A Coating Method for Improving the Breakdown Voltage of Tantalum Capacitors

A breakdown voltage, tantalum capacitor technology, applied in the direction of capacitor electrodes, capacitor parts, etc., can solve problems such as impossibility to reach 100%, unsatisfactory complementary forming effect, affecting capacitor leakage current and reliability, etc., to achieve easy control, The effect of increasing the complementary forming voltage and improving the breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

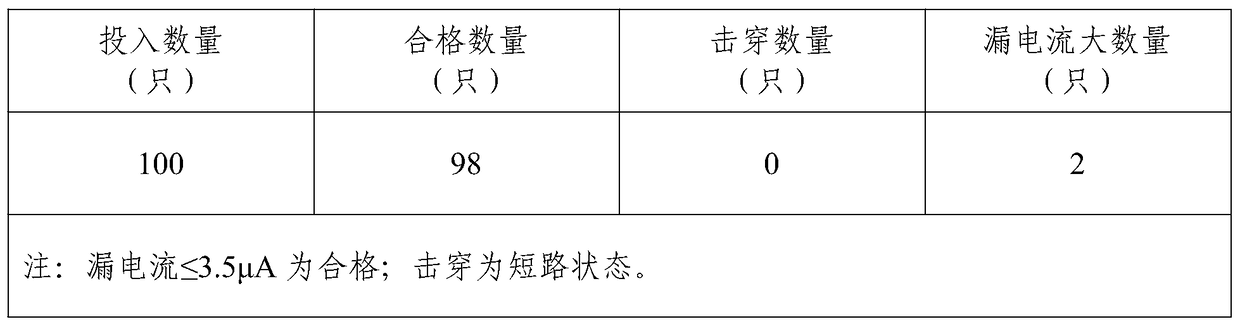

Embodiment 1

[0023] A coating method for improving the breakdown voltage of tantalum capacitors, taking the CAK45 chip tantalum capacitor 75V4.7μF designed with 3500μF·V / g specific volume tantalum powder as an example, it includes the following steps:

[0024] (1) Take the tantalum core that has been thermally decomposed and ready to be repaired, and immerse it in a sodium hydroxide solution with a concentration of 5% for 20 minutes, and the tantalum block is immersed in such a depth that it is completely submerged under the liquid surface;

[0025] (2) Immerse the tantalum core impregnated with sodium hydroxide solution in deionized water at a temperature of 80-100°C for 40 minutes, and perform high-temperature cleaning on the tantalum core. The immersion depth of the tantalum block is completely submerged under the water surface;

[0026] (3) Put the tantalum core in an oven at 125°C for 15 minutes;

[0027] (4) Immerse the tantalum core in the nitric acid aqueous solution with a concent...

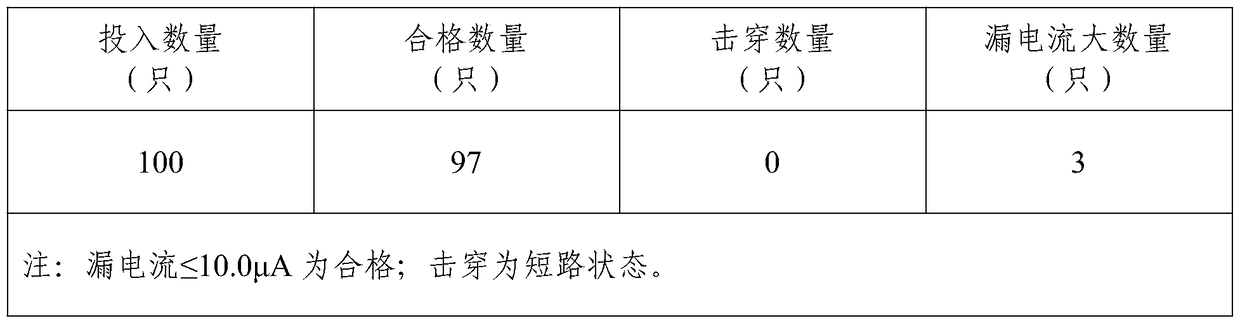

Embodiment 2

[0031] A coating method for improving the breakdown voltage of tantalum capacitors, taking the CAK45 chip tantalum capacitor 100V10μF designed with 2500μF·V / g specific volume tantalum powder as an example, it includes the following steps:

[0032] (1) Take the tantalum core that has been thermally decomposed and is to be repaired, and immerse it in an ammonia solution with a concentration of 20% for 10 minutes, and the tantalum block is immersed in such a depth that it is completely submerged under the liquid surface;

[0033] (2) Immerse the tantalum core impregnated with the ammonia solution in deionized water at a temperature of 80-100°C for 90 minutes, and perform high-temperature cleaning on the tantalum core. The immersion depth of the tantalum block is completely submerged under the water surface;

[0034] (3) Put the tantalum core in an oven at 150°C for 10 minutes;

[0035] (4) Immerse the tantalum core in the acetic acid aqueous solution with a concentration of 0.05‰...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com