Gear Cutting Machine

a cutting machine and gear technology, applied in the direction of gear teeth, gear teeth, gear-teeth manufacturing apparatus, etc., can solve the problems of limited grinding arm length, limited internal toothed arrangement maximum grindable width, and inability to use dressing devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

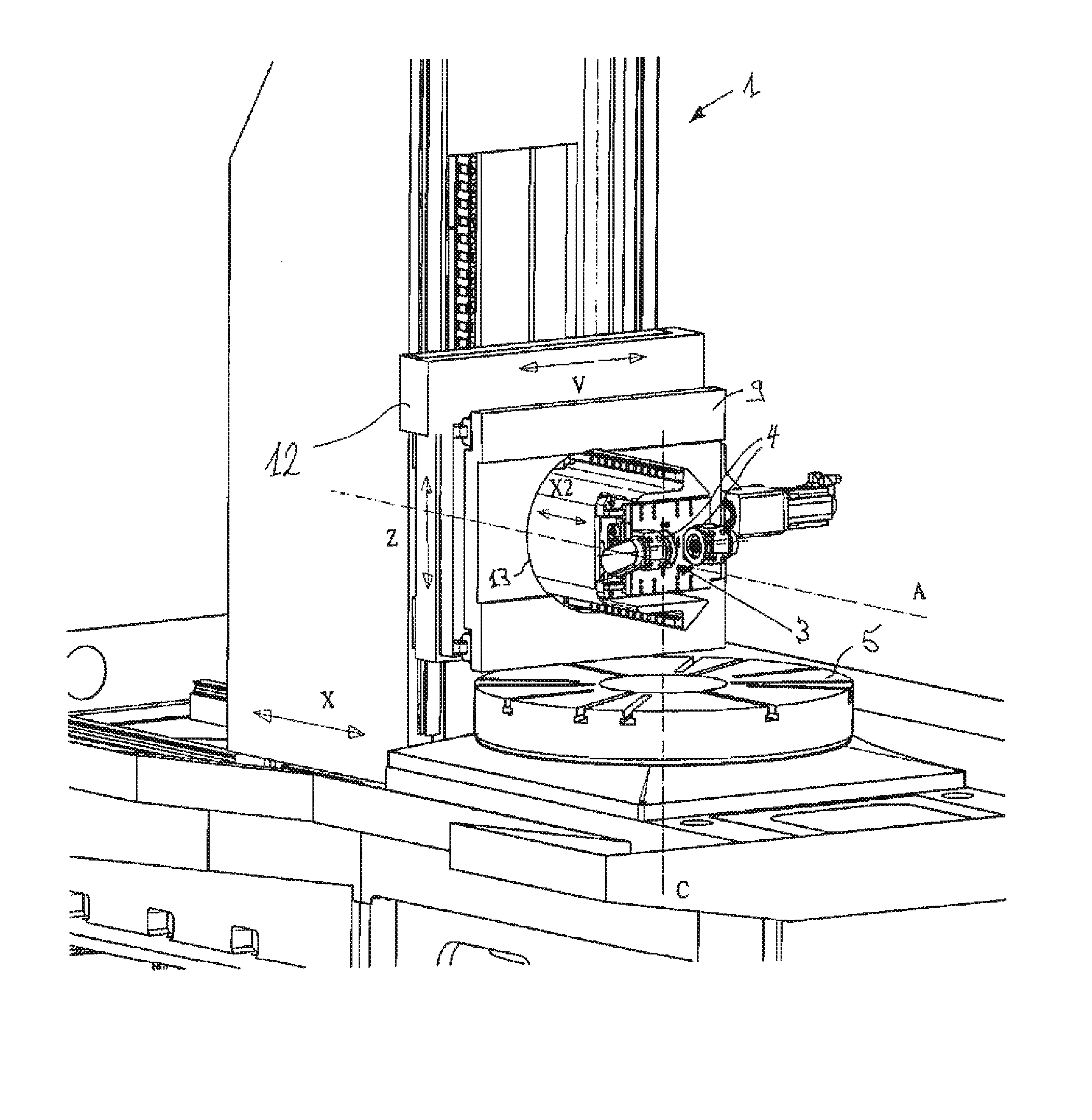

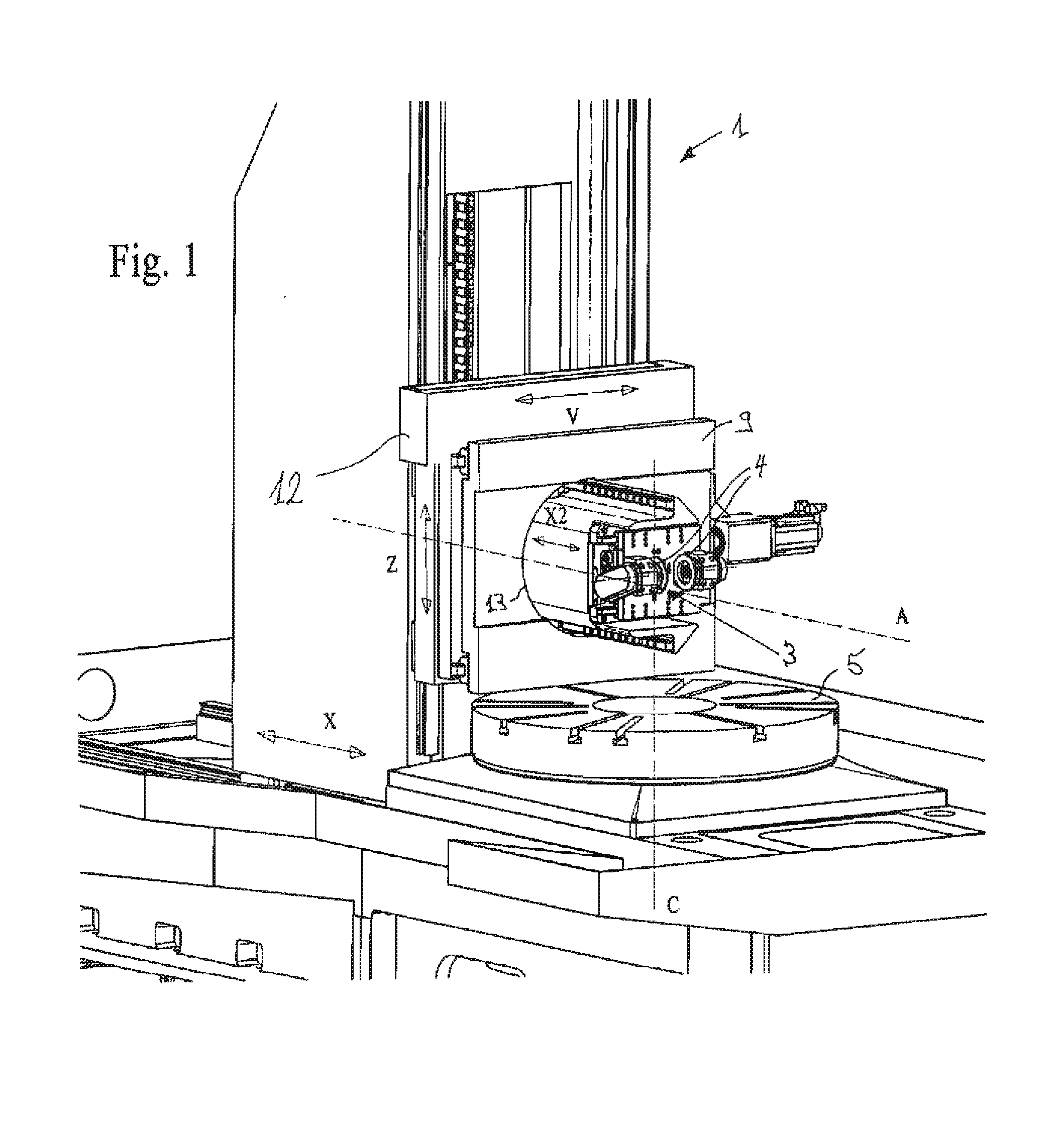

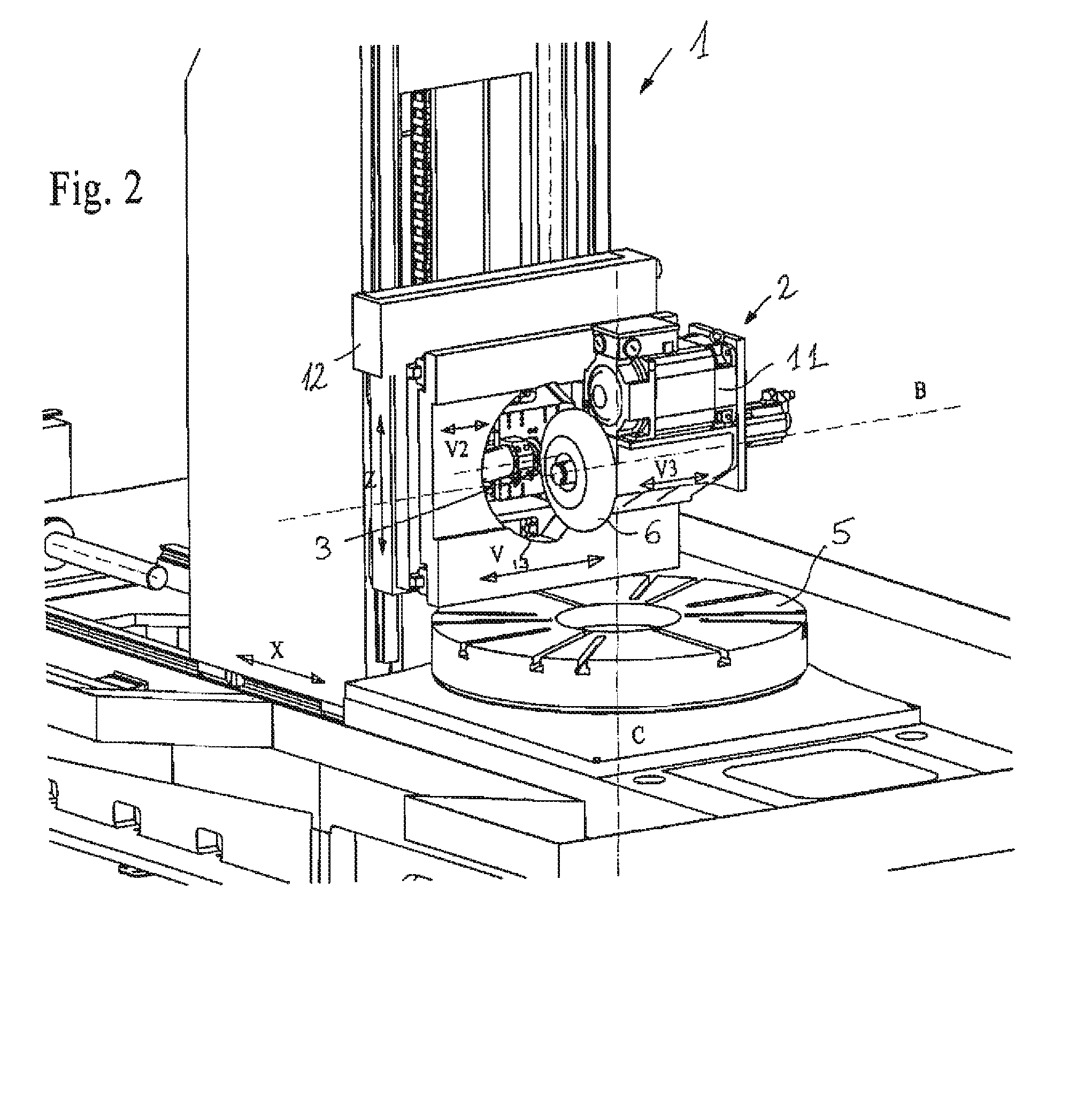

[0034]The general design of the gear cutting machine will be explained in more detail with reference to FIG. 1. It has a machine table 5 for the installation of a tool receiver and a workpiece can be clamped onto said machine table. The machine table 5 is in this respect rotatable about an axis C which is advantageously aligned in a perpendicular manner. Alternatively, however, horizontally aligned workpiece receivers can also be used. The gear cutting machine 1 furthermore has one or more installation surfaces 9 for the installation of a machining head 2, 7 (see FIG. 2 and FIG. 3 respectively). Either an external grinding head 2 for the machining of the external profile of a workpiece can be installed on the gear cutting machine 1 or an internal grinding head 7 for the machining of the internal profile of a further workpiece (see FIG. 2 and FIG. 3 respectively). One or more grinding tools 6, 8 can be clamped on the respective machining heads 2, 7. The grinding tools 6, 8 are in thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degrees of freedom | aaaaa | aaaaa |

| rotation | aaaaa | aaaaa |

| axis of rotation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com