Patents

Literature

375 results about "Gear cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

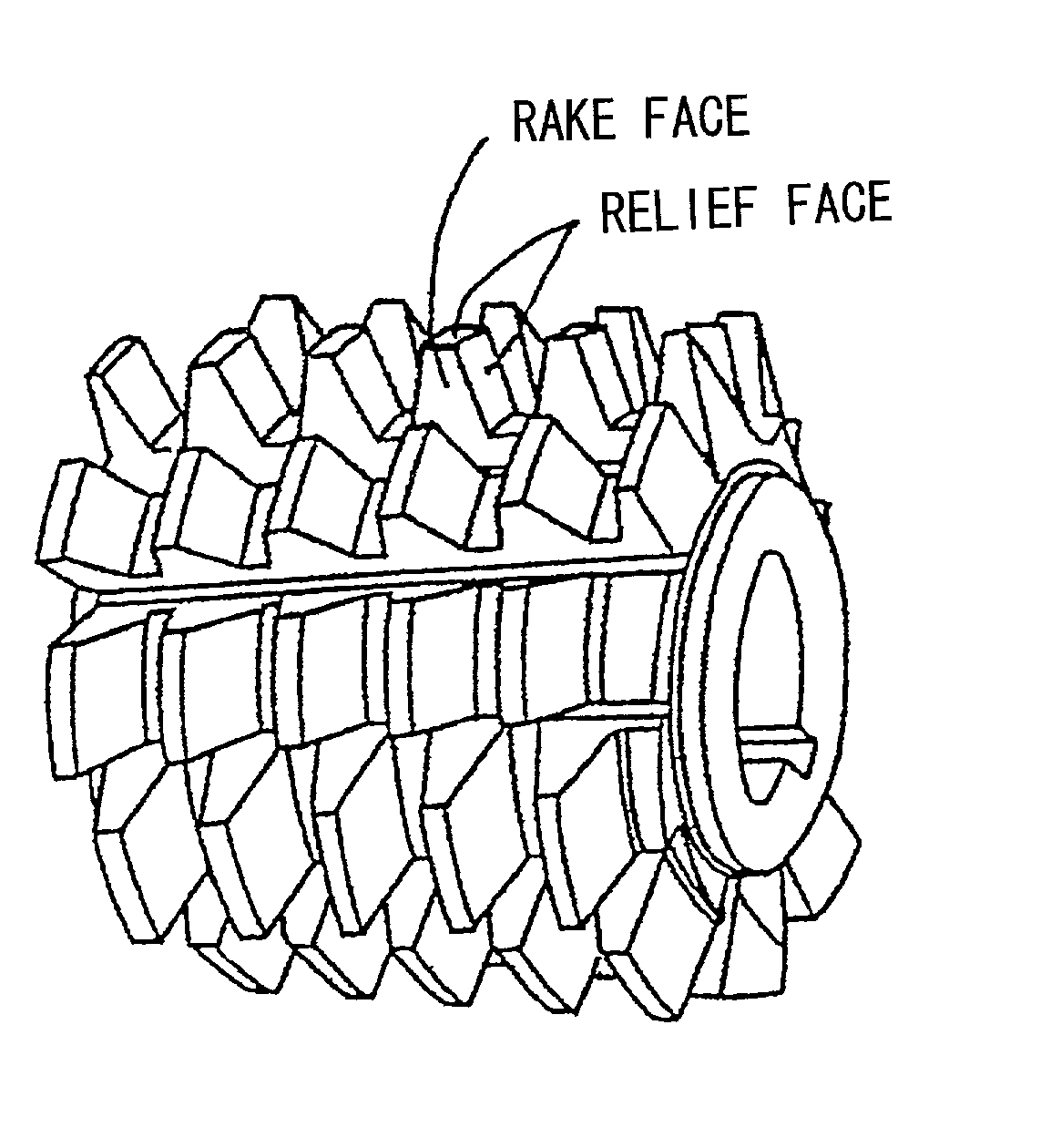

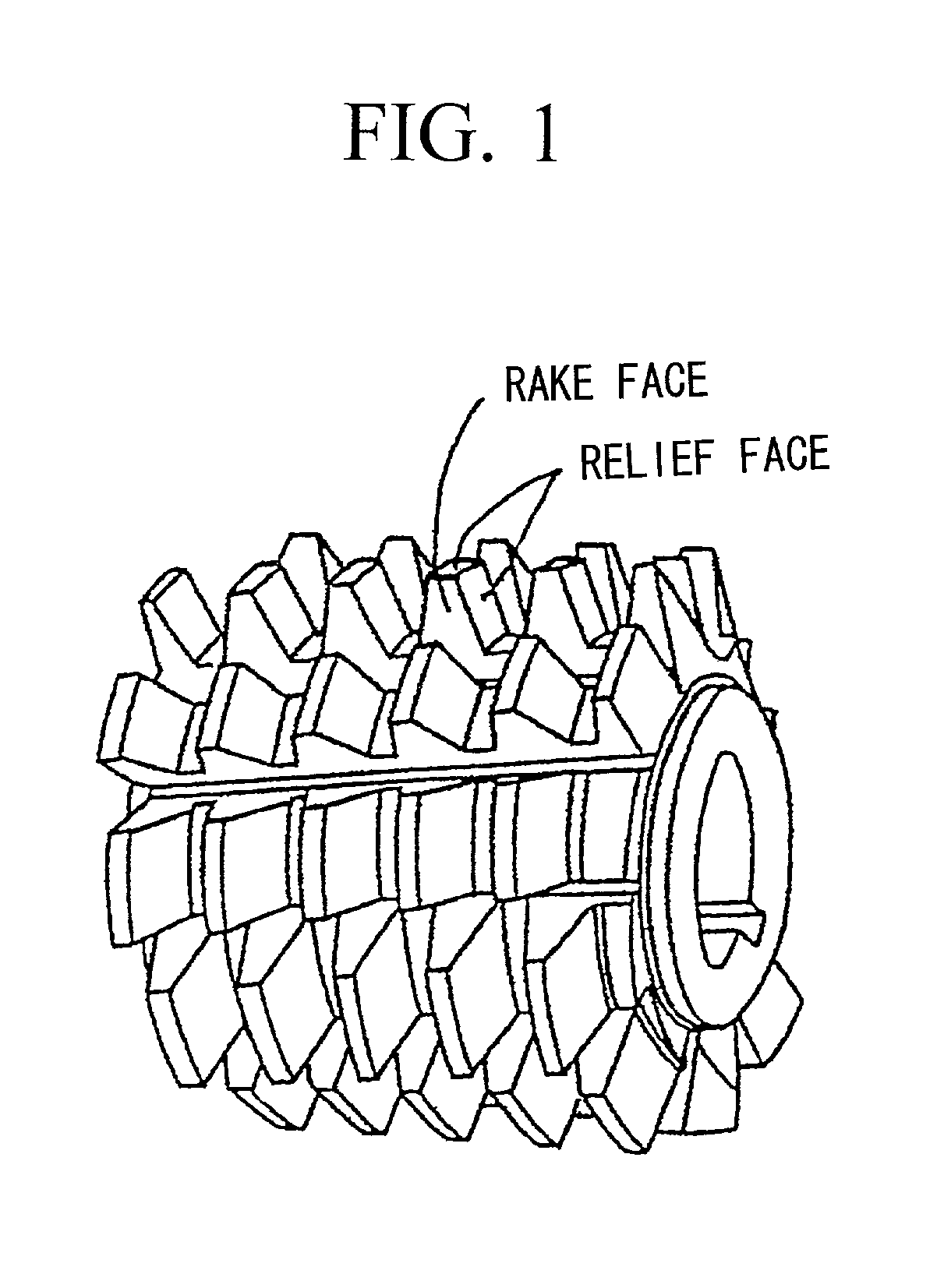

Gear cutting is any machining process for creating a gear. The most common gear-cutting processes include hobbing, broaching, milling, and grinding. Such cutting operations may occur either after or instead of forming processes such as forging, extruding, investment casting, or sand casting.

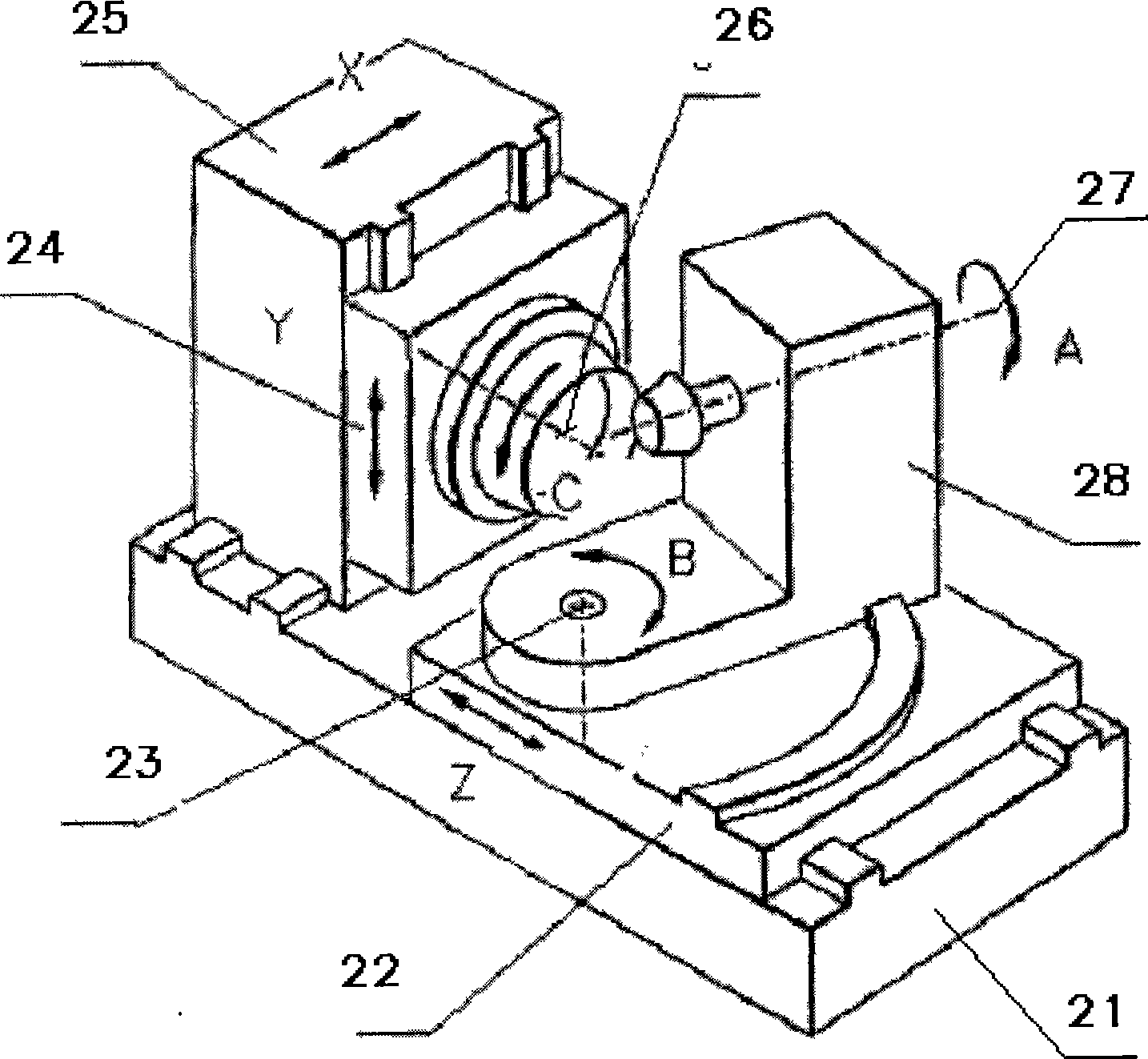

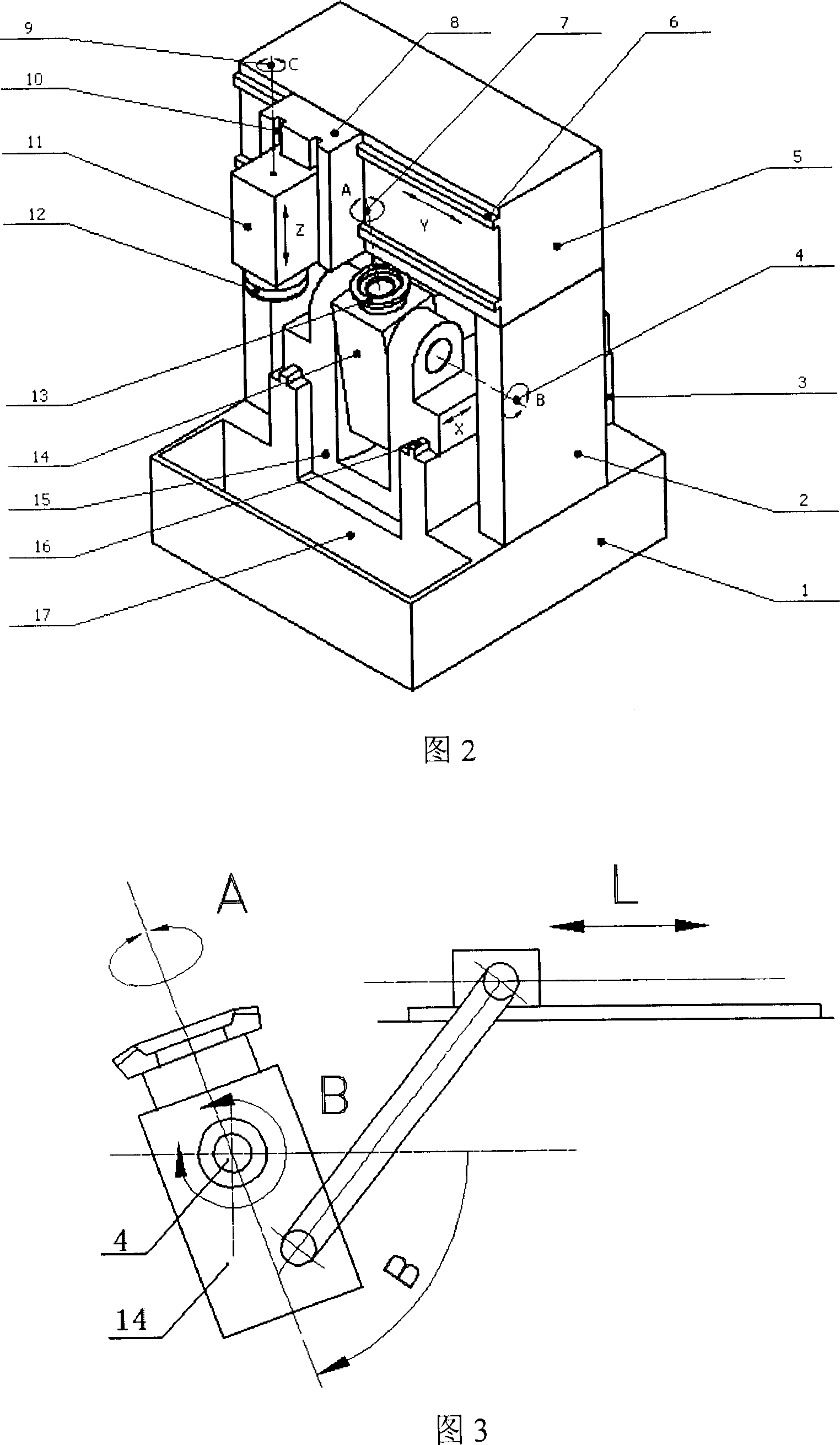

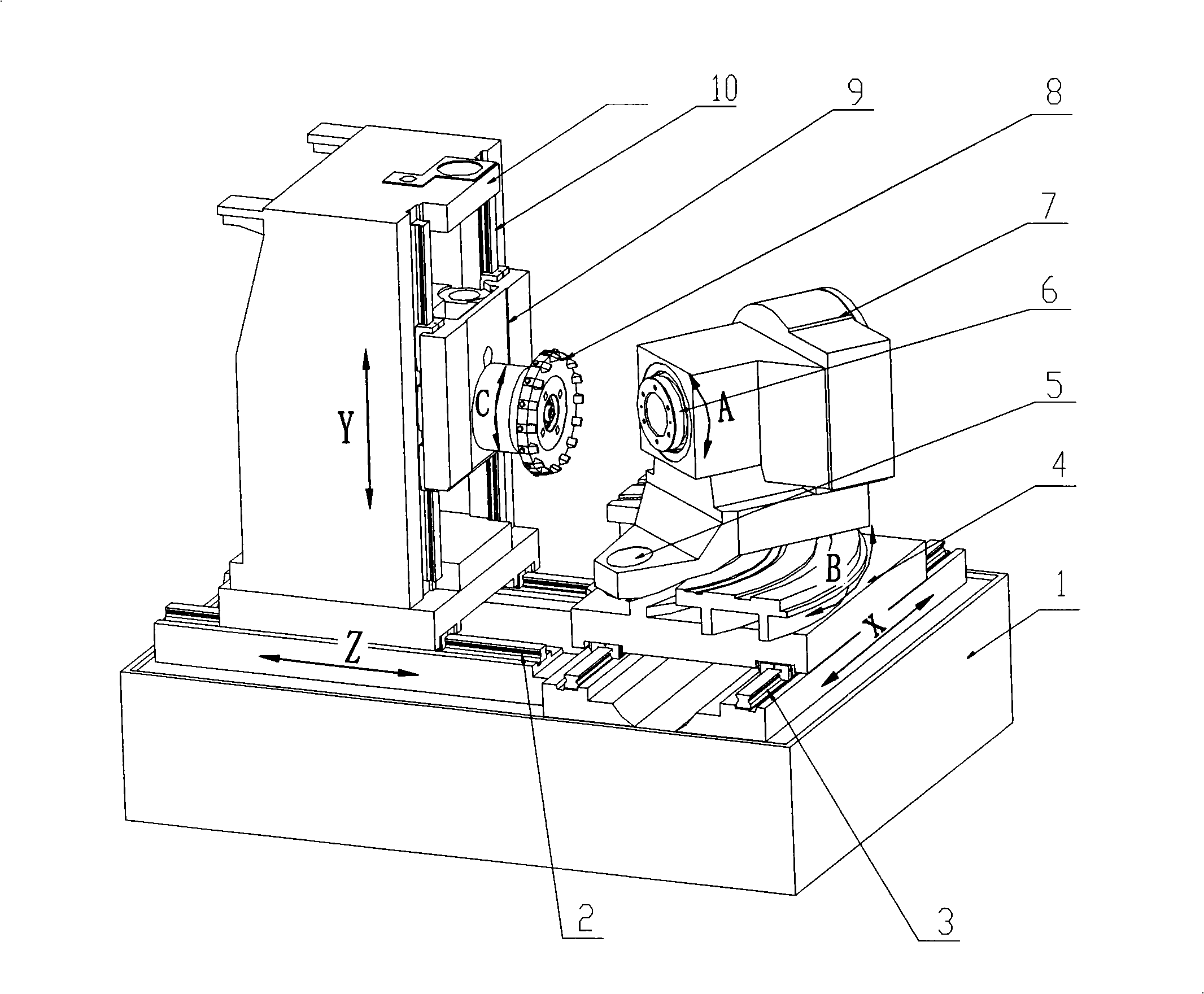

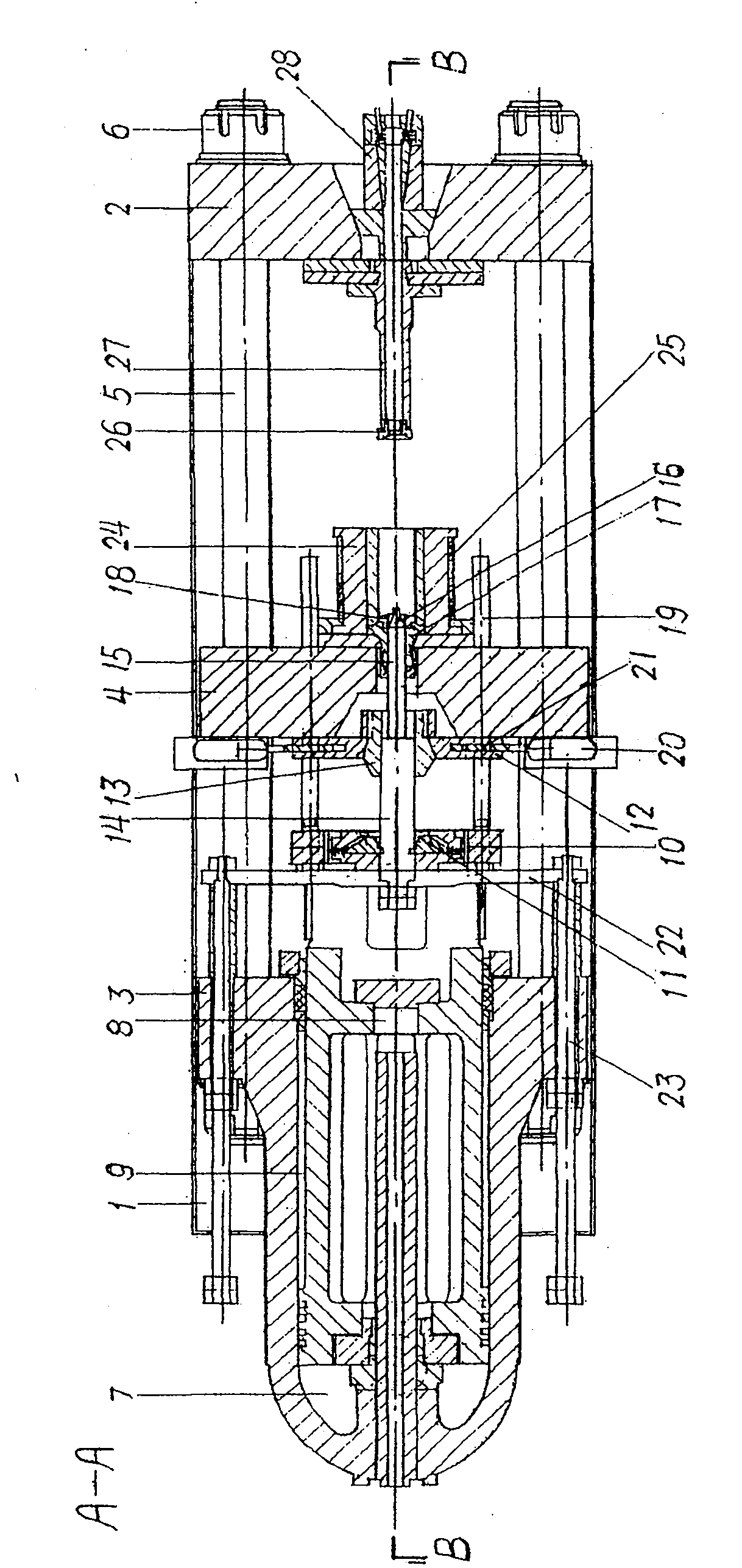

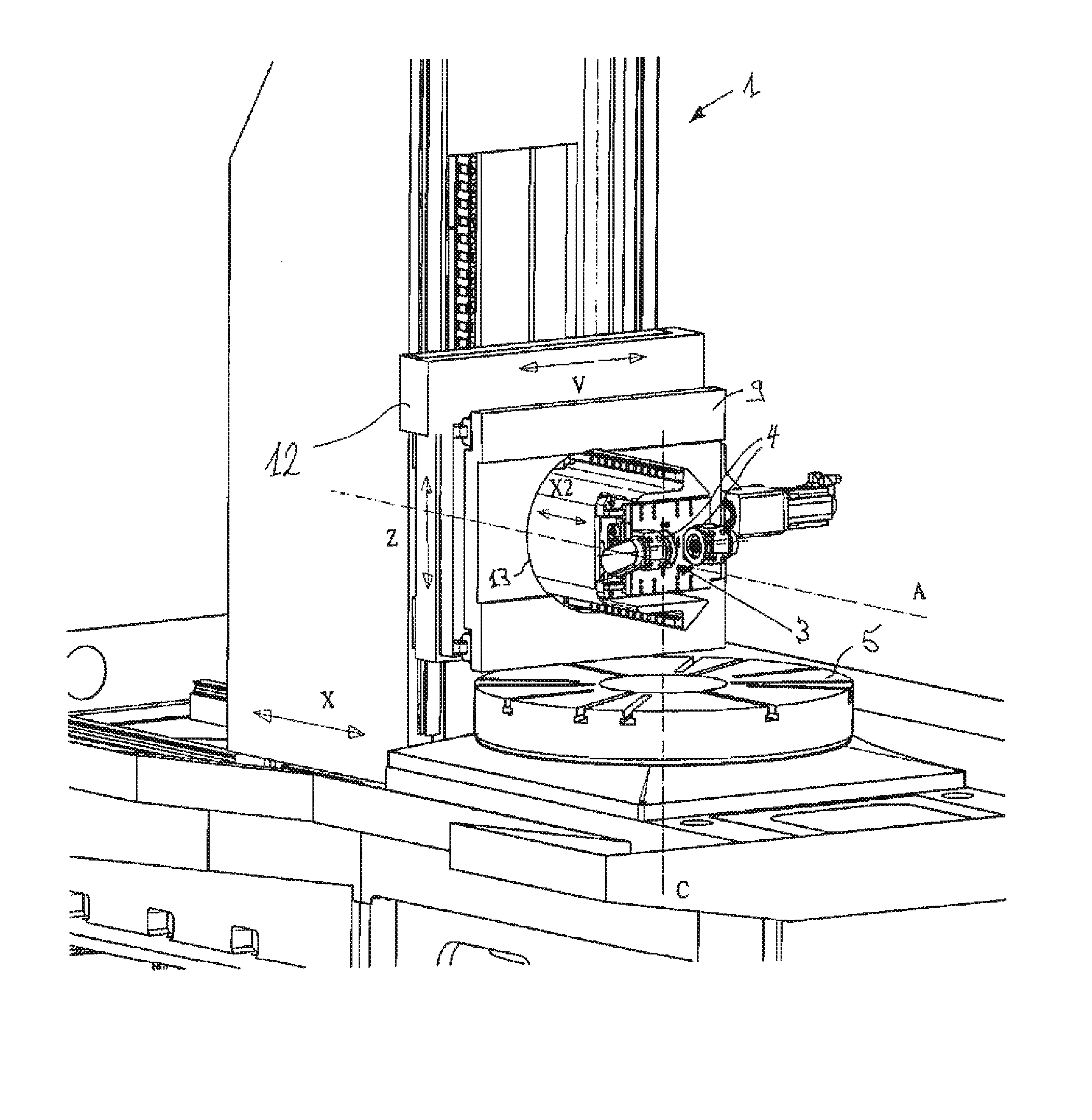

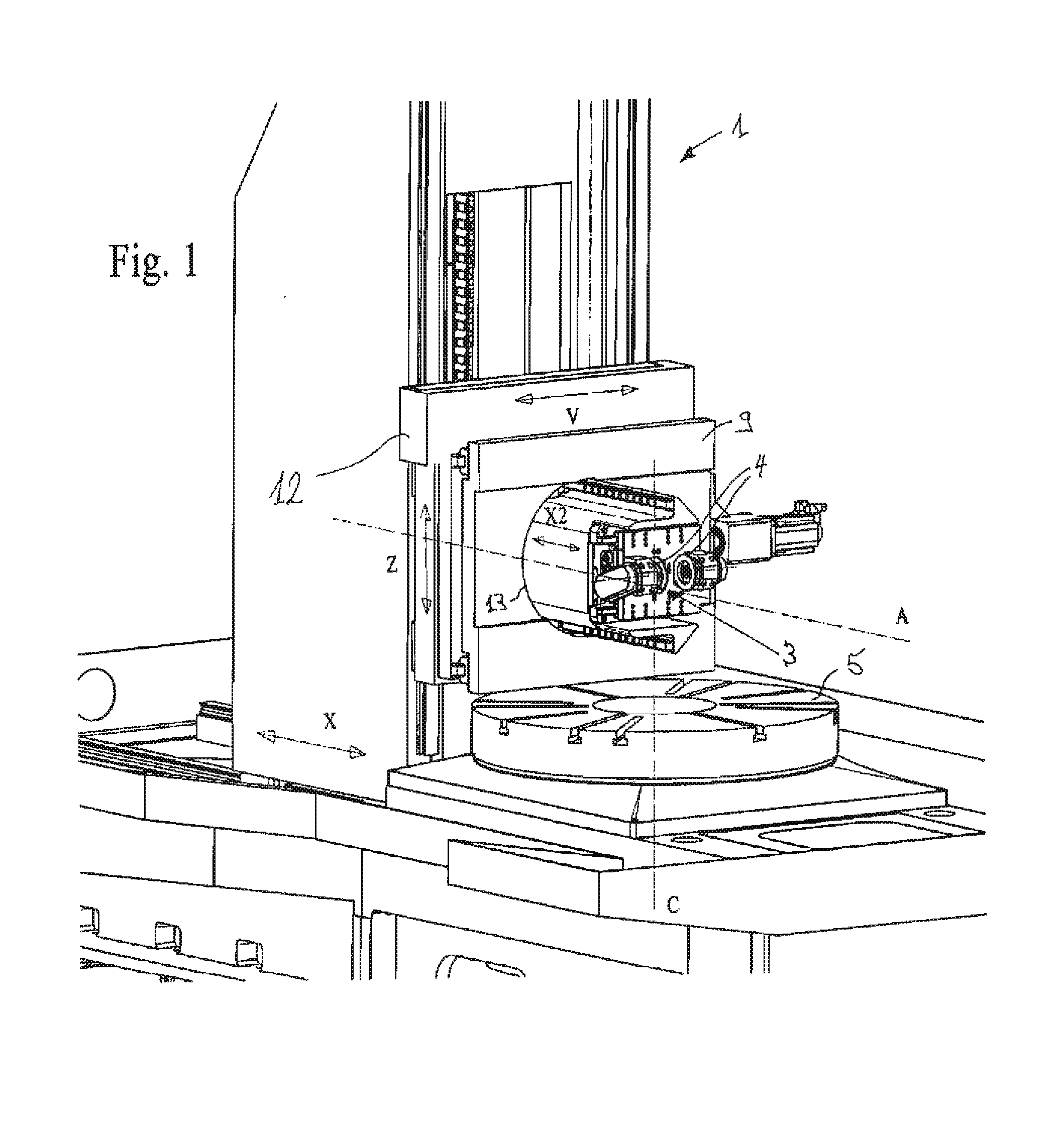

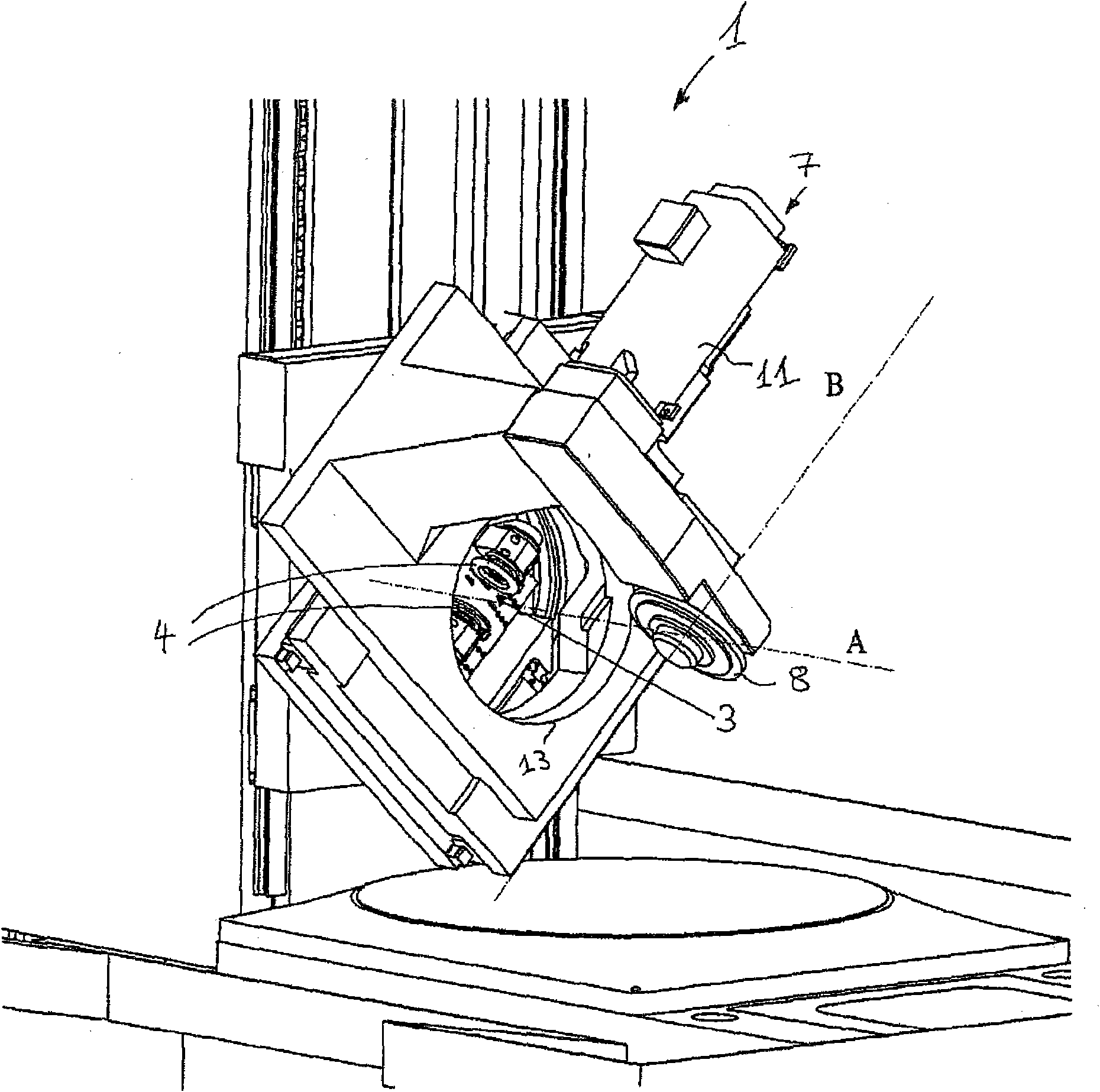

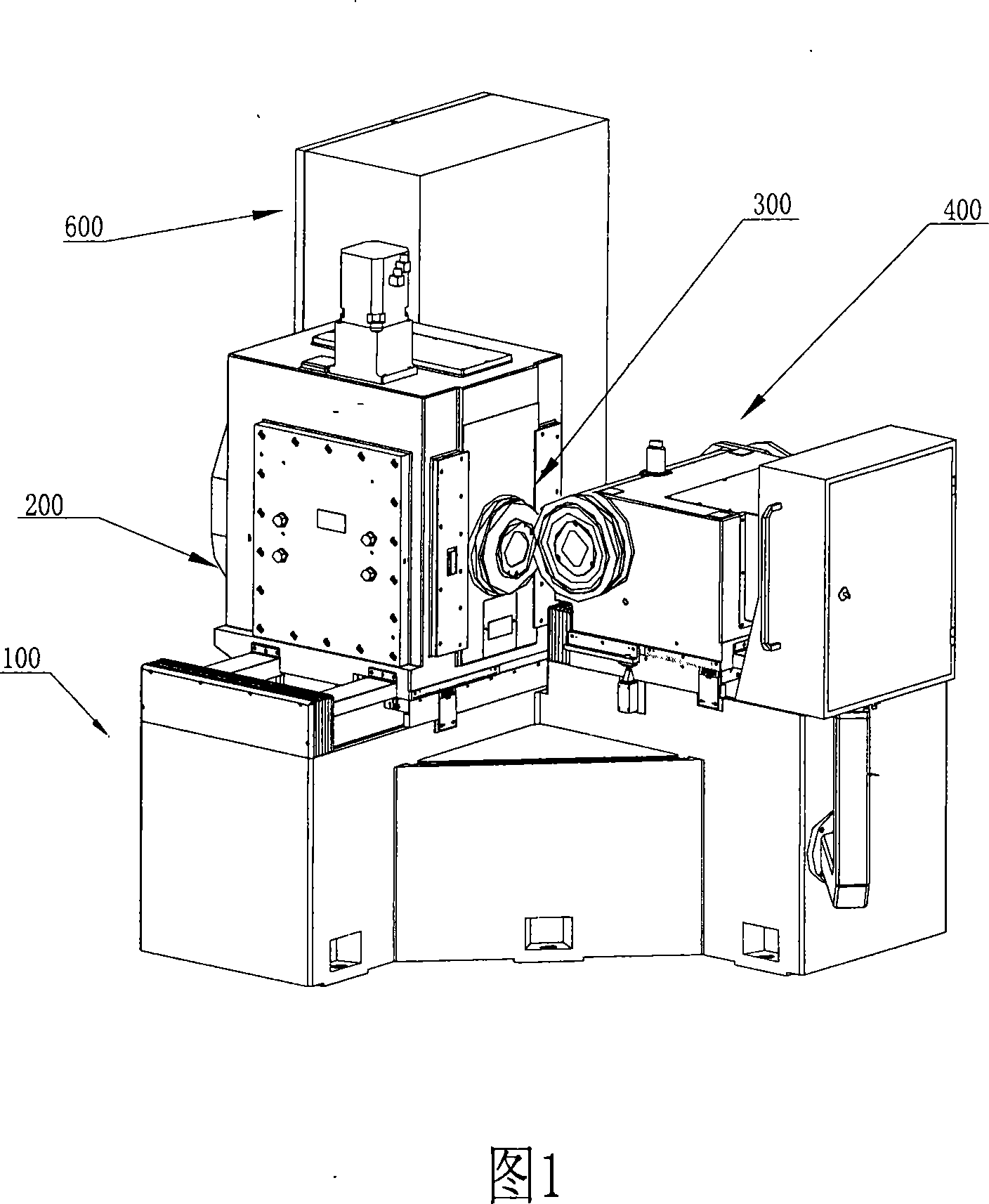

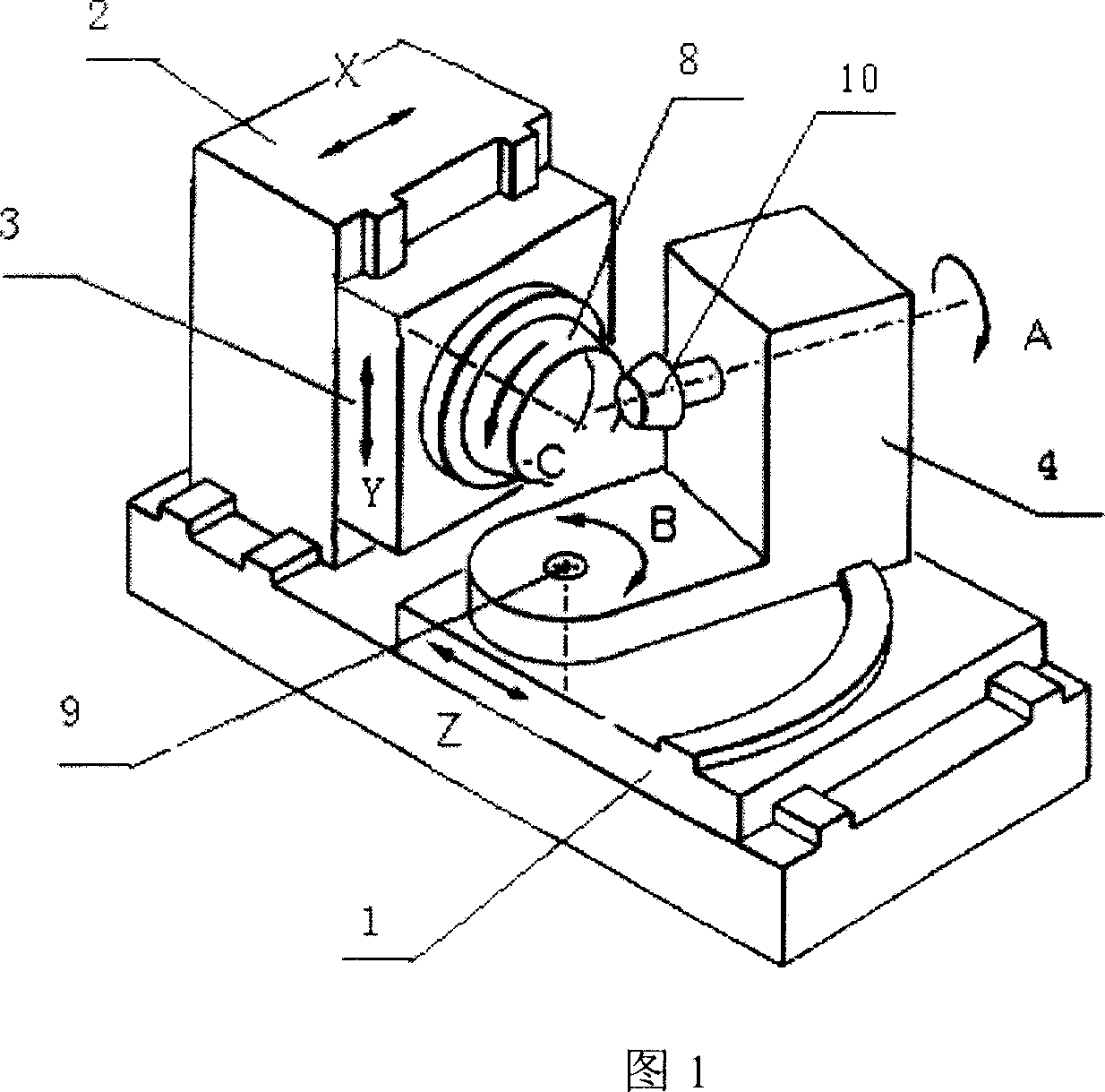

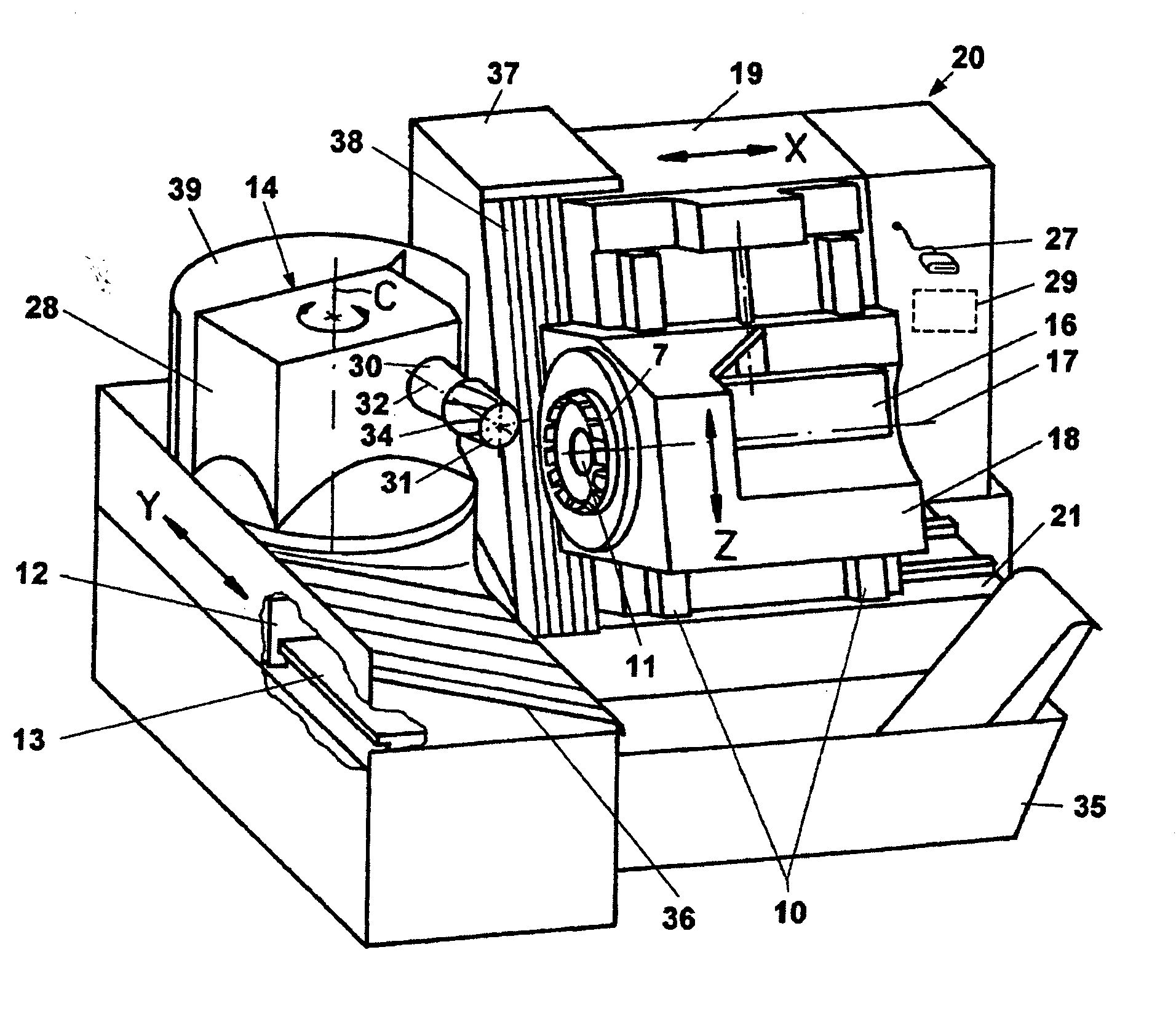

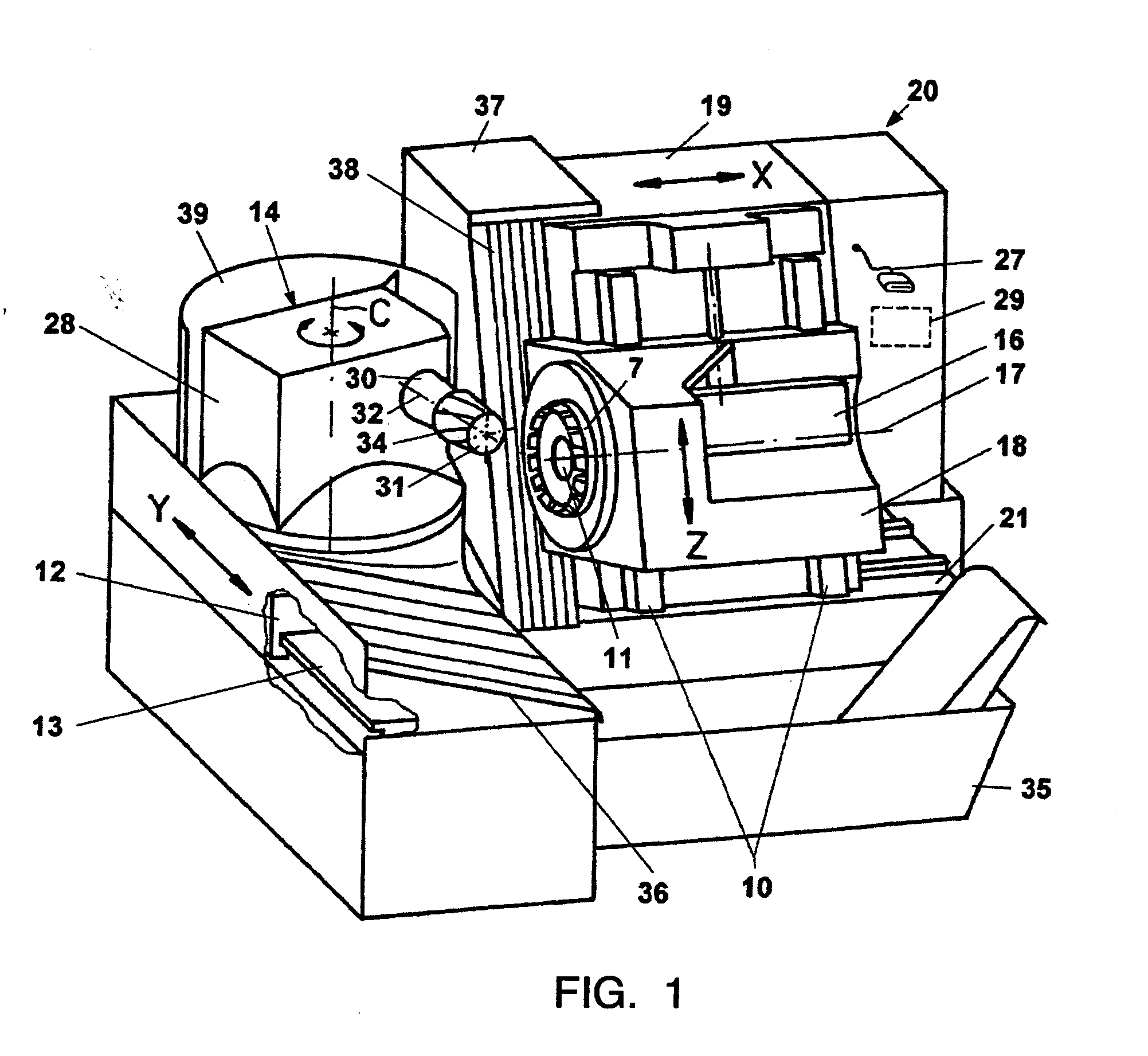

Six-axis five-linkage spiral taper gear cutting machine tool

InactiveCN101508039AEasy loading and unloadingEasy to realize automatic loading and unloadingLarge fixed membersMetal working apparatusGear cuttingEngineering

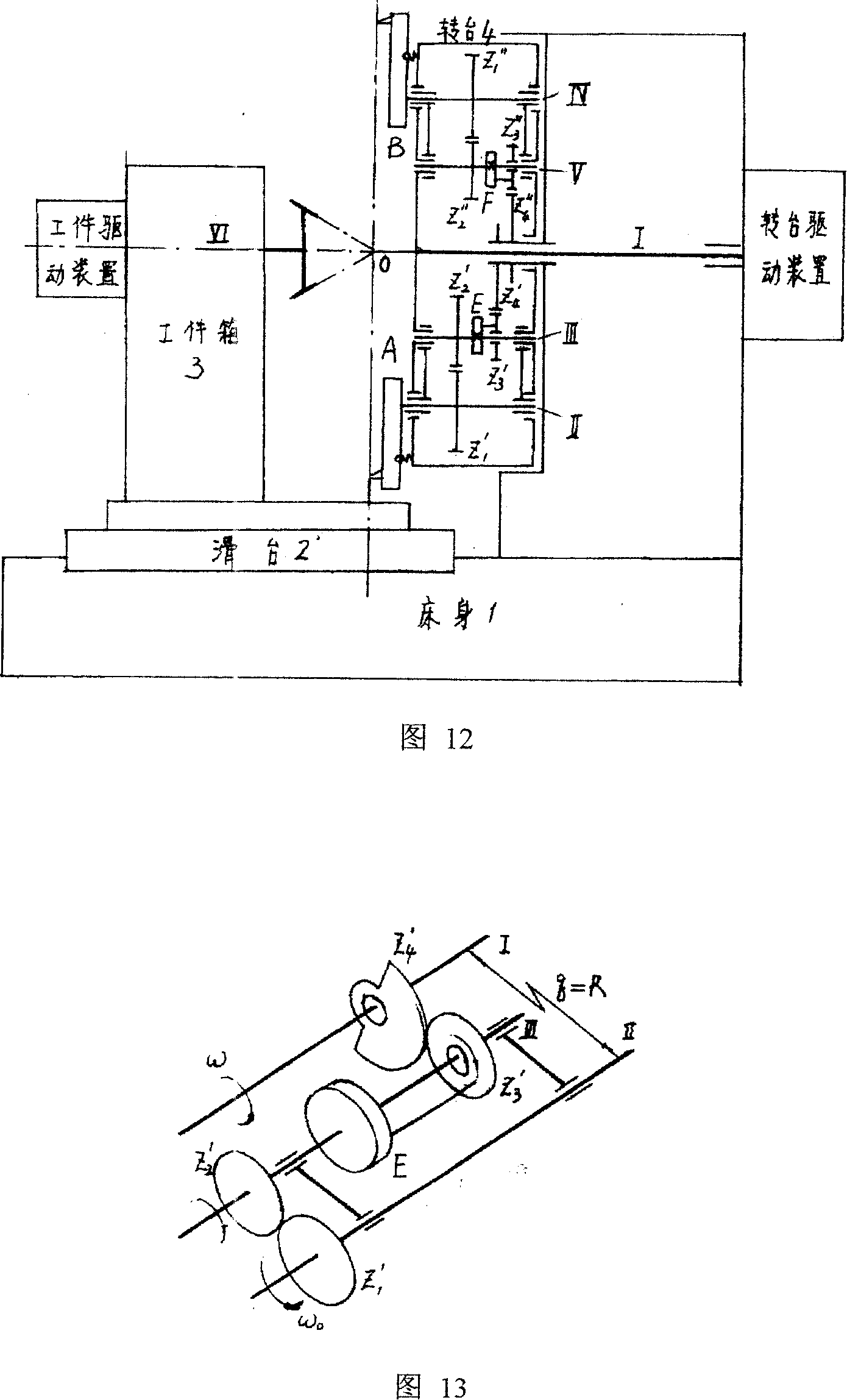

The invention relates to a six-axis five-linkage spiral bevel gear cutting machine. A lathe bed is provided with a fixed upright post and an X-direction linear guiderail with an X-axis slipway which is driven by a driving mechanism to move along the guiderail; the X-axis slipway is provided with a rotary table and a rotary table driving mechanism; the rotary table is provided with a workpiece box with a workpiece main shaft which is driven by the driving mechanism to rotate; one lateral surface of the upright post is provided with a Y-direction linear guiderail perpendicular to the X-direction linear guiderail; the Y-direction linear guiderail is provided with a Y-axis slipway which is driven by the driving mechanism to move along the guiderail; the Y-axis slipway is provided with a Z-direction linear guiderail perpendicular to the Y-direction linear guiderail; the Z-direction linear guiderail is provided with a tool box which is driven by the driving mechanism to move along the guiderail; and the tool box is provided with a rotatable tool spindle. The six-axis five-linkage spiral bevel gear cutting machine has the advantages of simple and stable structure, good reliability, good rigidity, few parts, small occupied area, easy protection and chip removal, and convenient assembly and disassembly of workpieces and tools.

Owner:CHANGSHA HALIANG KAISHUAI PRECISION MASCH CO LTD

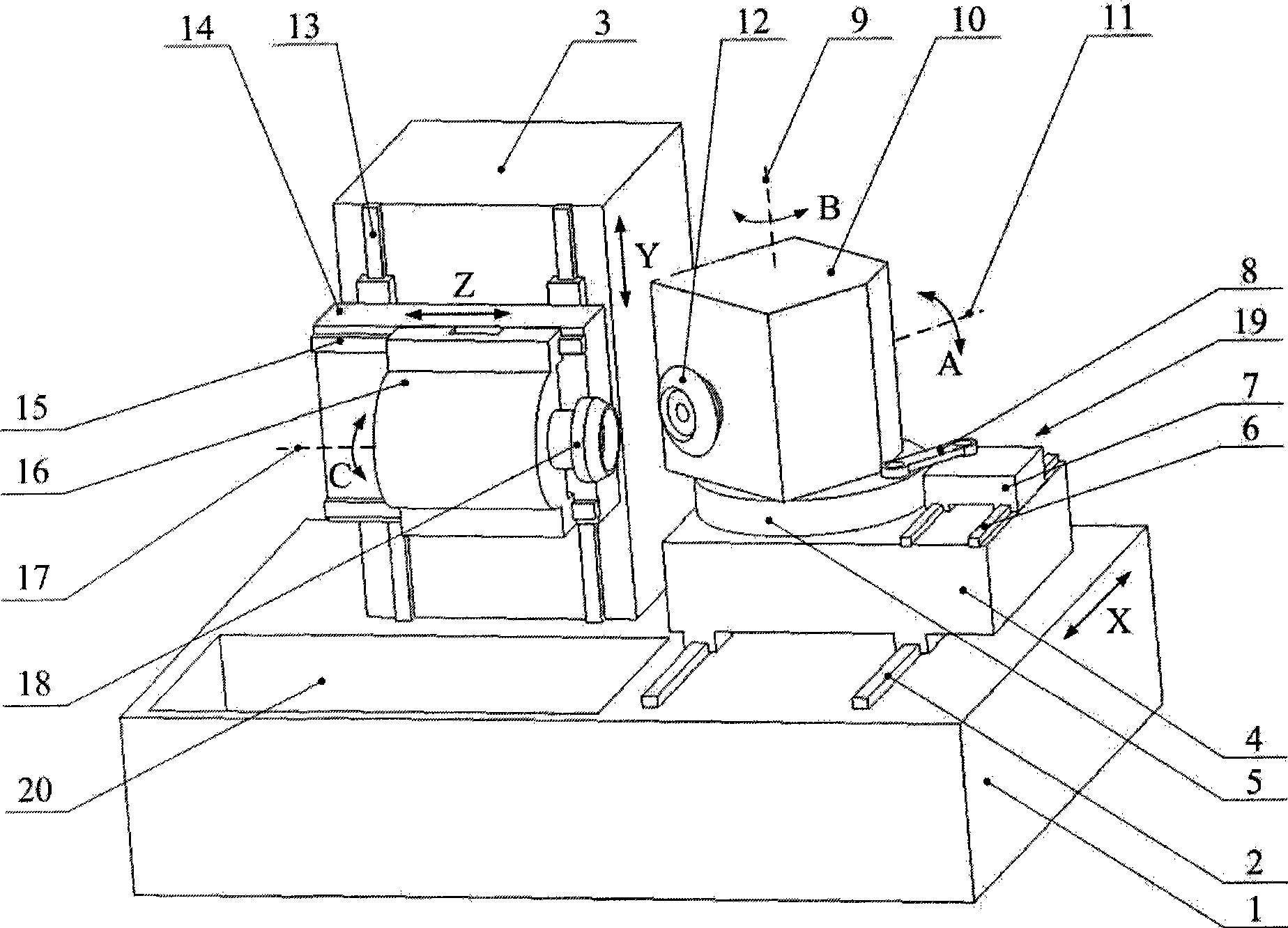

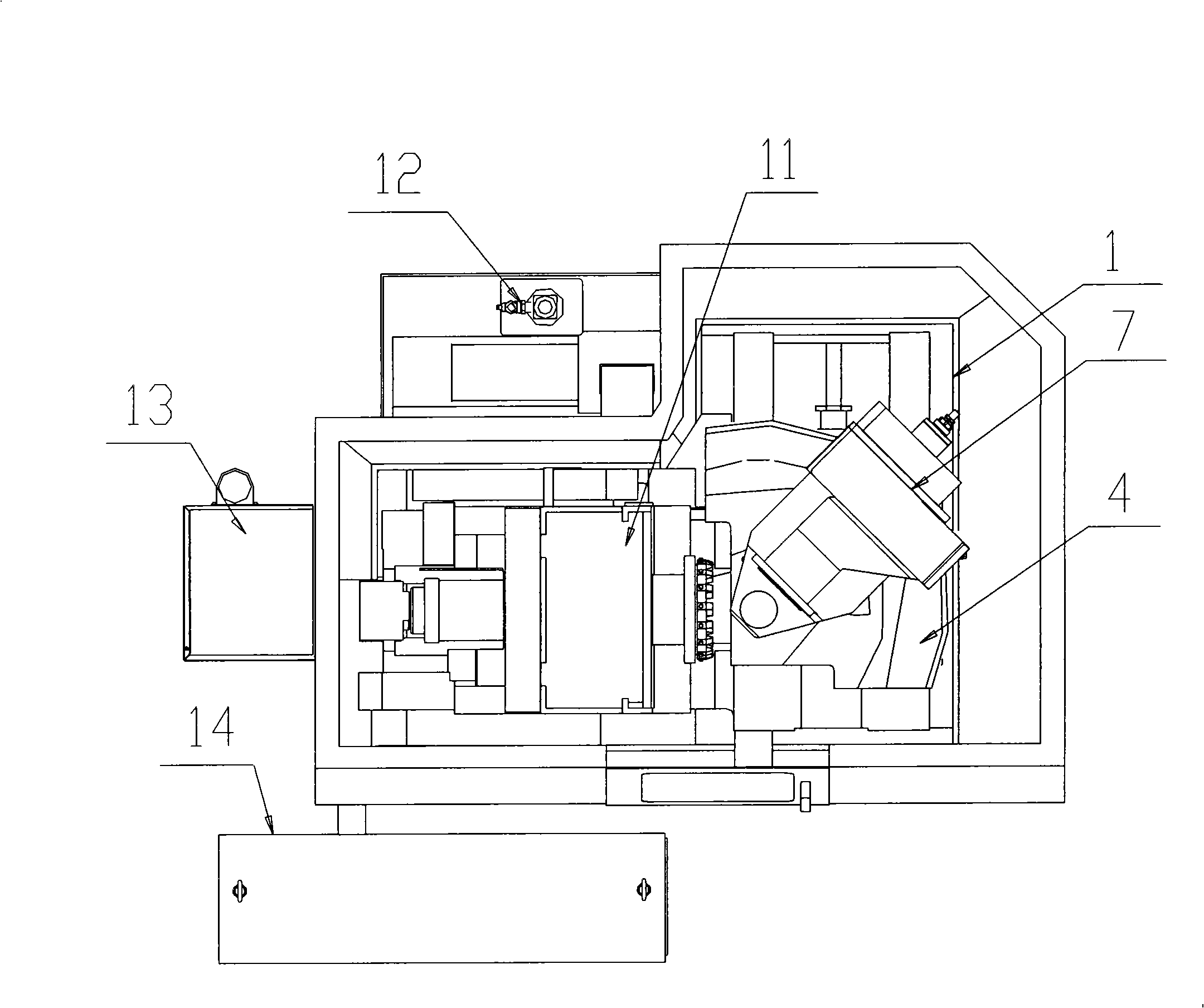

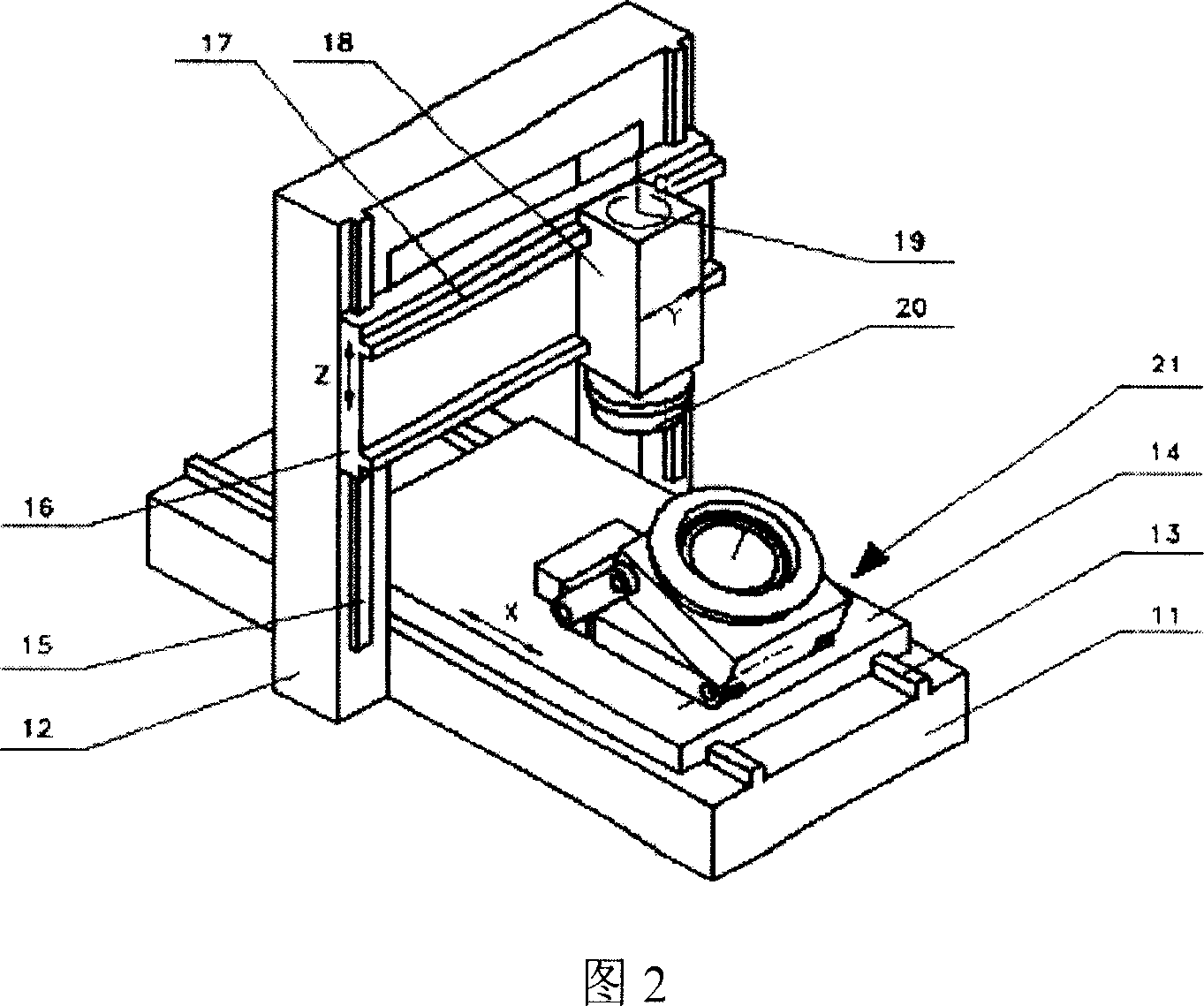

Six-five axis spiral awl gear cutting machine

InactiveCN101015870ACompact structureEasy to assembleLarge fixed membersGear teethEngineeringGear cutting

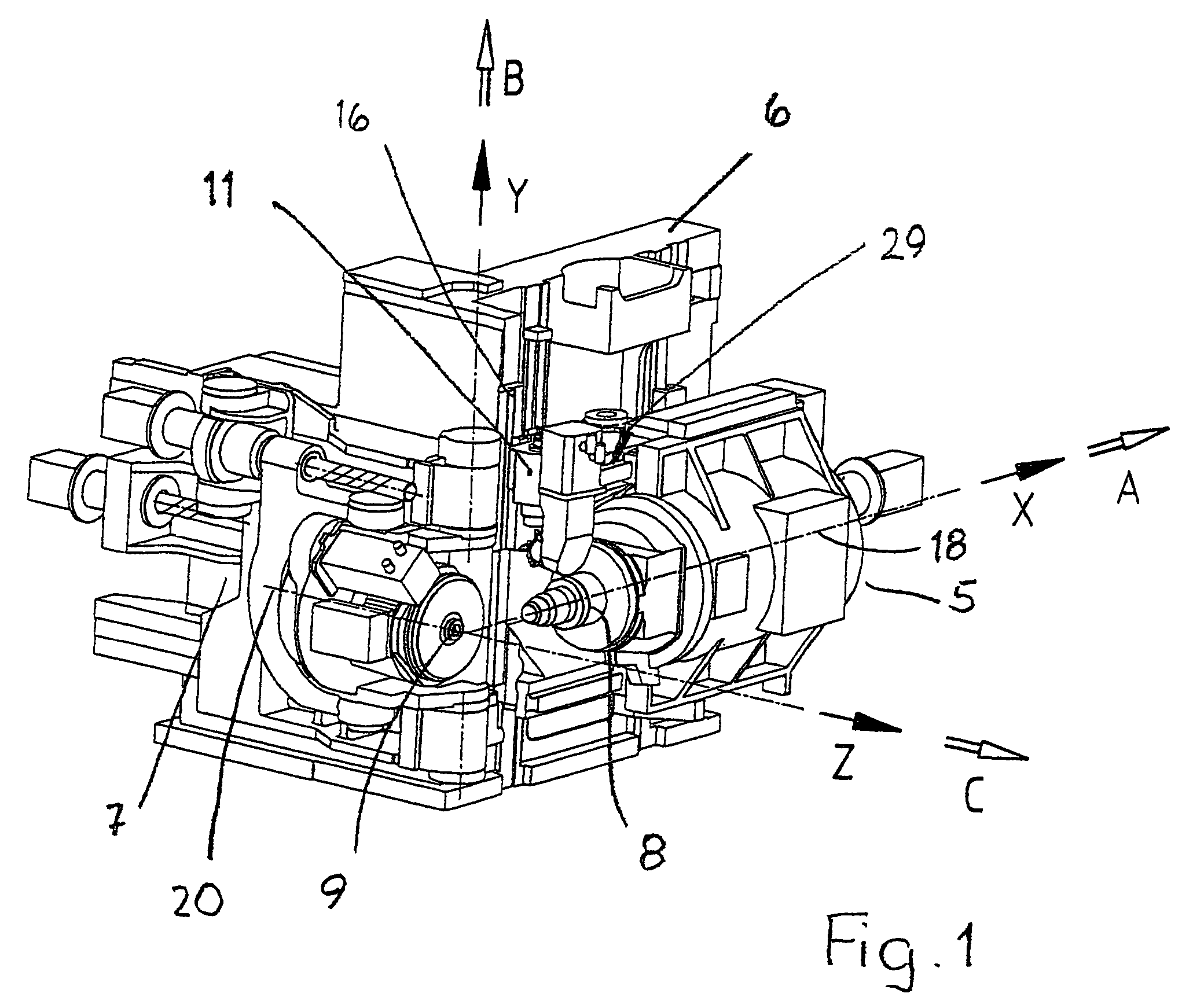

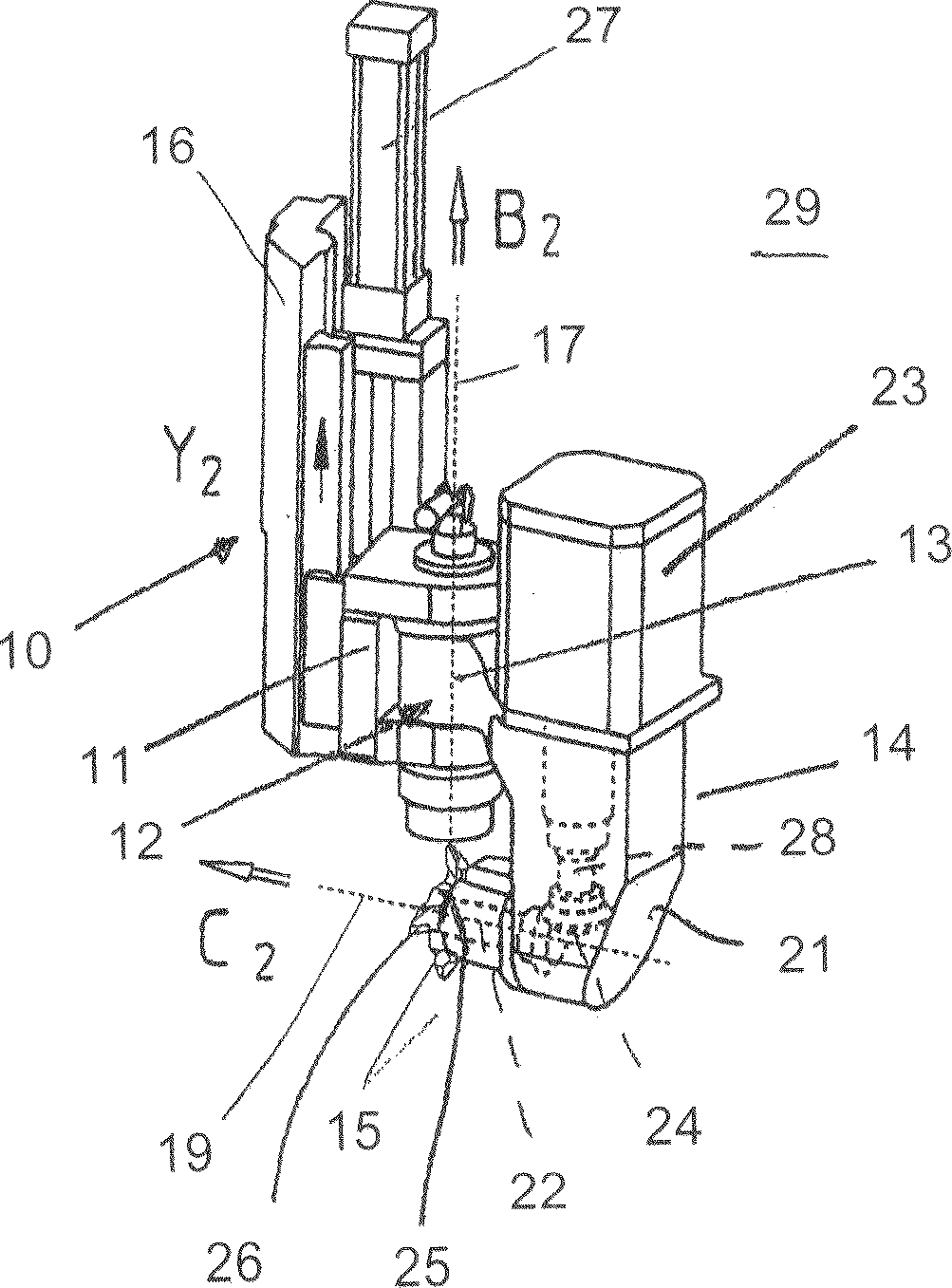

The invention relates to a six-axle five-linkage screw taper gear turning machine, wherein two sides of the machine are arranged with posts, a beam is mounted at the top of the posts, the middle of the machine is disposed with a X-track engaged with a movable X-axle block, one side of the beam is arranged with a Y-track with a movable Y-axle block, the Y-axle block is arranged with a Z-track with a movable Z-axle block mounted with a tool box, the tool box rotates driven by a driver and is mounted with a C axle with blades, the X-axle block is mounted with a work-piece box arranged with A axle for rotating and mounting work-piece driven by the driver, the work-piece box via B axle is hinged on the X-axle block and rotates around B axle. The invention has simple structure, high stability and efficiency.

Owner:HUNAN ZDCY (ZHONGDA CHUANG YUAN) CNC EQUIP CO LTD

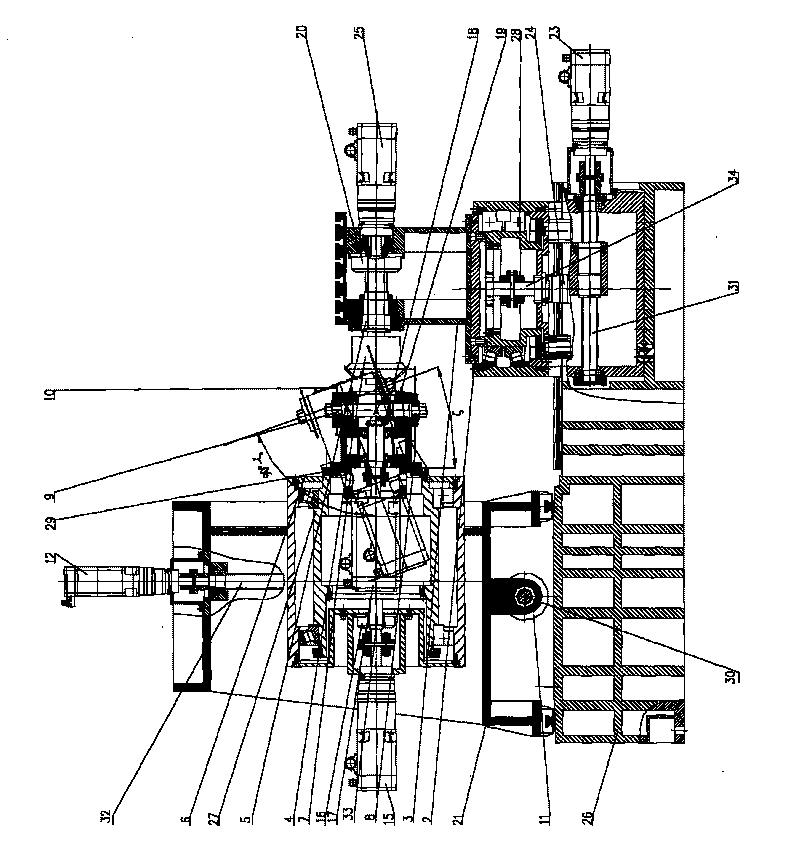

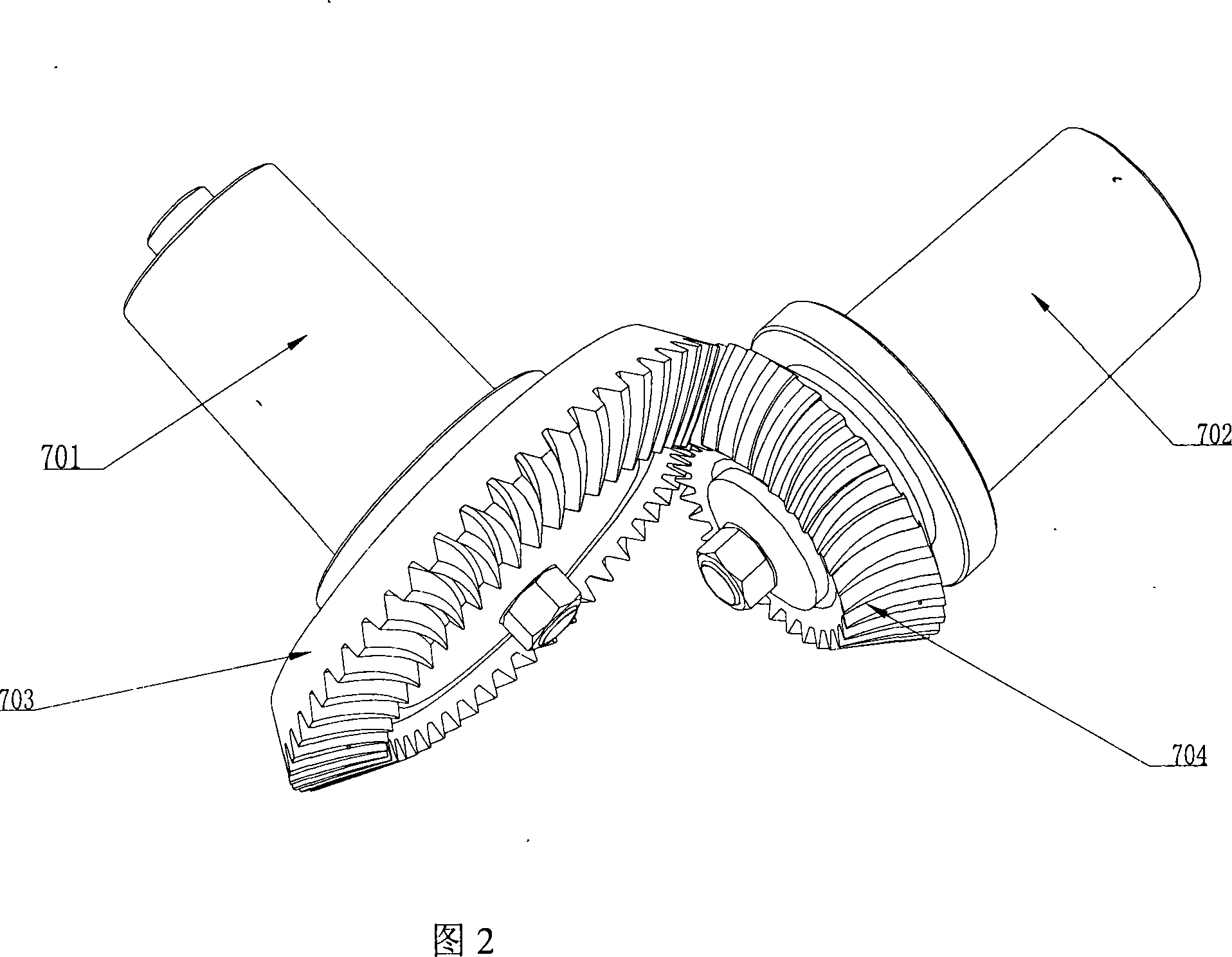

Spiral bevel gear cutting machine tool and gear cutting method

The invention discloses a spiral bevel gear cutting machine tool and a gear cutting method. The gear cutting machine tool comprises a cutting tool system, a workpiece system, a machine tool body and a numerical control system, wherein the cutting tool system comprises an XZ working table, an X-axis lead screw, a Z-axis lead screw, a short shaft, a tool base revolving drum, a tool base, No.1 milling cutters, a milling cutter shaft, No.2 milling cutters, a gear shaft and a correcting wedge. The rotating centre line of the tool base revolving drum and the rotating centre line of the short shaft are collinear; the right end surface of the tool base revolving drum is fixedly connected with an annular flange plate at the left end of the tool base by the correcting wedge; the right end of the tool base is provided with the milling cutter shaft; the rotating centre line of the milling cutter shaft and the rotating centre line of the short shaft are intersectant; and both ends of the milling cutter shaft are provided with the No.1 milling cutters, the No.2 milling cutters or grinding wheels. The left end surface of the tool base is provided with a drive motor; the drive motor is meshed with a bevel gear on the milling cutter shaft by the gear shaft; and the rotating centre line of the output shaft of the drive motor and the rotating centre line of the milling cutter shaft are vertically intersectant. The invention also provides a method for processing helical bevel gears by utilizing the machine tool.

Owner:JILIN UNIV

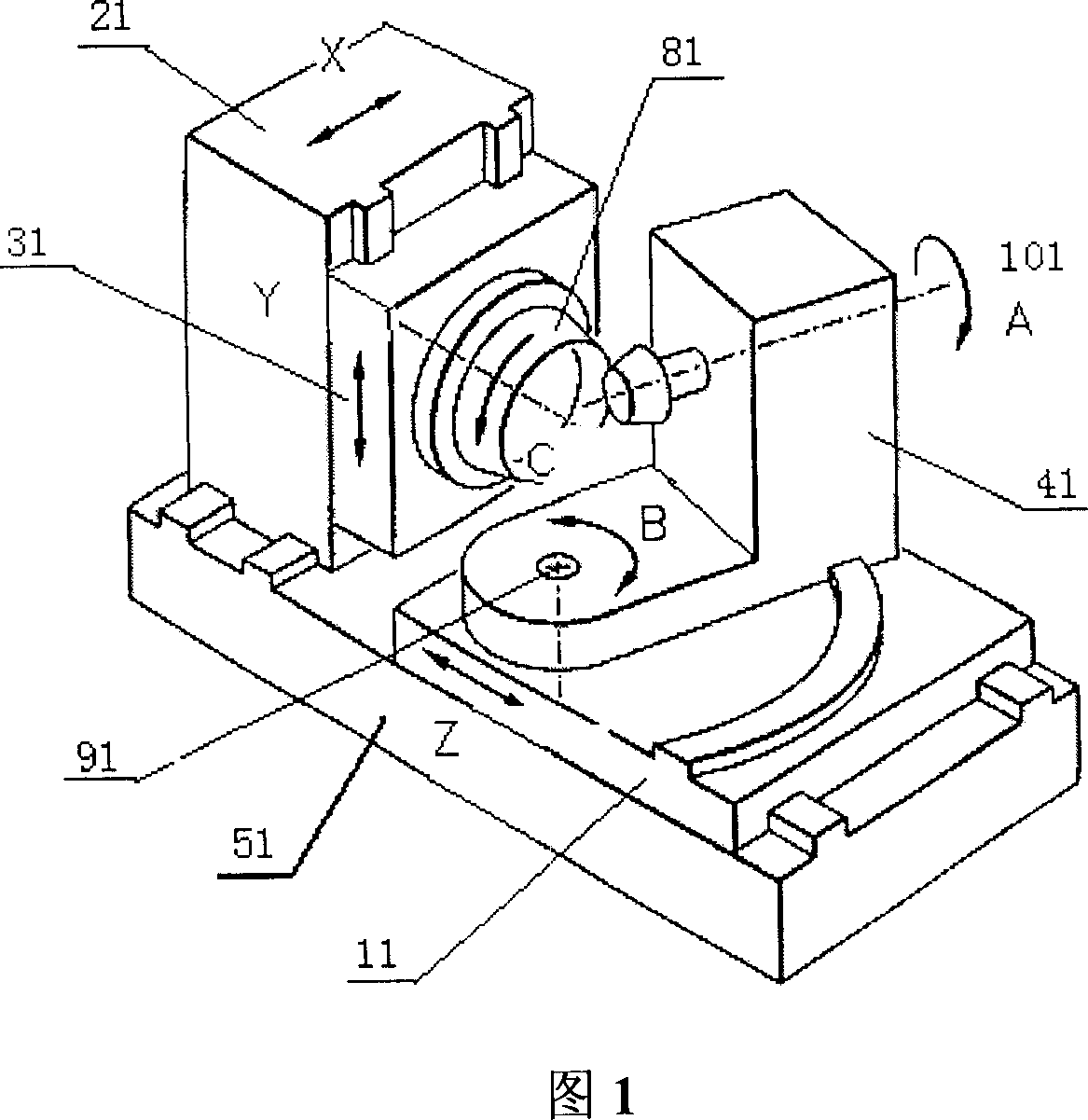

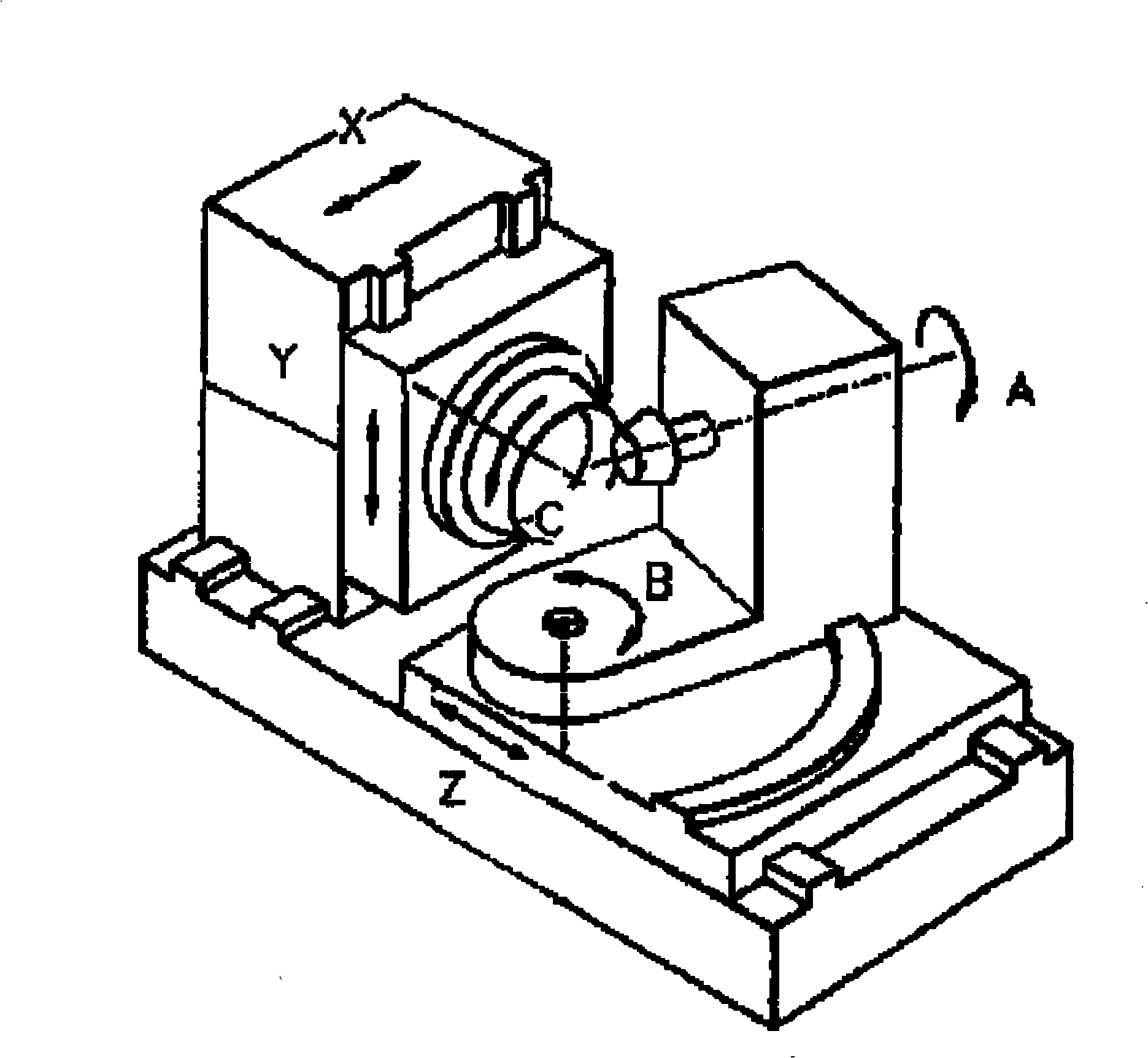

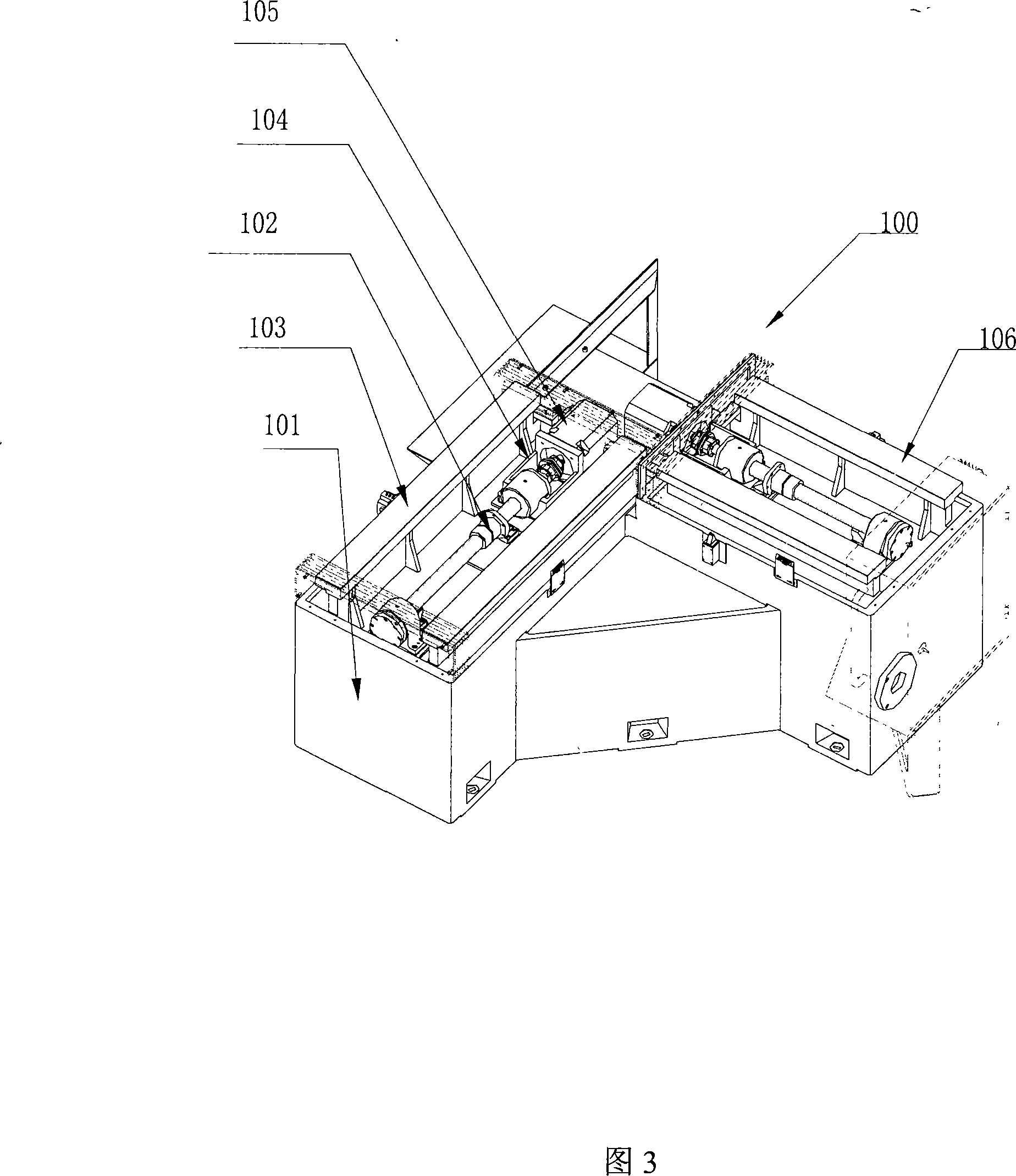

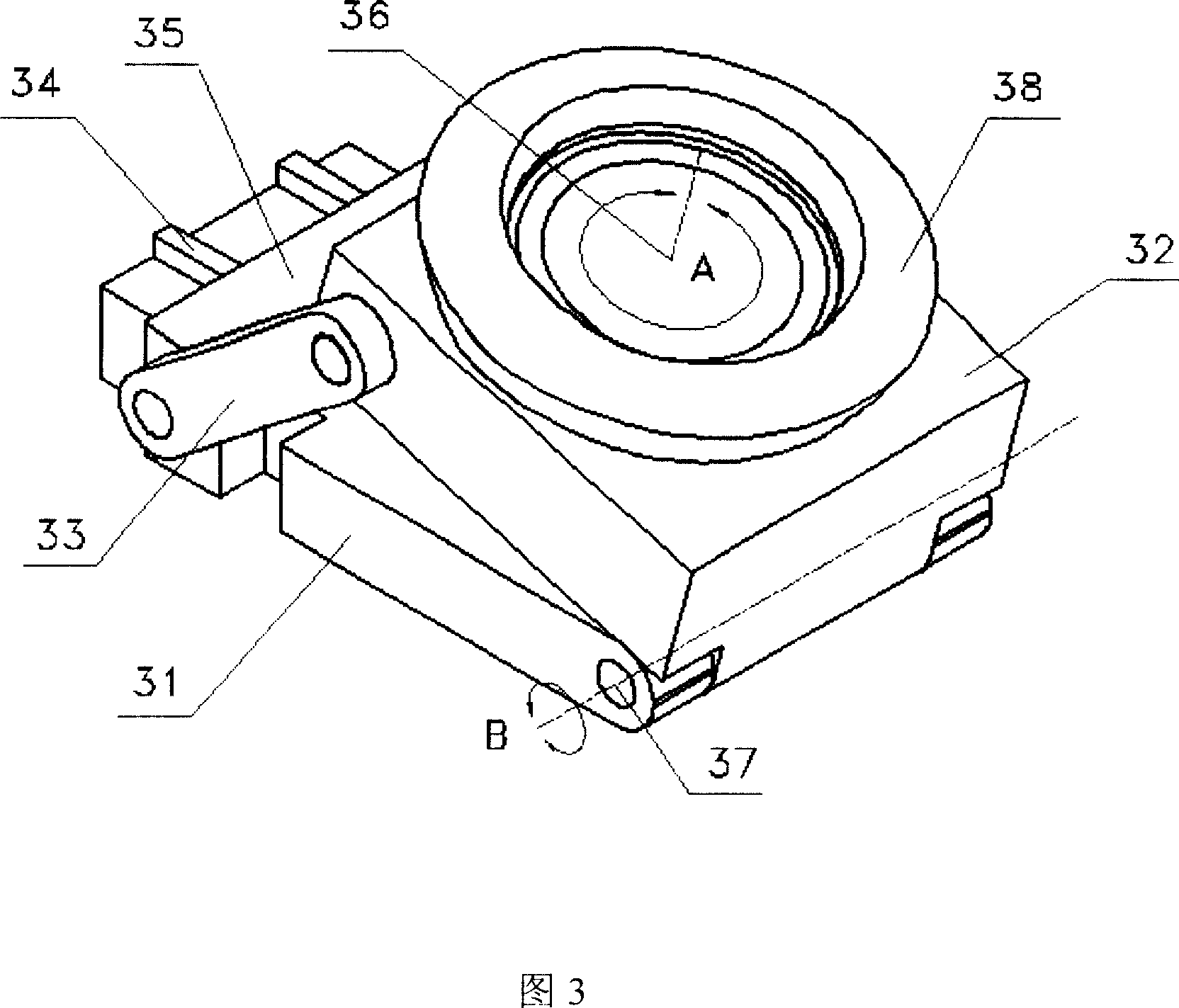

Four-shaft four-linkage numerical control spiral bevel gear milling machine arrangement

InactiveCN101342617AEasy loading and unloadingGood effectLarge fixed membersGear-cutting machinesNumerical controlReciprocating motion

The invention relates to a four-axis and four-linkage numerical control generating machine of arc bevel gear and belongs to the field of the gear generating machine technology. The invention comprises a machine body, a workpiece box and a cutting tool box. The machine body is fixedly provided with a straight guide rail of Z-axis and a straight guide rail of X-axis. The straight guide rail of X-axis drives a saddle to do the straight line motion via a servo motor. The saddle is provided with a workpiece box and rotates around a rotary shaft to do the rotary motion of B-axis for adjusting the required cone angle of gear root. The workpiece box is provided with a workpiece spindle which is driven by the servo motor to do the rotary motion of A-axis. The straight guide rail of Z-axis drives a vertical column to do the straight motion of Z-axis via the servo motor. The vertical column is fixedly provided with a straight guide rail of Y-axis which drives the cutting tool box to do the straight and reciprocating motion in the vertical direction of Y-axis via the servo motor. The main motor on the cutting tool box drives the cutting tool disk which is provided with the cutting tool to rotate for doing the rotary motion of C-axis of gear cutting. The four-axis and four-linkage numerical control generating machine of arc bevel gear has the advantages of simple structure, humanized layout, convenient loading and unloading of the workpiece, good dynamic rigidity and dynamic balancing, and small occupied area.

Owner:天津精诚机床股份有限公司

High-speed tool steel gear cutting tool and manufacturing method therefor

The invention provides a high-speed tool steel gear cutting tool in which fracture or chipping does not occur at the cutting edge, and which realizes excellent cutting performance over long periods. Moreover, a method of manufacturing a gear cutting tool including: a step for quenching a tool material comprising high-speed tool steel and which has been rough processed to a shape corresponding to a final shape of a gear cutting tool, to transform a structure of the tool material into martensite, a step for temperling the tool material after quenching to transform any residual austenite dispersingly distributed throughout a matrix of the martensite structure formed by the quenching, into martensite, and a step for finishing the tool material after tempering to a final shape, is characterized in that the tool material after quenching is subjected to sub-zero treatment involving cooling and holding at a temperature of less than -150° C.

Owner:MITSUBISHI MATERIALS CORP

Chipless forming method for gear stick and section gear through hot extrusion

InactiveCN101905250AExtend your lifeImprove plasticityExtrusion diesFurnace typesEngineeringThick wall

The invention discloses a chipless forming method for a gear stick and a section gear through hot extrusion by utilizing an alloy steel horizontal type backward extruder, solving the problems that the existing gear cutting process has more working procedures, low efficiency, large metal loss, more operators for machine tool processing and high production cost and the like by utilizing the chip processes of lathing, milling, drilling, inserting and grinding. The method comprises the following steps: an inner cooling combined type double-conical surface gear squeezing die, a recipient and a floating pecker combined mandril are adopted by taking the producing principle of alloy steel thick wall special seamless steel tubes as an example; scale-free heating is rapidly carried out on the blank; lubricating warm-extrusion molding is carried out; center punching, shaft hole slotting and tooth surface extrusion are finished at a time; and the finished product of the gear stick is directly produced, then is subject to waste heat annealing, slicing by wire-electrode cutting and heating process to be manufactured into a finished product. Compared with a chip gear-cutting molding method, the invention has simplified working procedure, few labor, high efficiency, less metal loss, high gear strengthen and reduces the production cost, and then tooth surface precision reaches the standard. The method of the invention is a significant technological innovation of straight tooth and oblique tooth cylindrical gear process technologies.

Owner:周家镳

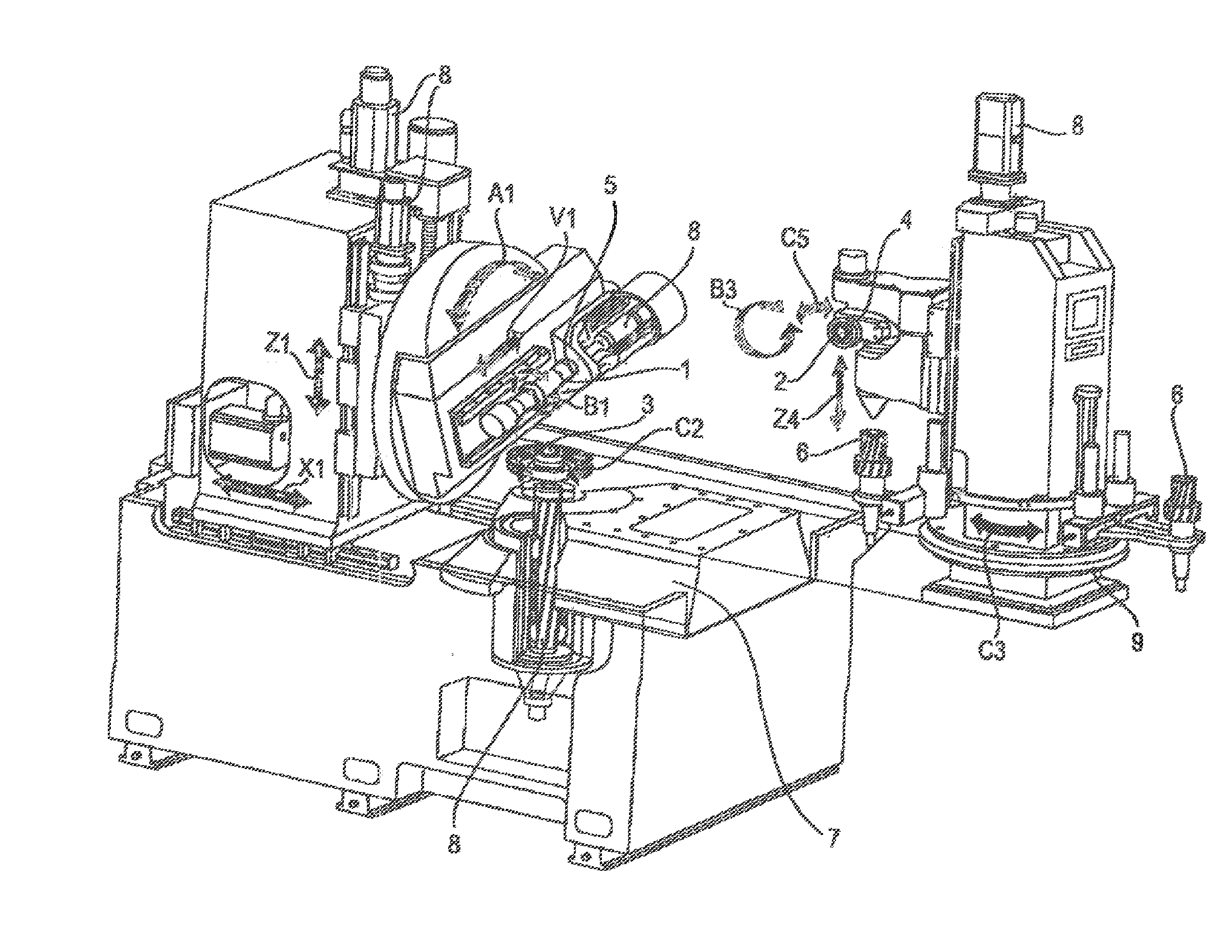

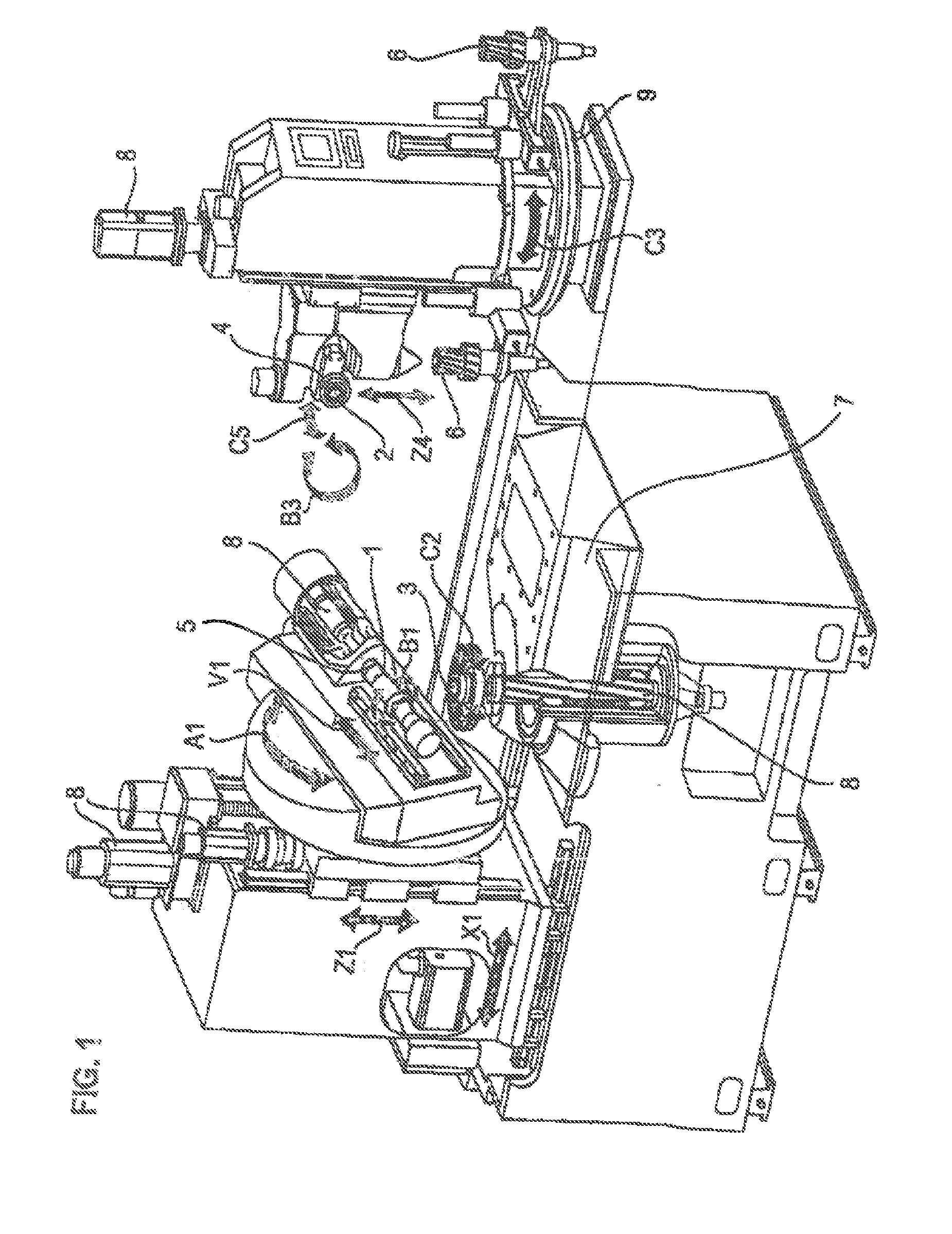

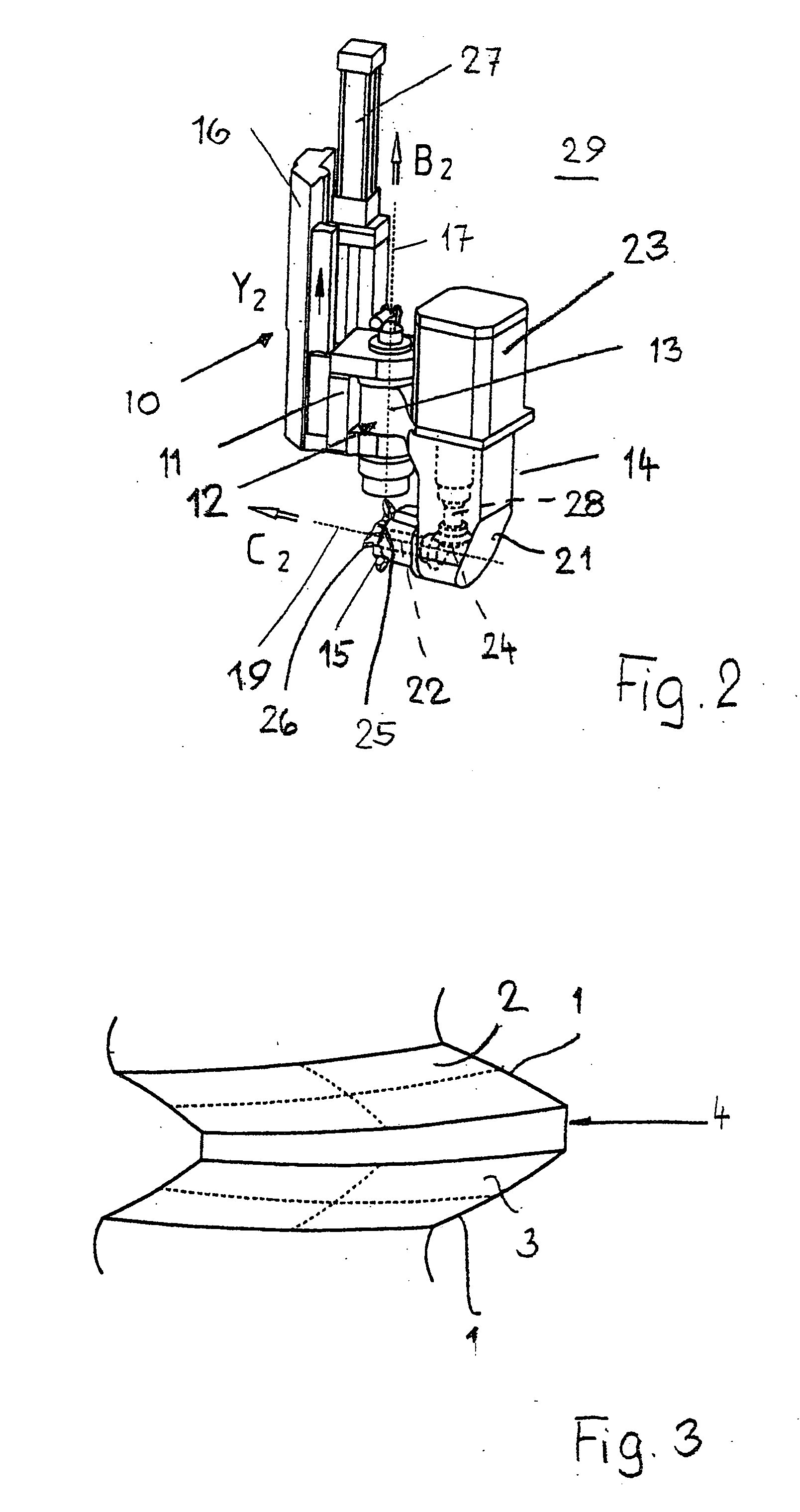

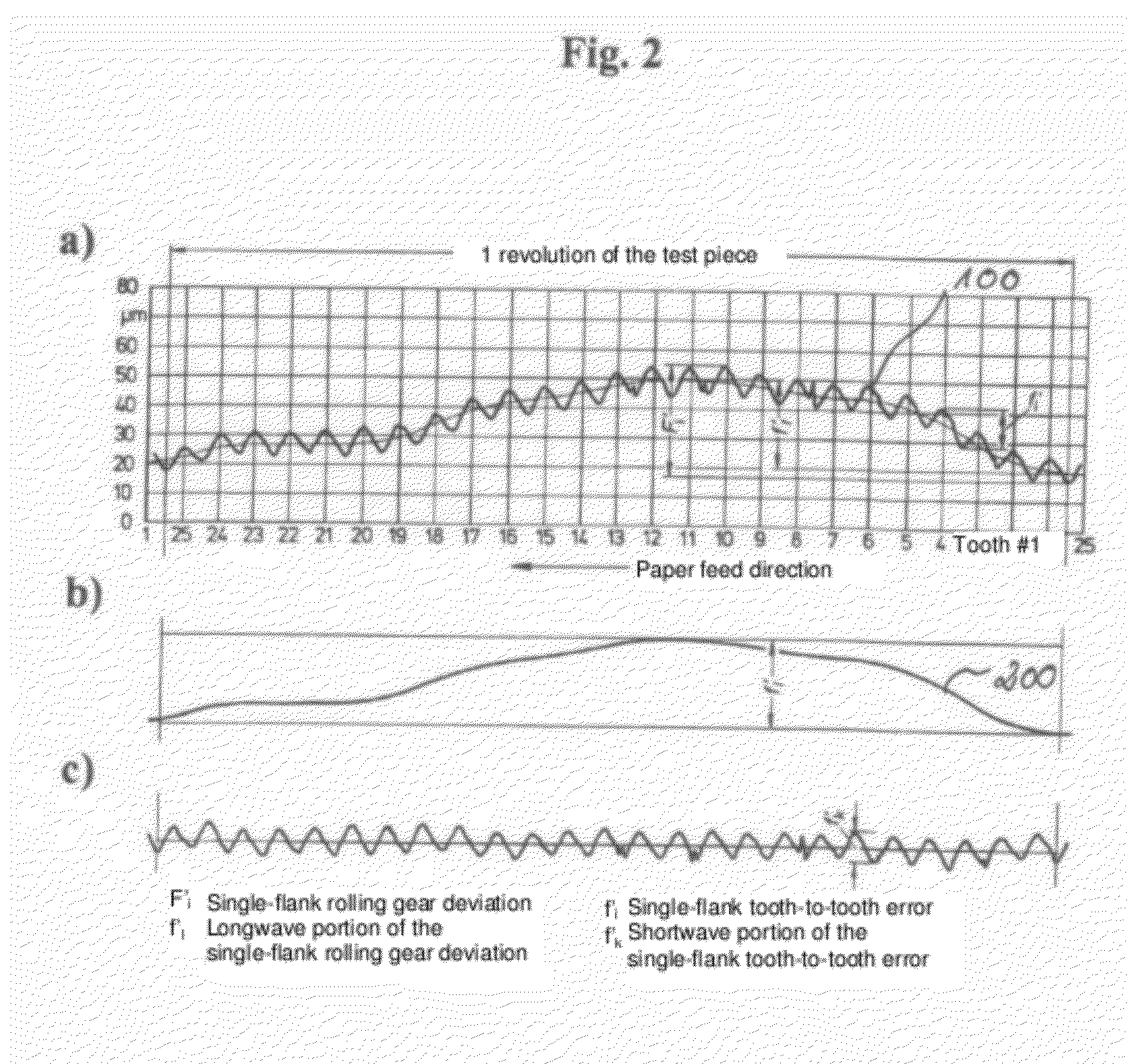

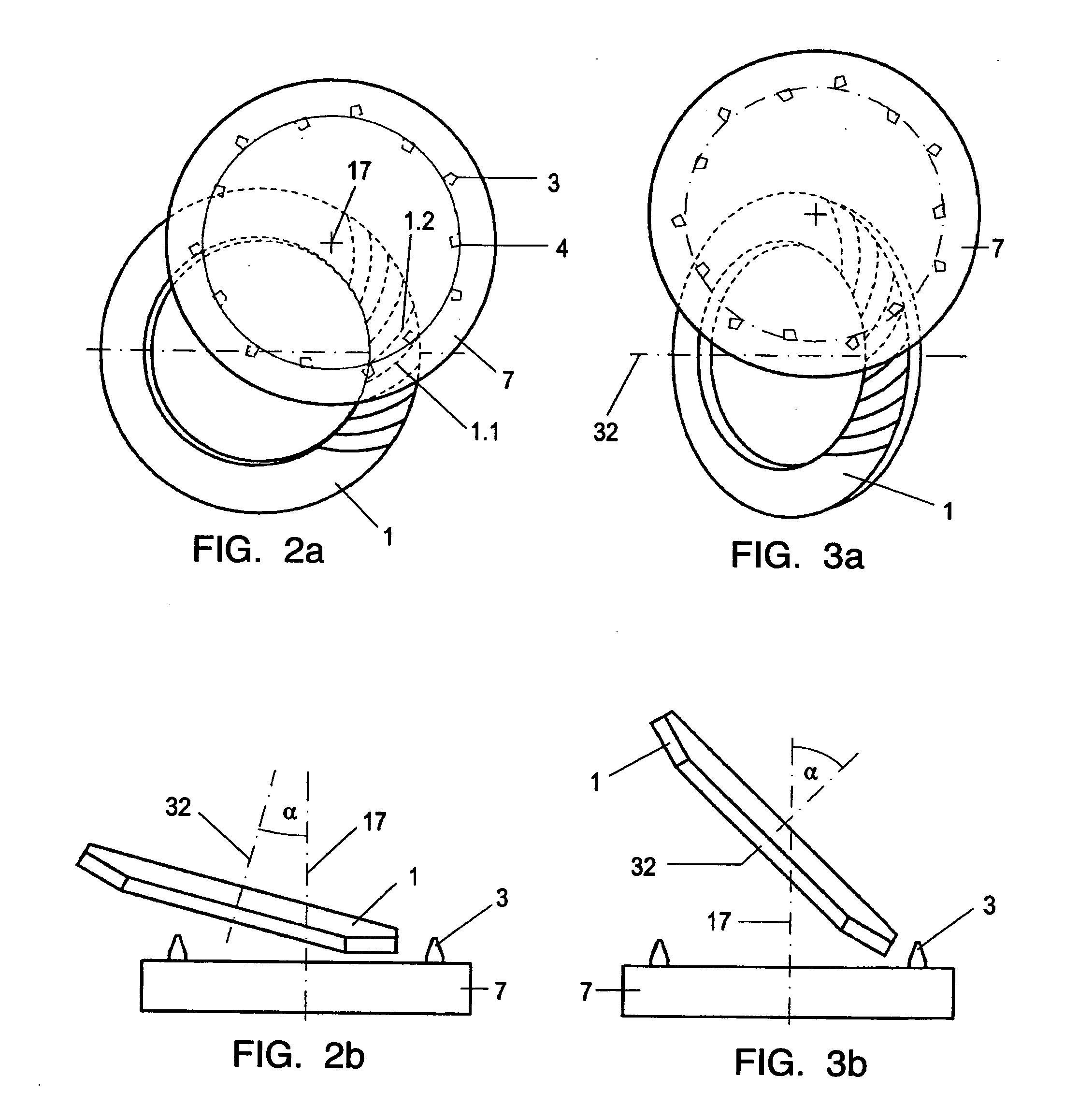

Machining Method for Hard-Fine Machining of Noise-Optimized Gears on a Gear-Cutting Machine

ActiveUS20140256223A1Improve uniformityAvoid and at least minimize vibration excitationAutomatic control devicesGrinding feed controlRotational errorEngineering

The present invention relates to a method for hard-fine machining of tooth flanks with corrections and / or modifications on a gear-cutting machine, wherein respective toothed wheel pairings which mesh with one another within a transmission or a test device are machined while taking account of the respective mating flanks, and wherein the tooth flanks of the relevant workpieces are provided with periodic waviness corrections or waviness modifications. In accordance with the invention, the rotational error extent is determined by means of rotational distance error measurement of the toothed wheel pairs in a gear measuring device and / or transmission. This measurement result serves as an input value for defining the amplitude, frequency and phase position for the periodic flank waviness corrections on the tooth flanks of the toothed wheel pairings for production in the gear-cutting machine.

Owner:LIEBHERR VERZAHNTECHNIK GMBH

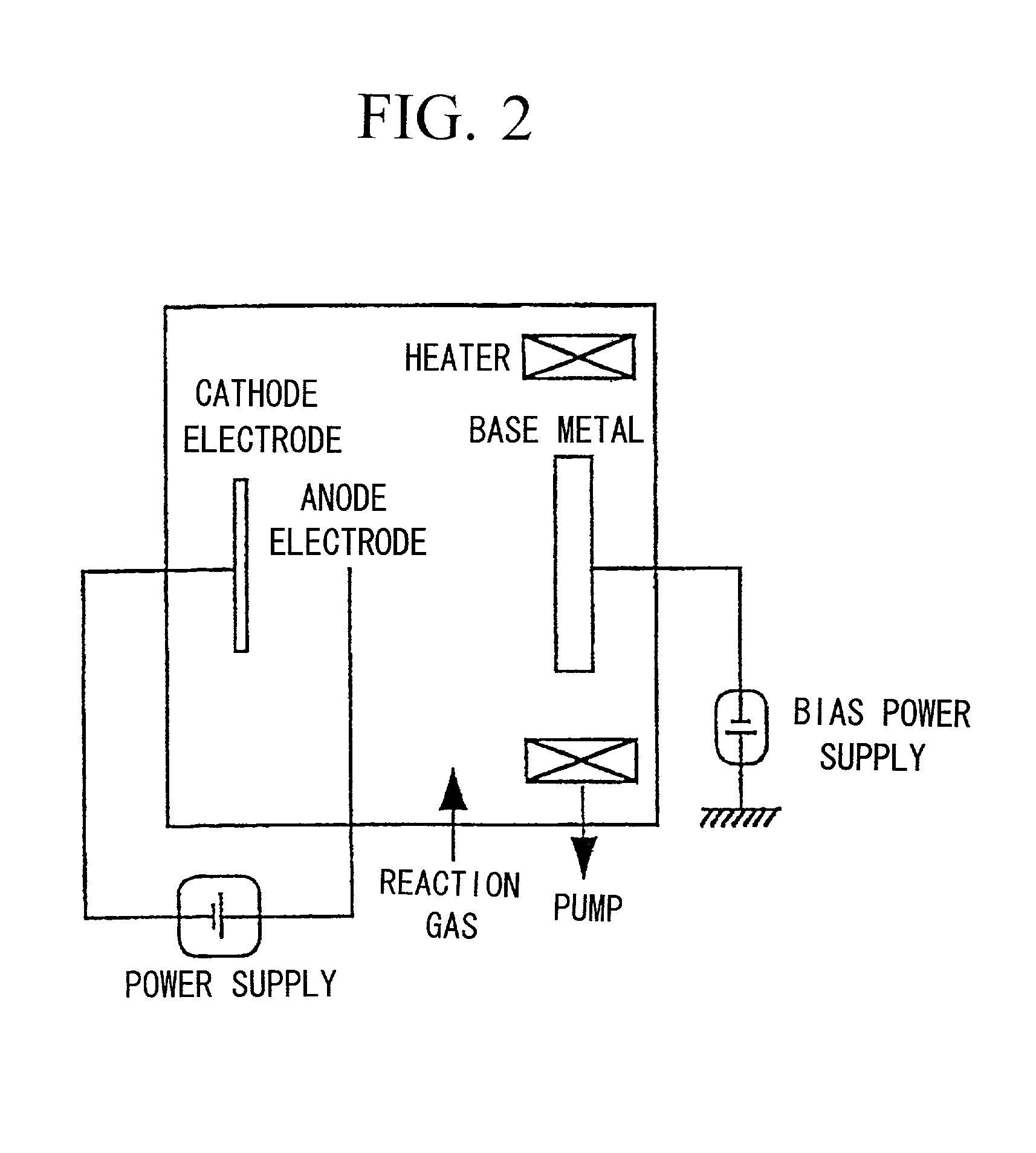

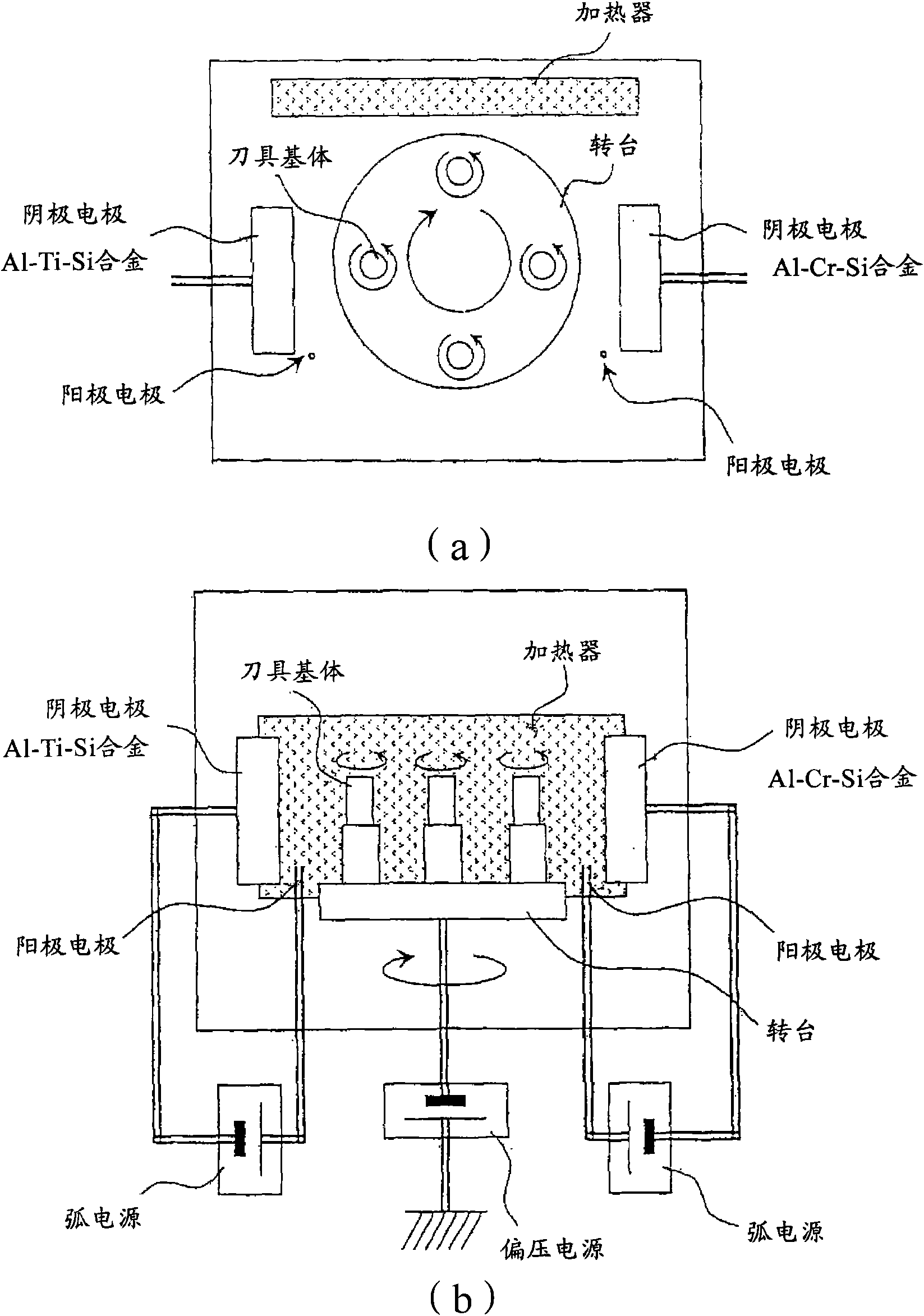

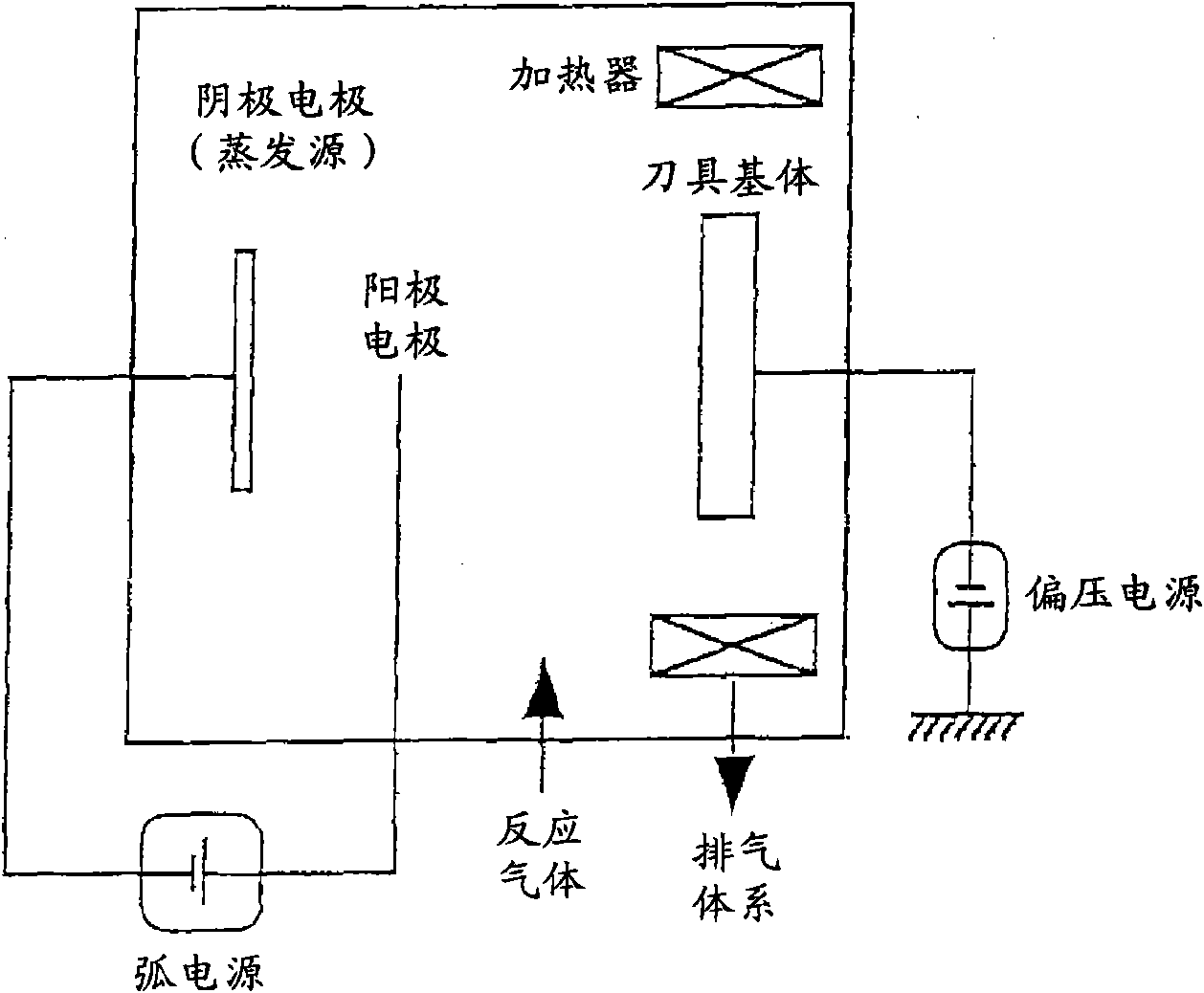

Surface-coated cutting tool

ActiveCN101678467AExcellent high temperature hardnessExcellent high temperature toughnessMilling cuttersVacuum evaporation coatingThin layerCemented carbide

A surface-coated cutting tool which has excellent chipping resistance and wearing resistance in high-speed cutting processing such as high-speed gear cutting processing, high-speed milling processing,and high-speed drilling processing. The surface-coated cutting tool comprises a tool base, e.g., a cemented carbide base, cermet base, or high-speed tool steel base, and at least a hard coating layerformed on a surface of the tool base and having a multilayer structure composed of a thin layer (A) and a thin layer (B) alternating therewith. The thin layer (A) is constituted of an (Al,Cr,Si)N layer satisfying the empirical formula ¢AlXCrYSiZ!N (wherein 0.2 <= X <= 0.45, 0.4 <= Y <= 0.75, 0.01 <=Z <= 0.2, and X+Y+Z=1 in terms of atomic ratio), and the thin layer (B) is constituted of an (Al,Ti,Si)N layer satisfying the empirical formula ¢AlUTiVSiW!N (wherein 0.05 <= U <= 0.75, 0.15 <= V <= 0.94, 0.01 <= W <= 0.1, and U+V+W=1 in terms of atomic ratio).

Owner:MITSUBISHI MATERIALS CORP

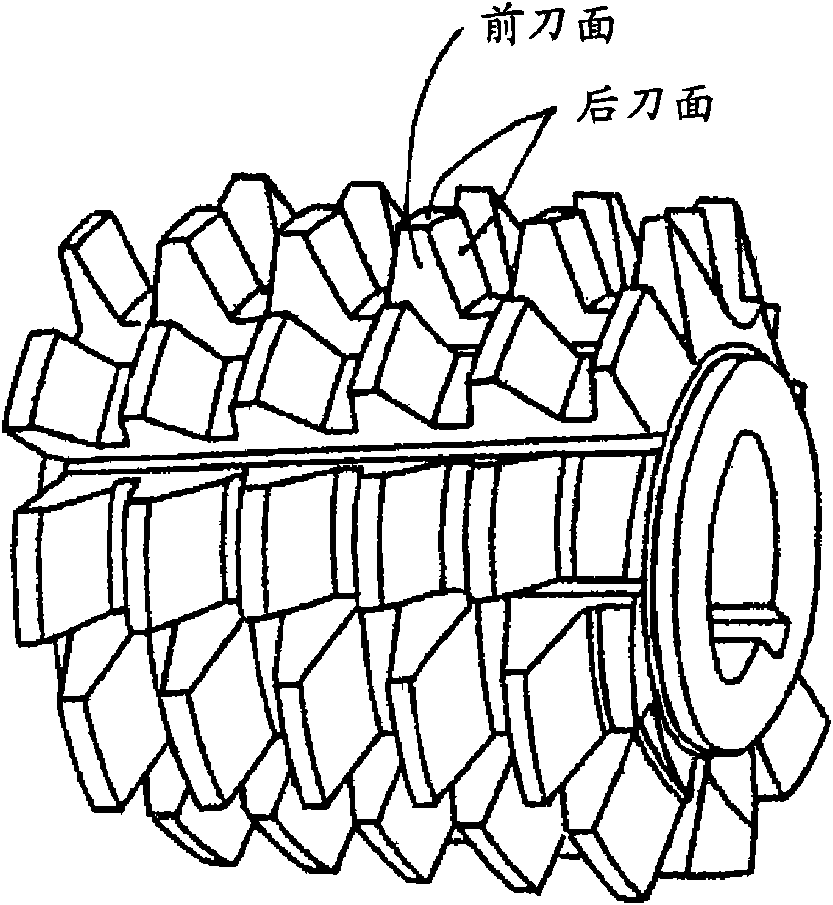

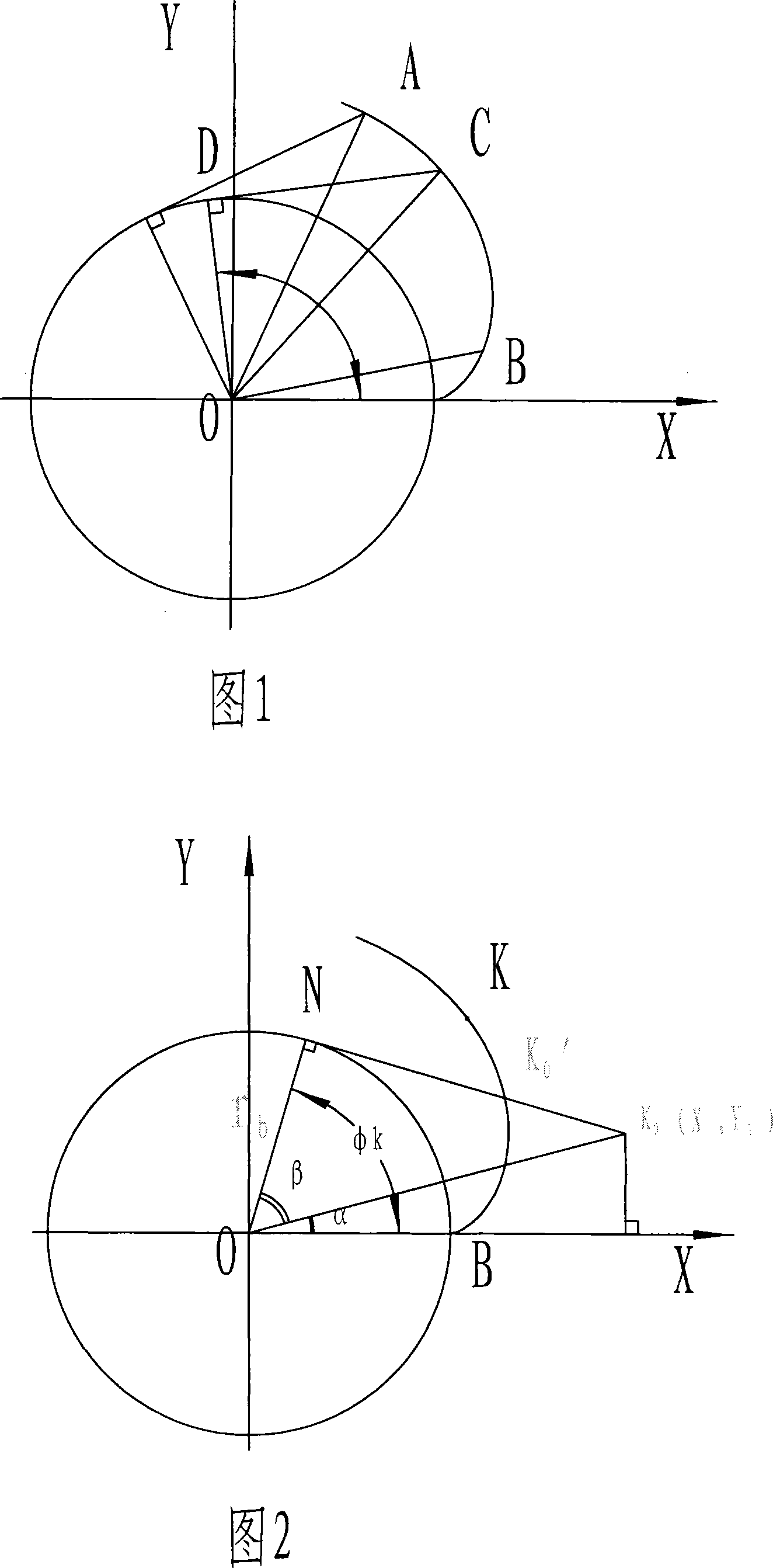

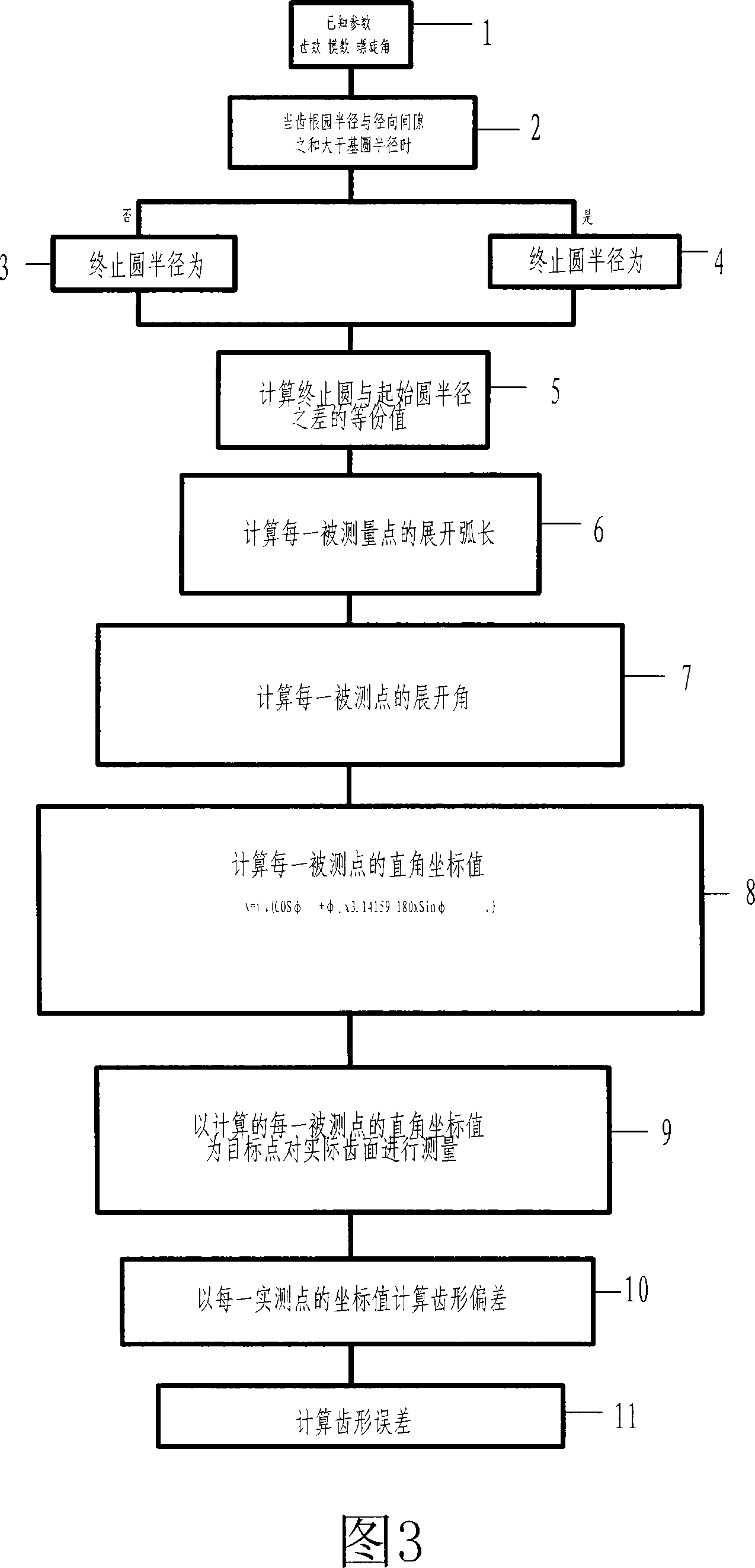

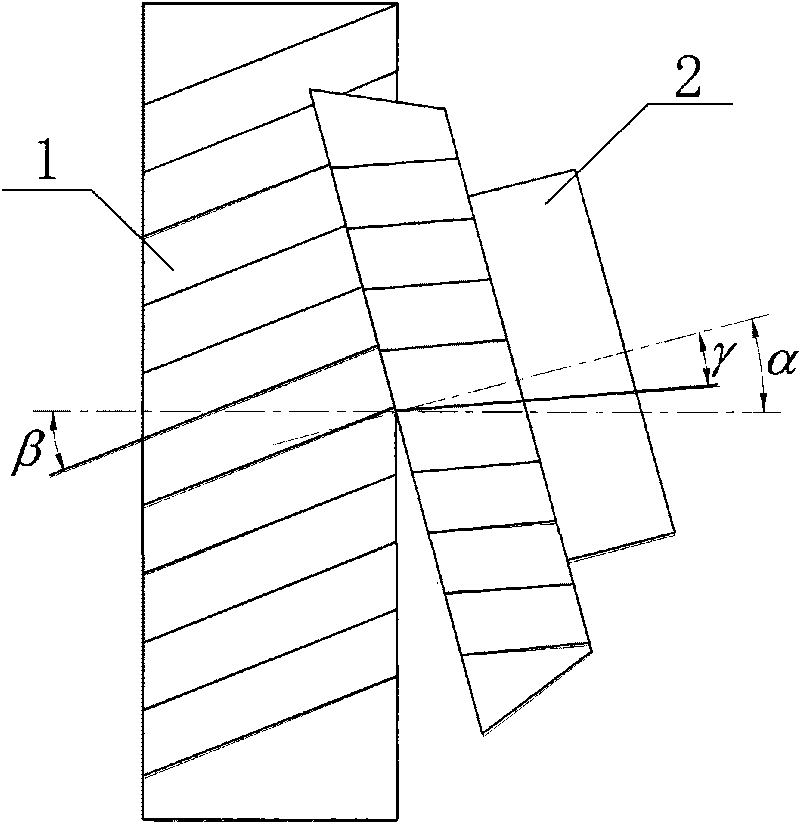

Beveled wheel tooth error three-coordinate measuring method

InactiveCN101191723AEvenly distributedSolve the problem of uneven collection pointsMachine gearing/transmission testingInvolute gearObject point

The invention provides a three-coordinate measuring method for bevel gear tooth form error; the procedures of the method are that: (1) the stop position of measuring bevel gear tooth form error is defined by calculation; (2) positions of other measuring points on the checking part are defined; (3)the actual tooth face is measured by taking the stop position and the theoretical coordinates of measuring points as object points; (4) the tooth form error is worked out. By applying the method of the invention in the tooth form error measurement, the repeatability error can be controlled below 0.004mm, thereby markedly improving the measuring accuracy and being capable of measuring the involute gear below six-grade accuracy. The trend of the involute form of the measuring result is relatively obvious, based on which the depth of the tooth root and the tooth head can be analyzed. According to the measuring result, the gear-cutting machine is guided to be adjusted, achieving good effects.

Owner:AVIC HUIYANG AVIATION PROPELLER

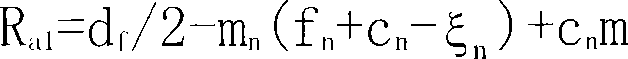

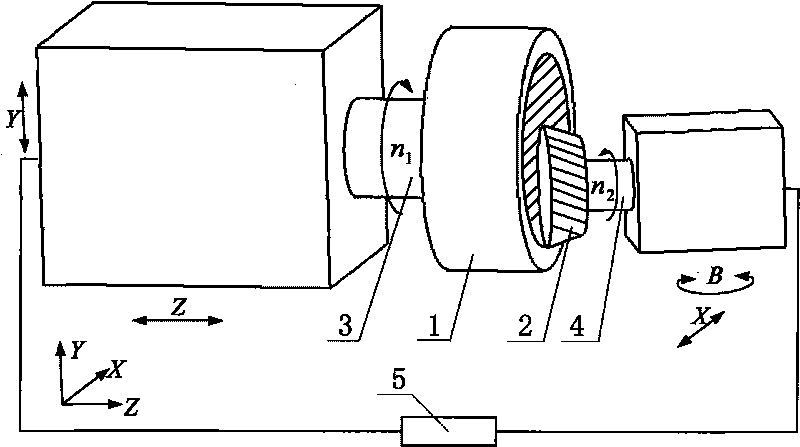

Method for machining cylindrical gear cutting teeth

InactiveCN101733486ASolve processing problemsImprove efficiencyGear teethManufacturing cost reductionGear wheel

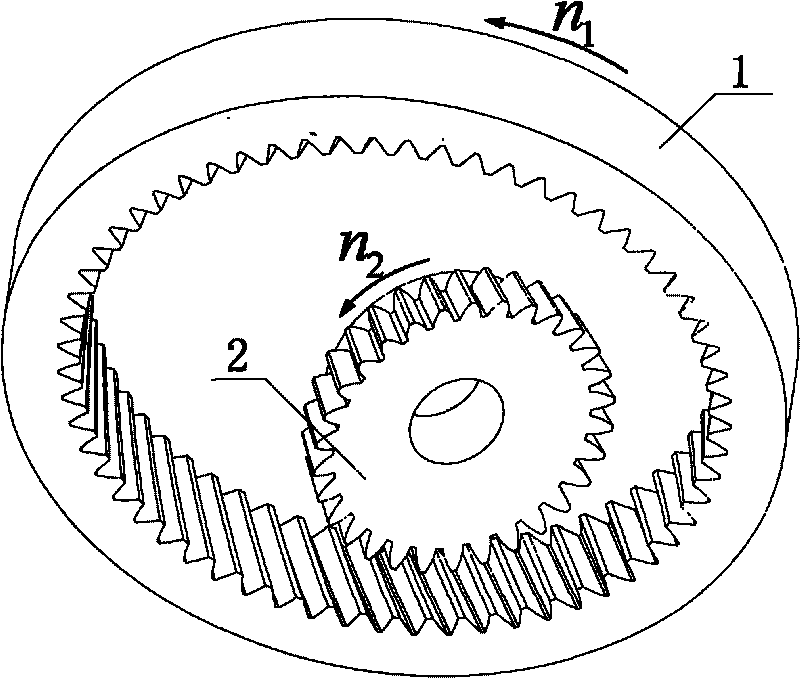

The invention discloses a method for machining cylindrical gear cutting teeth. The rotation speeds of a workpiece and a cutter are n1 and n2 respectively, the ratio of the n1 to the n2 is equal to the ratio of the tooth number of the cutter and the workpiece, and the cutter is equivalent to a gear engaged with the workpiece. During machining, the axes of two main shafts of the workpiece and the cuter form a crossed axis angle alpha, and the angle alpha is the algebraic sum of a tooth directional spiral angle beta of the workpiece and a tooth directional spiral angle gamma of the cutter. The blade shape of the cutter is designed to be conjugate with the tooth shape of the workpiece; the rotations of the workpiece and the cutter are controlled by a multi-axis movement controller; and the cutter has axial feed and radial feed. At a cutting point, the cutting speed V is changed along with the change of the cutting point on the blade to form a cutting action so as to finish cutting and shaping of a gear tooth surface of the workpiece. The machining for a non-penetrating involute inner tooth can be finished without a tool withdrawal groove and cannot be finished by the existing gear machining technology. An inserting tooth and a pull tooth can be replaced, the machining precision and efficiency can be improved, and the manufacturing cost can be greatly reduced.

Owner:TIANJIN UNIV +1

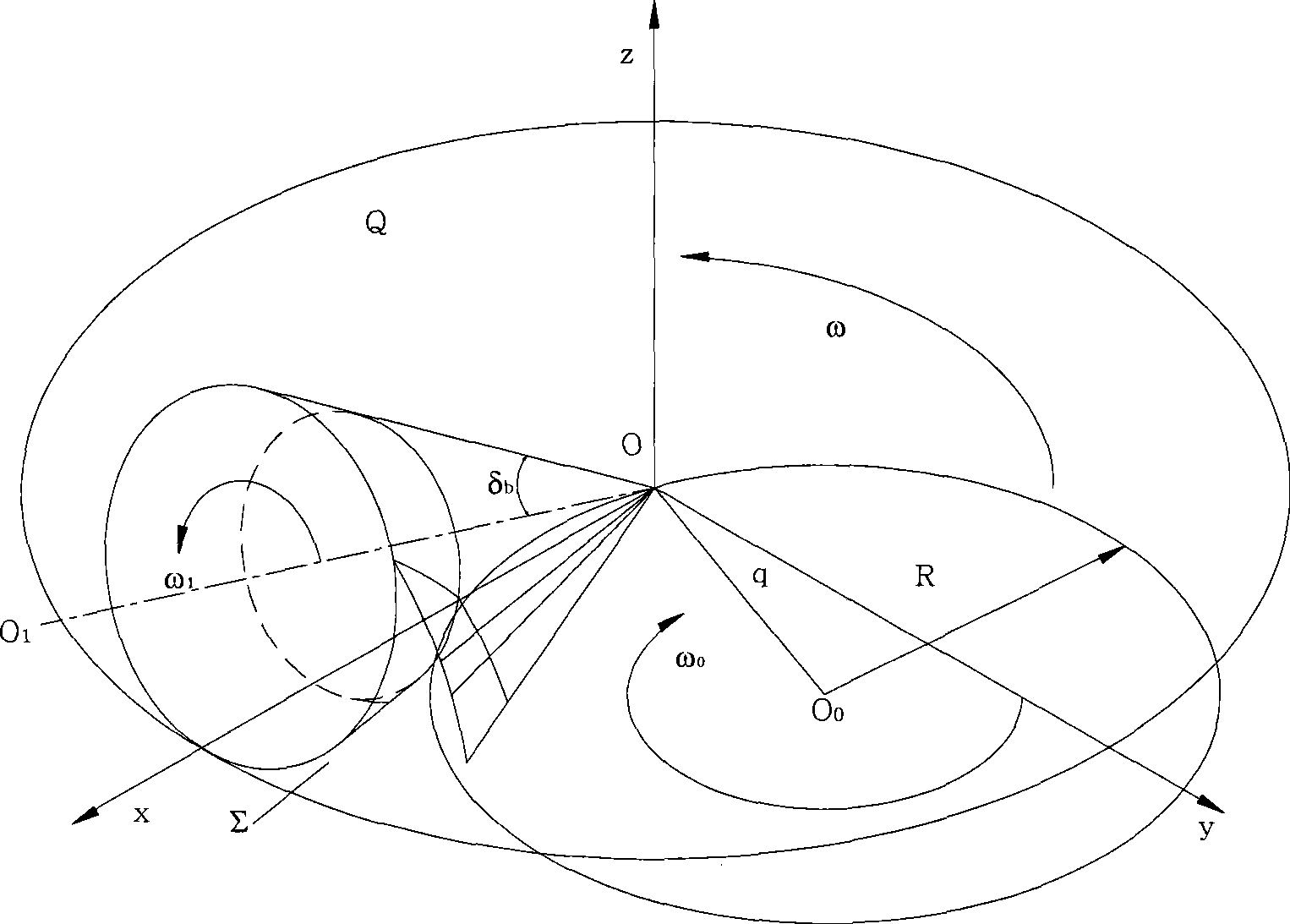

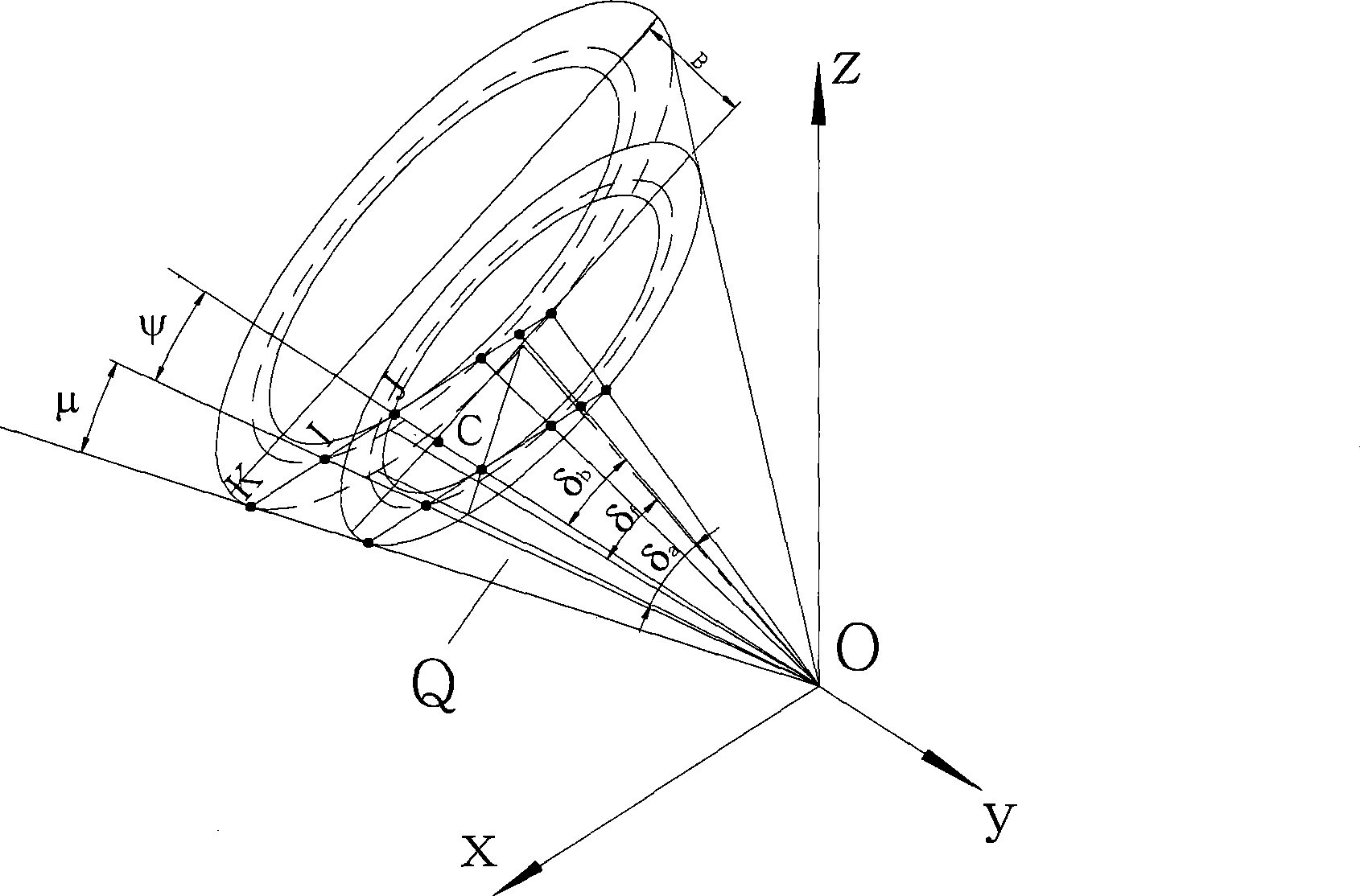

Method for producing cutter teeth of spiral bevel gear with spherical involute profile of tooth tapered tooth

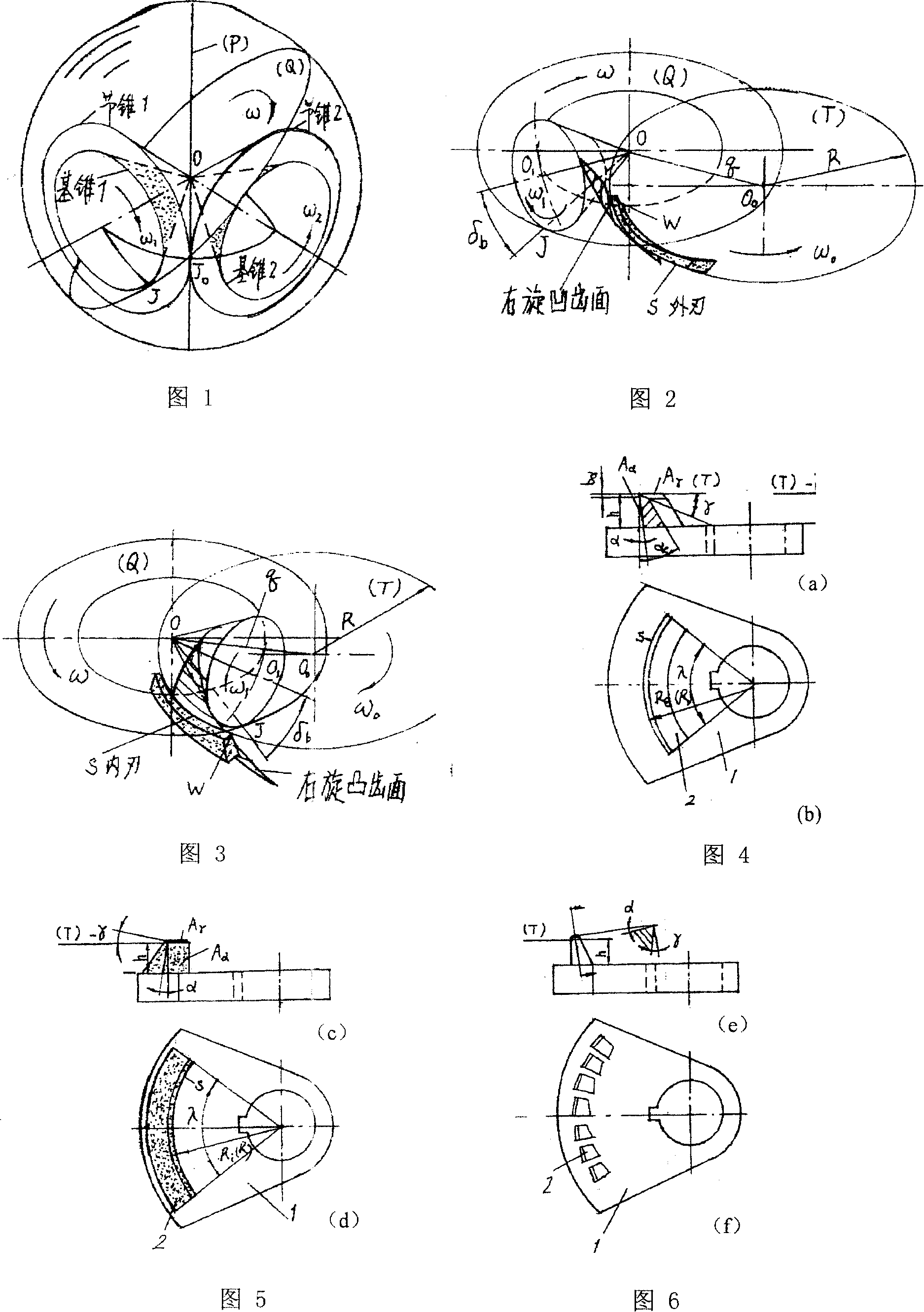

InactiveCN101152677AImprove mesh qualitySimple configurationMilling equipment detailsGear teeth manufacturing toolsGear wheelEngineering

The invention relates to a gear cutting method for manufacture of spiral bevel gear with spherical involute tooth profile shrinkage tooth which is the gear cutting method that an arc-shaped cutting edge skiving cutterhead with turning radius of R on an end surface (T) is adopted for turning of spherical involute tooth profile and the shrinkage tooth is adopted to manufacture the tooth surface of the spiral bevel gear. When in cutting, a tooth casting is tangental to spherical large round plane (Q) represented by machine tool shaking station turning plane and maintains pure rolling according to base cone, rotating speed of every shaft of the machine tool is set up according to following speed ratio relations: when rotating speed of the shaking station is omega, rotating speed of the tooth casting is (1) type, wherein, ZQ is hypothetical tooth number of the shaking station, rotating speed of a cutterheadshaft is (2) type, and omega is opposite to the direction of omega 0; skiving cutterhead knife edge S is tangental to processed tooth surface and tooth surface fine turning process without generation of undercut is finished in the state of large bevel turning. Engaging quality of the cutting gear manufactured with the method is improved, with transient speed ratio constancy and insensitivity of influence of contacting area by transmission included angle alteration, moreover, the gear processed with the method can be exchanged and the invention simplifies the design of the gear and machine tool.

Owner:彭福华

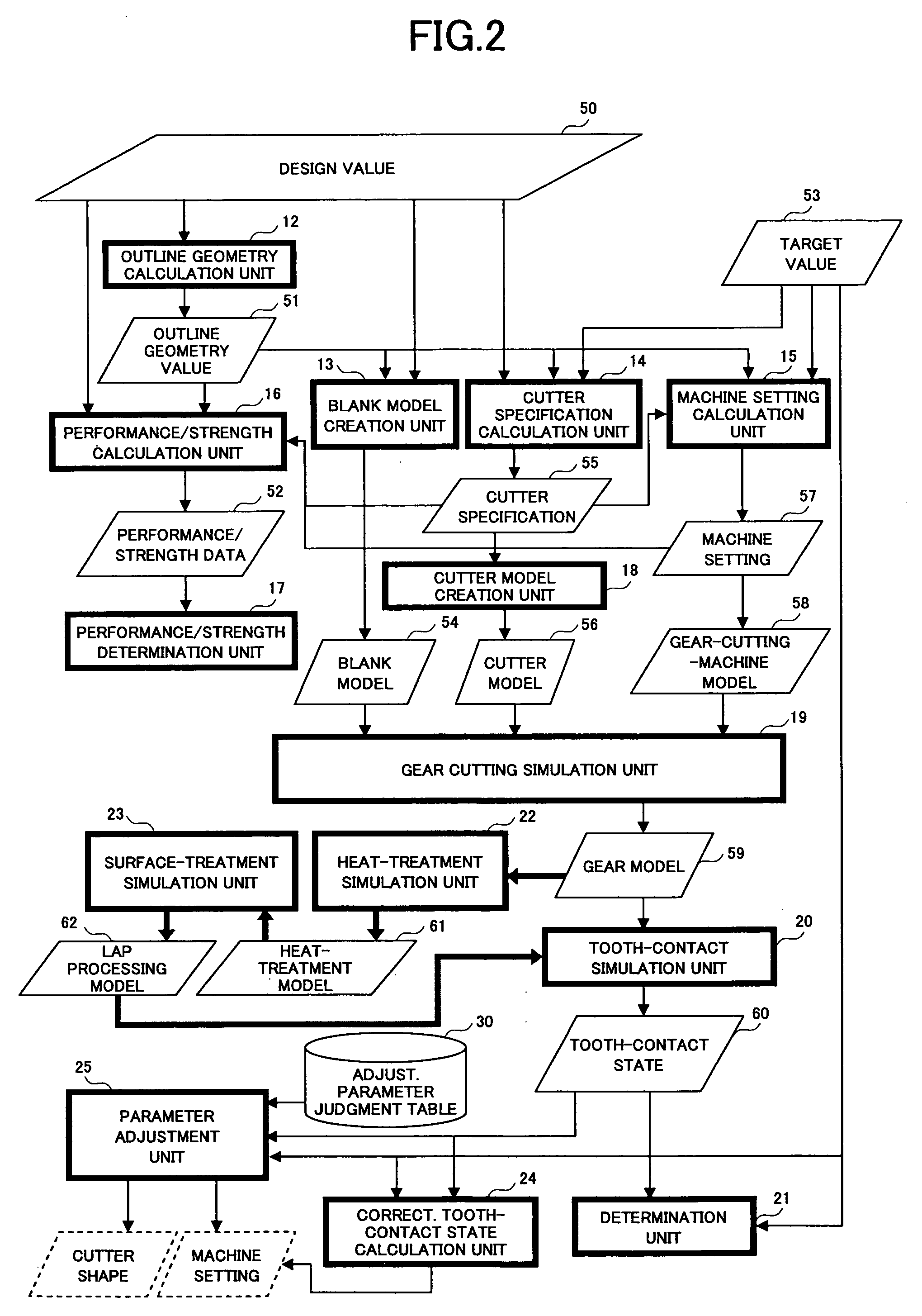

Gear cutting simulation method, gear cutting simulation program, and gear cutting simulation device

InactiveUS20050159938A1Eliminate the problemSure easyComputer controlSimulator controlEngineeringGear cutting

In a gear cutting simulation method and device, a gear-cutting-machine model which specifies relative positions between a blank model and a cutter model is created. A gear model is created as a result of simulation of gear cutting which is performed with the blank model and the cutter model arranged in the gear-cutting-machine model.

Owner:SUMITOMO HEAVY IND LTD

Gear cutting oil

Metalworking fluids contain active sulfur, a certain kind of inactive sulfur called “available sulfur”, and fat in a base oil of a lubricating viscosity. The metalworking fluids are chlorine free and phosphorous free. Boundary lubrication is provided by the fat, while extreme pressure lubrication is provided by the sulfur. Available sulfur is inactive sulfur minus any contribution of inactive sulfur from sulfurized saturated fats. Active sulfur and available sulfur are present in balanced proportions, while fat is present at an amount effective to provide boundary lubrication. Use of the fluids reduces tool wear over a long period of action and over a variety of boundary and extreme pressure conditions.

Owner:GM GLOBAL TECH OPERATIONS LLC

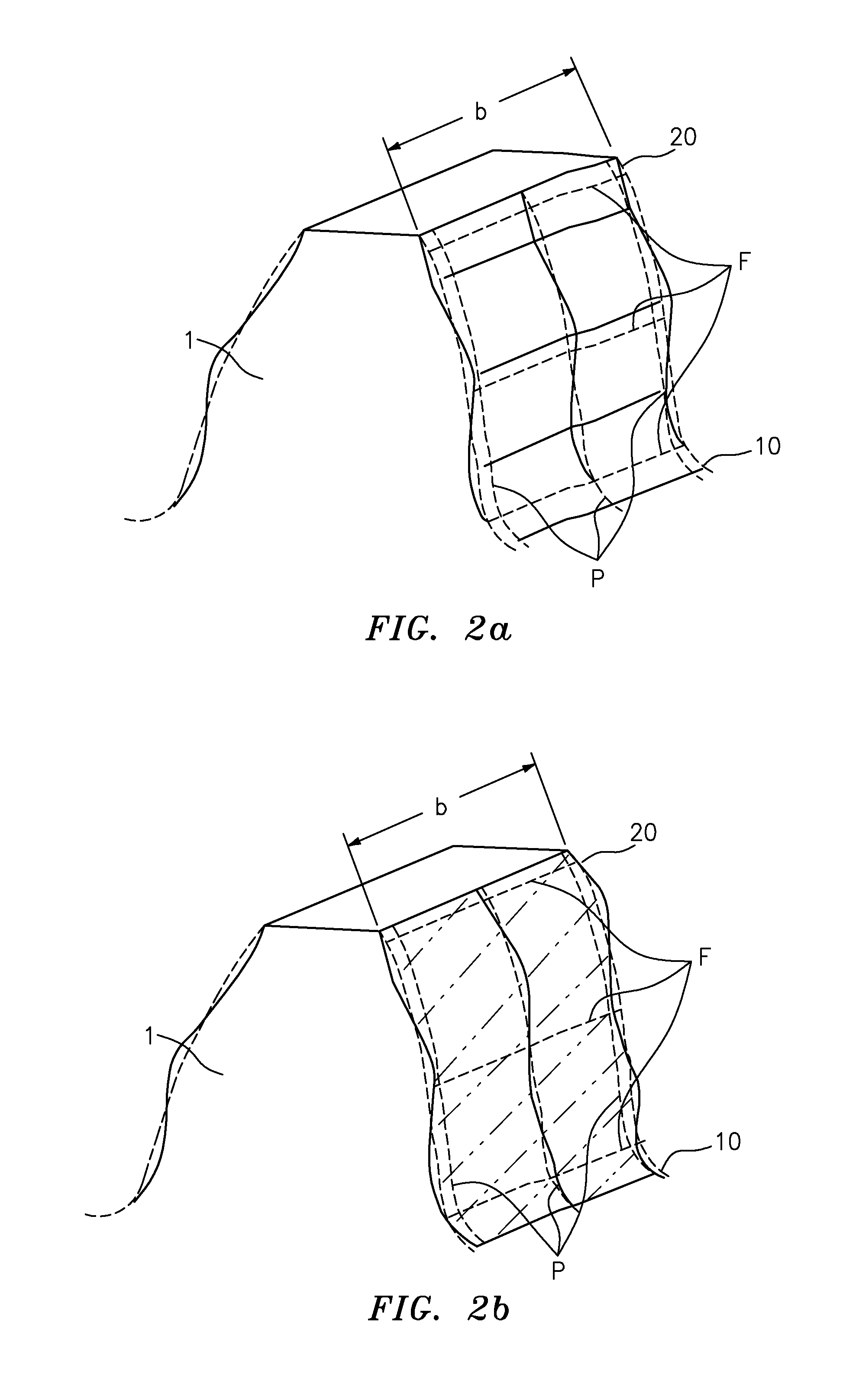

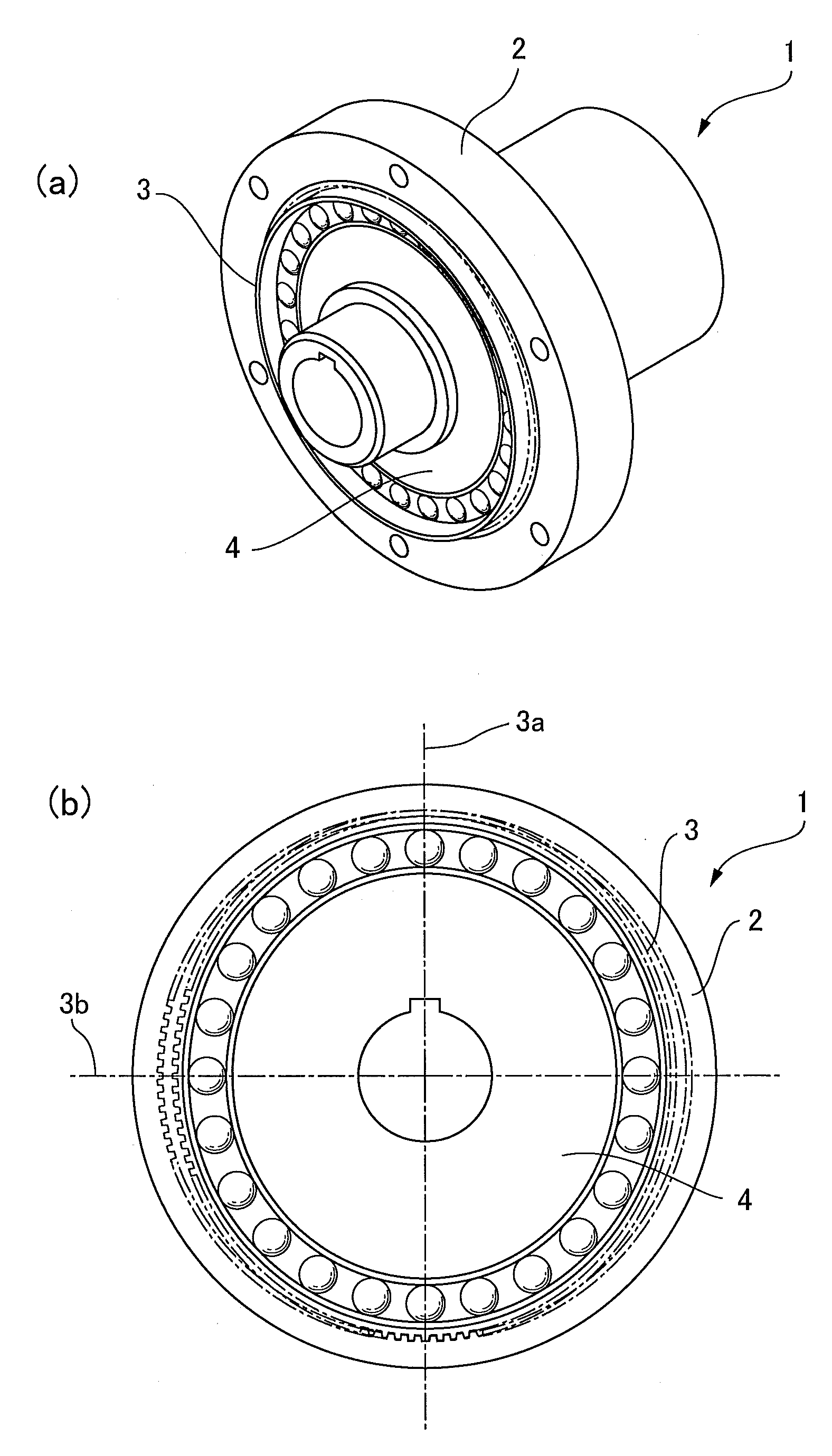

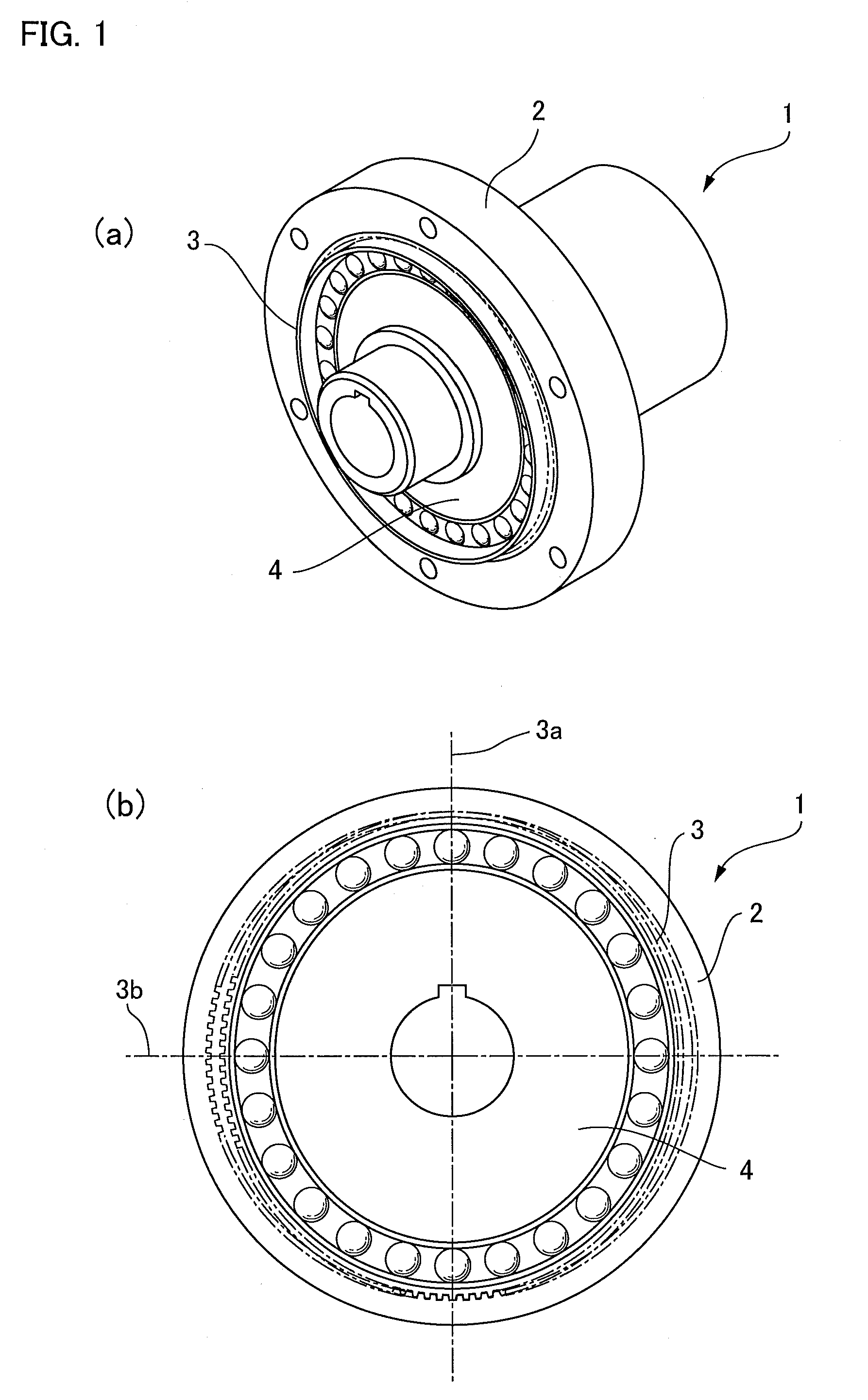

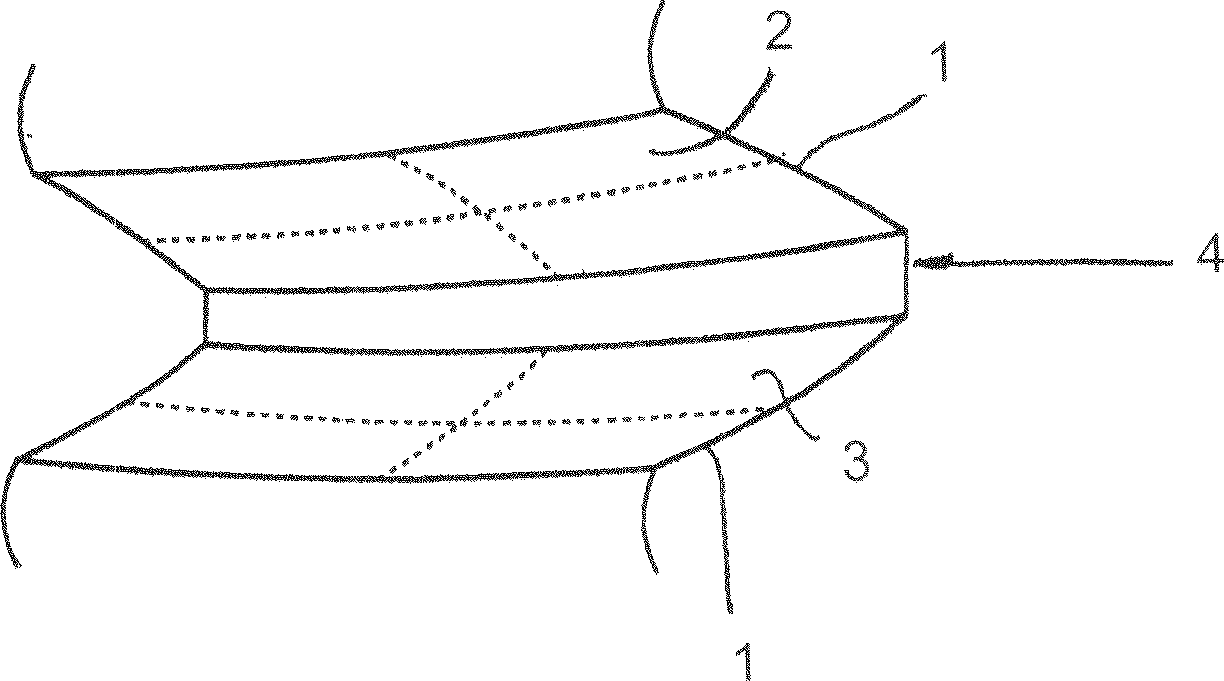

Wave Gear Device

A bending state known as “coning,” in which the amount of bending of the flexspline gradually decreases in accordance with the distance from the open end of the spline, occurs in cup-type or “silk hat”-type wave gear devices. A tooth profile in which the tooth depth is kept constant and in which the bottom lands and top lands are parallel to each other along the tooth trace direction is used as the basic tooth profile for the circular spline and the flexspline of the wave gear device. A taper surface is formed on a part of the top land near the open end of the flexspline in the basic tooth profile, whereby a modified tooth profile is obtained. The modified tooth profile is employed as the tooth profile for both of the splines. Both of the splines can be caused to mesh together without generating coning-induced interference. Both of the splines can also be subjected to gear cutting by a simple process using a typical machining mechanism.

Owner:HARMONIC DRIVE SYST IND CO LTD

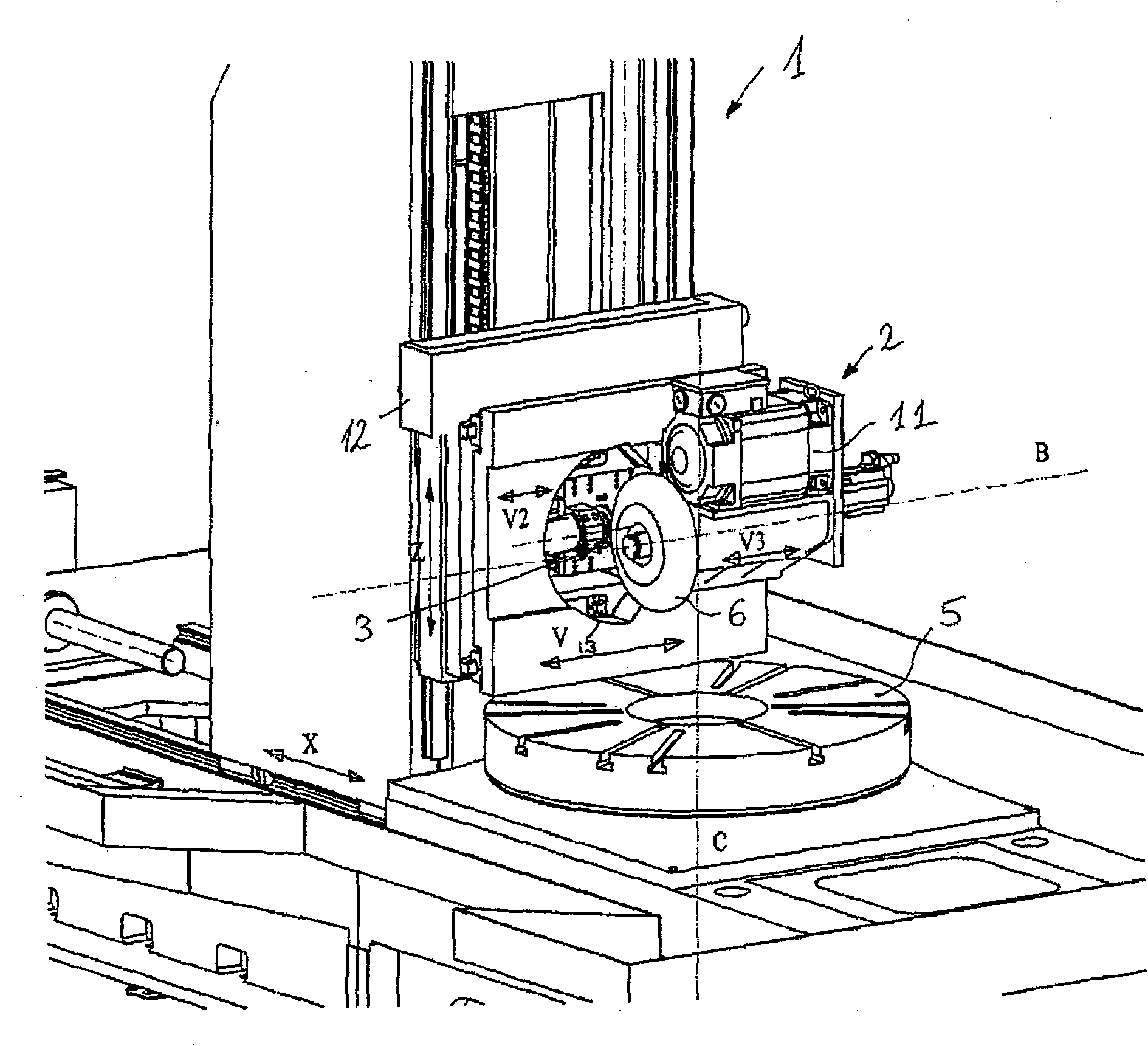

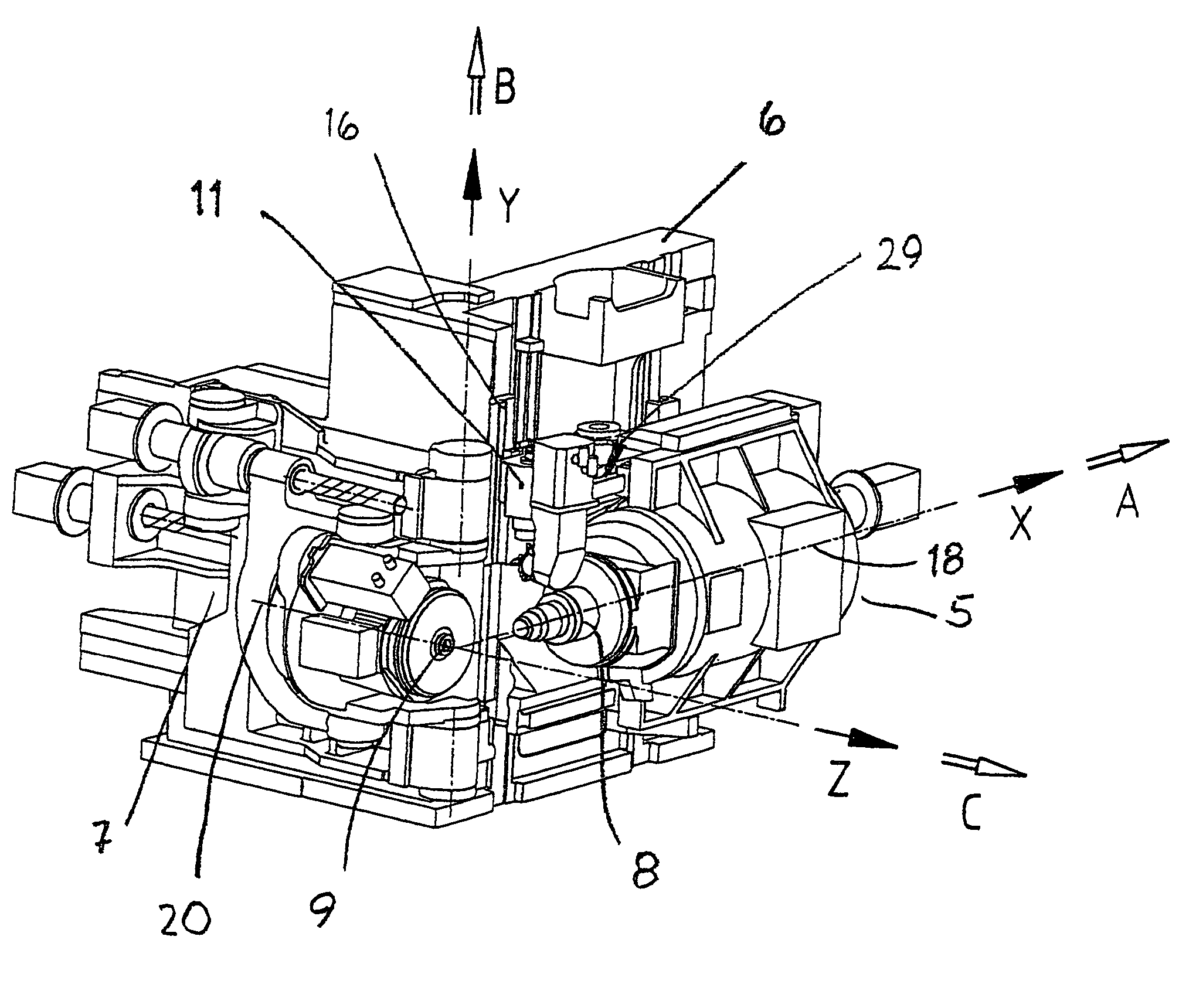

Gear Cutting Machine

InactiveUS20100304642A1Avoid disadvantagesSimple methodGrinding carriagesGrinding drivesGear wheelGear cutting

The invention relates to a gear cutting machine for the grinding of external profiles and / or internal profiles of workpieces having at least one machining head which can be rotated about an axis and which has a grinding tool, and having a dressing unit. In accordance with the invention, the dressing unit is supported in the region of the pivot axis of the machining head such that it is pivotable about the common pivot axis together with the machining head and such that it can be moved along the pivot axis toward the grinding tool to be dressed.

Owner:LIEBHERR VERZAHNTECHNIK GMBH

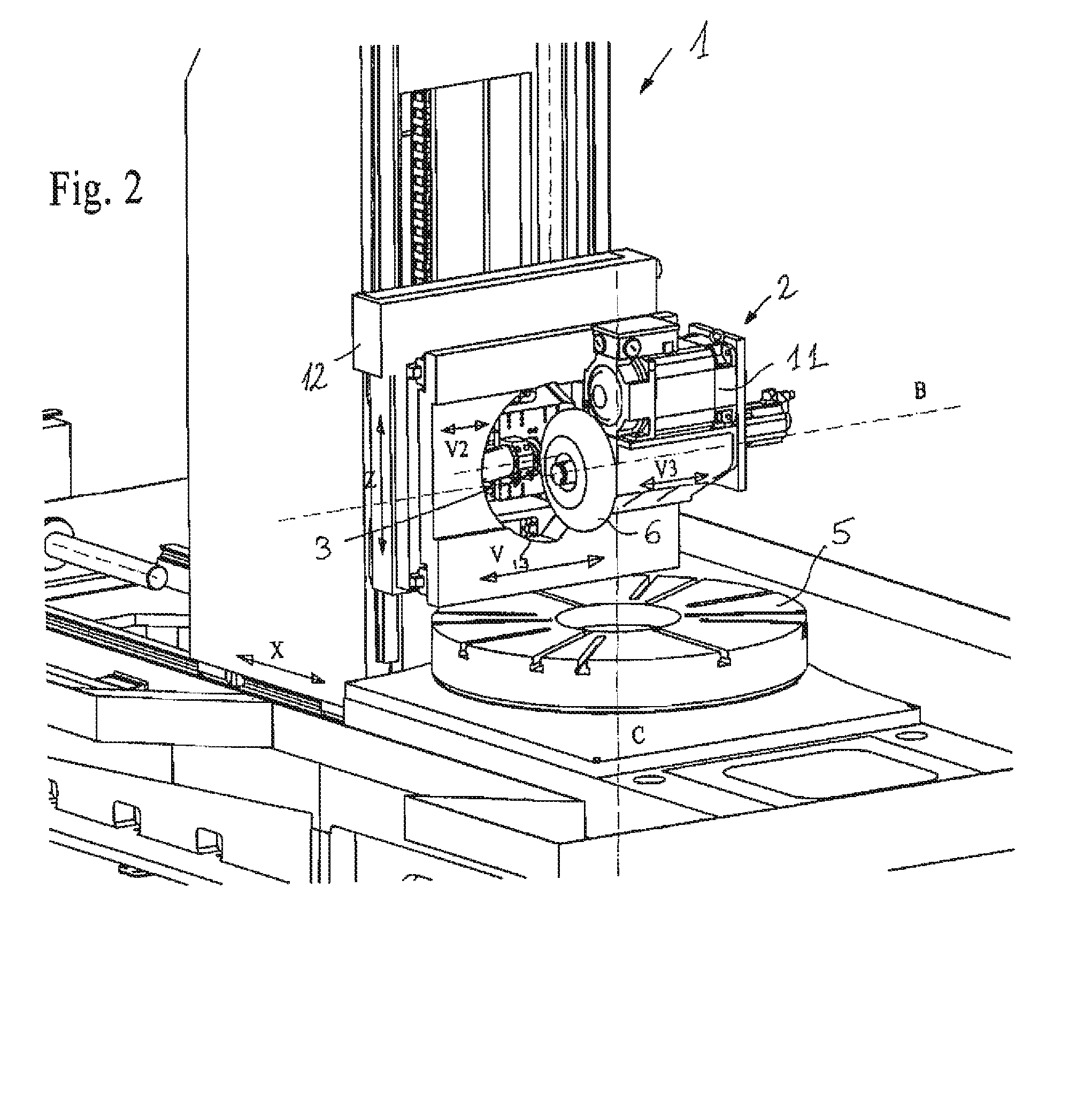

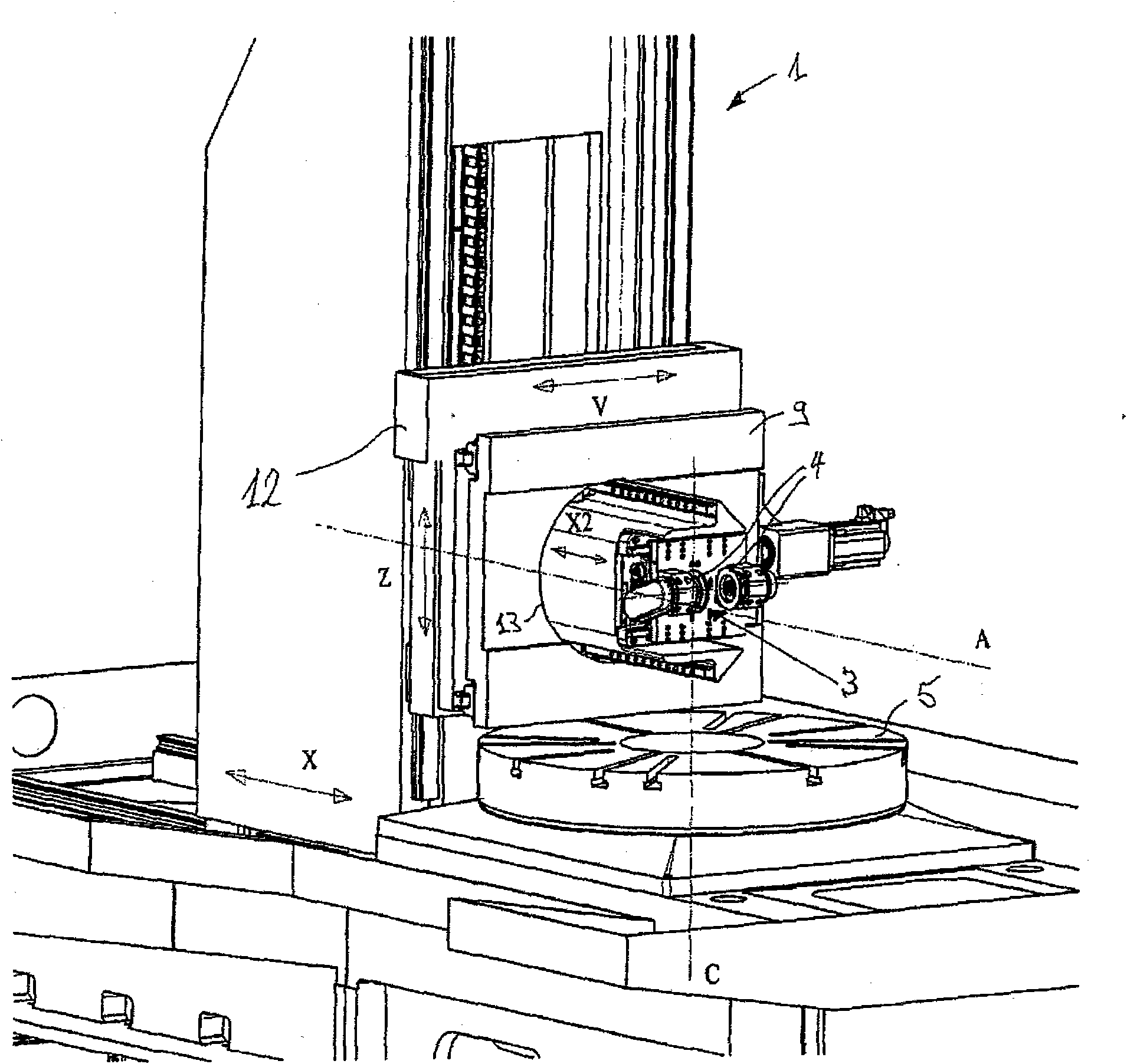

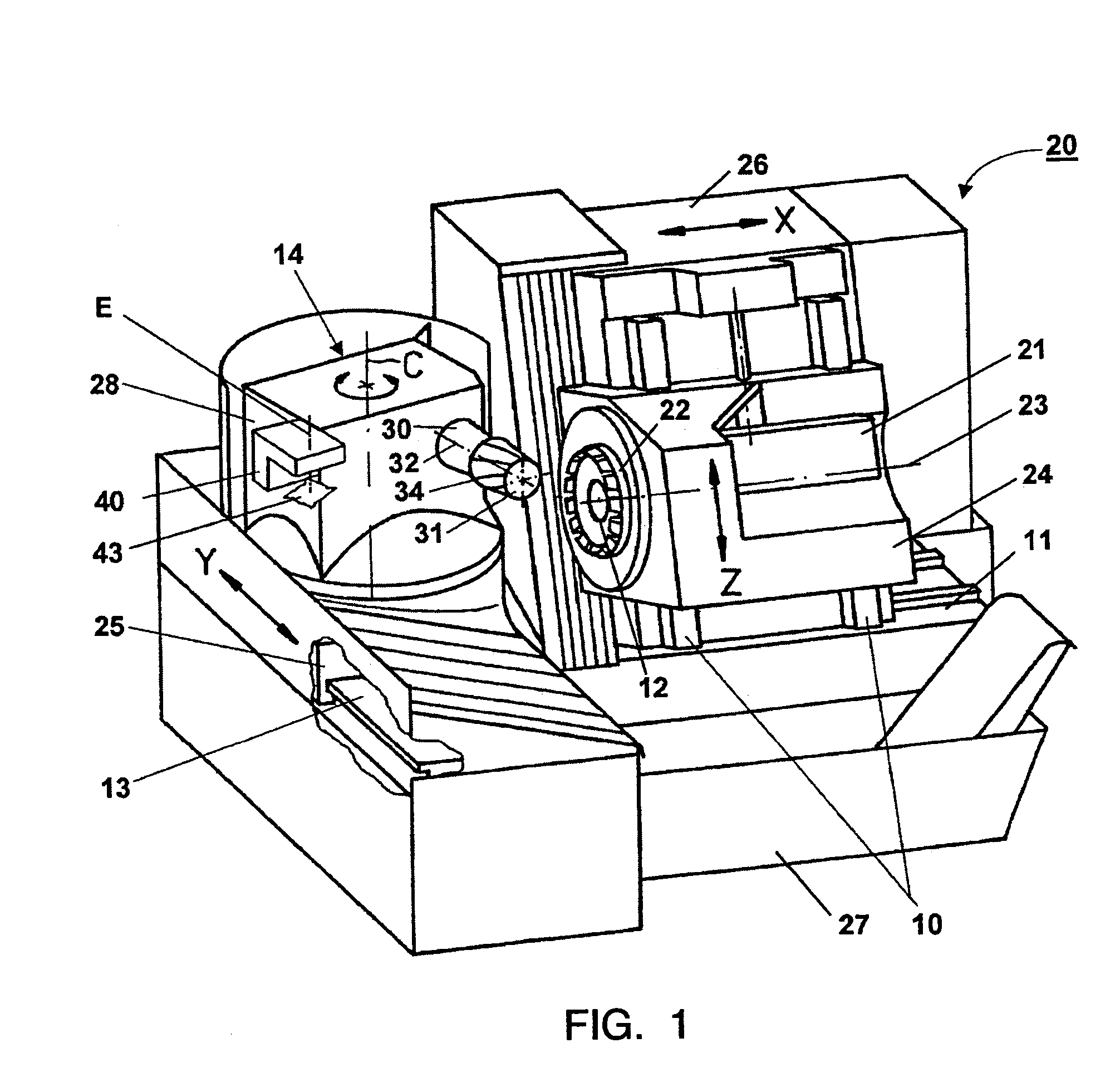

Gear cutting machine, in particular bevel gear cutting machine, having a device for chamfering / deburring the edges of a work piece

A gear cutting machine wherein a chamfer / deburr device and tool are fastened to a fixed component of the gear cutting machine. In this way, it is possible to adjust the chamfering / deburring tool into the working position in a simple and dependable manner to remove the edges from a gear. The device preferably has a linear track as well as a pivot axis, which can position the tool into the optimum position for the chamfering and / or deburring of the gear.

Owner:GLEASON WORKS

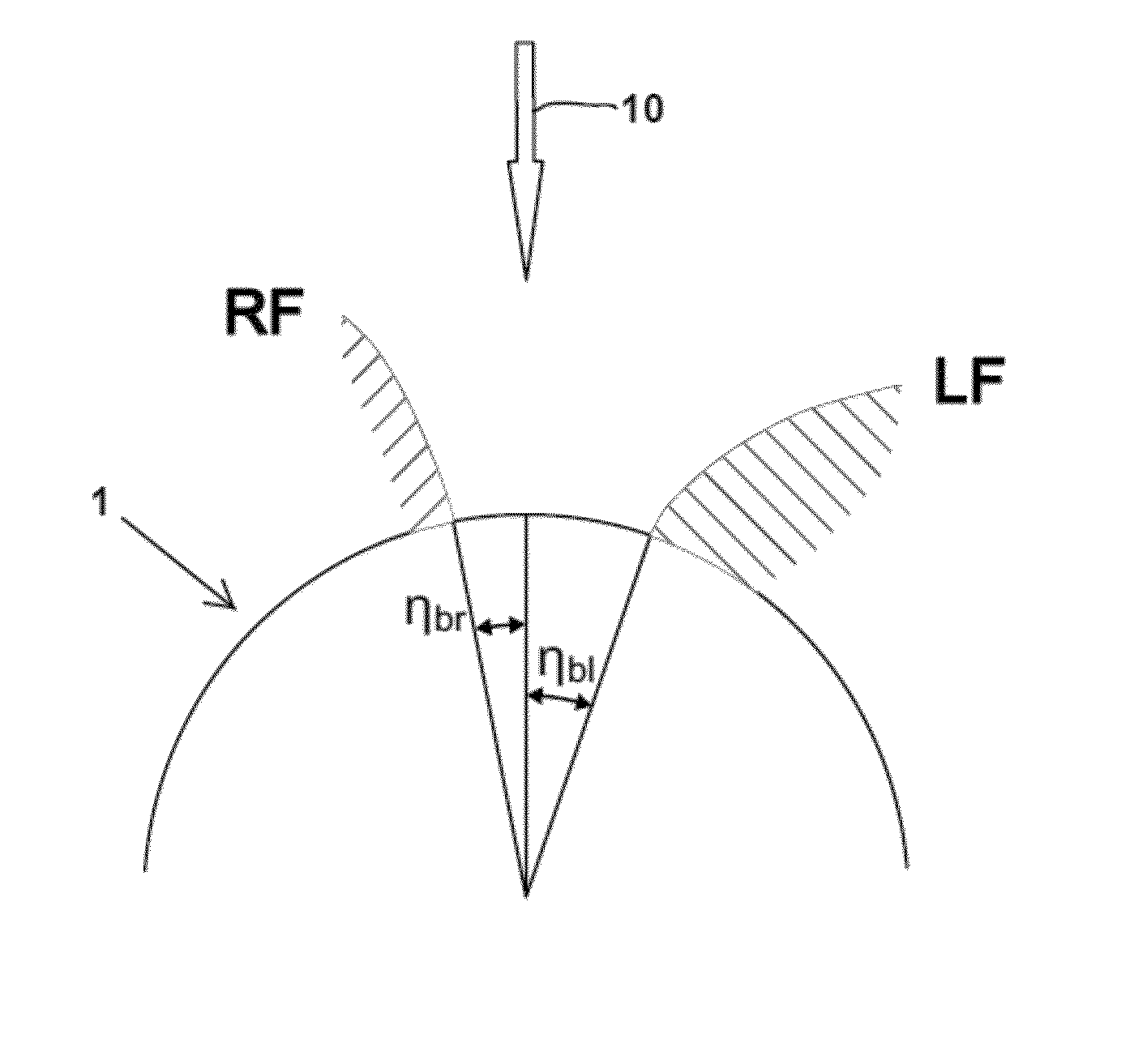

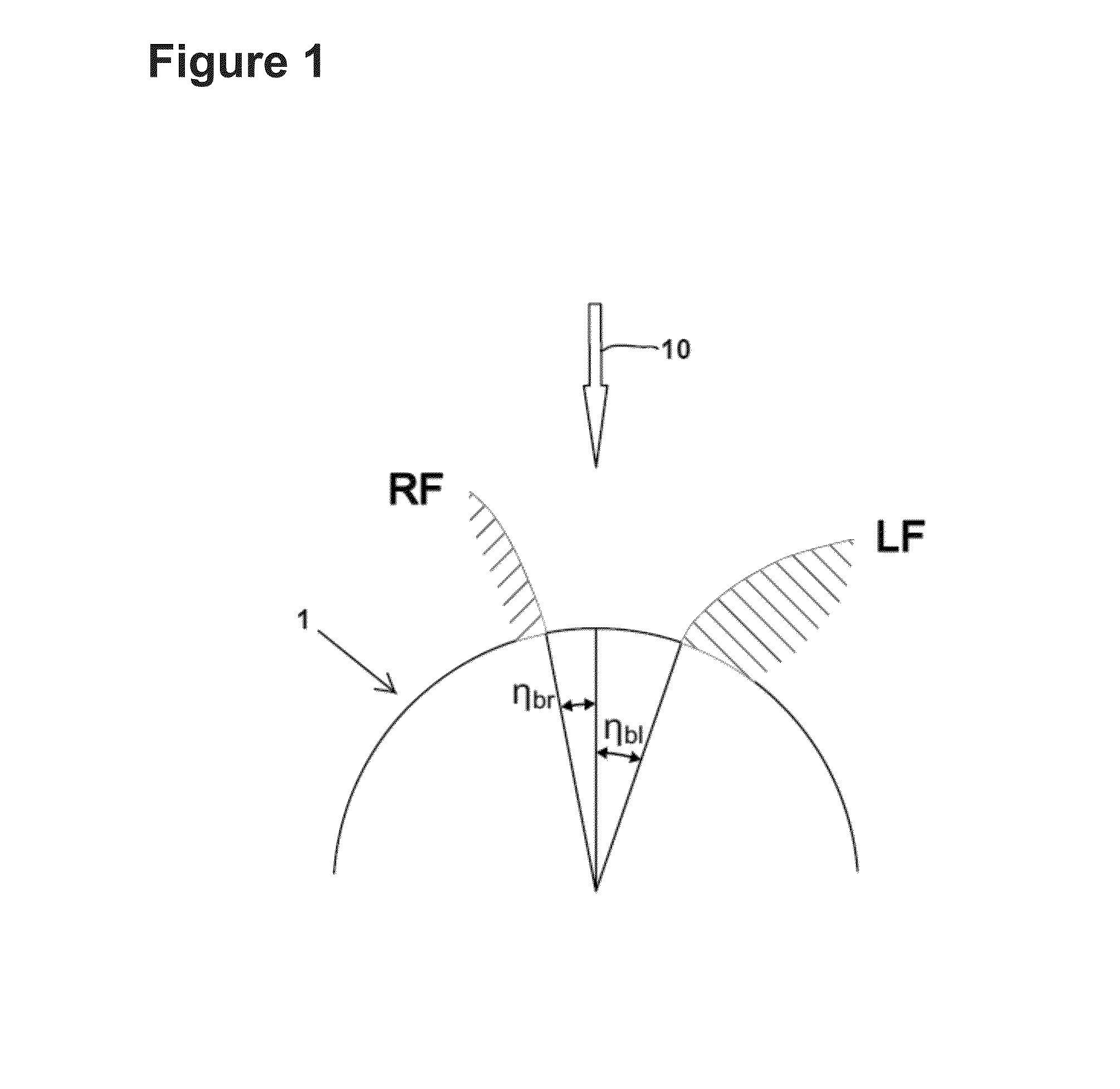

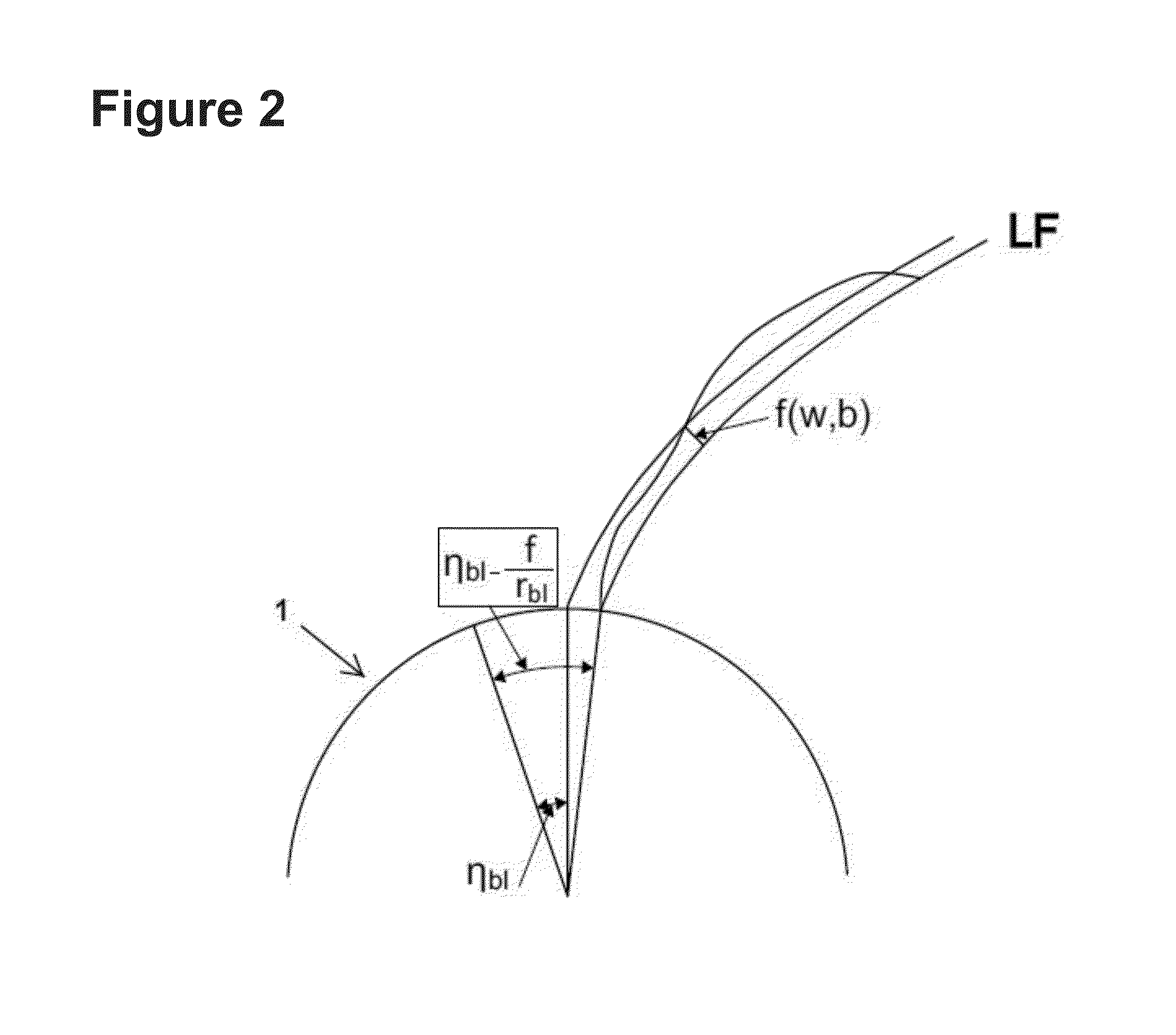

Method for the location determination of the involutes in gears

ActiveUS20150338201A1Angles/taper measurementsMeasurement/indication equipmentsInvoluteRelative motion

A method for the location determination of the involutes of a pre-gear cut workpiece within a gear-cutting machine using a gear-cut tool comprising the method steps: generating first and second relative movements between the workpiece and the tool; detecting respective, resulting first and second contact between a first tooth flank of the tool and a first tooth flank of the workpiece; and detecting a respective first and second set of coordinates for representing the relative movement of the workpiece and the tool; and determining the angles of rotation, the feeds, the axial distance and the crossed-axes angle of the tool and the workpiece based on the first and second set of coordinates and subsequent calculation of the location of the involutes on the basis of the angles of rotation, the feeds, the axial distance and the crossed-axes angle.

Owner:LIEBHERR VERZAHNTECHNIK GMBH

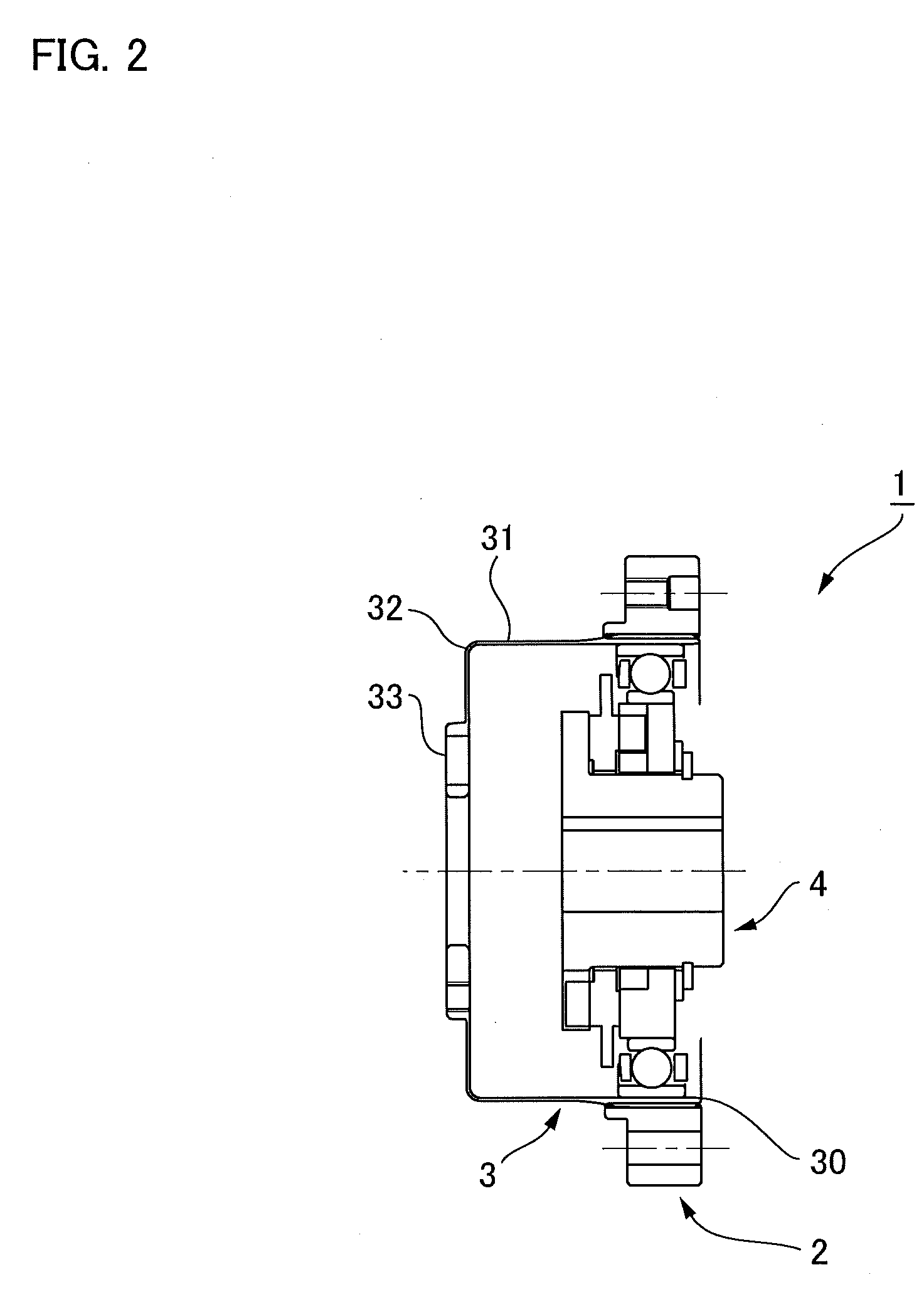

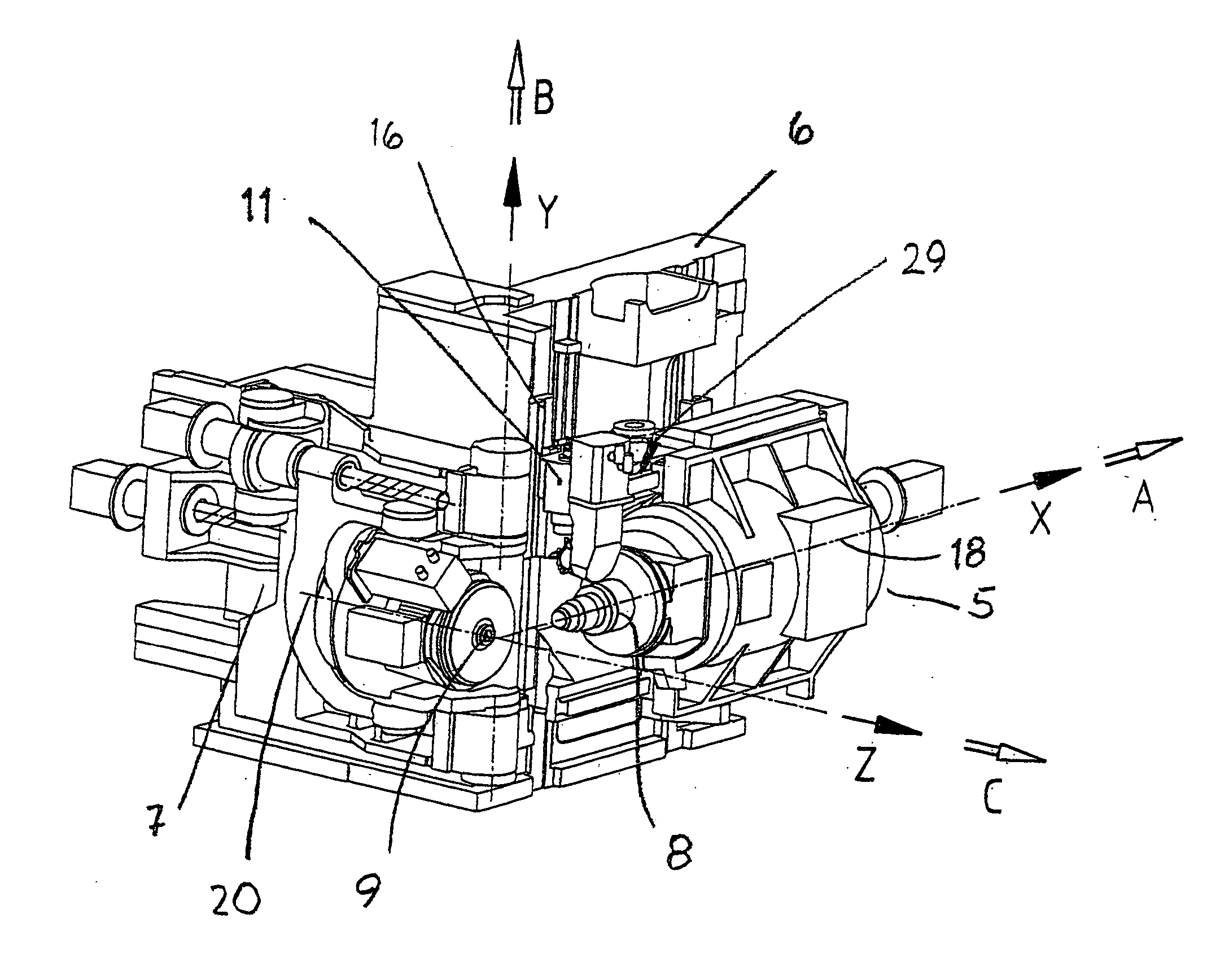

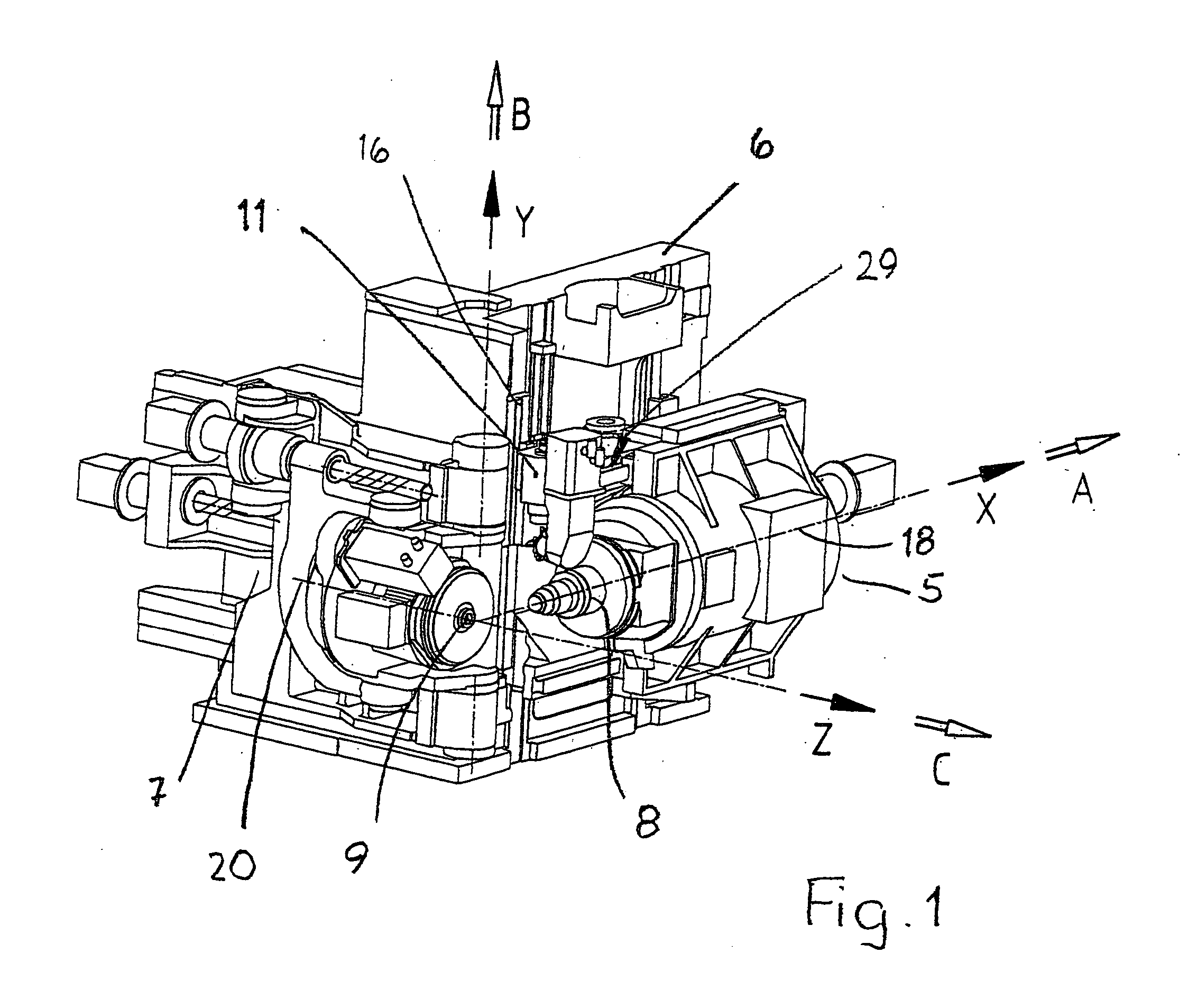

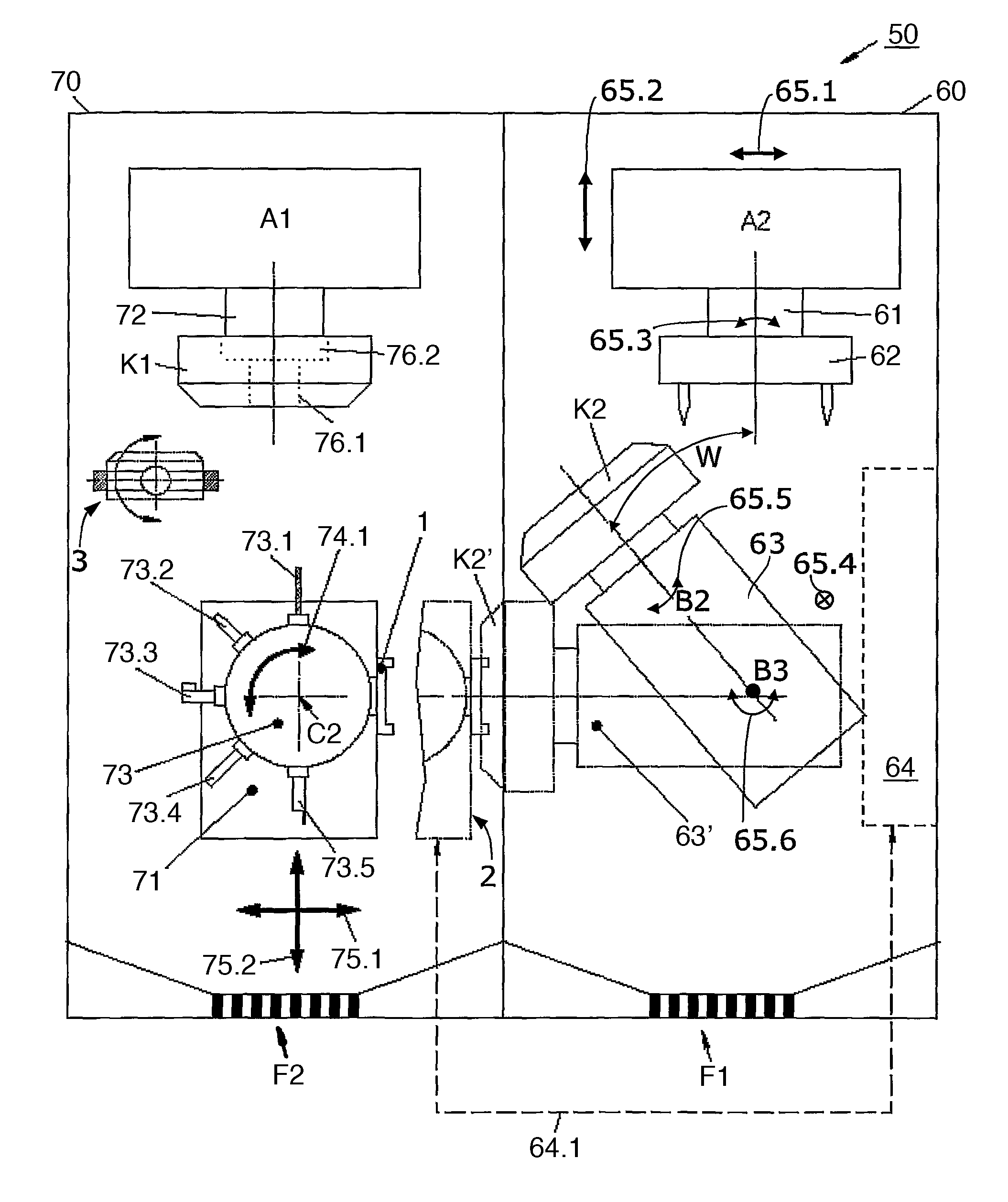

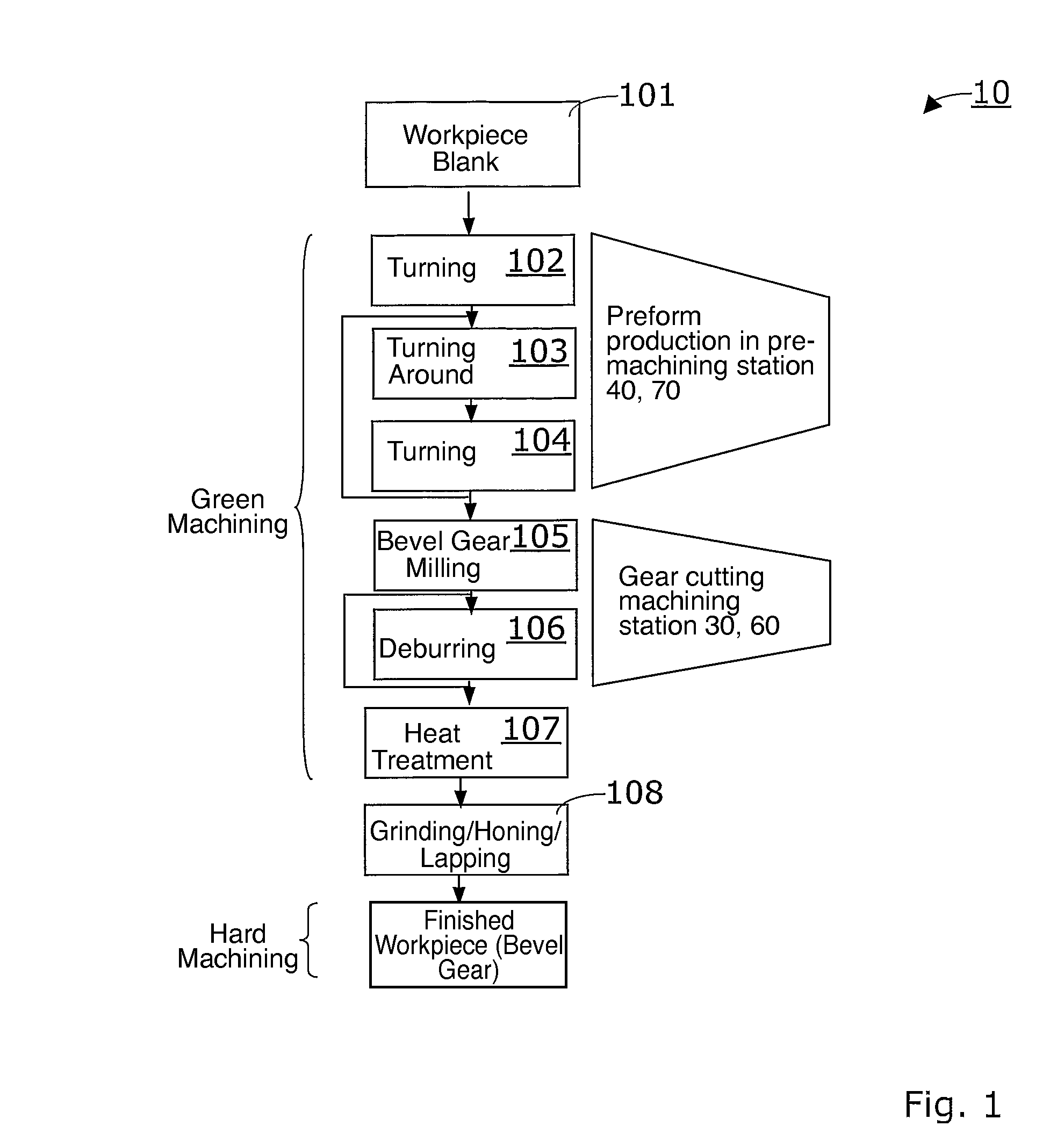

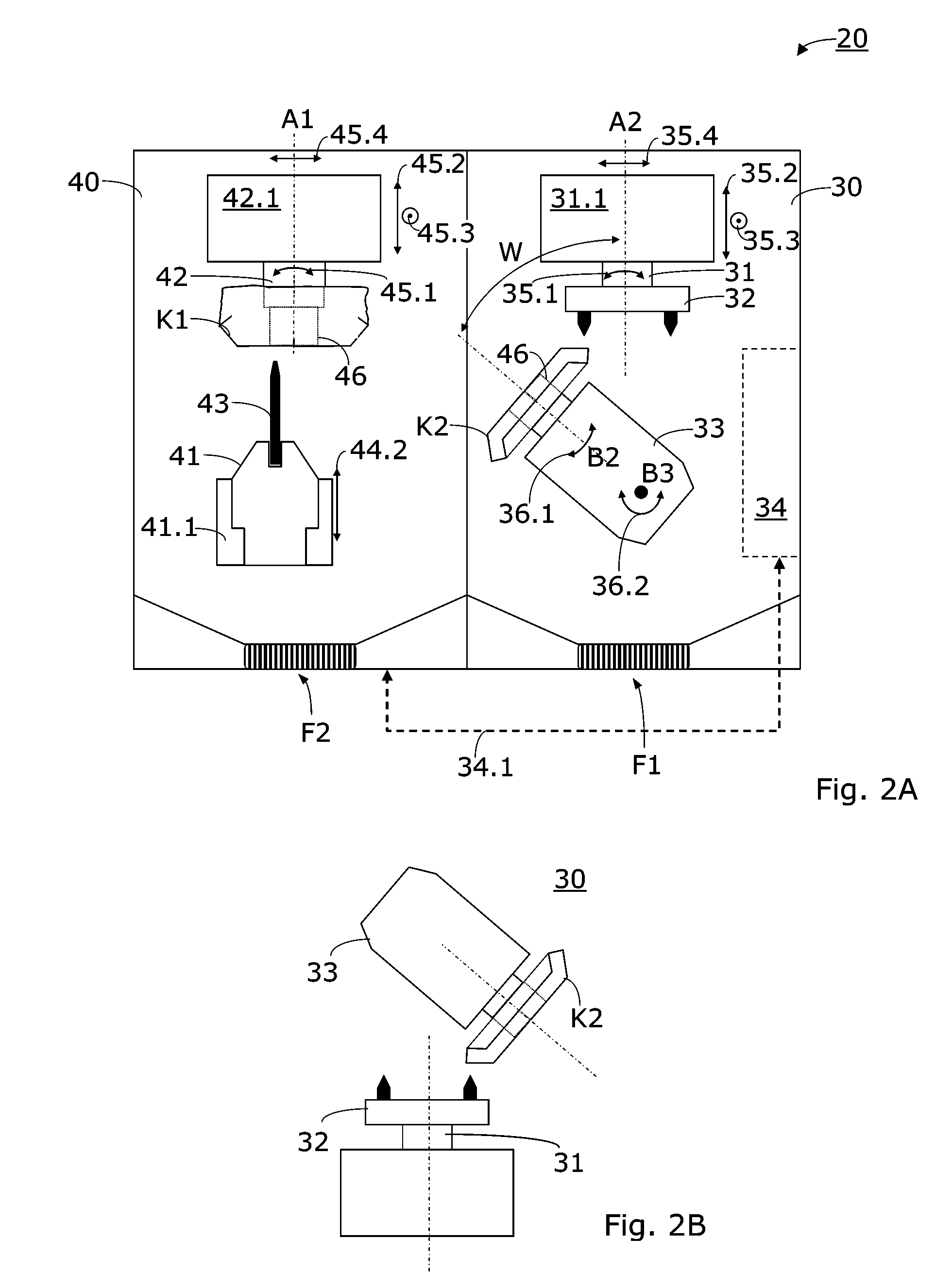

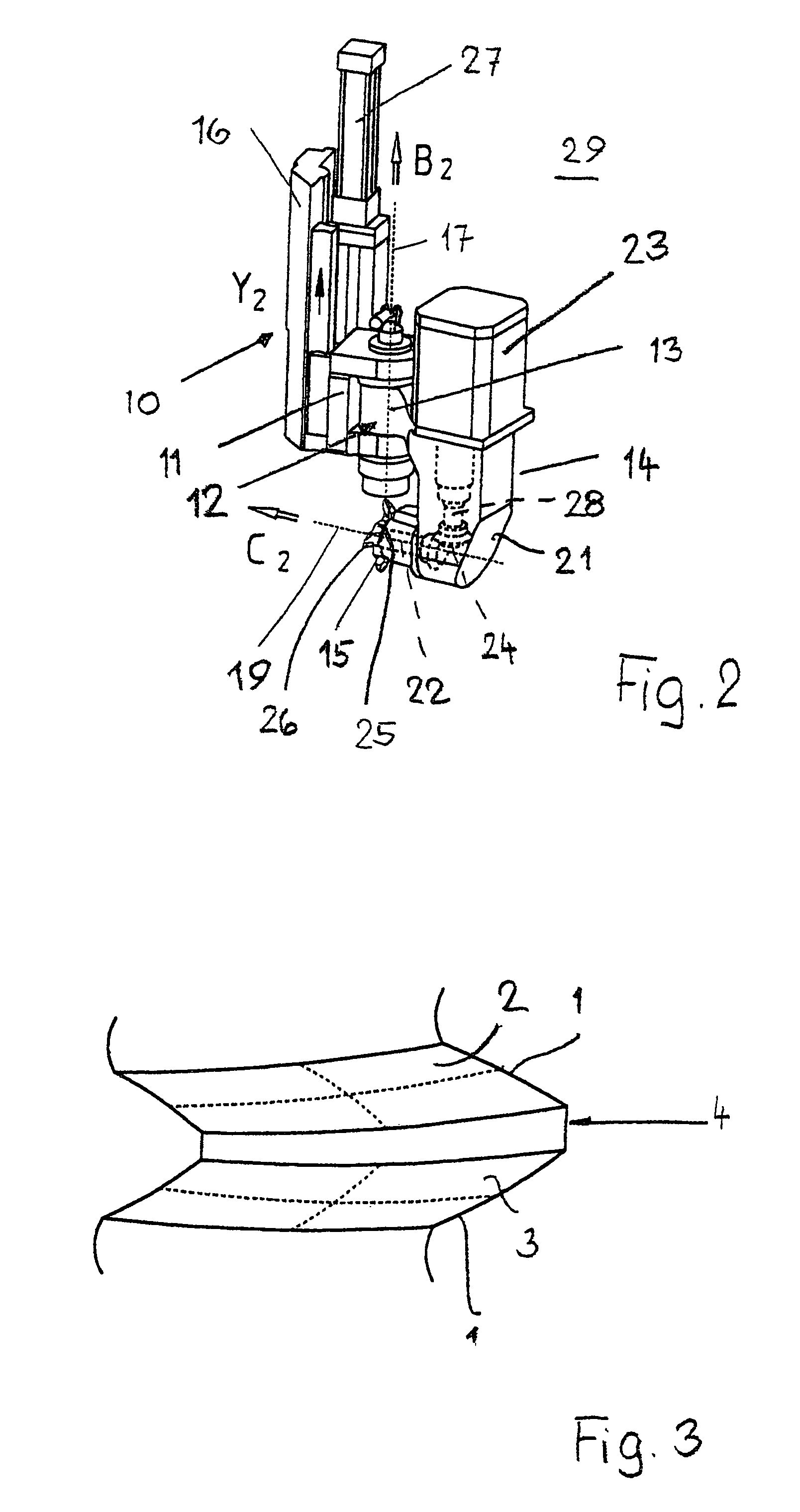

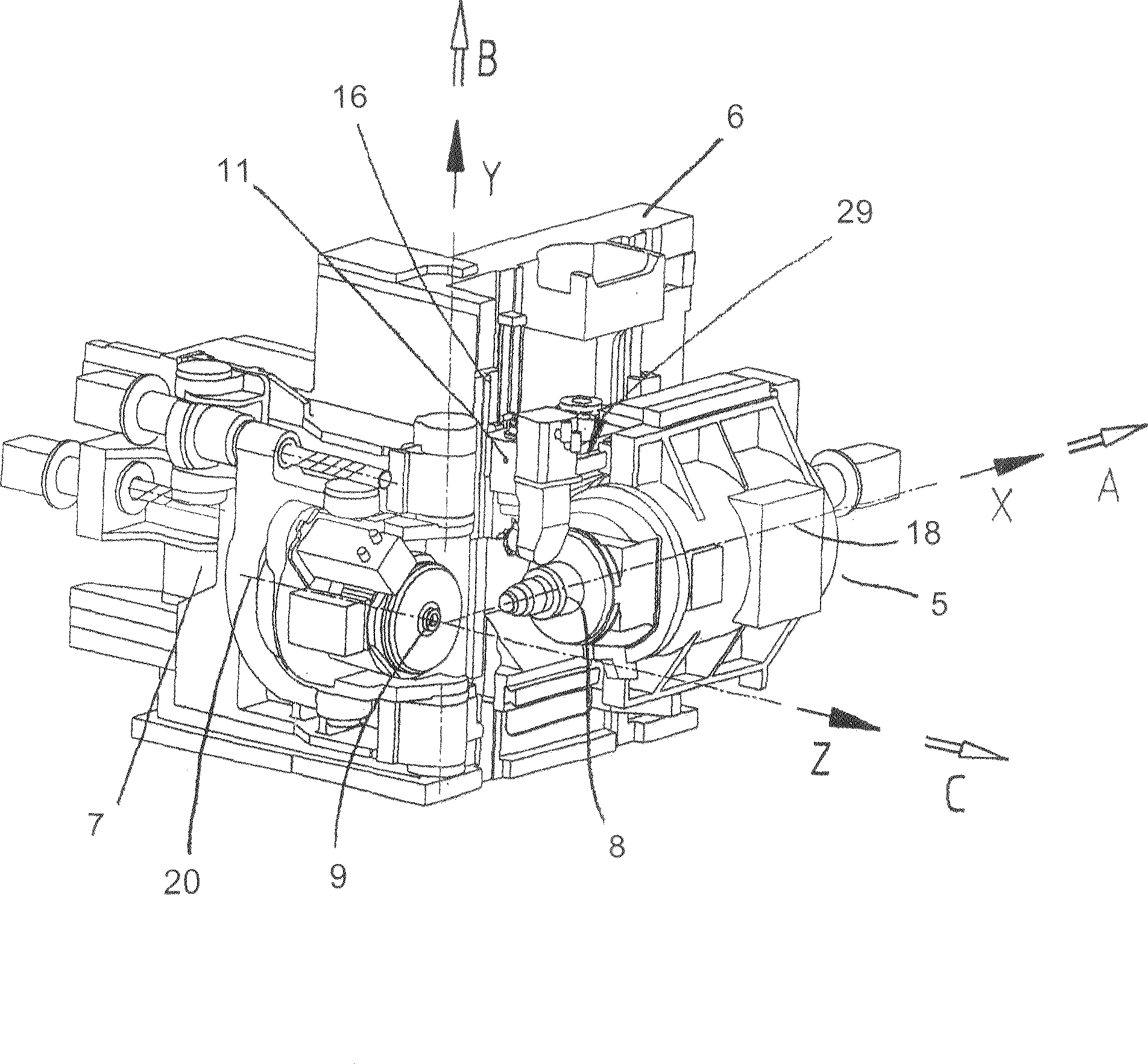

Device and method for green machining bevel gears

InactiveUS8151437B2Easy to manufactureAttachable milling devicesMeasurement/indication equipmentsGear wheelEngineering

The invention relates to a device for green machining bevel gears, including a CNC machining station for gear cutting a wheel blank (K2). The machining station includes a tool spindle which is used to receive a gear cutting tool and a work piece spindle which is used to receive the gear blank (K2). The machining station also relates to a machining station which operates in a vertical manner. The device also comprises a vertical processing station having a tool holder and a work piece spindle which is used to receive a work piece blank (K1). The machining station mechanically forms a functional unit together with the pre-machining station, wherein the work piece blank (K1) undergoes green machining in the pre-machining station, and is transferred as a gear blank (K2) to the first machining station after the first green machining where it is cut into a gear. The machining station and the pre-machining station are linked together in terms of data and control.

Owner:KLINGELNBERG AG

Gear cutting machine

InactiveCN101898331AAvoid imprecisionShorten the timeAbrasive surface conditioning devicesGear-cutting machinesEngineeringGear cutting

The invention relates to a gear cutting machine for the grinding of external profiles and / or internal profiles of workpieces having at least one machining head which can be rotated about an axis and which has a grinding tool, and having a dressing unit. In accordance with the invention, the dressing unit is supported in the region of the pivot axis of the machining head such that it is pivotable about the common pivot axis together with the machining head and such that it can be moved along the pivot axis toward the grinding tool to be dressed.

Owner:LIEBHERR VERZAHNTECHNIK GMBH

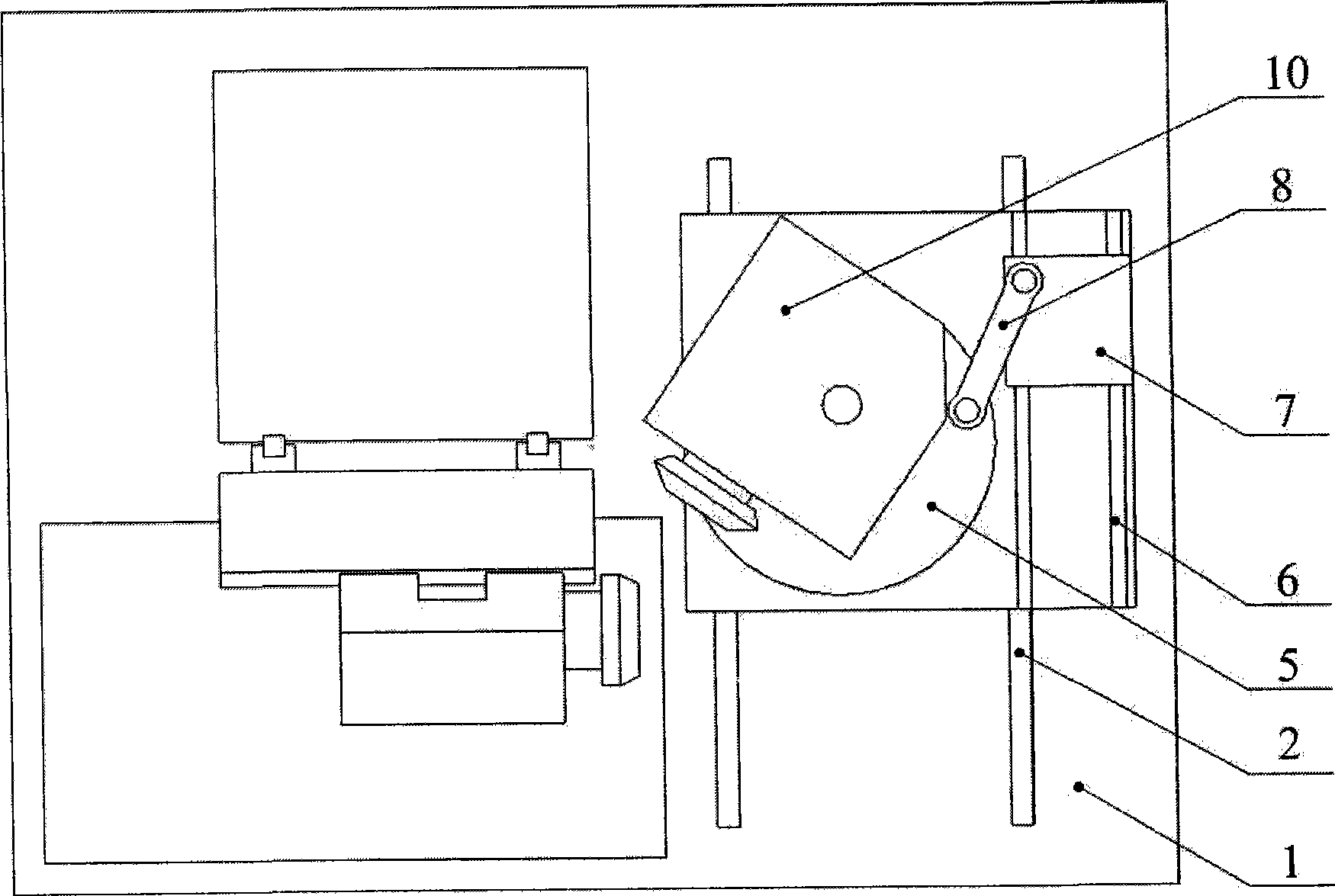

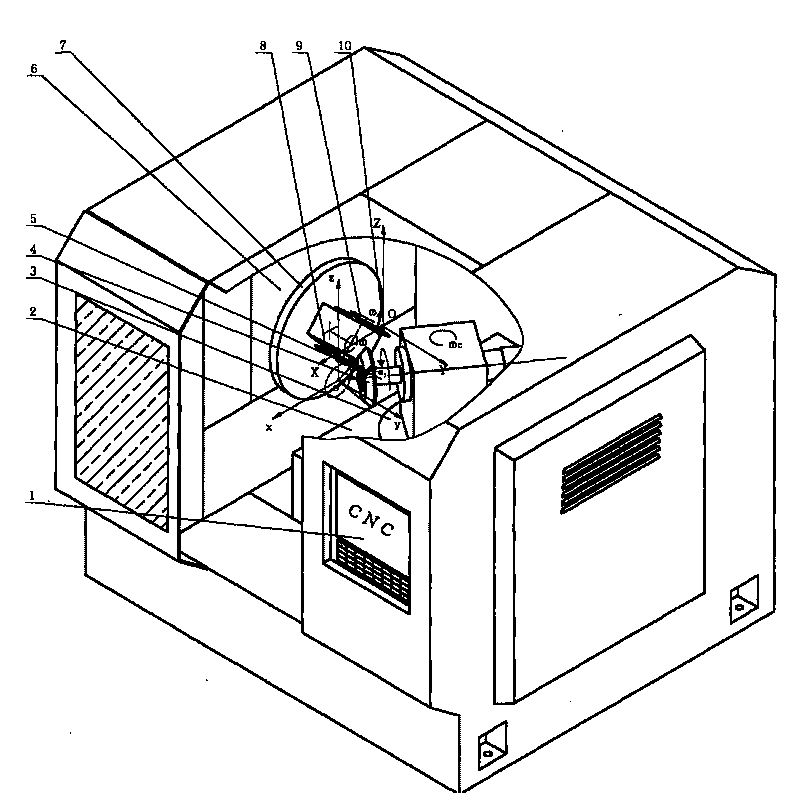

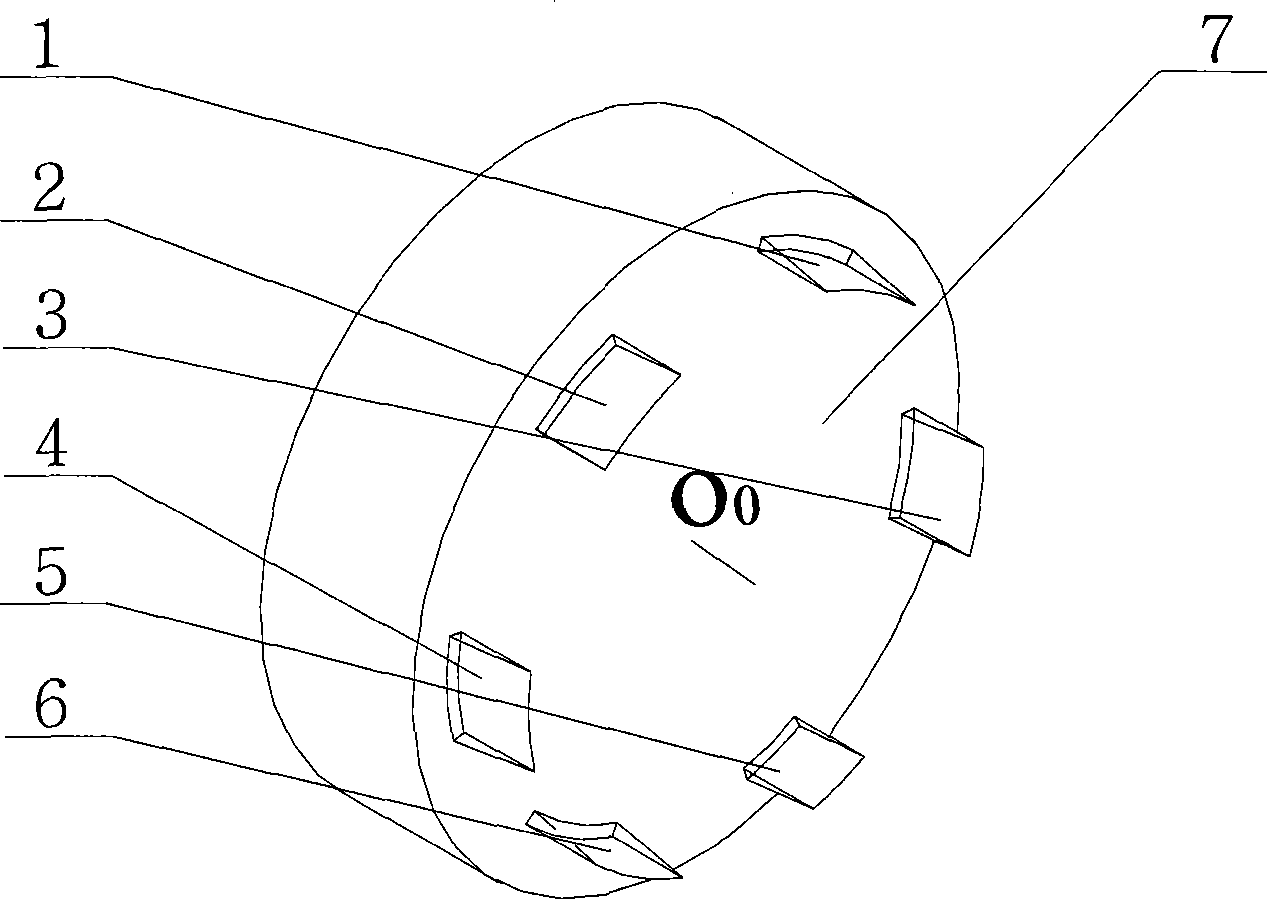

Spherical involute spiral bevel gear cutting method and machine tool

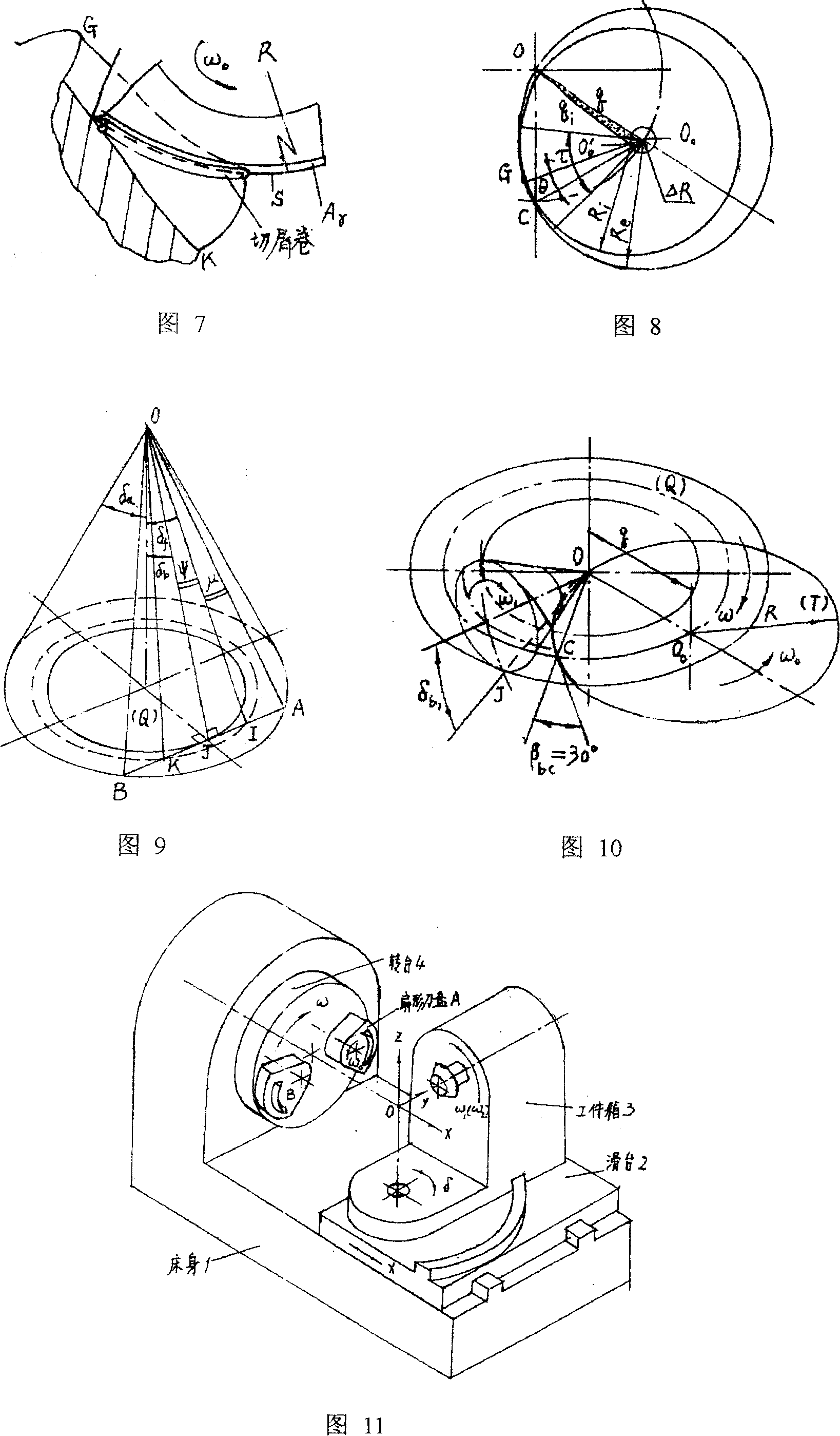

InactiveCN101391322ASimple structureSuitable for the use of numerical control technologyGear teeth manufacturing toolsGear-cutting machinesNumerical controlCircular cone

The invention discloses a cutting method for a bevel gear with spherical involute toothed circular arc teeth and a machine tool thereof. The cutting method comprises a circular arc cutter edge conjugation generating method and an envelope method. A cutter shaft and a gear blank shaft for implementing the circular arc cutter edge conjugation generating method rotate directionally with rotating rates (Omega0) and (Omega1), a cutter edge enters into cutting, a cage chair rotates according to that Omega is equal to Omega1sinaDeltab, the formation of pure rolling of a gear blank base cone and the big circular plane of the spherical surface is guaranteed to complete the processing of spherical involute toothed flank. The cage chair with a real axis is driven to rotate by a servo motor, and for the cage chair without a real axis, the synthesis movement of the y and z directions of a coordinate system forms a cage chair to rotate with the rotating rate (Omega). When the envelope method is implemented, cutter teeth of short arc and even point cutter edge are adopted. Points with the number of k are taken on the circular arc line AC of generating the flank, each cutting can form a spiral line on the flank, the circular arc cutting feed angle Delta Theta of a gear cutter head per cutting is set, and the flank which is composed of spiral lines with the number of k is enveloped and generated by sequentially k-times cutting feed. A third shaft and a forth shaft link a numerical control gear cutting machine to implement the gear cutting method.

Owner:JILIN UNIV

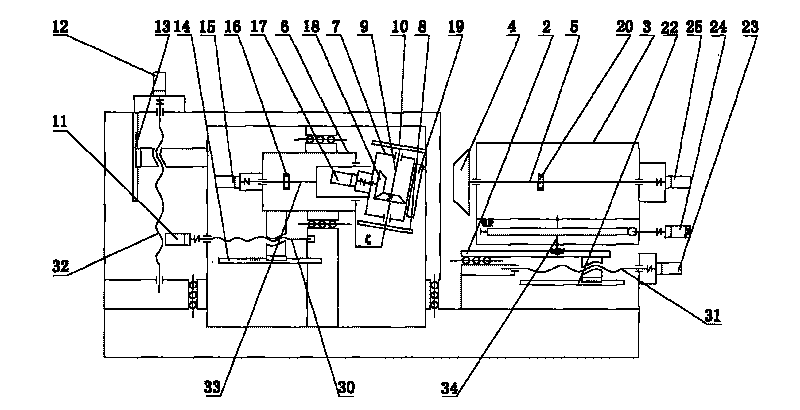

Numerical control bevel gear rolling inspection machine

InactiveCN101162184AMotion detection results are accurate and reliableFully automatedMachine gearing/transmission testingWork measurementNumerical controlDrive shaft

The invention discloses a numerical control bevel roll tester, the structure of the invention comprises: a lathe bed respectively provided with a drive guide rail and a driven guide rail which are perpendicular to each other, an upright post arranged on the driven guide rail of the lathe bed, a driving headstock arranged on the drive guide rail of the lathe bed, automatic travel mechanisms which are respectively arranged between the bottom of the upright post and the lathe bed and between the bottom of the driving headstock and the lathe bed, and a driven headstock which is arranged in the upright post and provided with an automatic travel mechanism which can move in vertical direction. The driving headstock and the driven headstock are respectively provided with a drive main shaft and a driven main shaft which are perpendicular to each other and positioned horizontally, a gear pair to be tested is respectively arranged in the inner holes of the drive main shaft and the driven main shaft; the drive main shaft is connected with a drive mechanism which drives the drive main shaft to rotate. The invention has the advantages that: the automatic aligning teeth, the autoloading and torque display, the automatic measurement and the automatic test according to the preset programs in the rolling test process of the bevel gear pair are solved, and precise parameters are provided for the cutting machine modifying gear cutting parameters.

Owner:TIANJIN NO 1 MACHINE TOOL WORKS

Gear cutting machine, in particular bevel gear cutting machine, having a device for chamfering / deburring the edges of a work piece

Owner:GLEASON WORKS

Method of measuring and testing a workpiece and gear cutting machine

The present disclosure relates to a method of measuring and inspecting a workpiece belonging to a gear pair, wherein the method is carried out on a gear cutting machine producing the workpiece, wherein a mating test piece mounted at the working head, in particular at the cutting head, is moved in the direction of the workpiece clamped in the workpiece mount of the machine table until the gear pair is in engagement and the corresponding working axial spacing is reached, the workpiece is driven via the drive movement of the mating test piece of the gear pair, the rotational position of the workpiece to be measured is recorded and the detected actual position is compared with a reference position and at least one value characterizing the rolling gear deviation of the workpiece is calculated while taking account of the comparison made.

Owner:LIEBHERR VERZAHNTECHNIK GMBH

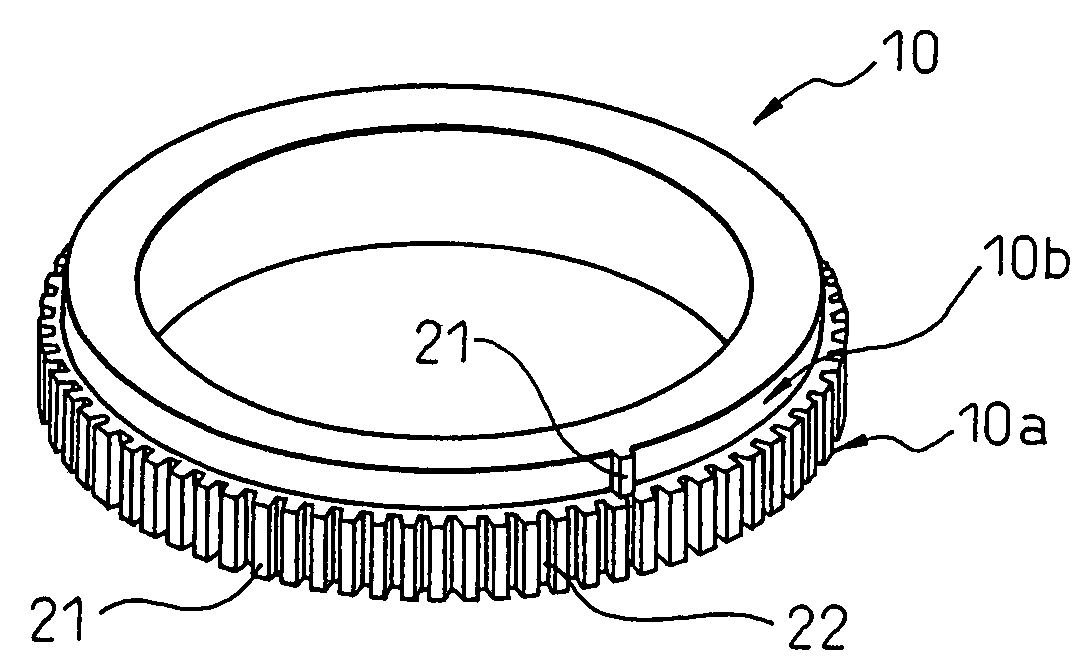

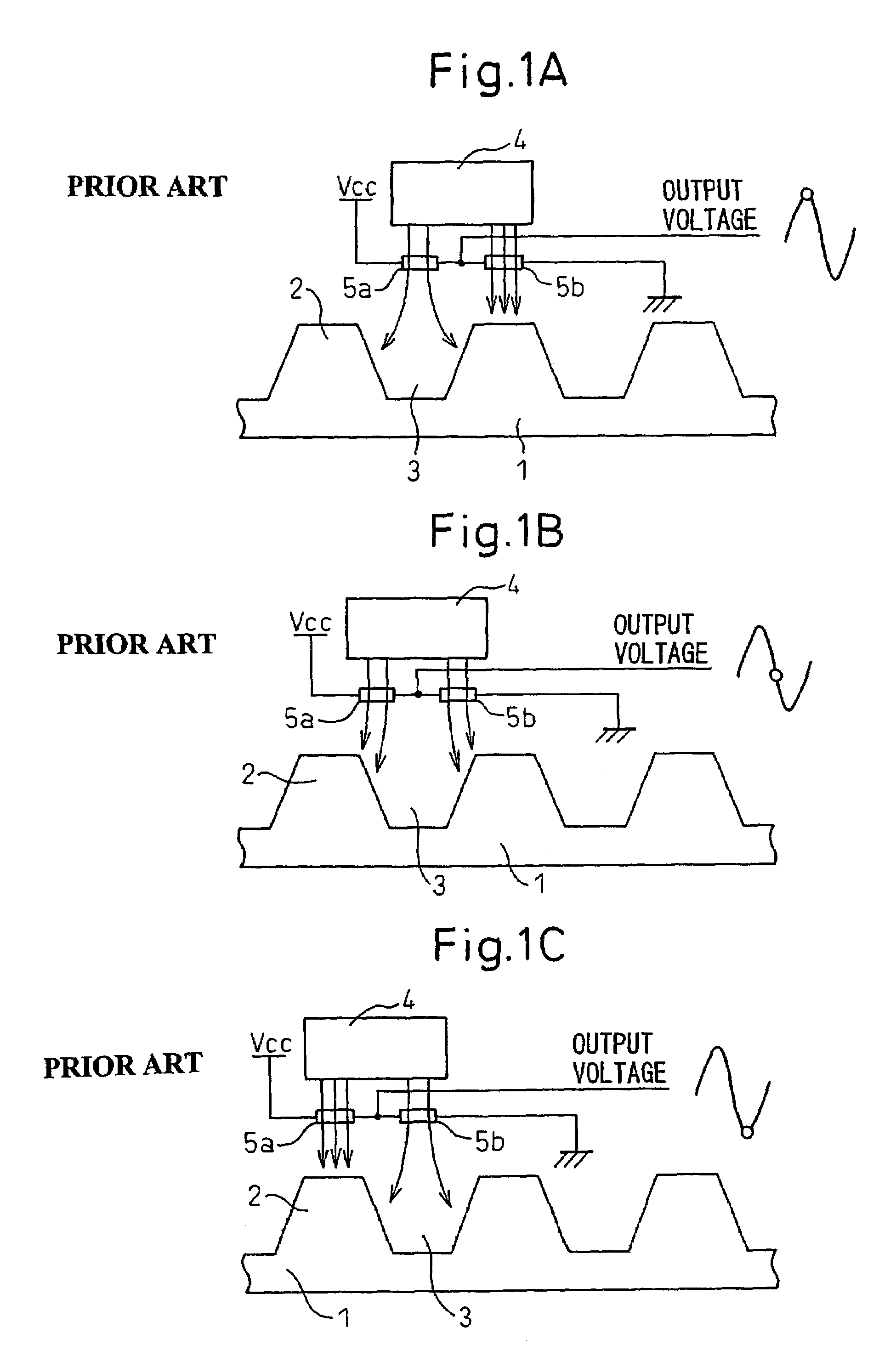

Magnetic type angle sensor

ActiveUS7400141B2Low costEasy to assembleMetal-working apparatusUsing electrical meansGear cuttingMagnetic sensing

A magnetic type angle sensor includes a rotary body having a first sensed part provided on a circumferential surface thereof with projecting parts and recessed parts at equal intervals in a circumferential direction thereof and a second sensed part provided on a circumferential surface thereof with a projecting parts at just one location, and a magnetic sensing device for sensing a change in a magnetic field along with rotation of the rotary body. The rotary body is formed with a plurality of projecting parts and recessed parts in a gear shape by gear cutting on the circumferential surface, then is cut with a groove at the center thereof in the axial direction thereof and has all projecting parts in a half section in the axial direction thereof cut off except for one.

Owner:FANUC LTD

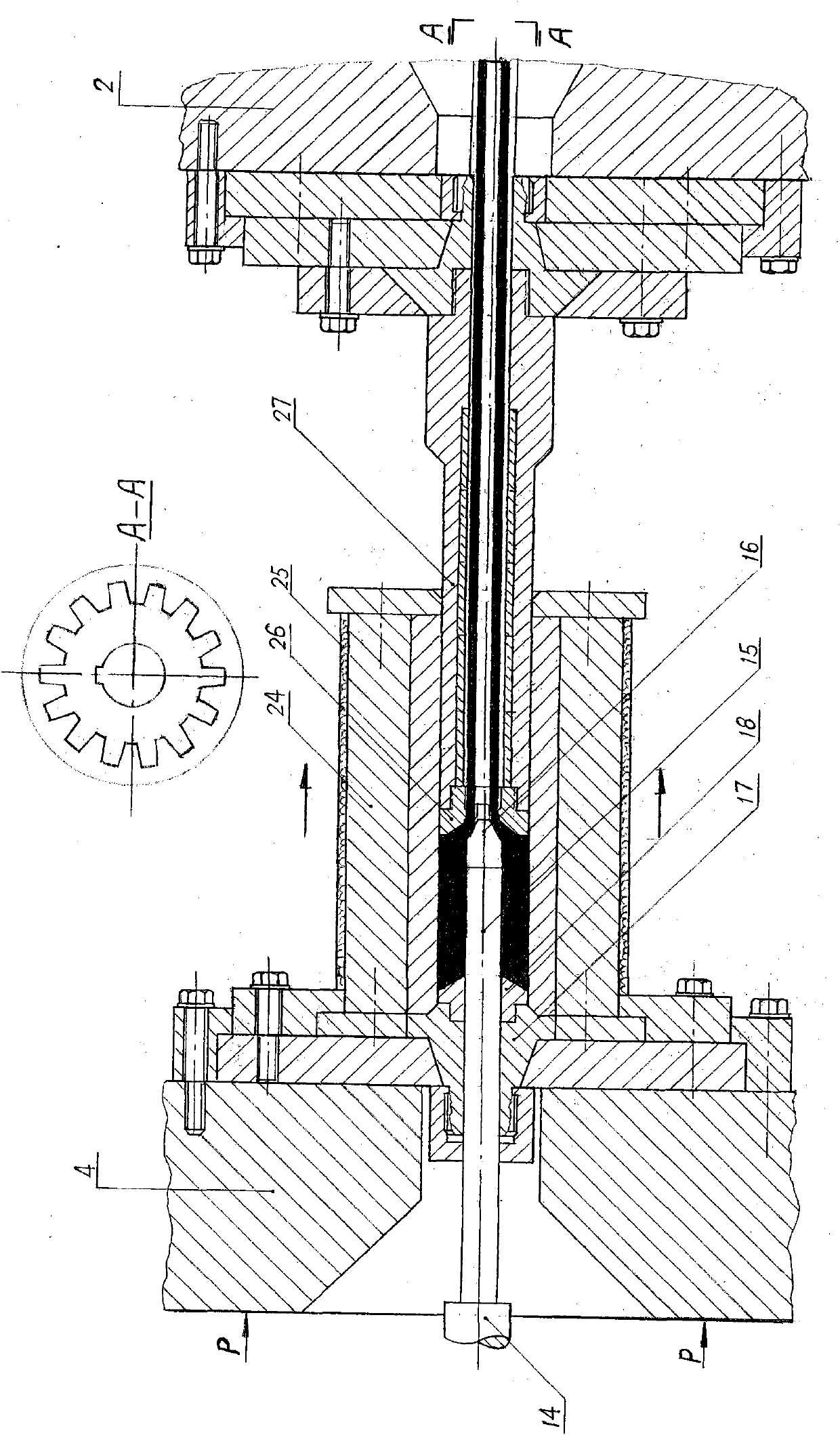

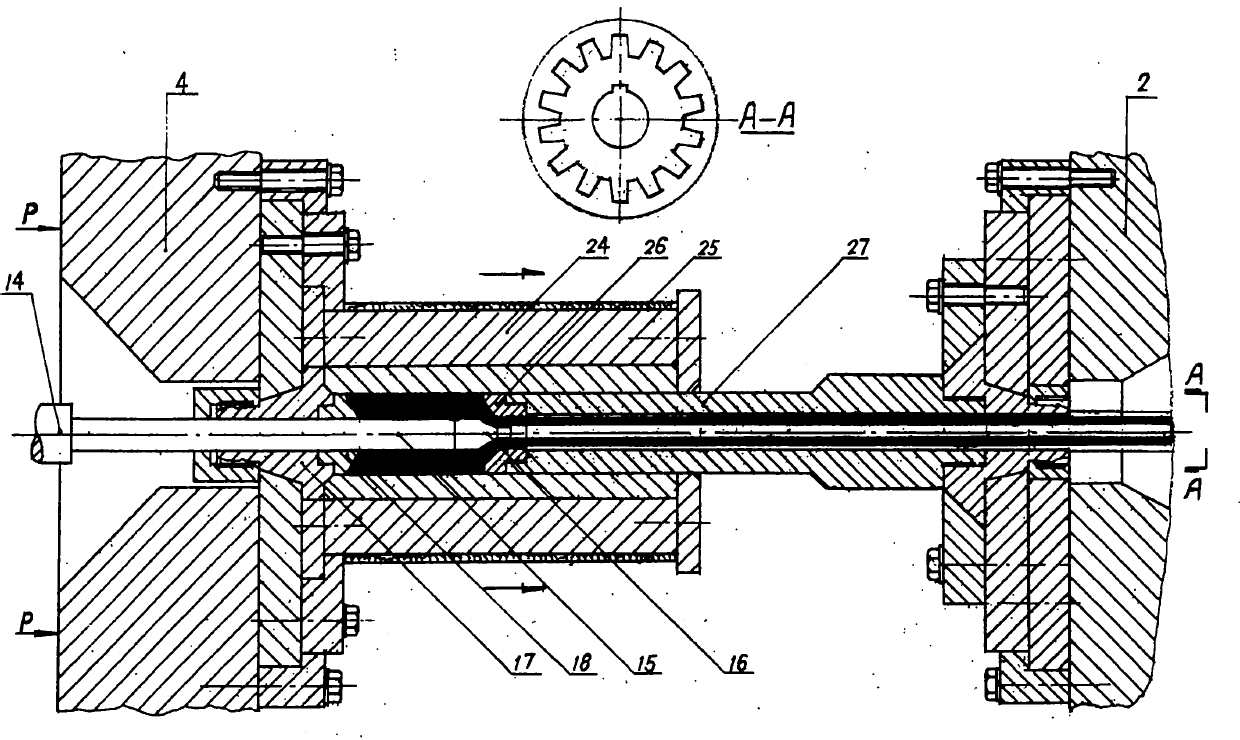

Large mode number helical awl gear cutting machine

InactiveCN1923419ASimple structureEasy to manufactureGear-cutting machinesGear teethEngineeringGear cutting

The invention relates to a large-module screw taper gear processing lathe. Wherein, said lathe has X straight track and relative X sliding table; the crane has Z straight track 15 and relative beam; said beam has Y straight track and relative blade box; the blade box has rotational blade main axle mounted with blade; the X sliding table is mounted with work piece table mounted with screw taper gear; said table can be disc one or axle one. The invention has simple structure, high stability and high reliability.

Owner:HUNAN ZDCY (ZHONGDA CHUANG YUAN) CNC EQUIP CO LTD

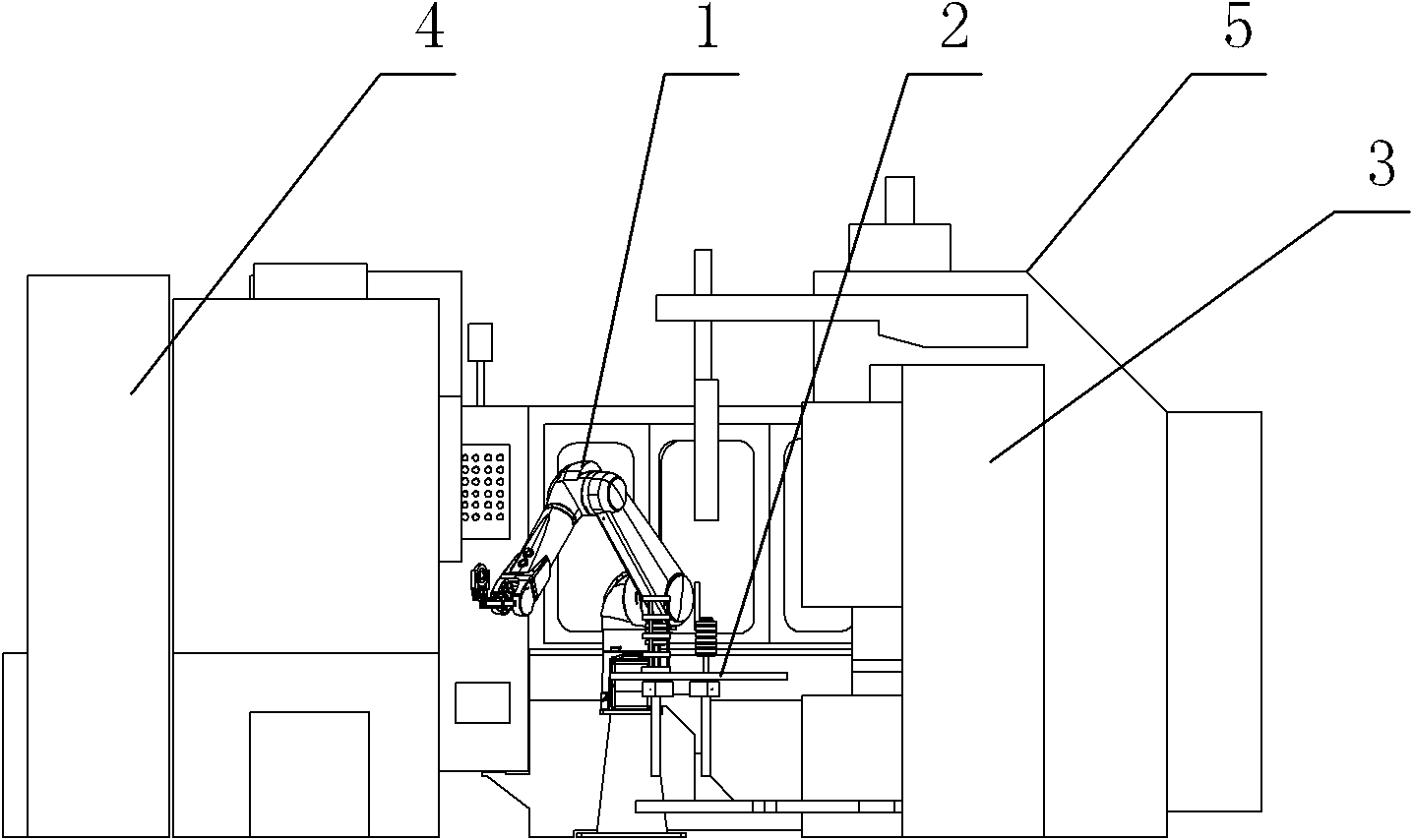

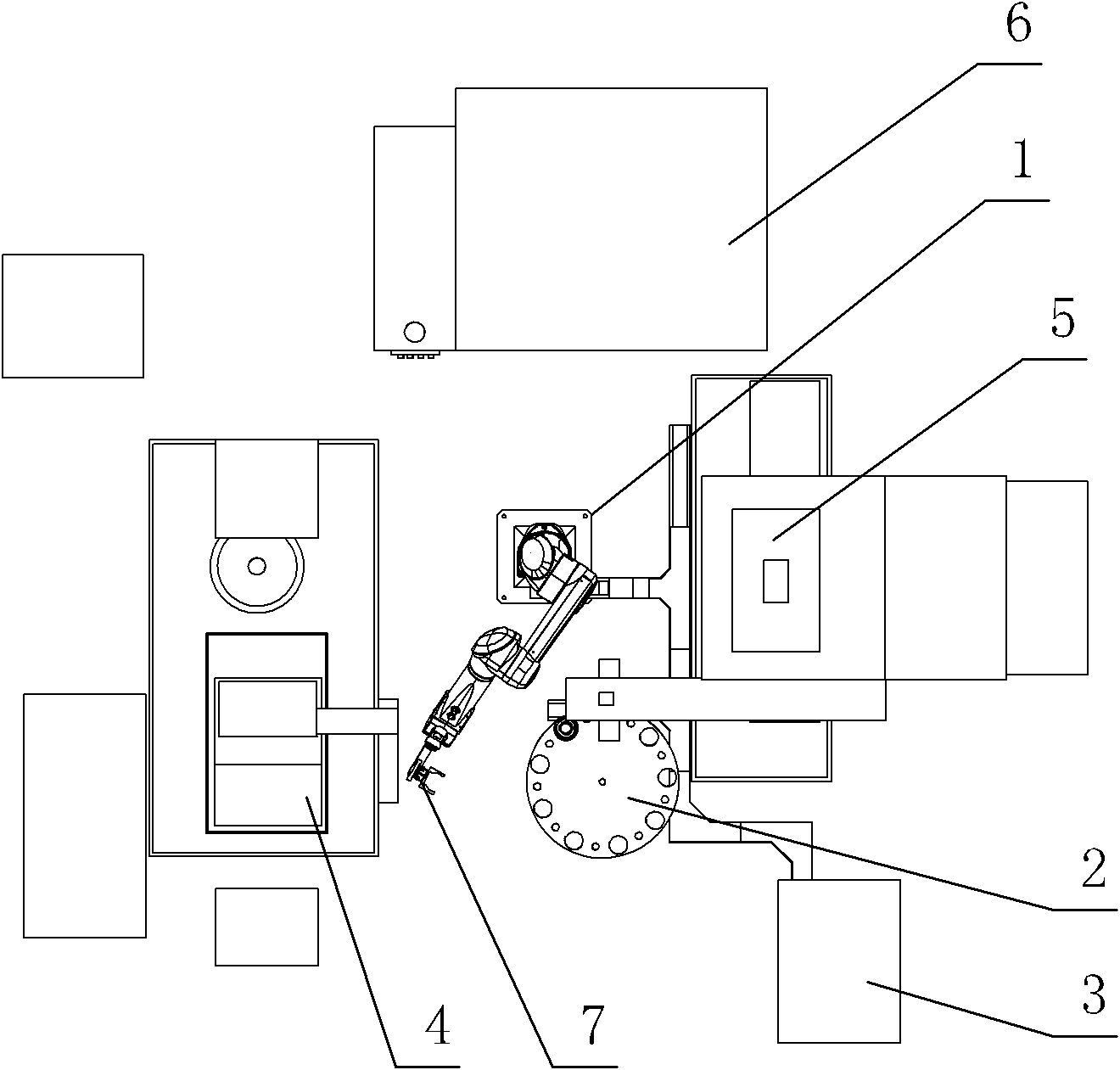

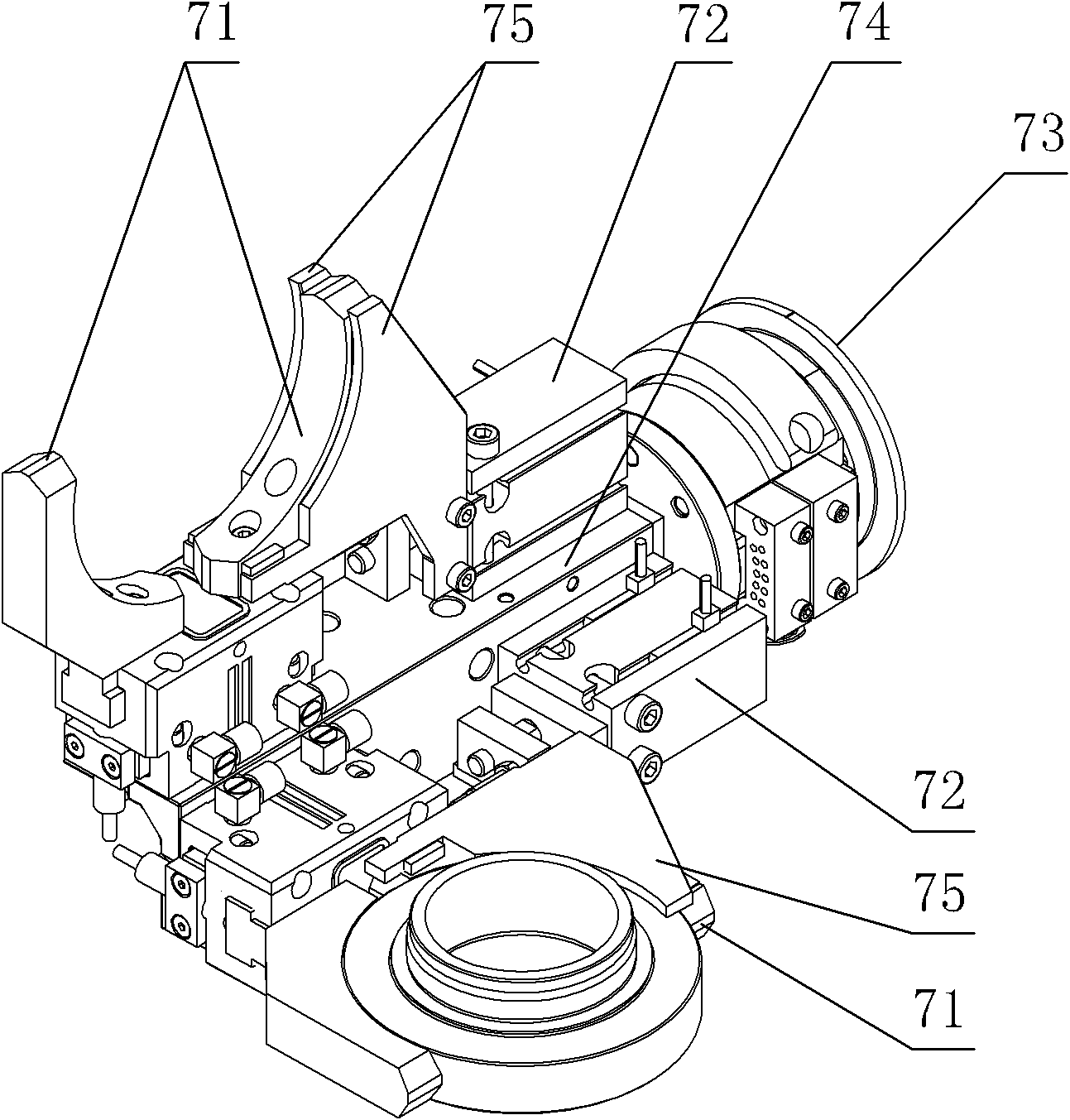

Automatic loading gear alignment method and device for articulated robot-based gear cutting machine

InactiveCN102114558APrecise alignmentReliable alignmentProgramme-controlled manipulatorGear-cutting machinesGear wheelEngineering

The invention relates to an automatic loading gear alignment method and a device for an articulated robot-based gear cutting machine. The method comprises the following steps: clamping a gear to be cut by a loader to move towards a cutter, leading the gear to be cut to be approximately parallel to the axis of the cutter after entering a gear alignment area, wherein the gear to be cut can rotate along the axis of the gear in the loader, the loader can swing back and forth relative to the cutter so as to close to the cutter until the gear to be cut enters a cutting position; and the device comprise an articulated robot and clamp claws arranged thereon, each clamp claw comprises a clamp claw base and two-finger translation manipulators, the two-finger translation manipulators comprise a cylinder and a pair of claw fingers, and the two claw fingers are provided with arc-shaped clamping surfaces. The method can fast lead the gear to be cut to be aligned and sent at the position to be cut, and the whole alignment process is automatically conducted by the loader, so that the operation is simple, the alignment is accurate and the production efficiency is high; and the device can lead the gear to be cut to close to the cutter by a fold line movement track, and complete the alignment operation of the gear during closing.

Owner:杭州英纳福自动化工程有限公司

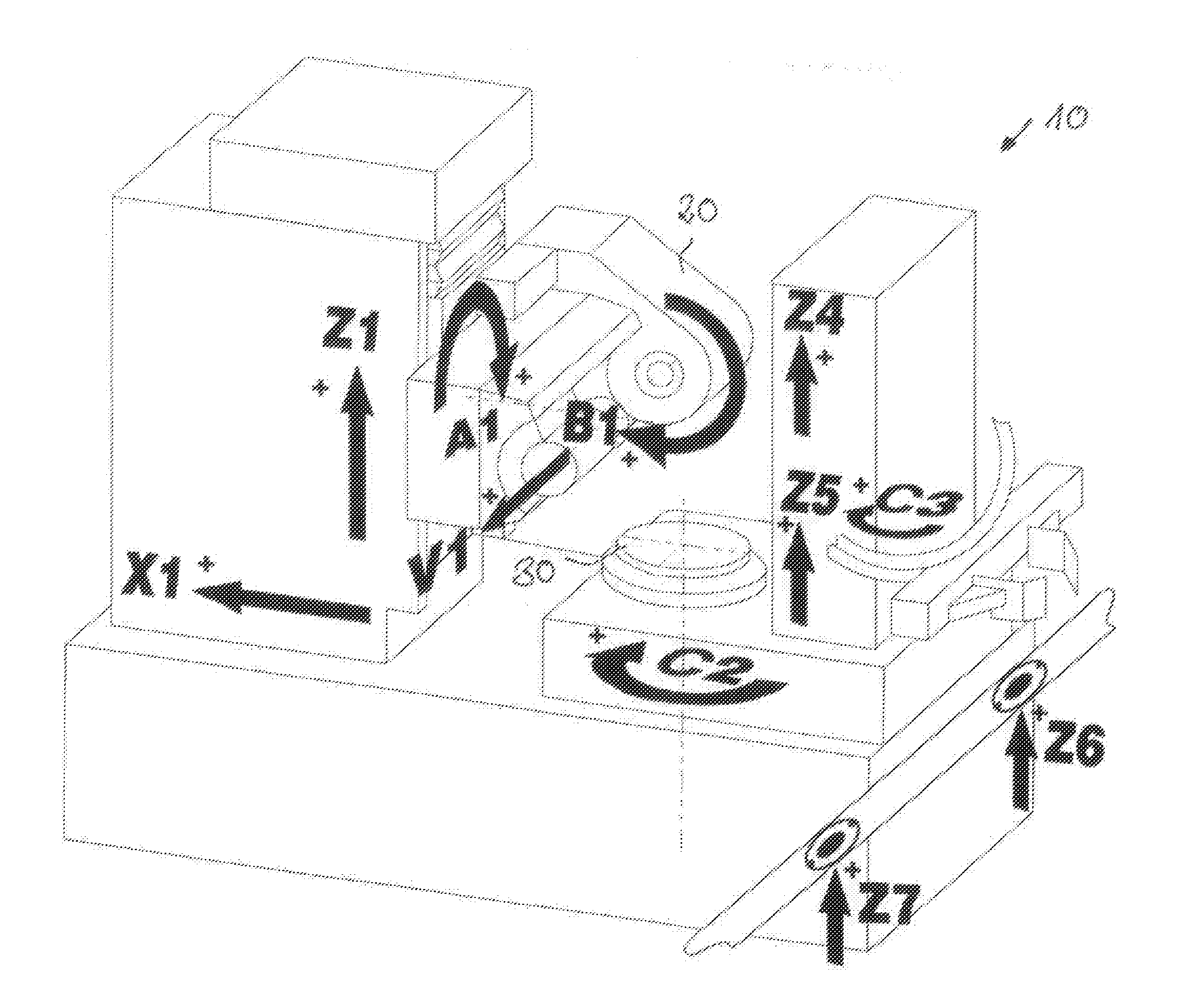

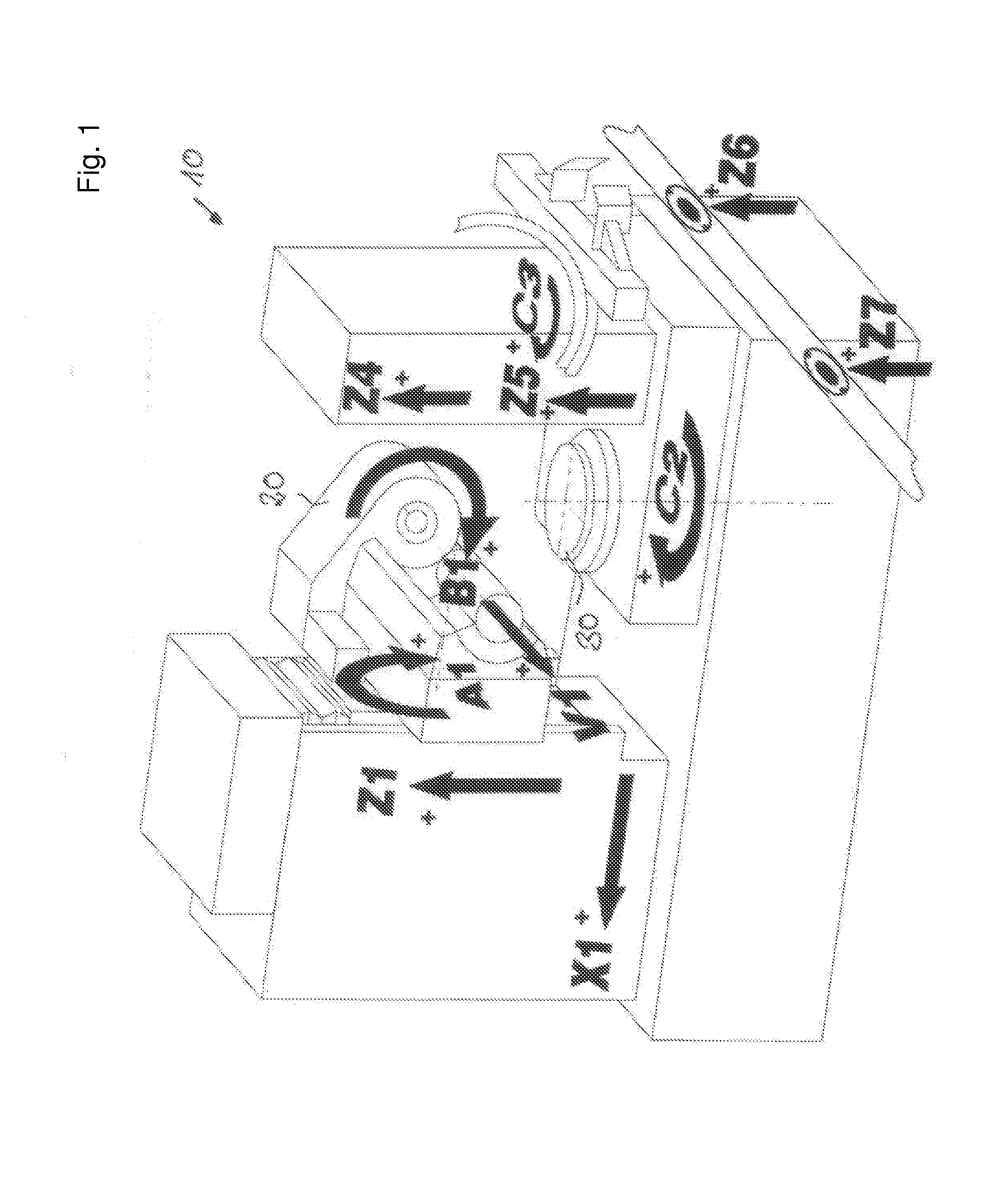

Bevel gear cutting machine for chamfering and/or deburring edges on the teeth of a bevel gear

A bevel gear cutting machine, which is designed for, among other things, chamfering and / or deburring edges on the teeth of a bevel gear. The gear cutting machine has a workpiece spindle which receives the bevel gear coaxially. A carriage is provided, which receives a plate-shaped cutter head having multiple bar blades. The gear cutting machine has multiple numerically controllable axes, which are activatable via a programmable controller, one of the axes forming a workpiece spindle axis of the workpiece spindle. Another axis is used as the tool spindle axis of the plate-shaped cutter head. The numerically controllable axes are implemented and positioned so that by adjusting at least one of the axes, the workpiece spindle, together with the bevel gear, may be inclined in relation to the cutter head in such a way that the bar blades, while the workpiece spindle rotates around the workpiece spindle axis and the cutter head rotates around the tool spindle axis simultaneously, plunge one after another into tooth intermediate spaces of neighboring teeth and execute a chamfering or deburring motion in relation to the edge.

Owner:KLINGELNBERG AG

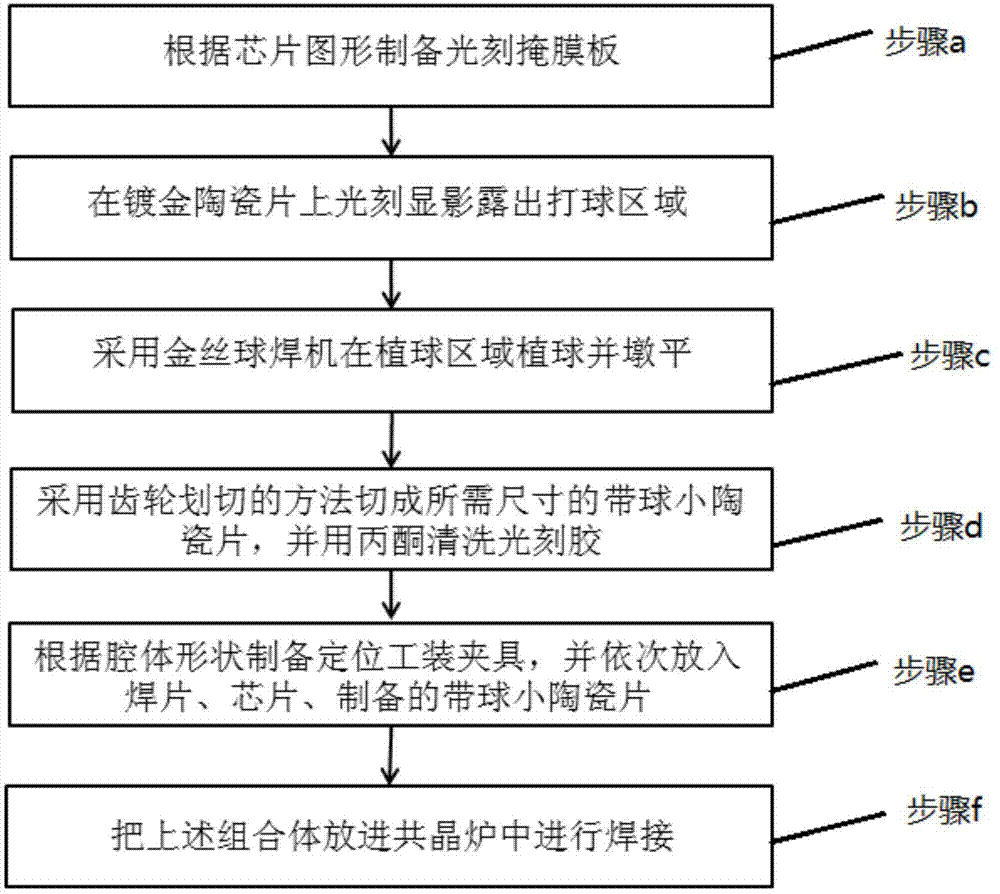

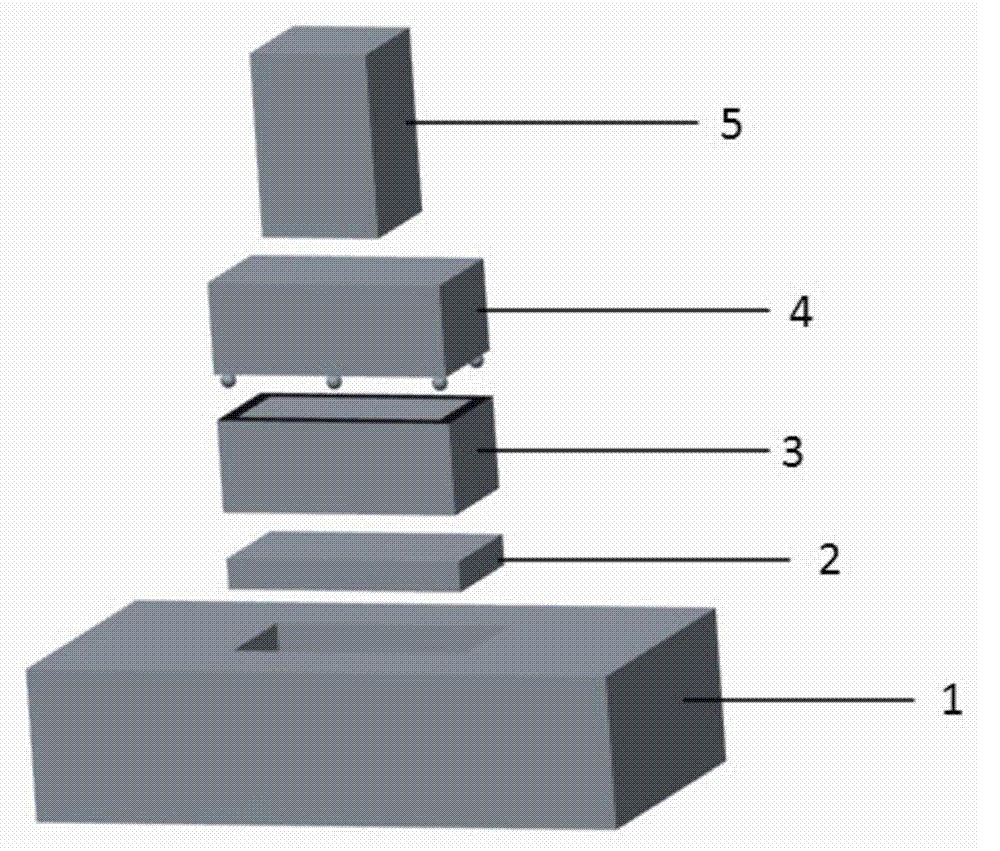

Method for achieving eutectic soldering of chips

ActiveCN103617957ASolve stressSolve the positioning problemSolid-state devicesSemiconductor/solid-state device manufacturingGold ballAdhesive

The invention provides a method for achieving eutectic soldering of chips. The method comprises the steps of a, compressible areas in the chips are determined, and a photoetching mask panel is manufactured; b, conducting adhesives in the compressible areas of the chips are removed through a photoetching develop method on a gilded ceramic wafer; c, ball points, used as protruding points, are planted at the position, where the adhesives are removed, on the ceramic wafer through a gold ball bonding method; d, the ceramic wafer is cut into small ceramic wafers consistent with the chips in size through a gear cutting method; e, a tool locating clamp is manufactured according to the shapes of cavities to be welded, and a small ceramic wafer pressing block clamp with gold protruding points makes contact with non-circuit areas of the chips through the protruding points; f, a pressing block is arranged on the small ceramic wafer pressing block clamp, and vacuum compressible soldering of the chips is indirectly achieved. The gilded ceramic wafer is used as the base material, the mature photoetching technology and the ball-bonding ball planting technology are used for manufacturing the protruding points to provide effective mechanical support for soldering, and the method is wide in application range.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

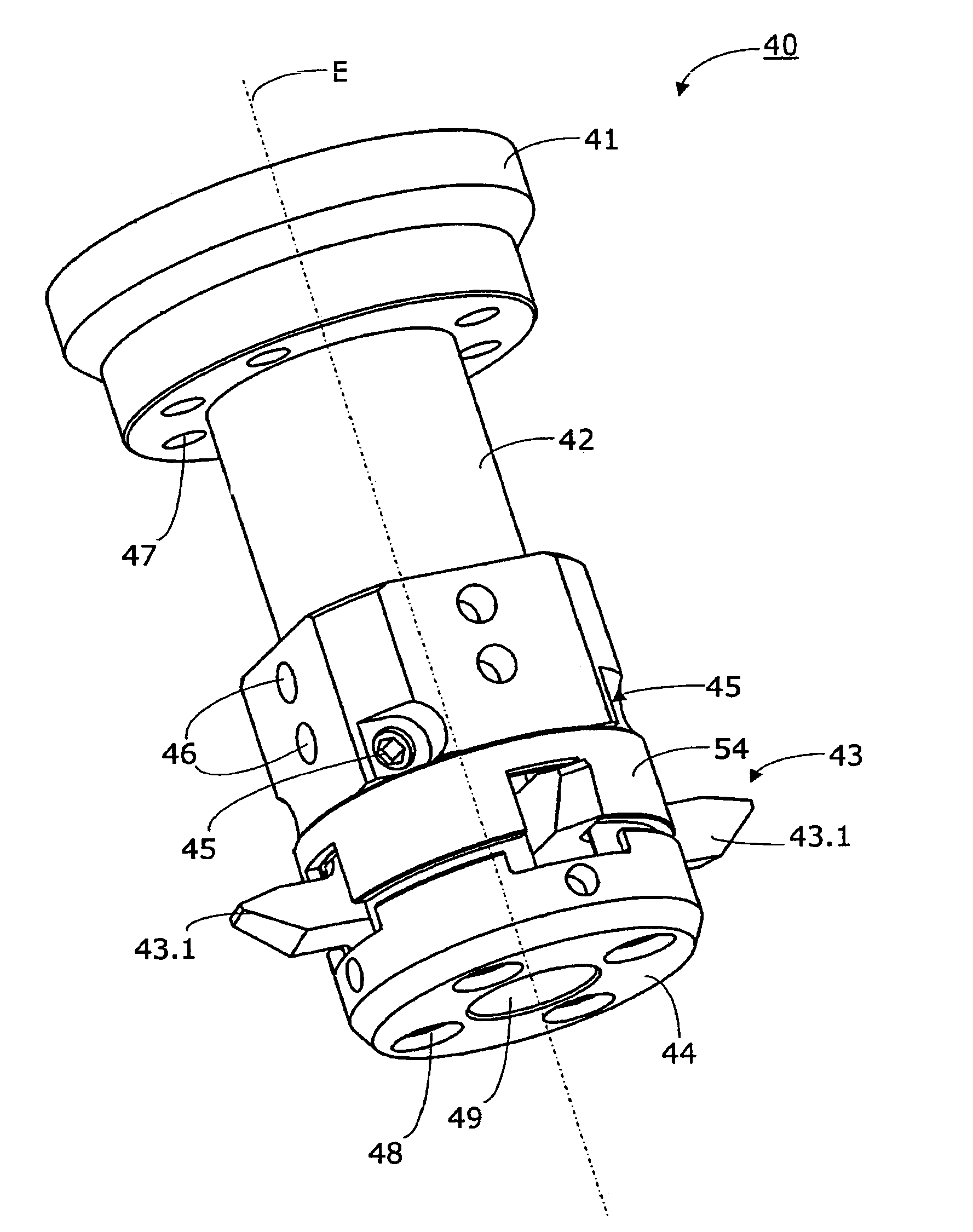

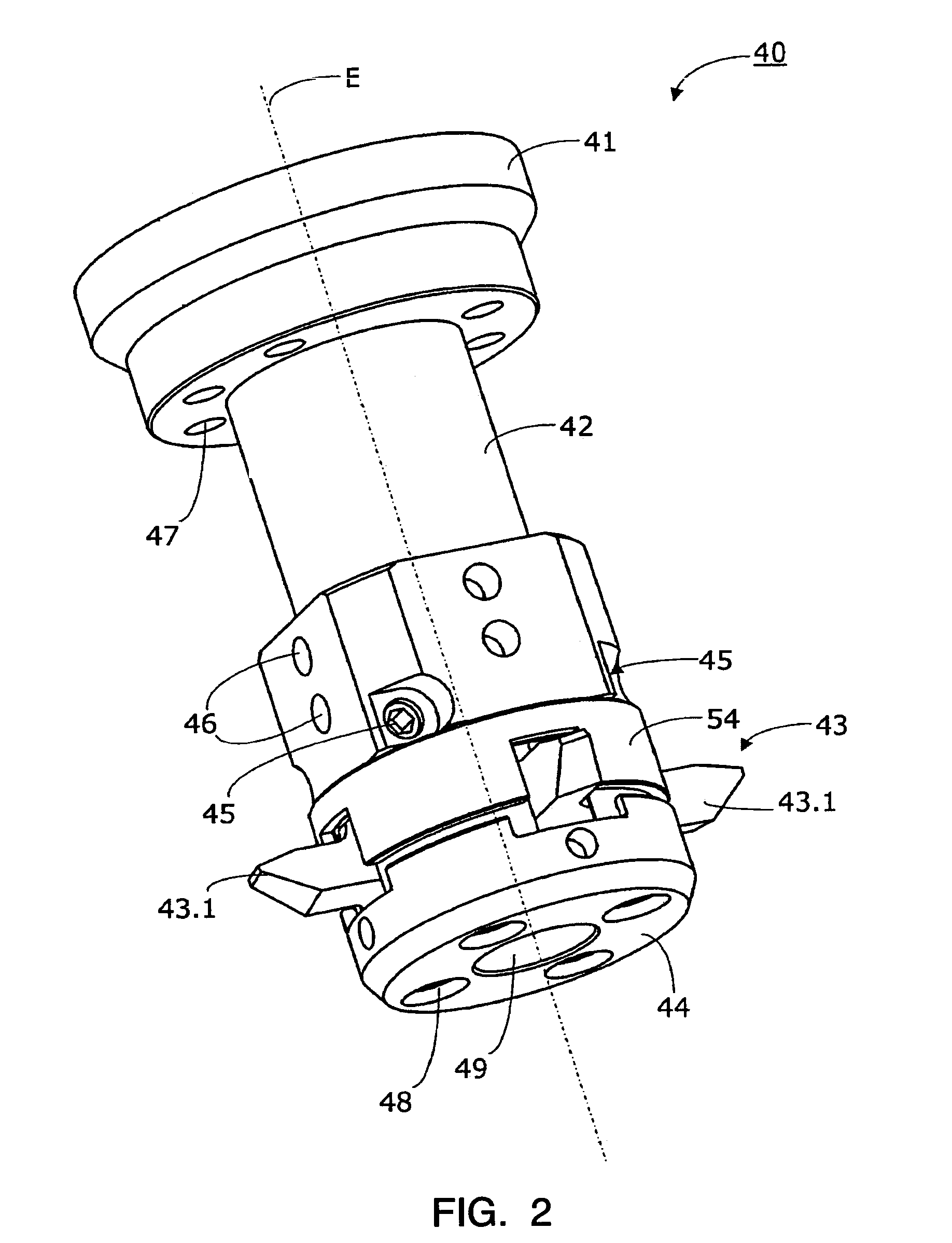

Deburring blade, device for mounting of deburring blades and bevel gear cutting machine for chamfering and/or deburring a bevel gear

ActiveUS7431544B2The degree of freedom becomes largerHandling device is simpleMilling cuttersLarge fixed membersEngineeringKnife blades

Bevel gear cutting machine for chamfering and / or deburring edges on the teeth of a bevel gear. The gear-cutting machine comprises a workpiece spindle, which receives the bevel gear coaxially of a spindle axis. Furthermore, a deburring spindle is provided for the receiving of a deburring tool and several numerically controllable axes are given. A deburring blade head with several blade cutter-like blade inserts serves as deburring tool, whereby the blade inserts are insertable in recesses of the deburring blade head essentially radially oriented to a deburring spindle axis (E) and comprise edges for chamfering and / or deburring.

Owner:KLINGELNBERG AG

Gear cutting machine having a device for chamfering / deburring the edges of a work piece

A gear cutting machine wherein a chamfer / deburr device and tool are fastened to a fixed component of the gear cutting machine. In this way, it is possible to adjust the chamfering / deburring tool into the working position in a simple and dependable manner to remove the edges from a gear. The device preferably has a linear track as well as a pivot axis, which can position the tool into the optimum position for the chamfering and / or deburring of the gear.

Owner:THE GLEASON WORKS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com