Nickel base mould material for hot extrusion of nonferrous metal and manufacturing method thereof

A technology of mold materials and non-ferrous metals, applied in metal rolling and other directions, can solve problems such as poor high temperature performance, lower production costs, easy cracking and failure, etc., achieve low manufacturing costs, reduce production costs, and improve service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides a nickel-based die material for hot extrusion of non-ferrous metals. The nickel-based die material is based on nickel, and molybdenum and tungsten with good high-temperature hardness and wear resistance are added to the nickel base material. Aluminum and titanium can precipitate strengthening phases during heat treatment to increase high temperature strength and hardness. The total weight of the nickel-based mold material is 100%, then the mold material specifically includes by weight percentage:

[0031] Carbon C 0.03~0.08%, Chromium Cr 15~20%, Cobalt Co 2~5%, Tungsten W 3~6%, Molybdenum Mo 9~12%, Aluminum Al 1~2%, Titanium Ti 2~4%, Iron Fe 10-15%, trace elements magnesium Mg0.01-0.015% and zirconium Zr 0.02-0.06%, the rest is nickel Ni, of which nickel Ni is used as the matrix; in practice, sulfur S and phosphorus P can also be added as needed Or one or more of boron B, the dosage when added is respectively: sulfur S 0.001-0.015%, phosphorus ...

Embodiment 2

[0047] This embodiment provides a nickel-based die material for hot extrusion of nonferrous metals, which can be used to prepare dies for hot extrusion of nonferrous metals. The total weight of the die material is 100%, and the die material includes: carbon C 0.05%, chromium C 17.0%, cobalt Co 4.0%, tungsten W 4.0%, molybdenum Mo 10.0%, aluminum Al 1.5%, titanium Ti 3.0%, iron Fe 13.0%, trace element magnesium Mg 0.013%, zirconium Zr 0.04% , the remaining part is nickel Ni, wherein nickel Ni is used as the matrix of the mold material.

[0048] The above-mentioned nickel-based mold material preparation method (heat treatment process) for non-ferrous metal hot extrusion is carried out according to the following steps:

[0049] (1) The above-mentioned nickel-based die materials for hot extrusion of non-ferrous metals are smelted by vacuum induction + vacuum self-consumption and then hot-rolled into Φ70mm bars.

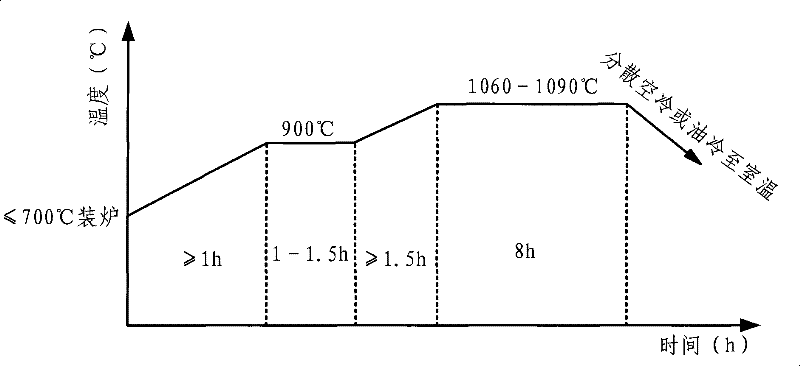

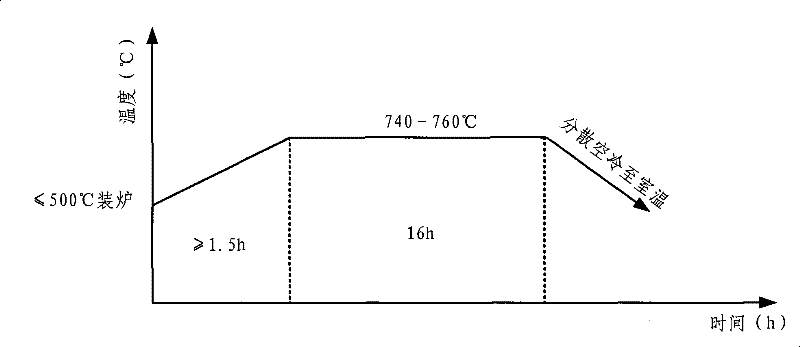

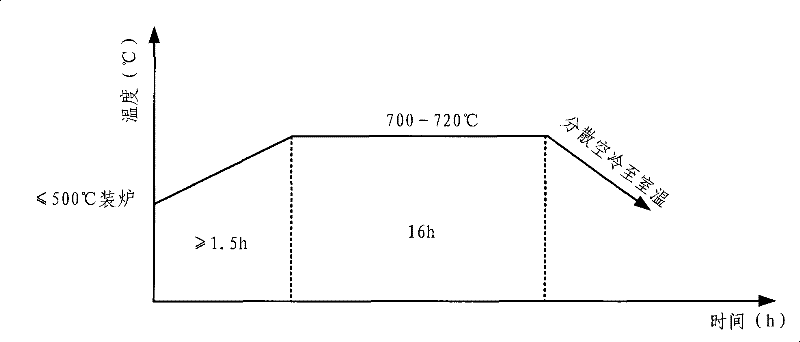

[0050] (2) Solution treatment: heat the hot-rolled bar to 1060-1090...

Embodiment 3

[0055] This embodiment provides a nickel-based mold material for hot extrusion of nonferrous metals, which can be used to prepare a mold for hot extrusion of nonferrous metals. The total weight of the mold material is 100%, and the mold material includes by weight percentage: Carbon C 0.04%, Chromium Cr 17.0%, Cobalt Co 4.0%, Tungsten W 4.0%, Molybdenum Mo 10.0%, Aluminum Al 1.2%, Titanium Ti 3%, Iron Fe 12.0%, Phosphorus P 0.008%, Trace Element Magnesium Mg 0.013%, zirconium Zr 0.04%, boron B 0.005%, and the rest is nickel Ni, wherein nickel Ni is used as the matrix.

[0056] The heat treatment process of the above-mentioned nickel-based mold material for hot extrusion of non-ferrous metals is carried out according to the following steps:

[0057] (1) The above-mentioned nickel-based mold material for hot extrusion of non-ferrous metals is smelted by vacuum induction + vacuum self-consumption and then hot-rolled into a bar of Φ70mm;

[0058] (2) Solution treatment: heat the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com