Spherical involute spiral bevel gear cutting method and machine tool

A technology of spiral bevel gear and spherical involute, which is applied in the direction of gear cutting machine, gear tooth manufacturing tool, gear tooth manufacturing device, etc., can solve the difficulty of adjusting the contact area, the processing gear is not interchangeable, and the spherical involute cannot be obtained. tooth shape etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

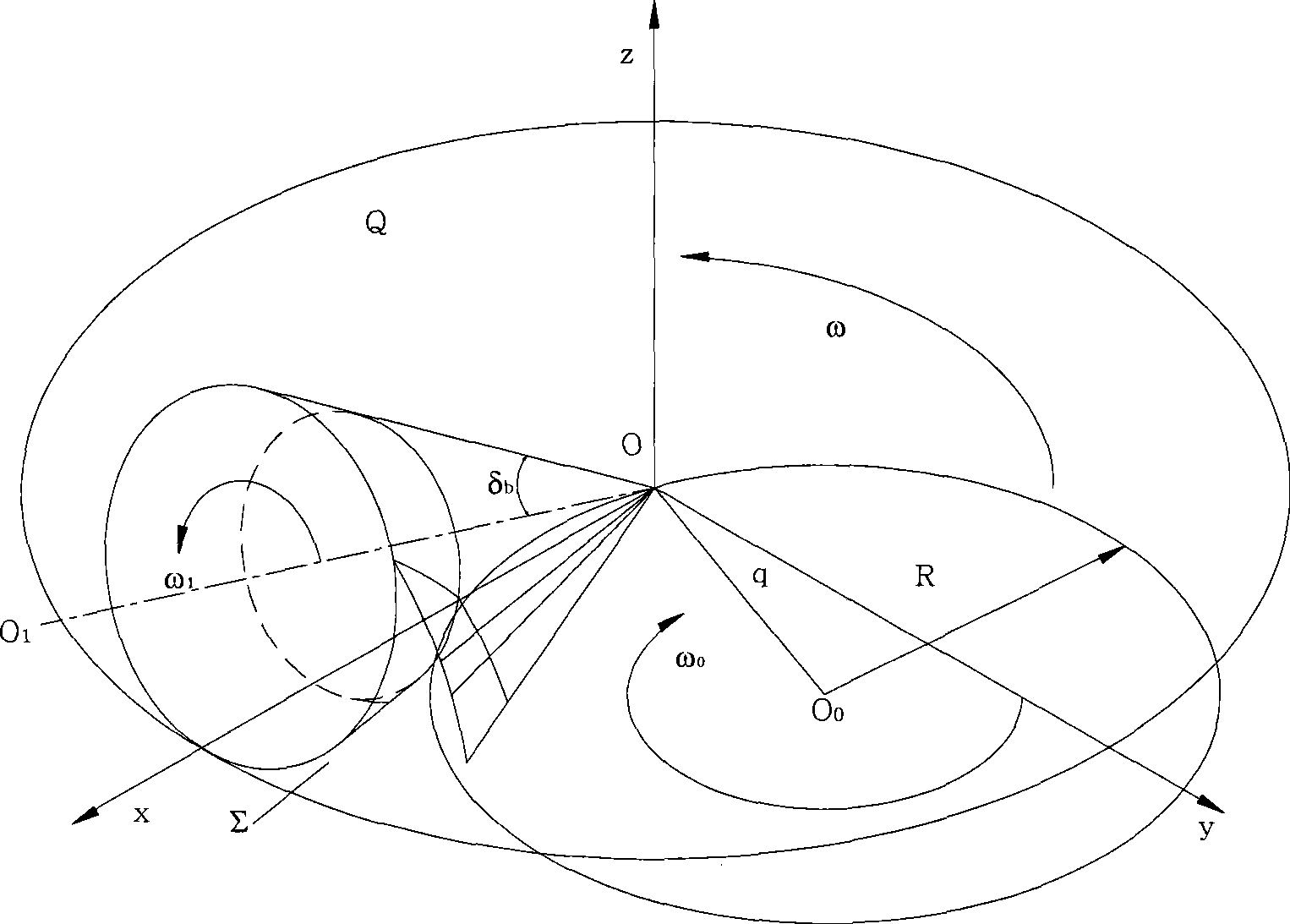

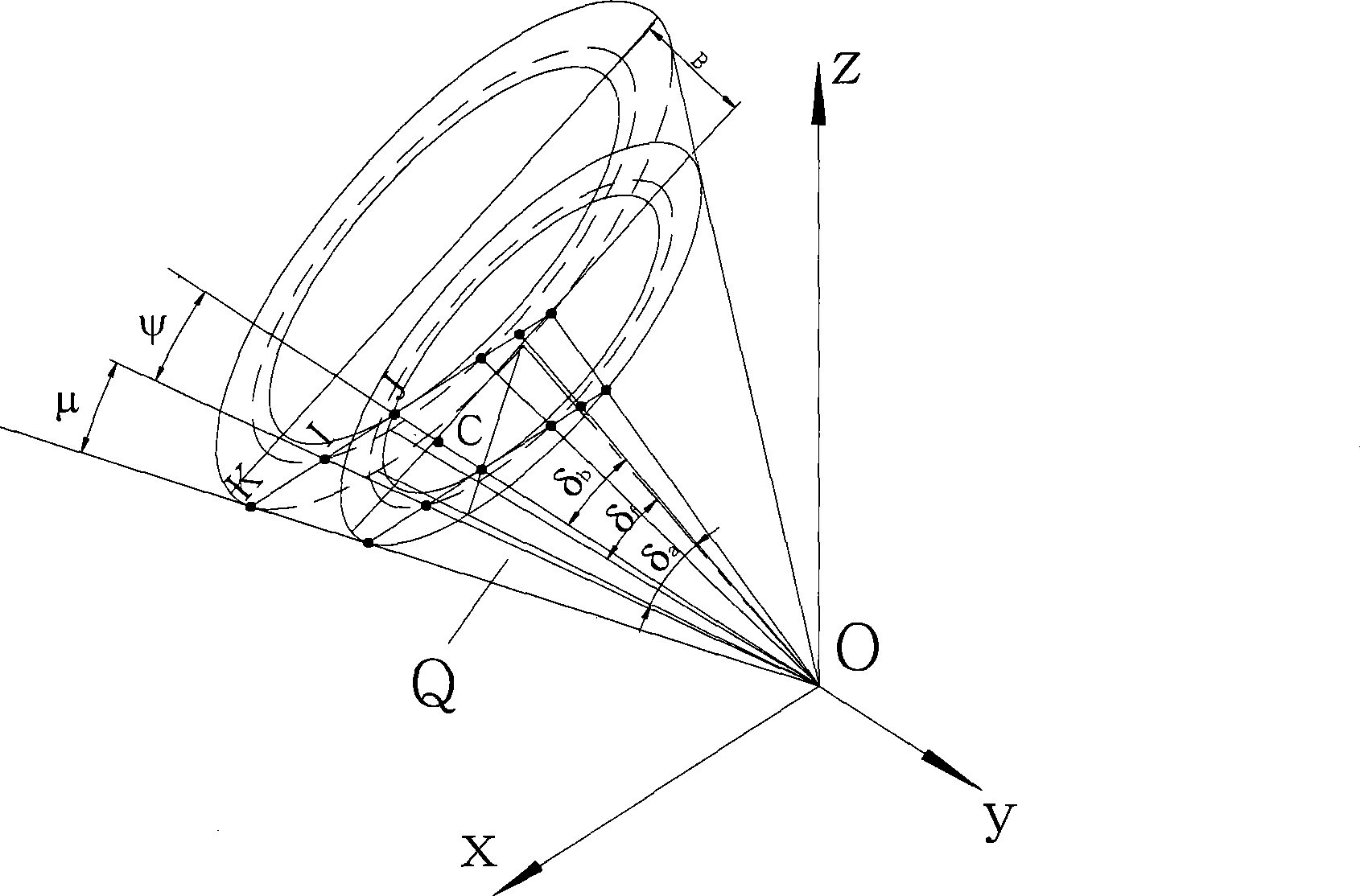

[0100] Parameter Calculation of Machine Tools and Cutting Gears for Three-Axis Linkage CNC Machining of Spherical Involute Spiral Bevel Gears

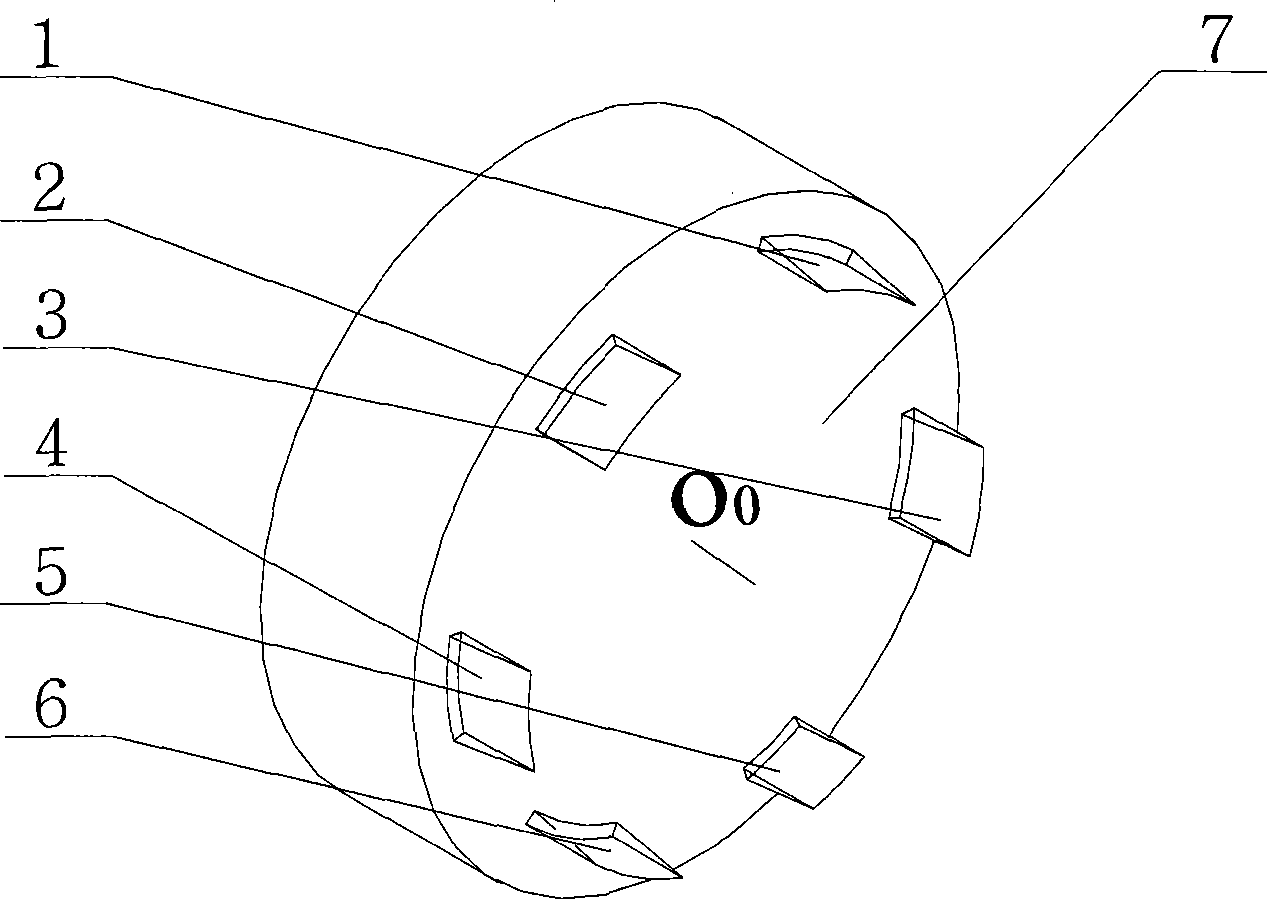

[0101] refer to Figure 5 and Figure 8 , The three-axis linkage CNC machining spherical involute spiral bevel gear machine tool is composed of a cutter head assembly 8, a bed 9, a cradle shaft assembly 10, a gear blank box 11, a turntable 12, and a slide table 13. Wherein the cutter head assembly 8 includes the cutter shaft O 0 , Installed on the cutter shaft O 0 The cutting tooth cutter head 7, eccentric mechanism etc. on. The gear blank box 11 is installed on the top of the turntable 12 to form a sliding connection, and the gear blank box 11 is equipped with a gear blank shaft O 1 , the slide table 13 equipped with the gear blank box 11 can move through the bottom of the slide table 13 and the chute and the slide rail above the turntable 12 (the symmetrical line of the chute and the slide rail and the gear blank axis O 1 The ax...

Embodiment 2

[0105] Parameter Calculation of Machine Tools and Cutting Gears for Four-axis CNC Machining of Spherical Involute Spiral Bevel Gears

[0106] refer to Figure 9 , cutter axis O 0 Installed on the vertical slide 14, the knife axis O 0 The axis of rotation is perpendicular to the vertical slide plate 14 (in Figure 9 -a middle cutterhead axis O 0 Projected as a point), the gear cutting cutter head 7 is fixedly installed on the cutter shaft O 0 On one end of the tool axis O 0 The other end of the vertical slide plate 14 is connected with the independent servo drive system, and the vertical slide plate 14 and the column 15 can be connected through the chute, the slide rail and the thread pair, and the vertical slide plate 14 can move up and down along the Z direction on the column 15, so it is installed with Cutter axis O of gear cutting cutter head 7 0 It can move up and down along the Z direction on the column 15 with the vertical slide 14, and the column 15 is fixedly ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com