Design method of harmonic gear device

A technology of harmonic gear and design method, which is applied in hoisting devices, transmission devices, components with teeth, etc., can solve problems such as processing difficulties, and achieve the effects of convenient methods, good meshing performance, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

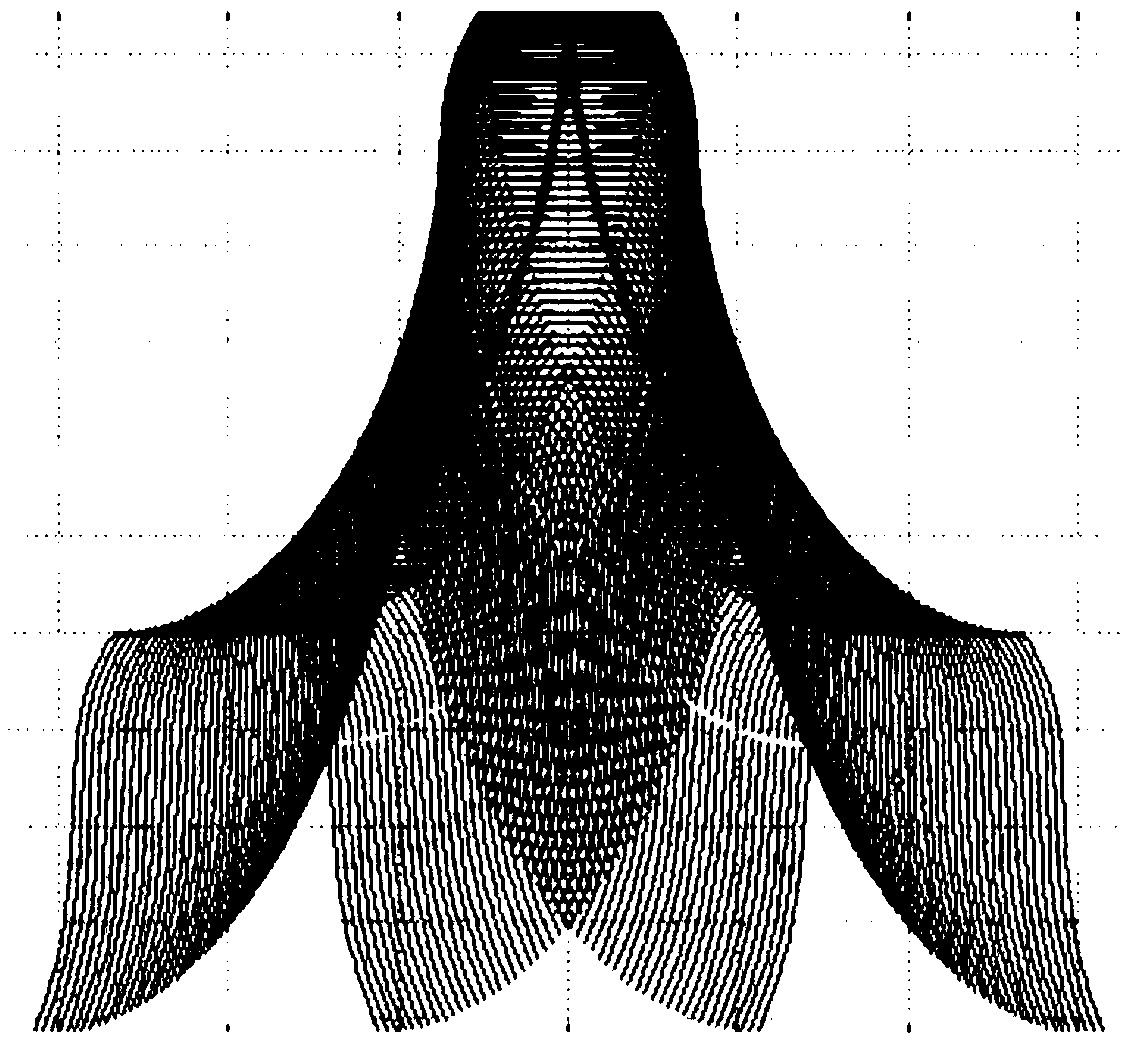

[0034] figure 1 is a simulation motion diagram of the flexible gear in the embodiment of the present invention.

[0035] Such as figure 1 As shown, the design method of a harmonic gear device in this embodiment is used to design and obtain a harmonic gear device that contains a rigid gear and a flexible gear, and the rigid gear and the flexible gear can realize spatial meshing, including the following steps:

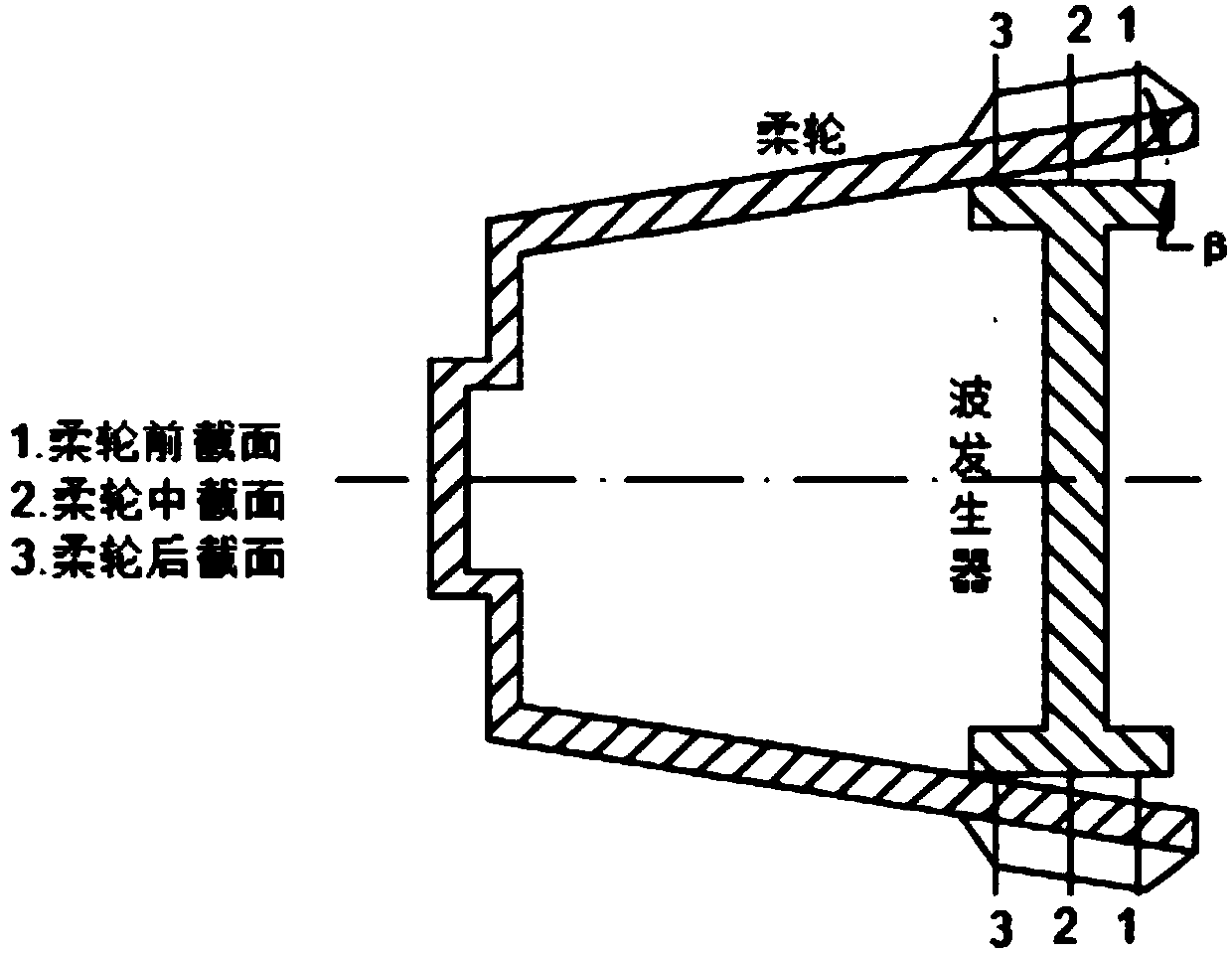

[0036] Step 1. In the direction perpendicular to the axis of the flexible gear, select the front, middle and rear sections of the flexible gear.

[0037] Step 2, obtain the motion trajectory of the flexible gear in the range of 0°-90° through MATLAB simulation, and obtain the discrete points of the tooth profile of each section of the rigid gear through the envelope method based on the simulated motion trajectory.

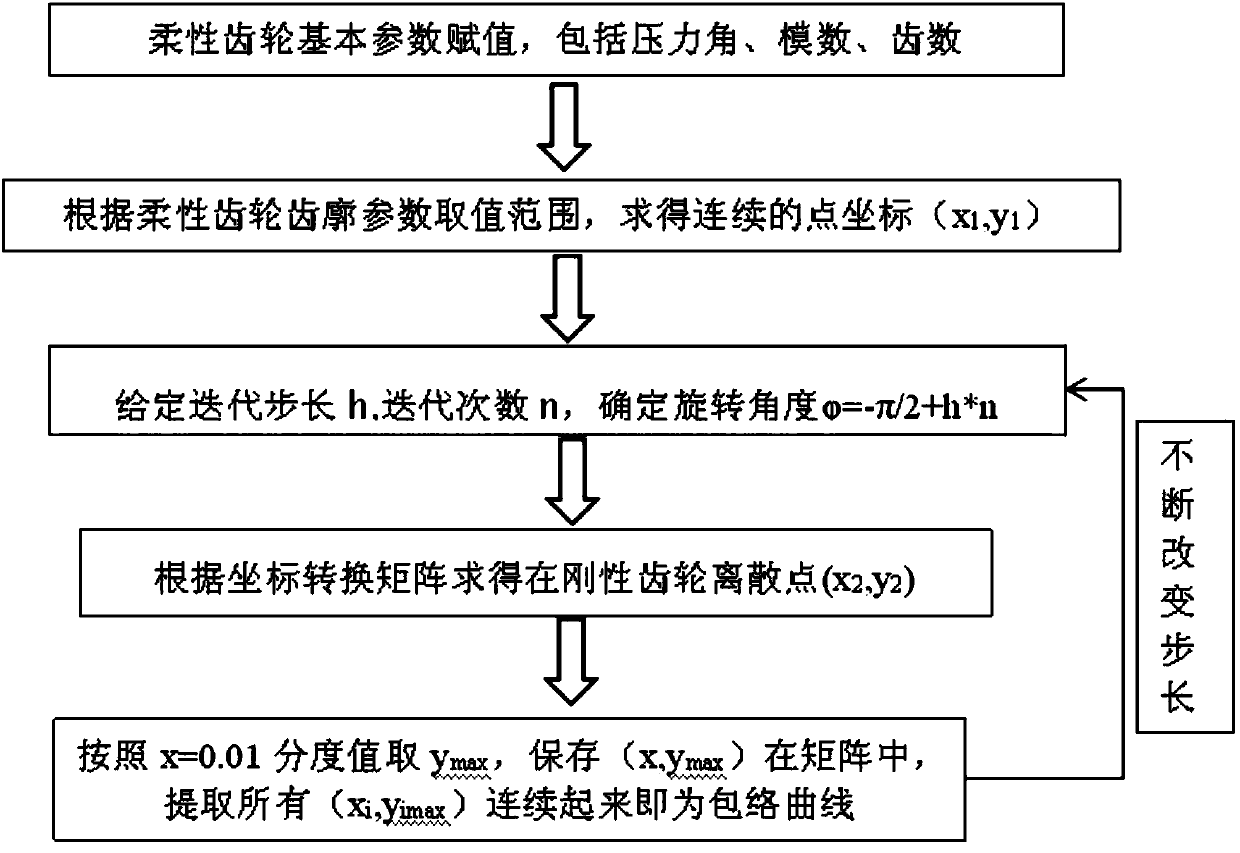

[0038] figure 2 is a schematic flow chart of the envelope method in the embodiment of the present invention.

[0039] Such as figure 2 As shown, the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com