Patents

Literature

45 results about "Envelope method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The envelope system, also known as the envelope budgeting method, is a popular method for visualizing and maintaining a flexible budget. The key idea is to prioritize cash income to meet separate categories of household expenses in physically separate envelopes.

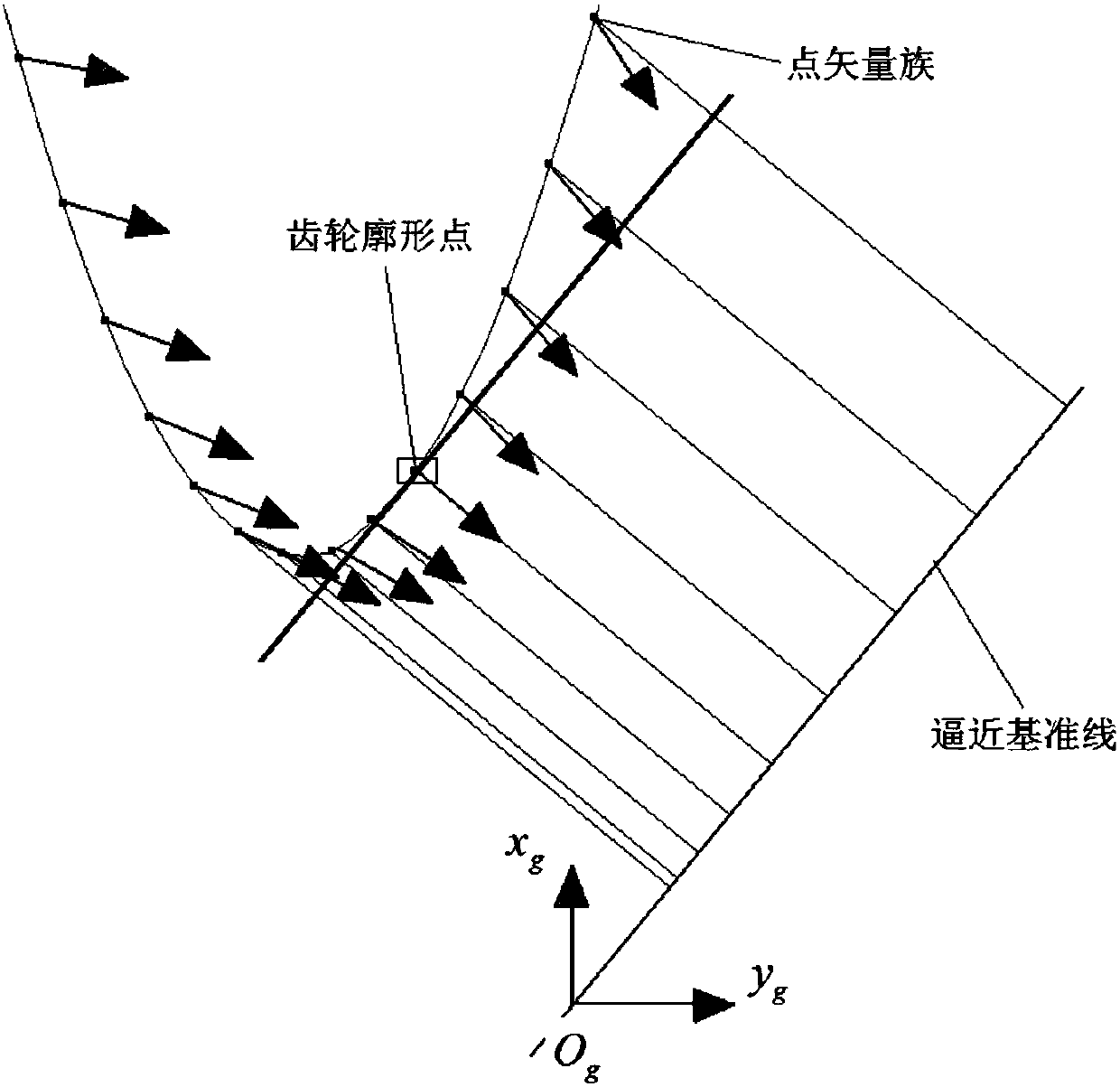

Point vector envelope method for determining processed spiral surface contour by forming cutter

ActiveCN104898556AEasy and fast profile envelope calculationDegougeNumerical controlEnvelope methodDiscrete points

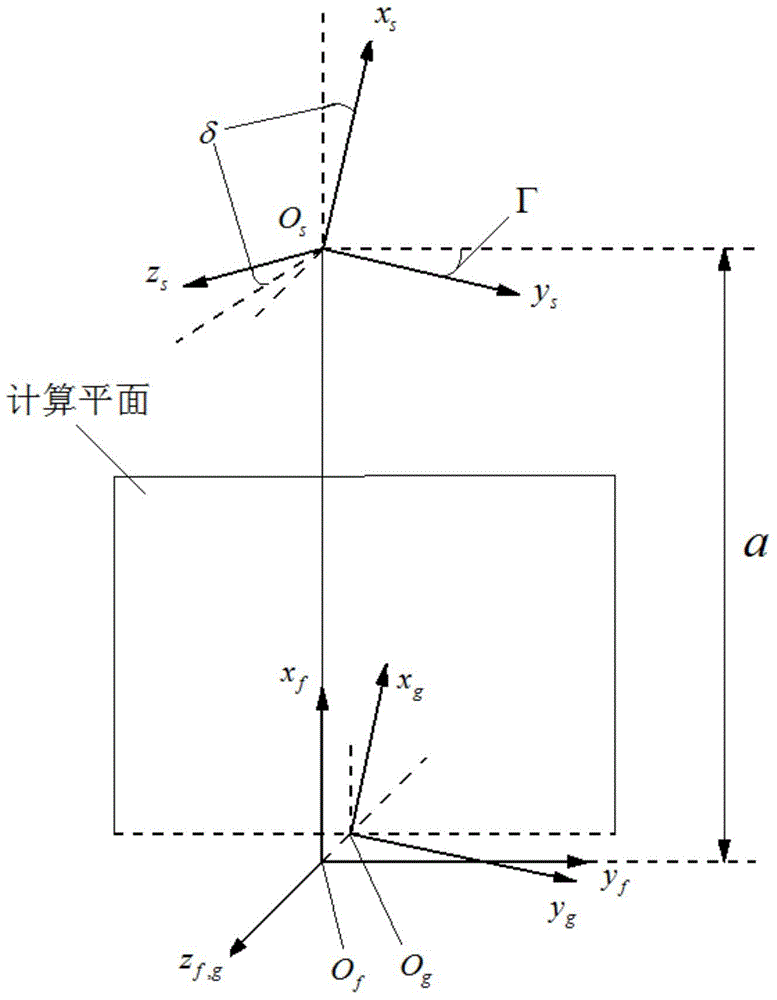

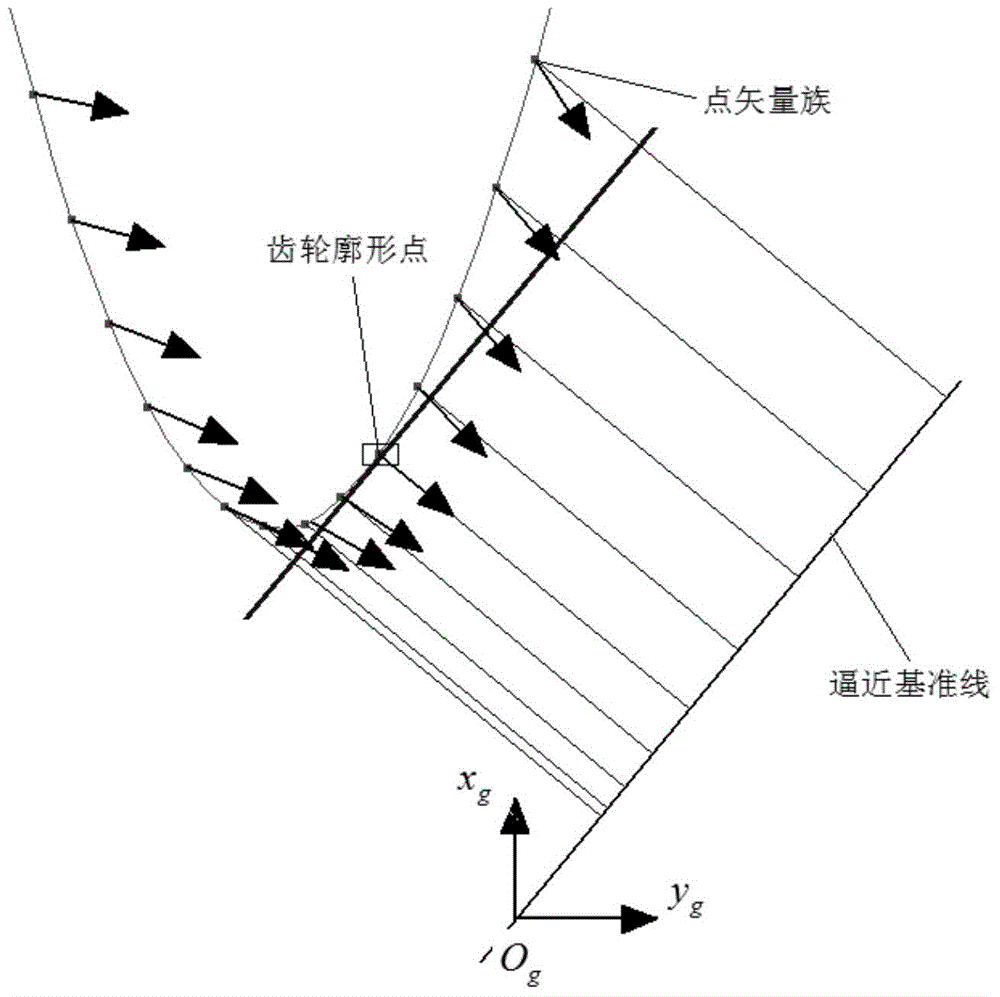

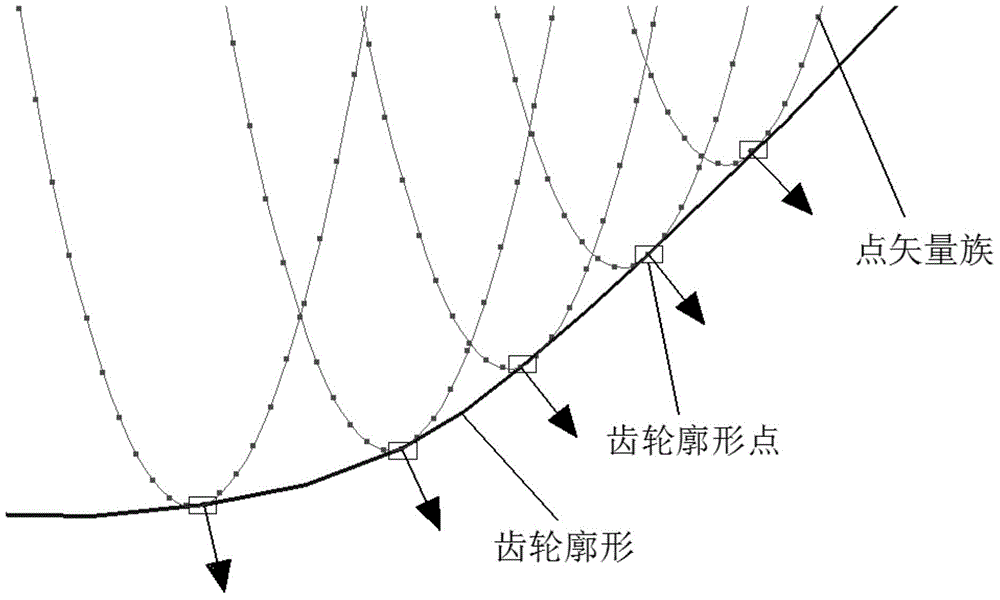

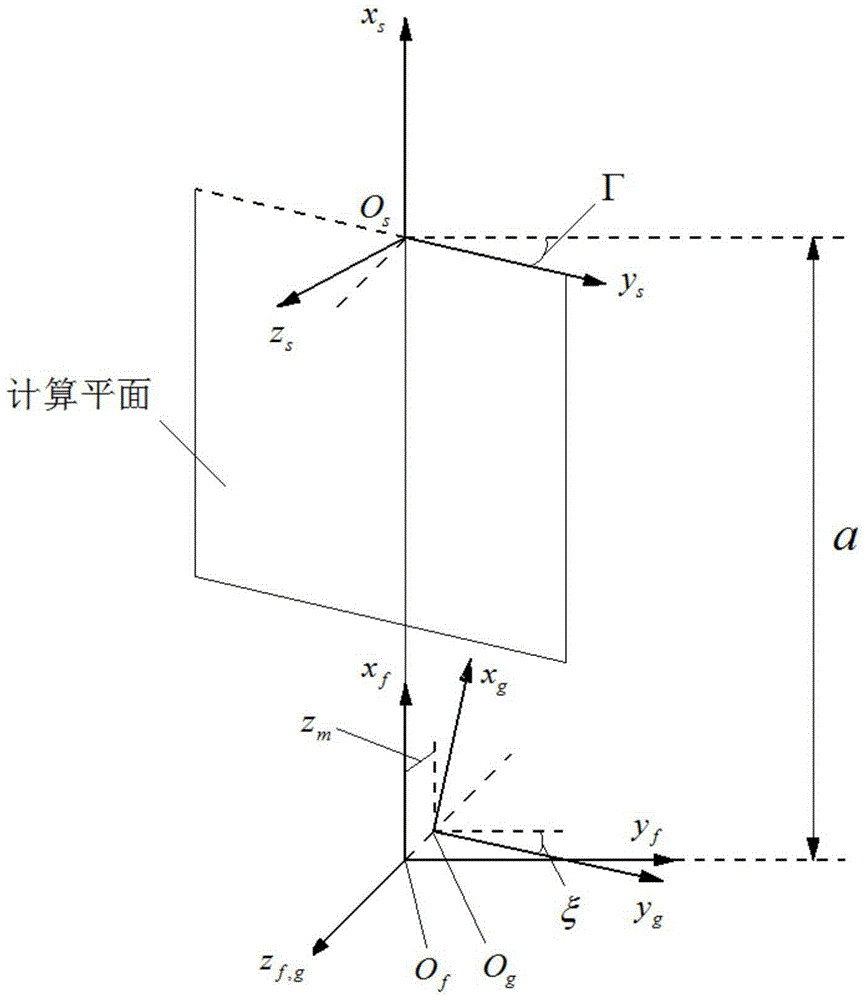

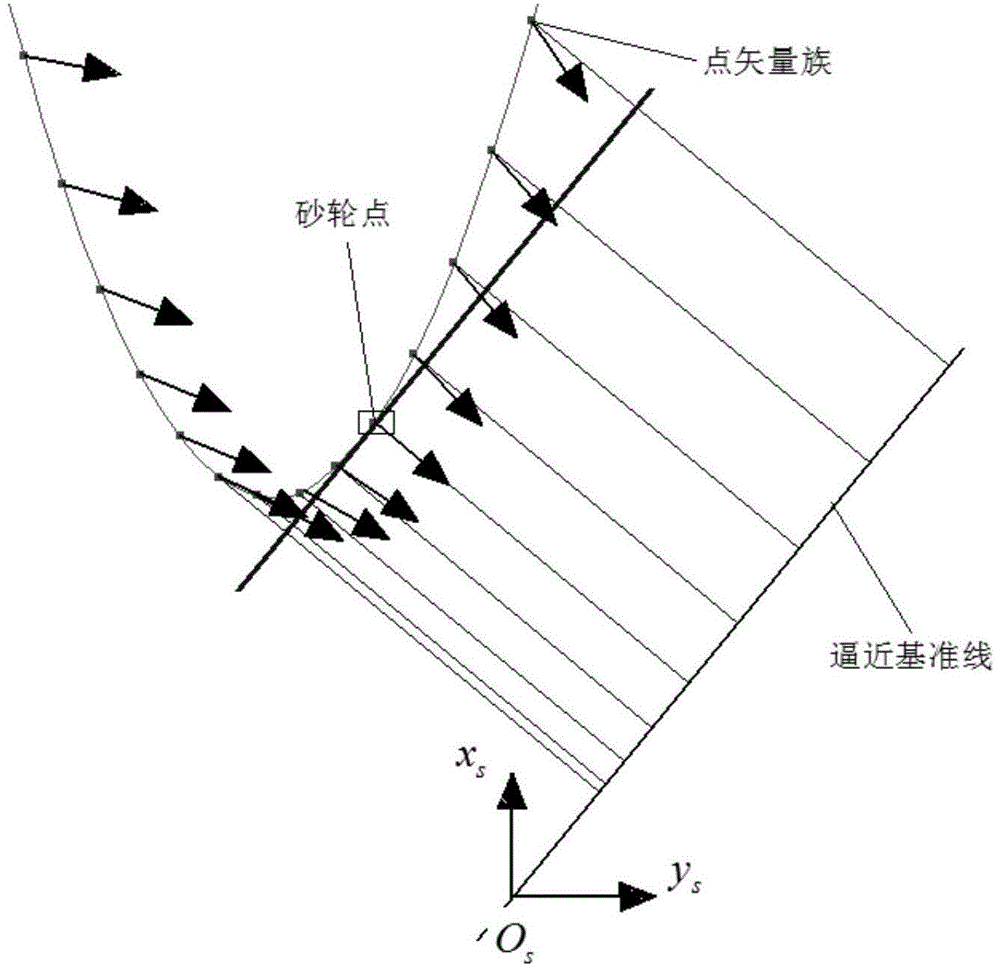

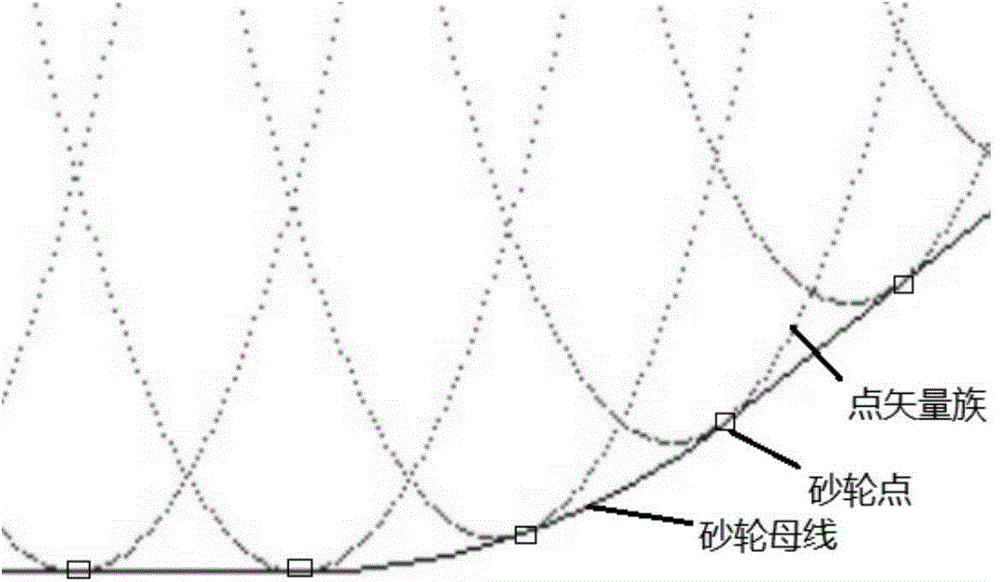

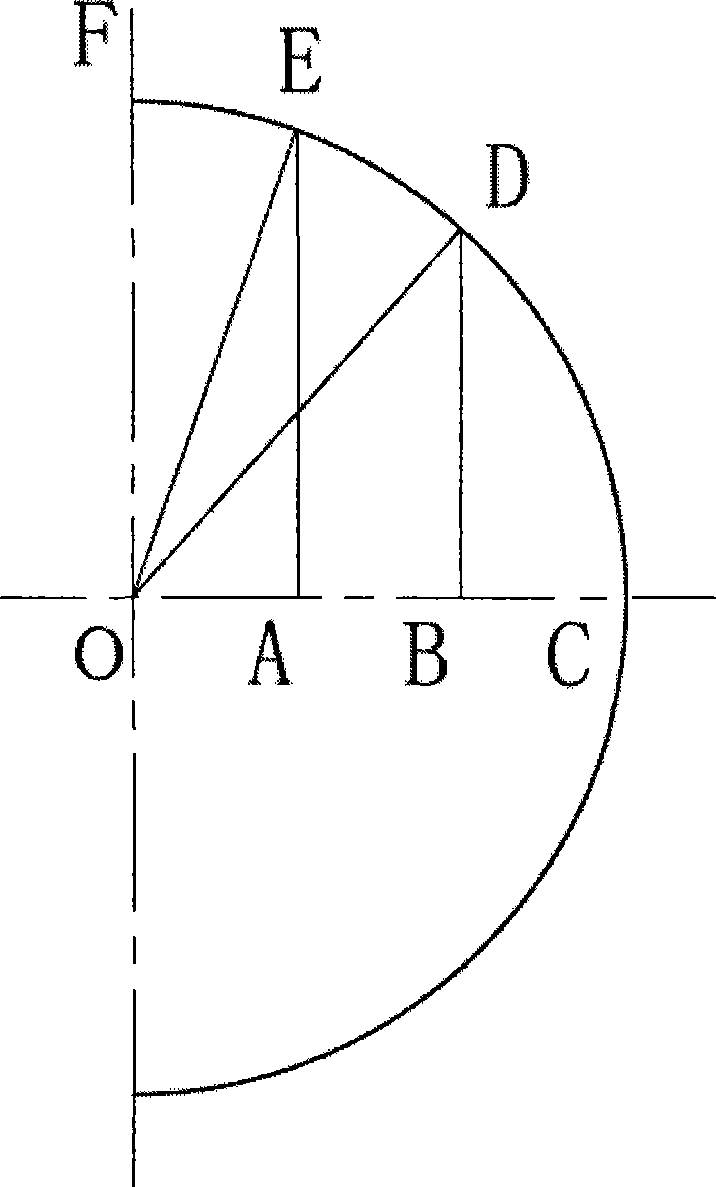

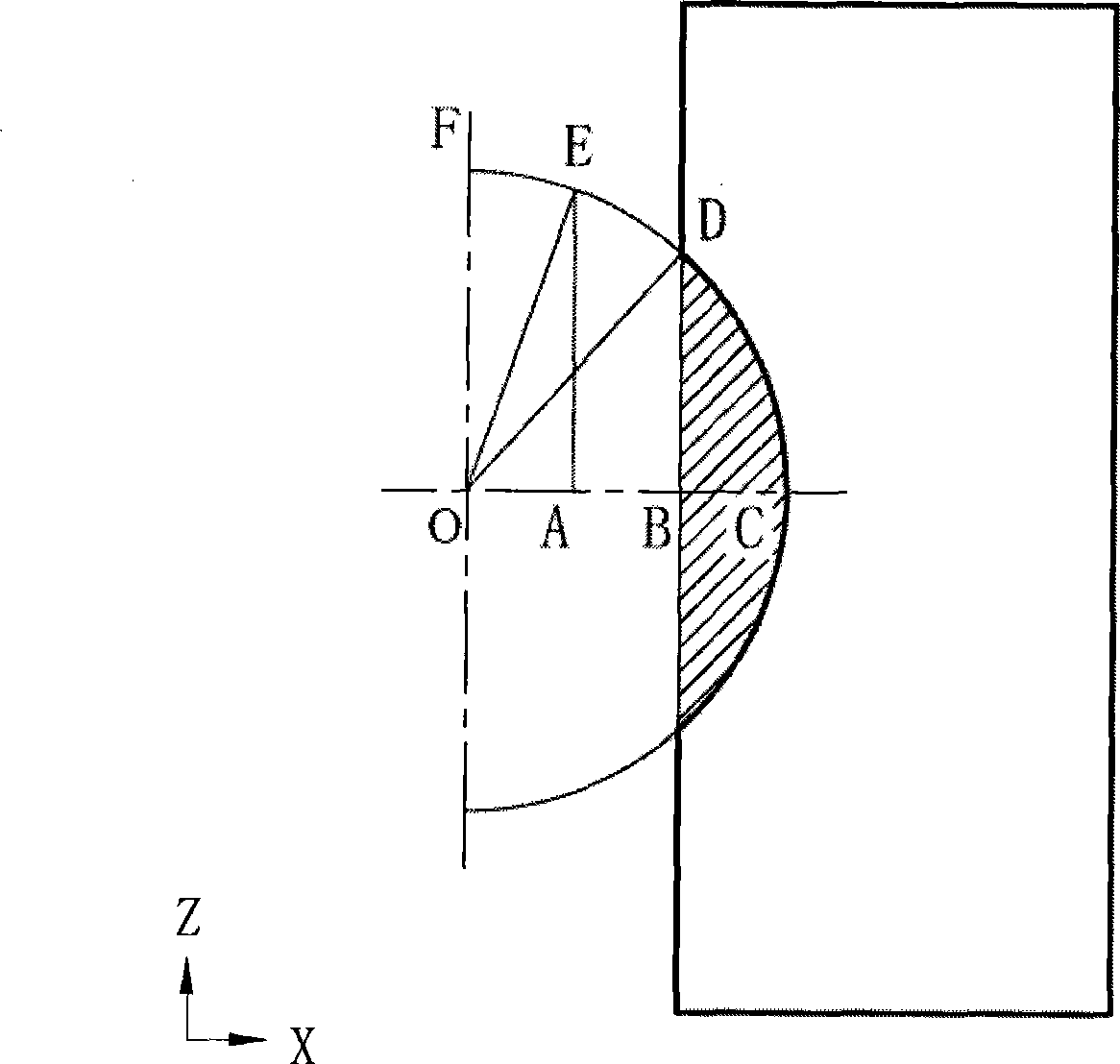

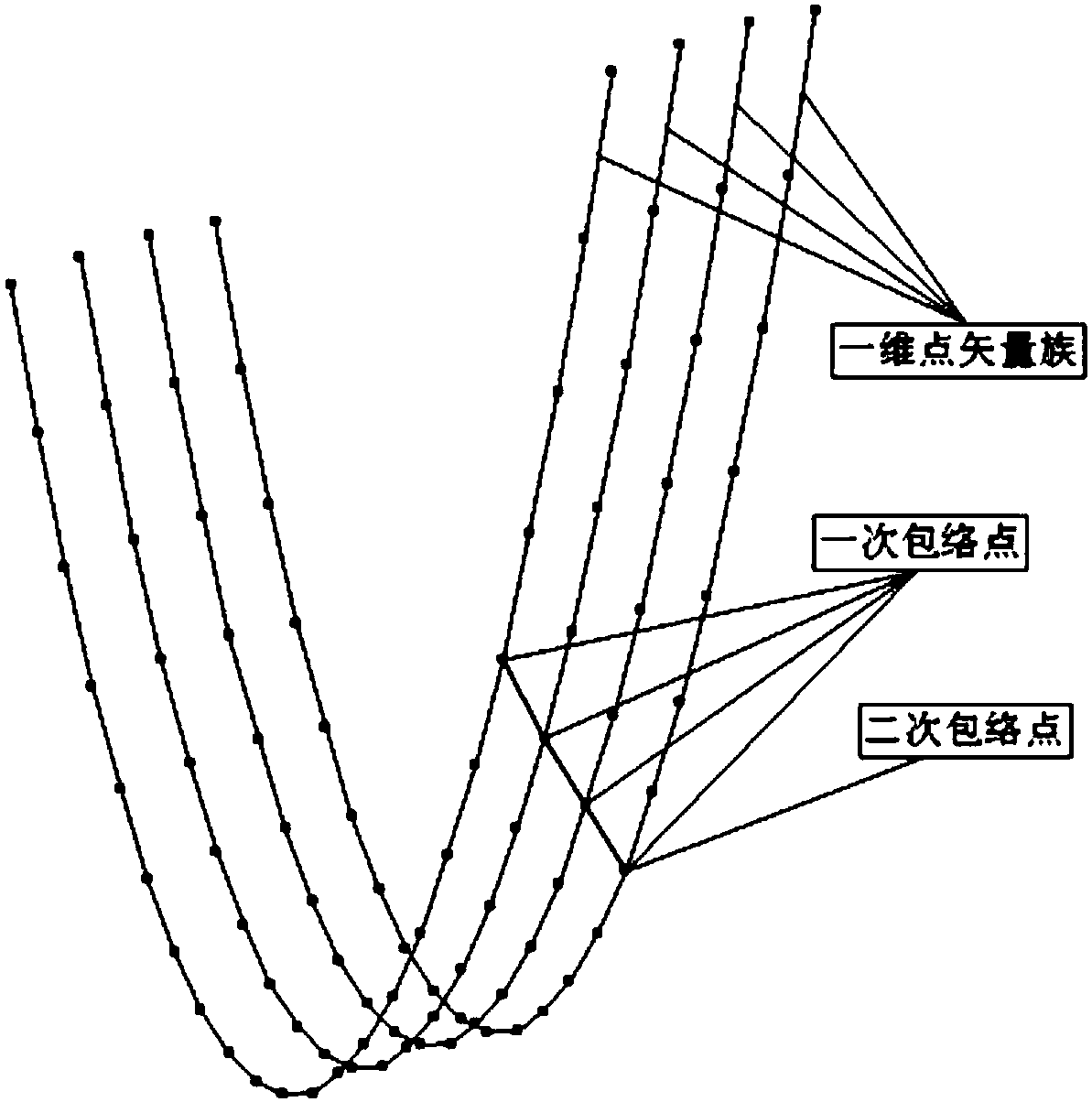

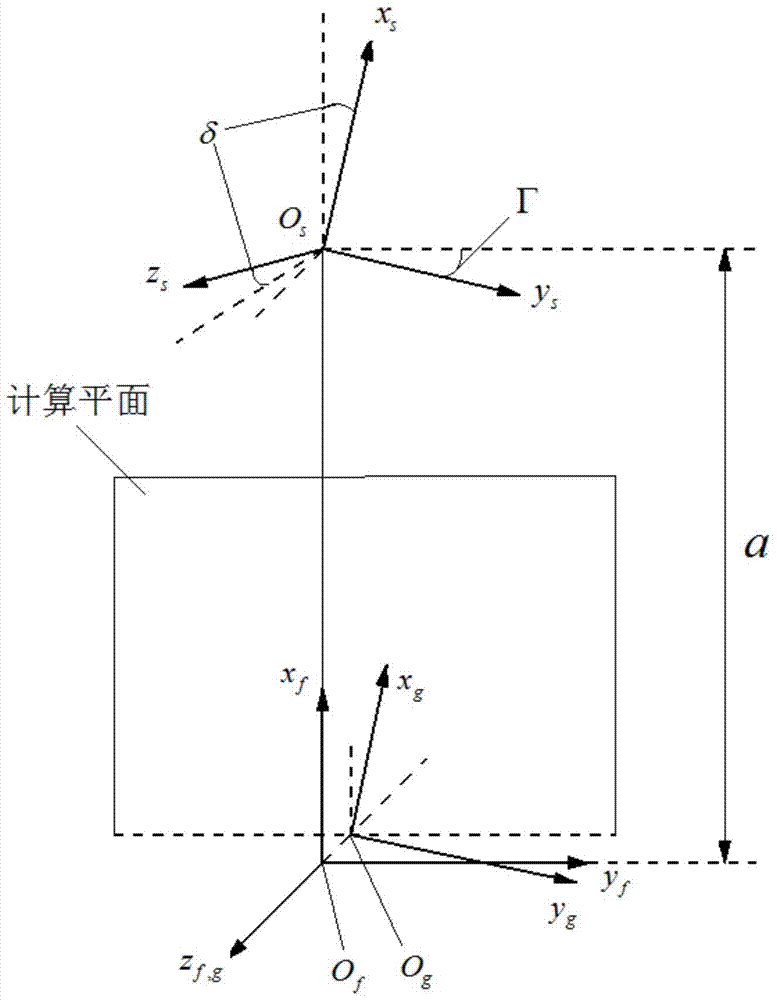

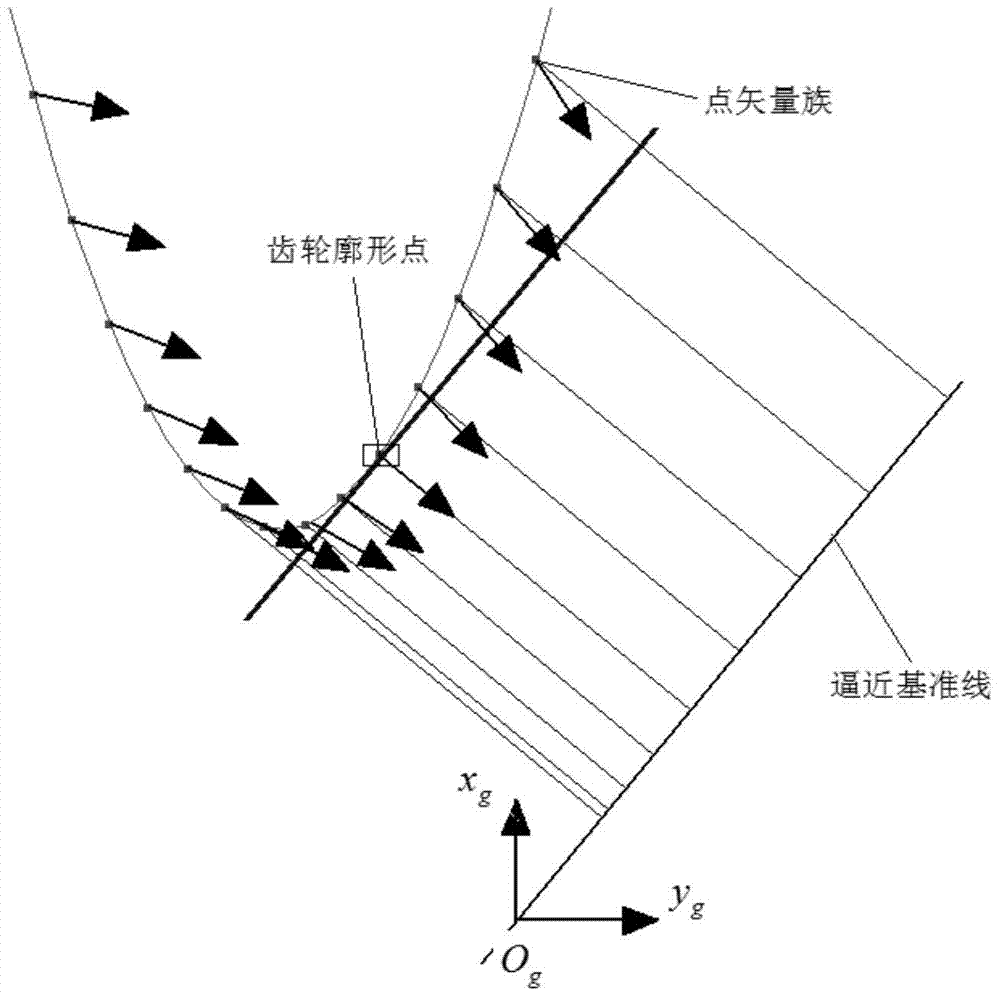

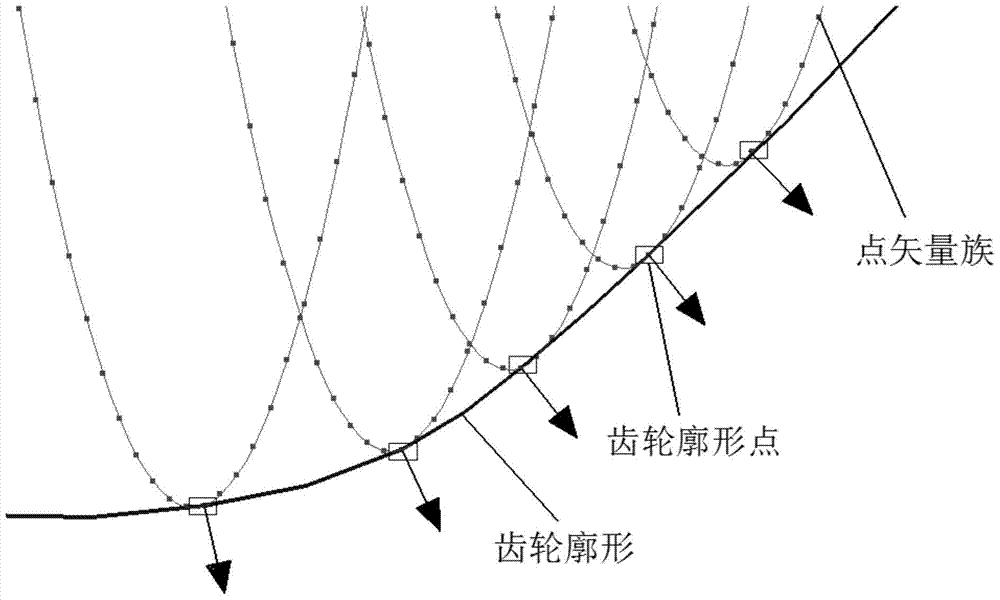

The present invention discloses a point vector envelope method for determining a processed spiral surface contour by a forming cutter, belonging to the field of spiral surface manufacture. Firstly, the point discrete of a forming cutter contour bus is carried out according to an average criterion, a point vector formed by a discrete point and the normal vector of the discrete point is used to completely describe a space discrete point. The gyratory motion trajectory of the contour bus point vector is subjected to discrete, and the process of enveloping the spiral surface by the forming cutter is completely simulated with the envelop movement of the point vector. The method of point vector approximating the spiral surface is used, a plane point vector envelop rule and an envelope approximation method are established, a point with a shortest orientation-distance to the spiral surface in a point vector family is determined as an envelope point, and finally the spiral surface contour is formed by all envelope points by fitting.

Owner:CHONGQING UNIV

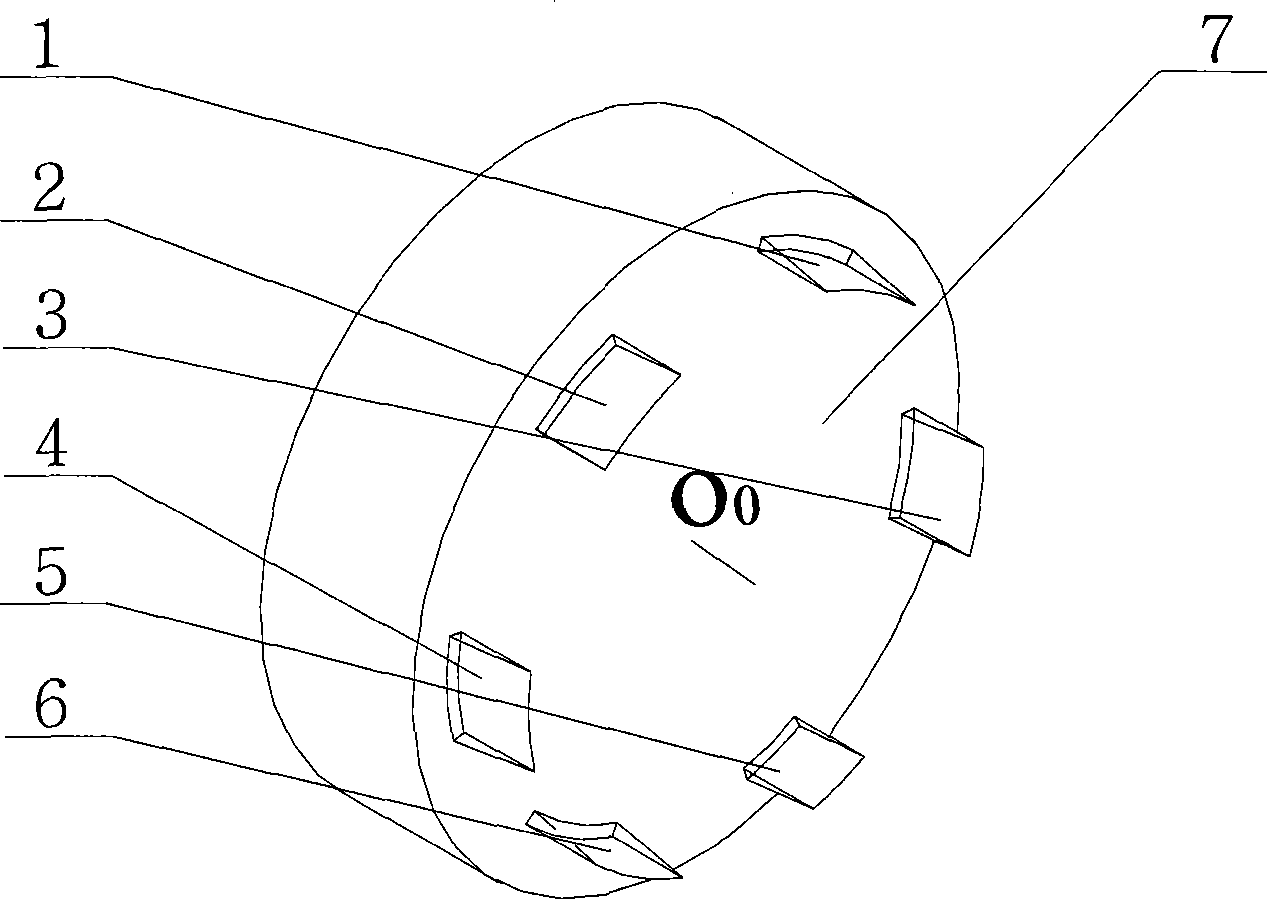

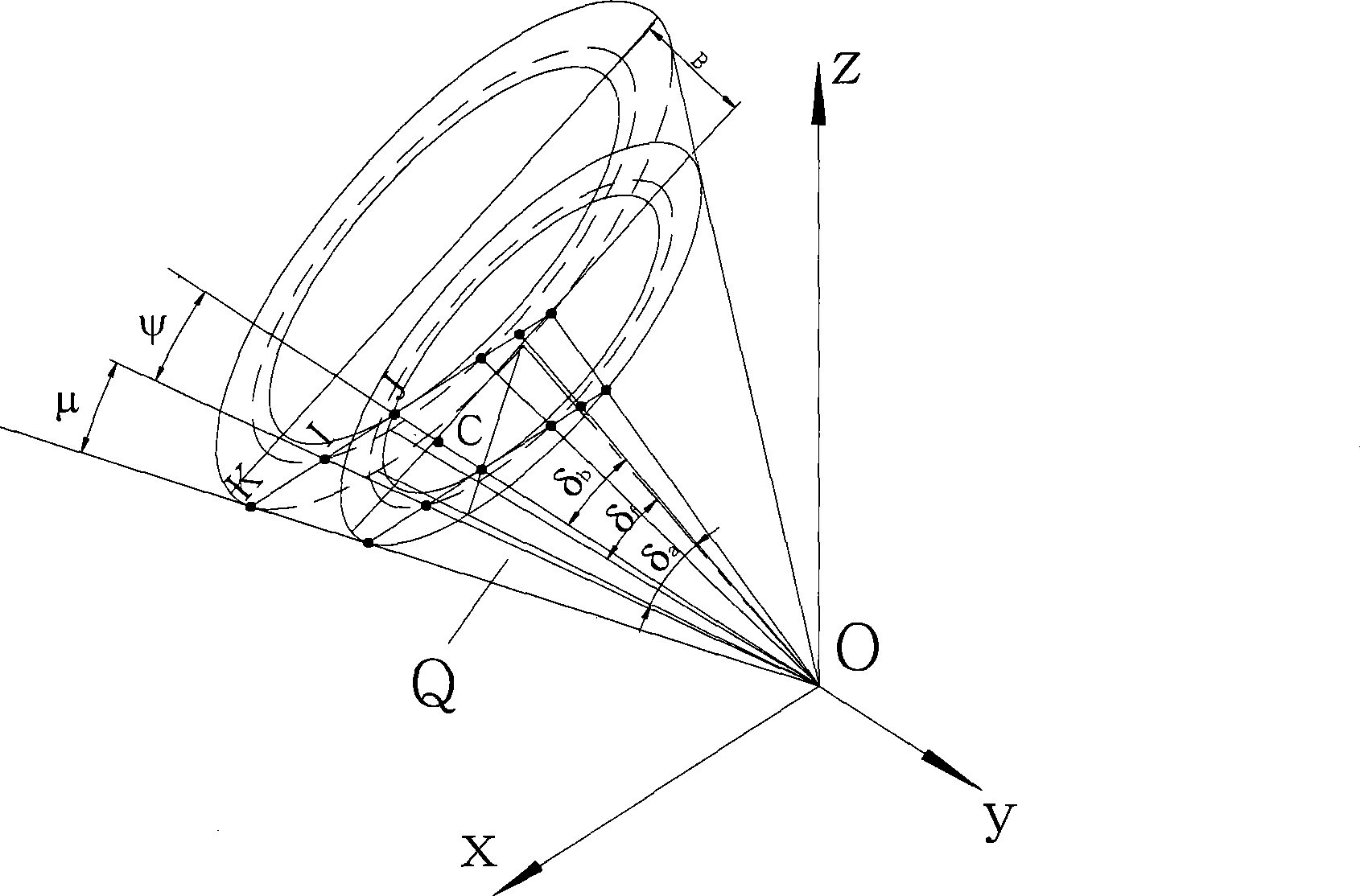

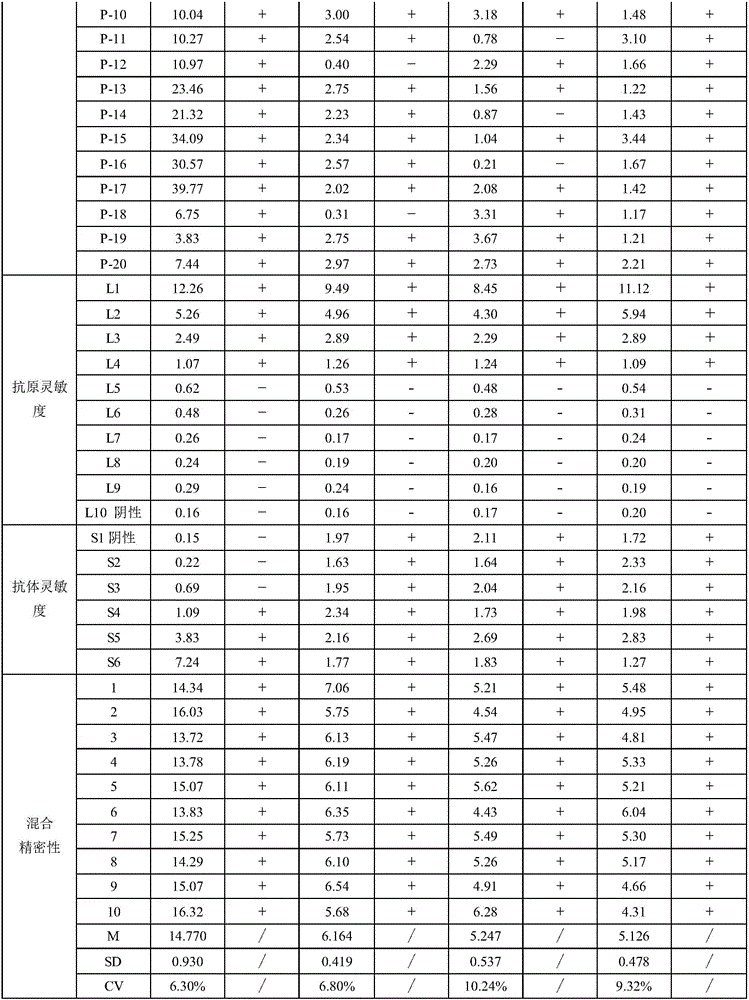

Spherical involute spiral bevel gear cutting method and machine tool

InactiveCN101391322ASimple structureSuitable for the use of numerical control technologyGear teeth manufacturing toolsGear-cutting machinesNumerical controlCircular cone

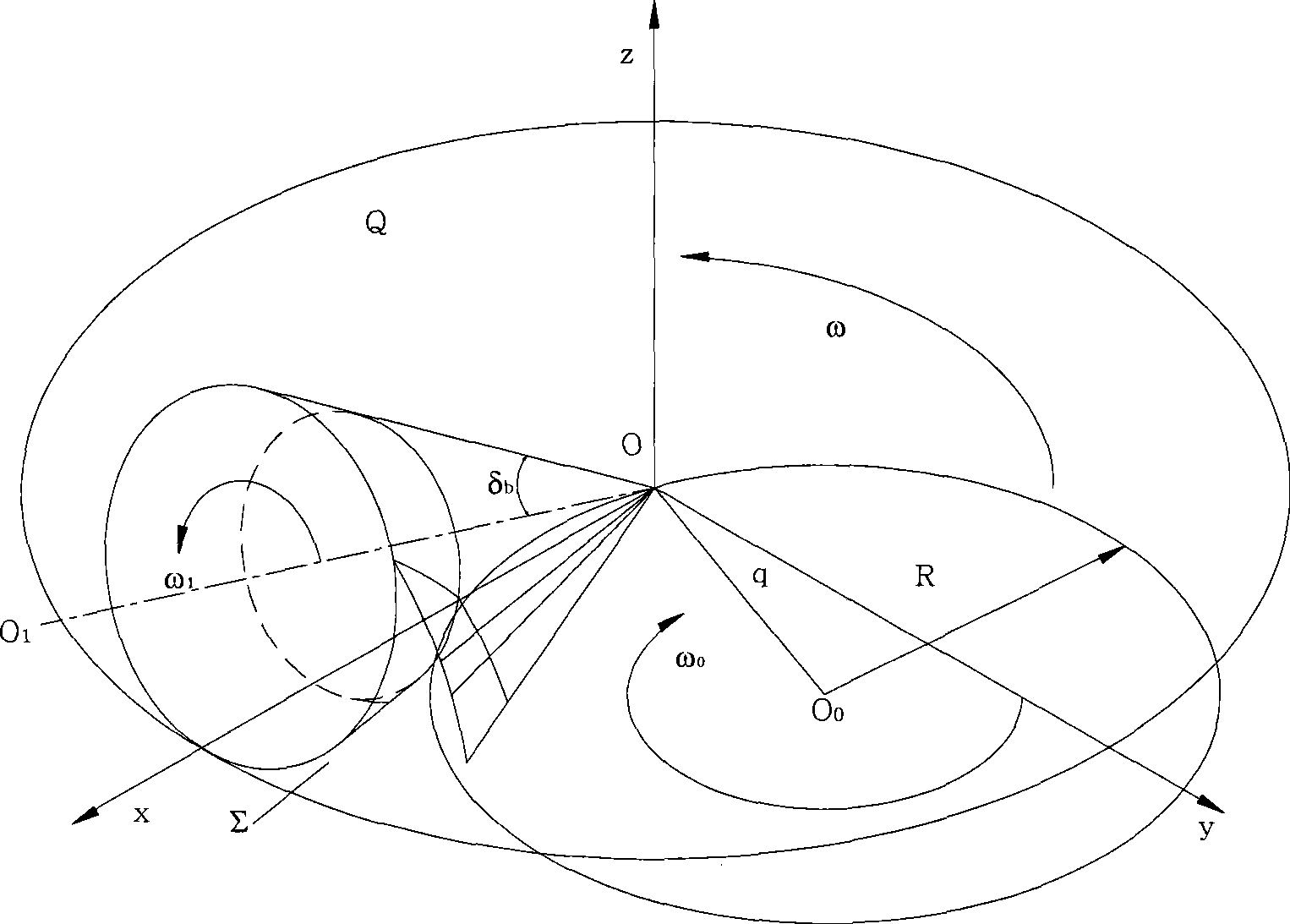

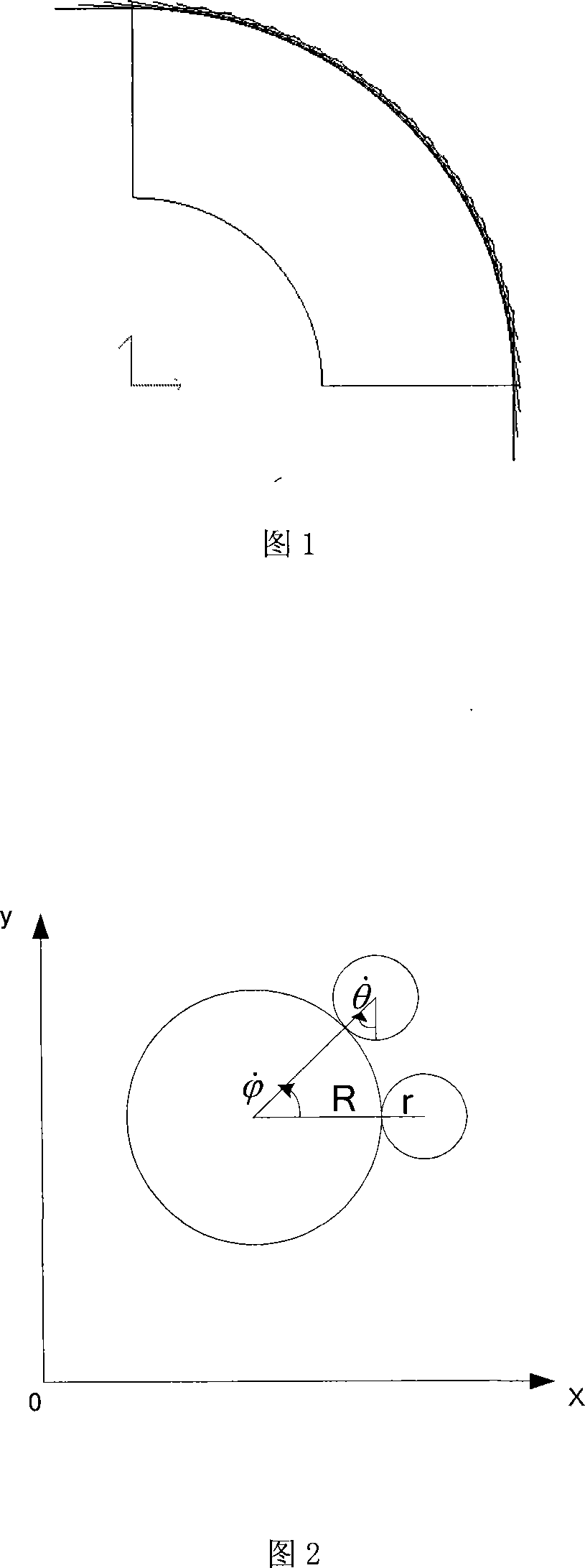

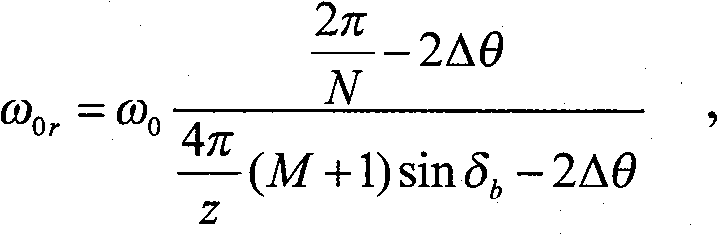

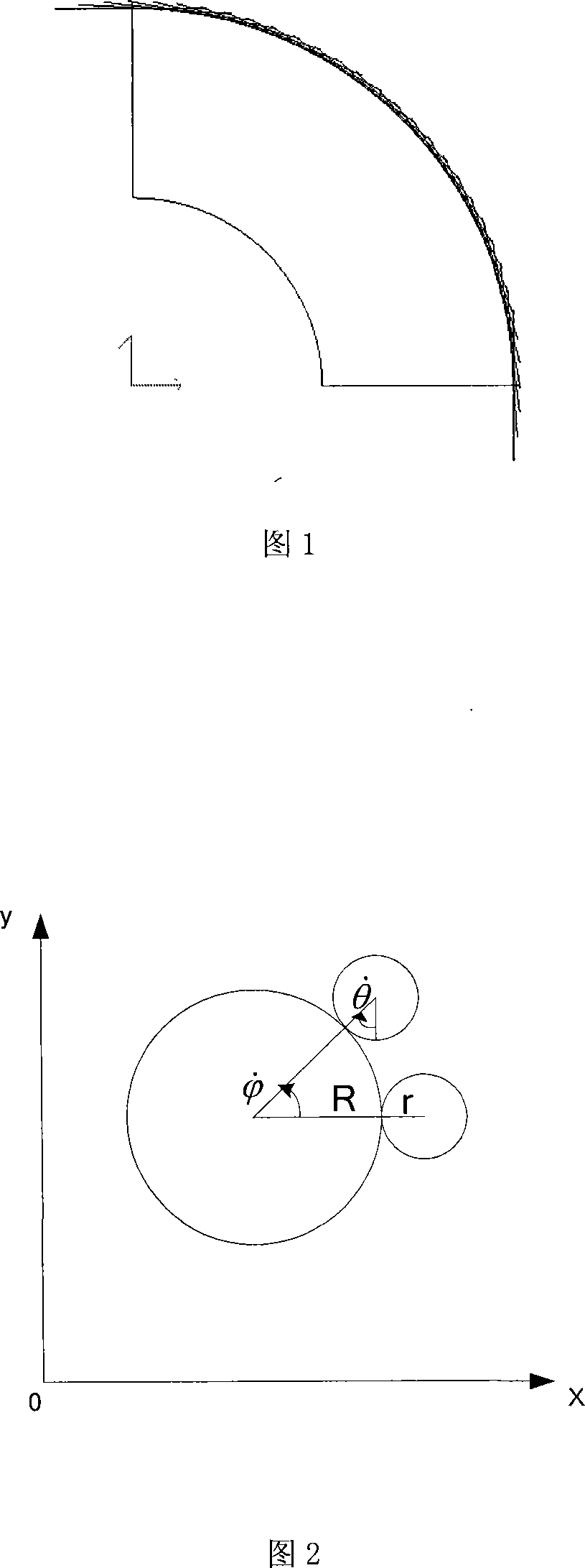

The invention discloses a cutting method for a bevel gear with spherical involute toothed circular arc teeth and a machine tool thereof. The cutting method comprises a circular arc cutter edge conjugation generating method and an envelope method. A cutter shaft and a gear blank shaft for implementing the circular arc cutter edge conjugation generating method rotate directionally with rotating rates (Omega0) and (Omega1), a cutter edge enters into cutting, a cage chair rotates according to that Omega is equal to Omega1sinaDeltab, the formation of pure rolling of a gear blank base cone and the big circular plane of the spherical surface is guaranteed to complete the processing of spherical involute toothed flank. The cage chair with a real axis is driven to rotate by a servo motor, and for the cage chair without a real axis, the synthesis movement of the y and z directions of a coordinate system forms a cage chair to rotate with the rotating rate (Omega). When the envelope method is implemented, cutter teeth of short arc and even point cutter edge are adopted. Points with the number of k are taken on the circular arc line AC of generating the flank, each cutting can form a spiral line on the flank, the circular arc cutting feed angle Delta Theta of a gear cutter head per cutting is set, and the flank which is composed of spiral lines with the number of k is enveloped and generated by sequentially k-times cutting feed. A third shaft and a forth shaft link a numerical control gear cutting machine to implement the gear cutting method.

Owner:JILIN UNIV

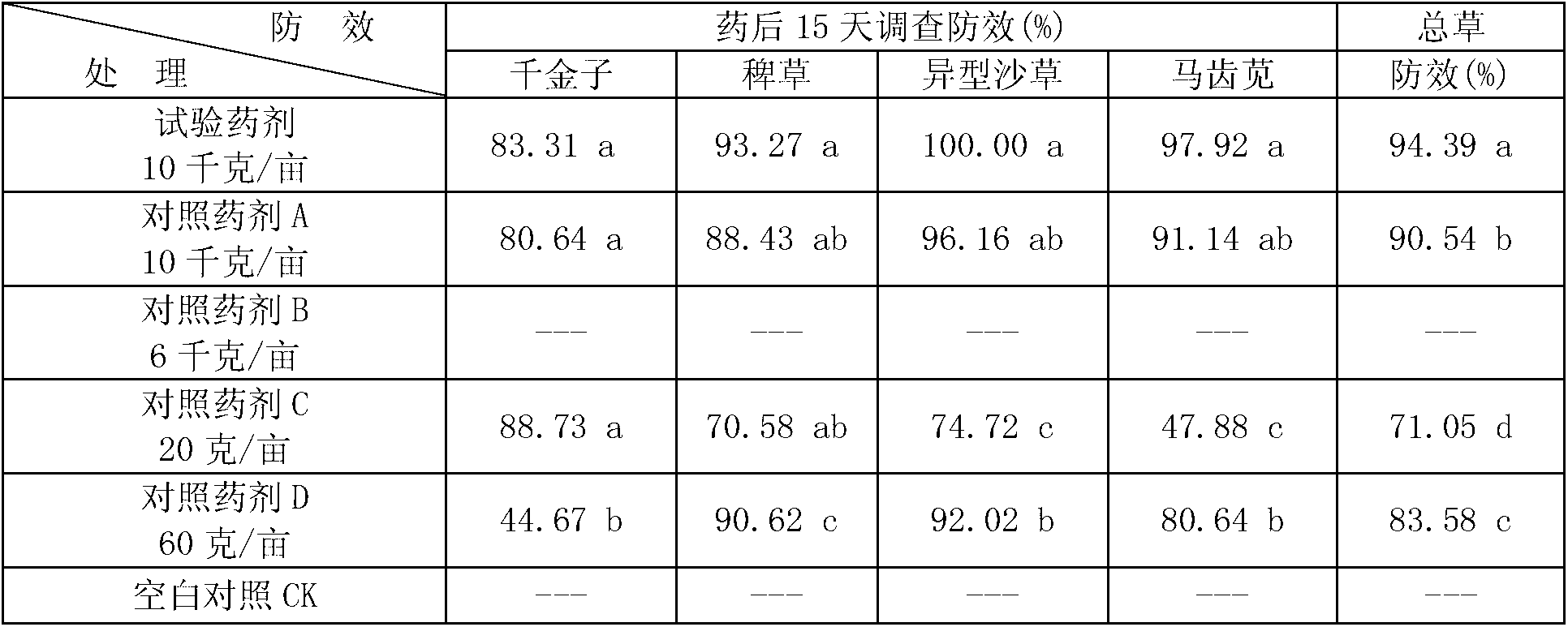

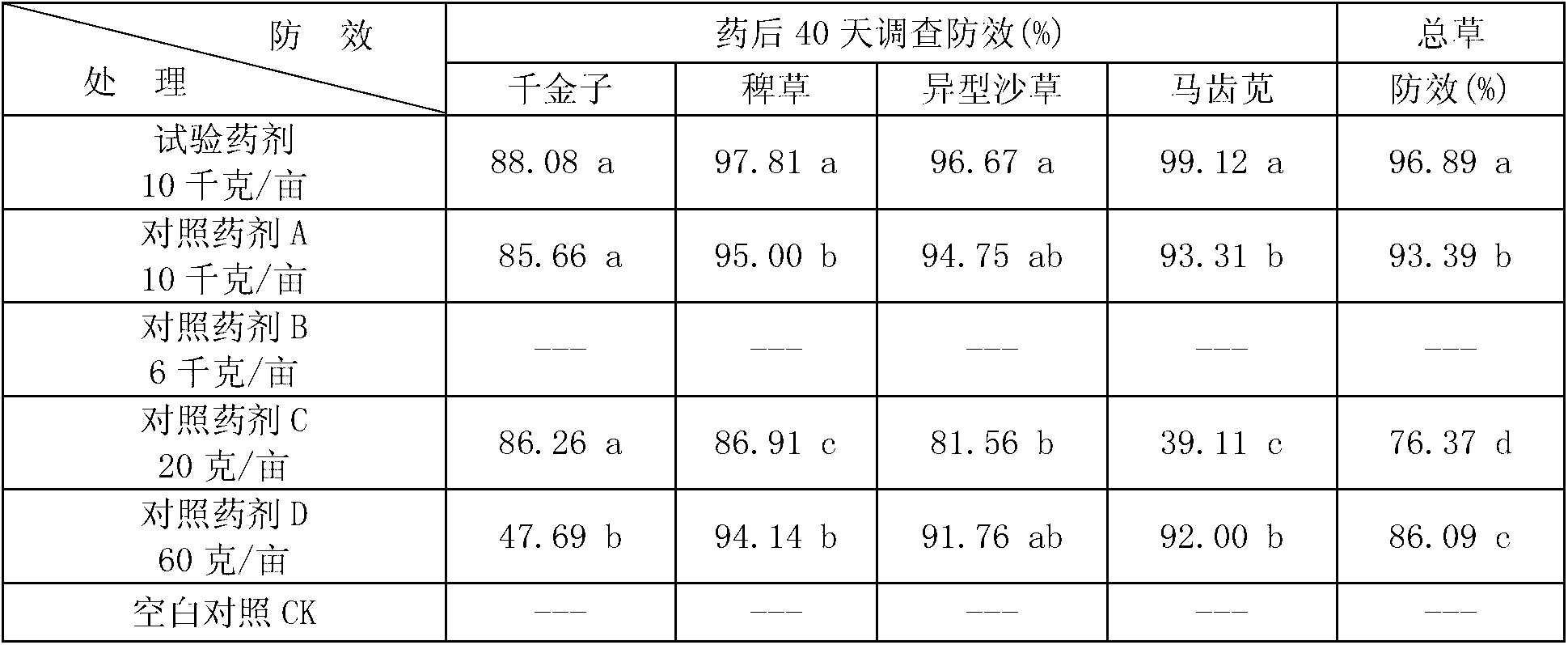

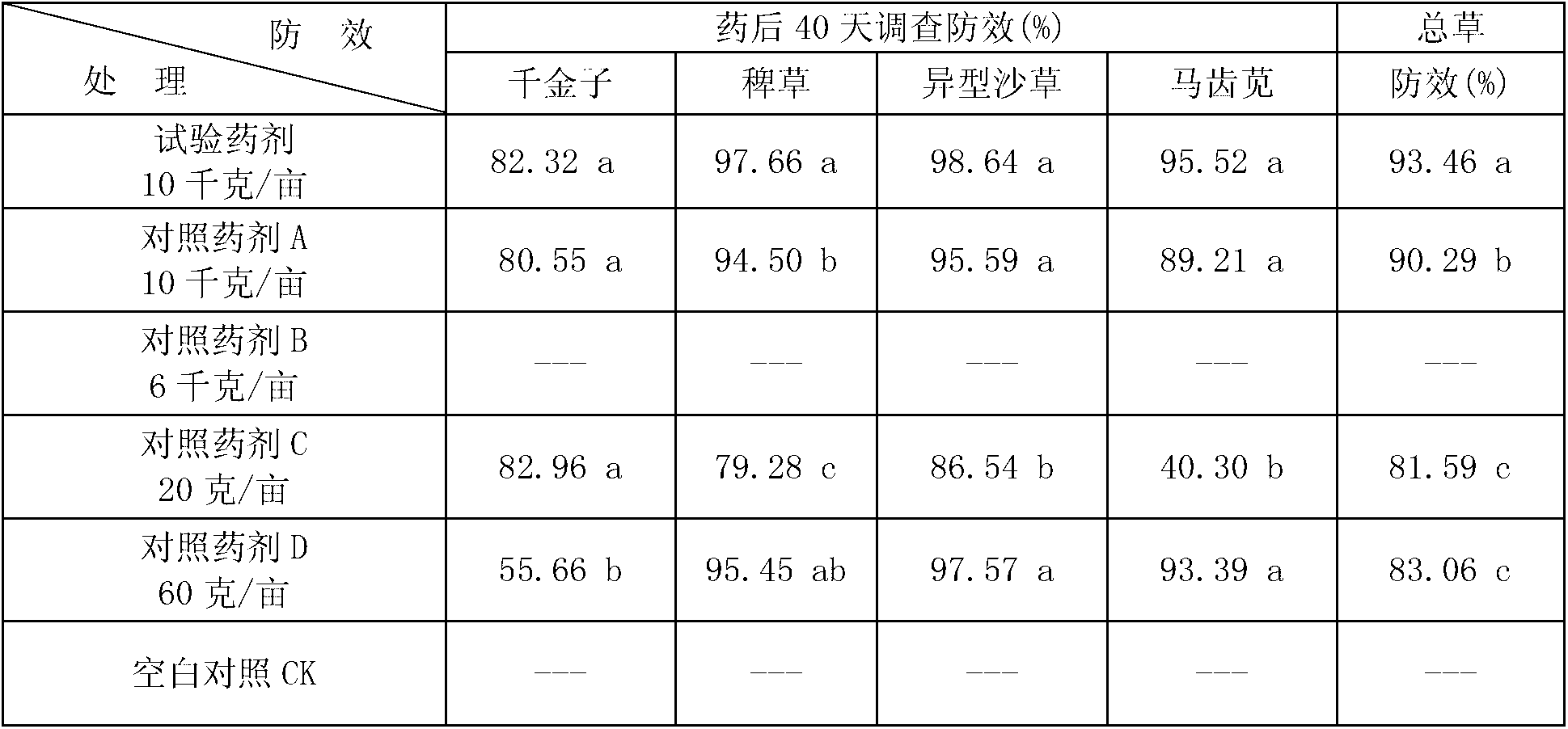

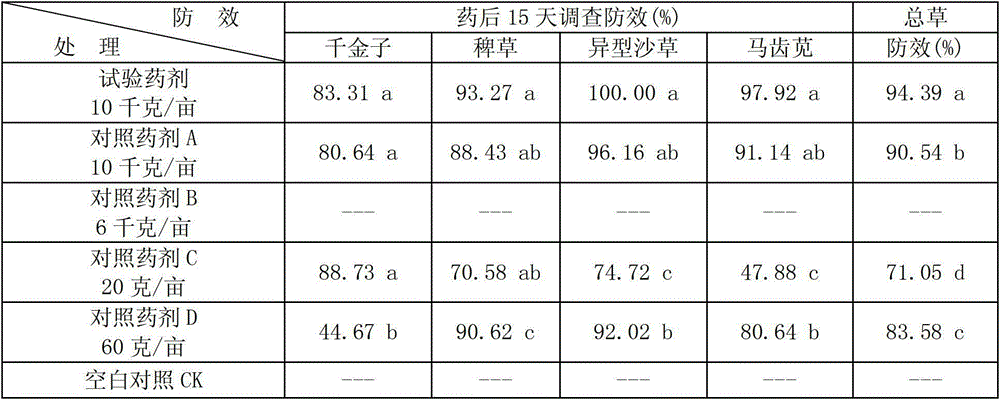

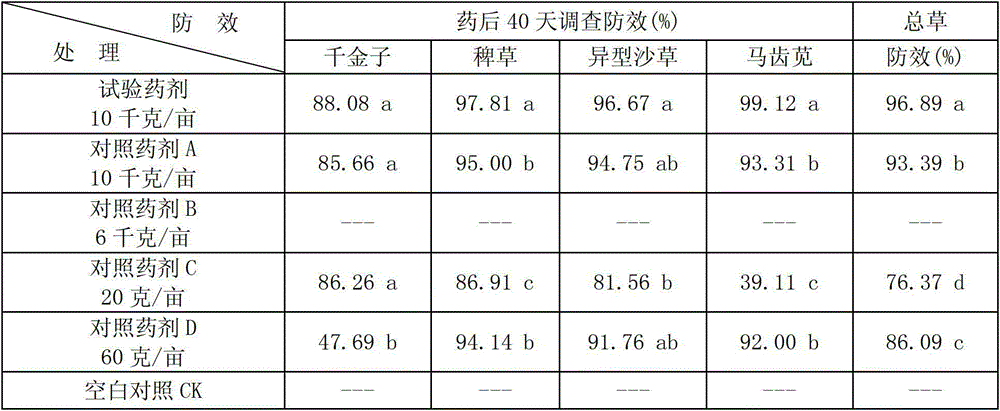

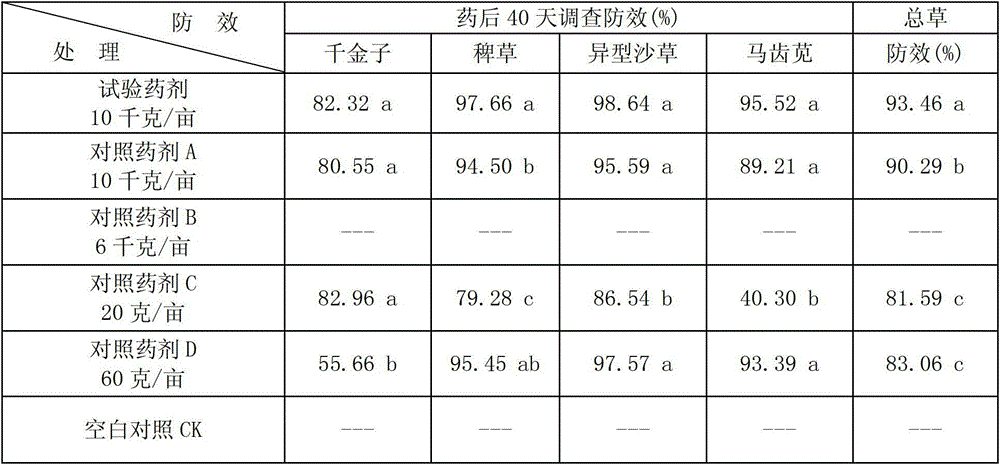

Pyrazosulfuron-mefenacet-containing weeding and insecticidal fertilizer and producing method thereof

The invention discloses a pyrazosulfuron-mefenacet-containing weeding and insecticidal fertilizer which is prepared by compounding herbicides, namely pyrazosulfuron and mefenacet, an insecticide and a carrier fertilizer, wherein the weight ratio of pyrazosulfuron to mefenacet is 1:(20-30). The invention further discloses a producing method of the fertilizer, which comprises the steps of taking water as a solvent and preparing a fertilizer granule by a spraying envelope method. The process flow is short, the quality is stable, the environmental pollution is low, the pesticide effect of the fertilizer is significant, and when the obtained fertilizer granule is applied in a paddy field, the fertilizer has multiple effects of fertilizing, weeding and pest killing, and can achieve the purposes of labor and time saving.

Owner:广西乐土生物科技有限公司

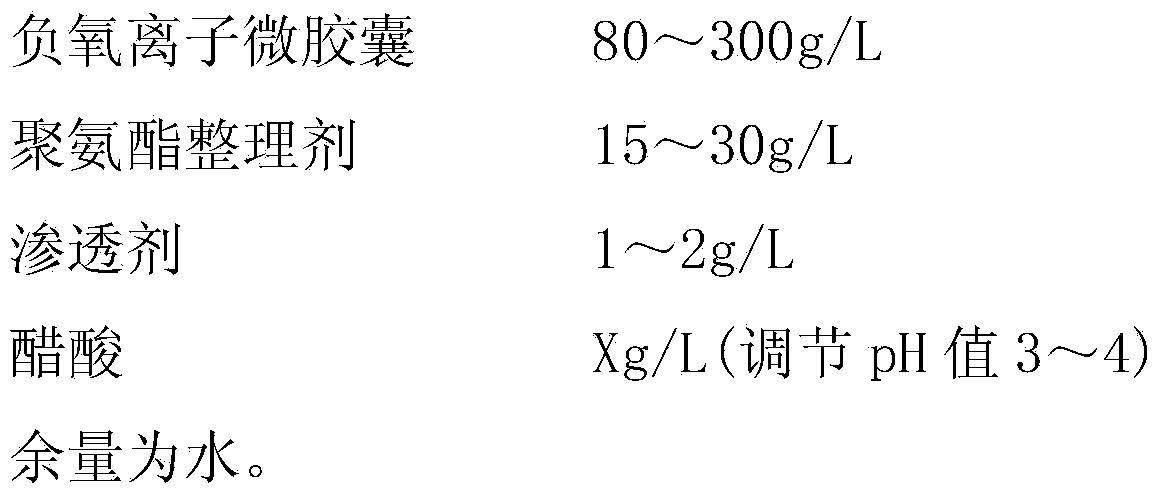

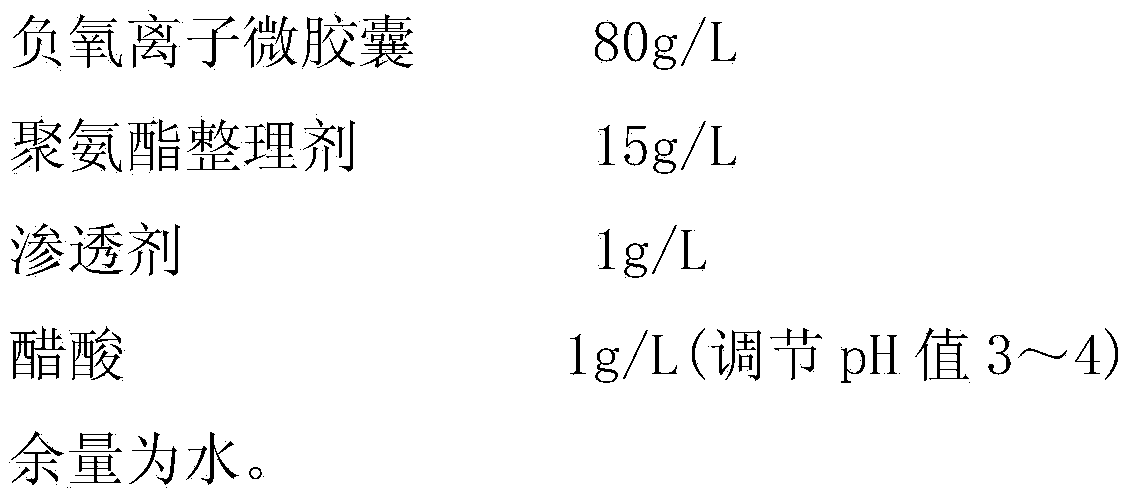

Preparing and applying method for negative oxygen ion microcapsules for fabric

InactiveCN104138734AOvercoming single applicationOvercome water resistanceFibre treatmentMicroballoon preparationFiberAlcohol

The invention relates to a preparing and applying method for negative oxygen ion microcapsules for fabric. The preparing method comprises the steps of core material preparing, wall material selecting and solution preparing. The preparing method specifically comprises the steps that firstly, raw materials of negative oxygen ions are ground by a grinding miller, the ground raw materials are placed in a certain amount of distilled water and stirred for 0.5-1 hour by an agitator, and a nanometer grinding rod type grinding machine is used for carrying out grinding; secondly, a physical envelope method is adopted, a wall material is prepared into a solution with a certain concentration, a negative oxygen ion nanometer core material, the distilled water and absolute ethyl alcohol are added into the solution according to the proportion, and the mixed solution is stirred under the conditions that the rotating speed is 1080 rmp and the temperature ranges from 40 DEG C to 60 DEG C for 1-3 hours and then is cooled for standing. The negative oxygen ion microcapsules are applied to cotton, fiber, real silk and other fabric. According to the method, the negative oxygen ions with a certain concentration can be released, good packaging and separating performance and slow releasing performance of the microcapsules are utilized to achieve the effects of protecting the core material and lasting releasing, and the detects that traditional negative oxygen ion materials are single in application and not washable overcome.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

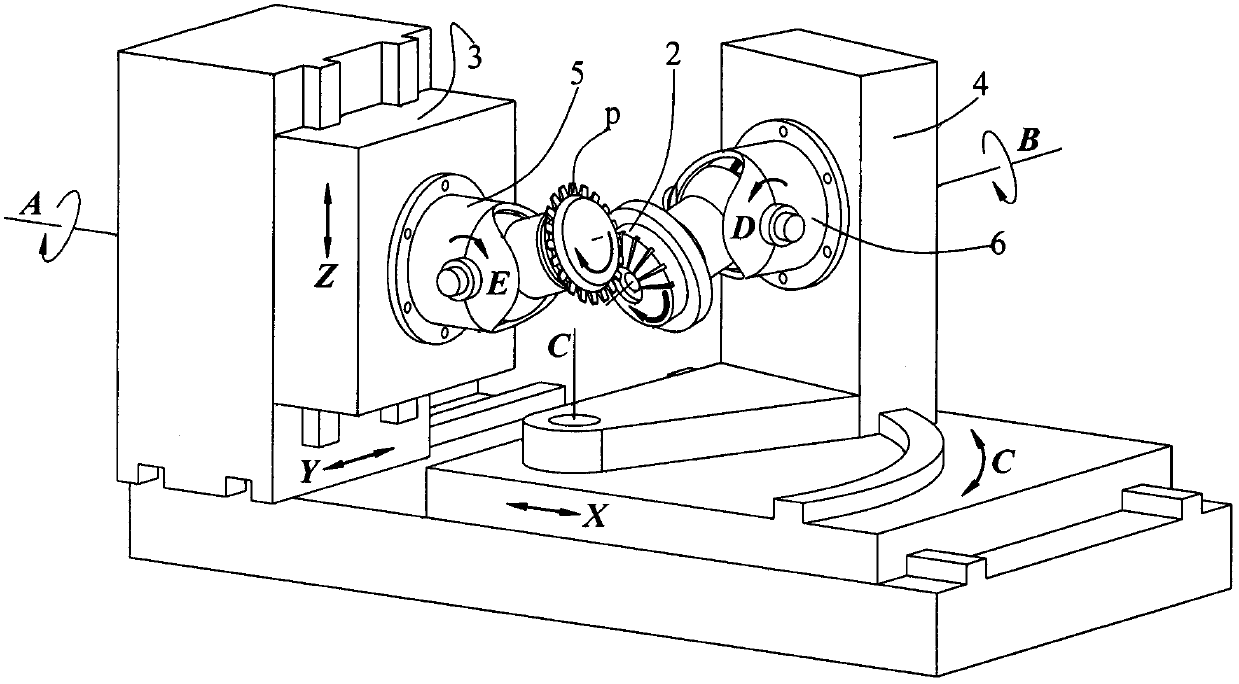

Point vector envelope method for determining tool profile in spiral curved surface forming processing

ActiveCN104898557AEasy and fast profile envelope calculationDegougeNumerical controlVector approximationShortest distance

The present invention discloses a point vector envelope method for determining tool profile in spiral curved surface forming processing, belonging to the manufacturing field of a spiral curved surface. Firstly, the mold line of a spiral curved surface is subjected to point discrete according to an average rule, a point vector formed by a discrete point and the normal vector of the discrete point is used completely describe a spiral discrete point, the spiral movement track of the mold line point vector is subjected to discrete, and the process of spiral curved surface envelope forming wheel is completely simulated with the envelope movement of the point vector. By using the method point vector approximation forming tool, a plane point vector envelope principle and an envelope approximation method are established, a point in a point vector family with a shortest distance to a forming tool is determined as the envelope point, and finally all envelope points are used to form a tool profile through the mode of fitting.

Owner:CHONGQING UNIV

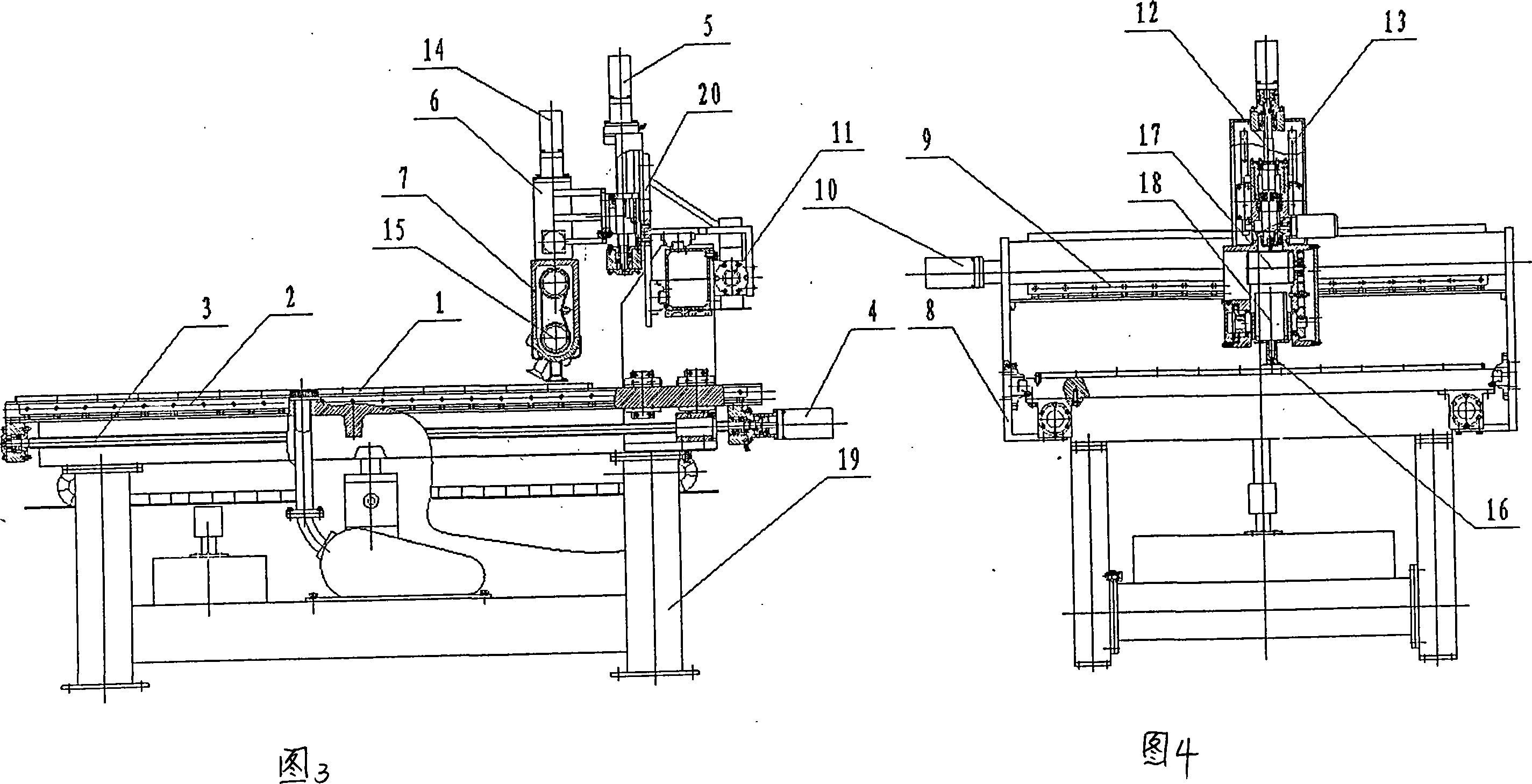

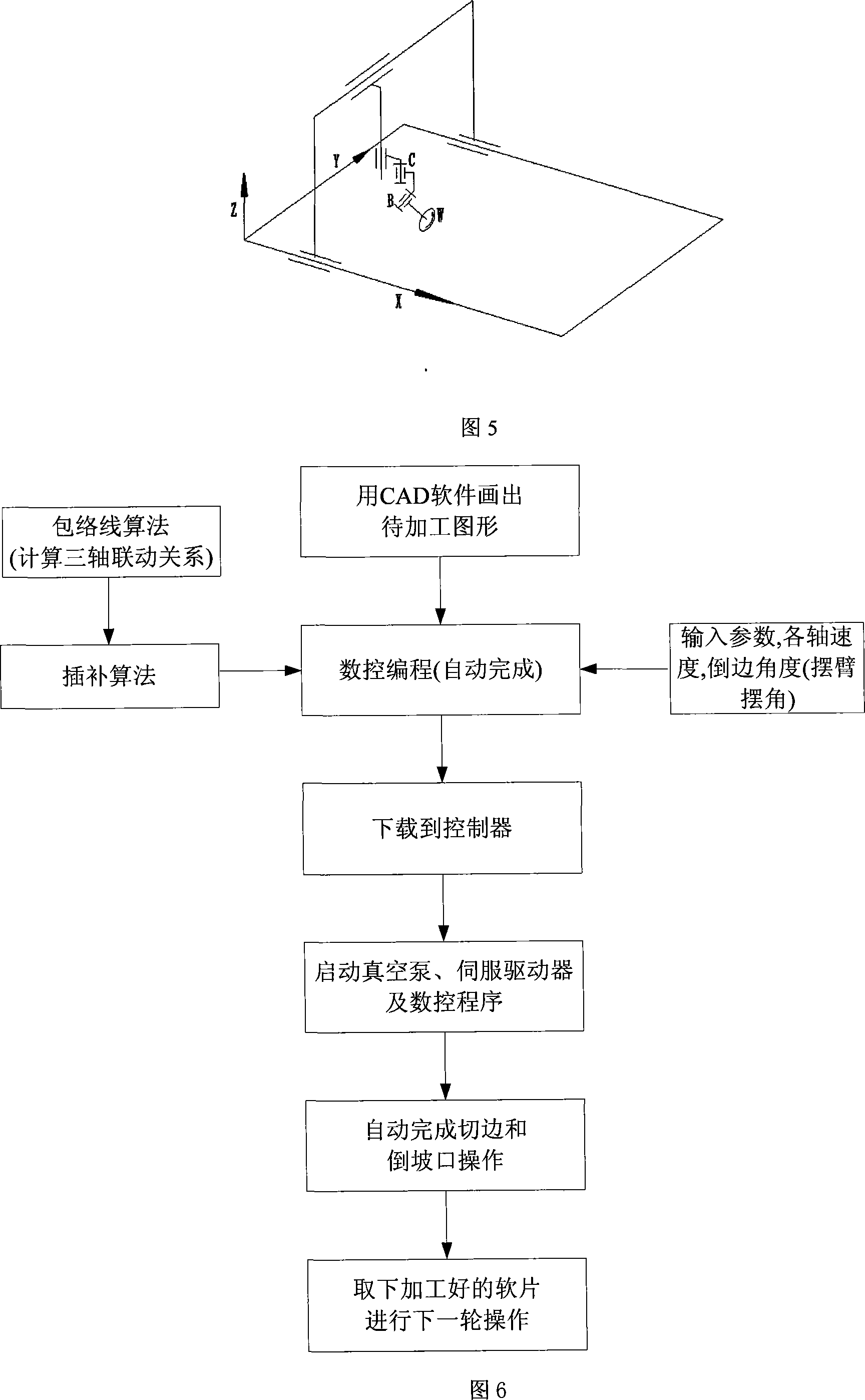

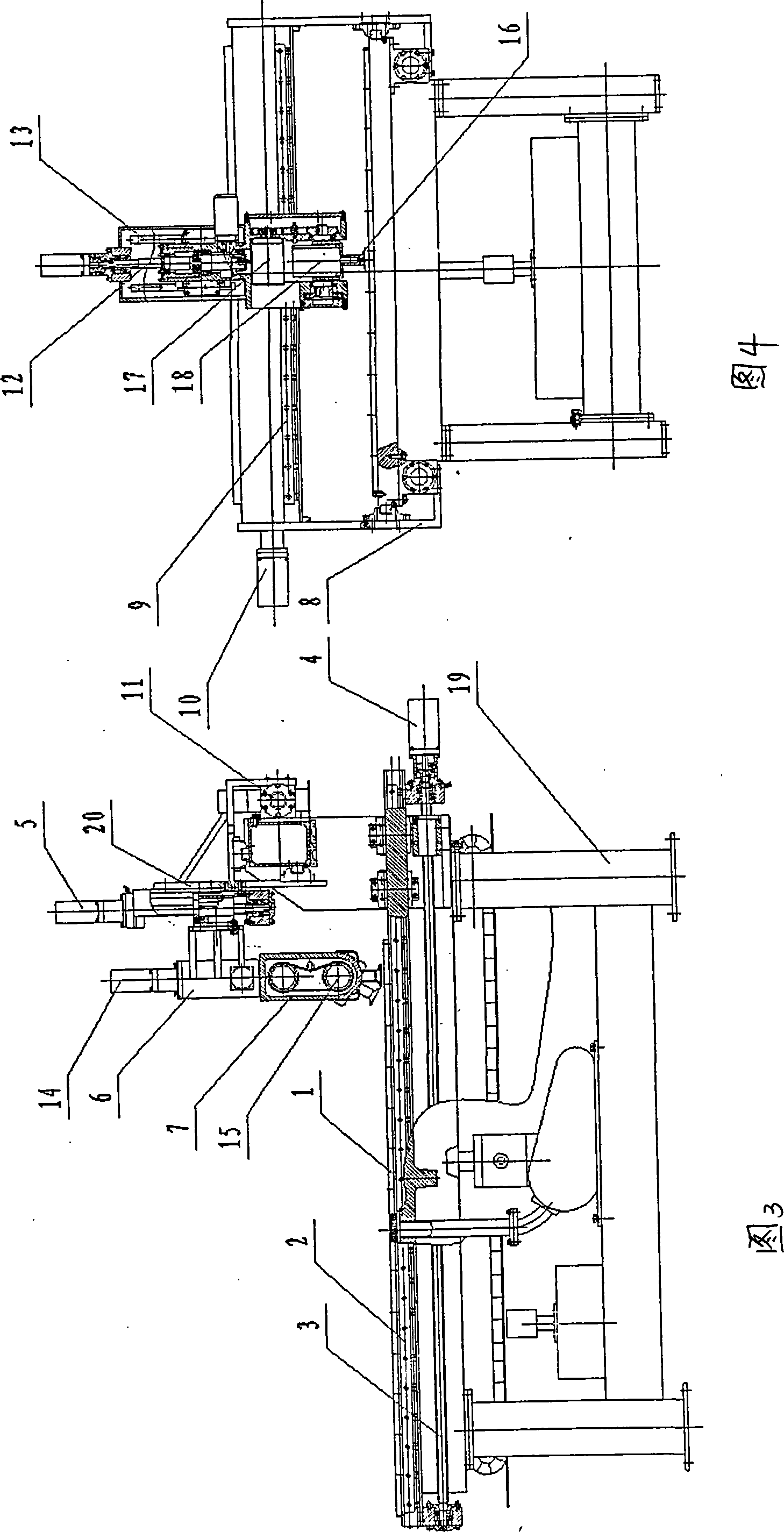

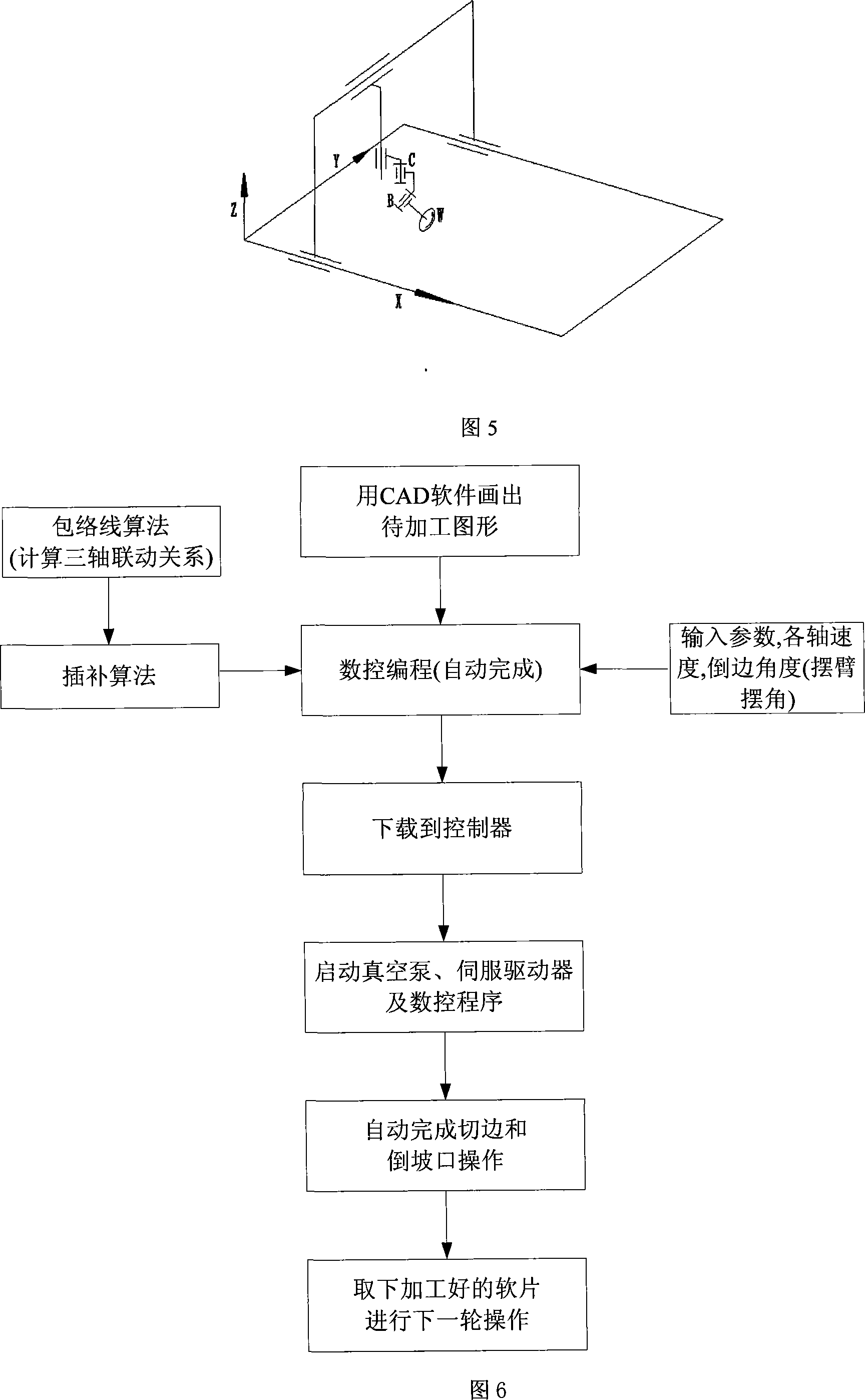

Equipment and method of envelope method processing film slitting chamfering

InactiveCN101229595AThe bevel angle can be adjusted arbitrarilyLess materialAutomatic control devicesFeeding apparatusMotor driveGear wheel

The invention relates to an equipment used for processing inverted beveled edges of flexible sheet and cut pieces by an envelope method and a method thereof, which comprises a body, a vacuum chuck, a large arm, a small arm, a lifting arm, a cutter head and a drive control device, wherein, the vacuum chuck is arranged on a vacuum chamber on the body; the large arm is arranged on the body through guide tracks at the two sides of the body; the small arm is arranged on the large arm; the lifting arm is vertically arranged on the small arm; transmissions are realized by a ball guide screw or a cog belt or a pinion and rack between the large arm and the body, the small arm and the large arm and the lifting arm and the small arm and a straight feed motion is realized by the guide track between the large arm and the body, the small arm and the large arm and the lifting arm and the small arm; a circular cutter holder is arranged on the lifting arm and a swing arm is arranged on the circular cutter holder; a spindle motor is arranged on the swing arm and the cutter head is arranged on a spindle head of the spindle motor. In the method, a disc shape cutter is used and the diameter of the disc shape cutter is smaller than the minimum curvature radius of pieces to be processed; in the process, the spindle motor drives the disc shape cutter to rotate continuously and keeps tangency between a cutting blade and a curve edge of the pieces to be processed. The invention can carry out operation of linear and arc converse beveled edges automatically and the angle of the beveled edges can be adjusted optionally, thus saving materials.

Owner:NORTHEASTERN UNIV LIAONING

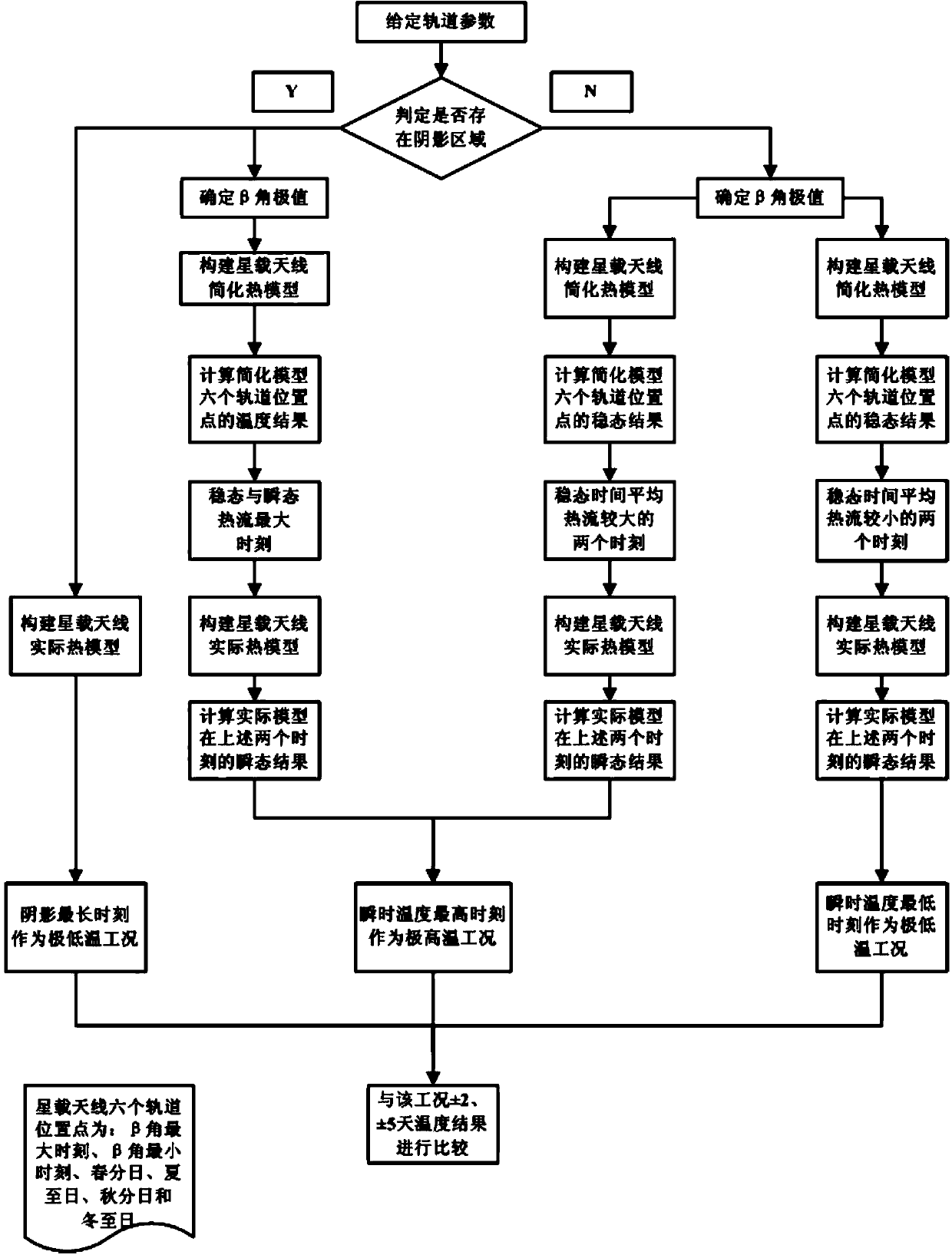

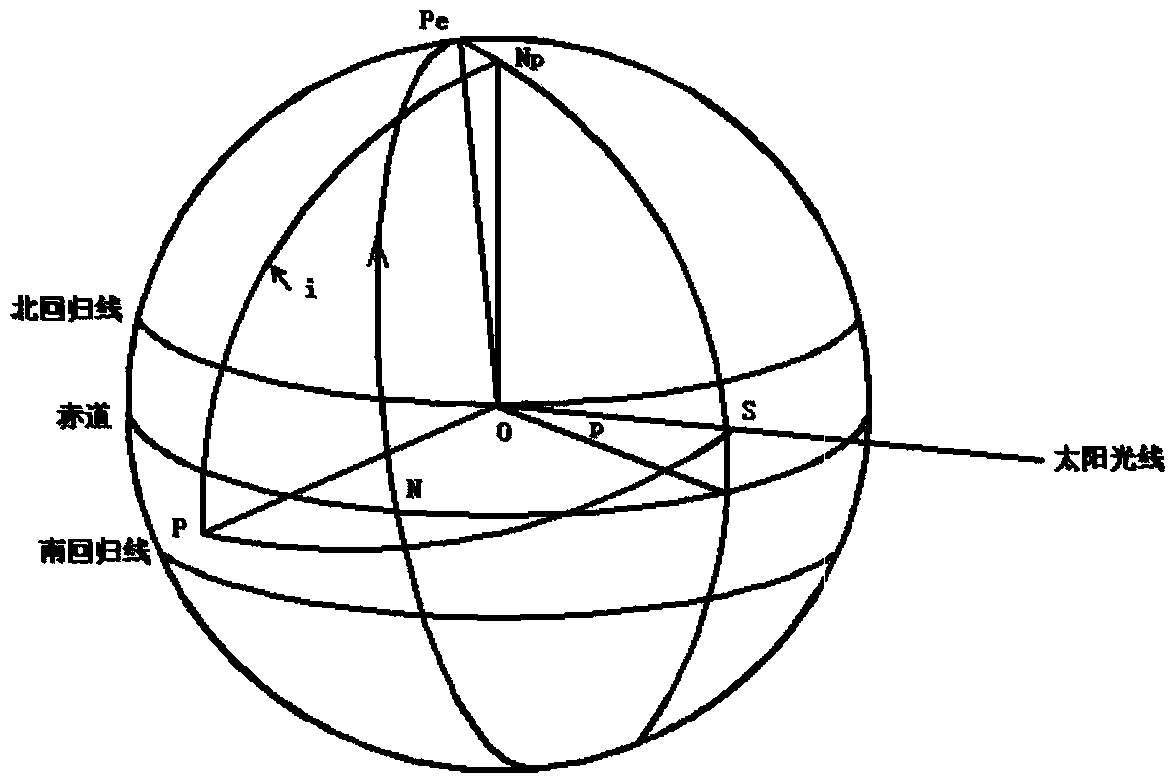

Method for forecasting extreme working conditions of in-orbit temperatures of spaceborne antenna

InactiveCN103778348ATo achieve the purpose of extreme working conditionsSpecial data processing applicationsHeat flowPredictive methods

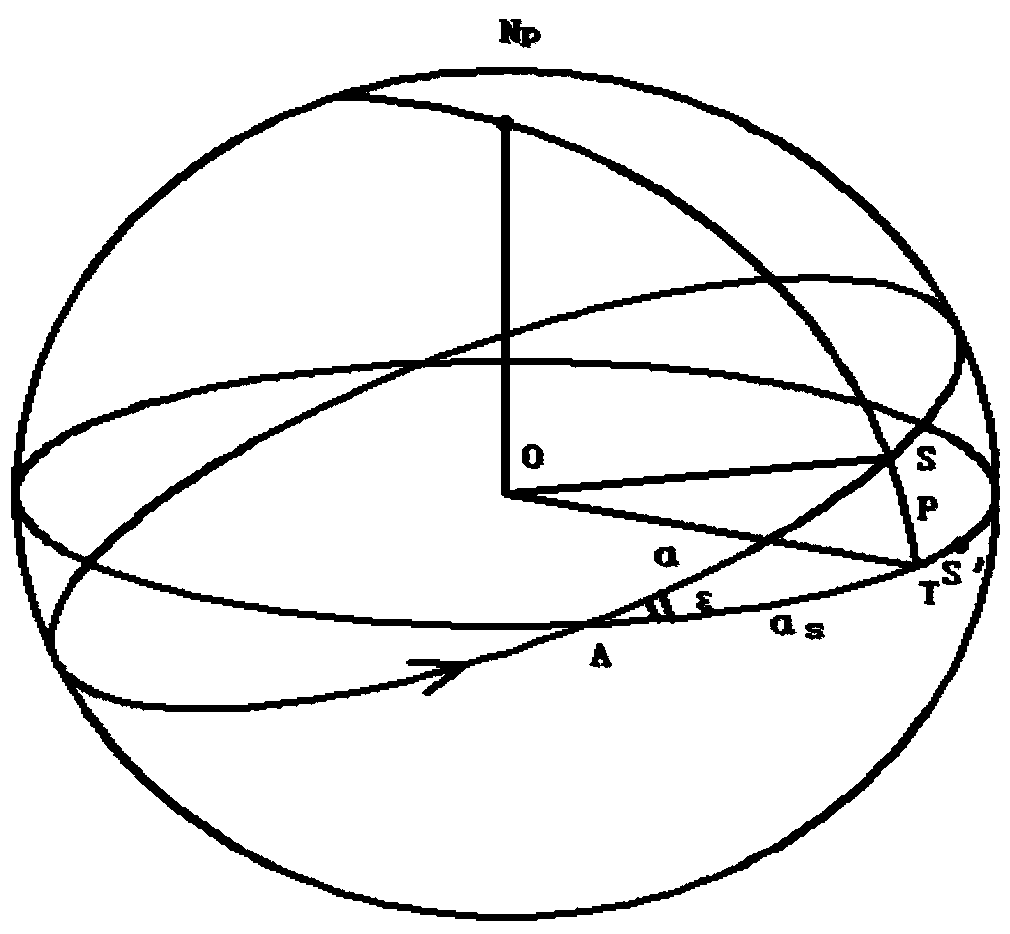

The invention discloses a method for forecasting extreme working conditions of in-orbit temperatures of a spaceborne antenna. The method comprises the steps of (1) calculating the change rule of the incident angles beta of the sun relative to an orbit plane within one year through given orbit parameters, (2) calculating a shined factor through the change rule of the angles beta within the year according to the parameters given in the step (1) and then determining whether a shadow moment exists within one period, (3) forecasting the extreme low-temperature working condition of the spaceborne antenna according to the existence of the shadow moment or not determined in the step (2), (4) forecasting the extreme high-temperature working condition of the spaceborne antenna according to the existence of the shadow moment or not determined in the step (2), (5) comparing each extreme temperature working condition with temperatures of 2 days and 5 days before and after the data of the working condition, and taking the temperature in the temperature working condition TMax as the extreme high-temperature working condition and the temperature in the temperature working condition TMin as the extreme low-temperature working condition. The method targets at the spaceborne antenna, and is capable of determining the shined factor of the orbit within the year by calculating the change rule of the incident angles beta of the sun relative to the orbit plane and then determining the dates of the extreme working conditions of the orbit; as a result, the extreme temperatures of the spaceborne antenna are calculated by loading an extremum heat flow by an envelope method, and then the purpose of forecasting the extreme working conditions of the spaceborne antenna is achieved.

Owner:SPACE STAR TECH CO LTD +1

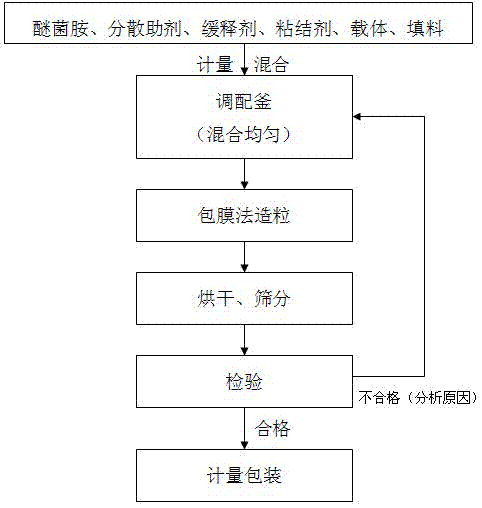

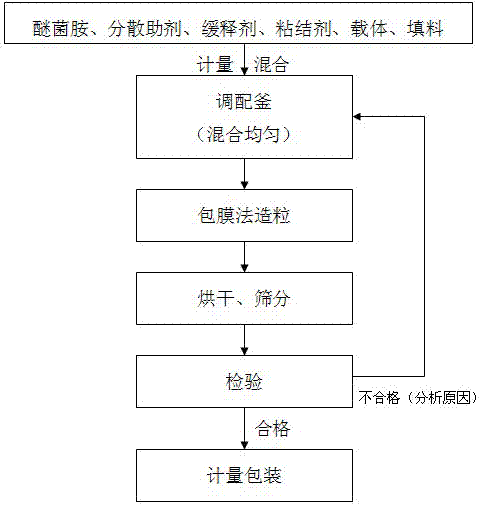

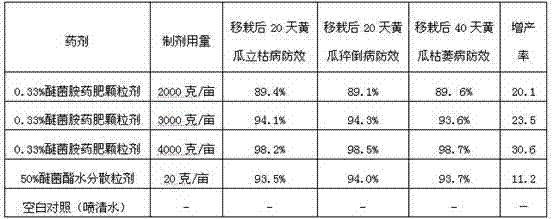

Dimoxystrobin-containing bactericidal insecticide fertilizer granules and preparation method thereof

InactiveCN102649653AFulfil requirementsCause depreciationFertilizer mixturesAdhesiveBULK ACTIVE INGREDIENT

The invention relates to dimoxystrobin-containing bactericidal insecticide fertilizer granules and a preparation method thereof. The bactericidal active ingredient is dimoxystrobin; and in terms of total weight of bactericidal insecticide fertilizer granules, the dimoxystrobin-containing bactericidal insecticide fertilizer granules comprise the following components in percentage by weight: 0.01-10 percent of dimoxystrobin, 30-60 percent of carrier fertilizer, 0.5-3 percent of dispersion auxiliary agent, 0.1-2 percent of slow release agent, 0.1-5 percent of adhesive and the balance of filler. The bactericidal insecticide fertilizer granules are prepared by uniformly mixing the components, granulating by an envelope method, drying and screening. The bactericidal insecticide fertilizer granules are provided by the invention have great significance to effective, scientific and rational utilization of resources and environment protection and has a positive promotion effect on reducing the agricultural investment and agricultural increase in both production and income.

Owner:GUANGDONG ZHONGXUN AGRI TECH

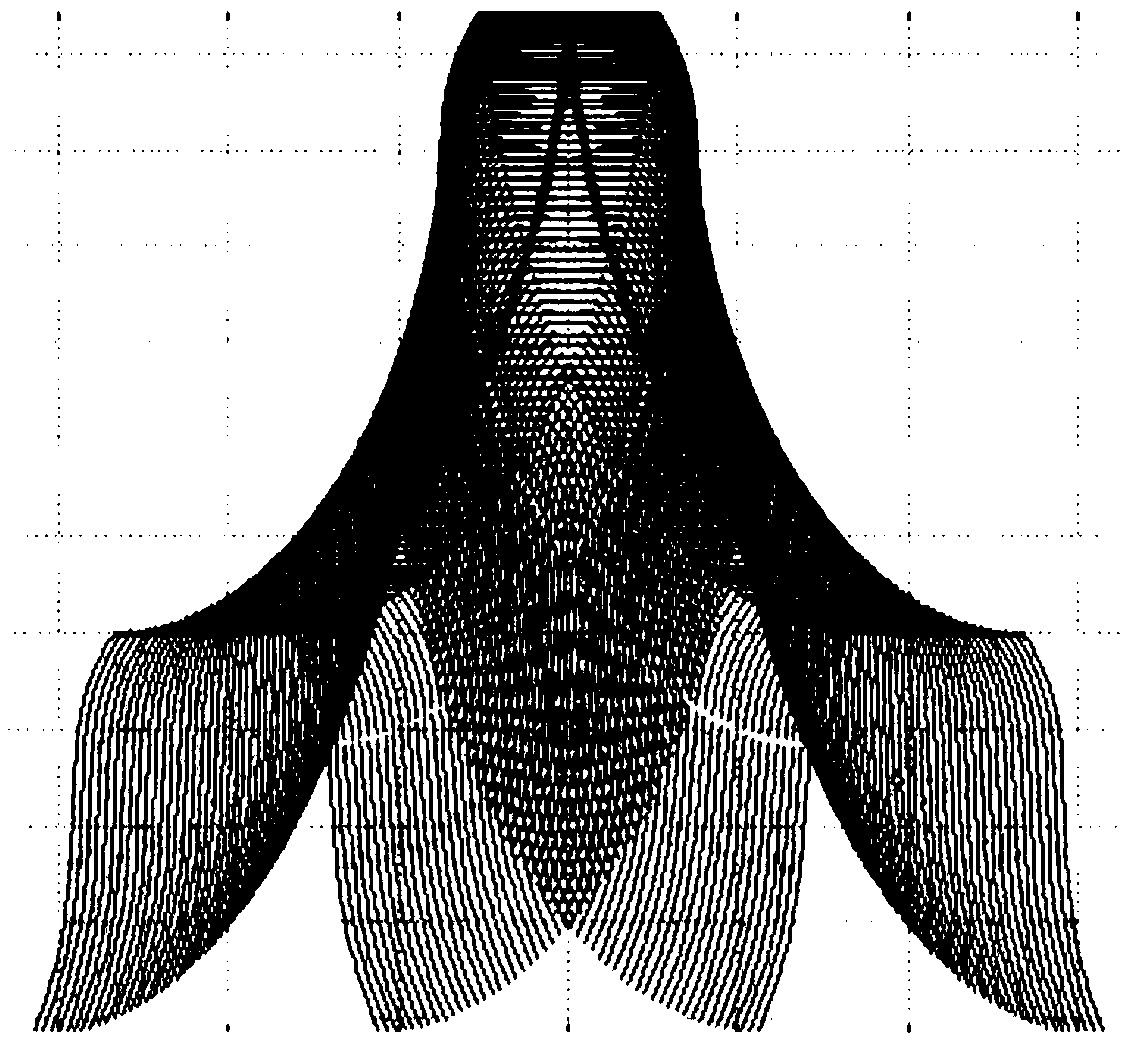

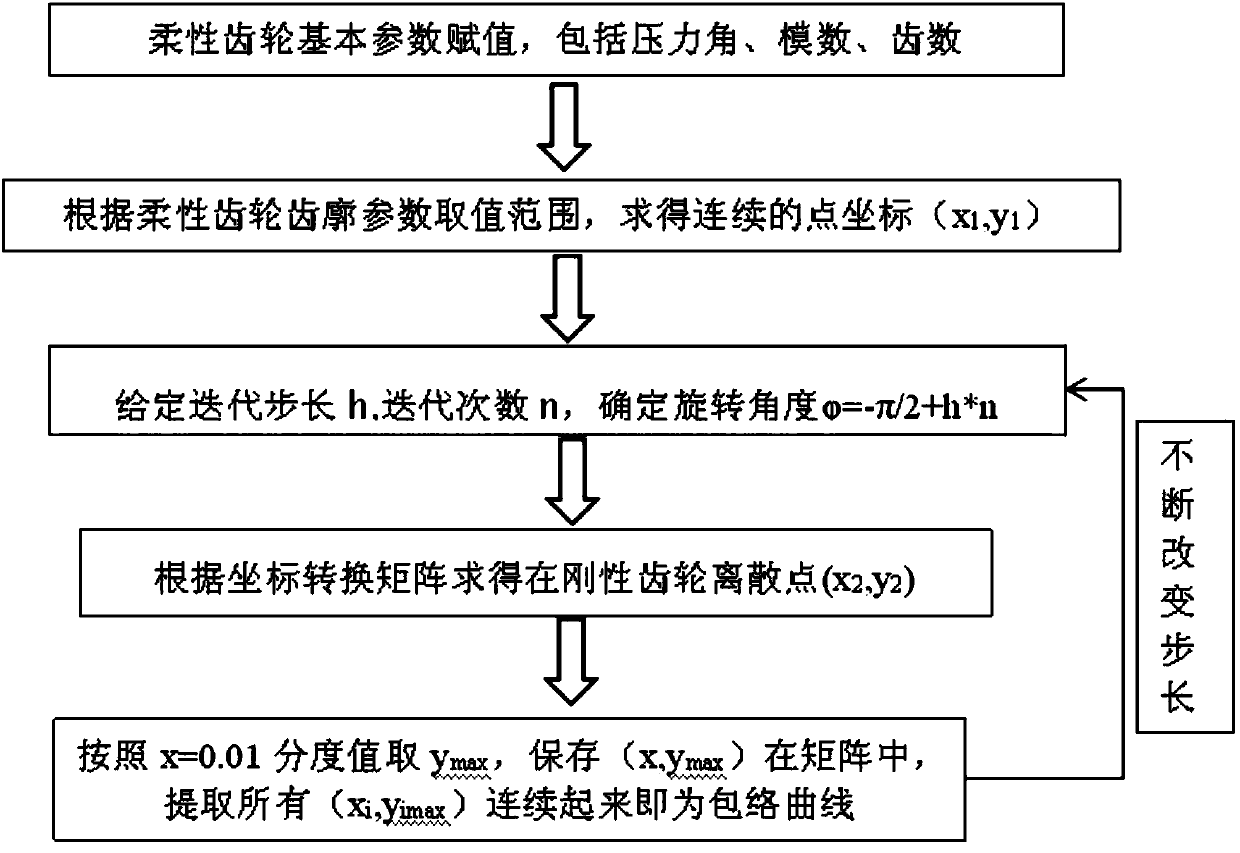

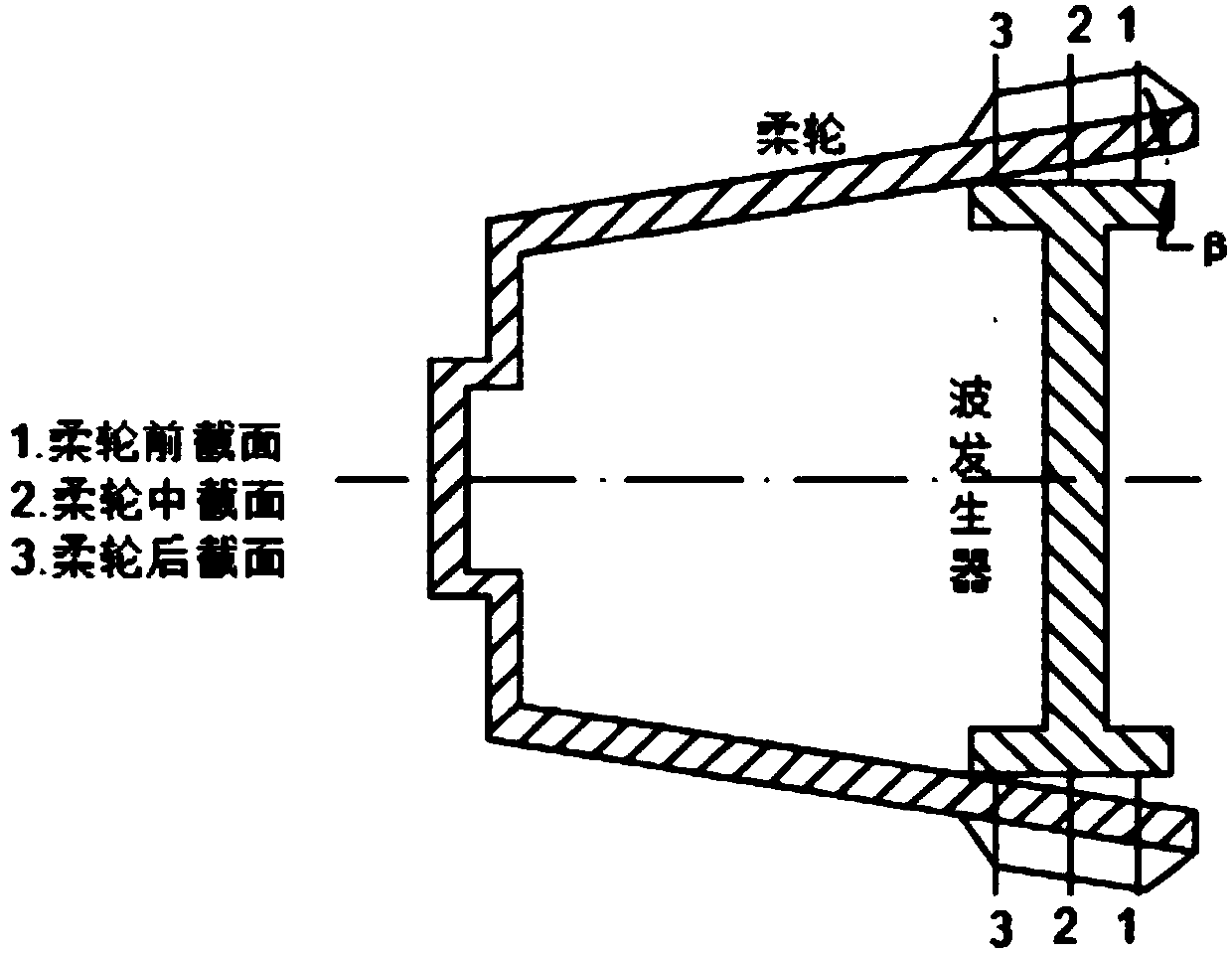

Design method of harmonic gear device

The invention discloses a design method of a harmonic gear device, and designs the harmonic gear device comprising a rigid gear and a flexible gear and the rigid gear and the flexible gear capable ofrealizing space engagement. The design method comprises the following steps: (1) in a direction perpendicular to the axis of the flexible gear, front, middle and back sections of the flexible gear areselected; (2) a discrete point of a tooth profile of each section of the rigid gear is obtained through an envelope method based on a simulation motion trajectory of the flexible gear; and (3) a complete tooth profile of the rigid gear is obtained according to the obtained discrete points of the tooth profiles of the three sections of the rigid gear. The design method prevents defects in the conjugate profile design through single-section motion or adjustment of flexible gear structure in a traditional design method, and is more accordant with actual working conditions of a harmonic gear transmission device; and the designed rigid gear device is high in overlap ratio, stable in transmission and capable of effectively improving the transmission efficiency.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

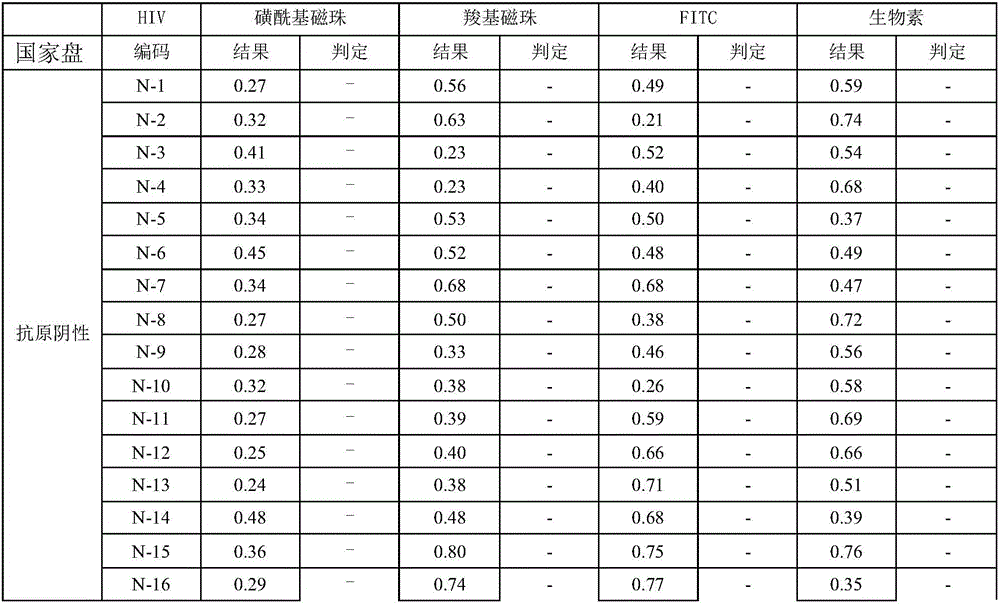

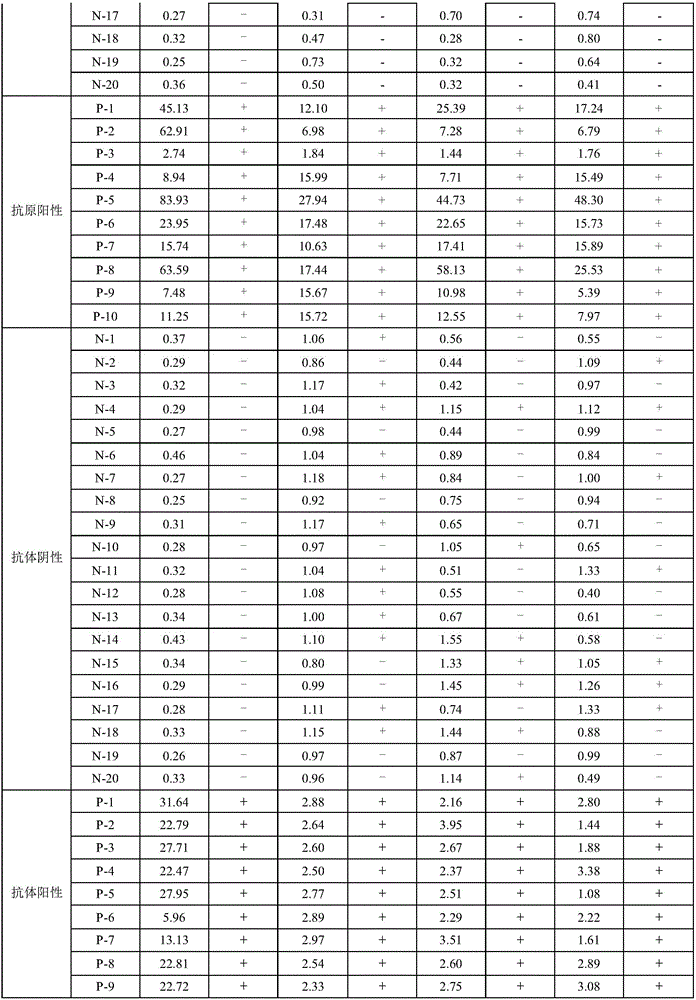

Human immunodeficiency virus antigen and antibody determination kit and preparation method

InactiveCN106290864AMinimal loss of antigenic activityWide linear rangeChemiluminescene/bioluminescenceAntigenParticulates

The invention discloses a human immunodeficiency virus antigen and antibody determination kit obtained through a magnetism particulate immuno chemistry luminescence method. The kit comprises a magnetic separation reagent, a conjugate reagent, a positive reference substance, a negative reference substance and a calibration solution; the magnetic separation reagent is prepared by combining magnetic particles with an envelope antigen and an envelope antibody, and the conjugate reagent is prepared by coupling a detection antigen and a detection antibody with alkaline phosphatase, wherein both the envelope antigen and the detection antigen are recombinant antigens, and both the envelope antibody and the detection antibody are mouse monoclonal antibodies; the calibration solution contains a to-be-detected antigen and a to-be-detected antibody; the magnetic particles have the hydrophobic surfaces and are modified by sulfonyl groups and combined with the antigen or antibody through an adsorption effect. The kit not only has the advantage that little activity of the antigen activity is lost through an envelope method, but also has the advantages that the magnetic particles achieve chemiluminescence and are easy to wash and wide in linear range; the advantages of little antigen loss and short reaction time and the advantages of being easy to wash and wide in linear range are combined for the first time, an inspection result can be consistent with that obtained through an enzyme-immunoassay method, and the reaction time is obviously shortened.

Owner:JIANGSU ZECEN BIOTECH CO LTD

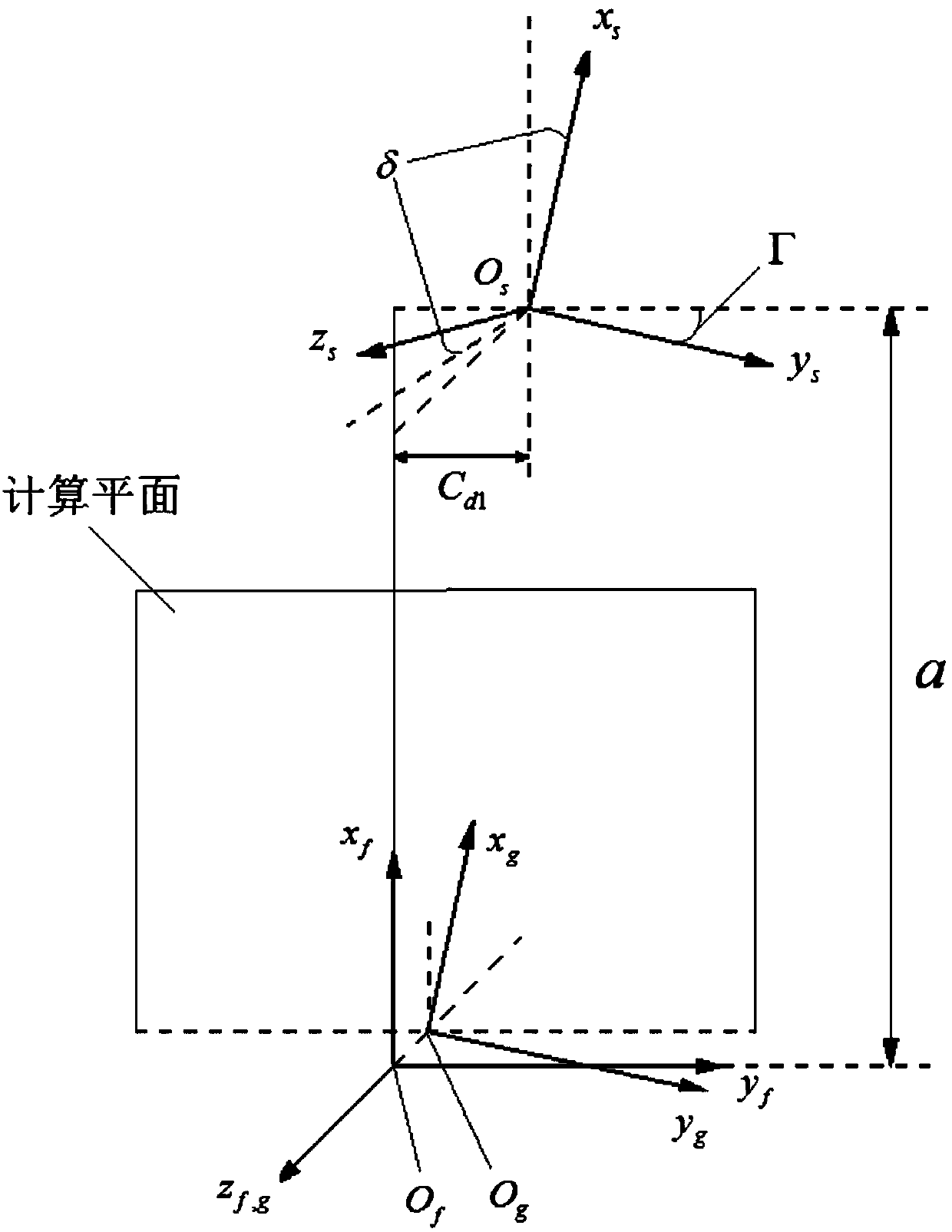

Optimal pinion tooth surface design method and processing method oriented to pre-control of meshing performance

ActiveCN108470102APre-control engagementIncrease flexibilityGeometric CADSpecial data processing applicationsEllipseEngineering

The invention discloses an optimal pinion tooth surface design method and an optimal pinion tooth surface processing method oriented to pre-control of a meshing performance. A pinion and straight-blade cutter one-parameter envelope method is similar to processing surface gear engagement. The pinion optimal tooth surface design method comprises the steps of preset of a geometrical transmission error, reverse solving of a pinion tooth surface and reconstruction of a pinion optimal tooth surface, wherein the geometrical transmission error is a 2-8-order polynomial function and is preset in a reverse solving process of the pinion tooth surface, and the optimal pinion tooth surface is reconstructed by use of a reversely solved tooth surface and lengths of a contact trajectory and an ellipse. The invention further describes the optimal pinion tooth surface processing method. The processing method comprises the steps of selecting a Qinchuan numerically-controlled machine tool QMK50A and a profile cutter, establishing an initial numerically-controlled law and correcting the numerically-controlled law. Through iterative correction of the numerically-controlled law, the numerically-controlled processing tooth surface approaches the optimal pinion tooth surface and a pinion is processed, and the method can effectively pre-control the geometrical meshing performance of meshing of the pinion and a surface gear.

Owner:XIAN UNIV OF SCI & TECH

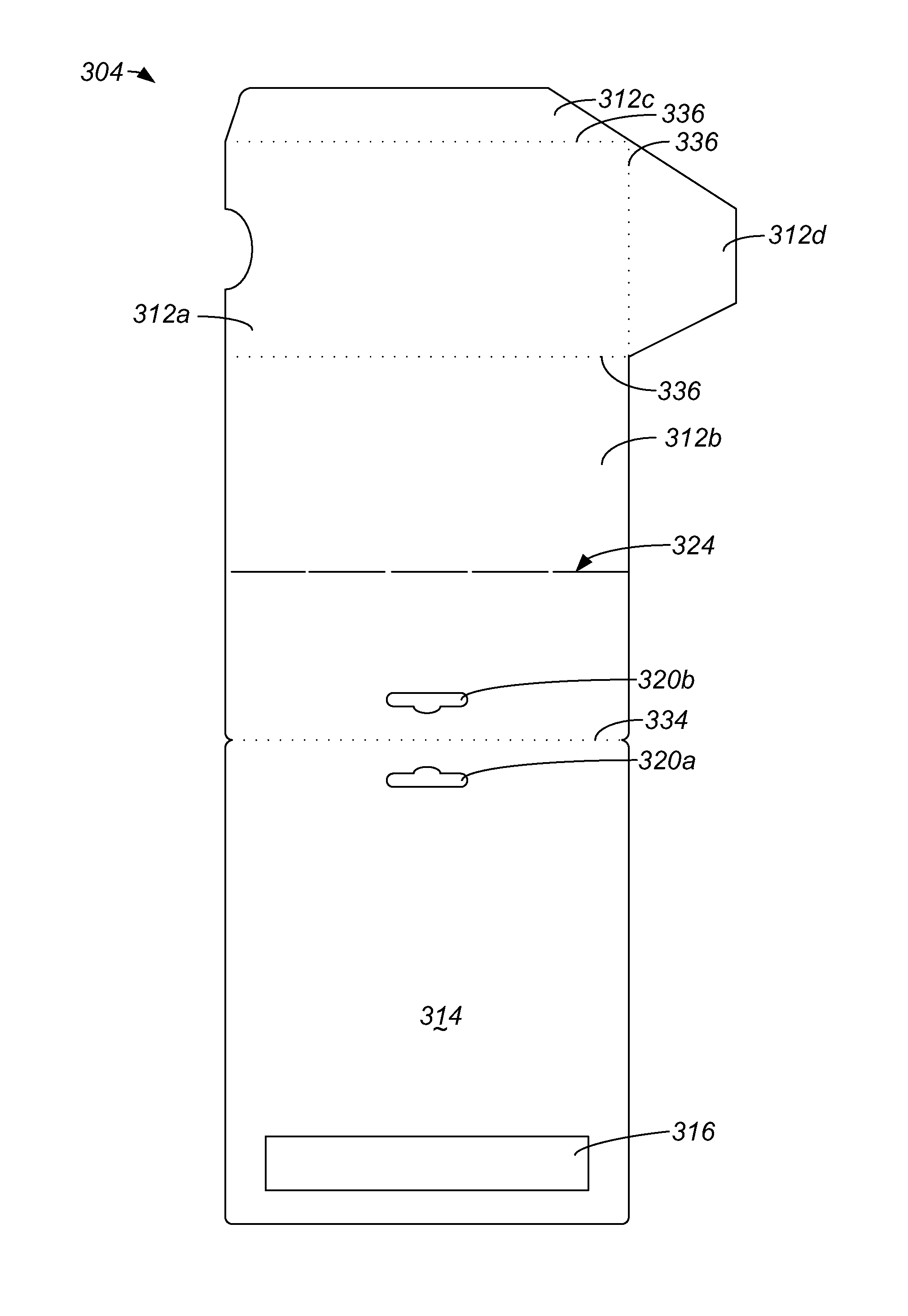

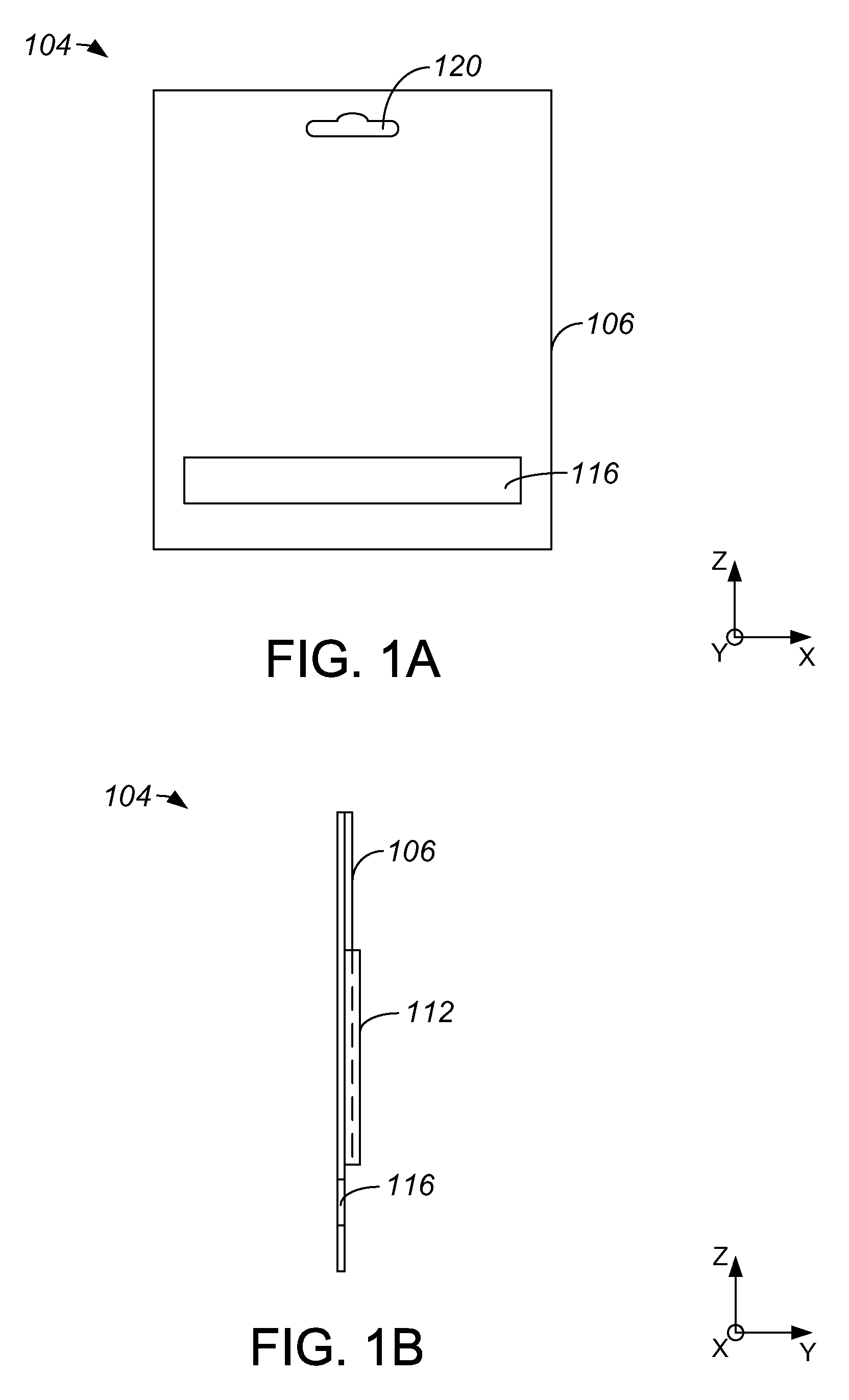

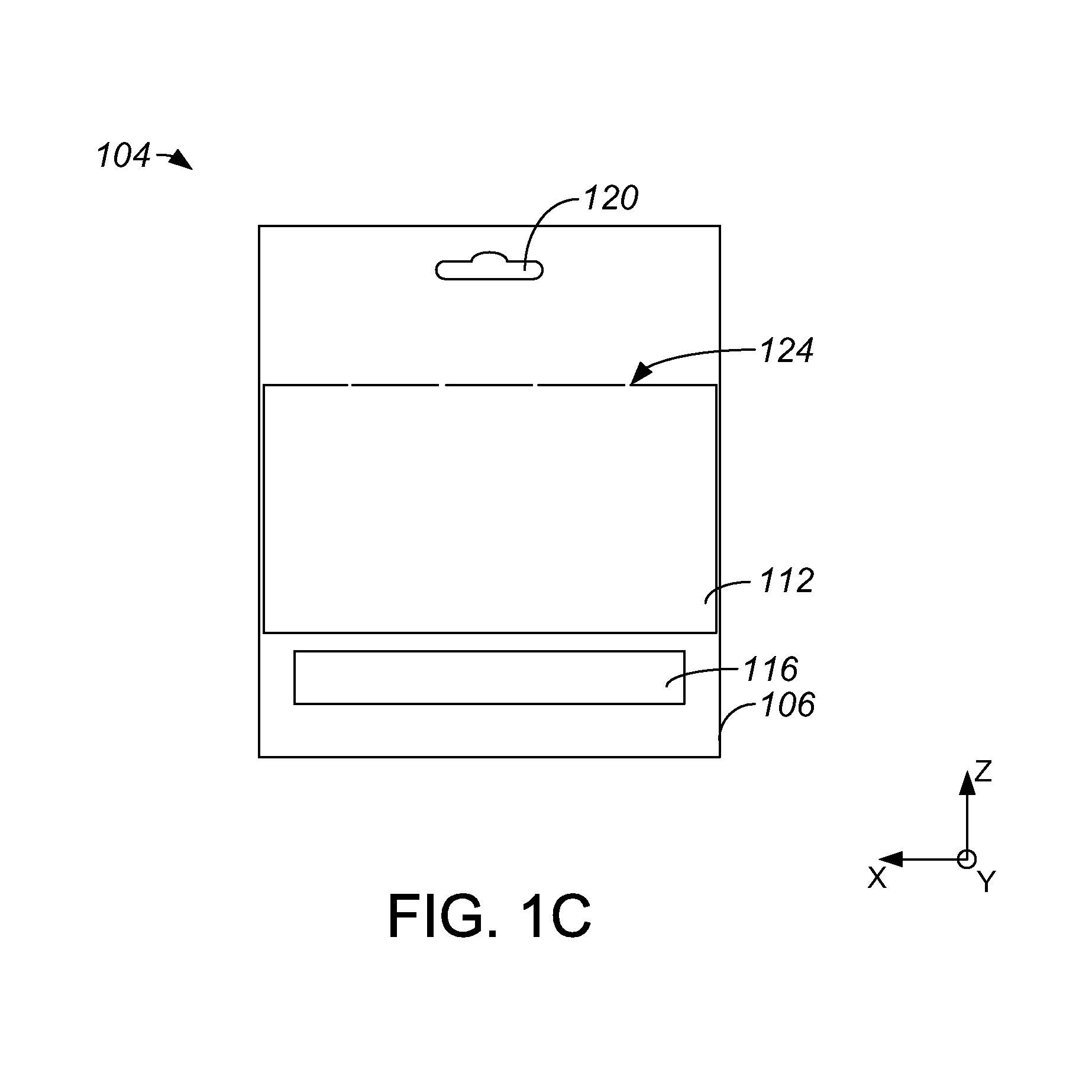

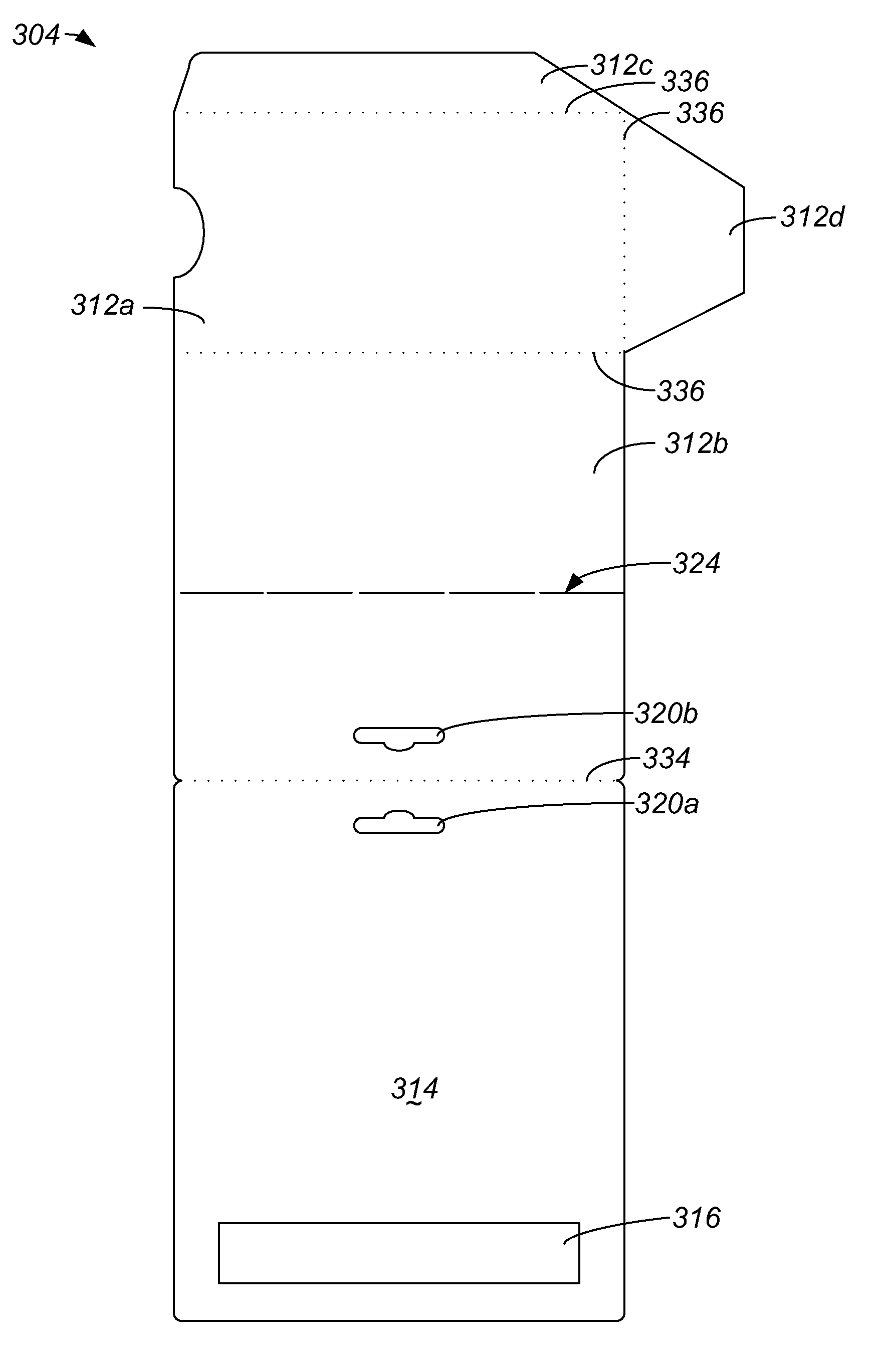

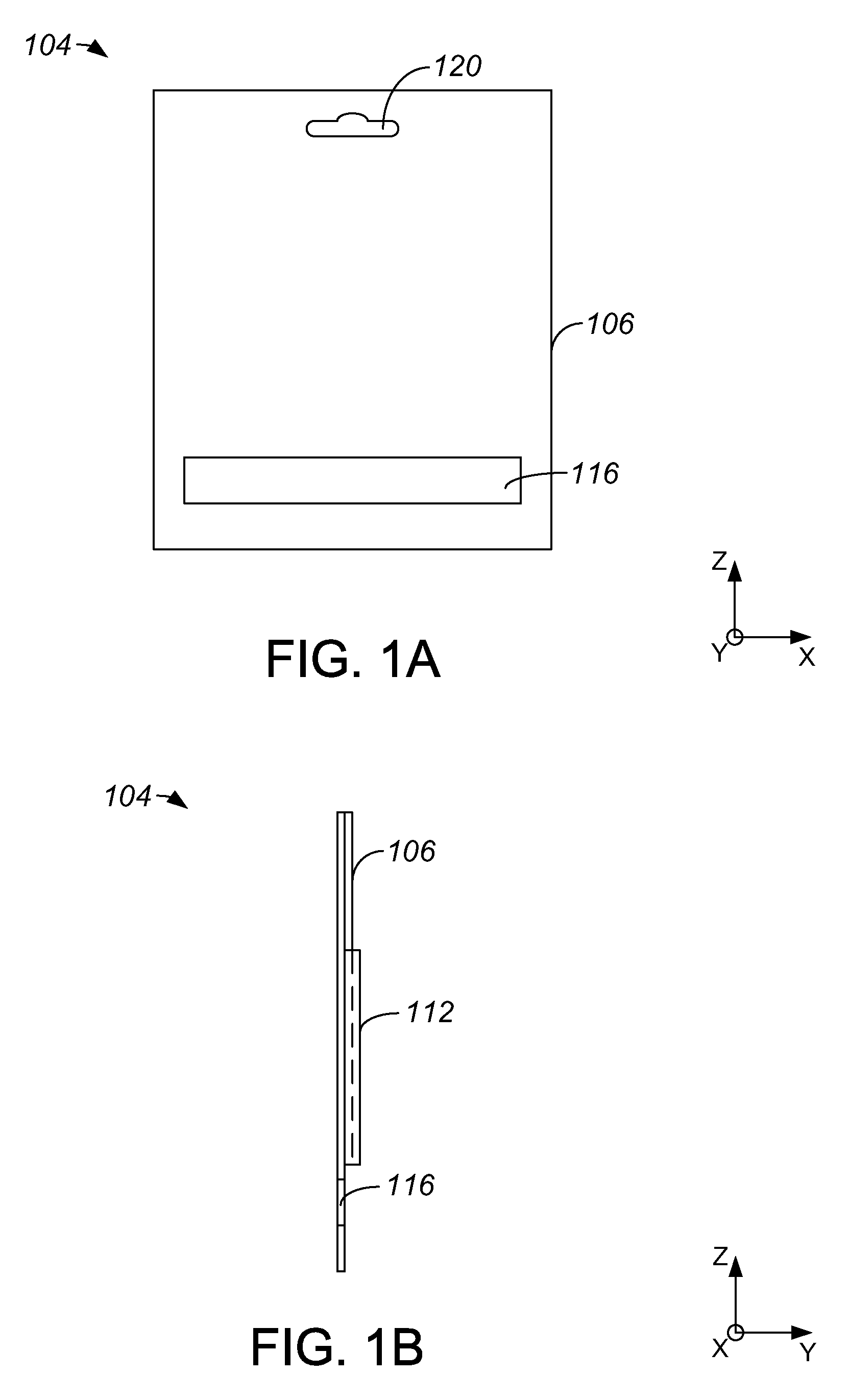

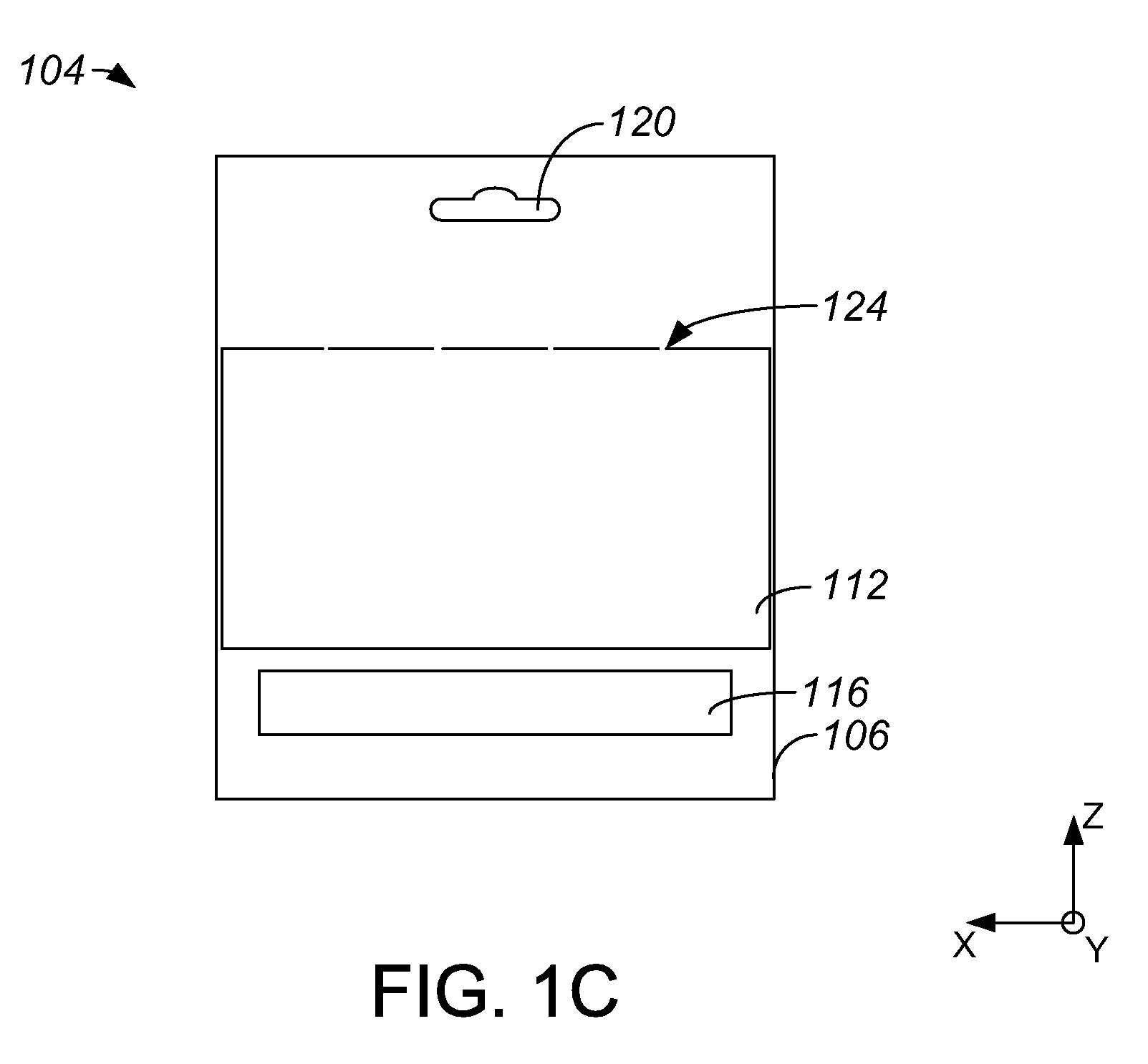

Carrier card arrangement with removable envelope

Owner:APPLE INC

Carrier Card Arrangement with Removable Envelope

Owner:APPLE INC

Molding method for cutting processing of pivoting support raceway

The invention provides a forming method used for cutting and processing a pivoting support raceway, which comprises bicircular-arc raceway processing and perpendicular raceway processing, wherein the bicircular-arc raceway processing comprises two steps: the first step comprises n cutting circulation (s), the cycle index n is equal to circular-arc radius R divided by each maximum feed amount L, wherein n is the positive integral equal to 1, 2, 3 and the like, each feed amount of circulating a circular-arc cutter along the axial direction of workpiece is n-1* (R / n), each cutting amount of the circular-arc cutter along the radial direction of the workpiece can be enabled to be the same, the vast majority of metal in a forming arc-surface area on the workpiece is cut off in the first step, and the rest metal is cut to form an arc forming surface through adopting an envelope method in the second step; the perpendicular raceway processing adopts a turning tool with the angle of a cutter point less than 90 degrees, the cutter setting on the X direction and the Z direction is finished by combing an edge cutter-setting method, the perpendicular shape is then circularly cut off according to a certain cutting feed route, and the tool smoothing is carried out finally; and the cutting process of the pivoting support raceway is finished by combining macroinstruction programming. The forming method can ensure that the cutting space is less than an allowable value and avoid the problems of lathe vibration caused by cutter breaking, and the like.

Owner:NANJING GONGDA CNC TECH

Method for performing enzymolysis and enrichment on alpha-linolenic acid (ALA) with perilla frutescens oil

InactiveCN102634416AHigh economic valueScientificUrea derivatives preparationOrganic compound preparationOleic Acid TriglyceridePerilla frutescens

The invention provides a method for performing enzymolysis and enrichment on alpha-linolenic acid (ALA) with perilla frutescens oil, relates to biotechnologies and fine chemical engineering technologies and mainly aims at reaching a key control point in the enrichment of the high-purity ALA with the same adjacent carbon atoms and the different ethylenic bonds so as to improve the content of the ALA in the perilla frutescens oil to more than or equal to 90% from 62.4% through enrichment. The method comprises the following specific steps of: performing enzymolysis on the perilla frutescens oil by lipase to obtain mixed fatty acid, and separating the mixed fatty acid to saturated fatty acid and mixed unsaturated fatty acid through a urea envelope method so as to obtain a solid phase and a liquid phase; extracting the saturated fatty acid from the solid phase with the recovery rate reaching 61%; extracting oleic acid, linoleic acid and ALA from the liquid phase, and performing temperature-gradient cooling on the liquid phase to obtain a solid phase and a liquid phase; extracting oleic acid and linoleic acid from the solid phase with the recovery rate reaching 59%; and extracting ALA from the liquid phase with the recovery rate reaching 51% and the content being 93.47%. The method has the most outstanding characteristic of enrichment of the high-purity ALA from the plant oil, thus having particularly remarkable social and economic benefits.

Owner:CHENGDU WANJIAFANG TECH

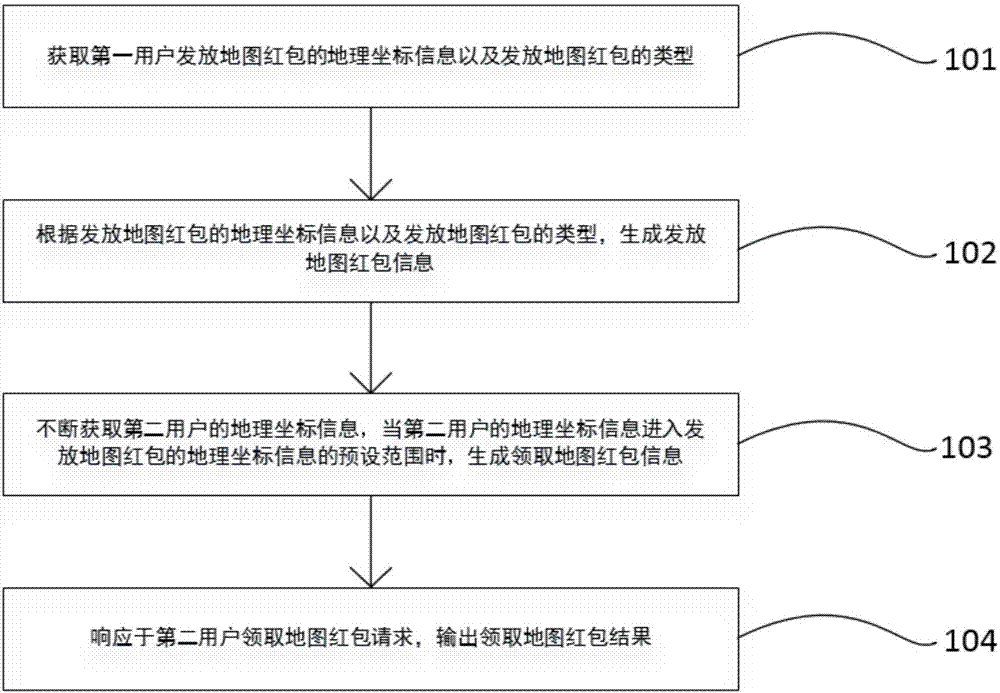

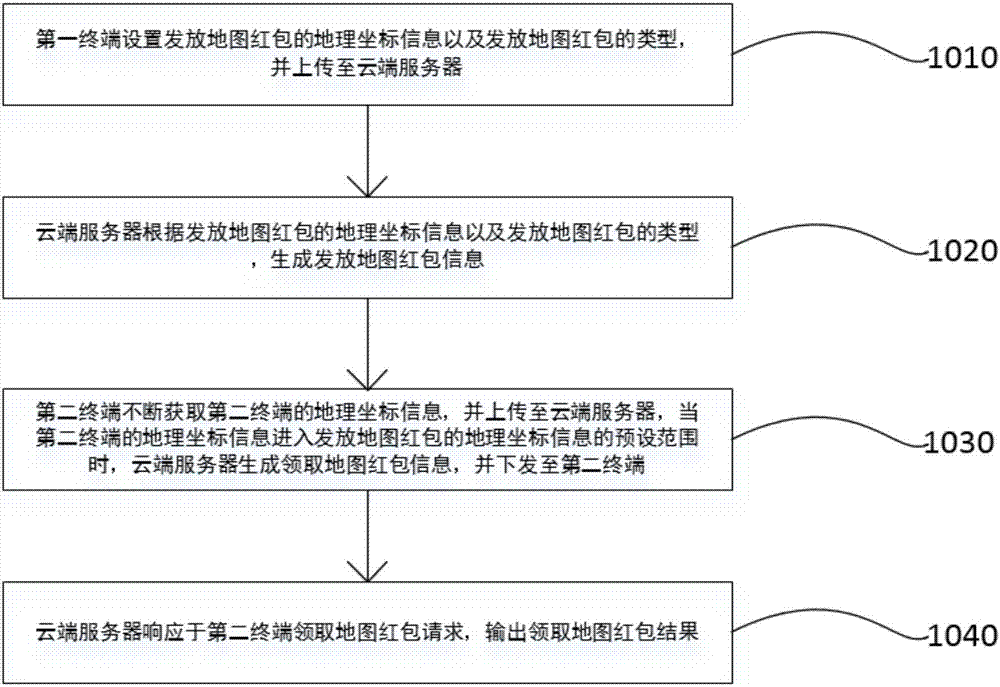

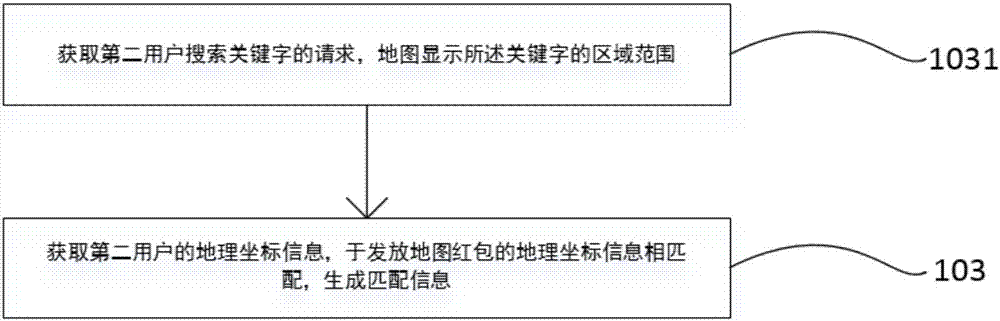

Internet-of-things-based map red envelope method and system

InactiveCN107515894AAdd funAchieve publicity effectTransmissionSpecial data processing applicationsSpare timeEnvelope method

The invention relates to the field of internet of things, in particular to an internet-of-things-based map red envelope method and system. The map red envelope method comprises the following steps of obtaining geographic coordinate information of a map red envelope given by a first user and a type of the given map red envelope; according to the geographic coordinate information of the given map red envelope and the type of the given map red envelope, generating given map red envelope information; continuously obtaining geographic coordinate information of a second user, and when the geographic coordinate information of the second user enters a preset range of the geographic coordinate information of the given map red envelope, generating map red envelope receiving information; and in response to a map red envelope receiving request of the second user, outputting a map red envelope receiving result. The method and the system have the beneficial effects that the user can look for the map red envelope through a map when receiving the map red envelope, so that the interestingness is enhanced, a new life style is brought for the user, and the user can exercise the body in spare time.

Owner:珠海分享赢天下科技有限公司

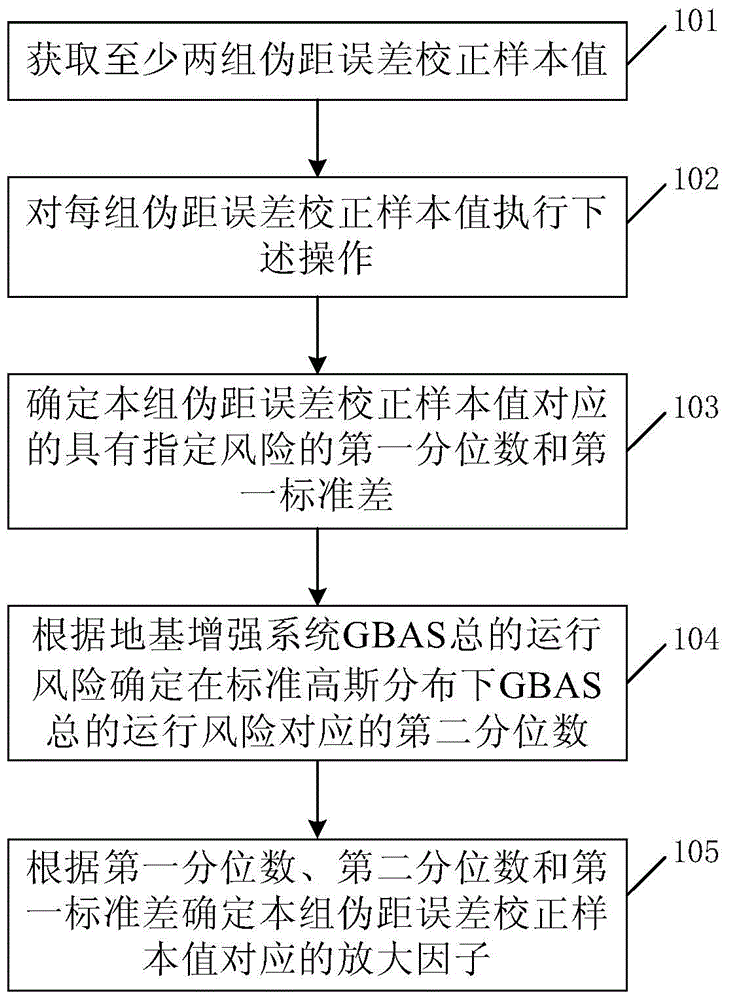

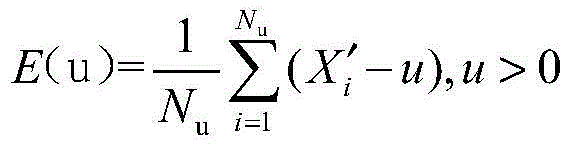

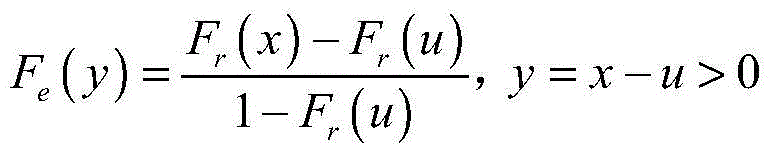

Extreme value theory-based error envelope method of satellite navigation ground-based augmentation system

The invention provides an extreme value theory-based error envelope method of a satellite navigation ground-based augmentation system. The method includes the following steps that: at least two groups of pseudo-range error calibration positive sample values are obtained; a first quantile which has an assigned risk and first standard deviation are corresponding to each group of pseudo-range error calibration positive sample values are determined; a second quantile which is corresponding to a total operating risk of the ground-based augmentation system (GBAS) under Standard Gaussian distribution is determined according to the total operating risk of the ground-based augmentation system (GBAS); and amplification factors corresponding to each group of pseudo-range error calibration positive sample values can be determined according to the first quantile, the second quantile and the fist standard deviation. With the above method adopted, the amplification factors can be calculated accurately, and the calculated pseudo-range calibration values can envelope actual errors, and the continuity of the system can be effectively improved.

Owner:BEIHANG UNIV

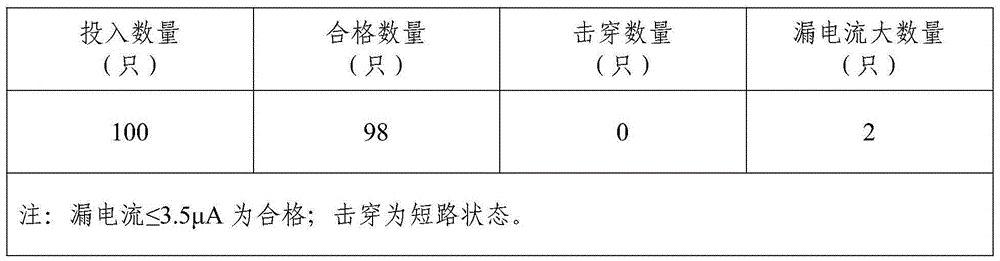

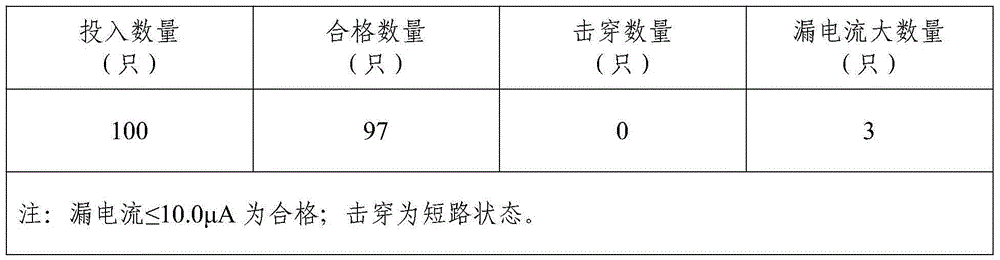

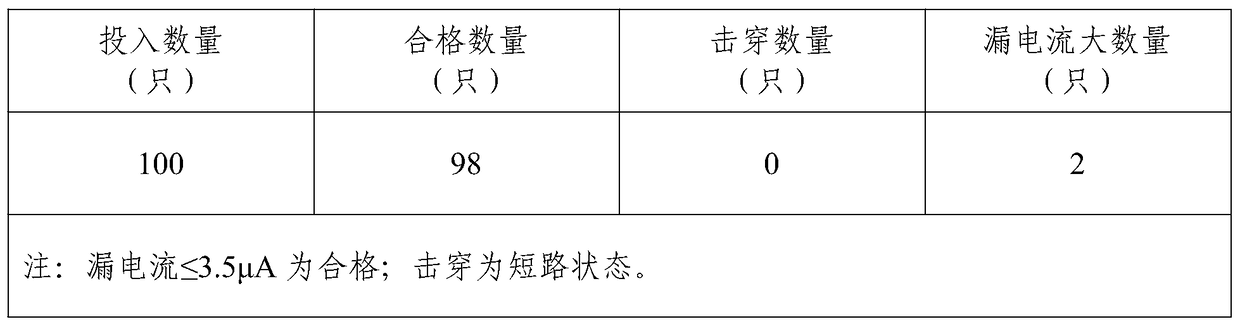

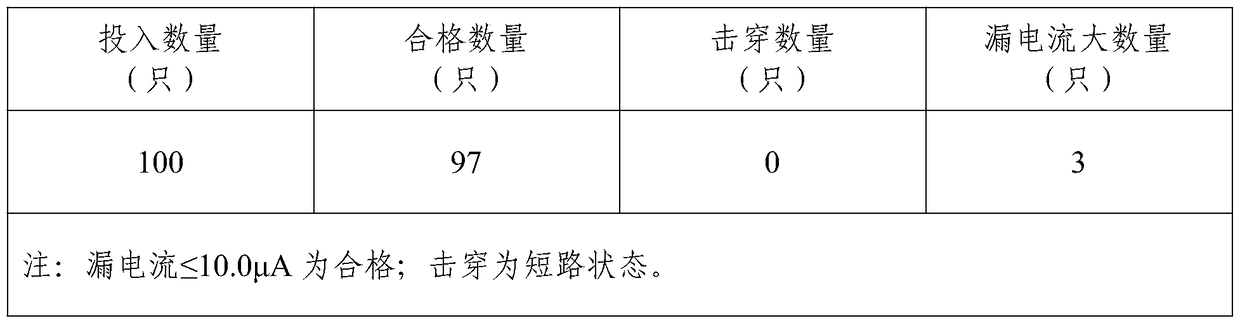

Envelope method for improving breakdown voltages of tantalum capacitor

ActiveCN106548870AImprove breakdown voltageImprove reliabilityCapacitor electrodesTantalum capacitorLaboratory oven

The invention provides an envelope method for improving breakdown voltages of a tantalum capacitor. The method comprises the following steps: immersing a tantalum fuse to be formed which is already subjected to thermal decomposition into deionized water with a temperature of 80 to 100DEG C for boiling washing; placing the tantalum fuse in a baking oven at a temperature of 125 to 150 DEG C for drying; immersing the tantalum fuse into an acid solution with a concentration of 0.001 to 0.01% in an electrolytic tank, and applying voltages to form the tantalum fuse; and placing the tantalum fuse after formation ends into the baking oven at the temperature of 125 to 150 DEG C for drying. Before the tantalum fuse is formed, the tantalum fuse is cleaned by use of a dipping alkaline solution method and a high-temperature boiling washing method, soluble Mn<2+> which is not thoroughly decomposed in the tantalum fuse is removed, and the breakdown voltages of the tantalum fuse are improved; and formation voltages are increased, MnO2 at a defect position generated due to thermal decomposition of a Ta2O5 medium membrane can be fully converted into Mn2O3 higher than resistance, leakage currents of a product are reduced, and the reliability of the capacitor is improved.

Owner:CHINA ZHENHUA GRP XINYUN ELECTRONICS COMP ANDDEV CO LTD

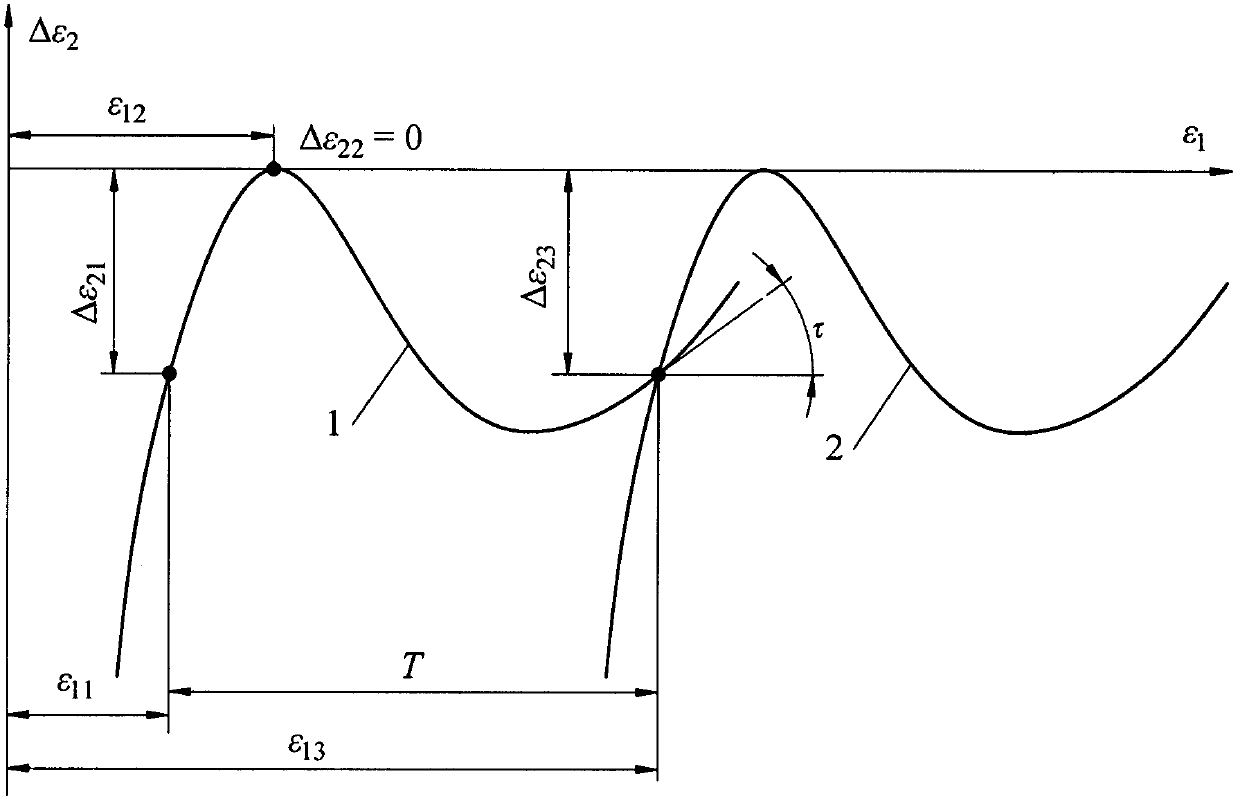

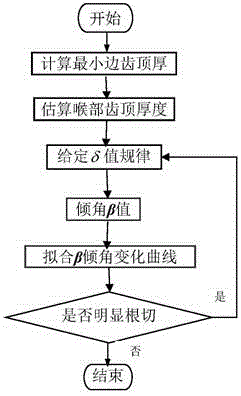

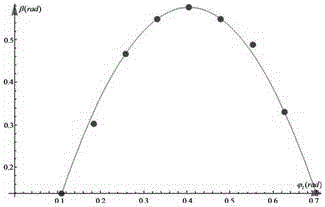

Method for determining beta angle changing curve of planar double enveloping worm

ActiveCN105422794AImprove accuracyImprove controllabilityPortable liftingGearing elementsHelical lineThroat

The invention discloses a method for determining a beta angle changing curve of a planar double enveloping worm. The method includes the steps that a space coordinate system is established according to a beta angle changing planar double enveloping worm forming principle, the beta value is set to be a function of worm gear turn angle phi<2>, and beta angle changing addendum thickness equation delta and tooth surface undercutting discriminant equation r1 are derived on the basis of an envelope method principle; the minimum side addendum thickness value delta<min> meeting the requirement of no sharpening is calculated according to worm parameters; the addendum thickness is made to change regularly and linearly in the worm helical line direction from side teeth to throat teeth; multiple worm gear turn angles phi<2> are obtained according to an equal difference rule to obtain the corresponding thickness values so as to form feature points (phi<2>, delta (beta)); the beta value which each point corresponds to is obtained through the beta angle changing addendum thickness equation, the beta curve is fitted, the fitted beta curve is substituted into the tooth surface undercutting discriminant equation, and an undercutting line is drawn on a worm tooth surface graph; and the undercutting ratio is estimated, if the design requirement is met, the operation is finished, if the design requirement is not met, throat addendum thickness delta<h> is reduced or the addendum thickness change rule is changed to a cosine rule, and the operation returns to the step 3.

Owner:YANSHAN UNIV

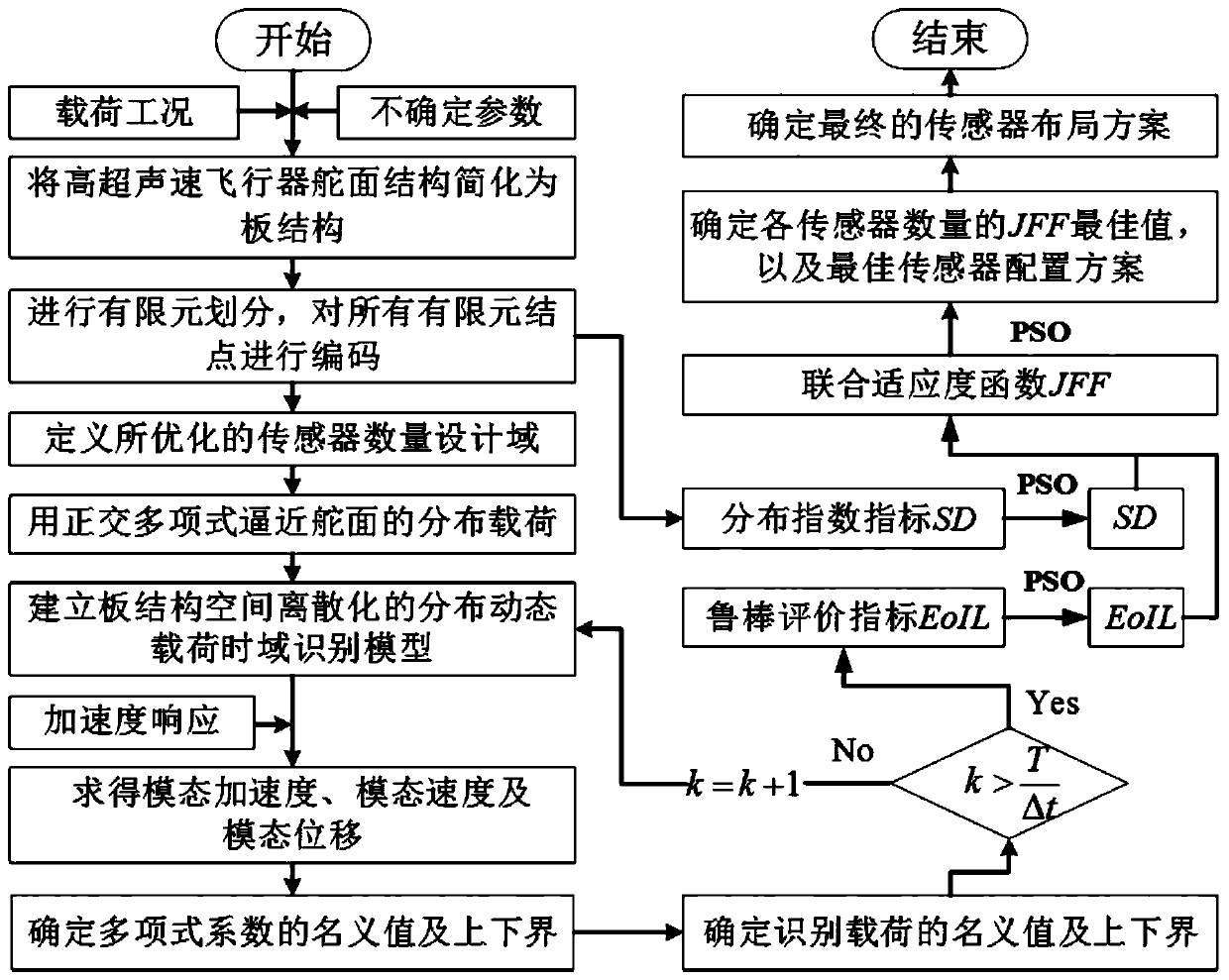

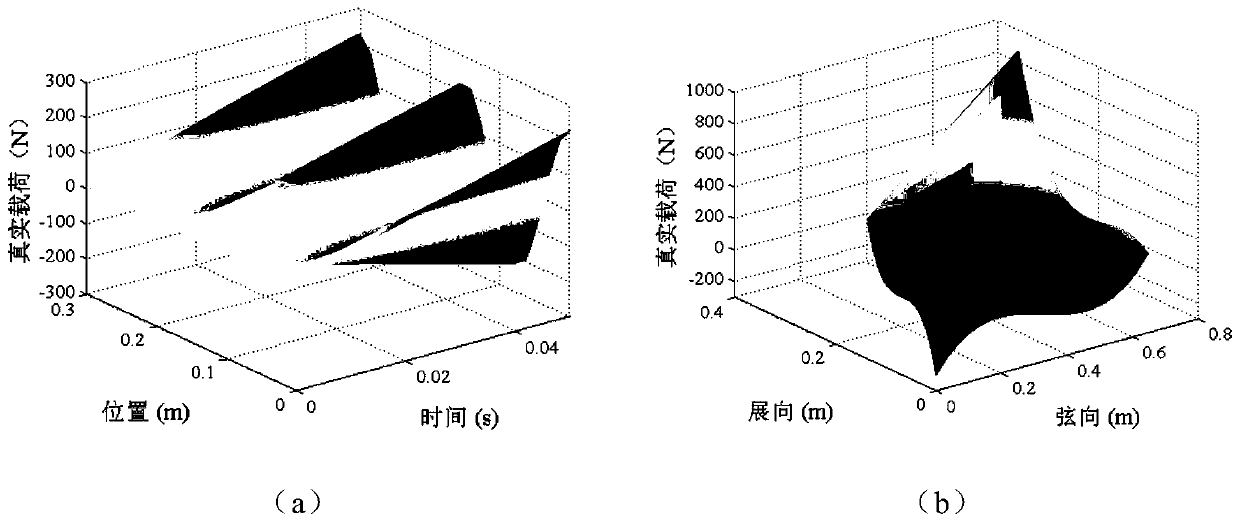

Sensor layout method for hypersonic flight vehicle control surface structure distribution load identification

ActiveCN110532607AImprove solution efficiencyGuaranteed performance of load identificationSustainable transportationForecastingFlight vehicleSimulation

The invention discloses a sensor layout method for hypersonic flight vehicle control surface structure distribution load identification. According to the method, the number and positions of sensors are taken as design variables, a comprehensive evaluation index is constructed based on a load identification robustness evaluation index representing the identification performance of the sensors and adistribution index reflecting the distribution performance of the sensors, and a sensor layout optimization model is established by taking the index as an optimization target. The method comprises the following steps: firstly, based on an interval process envelope method, establishing a dynamic distribution load identification model of an uncertain control surface structure, solving load identification parameters, and establishing a load identification robustness evaluation index; secondly, in order to eliminate redundant information in sensor configuration, establishing a distribution index;then, based on the two indexes, establishing a joint fitness function through a normalization and weight method; and finally, through an algorithm combining particle swarm optimization and sensor number updating, obtaining an optimal sensor layout of control surface structure distribution load identification.

Owner:BEIHANG UNIV

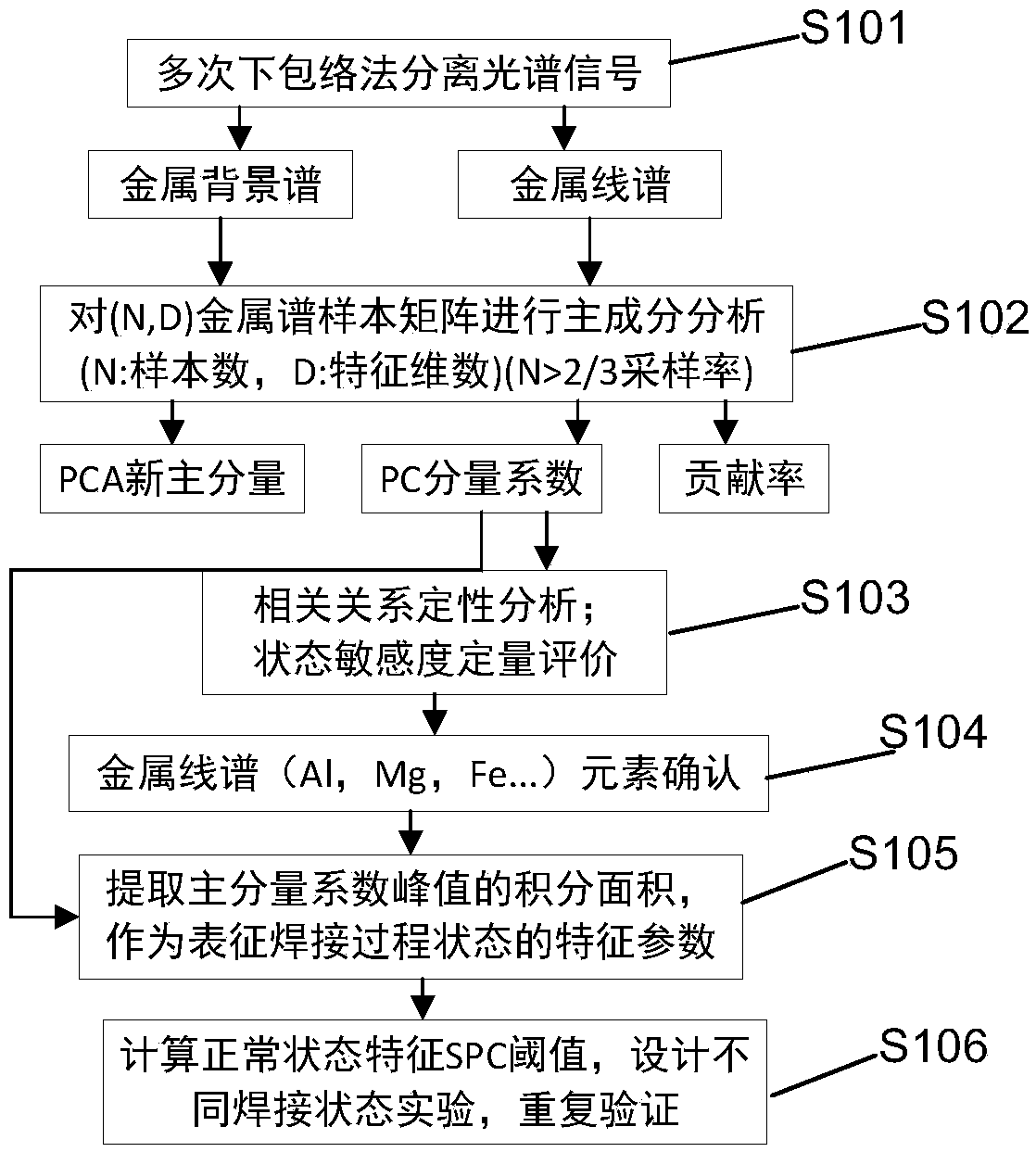

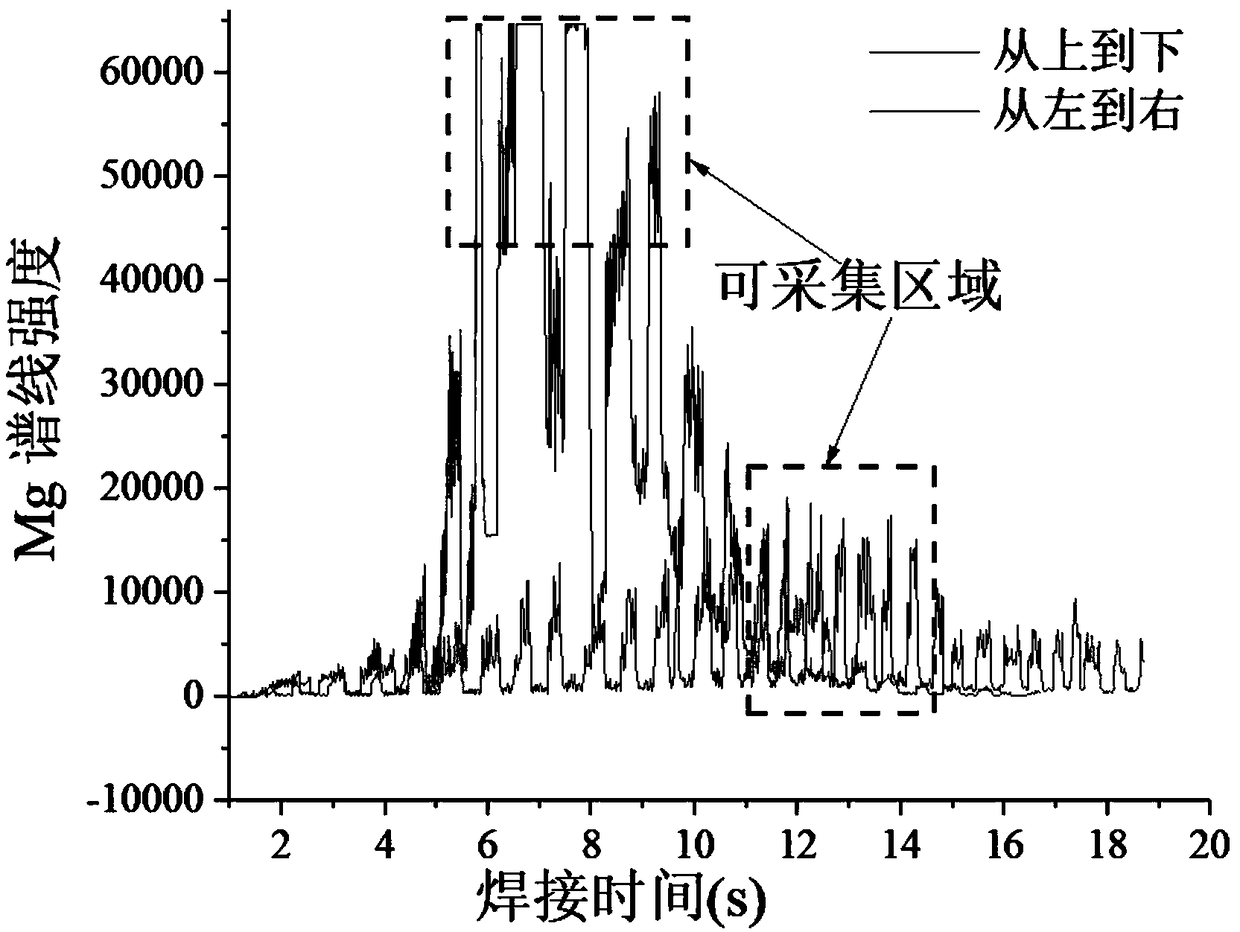

Aluminum alloy fusion welding process state detection method and device

ActiveCN109324033ALower resolution requirementsImprove robustnessAnalysis by electrical excitationPrincipal component analysisChemical element

The invention discloses an aluminum alloy fusion welding process state detection method. The method comprises the following steps of S1, acquiring a metal spectral signal in an aluminum alloy fusion welding process, and separating the metal spectral signal by adopting an envelope method to obtain metal background spectrums and metal wire spectrums; S2, carrying out principal component analysis onthe metal wire spectrums to obtain eigenvector coefficients and eigenvector curves of first main components of the metal wire spectrums; S3, confirming chemical elements corresponding to each peak value in the eigenvector curves obtained in the step S2; and S4, according to the eigenvector coefficients obtained in the step S2, carrying out correlation qualitative analysis and sensitivity evaluation on the chemical elements determined in the step S3 according to wavelength pixels correspondingly obtained according to the eigenvector coefficients. The method is based on spectral information deepmining and feature extraction methods of metal spectral principal component analysis, and can realize detection of a state of an aluminum alloy fusion welding process.

Owner:XI AN JIAOTONG UNIV

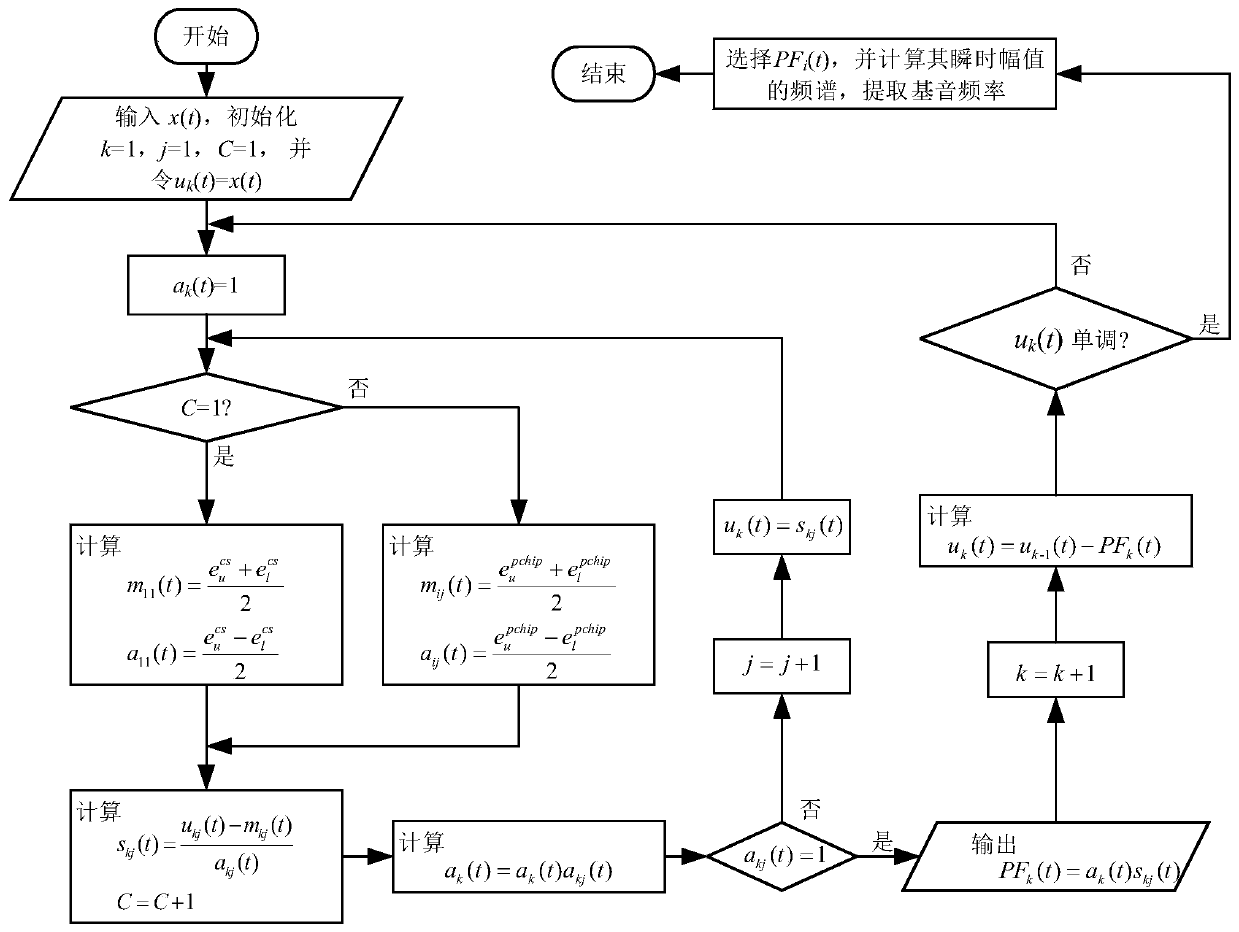

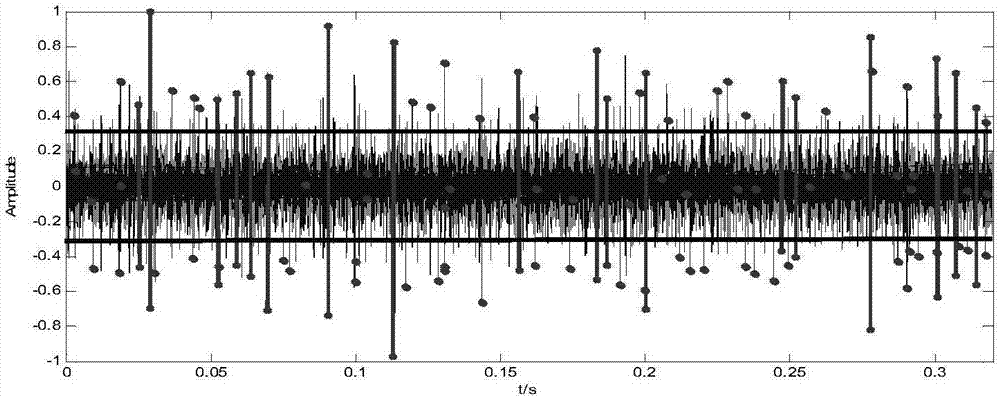

Local mean decomposition (LMD) improving method for speech fundamental frequency extraction

InactiveCN110289007ASolve the accuracy problemSolution success rateSpeech analysisFrequency spectrumDecomposition

The invention provides a local mean decomposition (LMD) improving method for speech fundamental frequency extraction. Firstly, an upper envelope and a lower envelope of a speech signal are calculated through an iterative envelope method of a cubic spline interpolation, and the local mean function and the envelope estimation function of the speech signal are calculated; after screening is completed once, in the subsequence screening process, an iterative envelope method of a piecewise cubic hermite interpolating polynomial is used for calculating the upper envelope and the lower envelope of the speech signal so as to obtain the new local mean function and envelope estimation function; after LMD is completed, the component with maximum energy is selected to calculate the frequency spectrum of the envelope function of the speech signal; and finally, the fundamental frequency of the speech signal is obtained. The iterative envelope methods with an under-envelope elimination function are introduced into an LMD method, a high-order interpolation curve and a low-order interpolation curve are combined to slow down over-envelopes, thus the local mean function and the envelope estimation function of the signal are built, and the calculating efficiency and convergence stability of the LMD method in the fundamental frequency extraction process of the speech signal are improved remarkably.

Owner:XI AN JIAOTONG UNIV

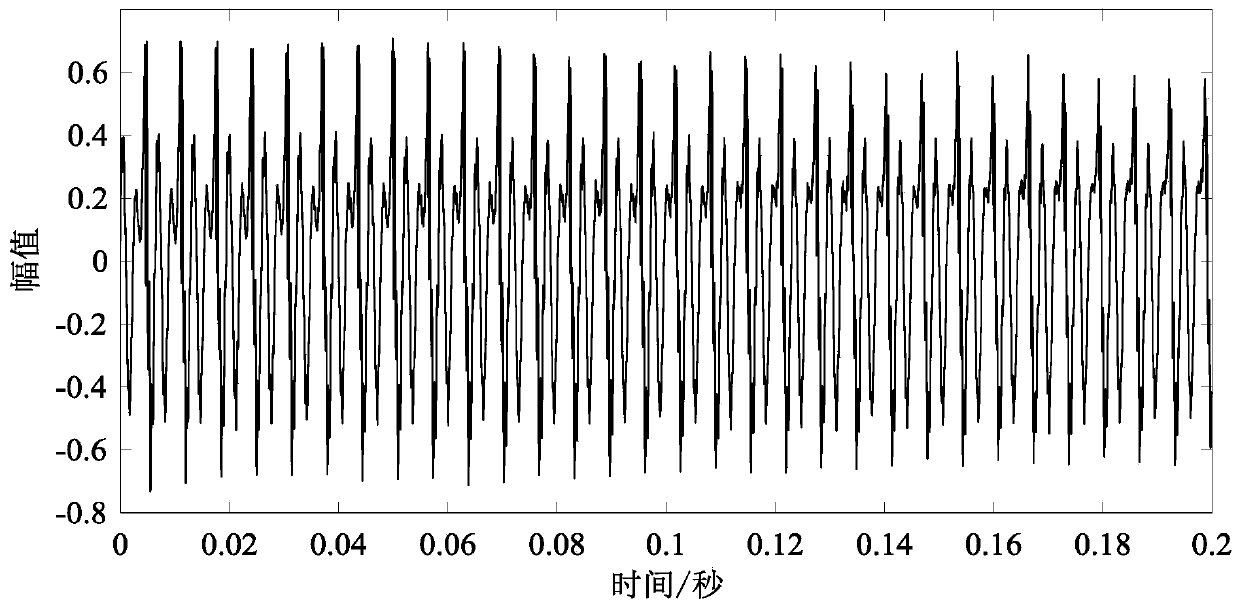

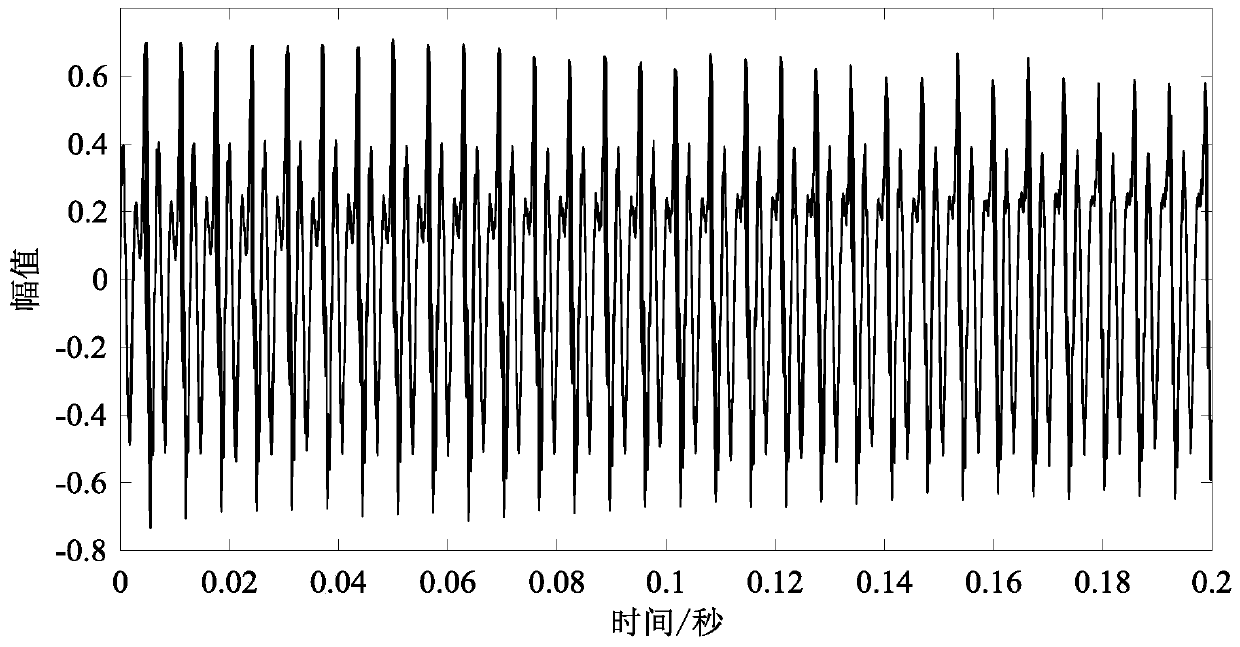

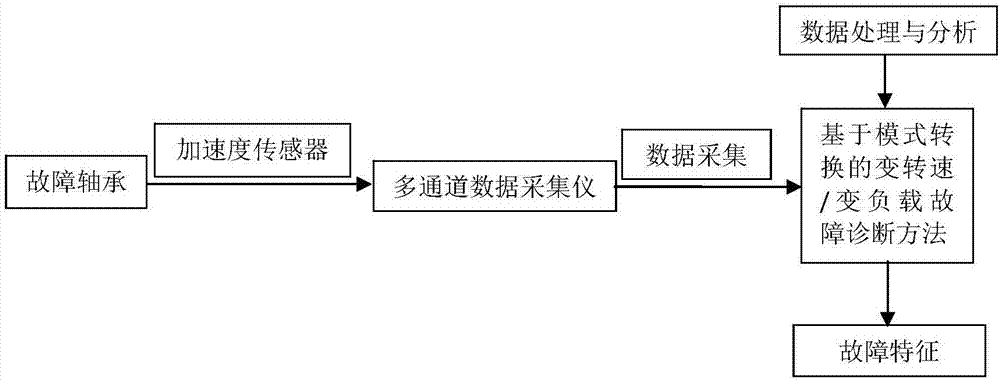

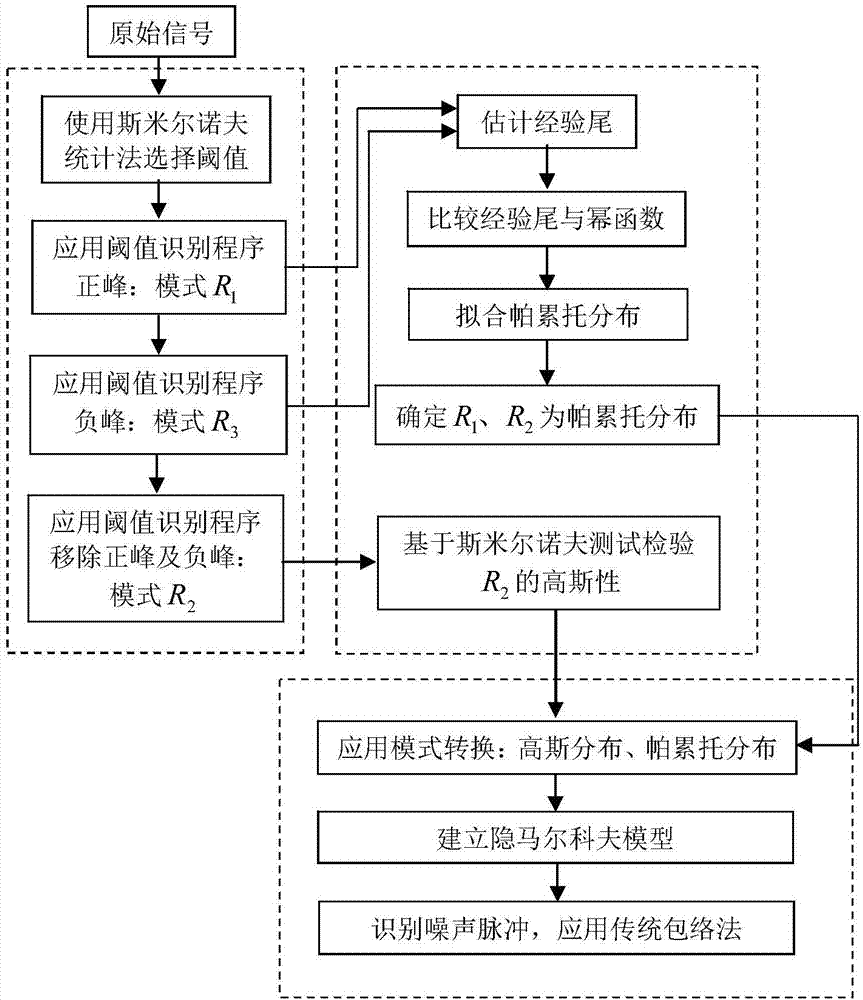

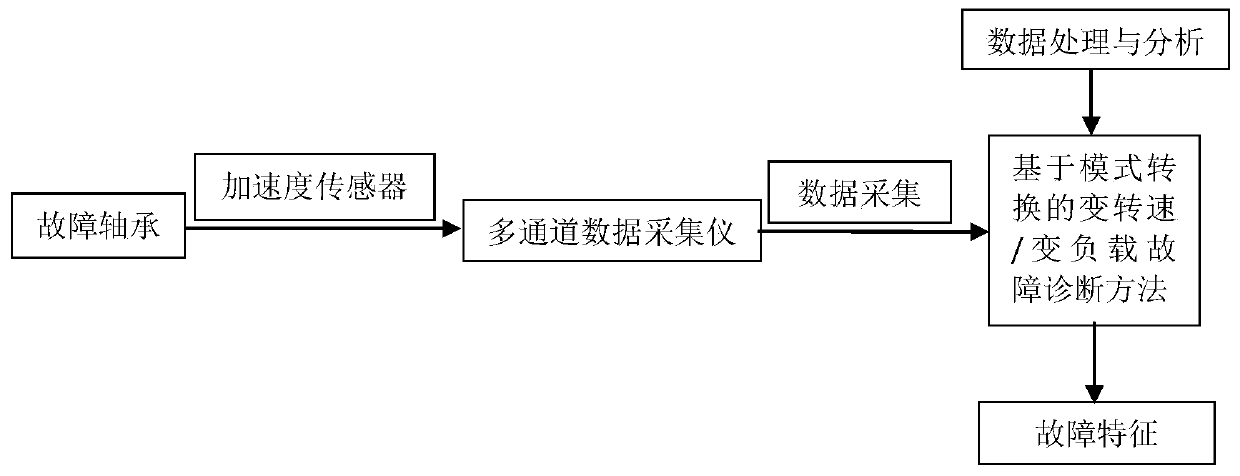

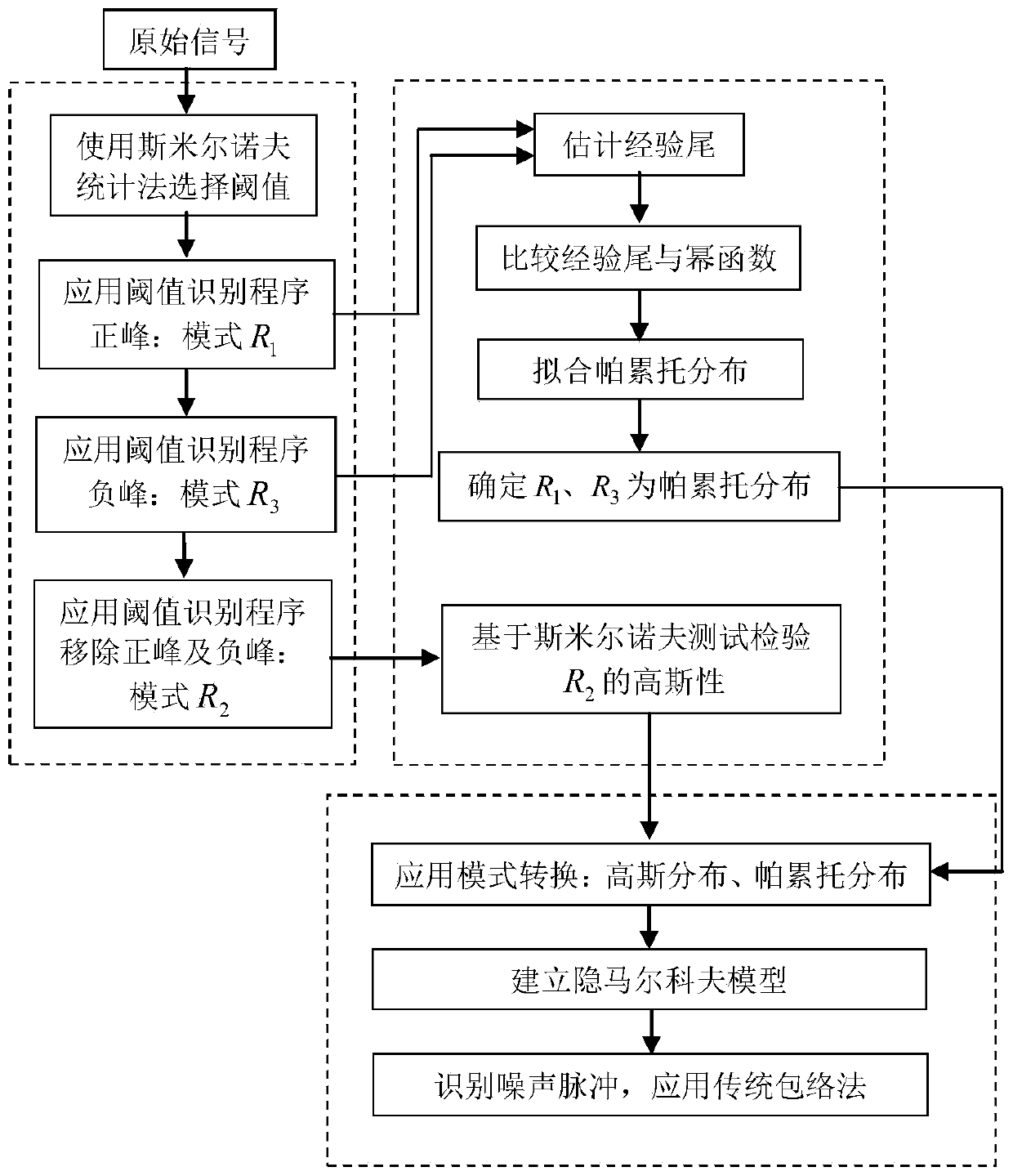

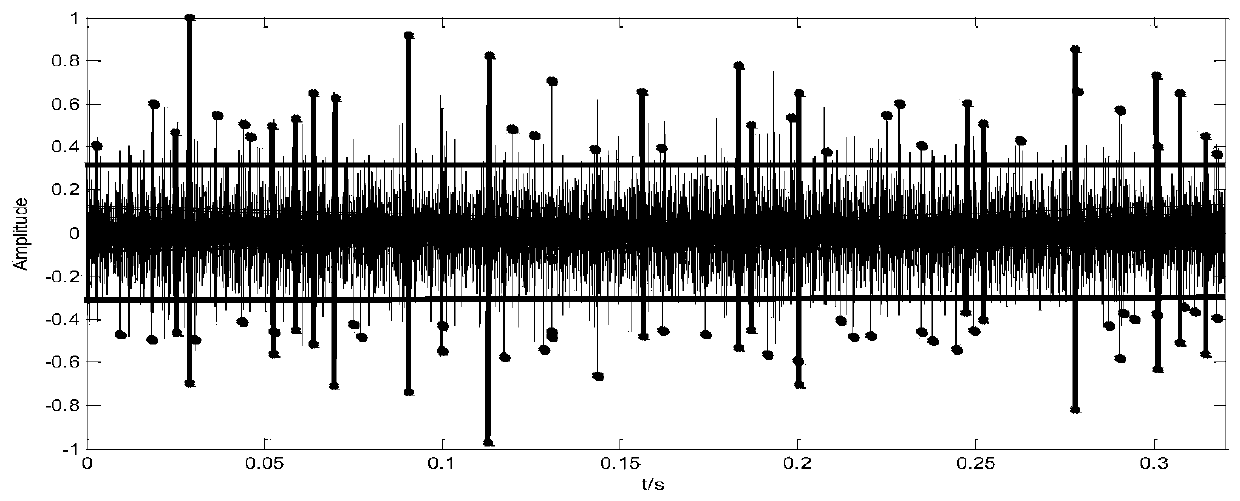

Variable speed/variable load rolling bearing fault diagnosis method based on mode conversion

ActiveCN107884188AImplement fault diagnosisAccurate analysis and processingMachine bearings testingCharacter and pattern recognitionSignal-to-noise ratio (imaging)High energy

The invention discloses a variable speed / variable load rolling bearing fault diagnosis method based on mode conversion. The method comprises the following steps: through assuming that fault rolling bearing vibration signals are at least composed of two signal sources with different distribution characteristics, a bearing vibration signal model is built; based on a threshold technology and a tail estimation method, the signals are preliminarily separated and analyzed to obtain signal modes with different distribution characteristics; an expectation-maximization theory is combined to build a hidden Markov model for the signals to acquire noise pulses, subtraction with original signals is carried out to further improve the signal-to-noise ratio of the signals; and finally, the traditional envelope spectrum is used to analysis the signals, and whether fault happens to the rolling bearing and the type of the fault are evaluated. On one hand, the problem that the vibration signals under a variable speed / variable load condition is hard to diagnose is overcome; and on the other hand, the problem that high-energy pulses change the envelope of the signals and thus, the traditional envelope method can not be applied in a condition of existence of non-Gaussian noise can be solved.

Owner:WENZHOU UNIVERSITY

Pyrazosulfuron-mefenacet-containing weeding and insecticidal fertilizer and producing method thereof

The invention discloses a pyrazosulfuron-mefenacet-containing weeding and insecticidal fertilizer which is prepared by compounding herbicides, namely pyrazosulfuron and mefenacet, an insecticide and a carrier fertilizer, wherein the weight ratio of pyrazosulfuron to mefenacet is 1:(20-30). The invention further discloses a producing method of the fertilizer, which comprises the steps of taking water as a solvent and preparing a fertilizer granule by a spraying envelope method. The process flow is short, the quality is stable, the environmental pollution is low, the pesticide effect of the fertilizer is significant, and when the obtained fertilizer granule is applied in a paddy field, the fertilizer has multiple effects of fertilizing, weeding and pest killing, and can achieve the purposes of labor and time saving.

Owner:广西乐土生物科技有限公司

Spherical involute spiral bevel gear cutting method and machine tool

InactiveCN101391322BStable structureSimple structureGear teeth manufacturing toolsGear-cutting machinesNumerical controlCircular cone

The invention discloses a cutting method for a bevel gear with spherical involute toothed circular arc teeth and a machine tool thereof. The cutting method comprises a circular arc cutter edge conjugation generating method and an envelope method. A cutter shaft and a gear blank shaft for implementing the circular arc cutter edge conjugation generating method rotate directionally with rotating rates (Omega0) and (Omega1), a cutter edge enters into cutting, a cage chair rotates according to that Omega is equal to Omega1sinaDeltab, the formation of pure rolling of a gear blank base cone and thebig circular plane of the spherical surface is guaranteed to complete the processing of spherical involute toothed flank. The cage chair with a real axis is driven to rotate by a servo motor, and forthe cage chair without a real axis, the synthesis movement of the y and z directions of a coordinate system forms a cage chair to rotate with the rotating rate (Omega). When the envelope method is implemented, cutter teeth of short arc and even point cutter edge are adopted. Points with the number of k are taken on the circular arc line AC of generating the flank, each cutting can form a spiral line on the flank, the circular arc cutting feed angle Delta Theta of a gear cutter head per cutting is set, and the flank which is composed of spiral lines with the number of k is enveloped and generated by sequentially k-times cutting feed. A third shaft and a forth shaft link a numerical control gear cutting machine to implement the gear cutting method.

Owner:JILIN UNIV

A Fault Diagnosis Method of Variable Speed/Variable Load Rolling Bearing Based on Mode Conversion

ActiveCN107884188BImplement fault diagnosisAccurate analysis and processingMachine part testingCharacter and pattern recognitionHigh energyEngineering

Owner:WENZHOU UNIV

Point-Vector Quadratic Envelope Method for Determining the Profile of Helical Surface by Generating Tool

InactiveCN105785914BImprove robustnessImprove control accuracyNumerical controlEngineeringEqualization

The invention belongs to the field of manufacturing a spiral curved surface, and relates to a point vector double-enveloping method for determining a machined spiral curved surface profile with an expanding tool.The method includes the steps that point dispersion is conducted on a profile bus of the expanding tool according to an equalization criterion, and normal vectors on dispersion points are added to form point vectors; a spiral motion trail of the point vectors along the curved surface of the tool and a straight line along the axis of the tool are expanded into a motion trail to conduct dispersion, the double-enveloping method of the planar point vectors is set up, the points, with the smallest directed distance from a gear, in a two-dimension point vector group is determined as enveloping points, and finally all the enveloping points are constructed into the machined spiral curved surface profile in a fitting mode.

Owner:CHONGQING UNIV

Equipment and method of envelope method processing film slitting chamfering

InactiveCN101229595BThe bevel angle can be adjusted arbitrarilyLess materialAutomatic control devicesFeeding apparatusMotor driveGear wheel

The invention relates to an equipment used for processing inverted beveled edges of flexible sheet and cut pieces by an envelope method and a method thereof, which comprises a body, a vacuum chuck, a large arm, a small arm, a lifting arm, a cutter head and a drive control device, wherein, the vacuum chuck is arranged on a vacuum chamber on the body; the large arm is arranged on the body through guide tracks at the two sides of the body; the small arm is arranged on the large arm; the lifting arm is vertically arranged on the small arm; transmissions are realized by a ball guide screw or a cogbelt or a pinion and rack between the large arm and the body, the small arm and the large arm and the lifting arm and the small arm and a straight feed motion is realized by the guide track between the large arm and the body, the small arm and the large arm and the lifting arm and the small arm; a circular cutter holder is arranged on the lifting arm and a swing arm is arranged on the circular cutter holder; a spindle motor is arranged on the swing arm and the cutter head is arranged on a spindle head of the spindle motor. In the method, a disc shape cutter is used and the diameter of the disc shape cutter is smaller than the minimum curvature radius of pieces to be processed; in the process, the spindle motor drives the disc shape cutter to rotate continuously and keeps tangency between a cutting blade and a curve edge of the pieces to be processed. The invention can carry out operation of linear and arc converse beveled edges automatically and the angle of the beveled edges can be adjusted optionally, thus saving materials.

Owner:NORTHEASTERN UNIV LIAONING

Point Vector Enveloping Method for Determining the Profile of Helical Surface by Forming Tool

ActiveCN104898556BEasy and fast profile envelope calculationEliminate interferenceNumerical controlEnvelope methodDiscrete points

The present invention discloses a point vector envelope method for determining a processed spiral surface contour by a forming cutter, belonging to the field of spiral surface manufacture. Firstly, the point discrete of a forming cutter contour bus is carried out according to an average criterion, a point vector formed by a discrete point and the normal vector of the discrete point is used to completely describe a space discrete point. The gyratory motion trajectory of the contour bus point vector is subjected to discrete, and the process of enveloping the spiral surface by the forming cutter is completely simulated with the envelop movement of the point vector. The method of point vector approximating the spiral surface is used, a plane point vector envelop rule and an envelope approximation method are established, a point with a shortest orientation-distance to the spiral surface in a point vector family is determined as an envelope point, and finally the spiral surface contour is formed by all envelope points by fitting.

Owner:CHONGQING UNIV

A Coating Method for Improving the Breakdown Voltage of Tantalum Capacitors

ActiveCN106548870BImprove breakdown voltageImprove reliabilityCapacitor electrodesTantalum capacitorEnvelope method

The invention provides an envelope method for improving breakdown voltages of a tantalum capacitor. The method comprises the following steps: immersing a tantalum fuse to be formed which is already subjected to thermal decomposition into deionized water with a temperature of 80 to 100DEG C for boiling washing; placing the tantalum fuse in a baking oven at a temperature of 125 to 150 DEG C for drying; immersing the tantalum fuse into an acid solution with a concentration of 0.001 to 0.01% in an electrolytic tank, and applying voltages to form the tantalum fuse; and placing the tantalum fuse after formation ends into the baking oven at the temperature of 125 to 150 DEG C for drying. Before the tantalum fuse is formed, the tantalum fuse is cleaned by use of a dipping alkaline solution method and a high-temperature boiling washing method, soluble Mn<2+> which is not thoroughly decomposed in the tantalum fuse is removed, and the breakdown voltages of the tantalum fuse are improved; and formation voltages are increased, MnO2 at a defect position generated due to thermal decomposition of a Ta2O5 medium membrane can be fully converted into Mn2O3 higher than resistance, leakage currents of a product are reduced, and the reliability of the capacitor is improved.

Owner:CHINA ZHENHUA GRP XINYUN ELECTRONICS COMP ANDDEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com