Method for producing green silicon carbide FEPA F P

A green silicon carbide, production method technology, applied in chemical instruments and methods, wet separation, other chemical processes, etc., can solve the problem of reducing anti-shredding ability and grinding efficiency, poor physical and chemical properties of particle surface, poor antistatic effect, etc. problem, to achieve the effect of enhancing anti-shredding ability, excellent particle shape and good affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

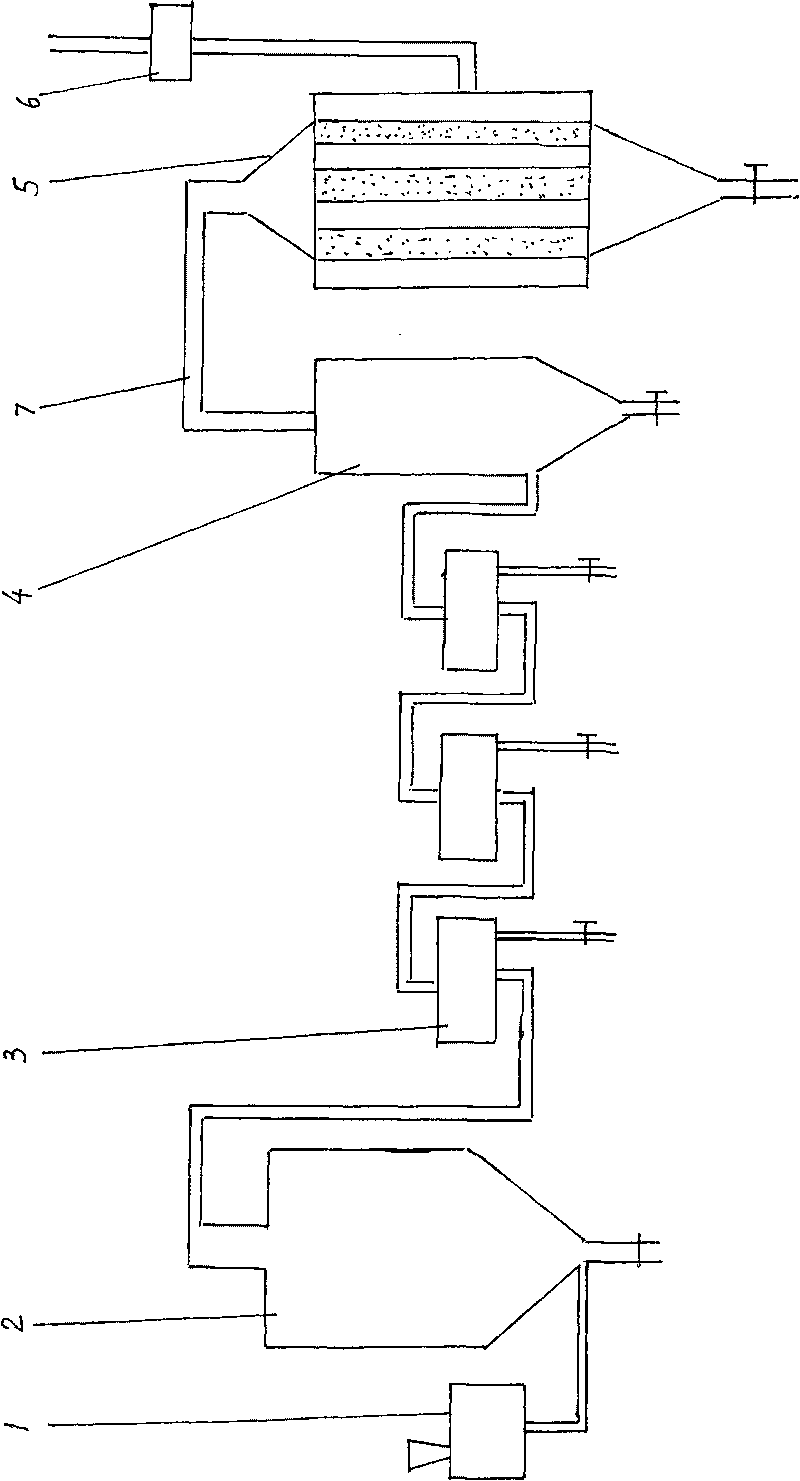

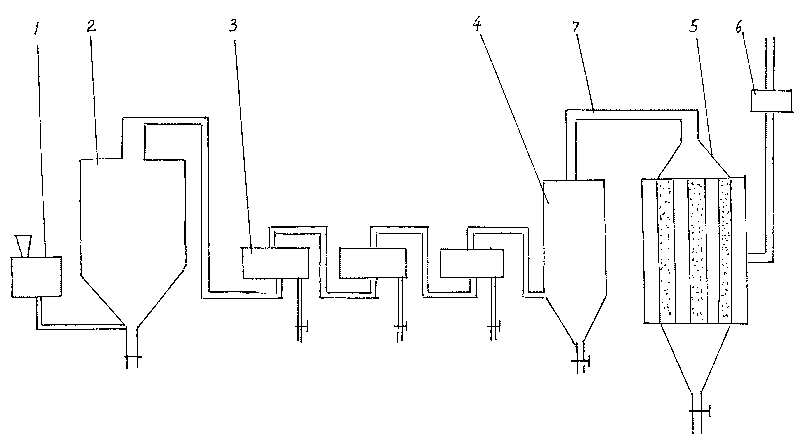

[0019] Below by specific embodiment, the present invention is described in detail as follows in conjunction with accompanying drawing:

[0020] The production method of this kind of green silicon carbide grinding and polishing micropowder includes the steps of raw material selection, crushing, air classification, water washing, water conservancy classification and surface coating, pressure filtration, drying, calcination, sieving and packaging and storage in sequence, as described in detail in Down:

[0021] 1. Selection of raw materials. Green silicon carbide raw materials obtained by high-temperature reaction of silica sand and carbonaceous materials require a particle size of less than 20mm, green silicon carbide content > 95%, and moisture content < 2%;

[0022] 2. Use Raymond Pulverizer 1 to pulverize, and the particle size of the machine is 0.005-0.200mm;

[0023] 3. Airflow classification: in figure 1 Among them, the airflow classification system includes a material h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com