Double-regenerative combustor

A burner and double heat storage technology, which is applied in the direction of burner, gas fuel burner, combustion method, etc., can solve the problem of aggravating the high-temperature deformation, ablation and damage of the front heat storage body, reducing the heat transfer performance of the heat storage body, Uneven thermal expansion and other problems can be improved to improve the use performance and thermal performance of the heating furnace, improve the structural stability and damage resistance, and improve the high temperature performance and damage resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to better explain the present invention, the main content of the present invention is further clarified below in conjunction with the accompanying drawings and specific embodiments, but the content of the present invention is not limited to the following embodiments.

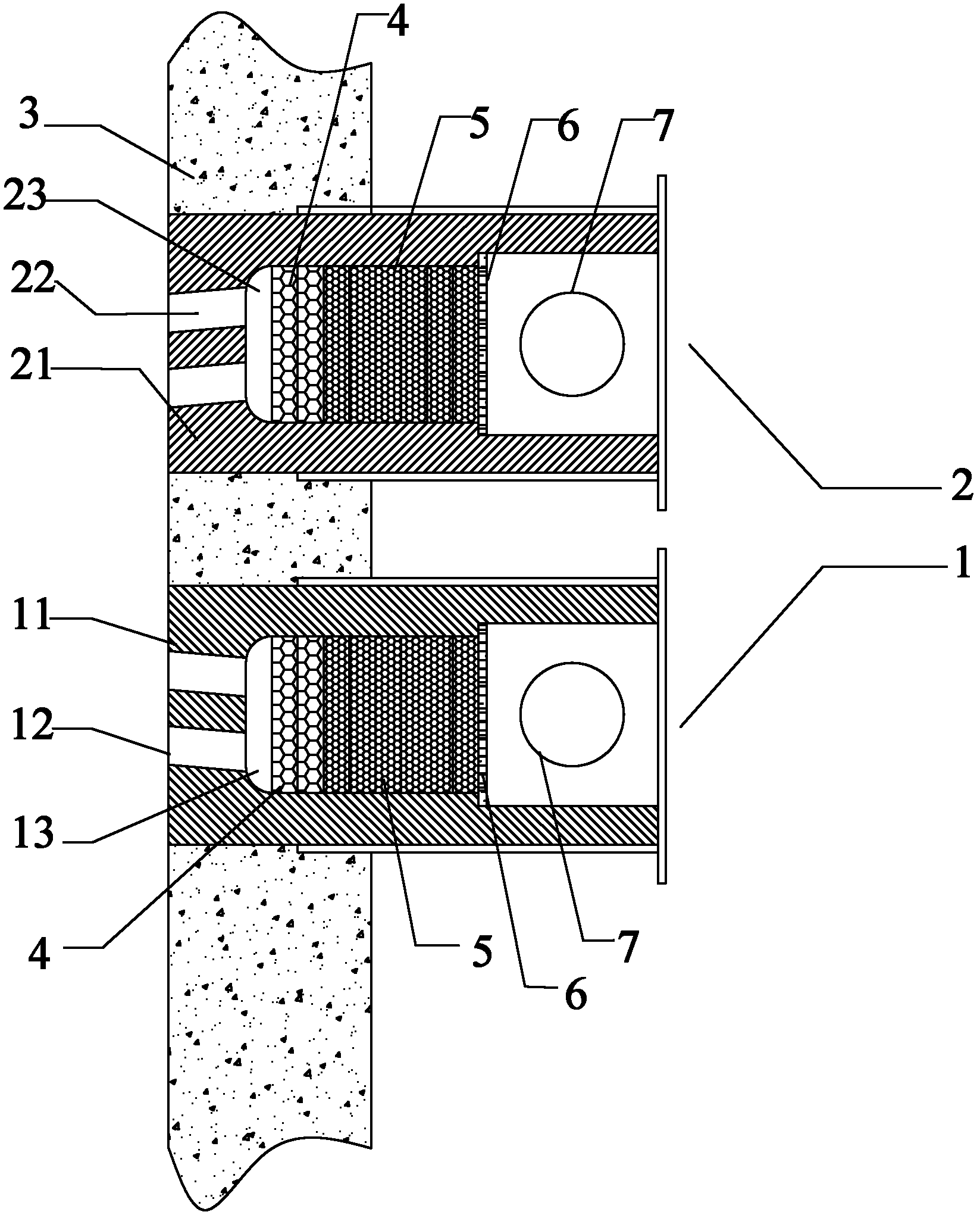

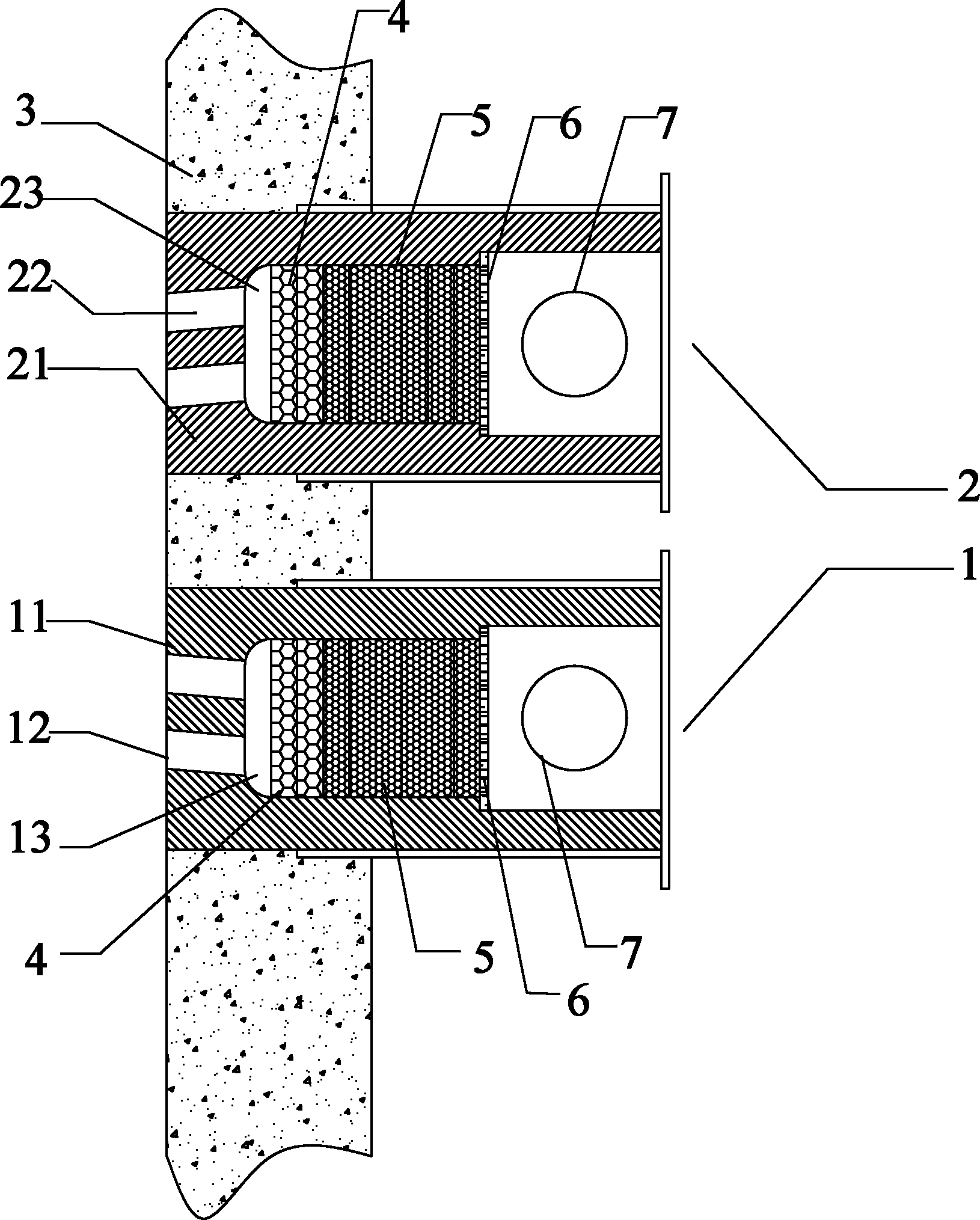

[0018] Such as figure 1The shown dual regenerative burners include a blast furnace gas burner 1 and a combustion air burner 2 embedded in pairs on the furnace wall 3, the blast furnace gas burner 1 includes a blast furnace gas burner brick body 11, and the combustion air burner The nozzle 2 includes a combustion air burner brick body 21 . One end of the blast furnace gas burner brick body 11 and the combustion air burner brick body 21 leading to the furnace is respectively arranged with 3 to 7 gas burner nozzles 12 and air burner nozzles 22, and their injection directions are mutually inclining and relative to The horizontal plane forms an included angle of 2-15°, and the horizontal inclination ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com