Surface-coated cutting tool

A cutting tool, surface coating technology, applied in the field of surface coating cutting tools, can solve the problems of deterioration, poor wear resistance, reduced wear resistance, etc., to achieve excellent high temperature hardness, excellent damage resistance, excellent wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

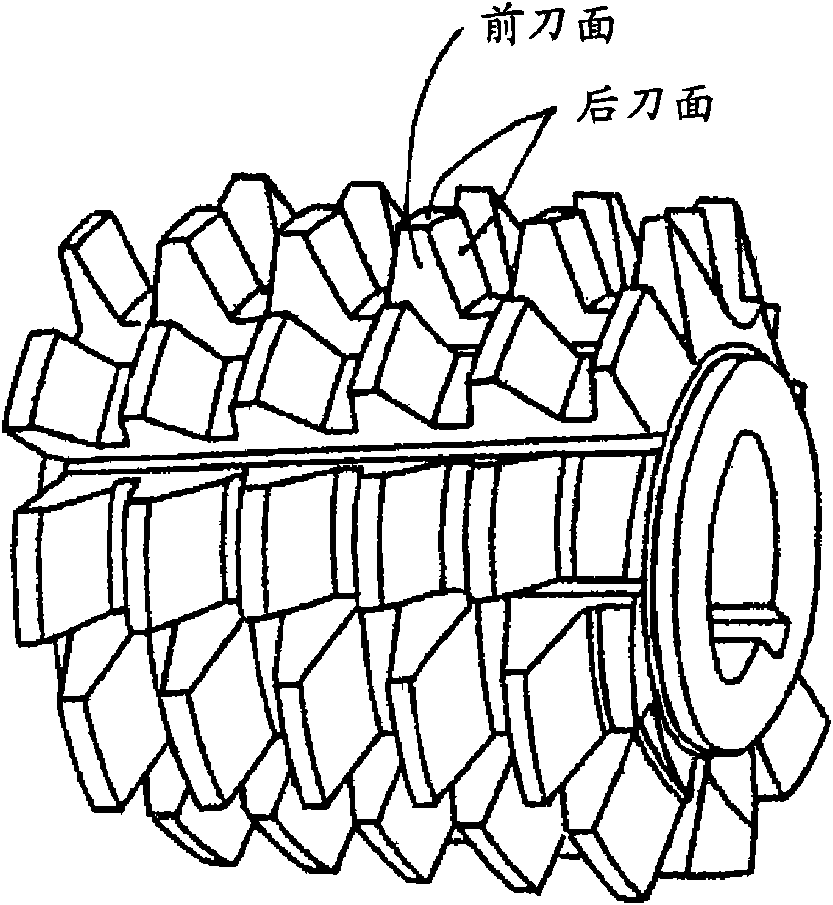

[0053] The material is made of JIS·SKH51 and JIS·SKH55 high-speed tool steel with a size of diameter: 90mm×length: 130mm, and is manufactured by machining with an overall size of outer diameter: 85mm×length: 100mm, and has four left Twisted x 16 slots in the shape of image 3 The main body (integral hob) of the high-speed steel cutting tool shown in the brief perspective view.

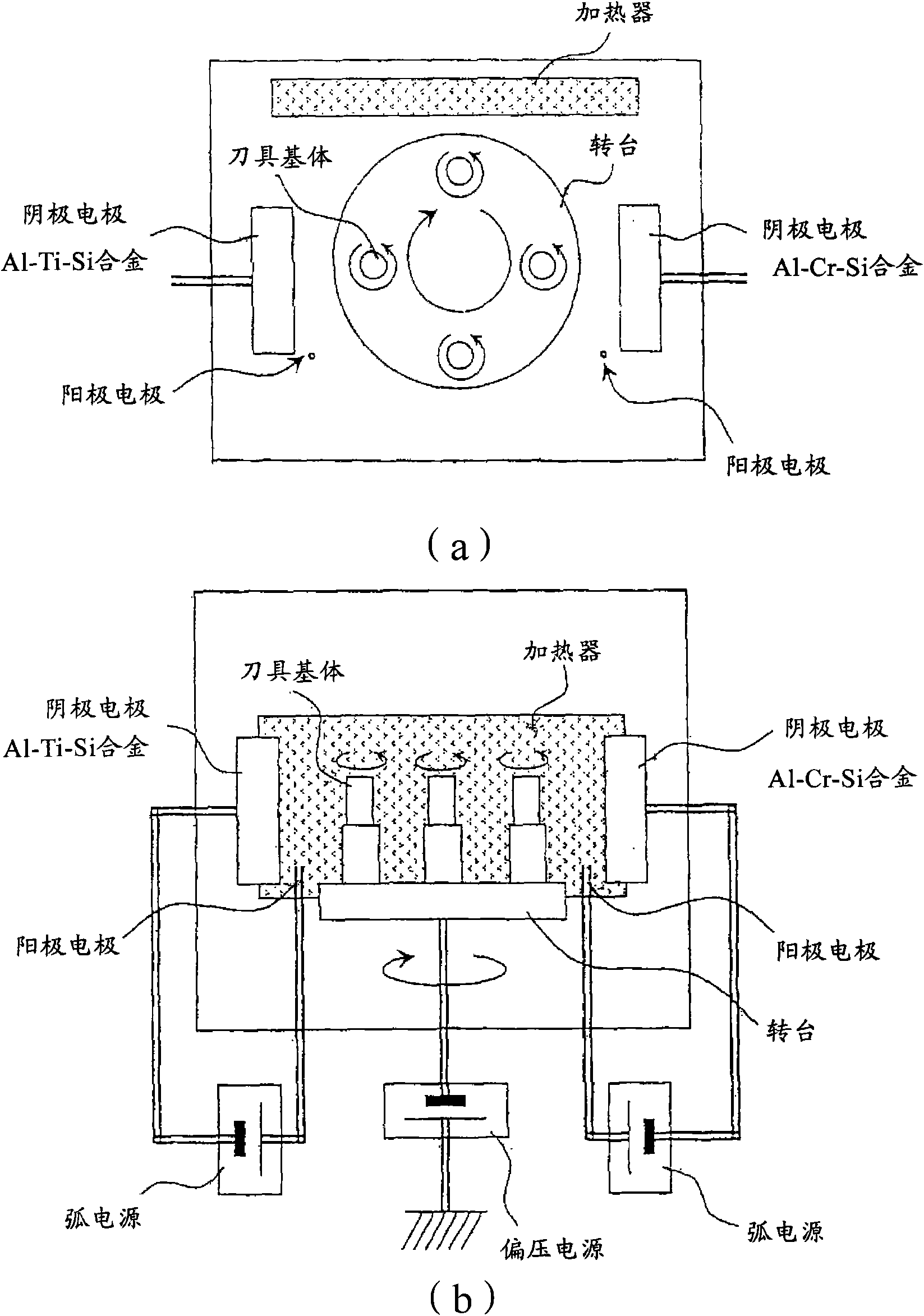

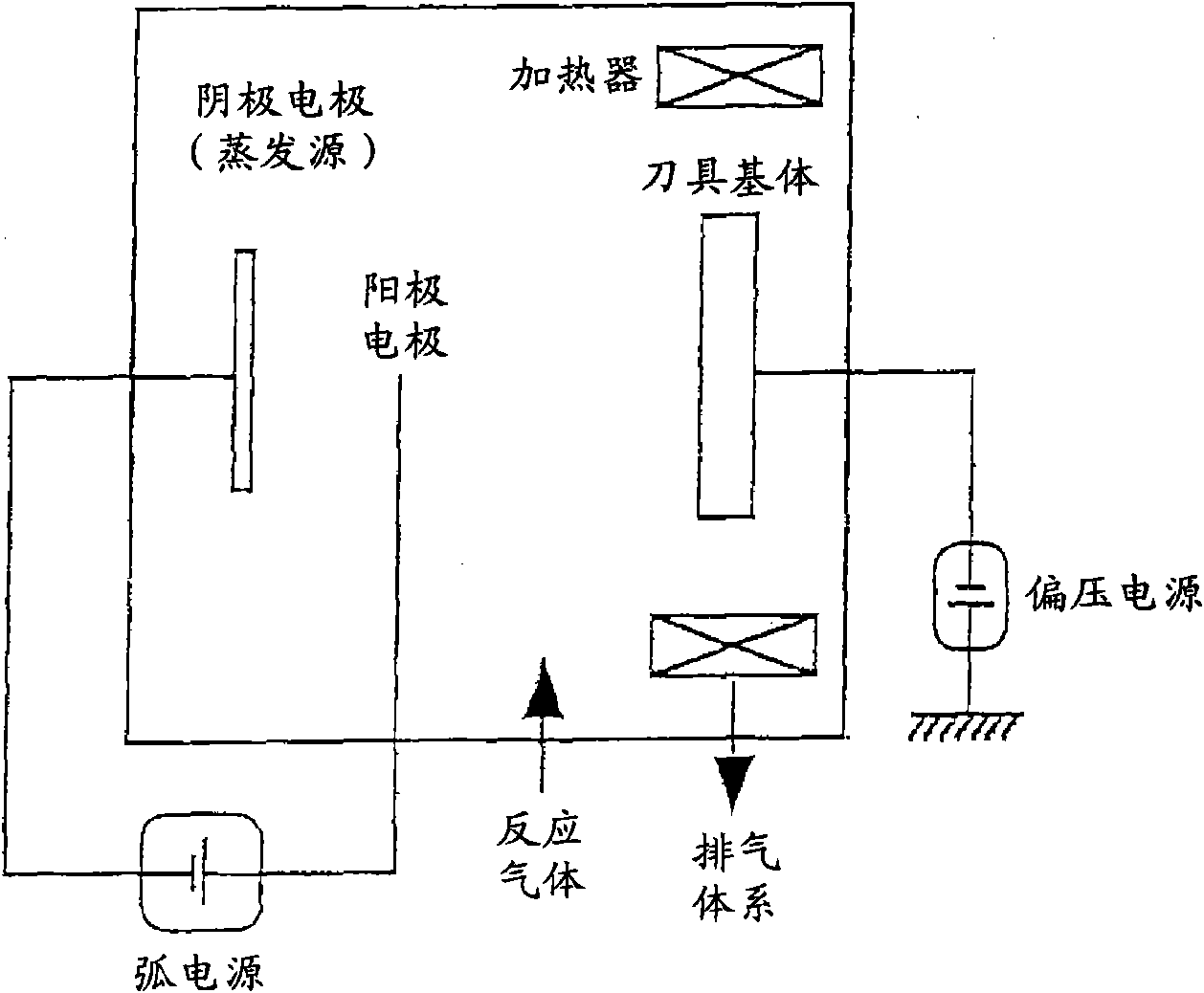

[0054] (a) Next, ultrasonically clean the main body (integral hob) of the high-speed steel gear cutting tool of the above two materials in acetone, and assemble it in a dry state along the outer periphery. figure 1 On the turntable in the shown arc ion plating apparatus, at a position at a predetermined distance from the central axis in the radial direction, the cathode electrodes (evaporation sources) facing each other across the turntable have the same characteristics as those shown in Table 1. The Al-Cr-Si alloy for forming the thin layer A having the composition corresponding to the target compos...

Embodiment 2

[0069] In addition, as the main body of the high-speed steel gear cutting tool, it is also manufactured by machining from a raw material with a size of outer diameter: 105mm×thickness: 22mm formed of high-speed tool steel made of JIS·SKH51 and JIS·SKH55, and has a pitch circle diameter: 100mm×Thickness: Overall size of 18mm, and has the shape of cutter teeth: 50 Figure 4 The disc-shaped gear shaper body base (shape 100 described in JIS·B·4356) shown in the schematic perspective view of .

[0070] Next, the surface of the above-mentioned high-speed steel gear cutter main body (gear shaper cutter) substrate is ultrasonically cleaned in acetone, and it is similarly assembled in a dry state. figure 1 In the arc ion plating device shown, under the same conditions as in the above-mentioned embodiment 1, the bottom layer of the target composition and target layer thickness shown in Table 1 is formed by vapor deposition along the layer thickness direction, and the bottom layer of th...

Embodiment 3

[0089] As raw material powders, medium-coarse WC powder with an average particle size of 5.5 μm, fine-grained WC powder with an average particle size of 0.8 μm, TaC powder with an average particle size of 1.3 μm, and NbC powder, ZrC powder with average particle diameter: 1.2 μm, Cr with average particle diameter: 2.3 μm 3 C 2Powder, VC powder with average particle size: 1.5 μm, (Ti, W)C [TiC / WC=50 / 50 in mass ratio] powder with average particle size: 1.0 μm, and average particle size: Co powder of 1.8 μm was mixed with these raw material powders in the compounding composition shown in Table 3, and wax was added and ball-milled in acetone for 24 hours. The compacts are heated up to a specified temperature in the range of 1370-1470°C at a rate of 7°C / min in a vacuum atmosphere of 6Pa, kept at this temperature for 1 hour, and then sintered under furnace cooling conditions. Three kinds of round bar sintered bodies with diameters of 8mm, 13mm, and 26mm were formed, and the above t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com