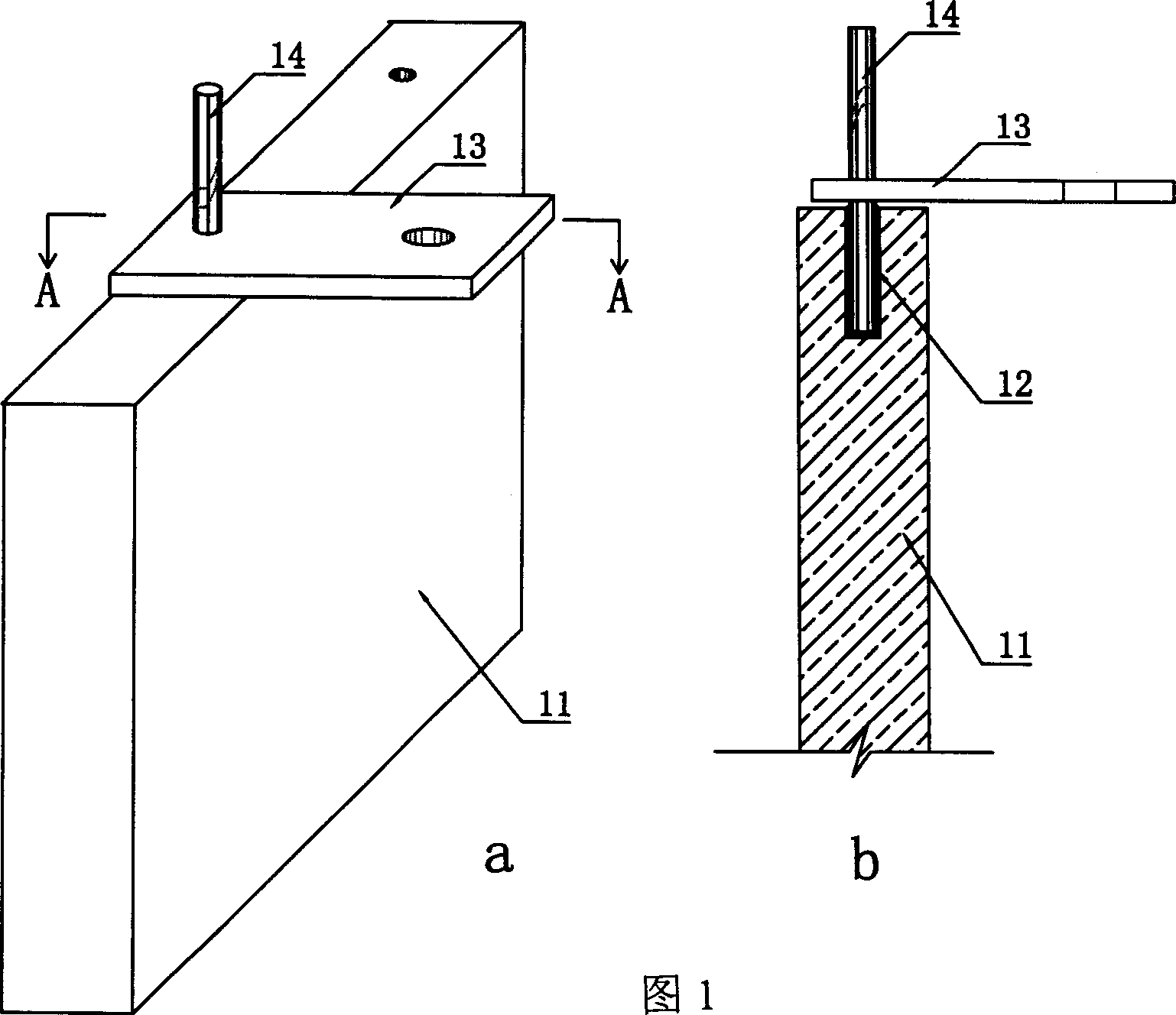

Gas-blowing and slag-gathering spray gun for assisting slag-off of molten iron and using method of spray gun

ActiveCN103114177AReduce wear rateReduce wearCharge manipulationCasting cleaning apparatusSlagEngineering

The invention discloses a gas-blowing and slag- gathering spray gun for assisting slag-off of molten iron and a using method of the spray gun. The gas-blowing and slag-gathering spray gun comprises a gun barrel, wherein the gun barrel is provided with an opening end and a closed end; spray ports are symmetrically formed on the barrel wall, close to the closed end, of the gun barrel based on the middle axis of the gun barrel; the middle axes of the spray ports are vertical to the middle axis of the gun barrel; and the ratio of the inner diameters of the spray ports to the inner diameter of the gun barrel is (0.35-0.70):1. The gas-blowing and slag-accreting spray gun has the characteristics of being simple in structure, long in service life, stable in gas-blowing and slag-accreting operation and the like. The gas-blowing and slag-gathering spray gun disclosed by the invention is combined with the using method of the spray gun, so that the molten iron slag gathering degree can be improved, the bare area of the molten iron is increased, the erosive wear to the molten iron tank wall is small, the slag-off iron loss is low and the slag-off time is short.

Owner:武汉钢铁有限公司

High-temperature walking beam furnace beam and column insulation lining slag-adhesion-preventing coating

The invention discloses a high-temperature walking beam furnace beam and column insulation lining slag-adhesion-preventing coating. The coating comprises the raw materials of, by weight: 55-60% of the bauxite clinker, 5-10% of magnesium aluminate spinel, 5-10% of calcined anthracite, 2-5% of flake graphite, 3-6% of silicon carbide, 4-6 % of alpha-Al2O3 powder, 4-6% silica micro-powder, 5-7% of calcium aluminate cement, 0.5-1.5% of metal silicon powder, 2.5-3.5% of water-soluble epoxy resin and water-soluble curing agent, 0.05-0.10% of explosion-proof fiber, 0.1-0.15% of sodium hexametaphosphate, 0.05-0.10% of an organic reducing agent, and 0. 04-0.07% of an organic silane coupling agent. With the slag-adhesion-preventing coating, the comprehensive targets are achieved, that service lives of the furnace beam and the column insulation lining are prolonged, furnace energy consumption and insulation lining surface slag adhesion amount are reduced, furnace maintenance cost is reduced, and high-temperature-oriented silicon steel production efficiency is improved.

Owner:武汉钢铁有限公司

Cemented Carbides

InactiveUS20080276544A1Avoid grain growthHigh hardnessPigmenting treatmentOther chemical processesIron groupAlloy

The present invention provides a cemented carbide with superior strength and toughness by refining the WC in the alloy uniformly and by restricting the growth of coarse WC efficiently. In this cemented carbide, WC with a mean particle diameter of no more than 0.3 microns serves as a hard phase and at least one type of iron group metal element at 5.5-15 percent by mass serves as a binder phase. In addition to this hard phase and binder phase, this cemented carbide contains 0.005-0.06 percent by mass of Ti, Cr at a weight ratio relative to the binder phase of at least 0.04 and no more than 0.2, with the remaining portion being formed from inevitable impurities. In particular, this cemented carbide does not contain Ta.

Owner:SUMITOMO ELECTRIC IND LTD +1

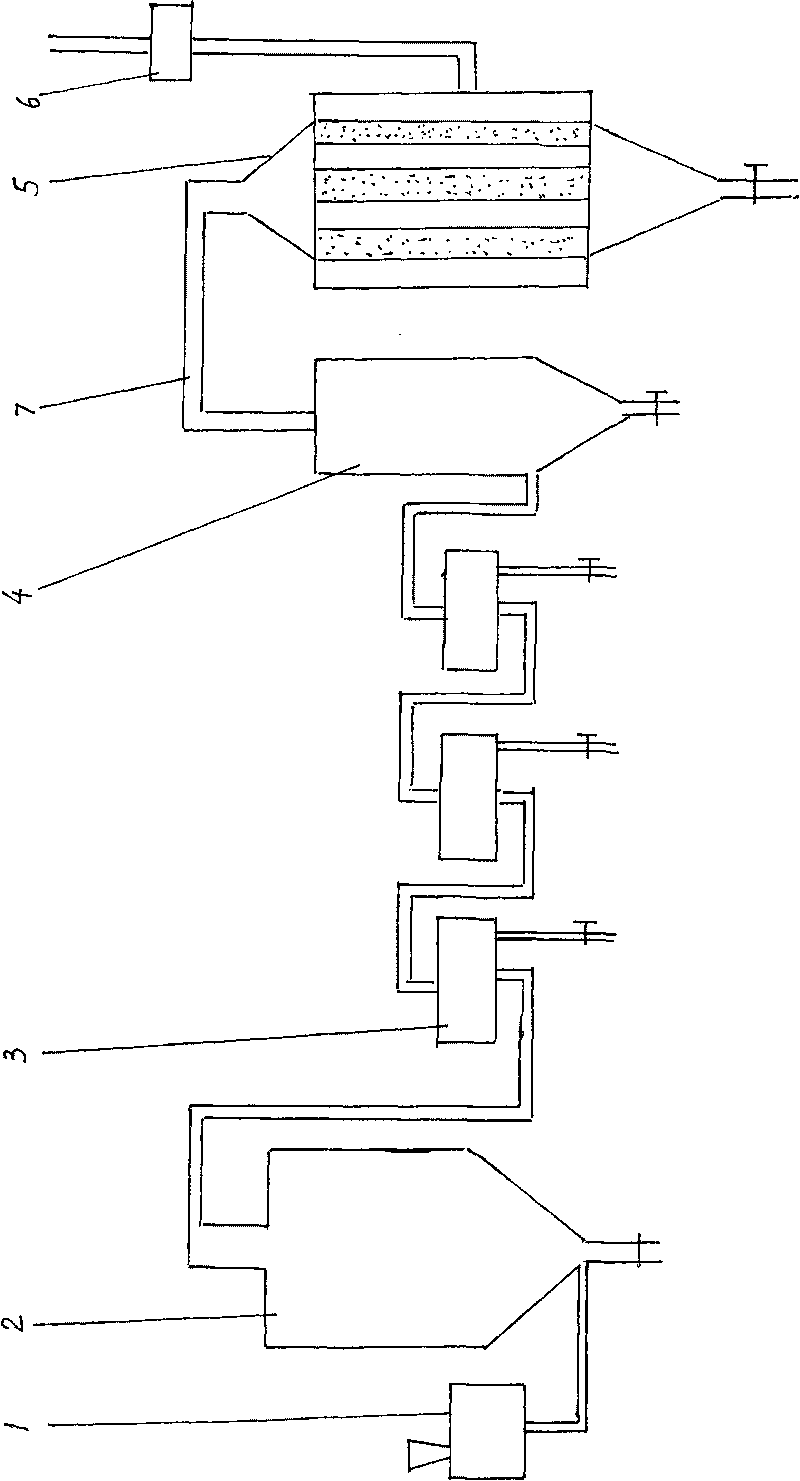

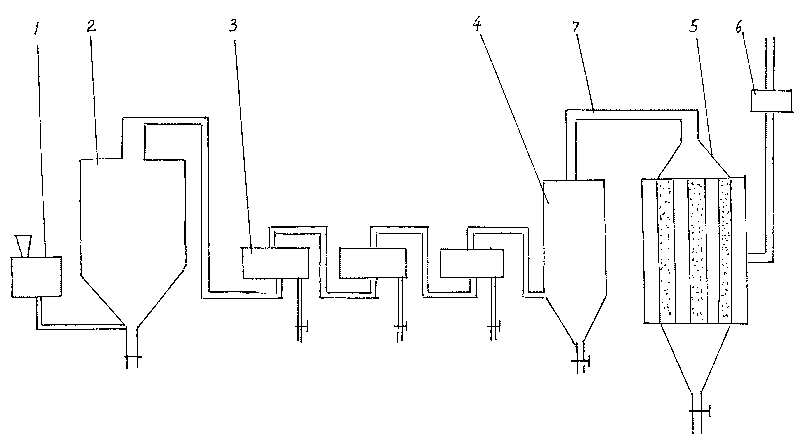

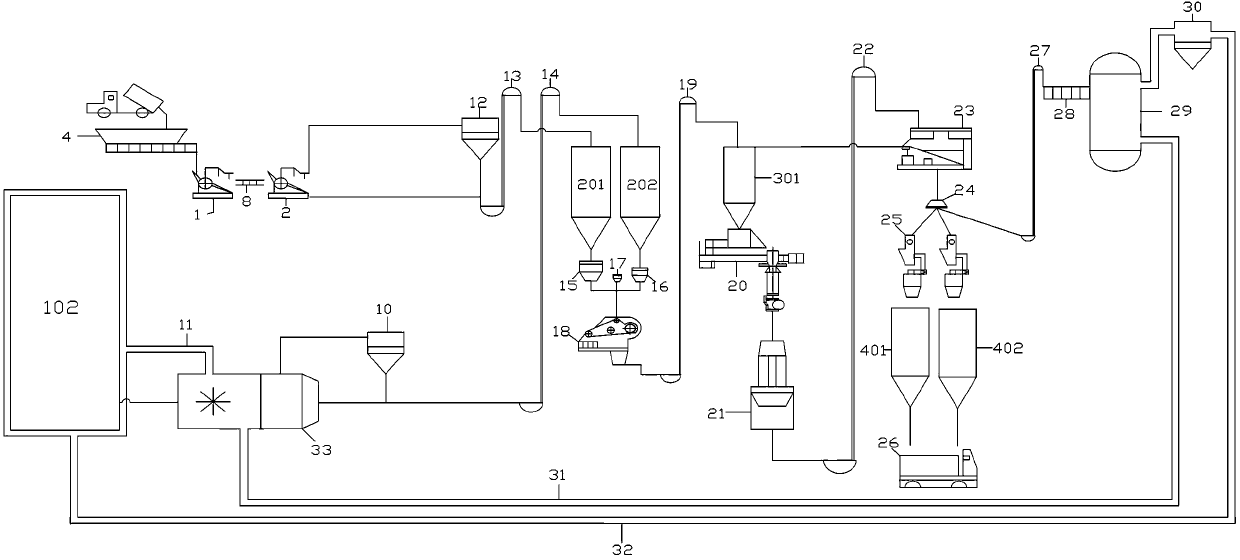

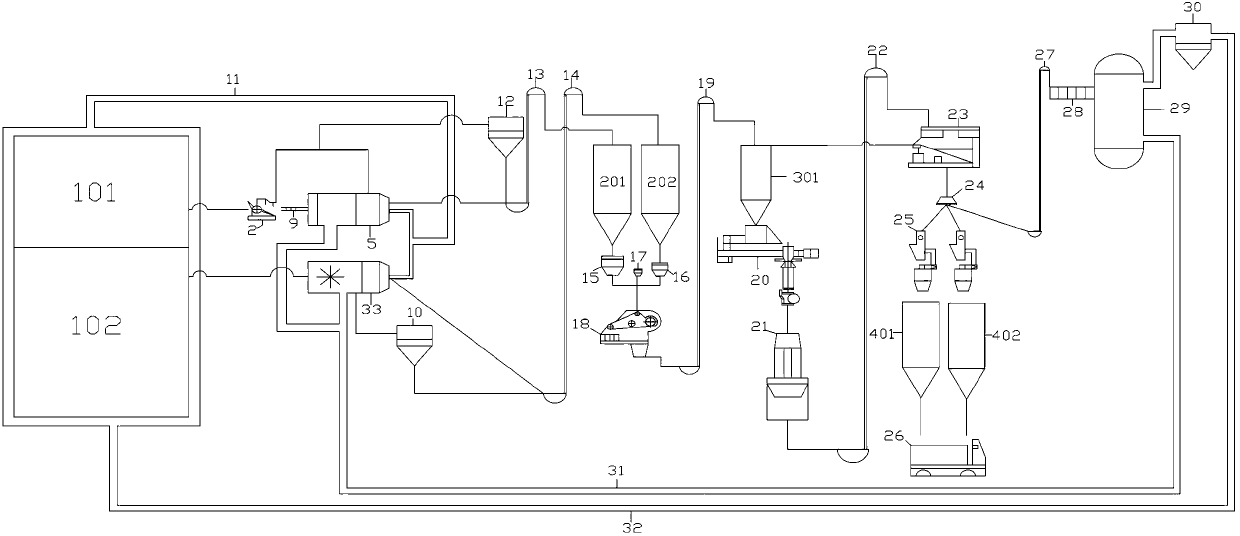

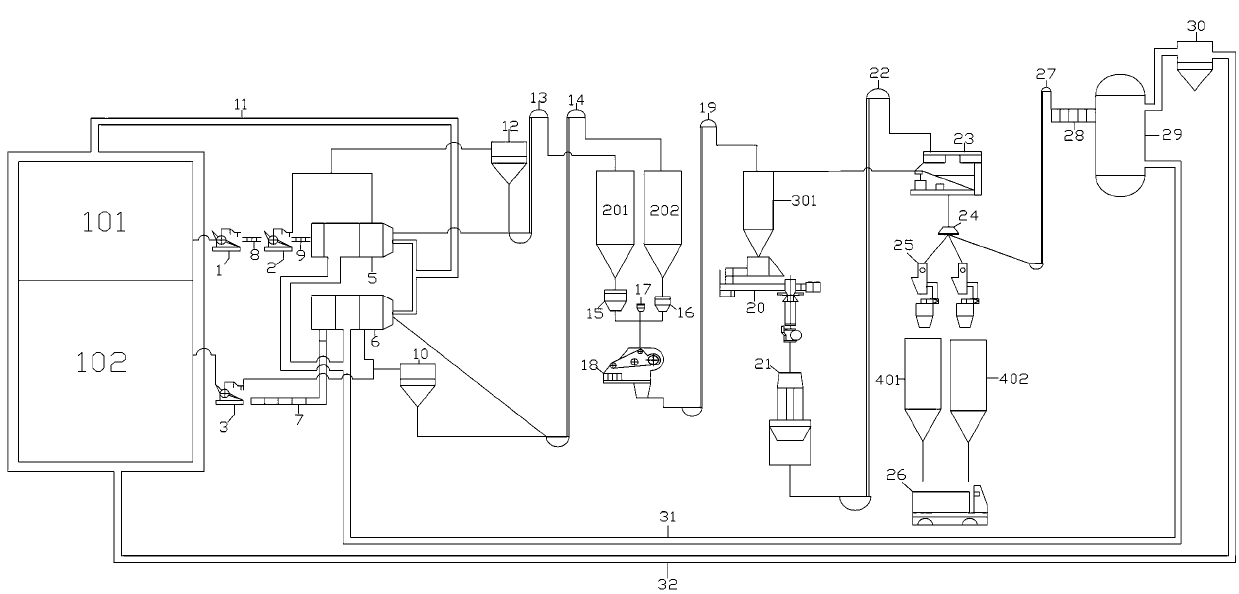

Process method and process system for preparing solid fuel through biomass and sludge

The invention discloses a process method and a process system for preparing solid fuel through biomass and sludge. The method comprises the step of mixing biomass dried raw materials with sludge dried raw materials which are aired, ground and dried to obtain the solid fuel, wherein sludge airing energy is one or the combination of any two or three of solar energy, waste gas generated by drying sludge raw materials and high-temperature fume generated by combusting the solid fuel, and sludge raw material drying energy is high-temperature and high-pressure steam generated by combusting the solid fuel. The system comprises a raw material treatment system, a molding system and a boiler system, wherein the raw material treatment system and the boiler system transfer heat energy to each other through first, second and third gas delivery pipelines. According to the method, the cost is low, the effect is good, environmental protection is realized and the solid fuel is suitable for large-scale production. The system is resource-saving and stable to operate.

Owner:东莞市图美环保科技有限公司

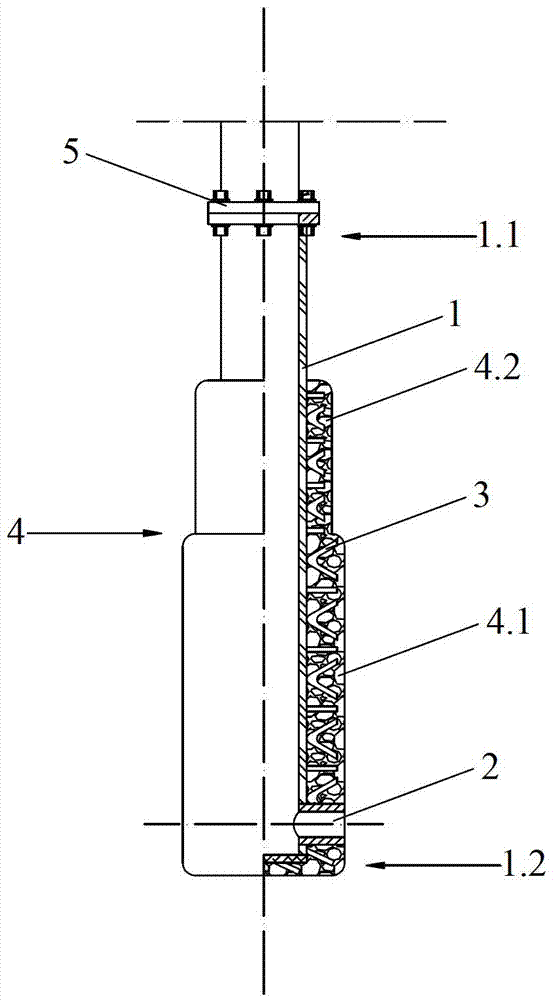

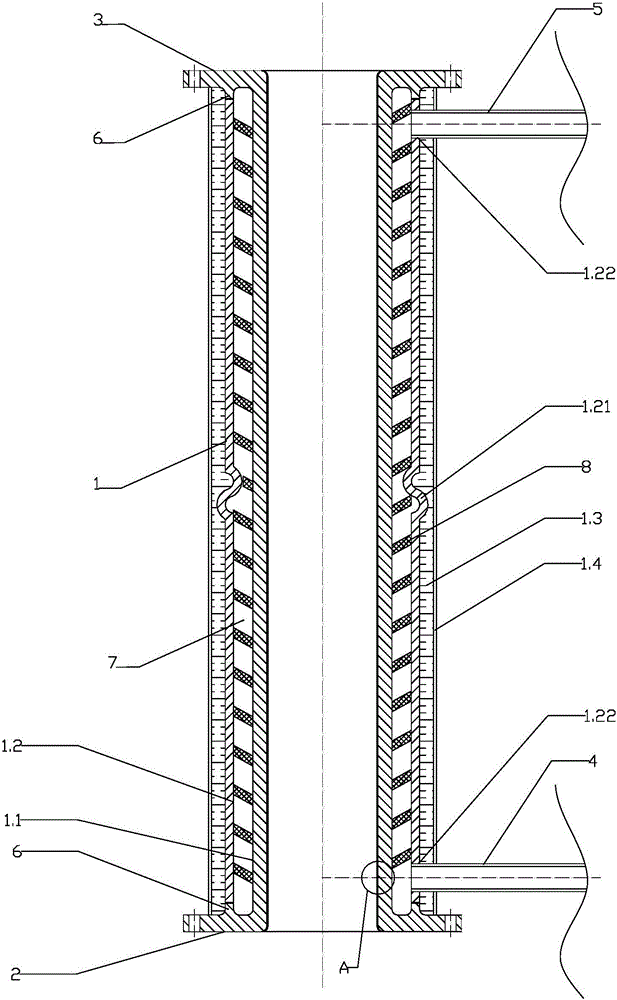

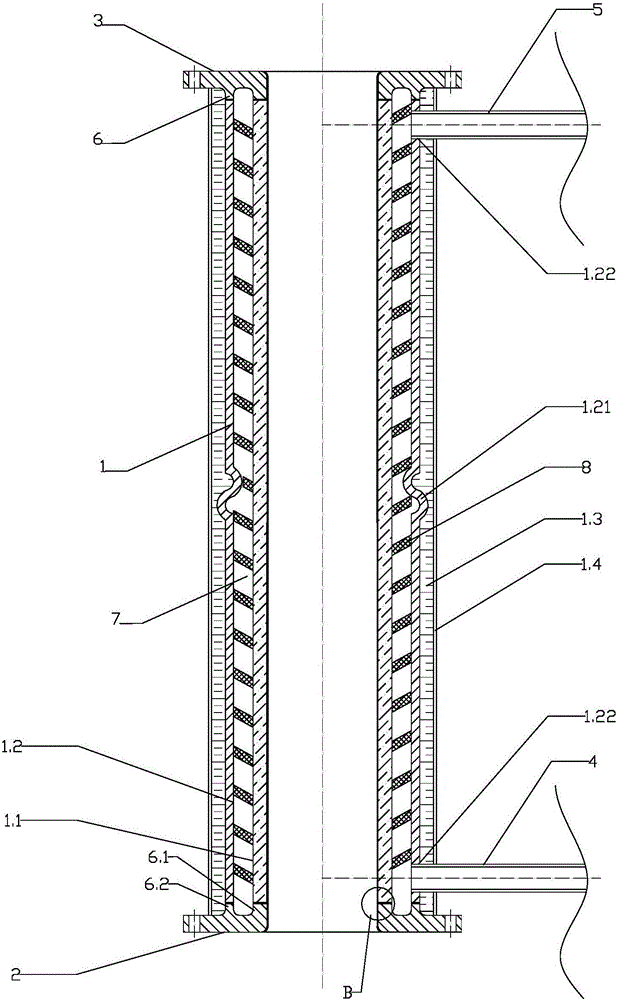

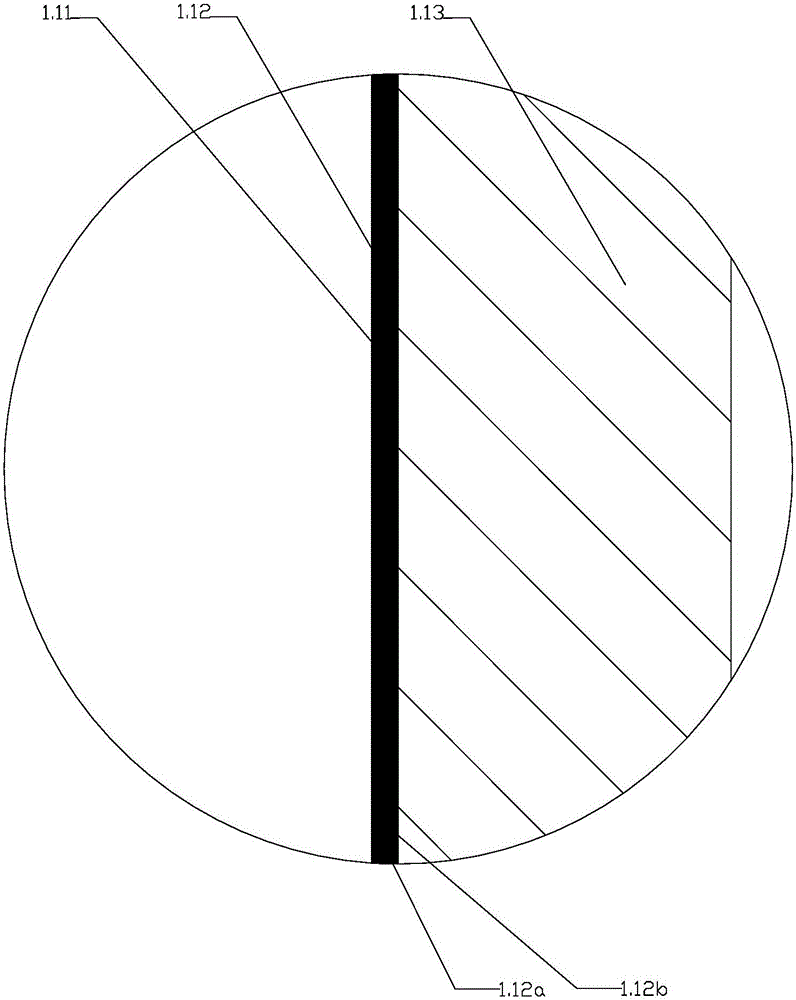

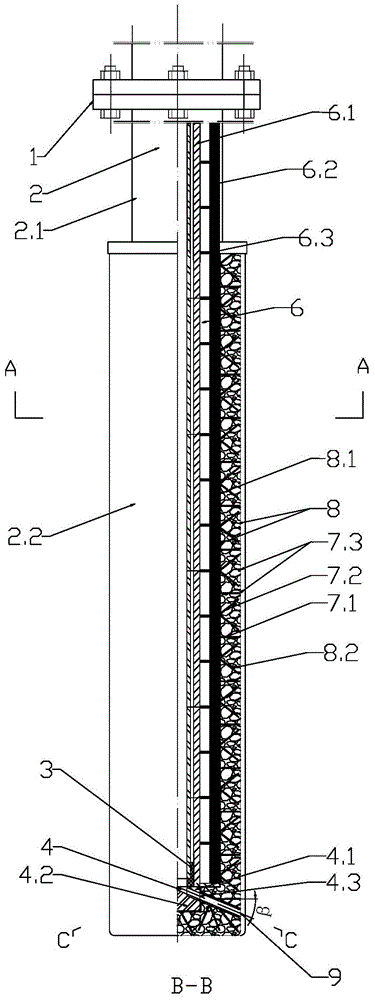

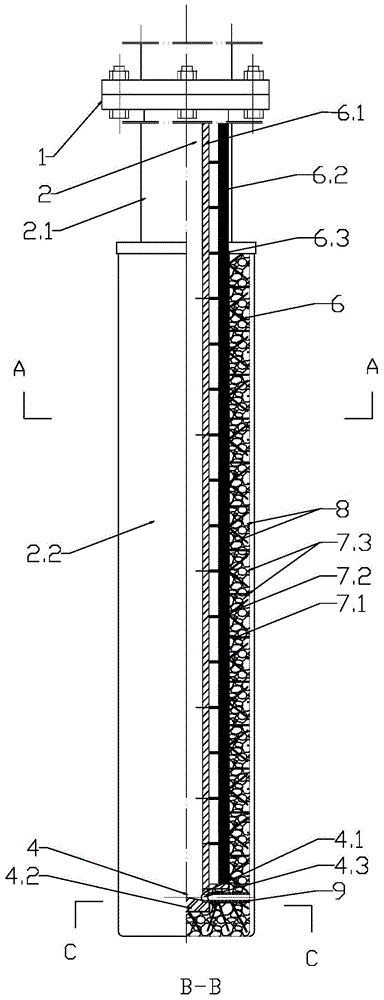

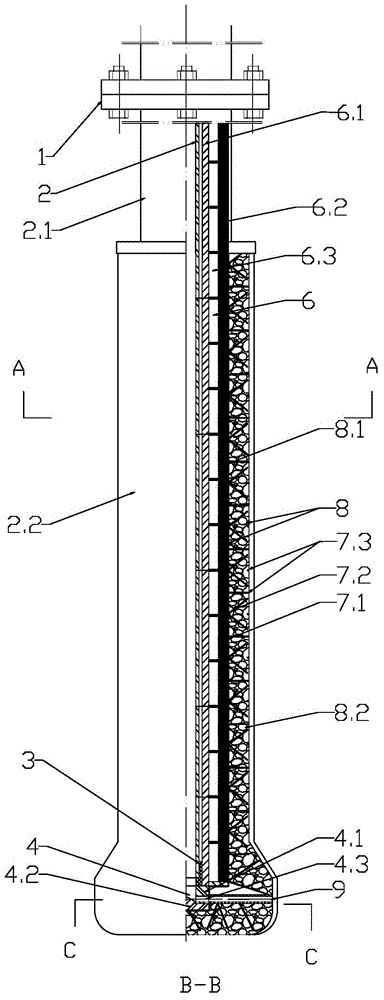

Coke oven ascension pipe raw gas evaporative cooling device and preparation method thereof

InactiveCN105043117APrevent oxidationAvoid carburizationIncreasing energy efficiencyWaste heat treatmentEngineeringCoke oven

The invention discloses a coke oven ascension pipe raw gas evaporative cooling device and a preparation method thereof. The device comprises a cooling pipe, a raw gas inlet flange and a raw gas outlet flange, wherein the raw gas inlet flange and the raw gas outlet flange are connected with the two ends of the cooling pipe respectively. The cooling pipe is sequentially composed of an inner sleeve, an outer sleeve, a heat preservation layer and a protection layer from inside to outside. Through holes are formed in the two ends of the side wall of the outer sleeve respectively. A water inlet steel pipe is installed on the through hole close to the raw gas inlet flange. A vapor outlet steel pipe is installed on the through hole close to the raw gas outlet flange. An annular expansion joint section is arranged at the portion, between the water inlet steel pipe and the vapor outlet steel pipe, of the outer sleeve. The high temperature structural strength and high temperature breakage resistant capacity of the cooling device are remarkably improved, the heat transfer behavior of the pipe wall of the inner sleeve of the cooling device is improved, the radial temperature distribution of the pipe wall is optimized, the efficient function coordination of multiple layers of materials is achieved, and the comprehensive use performance of the inner sleeve is improved; the aim of long-term efficient and stable running of the ascension pipe raw gas evaporative cooling device is finally achieved.

Owner:武汉钢铁有限公司

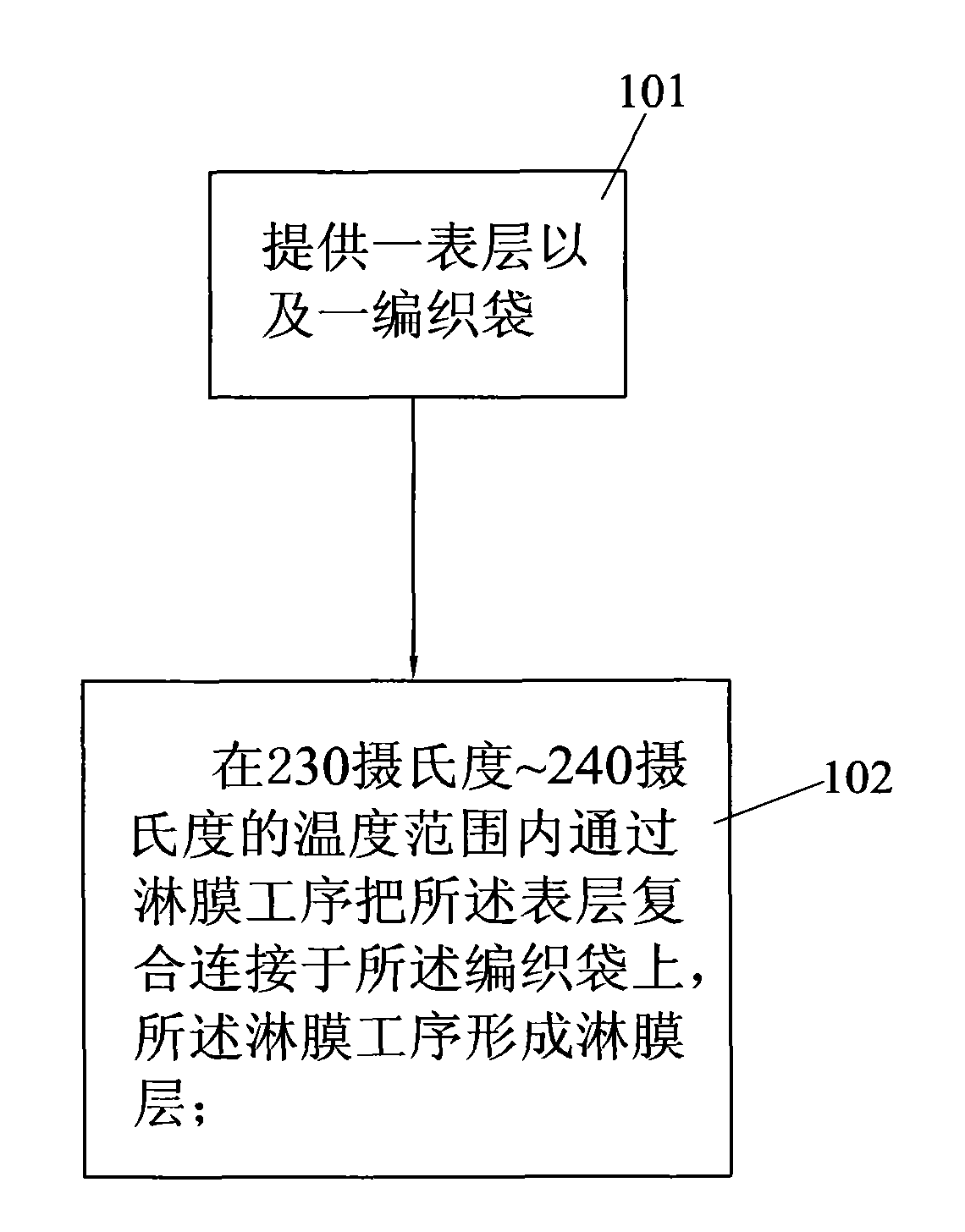

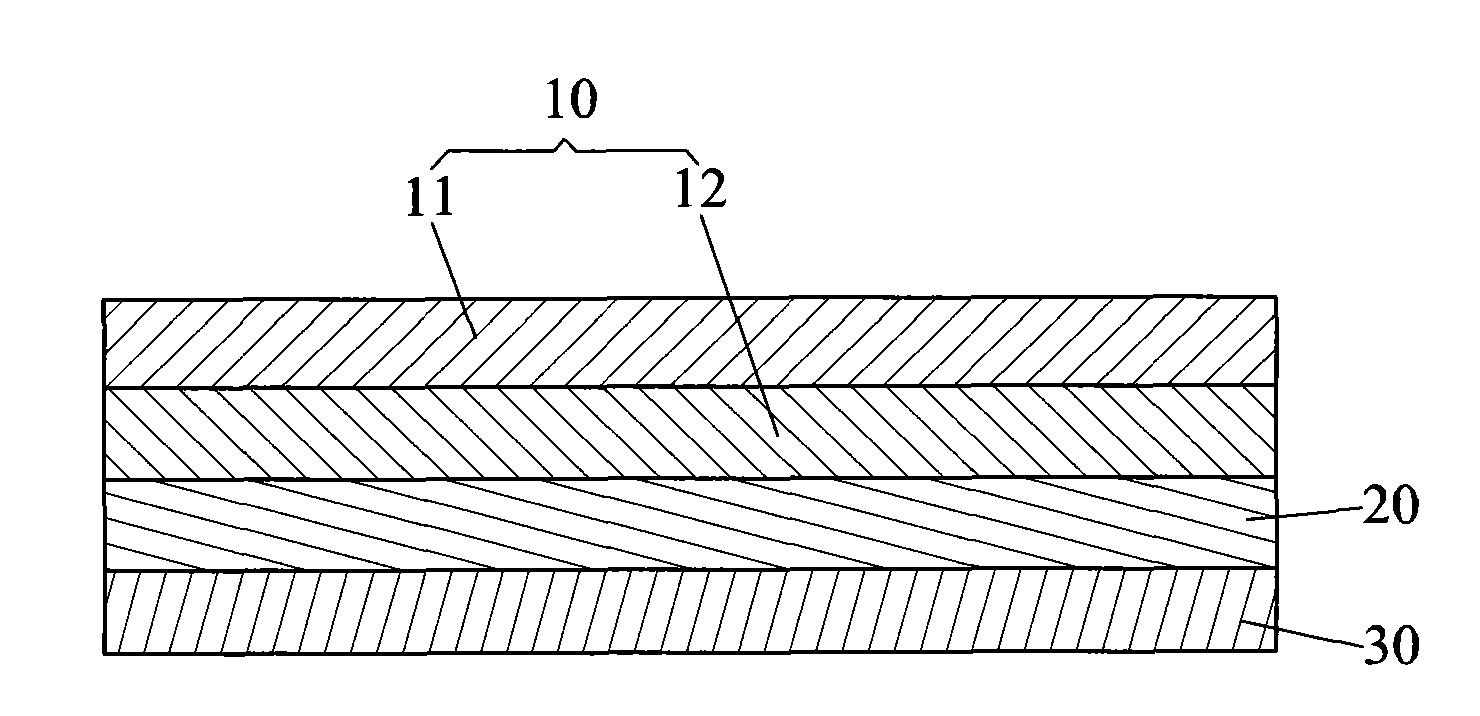

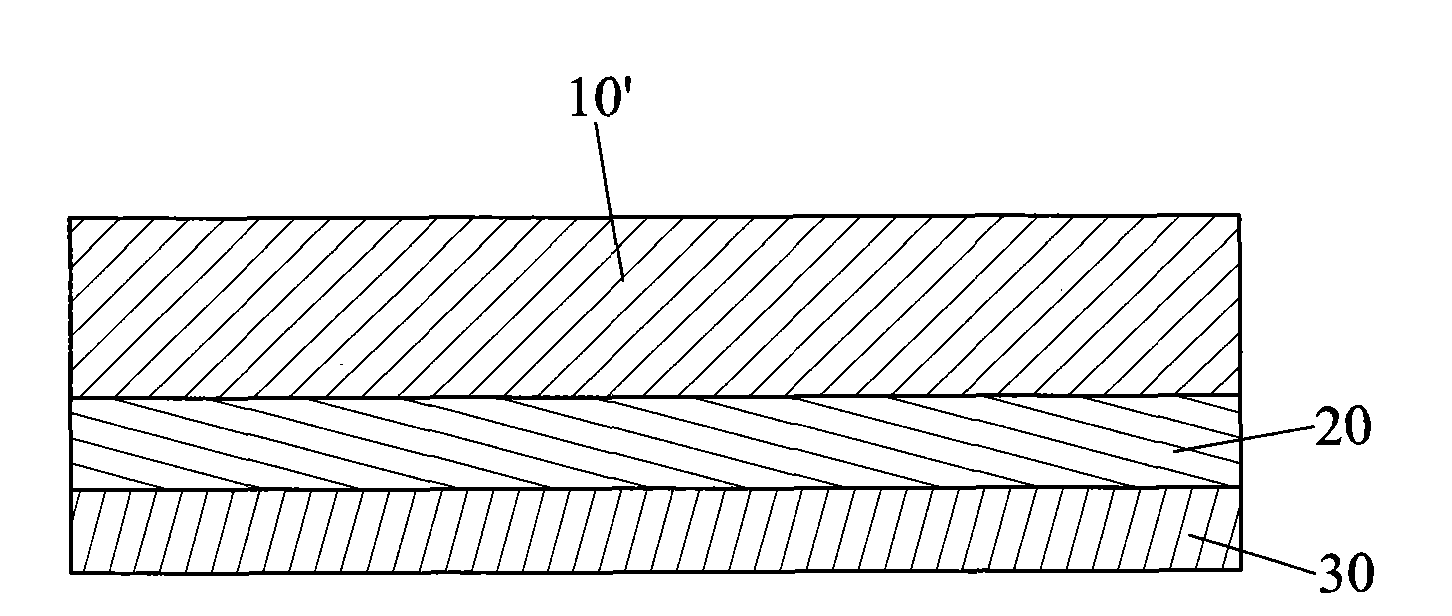

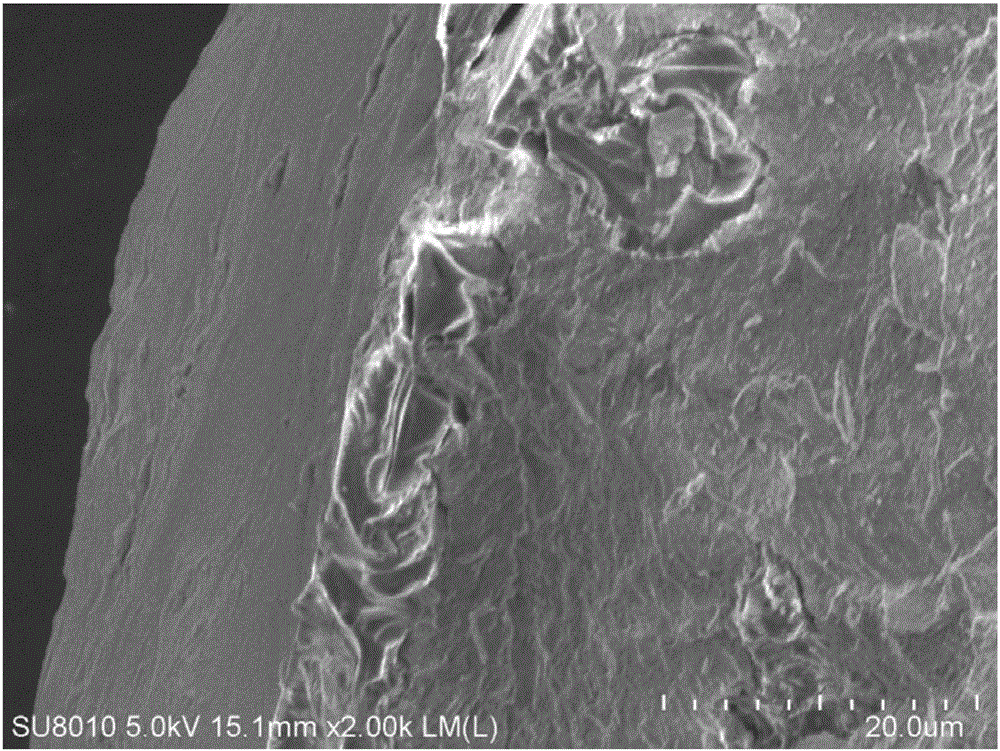

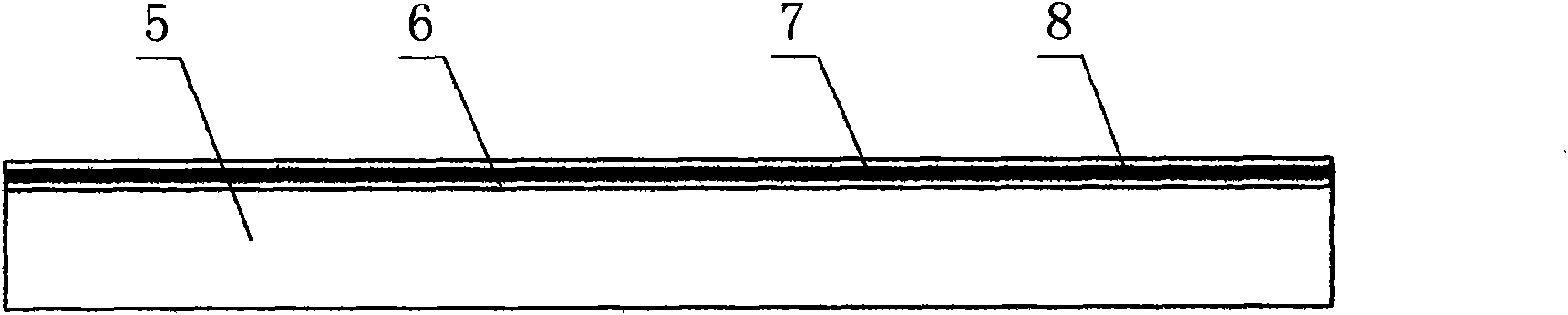

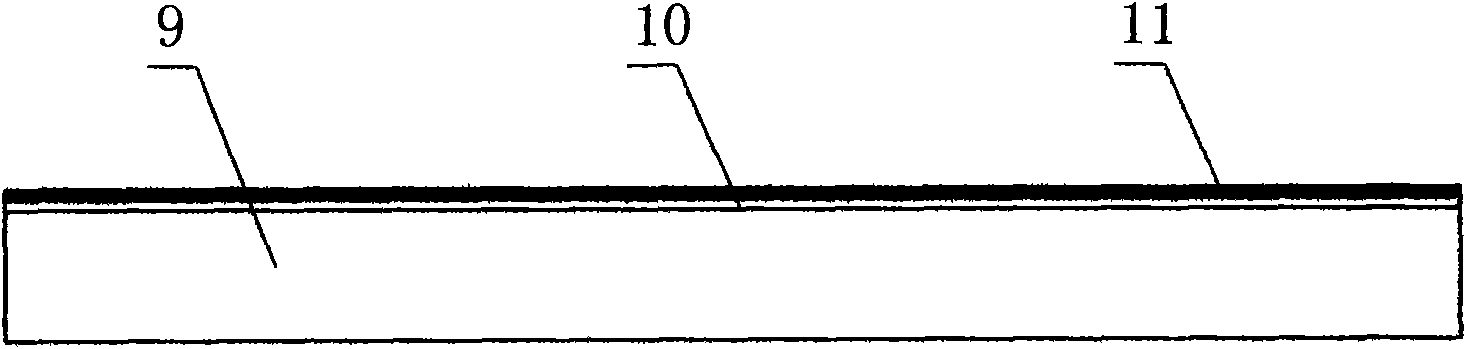

Manufacturing method of composite package

InactiveCN101954756AImproves breakage resistanceImprove melt indexContainer making machinerySurface layerPolymer science

The invention discloses a manufacturing method of composite packages, which comprises the following steps of providing a surface layer and a woven bag; compounding and connecting the surface layer to the woven bag through a filming procedure in the range of 230 DEG C to 240 DEG C, wherein filming materials used in the filming procedure comprises modified polypropylene and special polyethylene for filming, and the polypropylene contains a molecular weight regulator and other assistants; thus, the melt index of the filming materials is improved so as to improve the fluidity, promote to film at lower temperature, flatten the surfaces of the packages and improve the anti-break capability of the packages.

Owner:东莞市长盈塑料编织包装有限公司

Super-low density ceramic proppant and preparation method thereof

ActiveCN105131933AHigh strengthImproves breakage resistanceFluid removalDrilling compositionFracturing fluidManganese

The invention discloses a preparation method of a super-low density ceramic proppant and the proppant prepared by using the method. The proppant provided by the invention is obtained through the following steps: in a preparation process, taking bauxite, coal ash and clay as an inner core, adding an inner core pore-forming material, taking bauxite, coal ash and manganese ore powder as a shell, and performing pelletizing, sintering and screening. The invention provides a low-density higher-intensity proppant which can adapt to stratums with medium and high closing pressure, effectively reduces the running cost of oil field auxiliary equipment, reduces the consumption of fracturing fluid, alleviates the damage of the fracturing liquid to the stratums, and brings huge economic benefit for an oil field.

Owner:辽宁隆源砂业有限公司

Ultralow-density proppant and preparation method thereof

InactiveCN105062461AHigh strengthLow costFluid removalDrilling compositionPrecipitationPhenol formaldehyde resin

The invention relates to an ultralow-density proppant and a preparation method thereof. The proppant comprises porous ceramisite and resin films covering the porous ceramisite, wherein the porous ceramisite is obtained by mixing, granulating and calcining raw materials, and the raw materials comprise, in parts by weight, 65-94 parts of fly ash, 1-5 parts of potash feldspar, 1-3 parts of manganese powder and 2-30 parts of SiC micropowder; the resin film comprises epoxy resin on the inner layer and phenolic resin on the outer layer. The preparation method comprises steps as follows: the raw materials are uniformly mixed, granulated by a sugarcoating machine, dried and sintered at the high temperature, and the porous ceramisite is prepared and immersed in the epoxy resin diluent, a ceramsite immersion body is obtained and coated with the phenolic resin, and the ultralow-density proppant is obtained. The granularity of the proppant ranges from 20 meshes to 40 meshes, the acid resistance is good, the apparent density is as low as 1.70 g / cm<3>, the breakage rate under the pressure of 52 MPa is smaller than 4.0%, the density is low, precipitation is not easily caused, the proppant can be easily taken into a well, the use quantity of the proppant can be effectively reduced, and the fracturing construction cost is reduced.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Propping agent for resin coating film and preparation method thereof

InactiveCN102899019AImprove yieldImprove the separation effectFluid removalFilm coatingFilm-coated tablet

The invention discloses a propping agent for a resin coating film and a preparation method thereof. The propping agent comprises an aggregate, a resin, a curing agent and a dispersing agent, wherein the dosage of the resin is 1%-10% of the weight of the aggregate; the dosage of the curing agent is 0.5%-5% of the weight of the aggregate; and the dosage of the dispersing agent is 0.2%-2% of the weight of the aggregate. The propping agent for the resin coating film provided by the invention has the functions of allowing oil gas to smoothly penetrate and preventing water from penetrating through the propping agent, so that the separating effect of oil gas and water is enhanced by the functions and the oil extraction cost is lowered; due to the excellent hydrophobic property of the resin film, the propping agent has excellent water resistance, the anti-breaking capability of the propping agent is increased and the long-term flow-guiding effect is good; a triple film coating technology is adopted by the invention and the calcium stearate is taken as a dispersing agent, so that the quality is greatly increased, the yield is increased to above 80%, the cost is greatly lowered and the production efficiency is increased; and the preparation method provided by the invention is simple, the product yield is high and the breakage rate of the product is obviously reduced.

Owner:YIXING TENGFEI OIL FRACTARING PROPPANT

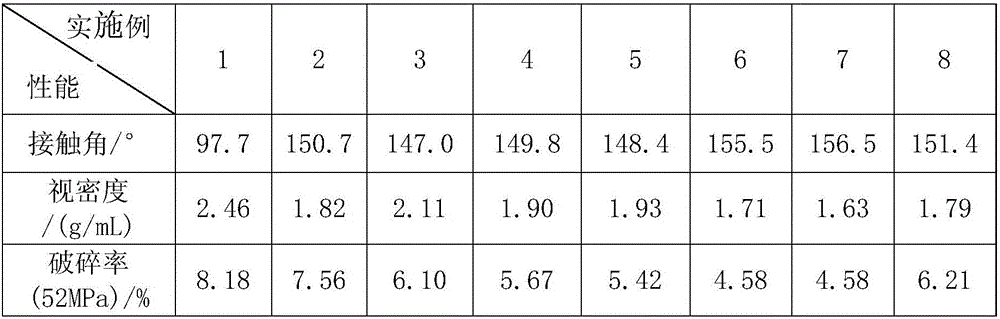

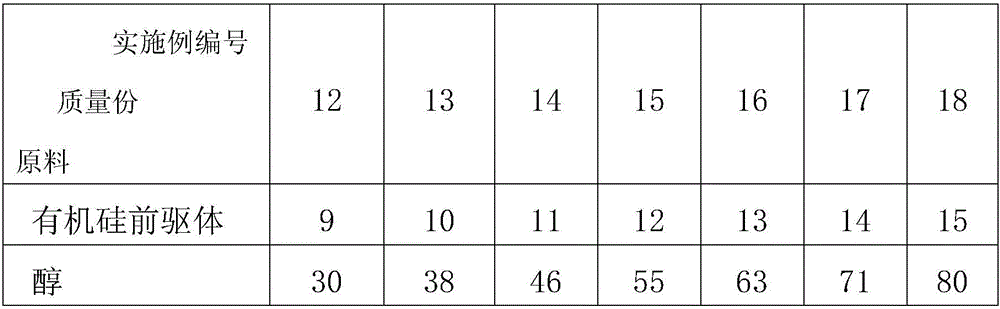

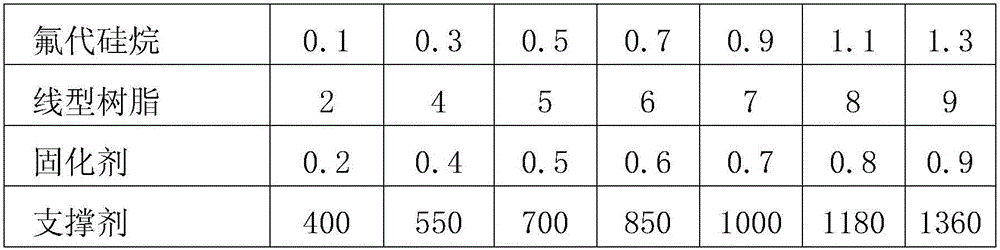

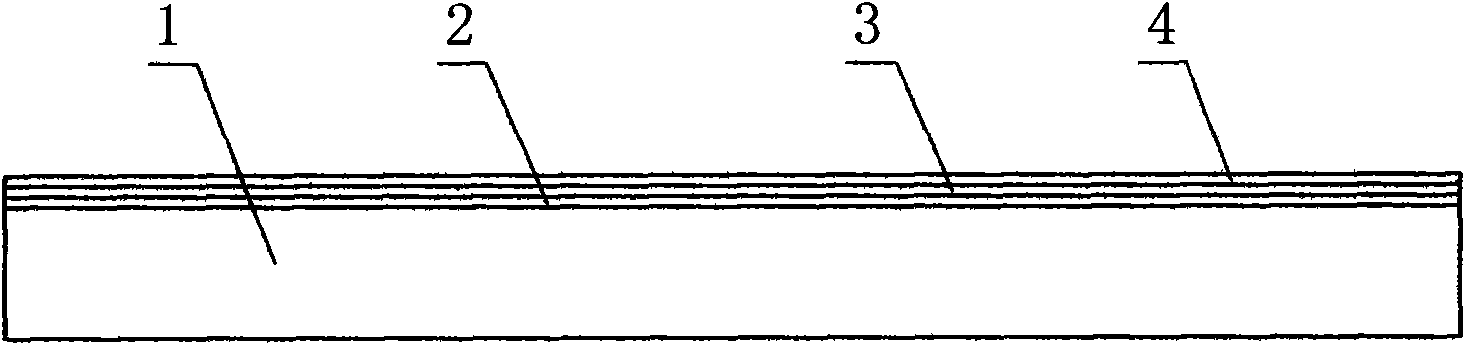

Preparation method of propping agent coated with superhydrophobic polymeric membrane

ActiveCN106147744AReduce contact areaAdhesionFluid removalDrilling compositionAlcoholShale oil and gas

The invention discloses a preparation method of a propping agent coated with a superhydrophobic polymeric membrane. The preparation method is characterized by comprising the steps that an organosilicone precursor and alcohol are mixed, the pH value is regulated to be 12-13 through alkali liquor, reacting is conducted for 0.5-5 h at the temperature of 30 DEG C to 70 DEG C, and then fluorosilane is added for reacting; liquor obtained after reacting and linear resin are mixed, and the temperature of the mixed liquor is increased to 70 DEG C to 100 DEG C; a curing agent is added, after the mixed liquor and a propping agent are mixed to be cured for 1-3 h at the temperature of 90 DEG C to 120 DEG C, curing is conducted for 1-3 h by increasing the temperature to 150 DEG C to 200 DEG C, and then the propping agent coated with the superhydrophobic polymeric membrane is prepared. According to the preparation method, the contact angle between the surface of the prepared polymeric membrane and water is larger than 150 degrees, the hydrophobicity of the surface of the propping agent can be greatly improved, the propping agent modified with the polymeric membrane serves as a key material of a hydrofracture technique, the exploitation quality of shale oil and gas can be improved, the exploitation yield of the shale oil and gas can be increased, and the practicability is high.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Ultraviolet light solidified glue film glass

The invention relates to ultraviolet light solidified glue film glass which comprises glass, oligomer, reactive diluent, photoinitiator, stabilizer, levelling agent and antifoaming agent, and a glass surface or a glass filming surface is sprayed or printed with a layer or a plurality of layers of ultraviolet light solidifying glue. After ultraviolet irradiation, an ultraviolet light solidified glue film is formed on the glass surface or the glass filming surface.

Owner:王广武

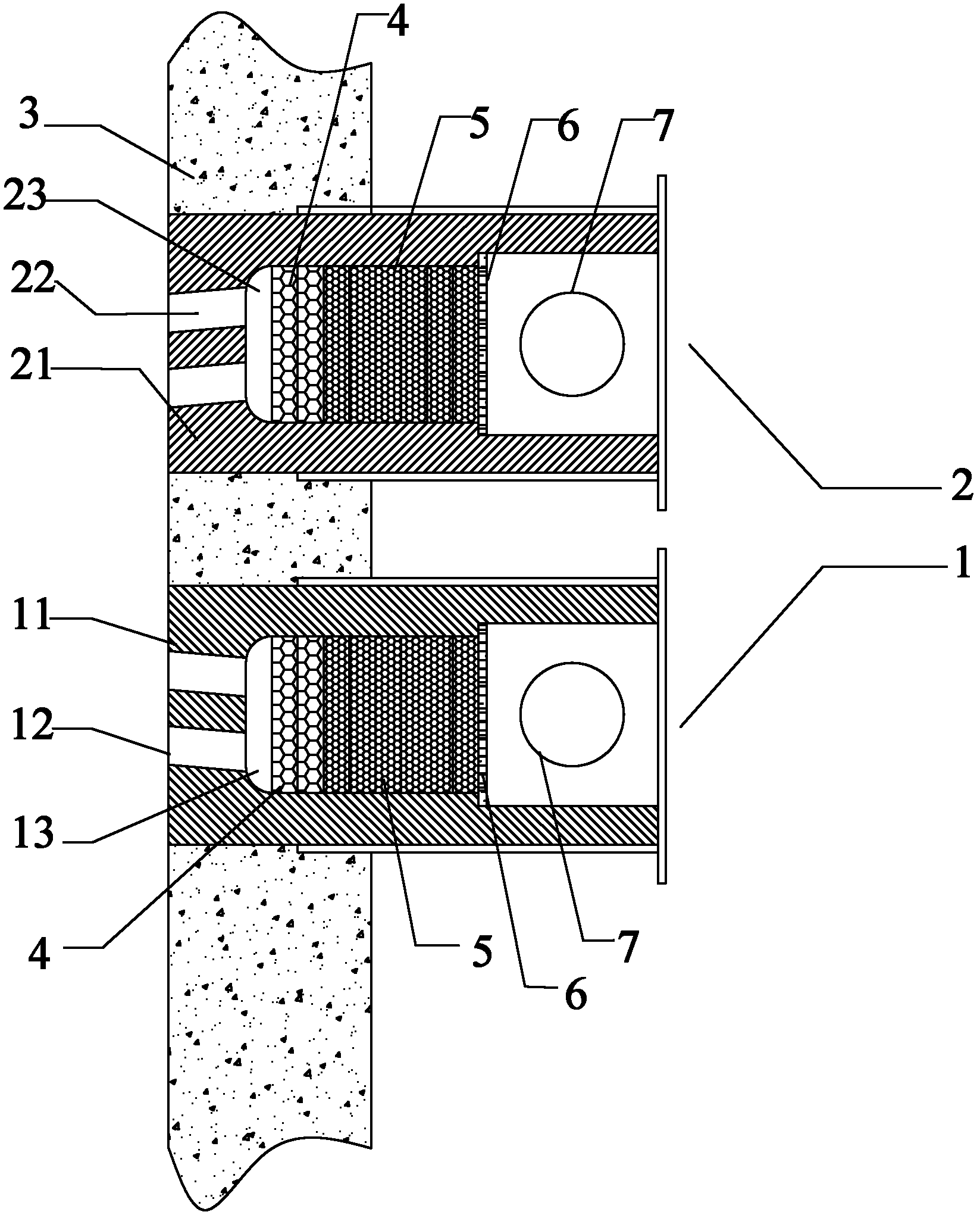

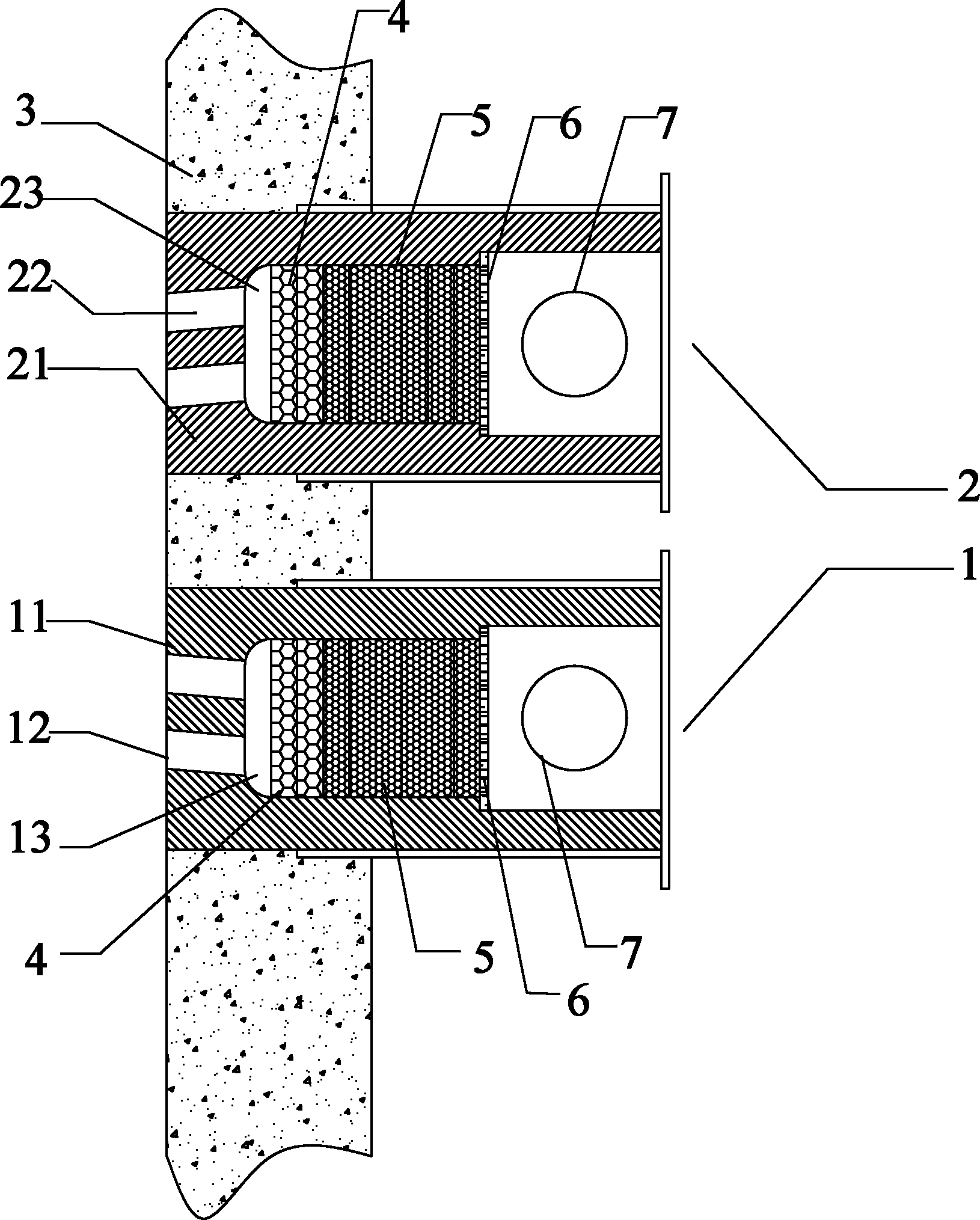

Double-regenerative combustor

InactiveCN102607030AImproves breakage resistanceReduce adverse effectsIndirect carbon-dioxide mitigationGaseous fuel burnerEngineeringHeating furnace

The invention discloses a double-regenerative combustor, which comprises a blast furnace gas burner and a combustion-supporting air burner which are embedded on the furnace wall in pair. The blast furnace gas burner and the combustion-supporting air burner comprises a blast furnace gas burner block and a combustion-supporting air burner block respectively, one end, leading to a furnace, of the blast furnace gas burner block is provided with gas burner nozzles, one end, leading to the furnace, of the combustion-supporting air burner block is provided with air burner nozzles, and the spaying directions of the nozzles inwardly incline to one another and form an included angle of 2-15 degrees relative to the horizontal plane. A gas burner block hollow cavity is arranged at one end, facing the outer side of the furnace wall, of the blast furnace gas burner block, an air burner block hollow cavity is arranged at one end, facing the outer side of the furnace wall, of combustion-supporting air burner block, and a thick-walled honeycomb ceramic heat accumulator, a conventional honeycomb ceramic heat accumulator, a metal barrier and a pipe connecting box are arranged on each of the gas burner block hollow cavity and the air burner block hollow cavity from inside to outside. By the means, the purposes of effectively delaying damage process of the double-regenerative combustor, greatly prolonging the service lives of the burner blocks, and improving usability of the double-regenerative combustor and thermal property of the heating furnace are finally achieved.

Owner:武汉钢铁有限公司

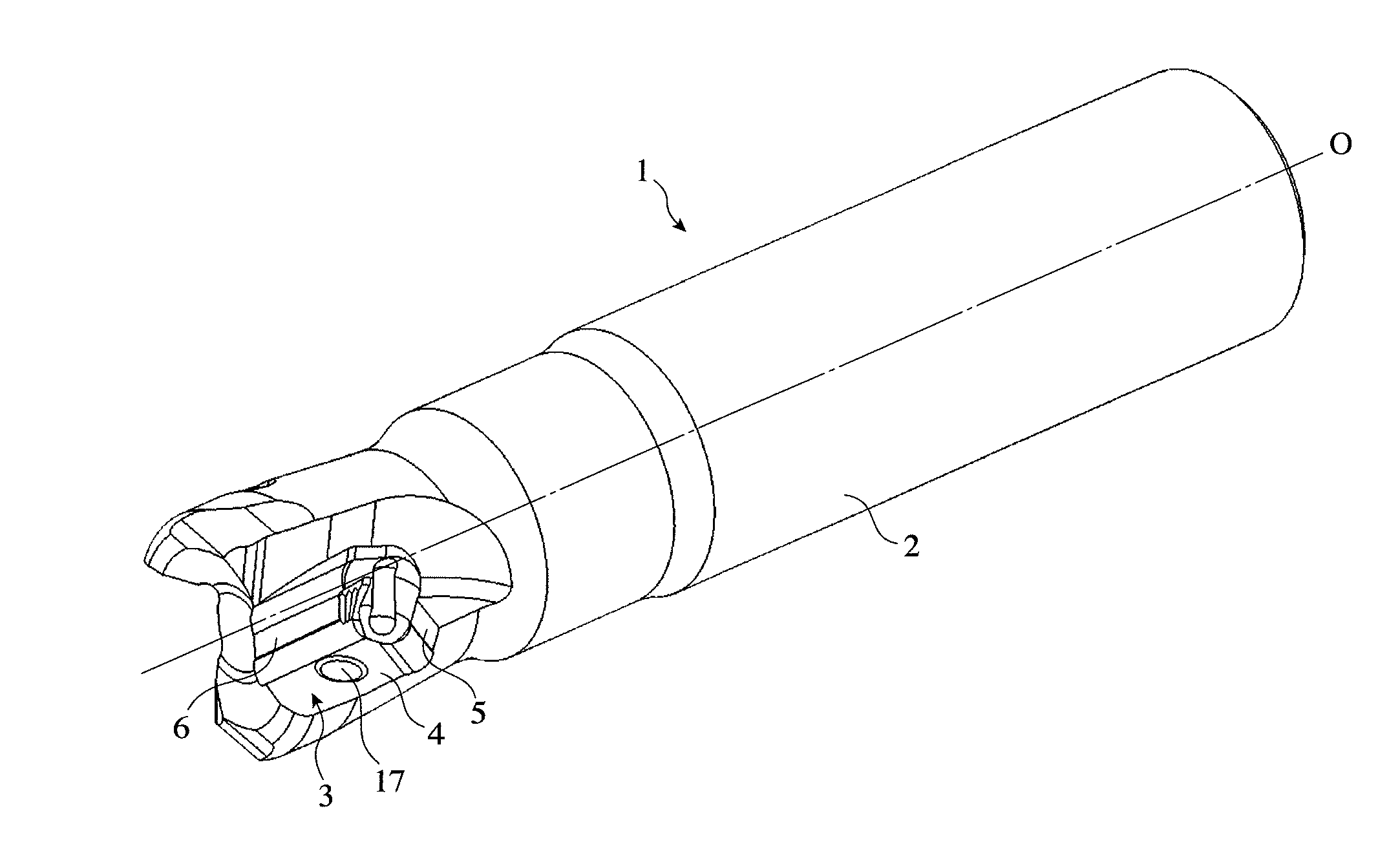

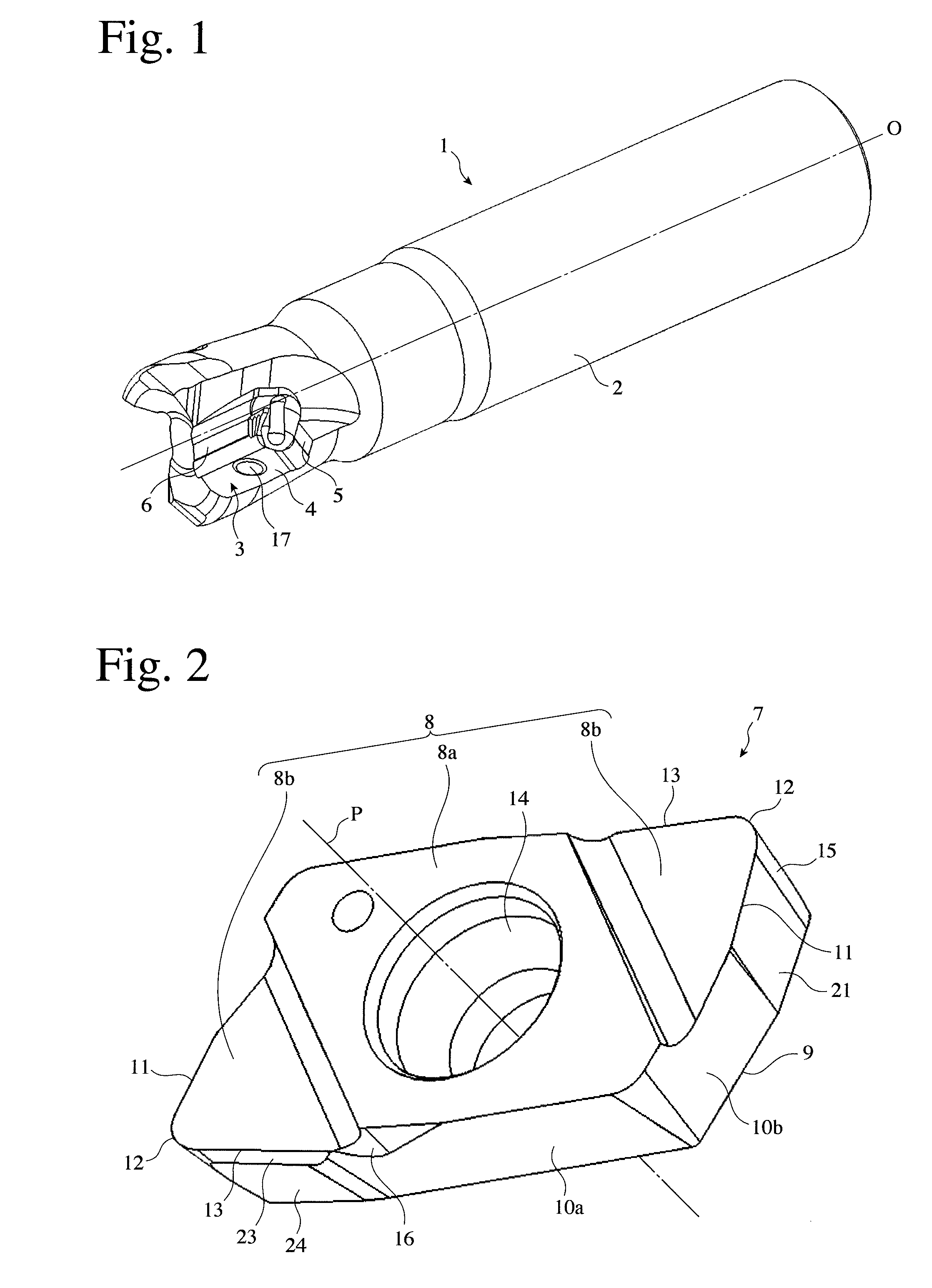

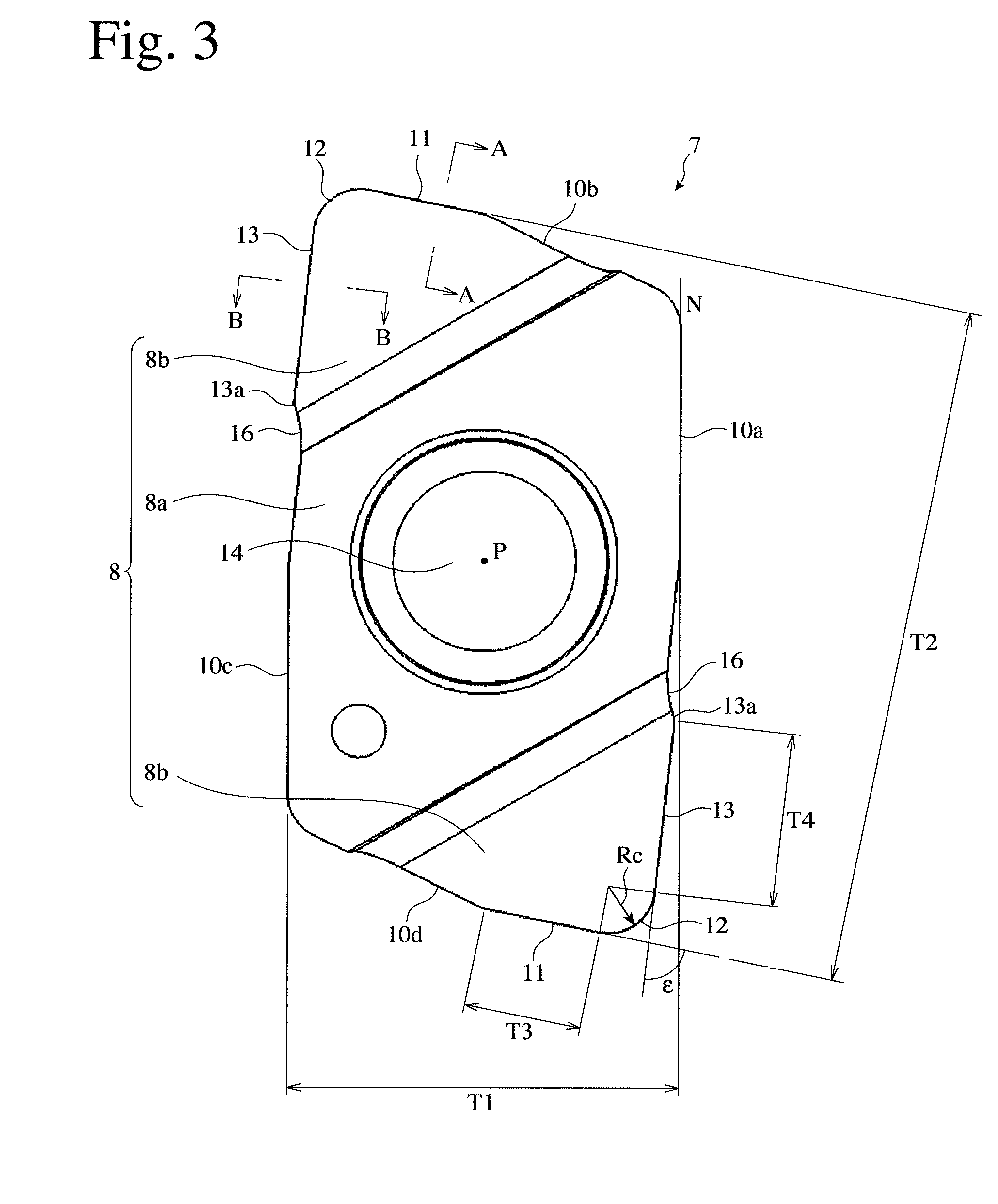

Indexable rotary cutting tool and insert used therein

ActiveUS20160214186A1Improves breakage resistanceImprove wear resistanceMilling cuttersMilling cutting insertsEngineeringMechanical engineering

An insert detachably attached to an indexable rotary cutting tool, comprising an upper surface having cutting edges along the ridgeline, a lower surface, side surfaces, and a center hole for a fastening screw; each cutting edge comprising a corner cutting edge formed in each acute corner portion, and a bottom cutting edge and a peripheral cutting edge formed along the ridgelines on both sides of the corner cutting edge; the bottom cutting edge and the peripheral cutting edge having different clearance angles; a flank of the corner cutting edge comprising an angle-changing surface portion having a clearance angle continuously changing in a region from the bottom cutting edge to the peripheral cutting edge; and the length of the peripheral cutting edge being restricted by a receding portion adjacent to an upper end of the peripheral cutting edge.

Owner:HITACHI TOOL ENG LTD

Direct injection molten iron desulphurization spray gun

The invention discloses a direct injection molten iron desulphurization spray gun for a metal particle magnesium or magnesium-based or calcium-based desulphurization agent. The direct injection molten iron desulphurization spray gun comprises a connecting flange and a gun barrel which are sequentially connected and communicated, wherein the gun barrel comprises a connecting section gun barrel and a gun body section gun barrel; the connecting section gun barrel comprises a gun core; a distributor is connected with the lower end of the gun core of the gun body section gun barrel; the distributor comprises an upper end short connecting pipe, a lower end plug platform and a plurality of through holes formed in the wall of the short connecting pipe; and each through hole is communicated with a jetting pipe, and the jetting pipes are distributed in a fire-proof pouring material liner positioned outside the side wall of the distributor. The direct injection molten iron desulphurization spray gun disclosed by the invention can be used for enhancing the jetting strength, extending the desulphurization reaction area and intensifying the gasification and dissolution of metal particle magnesium through structural design, and can be used for enhancing the adaptability on low-quality metal particle magnesium and jetting desulphurization of molten iron tanks with different sizes, extending the adaptive capacity of a process and reducing the consumption cost of the molten iron desulphurization metal particle magnesium through the improvement of desulphurization process steps.

Owner:武汉钢铁有限公司

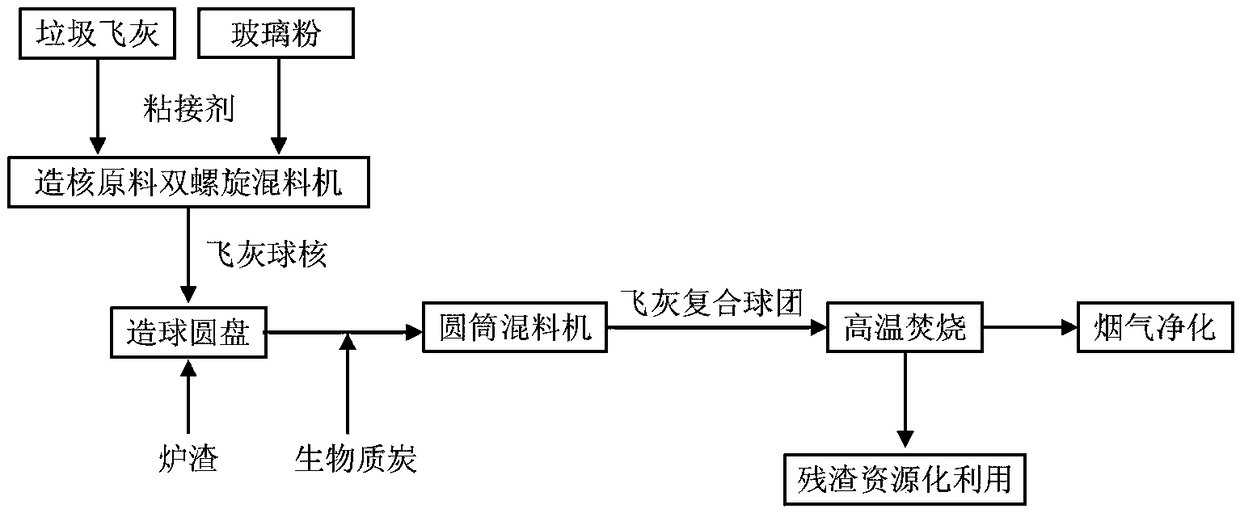

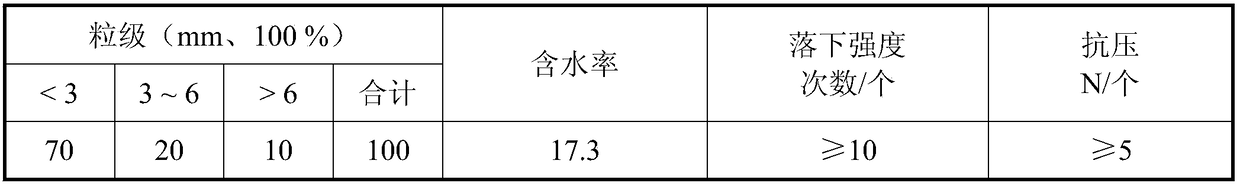

Garbage incineration fly ash high-temperature melting innocuous treatment process

ActiveCN109404916AShorten and simplify the balling processRealize nearby processingIncinerator apparatusBiomass carbonSlag

The invention relates to a garbage incineration fly ash high-temperature melting innocuous treatment process. The garbage incineration fly ash high-temperature melting innocuous treatment process comprises the steps that (1) garbage fly ash and glass powder are mixed to prepare fly ash ball cores; (2) fly ash composite pellets are obtained by adding slag to coat the surfaces of the ball cores; (3)the fly ash composite pellets are mixed with biomass carbon to obtain mixtures; and (4) the mixtures are directly accessed into an incineration device of an existing garbage incineration plant for high-temperature incineration, flue gas generated by incineration is purified by flue gas purification equipment of the garbage incineration plant, and incineration residue is subjected to residue treatment. According to the garbage incineration fly ash high-temperature melting innocuous treatment process, only the garbage fly ash and the glass powder are adopted to prepare the ball cores, the ballcores are coated with slag substances, and the obtained composite pellets are mixed with biomass carbon particles to form the mixtures, so that the ball forming process of the garbage fly ash is shortened and simplified, solid melting of heavy metals in the fly ash is facilitated, glass melts are formed, and leaching toxicity requirements are met; and meanwhile, the required equipment is less, andthe process is matched with the existing garbage incineration plant for implementation, so that nearby treatment of the garbage fly ash can be realized.

Owner:CHONGQING ANGRUIYUE SCI & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com