A casting alloy with high hardness and high specific yield strength under high temperature conditions and preparation method thereof

A yield strength, cast alloy technology, applied in the field of alloys, can solve the problems of poor resistance to high temperature softening ability, low high temperature hardness, low density, etc., and achieve the effect of high interface bonding strength, prominent high temperature hardness, and high preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

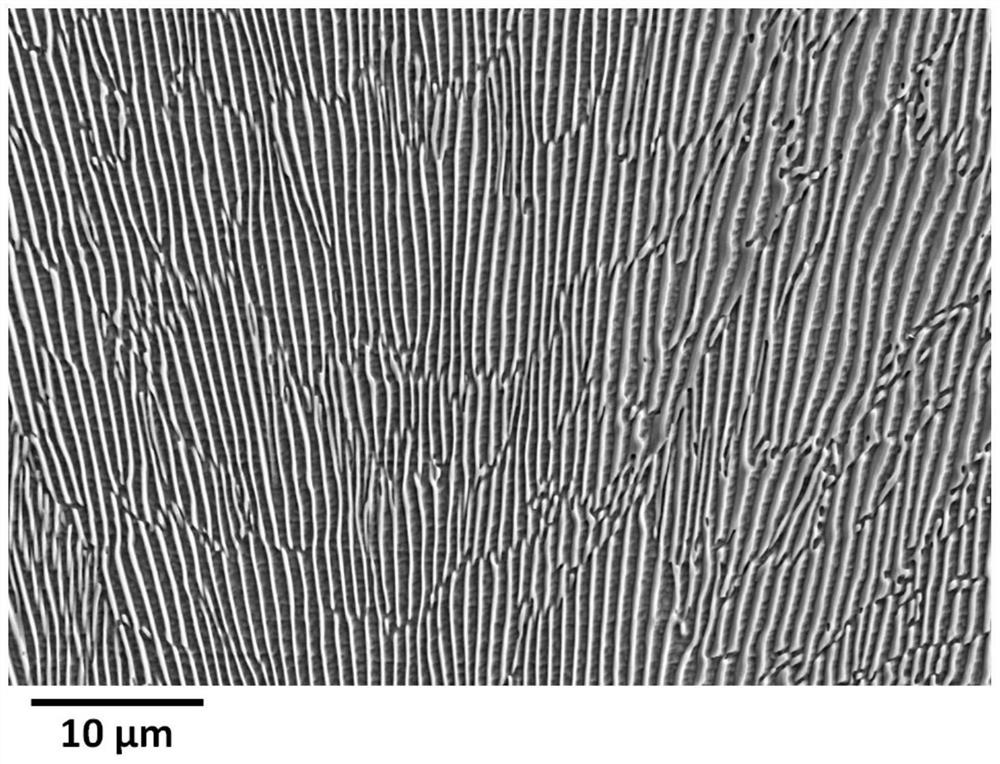

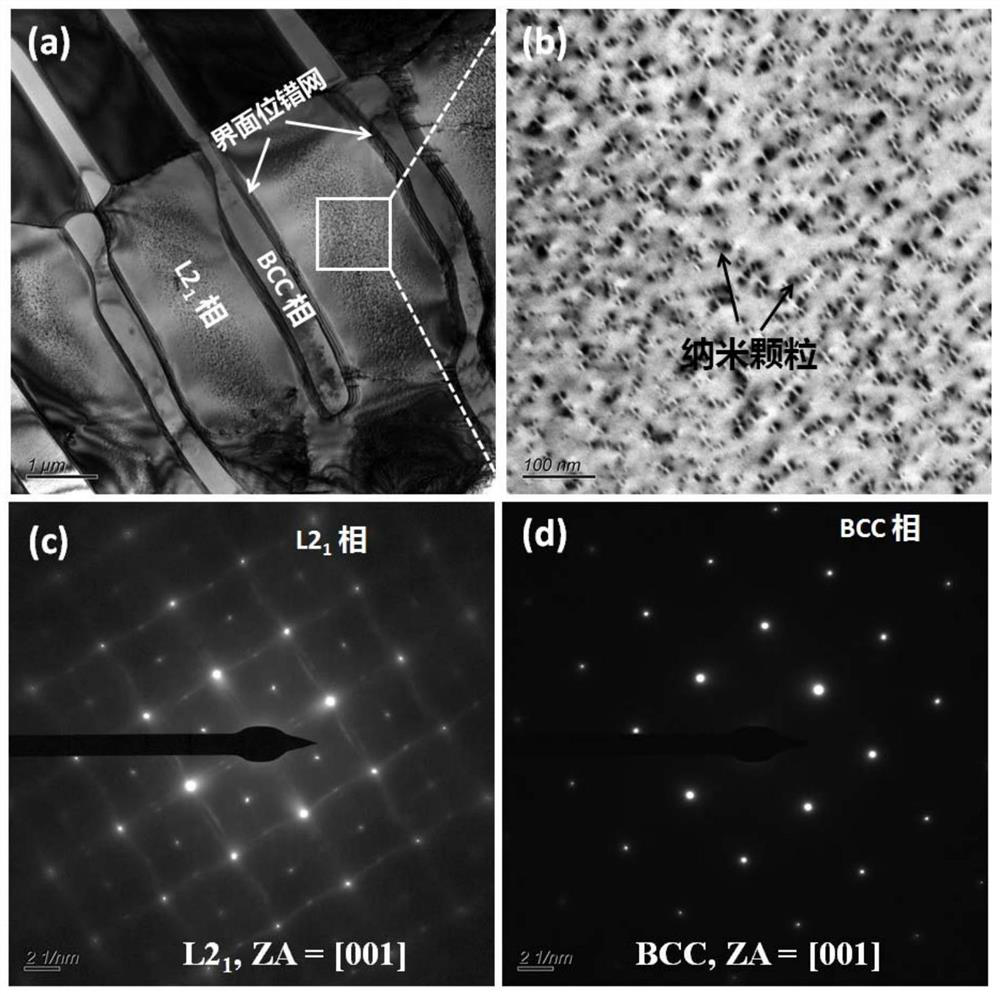

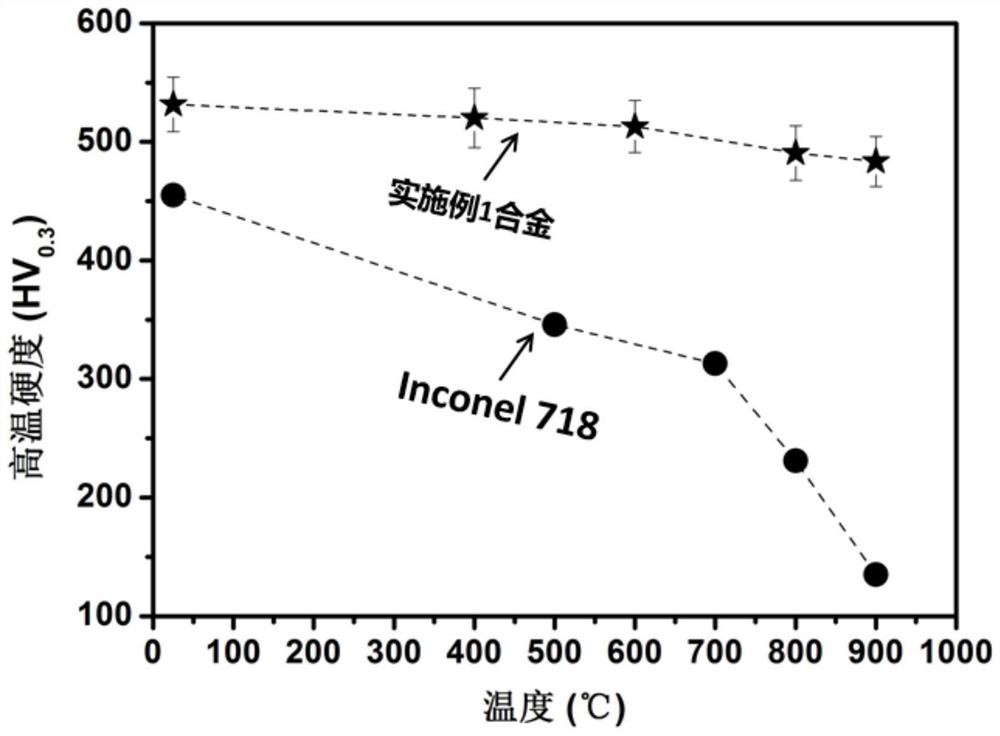

[0028] This embodiment discloses a casting alloy with high hardness and high specific yield strength under high temperature conditions, including the following components in molar ratio: Al: 19 parts; Ti: 18 parts; Ni: 37 parts; Cr: 26 parts . The Al, Ti, Ni, and Cr are all industrial-grade pure raw materials with a purity of more than 99.5 wt.%.

[0029] The preparation method of the cast alloy with high hardness and high specific yield strength under the high temperature condition of this embodiment is as follows: when the alloy is melted, Al is placed at the bottom, Ti and Cr are placed in the middle, Ni is placed on the top, and the furnace lid is closed, Tighten the lock, evacuate to below 10Pa, open the molecular pump to evacuate to 3×10 -3 Below Pa, fill with argon to (3~5)×10 2 Pa, turn on the heating power switch, slowly manually adjust the "power adjustment" knob (rotate clockwise, the rate of 5kW / 10min will increase), after the raw material is melted, slowly manua...

Embodiment 2

[0035] This embodiment discloses a casting alloy with high hardness and high specific yield strength under high temperature conditions, including the following components in molar ratio: Al: 17 parts; Ti: 17 parts; Ni: 34 parts; Cr: 12 parts ; V: 22 copies. The Al, Ti, Ni, Cr, and V are all industrial-grade pure raw materials with a purity of more than 99.5 wt.%.

[0036] The preparation method of the cast alloy with high hardness and high specific yield strength under the high temperature condition of this example is as follows: when the alloy is melted, Al is placed at the bottom, Ti, Cr and V are placed in the middle, Ni is placed at the top, and the furnace is closed. Cover, lock the lock, evacuate to below 10Pa, open the molecular pump to evacuate to 3×10 -3 Below Pa, fill with argon to (3~5)×10 2 Pa, turn on the heating power switch, slowly manually adjust the "power adjustment" knob (rotate clockwise, the rate of 5kW / 10min will increase), after the raw material is mel...

Embodiment 3

[0039] This embodiment discloses a casting alloy with high hardness and high specific yield strength under high temperature conditions, including the following components in molar ratio: Al: 17 parts; Ti: 17 parts; Ni: 34 parts; V: 32 parts . The Al, Ti, Ni, and V are all selected from industrial-grade pure raw materials with a purity of more than 99.5 wt.%.

[0040] The preparation method of the cast alloy with high hardness and high specific yield strength under the high temperature condition of this example is as follows: when the alloy is melted, Al is placed at the bottom, Ti and V are placed in the middle, Ni is placed on the top, and the furnace lid is closed, Tighten the lock, evacuate to below 10Pa, open the molecular pump to evacuate to 3×10 -3 Below Pa, fill with argon to (3~5)×10 2 Pa, turn on the heating power switch, slowly manually adjust the "power adjustment" knob (rotate clockwise, the rate of 5kW / 10min will increase), after the raw material is melted, slow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com