Center distance-regulating mechanism for steel plate-forming machine

A technology of adjusting mechanism and forming machine, applied in the direction of metal rolling mill stand, metal rolling stand, metal rolling, etc., can solve the problems of unsatisfactory equipment use effect, high production cost and inconvenience, etc. The effect of low procurement and production maintenance costs, beautiful and compact appearance, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

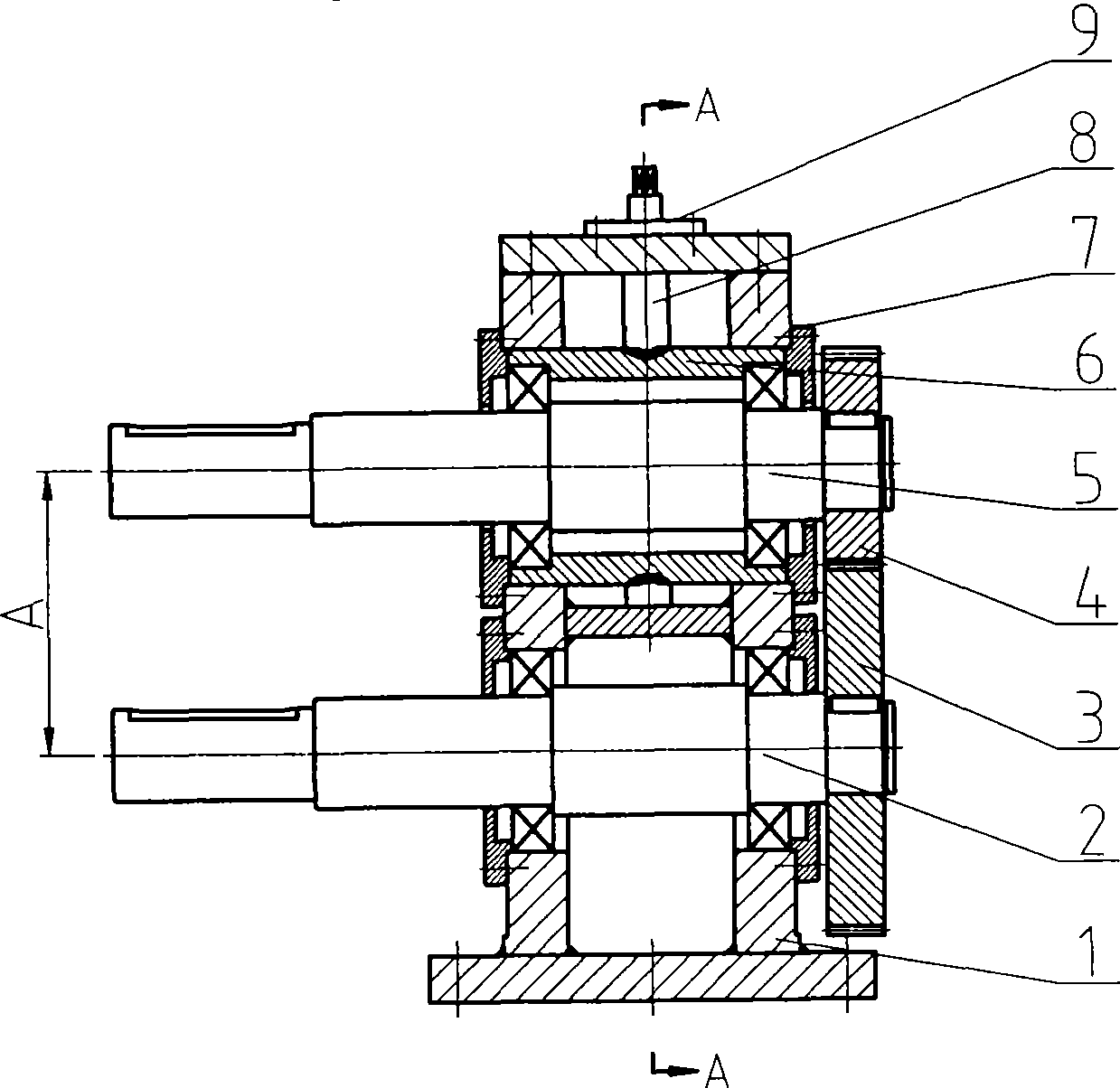

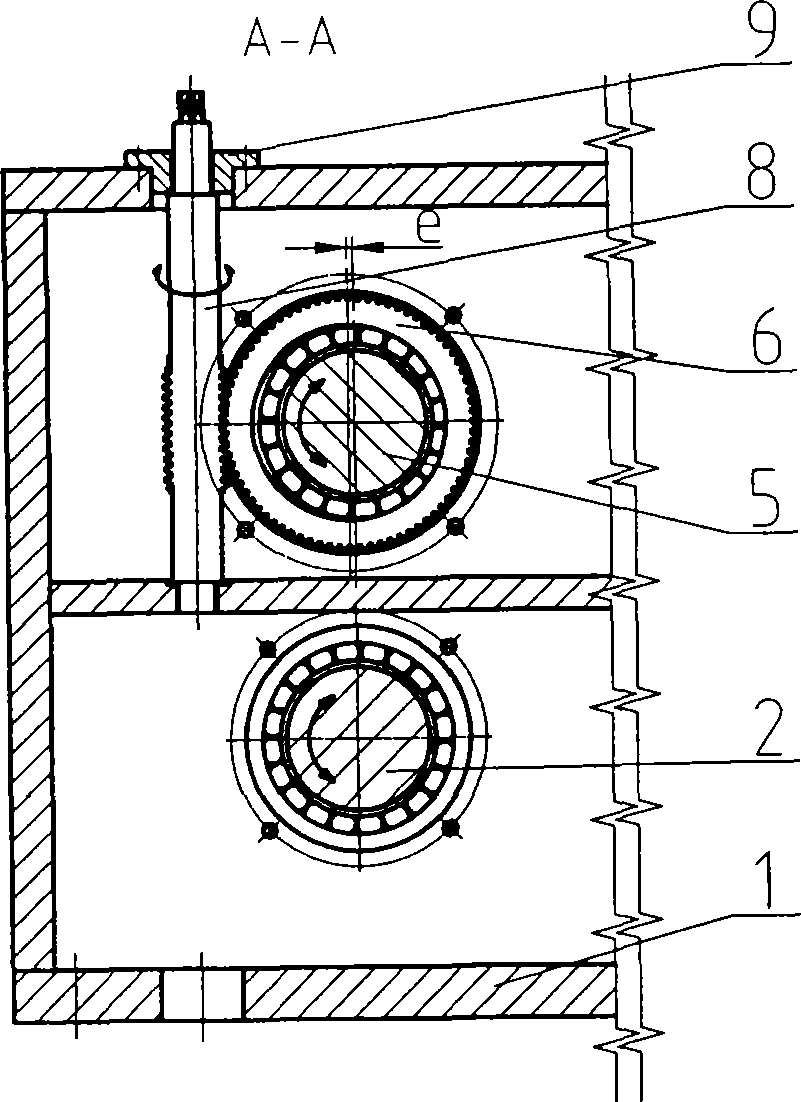

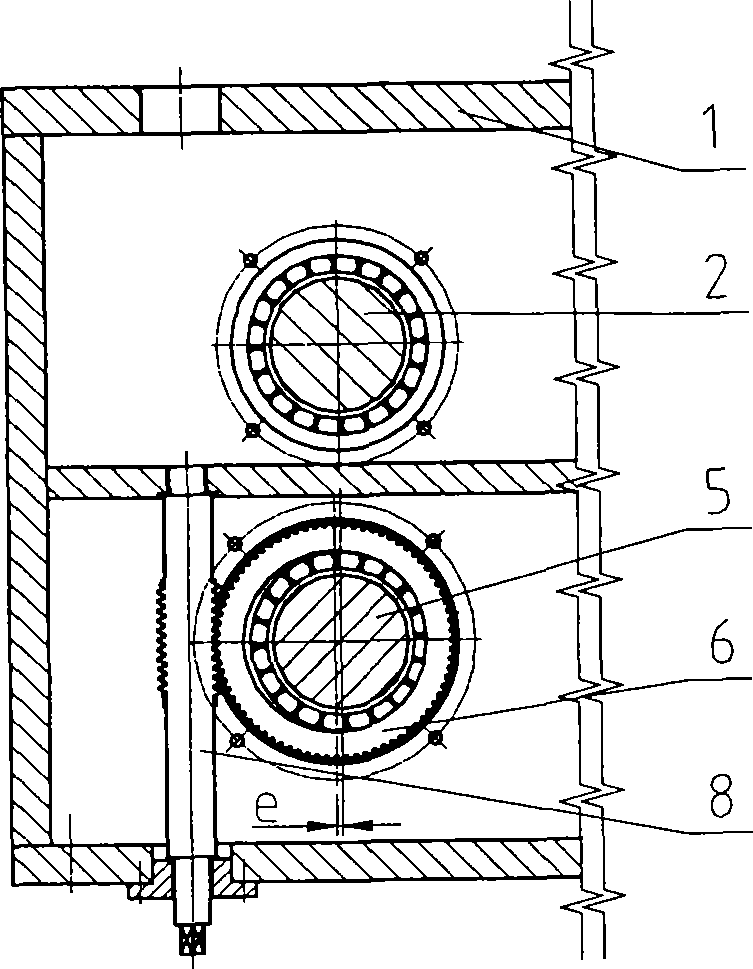

[0021] The present invention mainly consists of a frame 1, a fixed shaft 2 with a lower gear 3 on the frame 1, and an adjustment shaft 5 with an upper gear 4, an eccentric sleeve 6 sleeved on the adjustment shaft 5, and placed on the frame 1. The adjusting rod 8 with the adjusting mechanism 9 connected with the eccentric sleeve 6 is composed of end caps 7 placed at the axial ends of the eccentric sleeve 6; the bearing housing holes at the two ends of the eccentric sleeve 6 are coaxial and exist 1~1 with the outer circle of the eccentric sleeve 6 10mm eccentricity.

[0022] The specific implementation of the present invention is as follows:

[0023] As attached figure 1 with 2 As shown, when the plate thickness increases, the gap between the upper and lower shafts needs to be increased. When adjusting, the adjusting rod 8 moves upward to make the eccentric sleeve 6 rotate counterclockwise. Due to the eccentricity e, the adjusting shaft 5 moves upward, The distance A between the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com