Ultralow-density proppant and preparation method thereof

An ultra-low density, proppant technology, applied in chemical instruments and methods, earthwork drilling, mining fluids, etc., can solve the problems of high density of ceramsite proppant, limited bauxite resources, high cost, and improve the anti-fragmentation. capacity, lower construction cost, good acid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

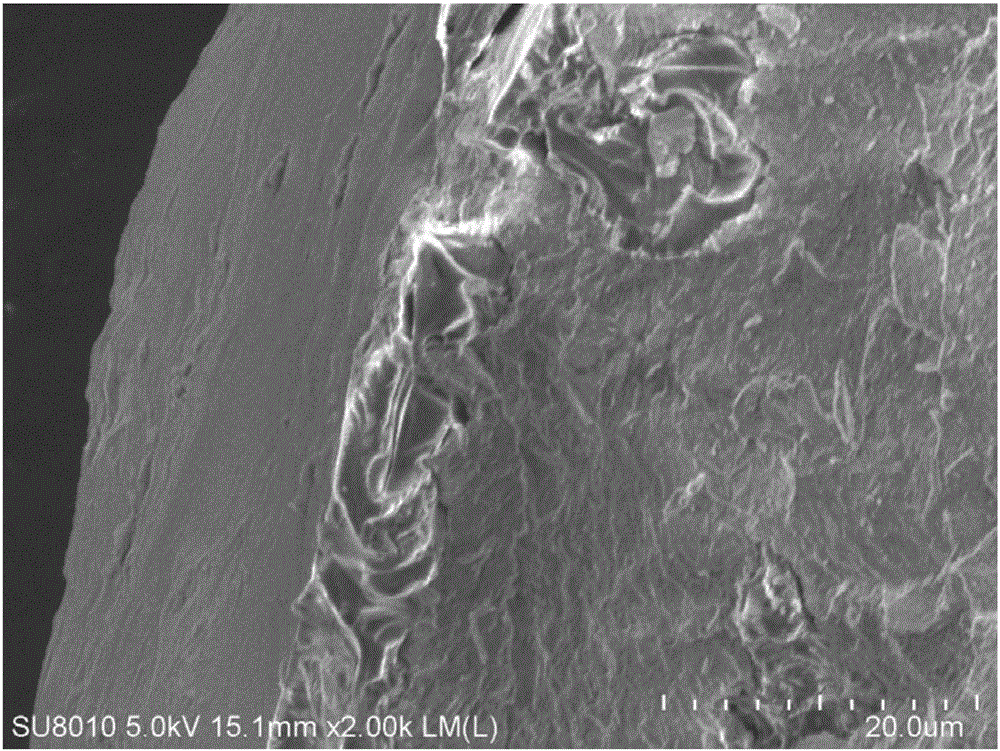

Image

Examples

Embodiment 1

[0029] A kind of ultra-low density proppant, preparation method is as follows:

[0030] (1) Preparation of ceramsite green body: mix the raw materials for preparing porous ceramsite evenly, put them into a granulator, add water to granulate, and sieve to obtain ceramsite green body. The method of adding water is to spray and add an appropriate amount of water to prepare porous ceramsite. The weight ratio of each component of the raw material is: 93 parts of fly ash, 5 parts of potassium feldspar, 2 parts of manganese powder, and 2 parts of SiC micropowder;

[0031] (2) Preparation of porous ceramsite: after drying the ceramsite green body obtained in step (1), calcining at 1300° C. for 2 hours, passing through a 20 / 40 mesh sieve to obtain porous ceramsite;

[0032] (3) Preparation of epoxy resin-coated ceramsite intermediate: After cleaning and drying the porous ceramsite obtained in step (2), take 100 g and modify it with a silane coupling agent solution, and immerse the poro...

Embodiment 2

[0035] A kind of ultra-low density proppant, preparation method is as follows:

[0036](1) Preparation of ceramsite green body: mix the raw materials for preparing porous ceramsite evenly, put them into a granulator, add water to granulate, and sieve to obtain a ceramsite green body. The weight ratio of the components is: 93 parts of fly ash, 5 parts of potassium feldspar, 2 parts of manganese powder, and 30 parts of SiC micropowder;

[0037] (2) Preparation of porous ceramsite: after drying the ceramsite green body obtained in step (1), calcining at 1200° C. for 3 hours, passing through a 20 / 40 mesh sieve to obtain porous ceramsite;

[0038] (3) Preparation of epoxy resin-coated ceramsite intermediate: After cleaning and drying the porous ceramsite obtained in step (2), take 100 g and modify it with a silane coupling agent solution, and immerse the porous ceramsite in the silane coupling agent solution, and stirred at 85°C for 10 hours, dried and added to 70g epoxy resin dil...

Embodiment 3

[0041] A kind of ultra-low density proppant, preparation method is as follows:

[0042] (1) Preparation of ceramsite green body: mix the raw materials for preparing porous ceramsite evenly, put them into a granulator, add water to granulate, and sieve to obtain a ceramsite green body. The weight ratio of the components is: 65 parts of fly ash, 3 parts of potassium feldspar, 2 parts of manganese powder, and 30 parts of SiC micropowder;

[0043] (2) Preparation of porous ceramsite: after drying the ceramsite green body obtained in step (1), calcining at 1220° C. for 3 hours, passing through a 20 / 40 mesh sieve to obtain porous ceramsite;

[0044] (3) Preparation of epoxy resin-coated ceramsite intermediate: After cleaning and drying the porous ceramsite obtained in step (2), take 100 g and modify it with a silane coupling agent solution, and immerse the porous ceramsite in the silane coupling agent solution, and stirred at 85°C for 10 hours, dried and added to 80g epoxy resin di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com