Patents

Literature

45results about How to "Reduce cutting area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

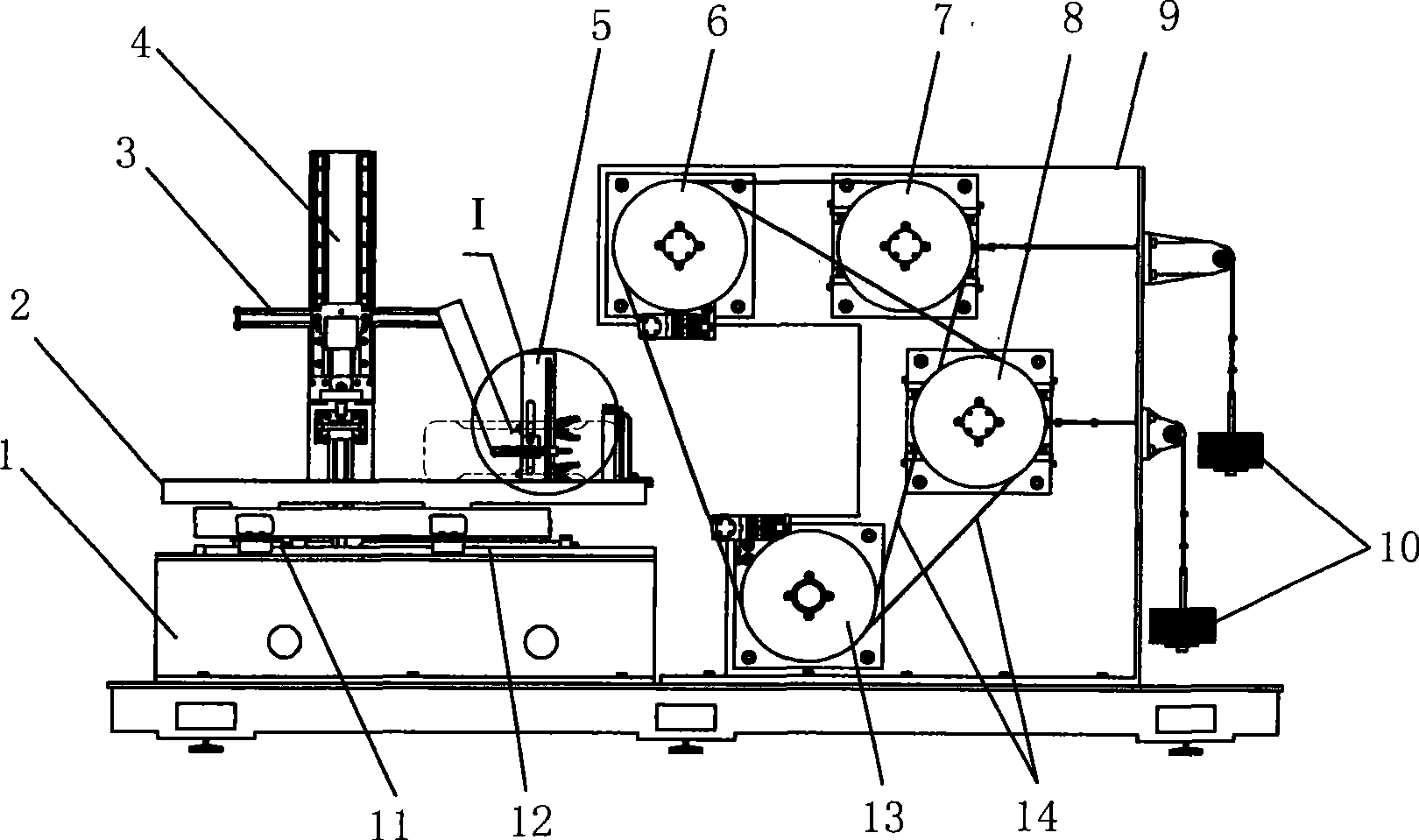

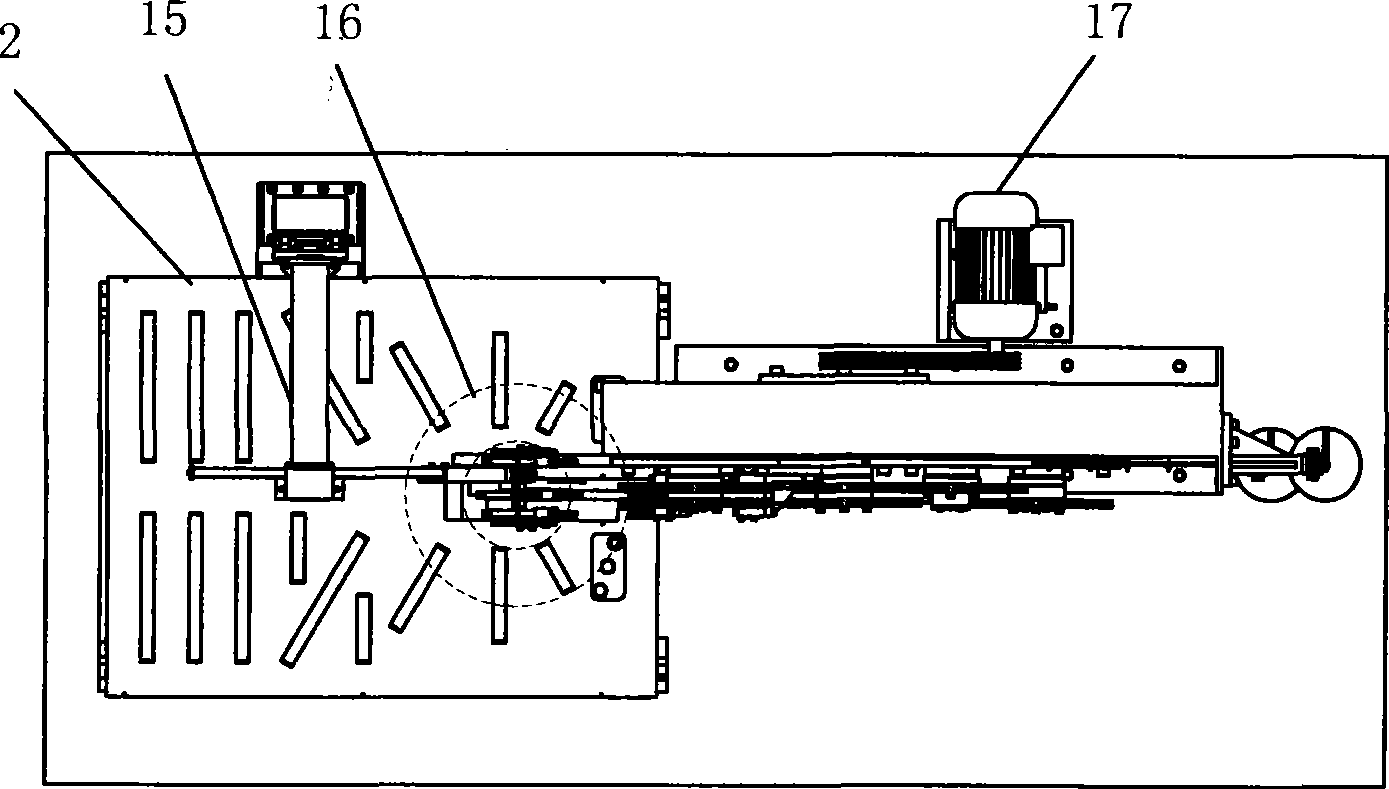

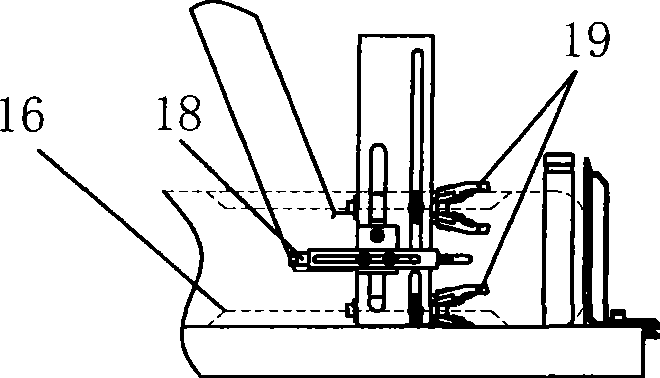

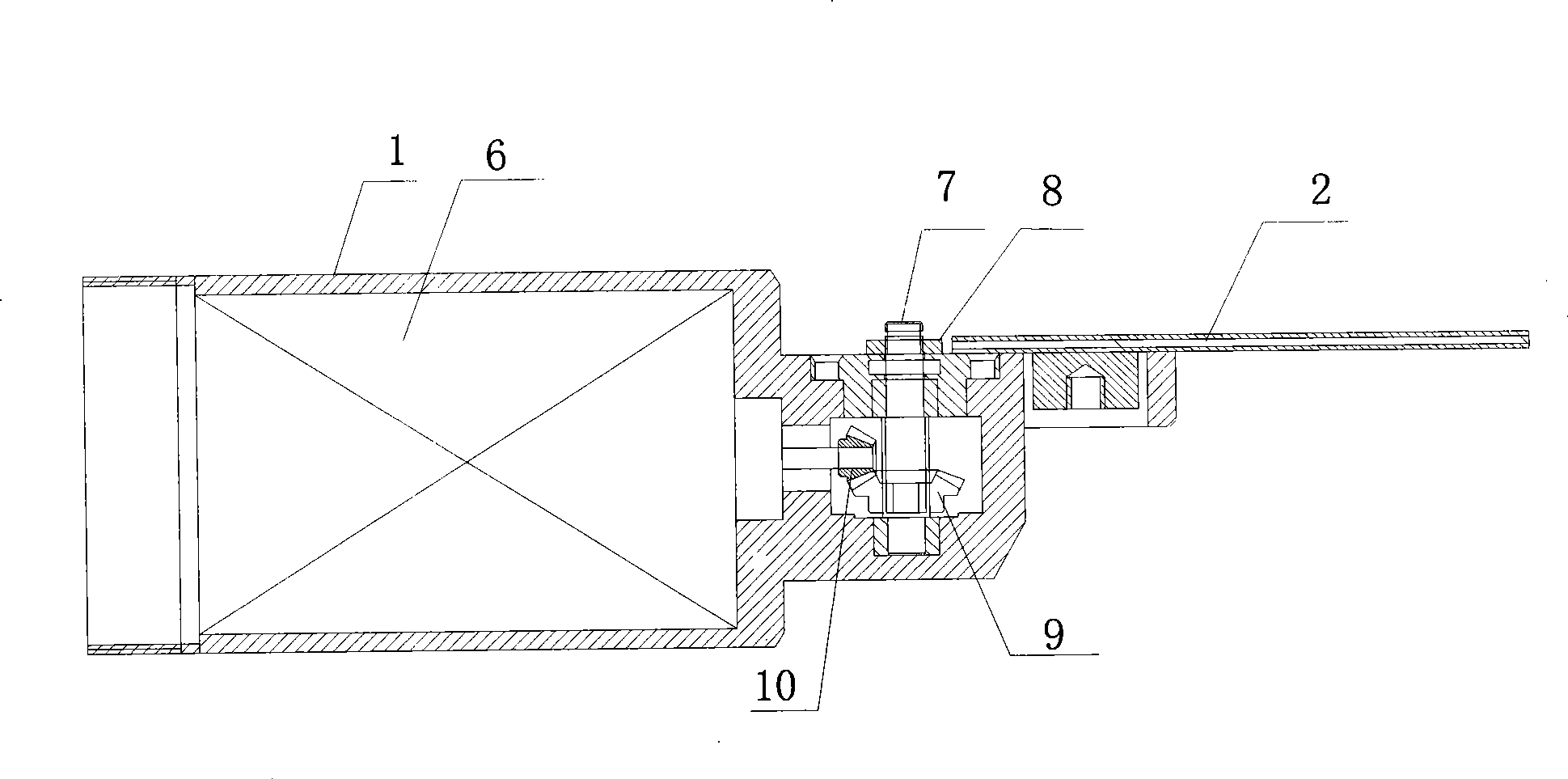

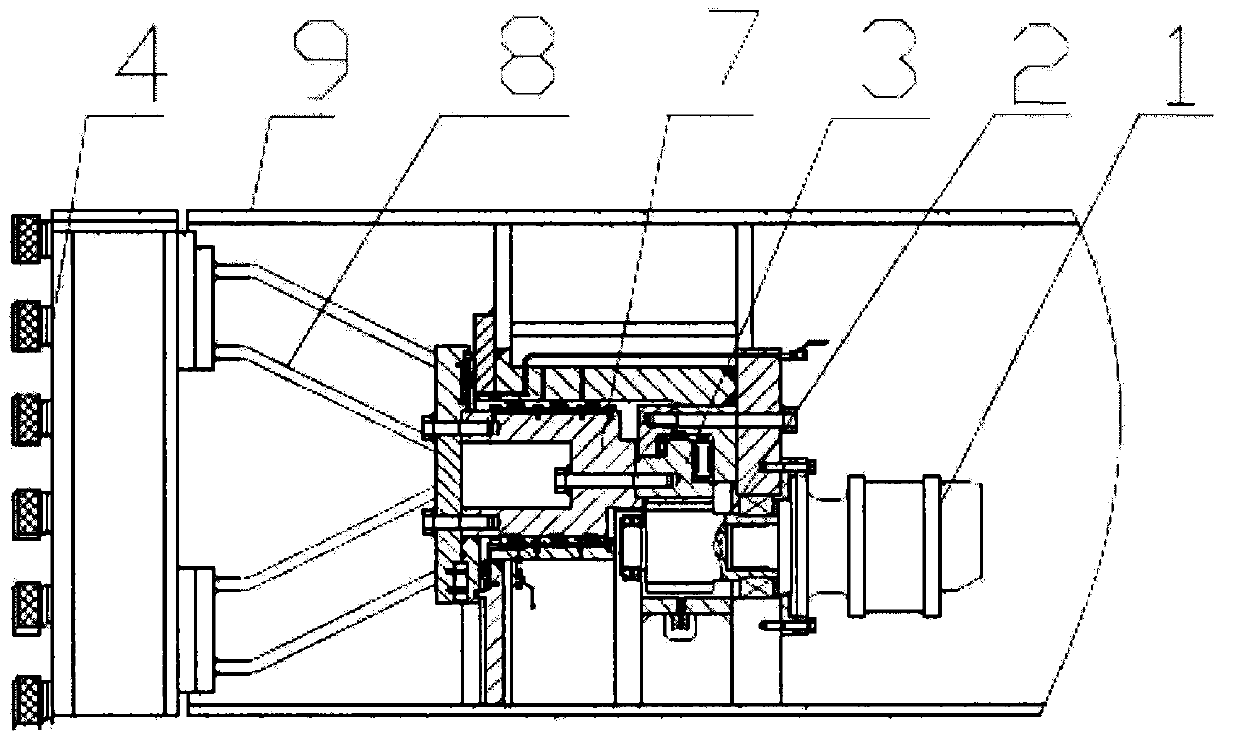

Cutting wire production method and cutting wire and tyre cutting device

ActiveCN101417478AExtended service lifeNot easy to peel offMetal working apparatusStone-like material working toolsDrive wheelEngineering

The invention provides a method for manufacturing a cutting wire and the cutting wire, and the method is characterized by taking a steel wire rope as the substrate and consolidating the abrasive material on the steel wire rope substrate by using metal binder or resinoid bond in electroplating manner. The abrasive material is normal or super hard abrasive material of different grain sizes. The processing technology of the cutting wire is reasonable, and the manufactured cutting wire has wide cutting range, good cutting quality and little pollution. The invention also provides a tire cutting device, comprising a lathe bed, a sliding working table which is provided with a fixture, an annular cutting device, driving wheels, driven wheels, a strainer for the annular cutting device and a cutting motor. The device is characterized in that the annular cutting device is an annular cutting wire which takes the steel wire rope as the substrate and consolidates the abrasive material on the surface. The driving wheels and the driven wheels have two sets and drive the two cutting wires to rotate synchronously, thus forming the double-cut cutting. The device has the advantages of high cutting efficiency, good cutting quality and little pollution.

Owner:青岛厚泽锦业技术有限公司

Cutting method for chip scale package glass

ActiveCN103302753AImprove cutting effectExtended service lifeFine working devicesChip-scale packageBlack films

The invention discloses a cutting method used for chip scale package glass with a black film attached to the back face. The cutting method comprises the following steps of: fixing a first tool and a second tool on the same feed unit by taking safe distance as an interval; positioning the first tool and the second tool in an initial cutting position by the feed unit; cutting apart the surface of a chip scale package glass workpiece to form a first shear mark by the first tool in a preset feed direction, wherein the depth of the first shear mark is less than the thickness of the chip scale package glass; enabling the second tool to follow the first tool in the feed direction which is the same as that of the first tool to cut off the chip scale package glass workpiece and the black film after the feed distance of the first tool exceeds the safety distance between the first tool and the second tool on the basis of the first shear mark by a second shear mark which the is less than the first shear mark in width, and stopping in a blue film; and continuously feeding the first tool and the second tool, and repeating the cutting steps. According to the method, the edge breakage problem brought by a traditional cutting method used for the chip scale package glass is reduced, and the black film is prevented from falling off and remaining on the blue film.

Owner:SHENZHEN STS MICROELECTRONICS CO LTD

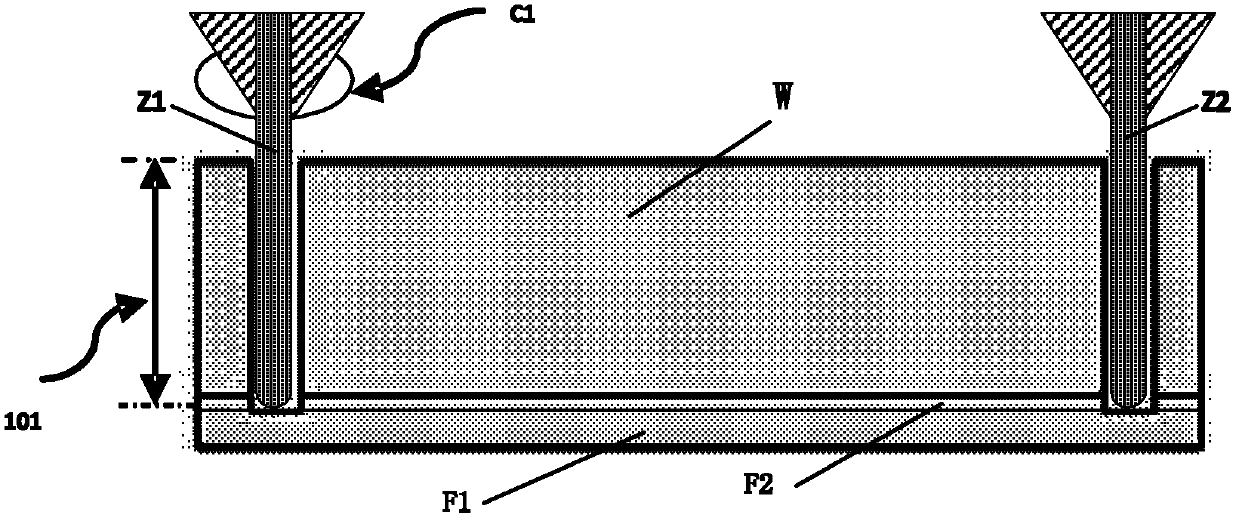

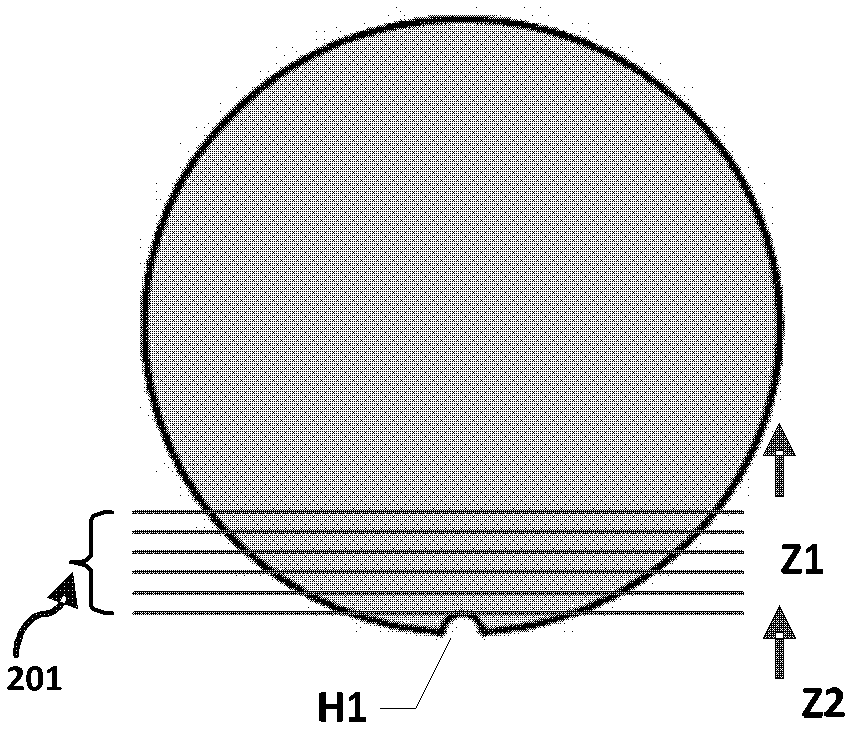

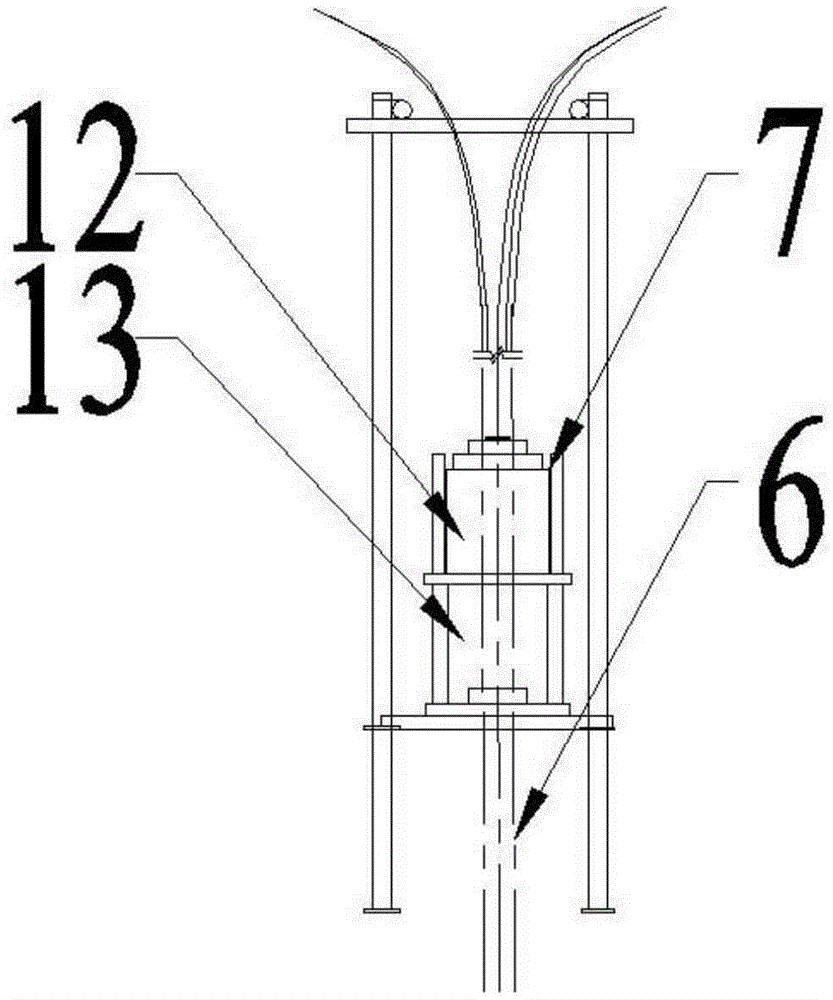

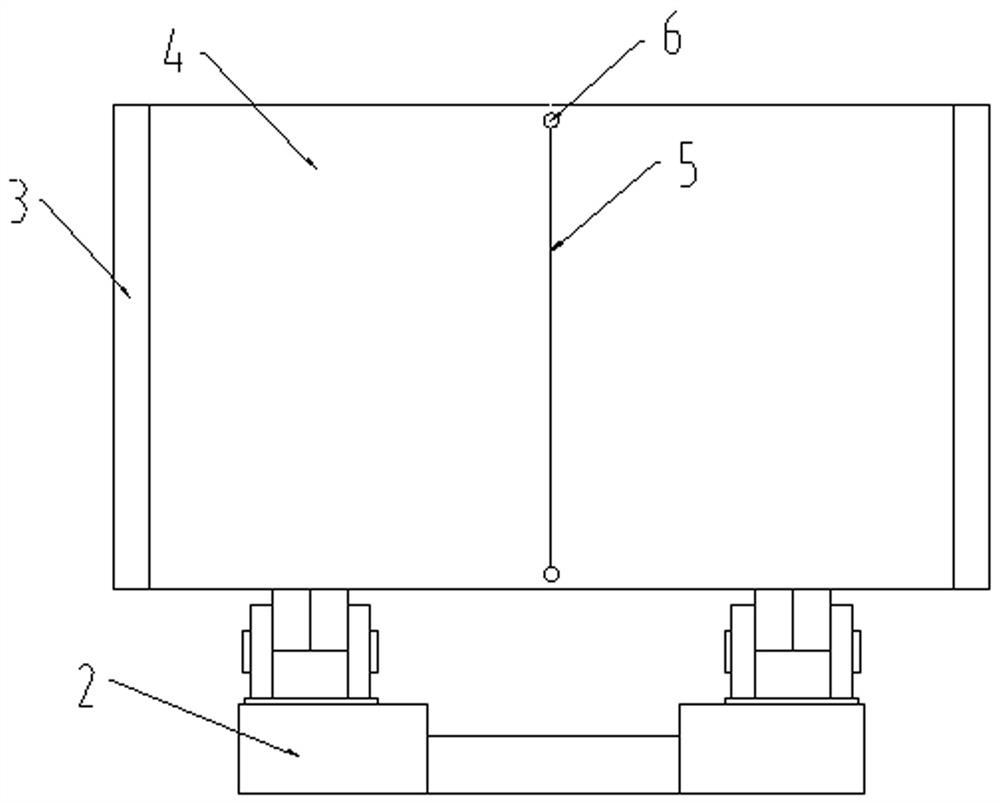

Integral lowering and removing system of span box girders based on bridge deck support and construction method of integral lowering and removing system

ActiveCN104652298AReduce cutting areaReduce demolition costsBuilding repairsBridge strengtheningBridge deckOperability

The invention relates to the technical field of bridge removing engineering, and particularly relates to an integral lowering and removing system of span box girders based on bridge deck support and a construction method of the integral lowering and removing system. The system comprises piers which are used for lowering the two ends of a box girder, and two sets of cantilever reaction systems which are symmetrically arranged on the two ends of the lowered box girder. Each cantilever reaction system comprises two main outriggers and a hoisting cable. The ends of the two main outriggers are anchored on the corresponding pier, and the other ends are spaced by a certain distance; the hoisting cable is slidingly connected to the end parts of the main outriggers, one end of the hoisting cable is connected with a lowering power system, and the other end of the hoisting cable is connected with a hoisting device which is used for hoisting the lowered box girder. The lowering power system is installed on the main outriggers. According to the integral lowering and removing system, the box girders are lifted and lowered through continuous jacks of which hoisting capacities are large, so that the cutting area of concrete is greatly reduced, and removing cost is effectively reduced; the invention has the characteristics such as good safety, controllability, operability and application prospect, and is not only suitable for removing the straight girder bridges, but also suitable for removing the curved bridges.

Owner:CCCC ROAD & BRIDGE SPECIAL ENG

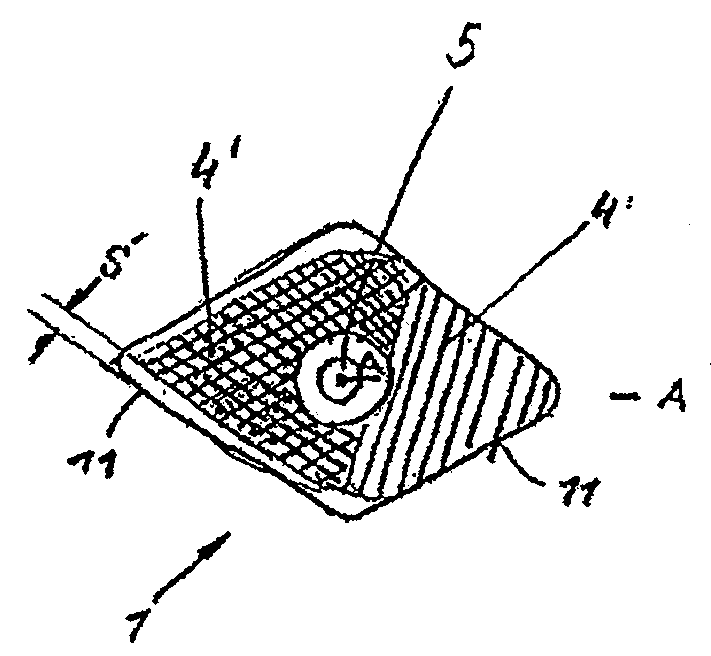

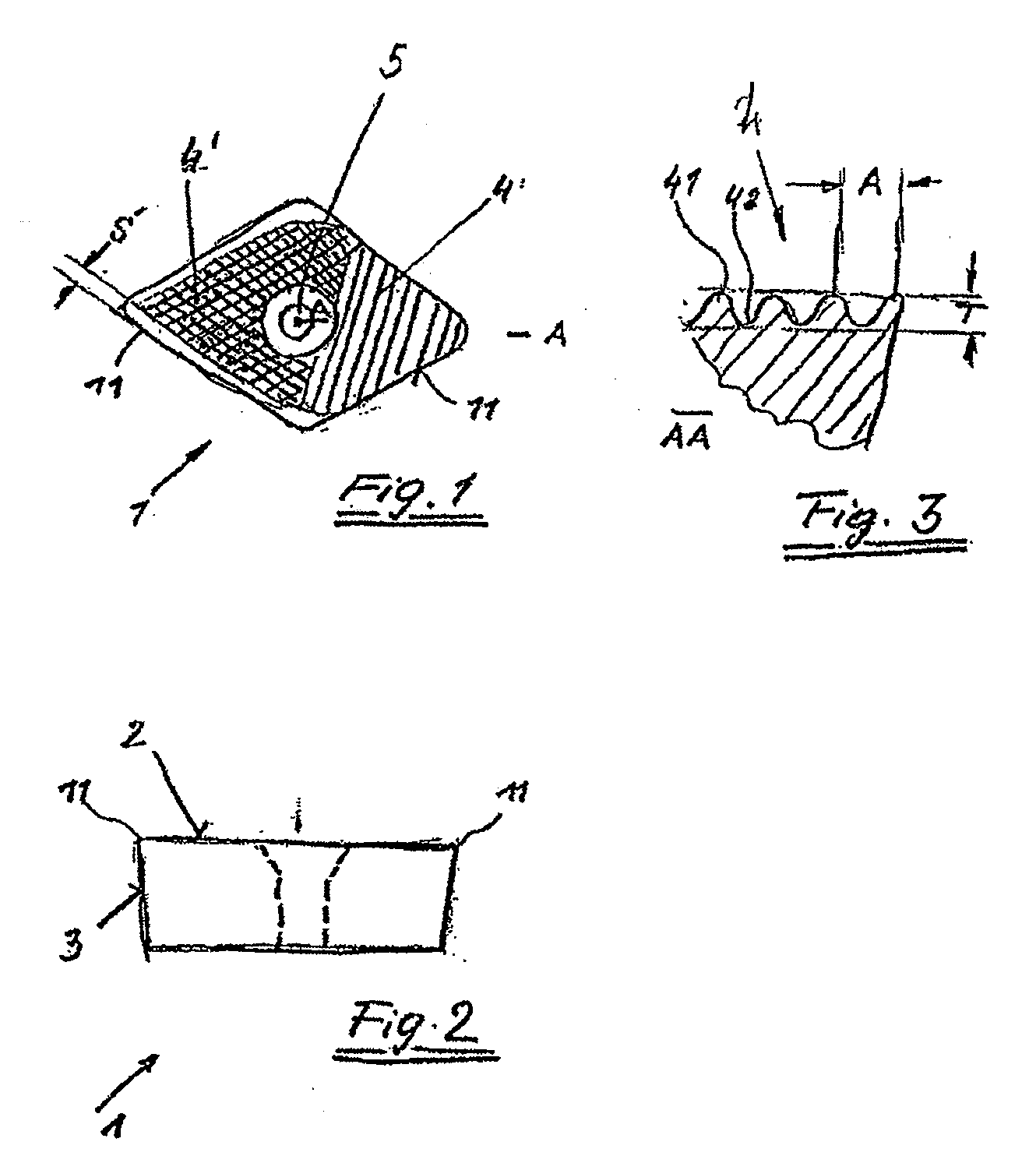

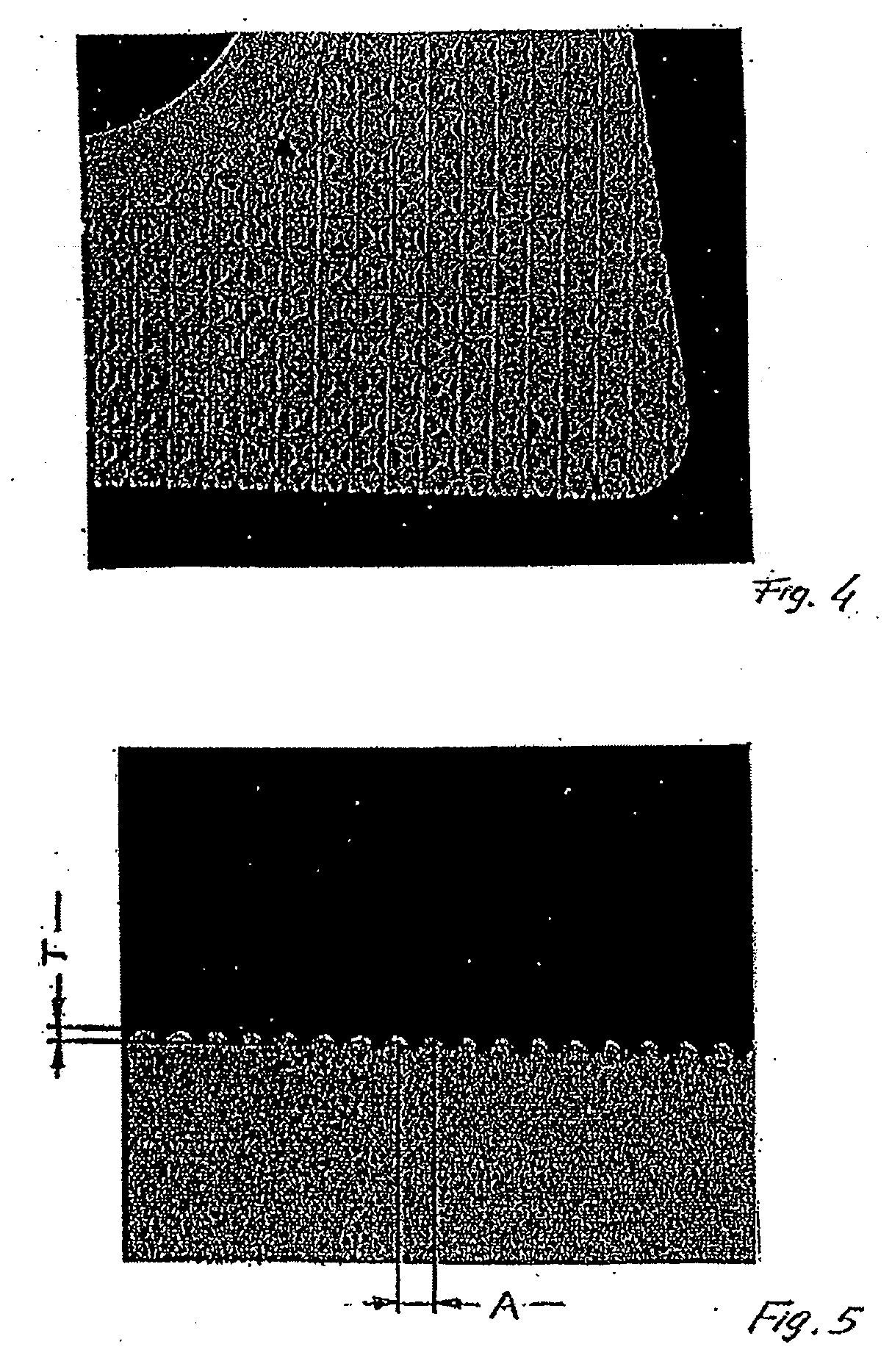

Cutting Insert Provided With Structured Surfaces

InactiveUS20080031698A1Quality improvementAdvantageousCutting insertsTurning toolsBiomedical engineering

Cutting insert for tools for cutting workpieces or objects, including at least one cutting edge, at least one lateral surface, and at least one cutting face comprising a fine structure having convex and concave areas. Additionally, the convex and concave areas, have a depth T and are respectively spaced apart from one another by a spacing A greater than 0.1 mm and less than 1.0 mm.

Owner:BOEHLERIT GMBH & CO KG

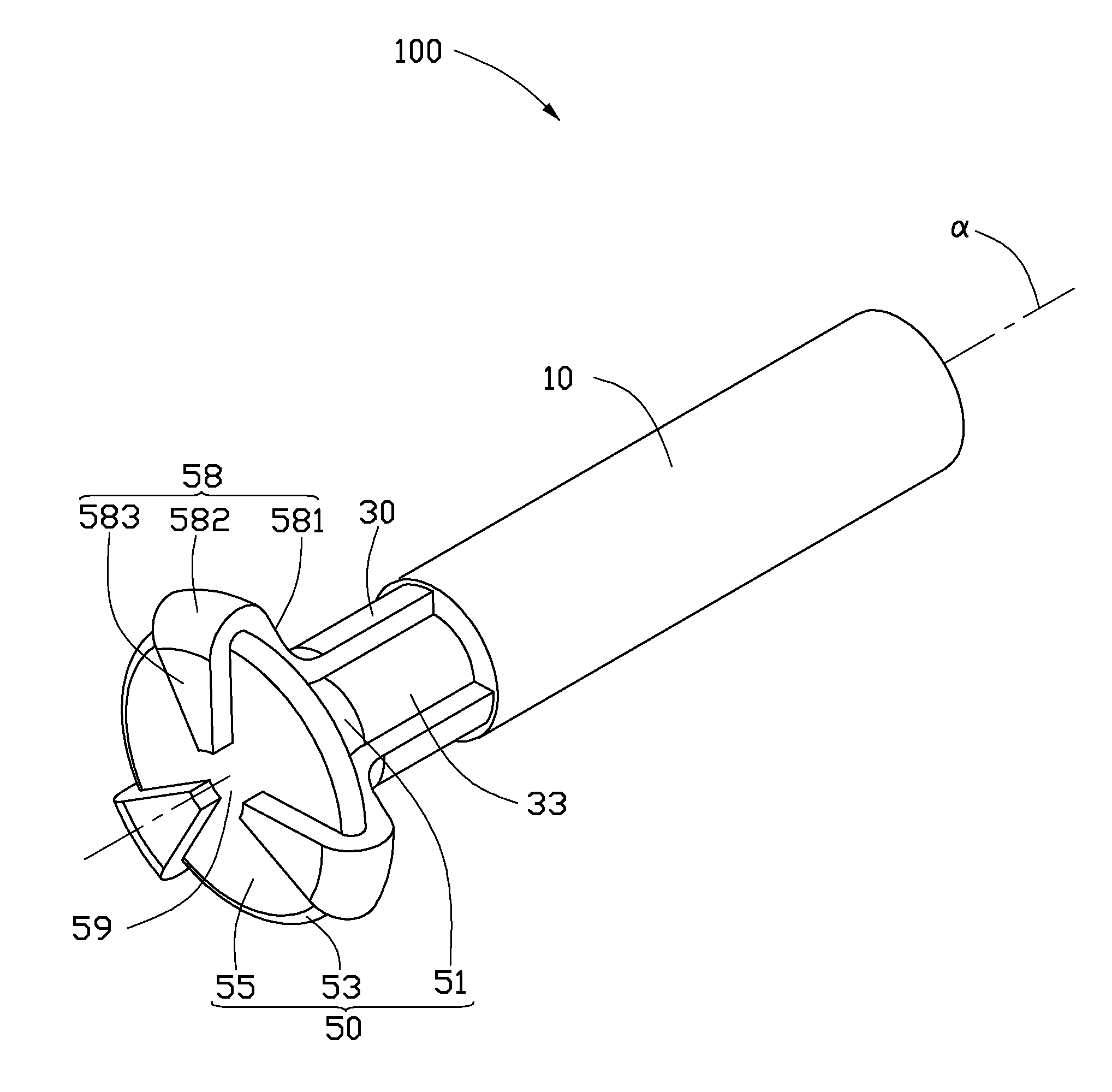

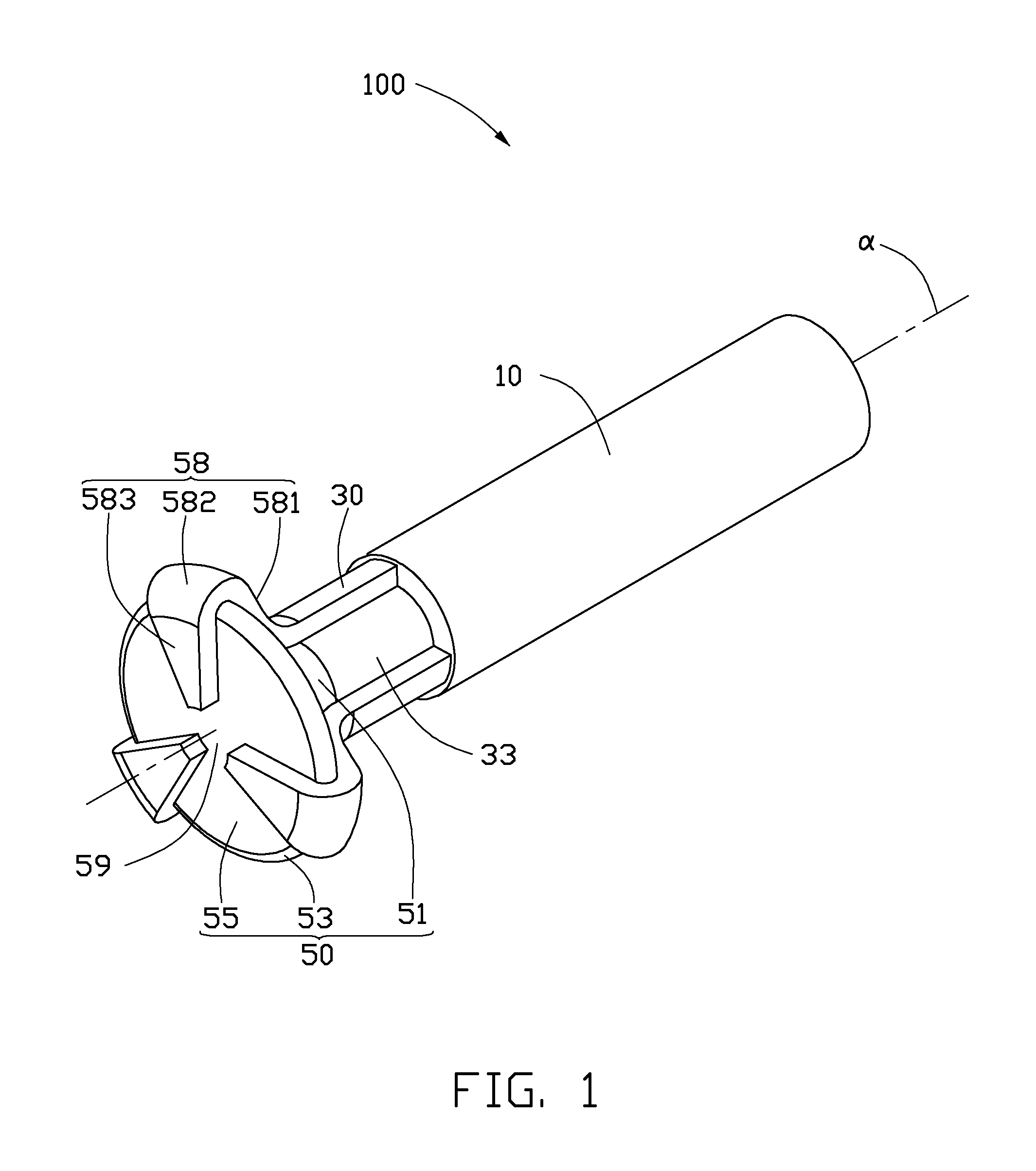

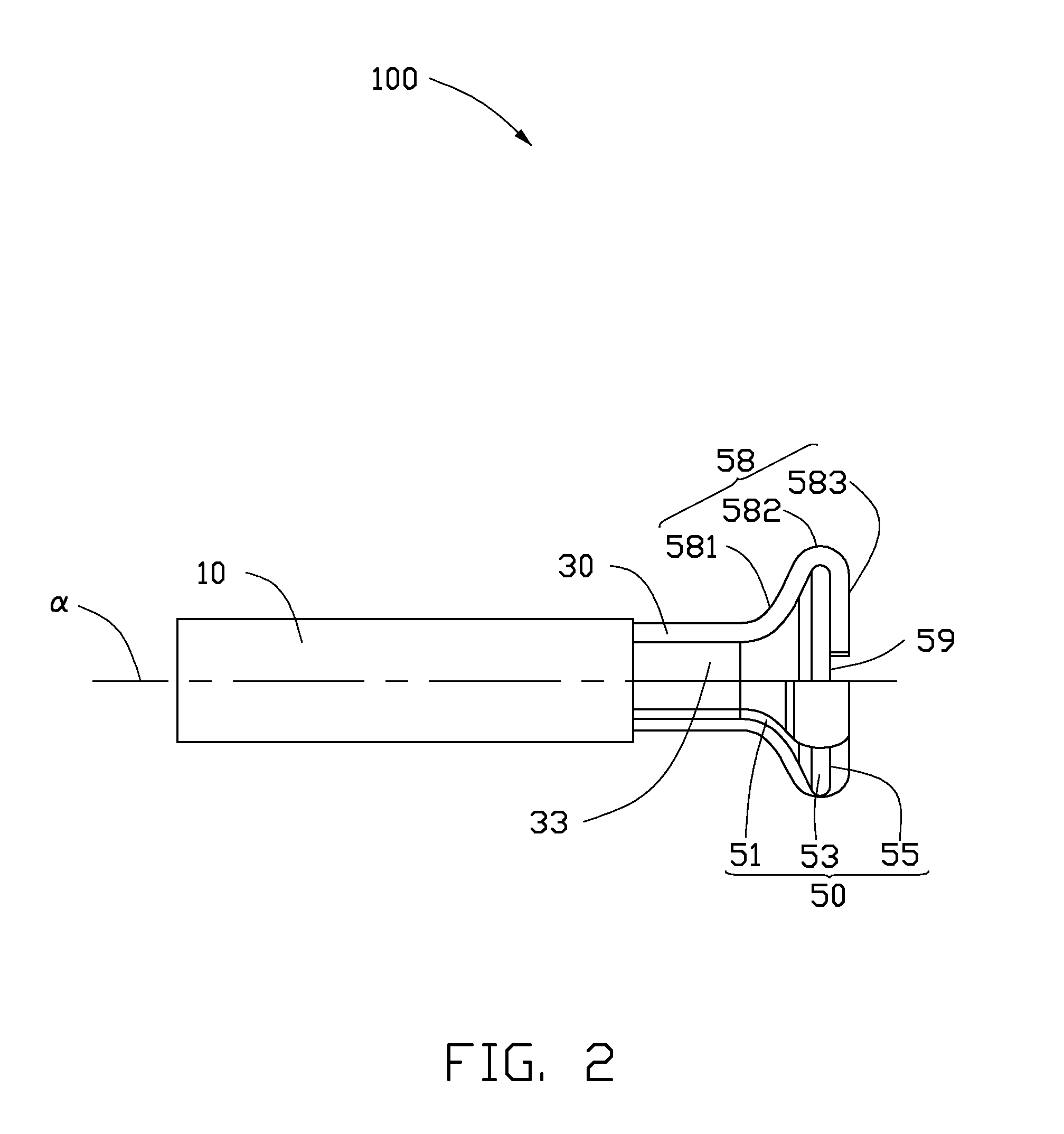

Milling cutter

InactiveUS20120282043A1Precise processingReduce cutting areaMilling cuttersShaping cuttersEngineeringMilling cutter

A cutter comprises a cutter handle, a cutter neck and a cutter head. The cutter neck interconnects the cutter handle and the cutter head. The cutter head comprises a connecting side surface adjoining the cutter neck, an outer annular surface, a distal end surface opposite to the connecting side surface and away from the cutter neck, and at least one cutting edge formed on the outer annular surface extending from the junction of the connecting side surface and the cutter neck toward the distal end surface, and at least one cutting trough formed on the cutter head adjacent to the at least one cutting edge extending from the junction of the connecting side surface and the cutter neck toward the distal end surface.

Owner:FU TAI HUA IND SHENZHEN +1

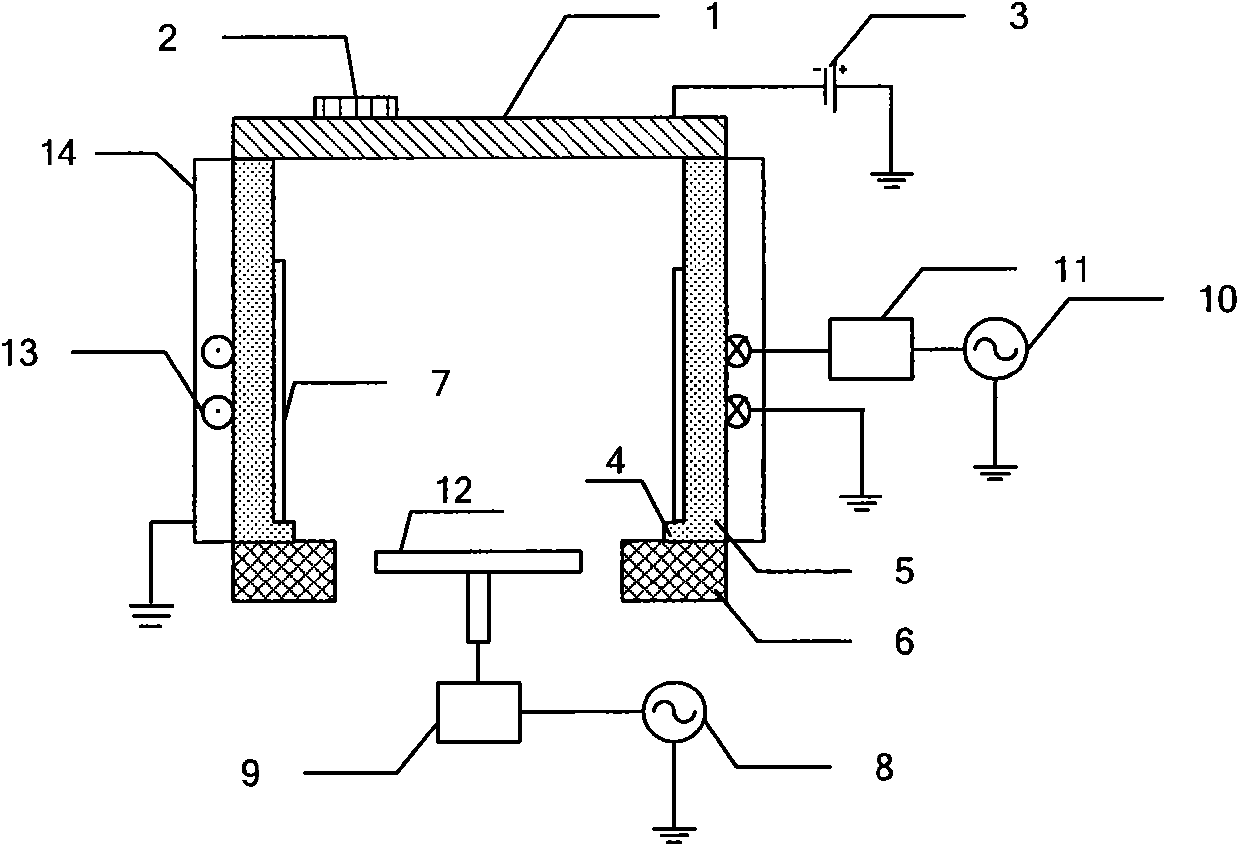

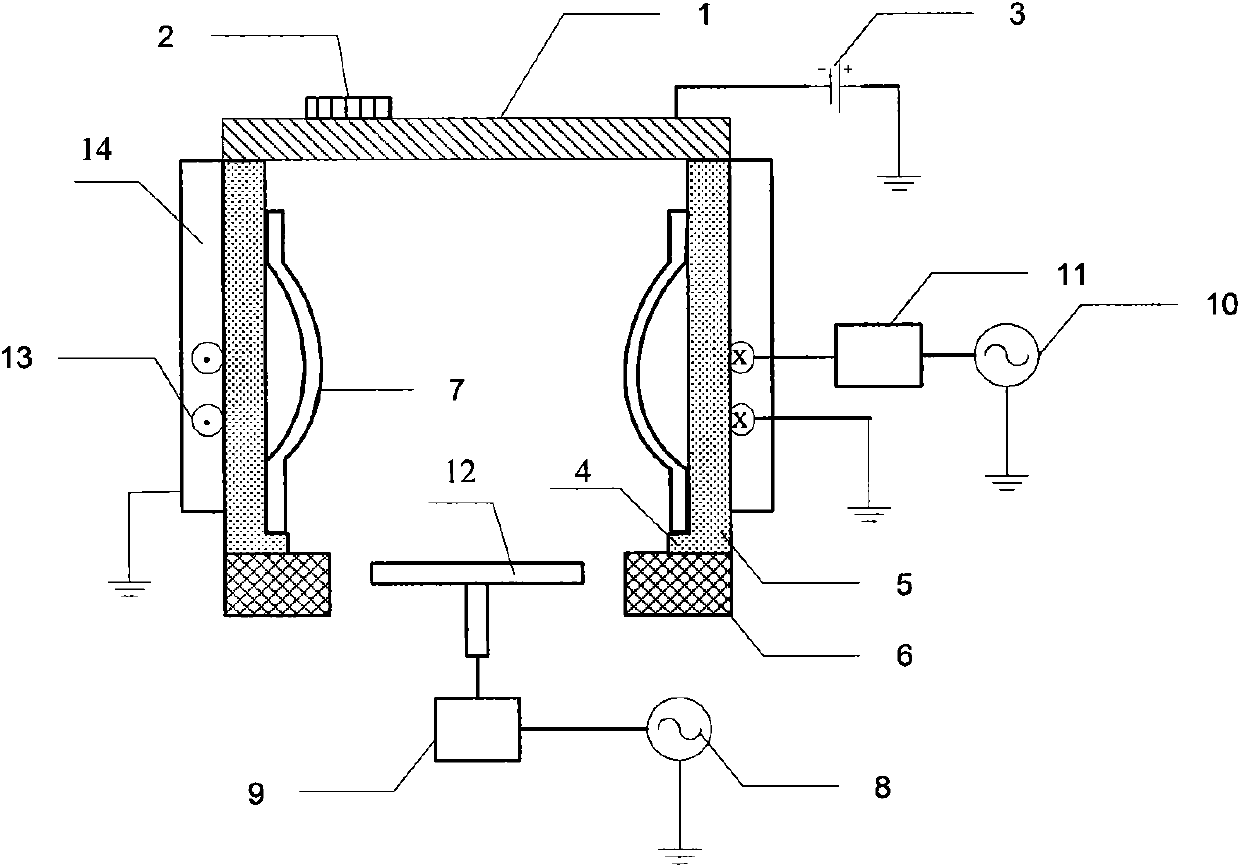

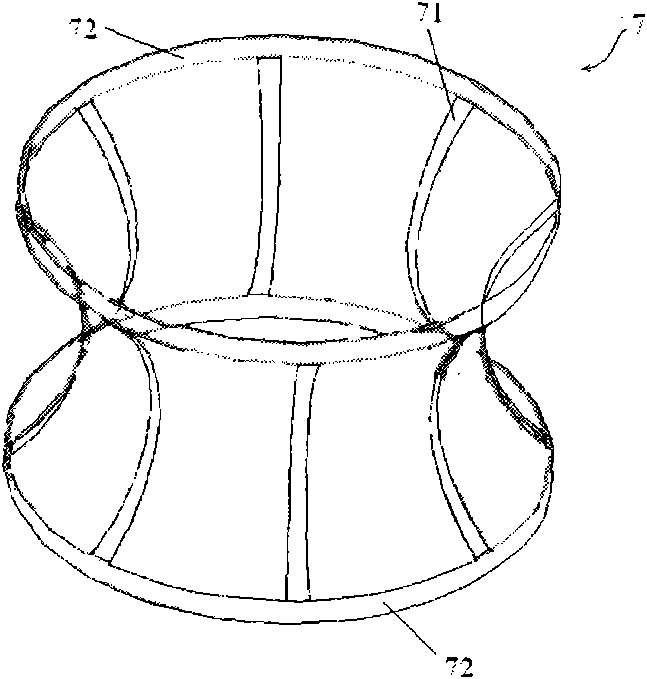

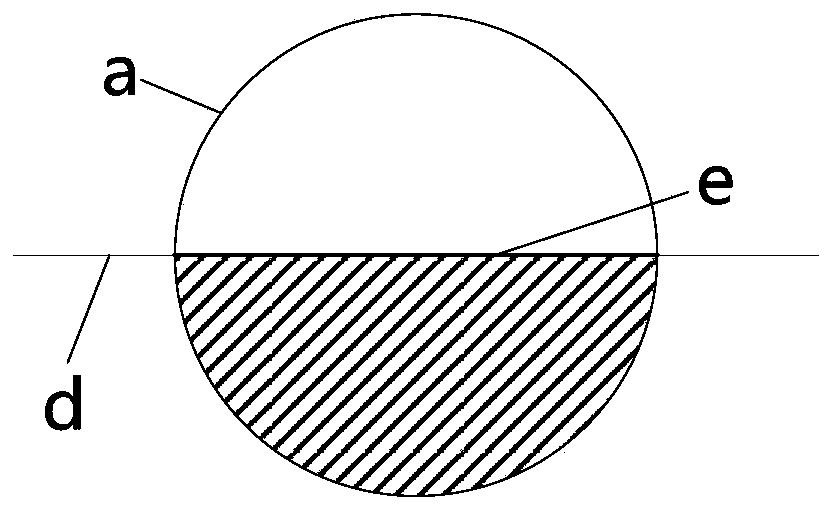

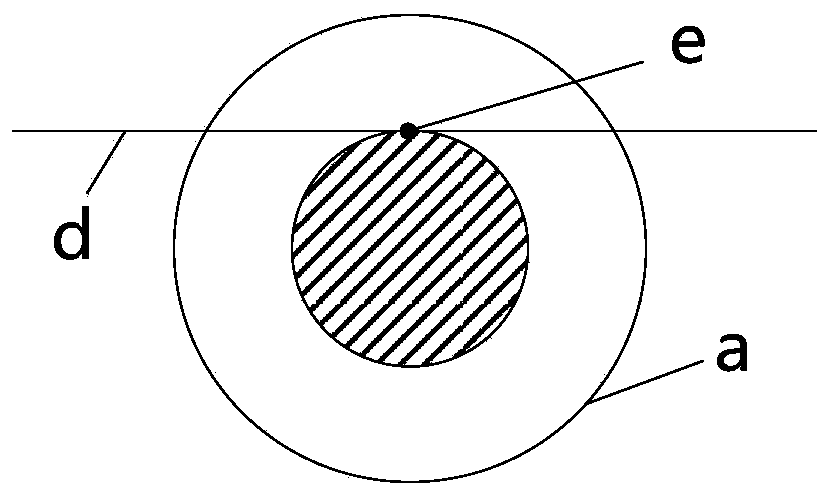

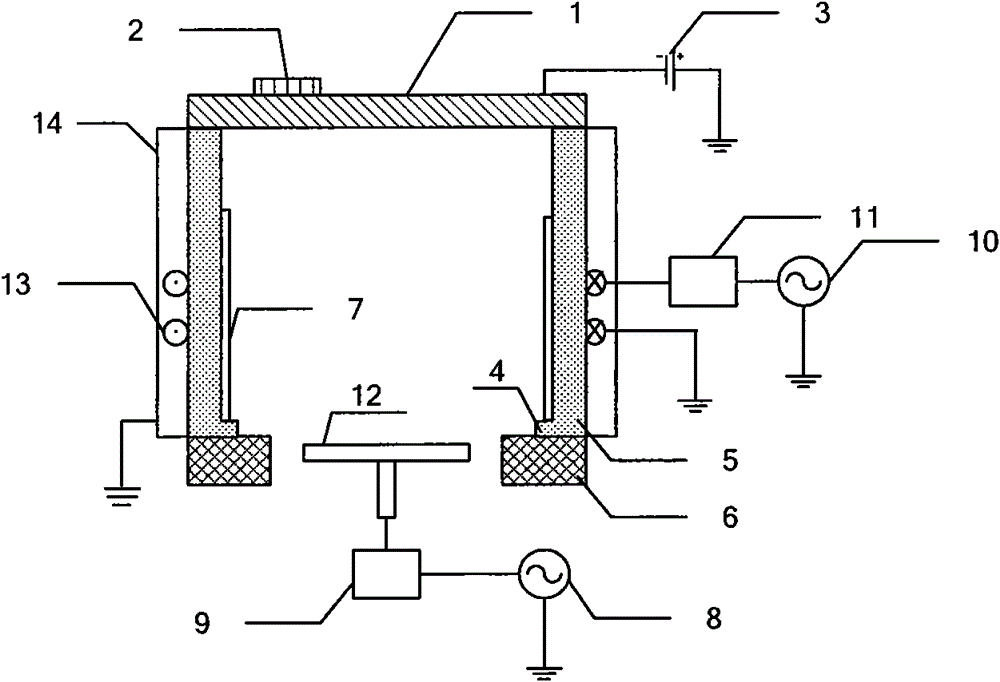

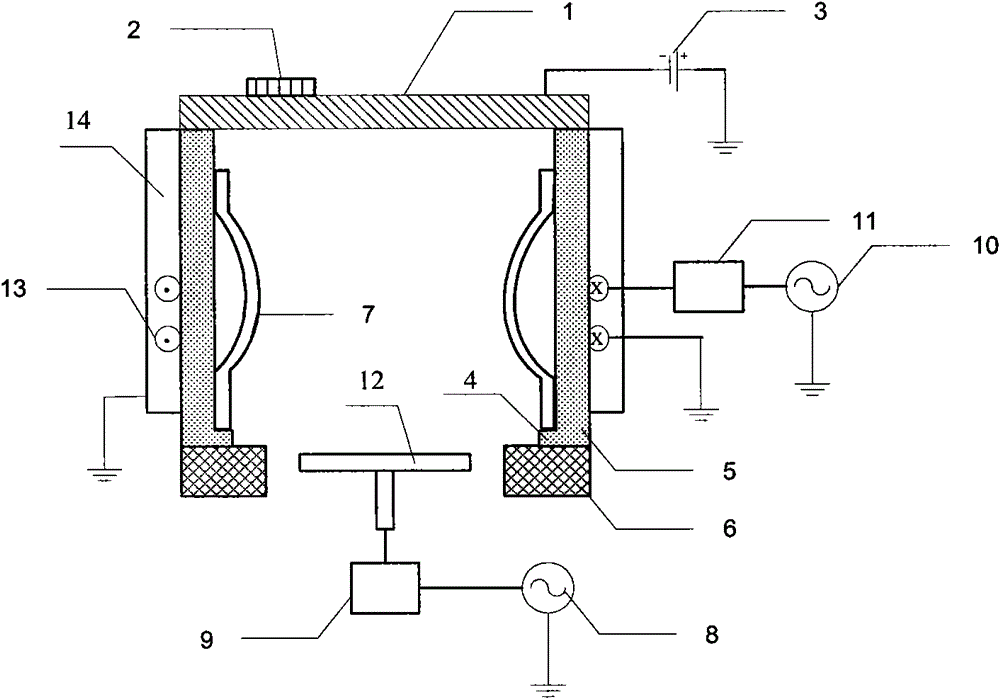

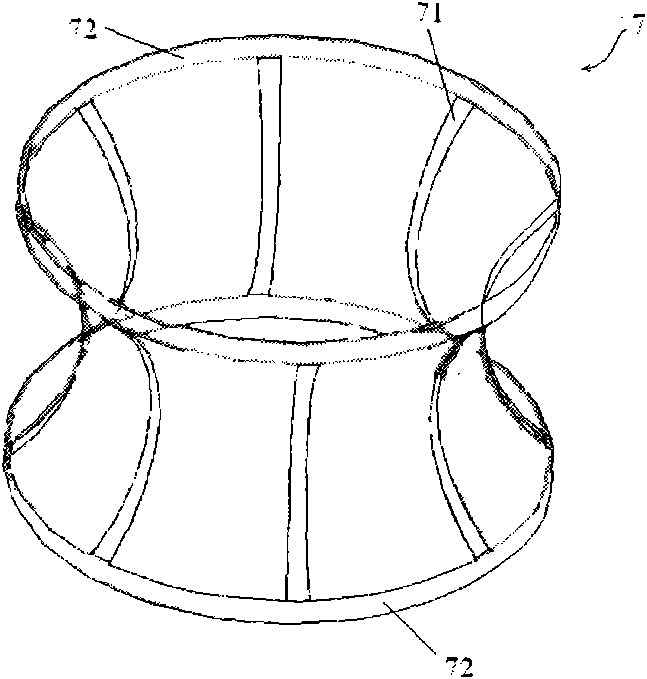

Shielding apparatus, processing method and device, semiconductor device

ActiveCN102573429ASolve high temperatureReduce eddy currentElectric discharge tubesMagnetic/electric field screeningEngineeringSemiconductor

The invention provides a shielding apparatus, a processing method and a device, and a semiconductor device. The shielding apparatus comprises a shell, the shell is provided with a plurality of through holes, and a sidewall curve of the shell is parallel to a magnetic line of force in a magnetic field where the shell is located. The technical scheme of the invention can reduce the cutting area of the magnetic field and the shielding apparatus, thereby reducing the vortex in the shielding apparatus, and reducing, even eliminating the conversion from magnetic field energy to heat, so that the loss of the magnetic field energy can be reduced, and the problem of higher temperature of the shielding apparatus also can be solved completely.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

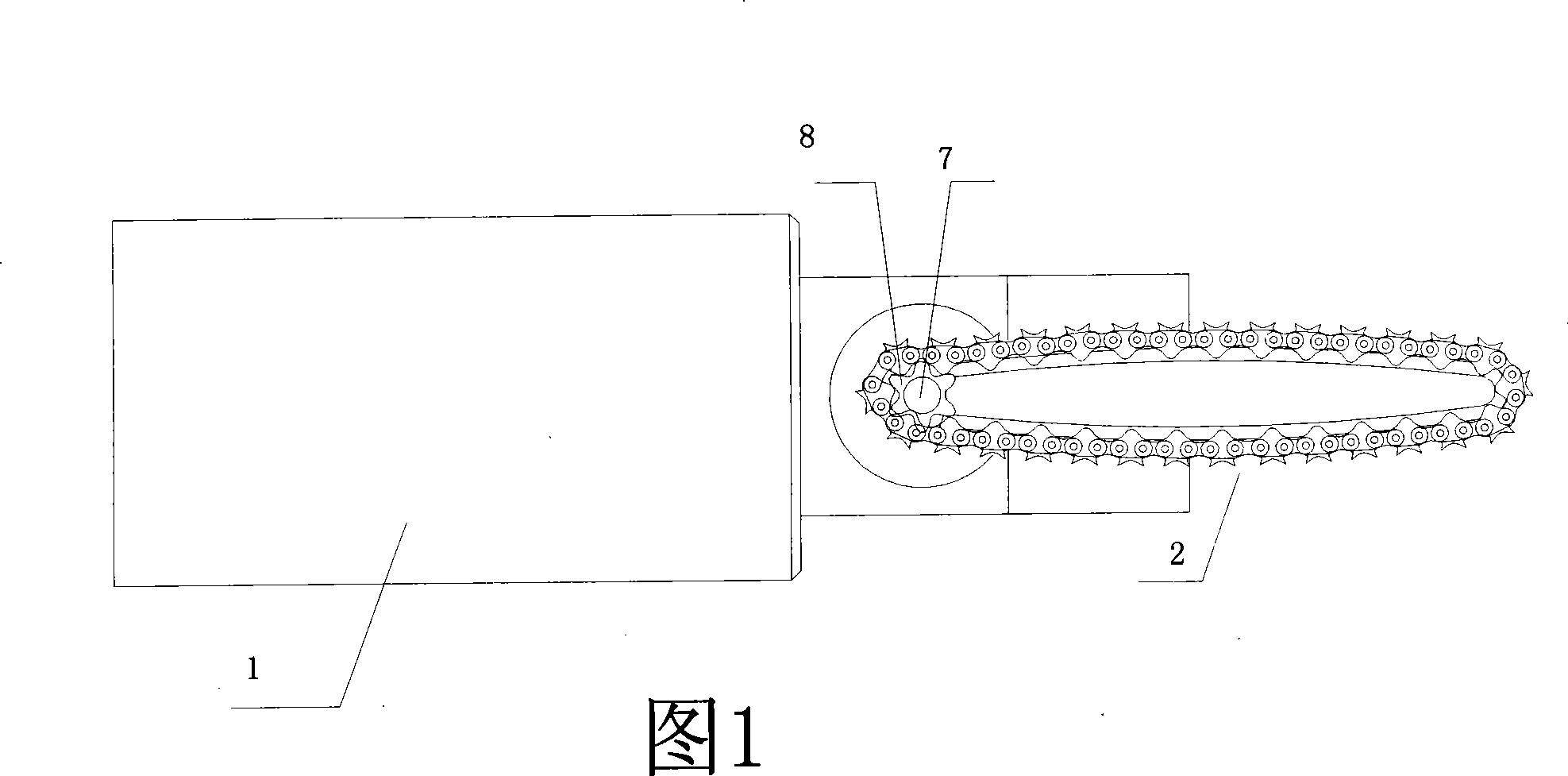

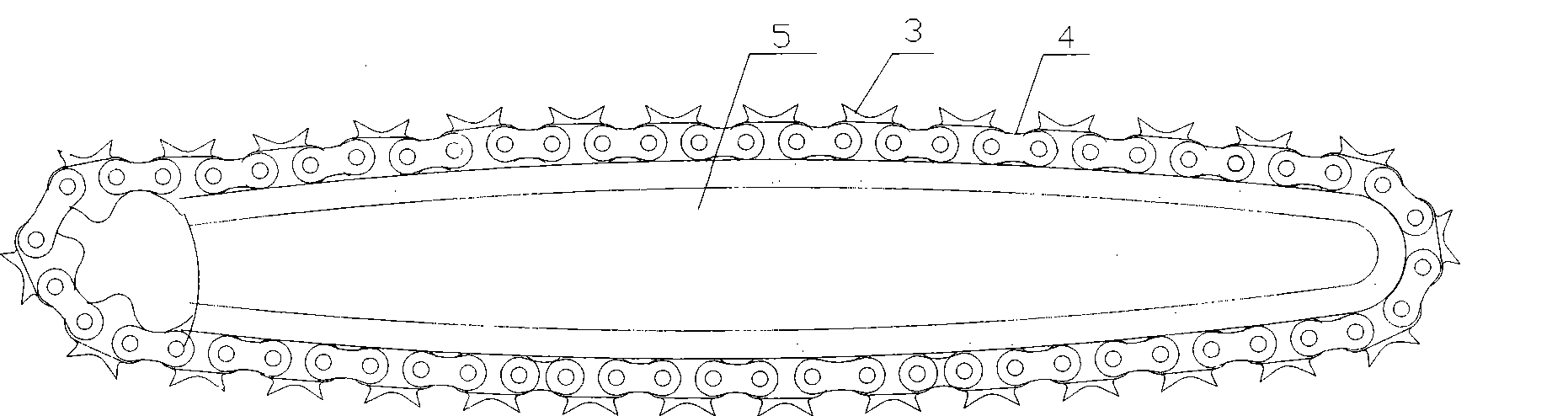

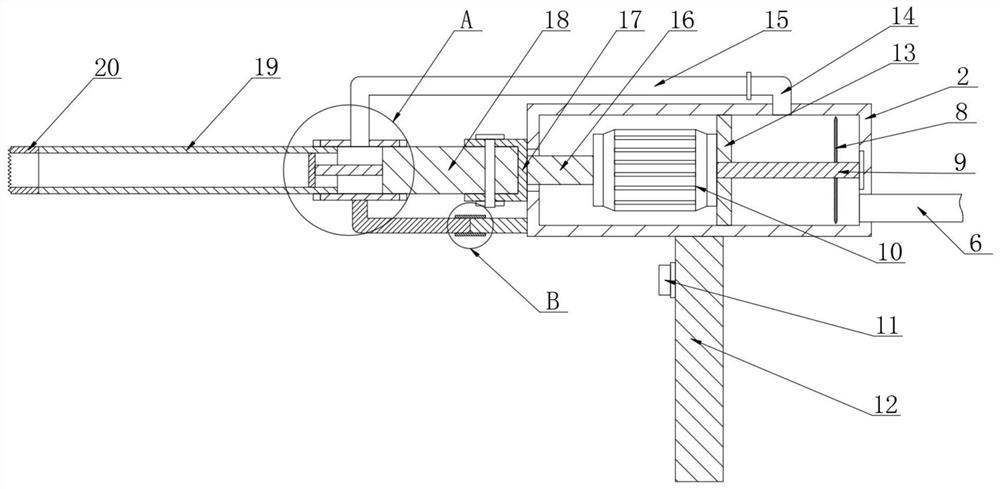

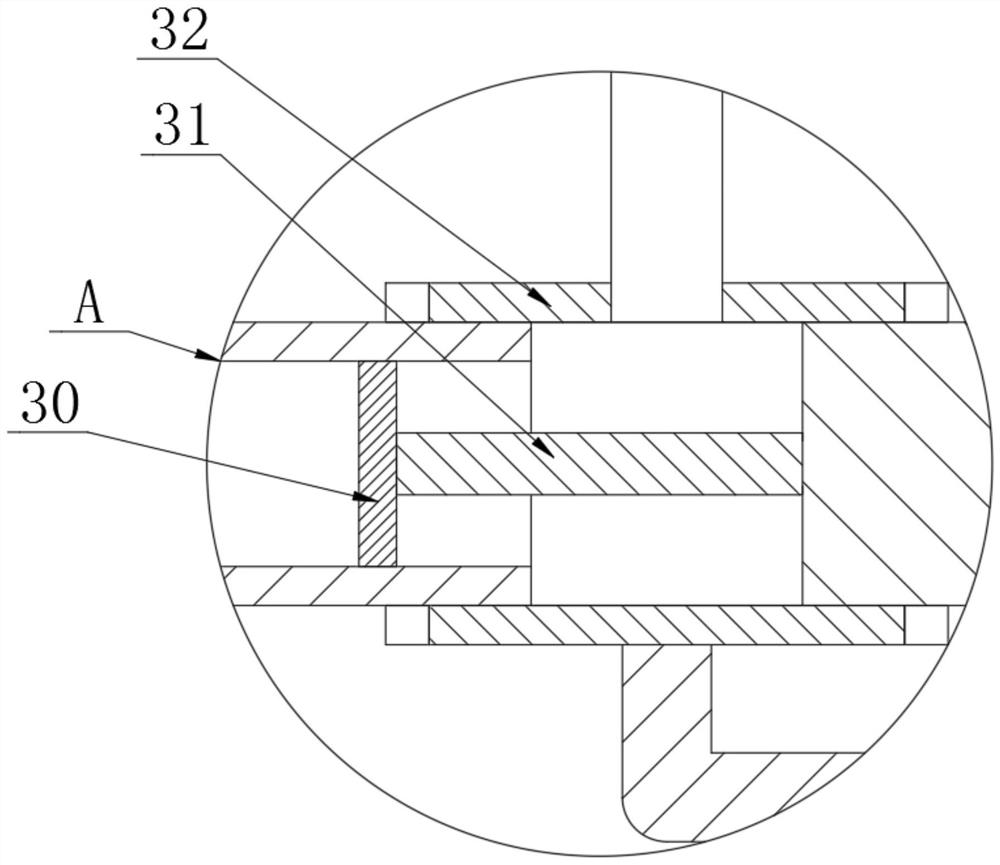

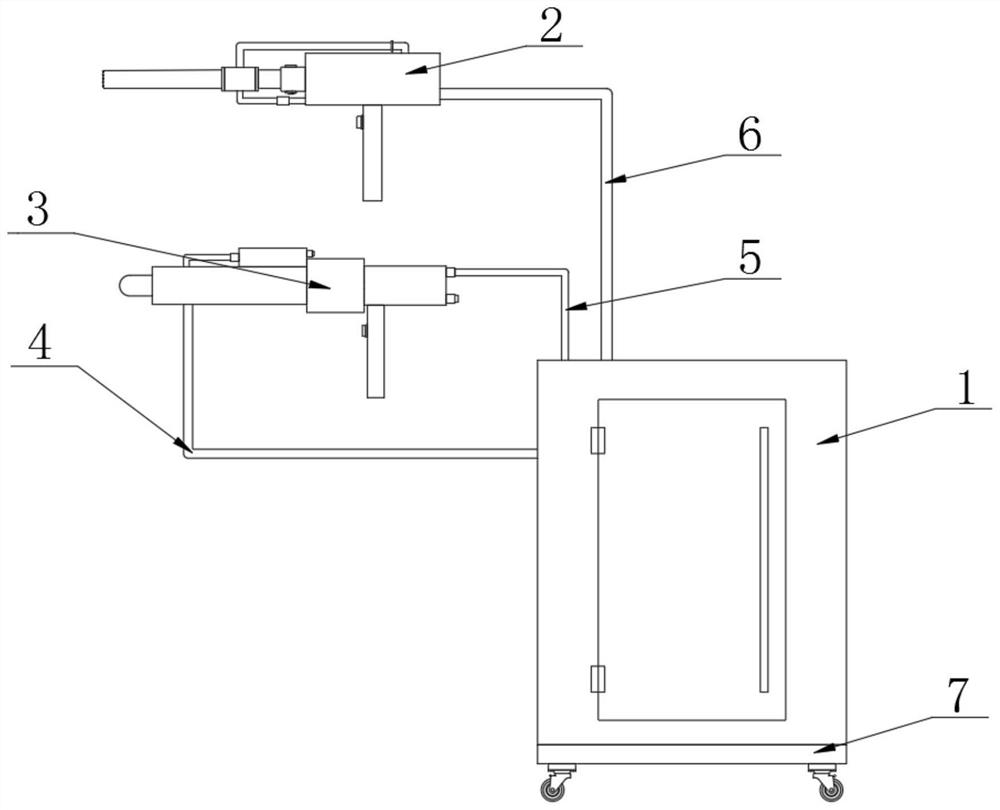

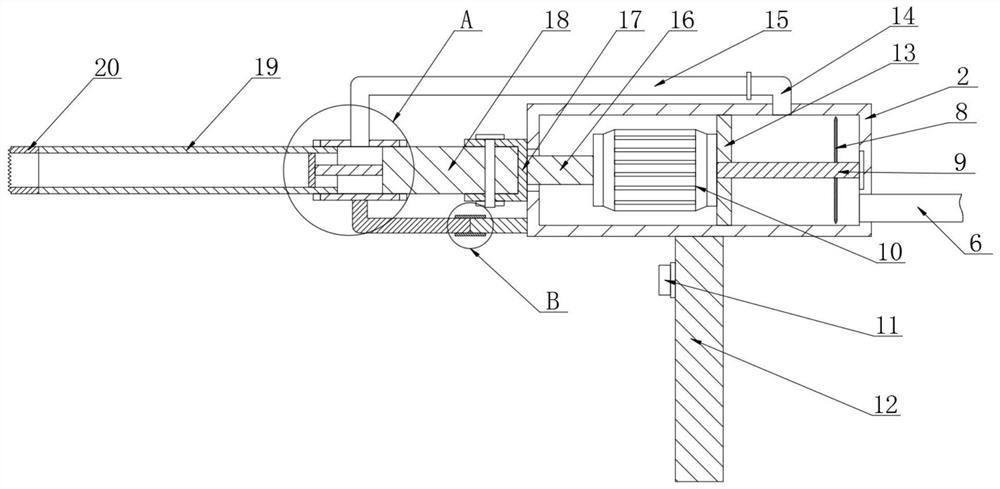

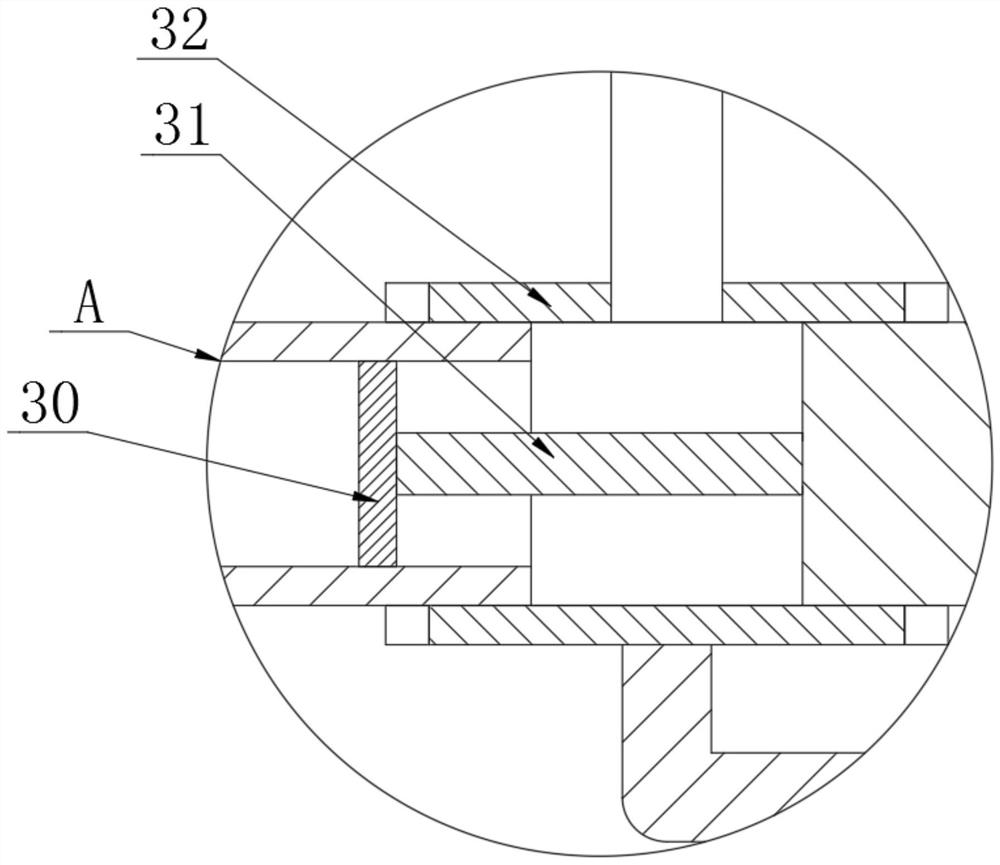

Electric osteotome

InactiveCN101361670AReduce volumeEasy to useMetal sawing toolsSurgical sawsEngineeringElectric motor

The invention provides an electric osteotome which comprises a blade and a handle, the blade is arranged on the handle and comprises a endless chain and a guide board, the endless chain is arranged in the periphery of the guide board and consists of cutting edges and chain sheets which are connected with adjacent cutting edges, and an electric motor is arranged inside the handle. The electric motor drives the endless chain of the blade to work around the periphery of the guide board. The electric osteotome has the advantages of flexible cutting direction transition, small cutting area, small volume and convenient usage.

Owner:BEIJING MONTAGNE MEDICAL DEVICE

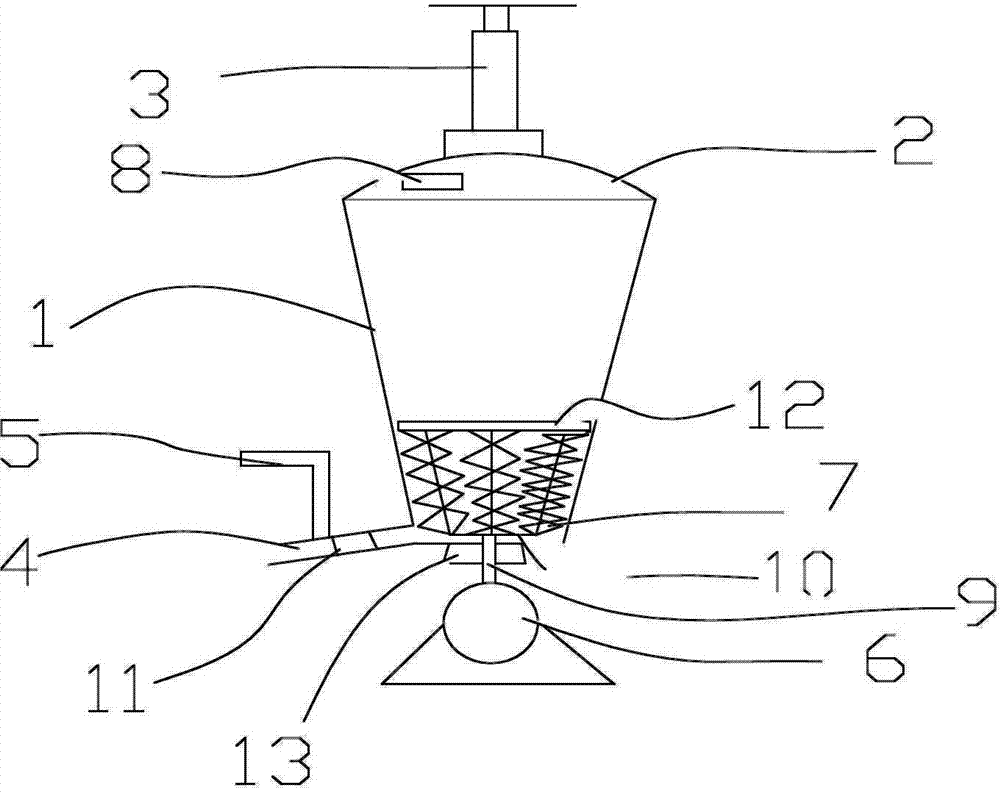

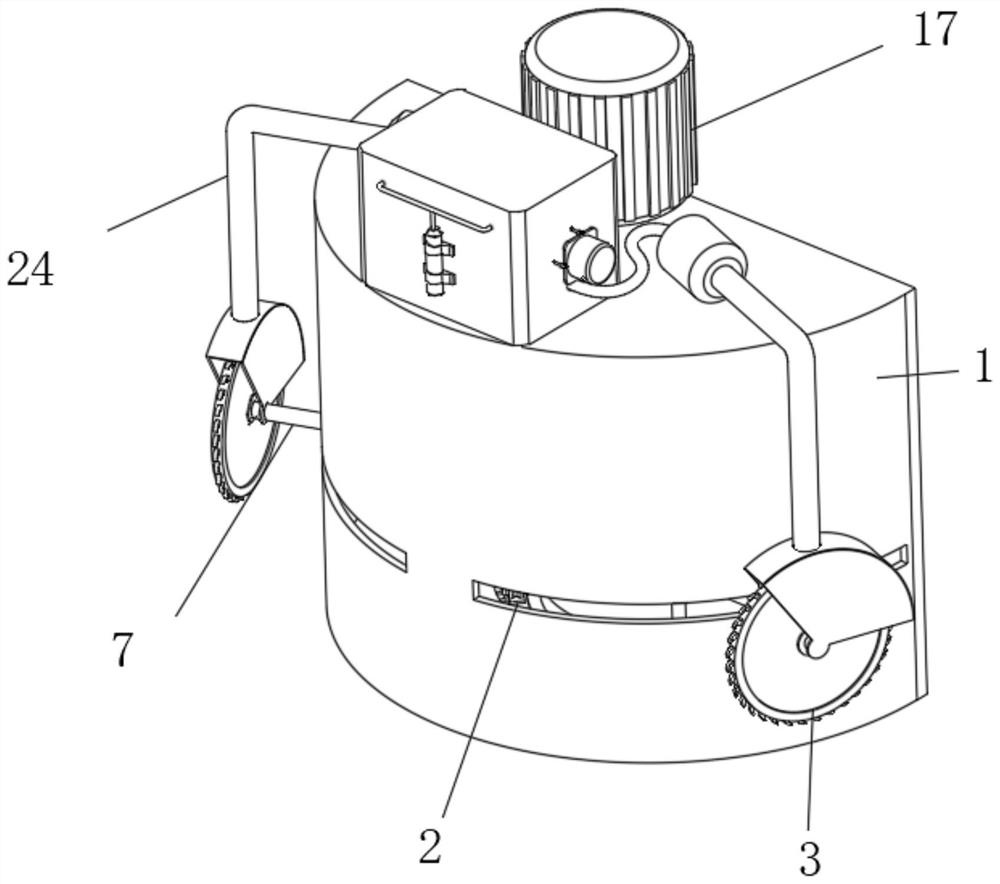

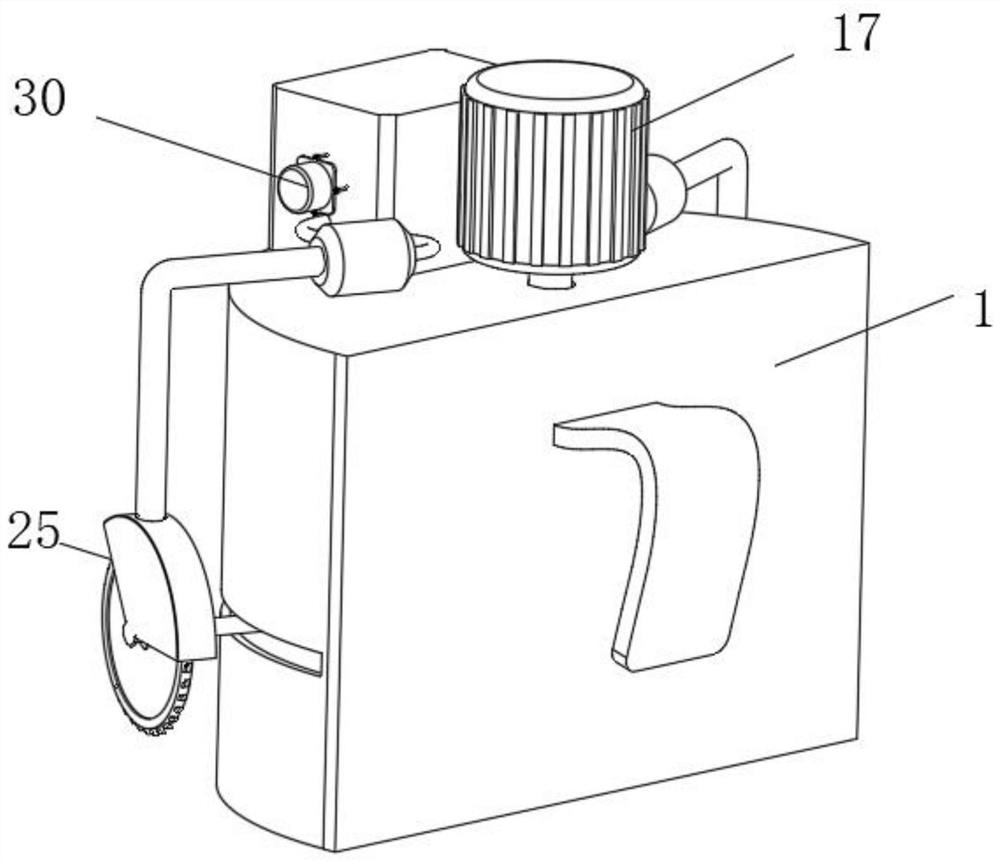

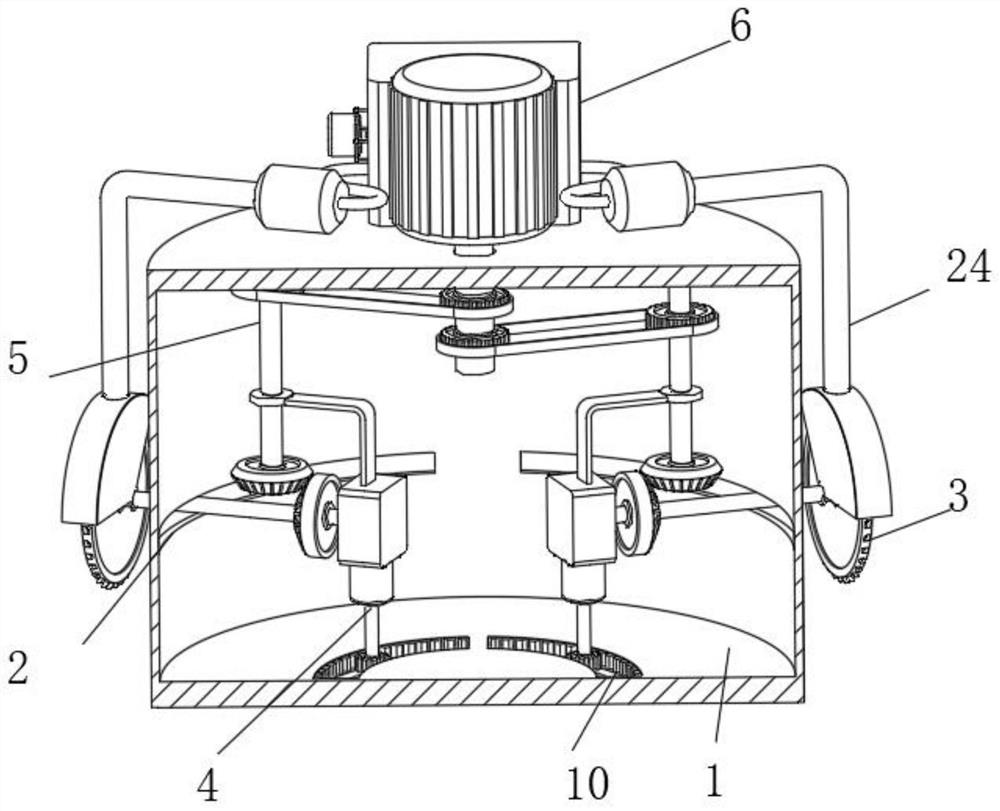

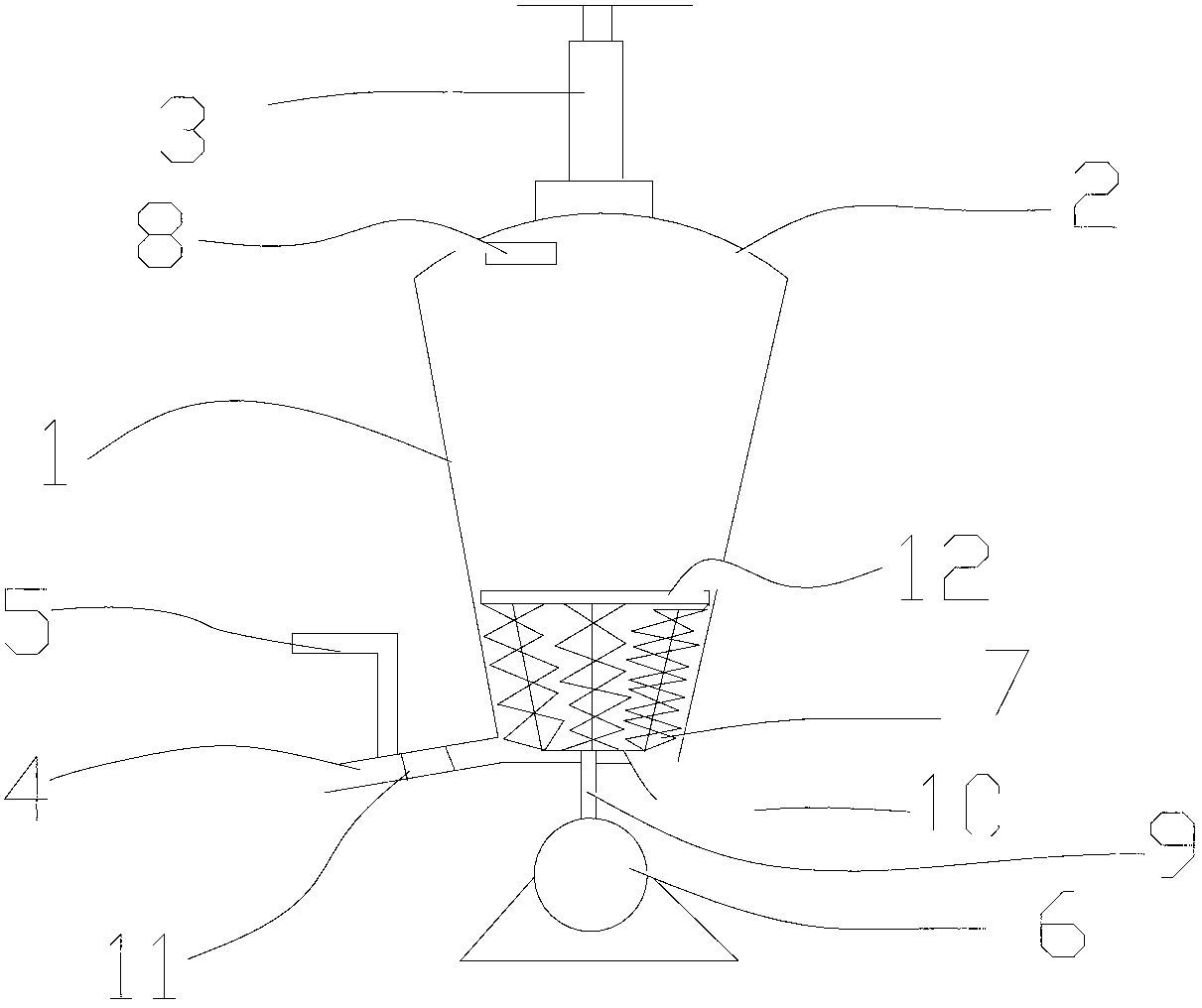

Vacuum heating juicer

The invention relates to a juicer, in particular to a vacuum heating juicer. The vacuum heating juicer comprises a juicer body, a cover, an air pumping device, a discharge tube, a knife rest, a knife, a heating device and a power device, wherein the air pumping device is arranged on the cover, the cover is arranged on the juicer body, the discharge tube is connected with the bottom of the juicer body and is in an downwardly-inclined shape, the knife is arranged on the knife rest and is of a saw-tooth shape, the knife rest is arranged at the bottom inside the juicer body, the heating device is arranged at the bottom outside the juicer body, and the power device is provided with a rotating rod which is connected with the knife rest. The vacuum heating juicer has the advantages that air inside the juicer body is exhausted through the air pumping device on the juicer body, vegetables and fruits are isolated from air in the juicing process so that juice can be prevented from being oxidized, and the effect of prolonging the storage life of nutrition and taste of fresh juice can be achieved. The discharge tube which inclines downwards has a guiding effect. Through the knife which is of the saw-tooth shape, the cutting area is reduced, and the fully-cutting effect is achieved. The heating device is used for heating the vegetable and fruit juice.

Owner:黄健

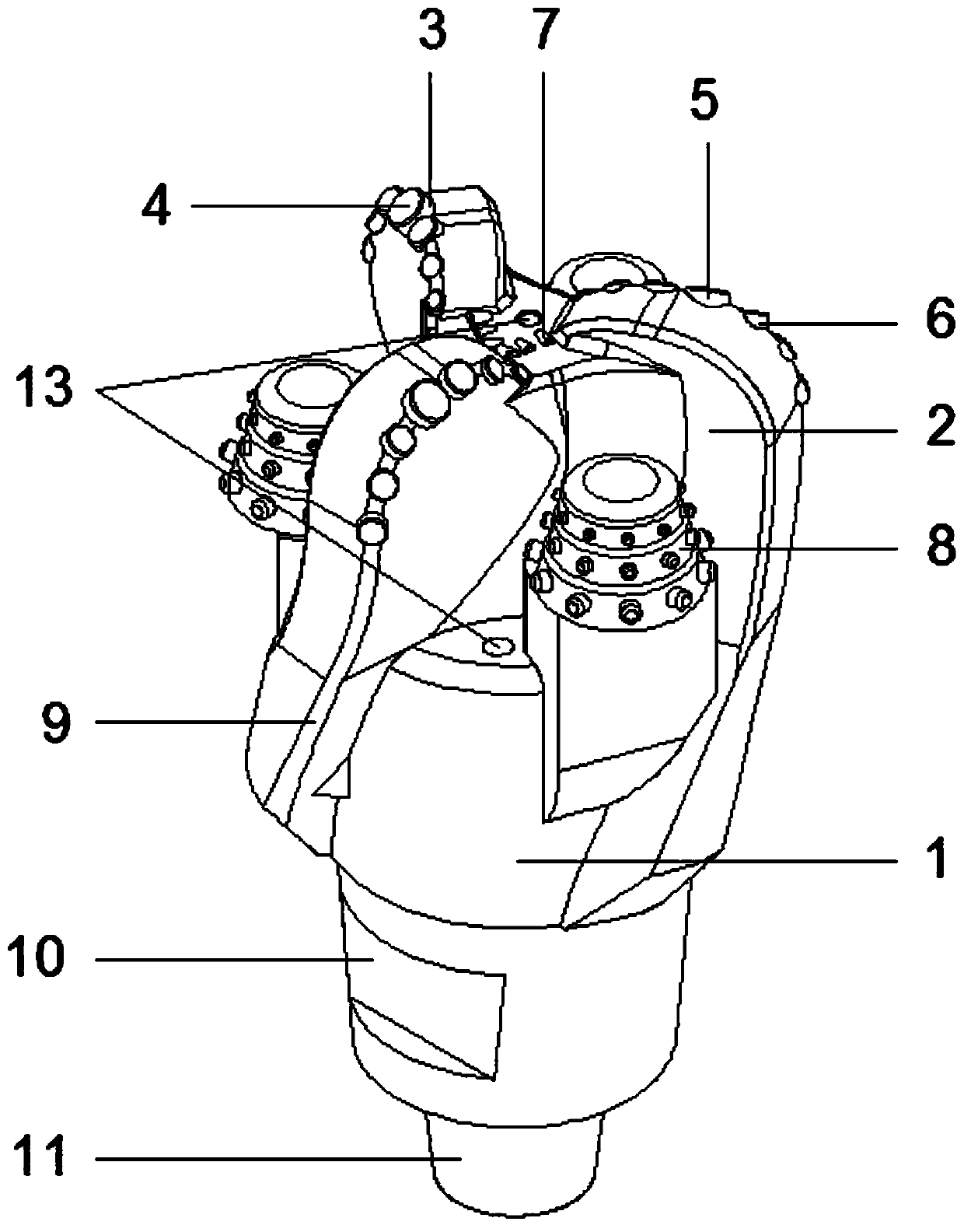

Secondary rock breaking drill bit for assisting pressurizing flow back through spiral blade

InactiveCN109898998AExtended service lifeReduce vibration amplitudeDrill bitsConstructionsWell drillingSpiral blade

The invention provides a secondary rock breaking drill bit for assisting pressurizing flow back through a spiral blade. The secondary rock breaking drill bit comprises a drill bit body, the blade anda cone; the blade is arranged at the top end of the drill bit body, and the blade and the drill bit body are of an integrated structure; and a gauge protection part is arranged on the outer wall of the blade. Through improvement for the rock breaking drill bit, primary cutting is conducted at the bottom of the drill bit to form primary rock debris, the rock debris returns to the cone under carrying flow back of a well-drilling fluid, the cone can conduct secondary breaking, the spiral blade slides in the longitudinal direction to be in surface contact with the well wall, a surface contact modeof the spiral blade is far greater than a line contact mode of a traditional straight blade, longitudinal vibration in the well-drilling process can be reduced, the rock debris generated by cutting of the drill bit flows back upwards under the action of vertical component force of the spiral face, fluid carrying the rock debris generates reactive force on the spiral blade surface, the drill bit can be pressurized, and thus the problems and deficiencies proposed in the background technology are effectively solved and overcome.

Owner:LANZHOU CITY UNIV

Method for repairing circular saw web of flying sawing machine

InactiveCN102500824ACutting costsReduce cutting areaSawing tools dressing arrangementsCold formedCircular saw

The invention relates to a method for repairing a circular saw web of a flying sawing machine. The method sequentially comprises the following technical processes of shaping the saw web, repairing broken teeth, shaping the tooth shape of a tooth grinding machine, quenching at high frequency and tempering at low temperature, so that the shortcoming of pure mechanical repairing of the tooth grinding machine is overcome; and saw teeth of the saw web have the original performance, and the service life of the saw web is not shortened; theoretically, the saw web can be repaired for over hundred times; the cutting area is reduced by about 0.1 to 0.5 percent every time when the saw web is repaired; therefore, the cost of the saw web during production of cold-formed sectional steel is reduced greatly; and the production cost is reduced.

Owner:SHANXI DINGRONG COLD FORMED SECTIONS

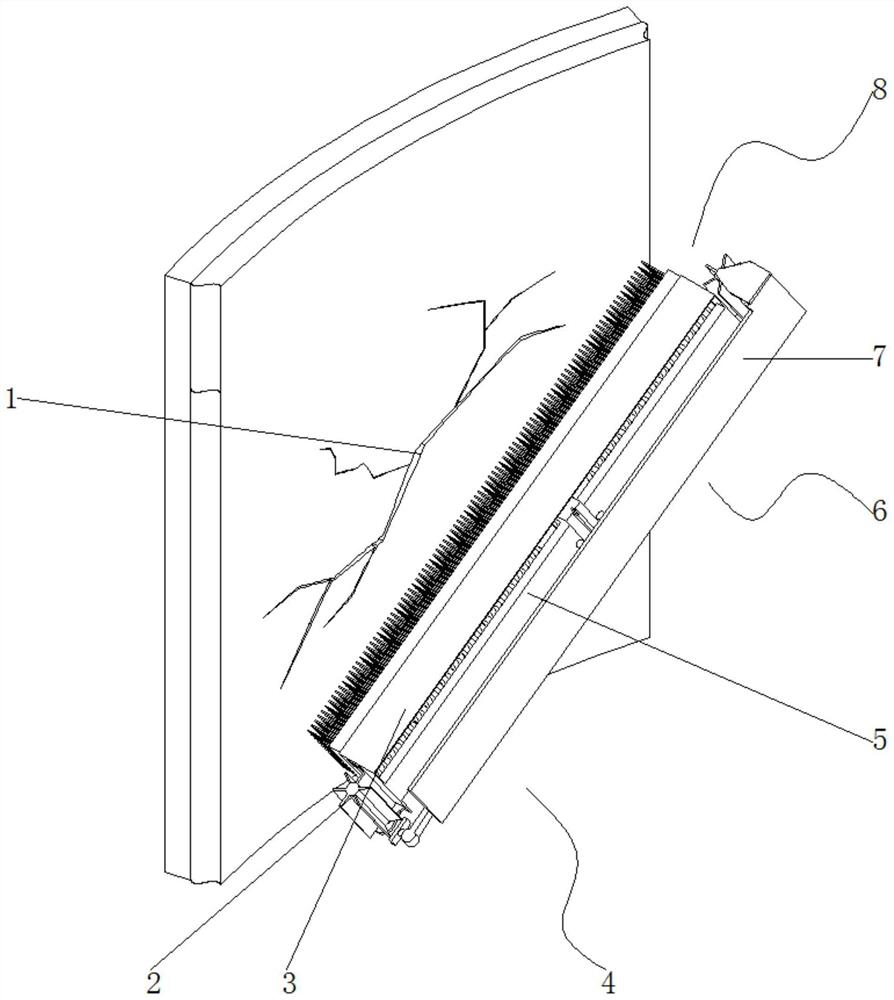

Tunnel crack detecting and repairing device

InactiveCN113356925AWith depth detection functionIntegrity guaranteedMining devicesUnderground chambersStructural engineeringMechanical engineering

The invention provides a tunnel crack detecting and repairing device. The tunnel crack detecting and repairing device is arranged on a crack. The tunnel crack detecting and repairing device a pre-detection mechanism and a repairing and polishing mechanism; the pre-detection mechanism and the repairing and polishing mechanism both correspond to a crack; and the pre-detection mechanism comprises a detection assembly and a driving assembly. The detection assembly is connected with the driving assembly, and the detection assembly corresponds to the crack. The detection assembly comprises an insertion plate, a plurality of baffles and insertion rods, and the insertion plate is connected with the driving assembly. According to the tunnel crack detecting and repairing device, the pre-detection mechanism and the repairing and polishing mechanism are matched with each other. Therefore, the device has the function of detecting the depth of the crack. Personnel can determine, through the pre-detection mechanism, places where cracks need to be cut and repaired and places which only need to be polished, so that the cutting area is reduced. The wall integrity is ensured to the greatest extent. Meanwhile, the repairing mode is more scientific and reasonable.

Owner:YIWU INDAL & COMMERICAL COLLEGE

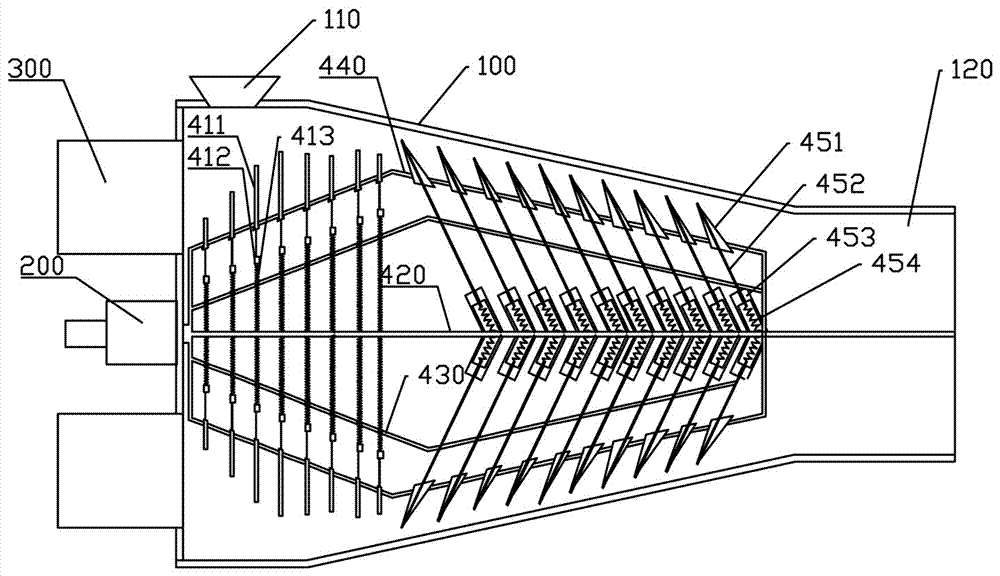

Self-adjusting loosening device

ActiveCN107090615AAutomatically adjust the degree of openingAvoid stalled situationsFibre cleaning/opening by toothed membersFibre cleaning/opening machinesFiberEngineering

The invention relates to a mechanical loosening device, in particular to a self-adjusting loosening device which comprises a loosening cabin, a loosening drum, an air inlet pipe, and a rotating power element which drives the loosening drum to rotate, wherein the loosening cabin of a truncated cone shape, includes a feed hopper arranged at the top end of the loosening cabin and a discharge port installed on the right wall of the loosening cabin; the air inlet pipe is communicated with the left wall of the loosening cabin, and the loosening drum is rotatably connected in the loosening cabin; the loosening drum includes a fast cutting mechanism, a loosening mechanism, a rotating shaft and an inner blocking cylinder which is arranged in the loosening drum; a drum wall of the loosening drum and the inner blocking cylinder are both fixed on the rotating shaft which is rotatably connected on the loosening cabin and connected with the rotating power element, and the drum wall is divided into a feed part of a coniform shape and a discharge part of a truncated cone shape. In order to solve the problem of winding fibers on the loosening drum, the self-adjusting loosening device aims to provide the self-adjusting loosening device capable of avoiding fiber winding.

Owner:CHONGQING TIANYUN AUTO PARTS

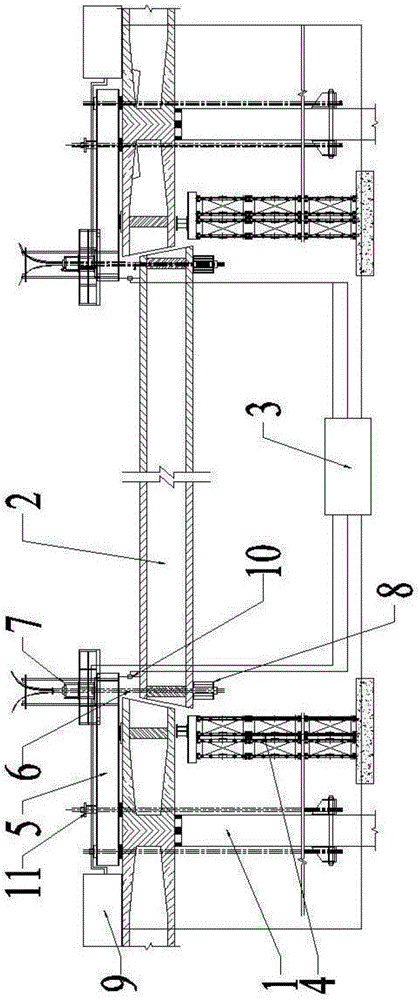

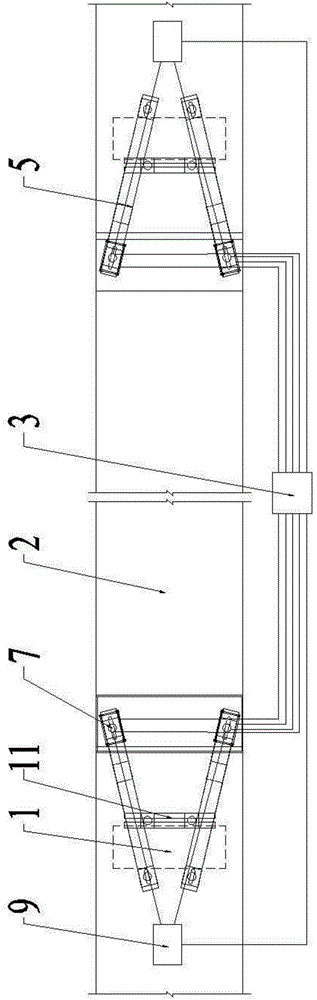

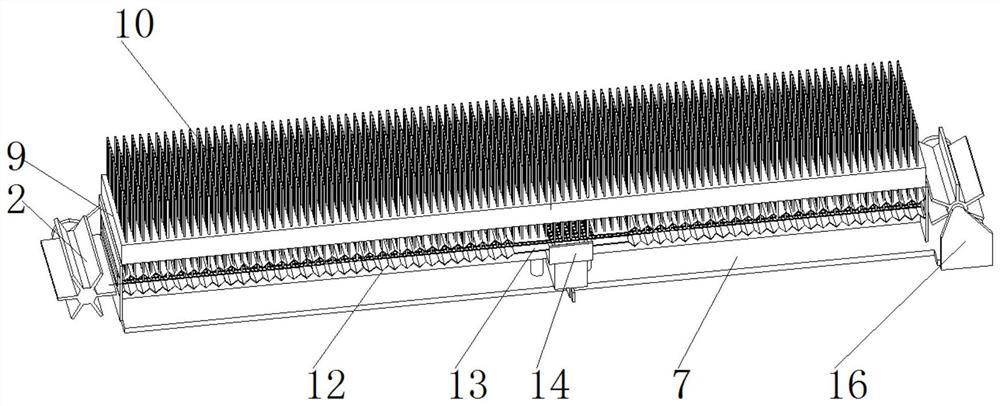

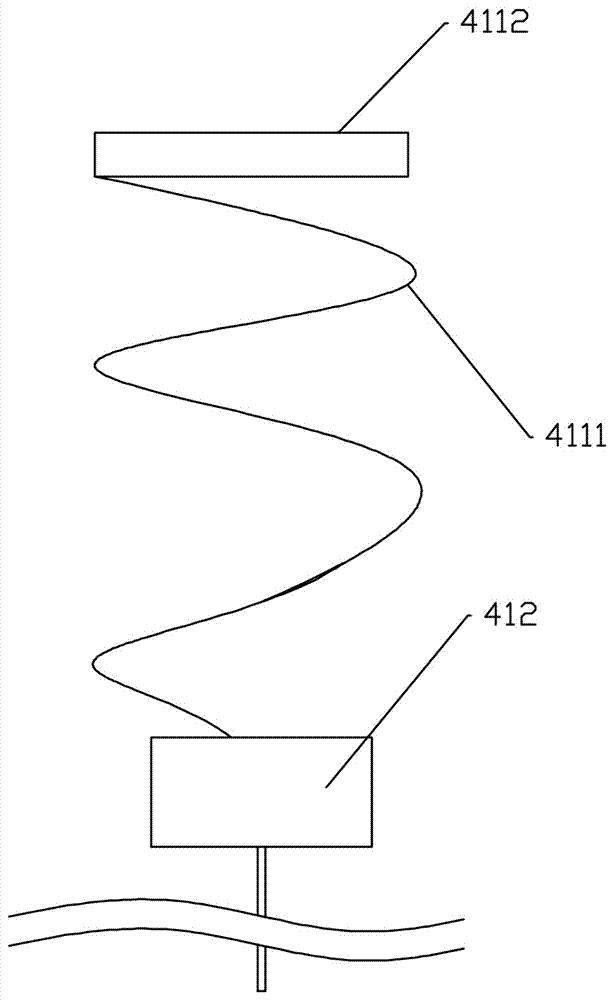

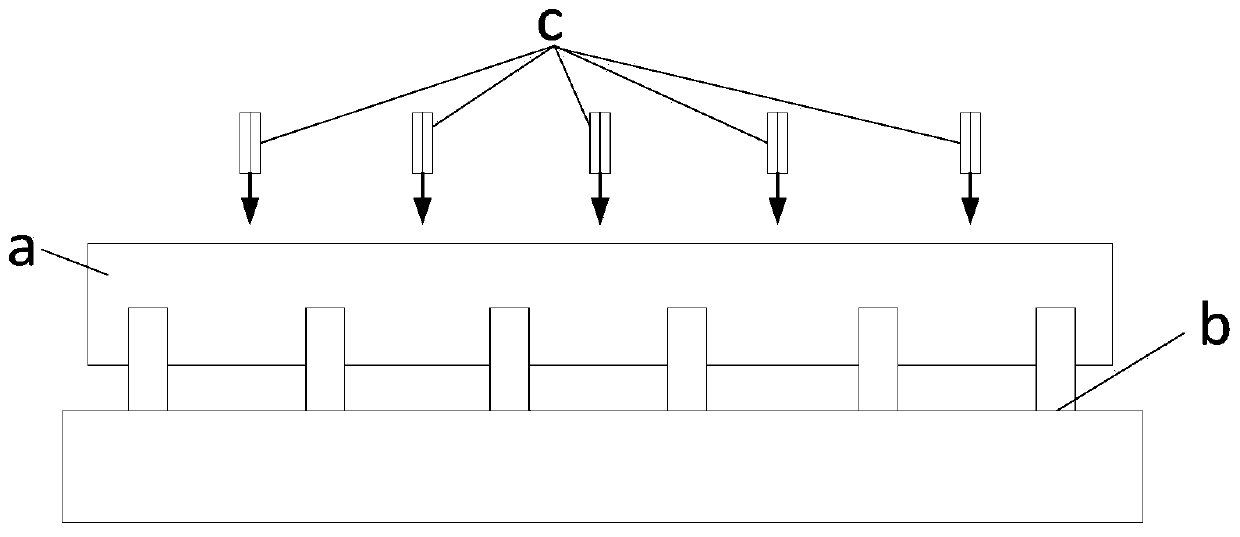

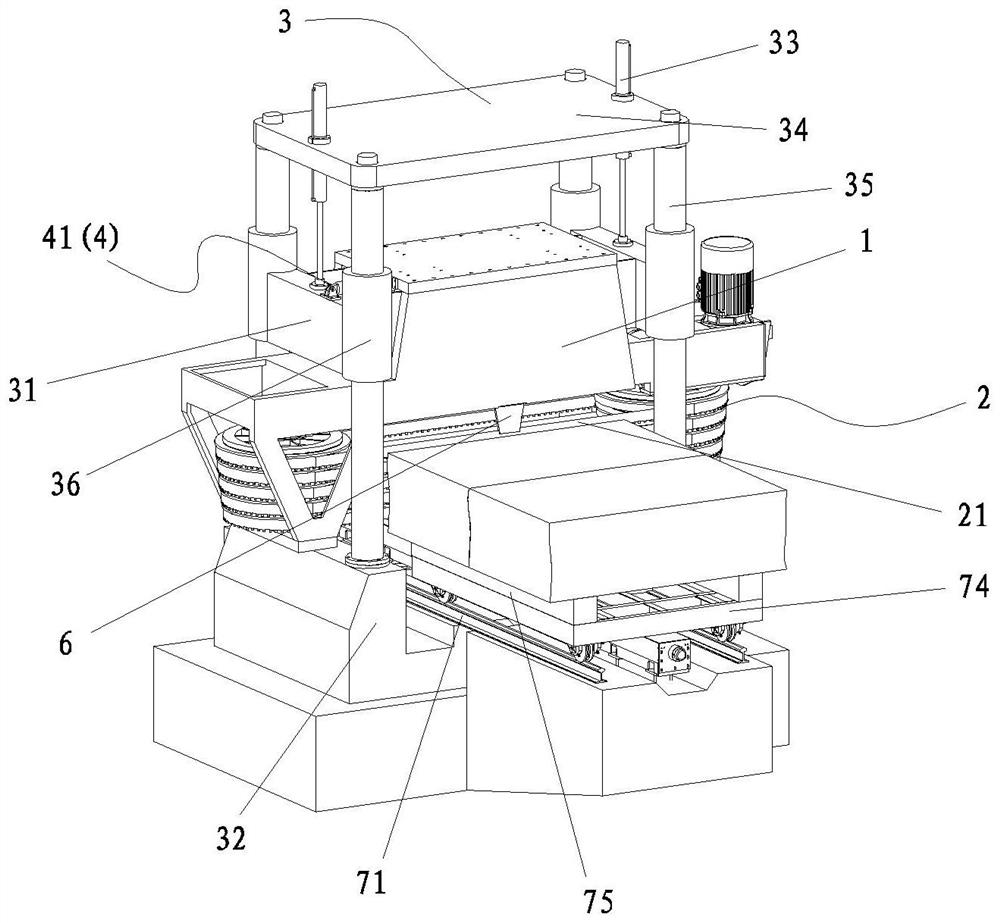

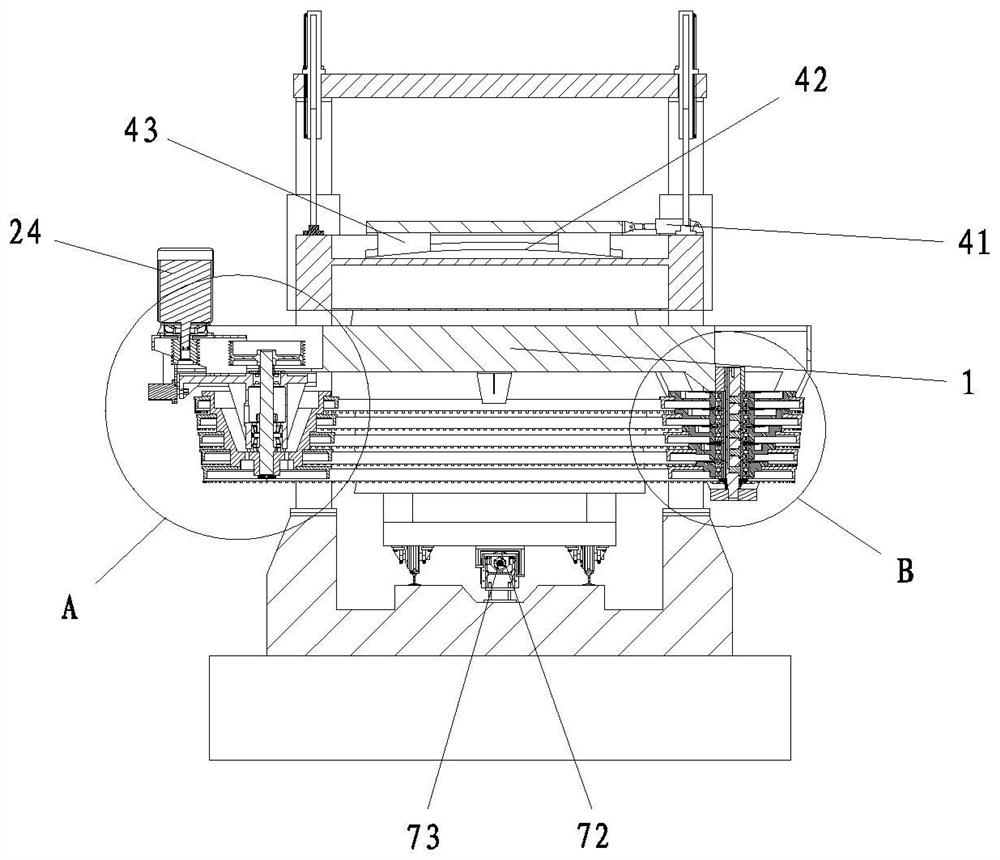

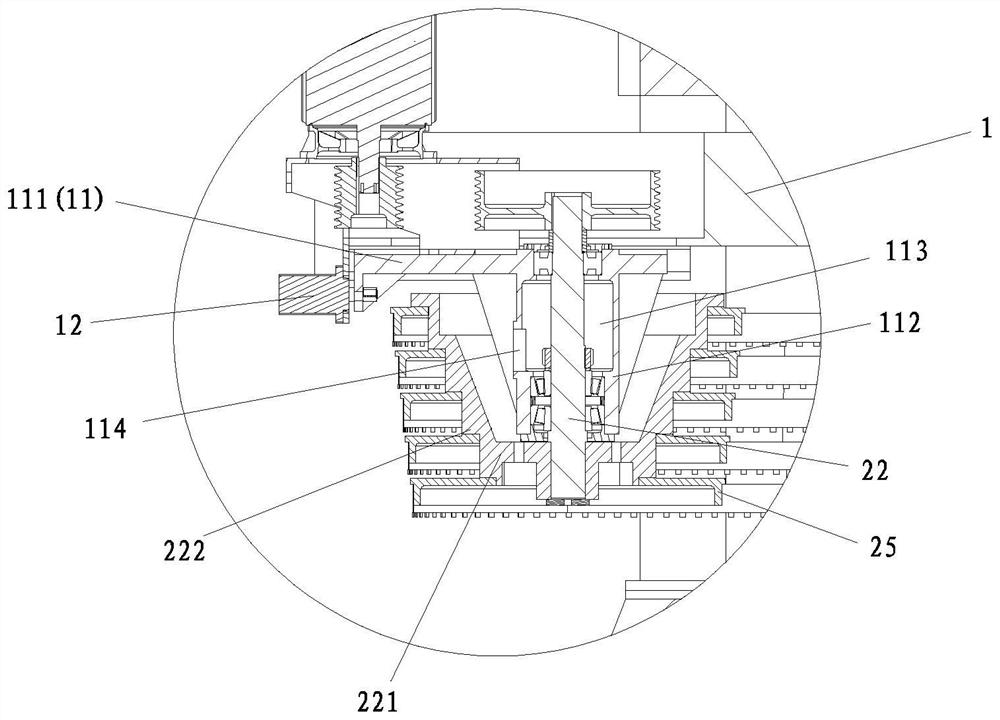

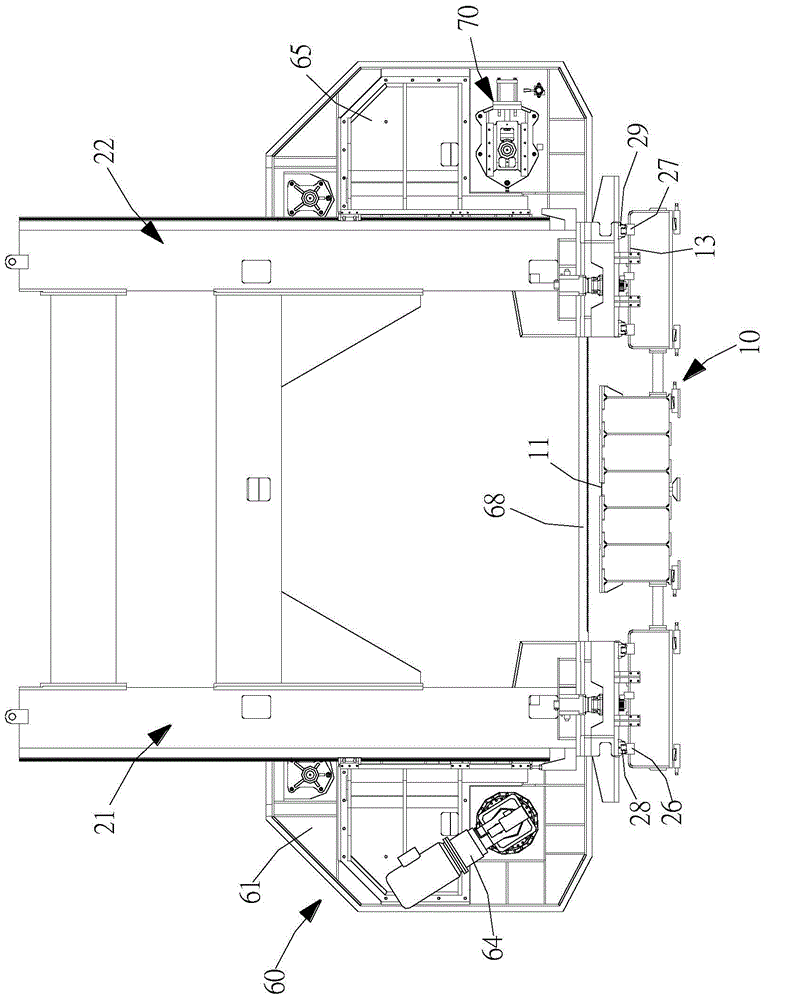

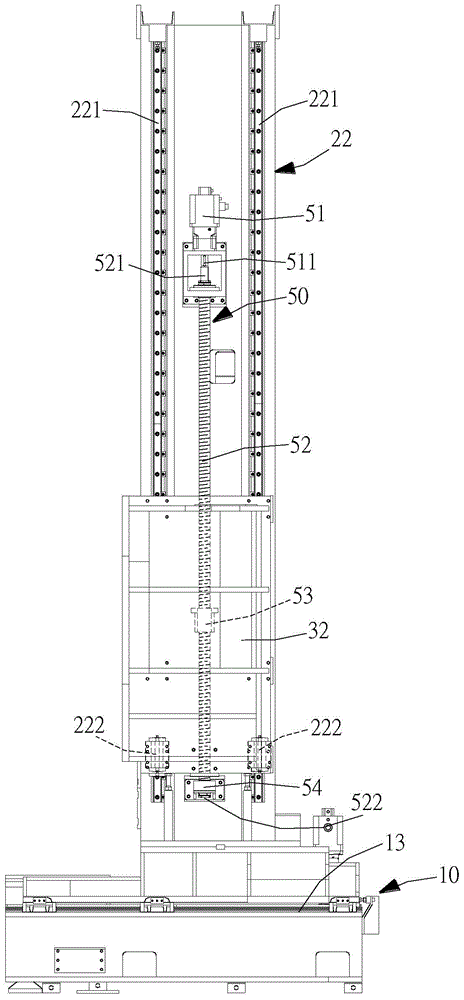

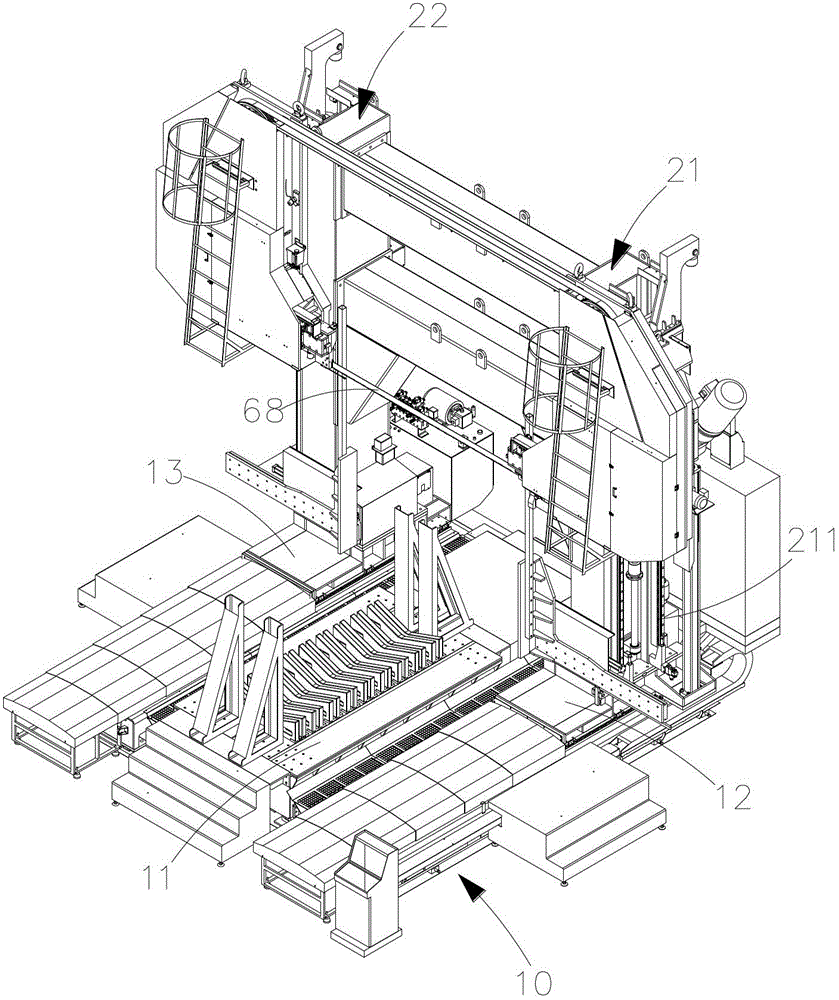

Efficient multi-cutter cutting machine for workpiece rotation

PendingCN111559023AReduce lossShort contact lengthWorking accessoriesFine working devicesIndustrial engineeringCutting tool

The invention discloses an efficient multi-cutter cutting machine for workpiece rotation. The efficient multi-cutter cutting machine comprises a base and a rack arranged above the base, wherein the base is provided with a crystal support assembly used for supporting workpieces; a cutting assembly used for cutting the workpieces is arranged above the rack and comprises cutting tool bits, a diamondwire drive mechanism and a walking drive assembly, wherein the cutting tool bits are used for achieving workpiece cutting through diamond wires, the diamond wire drive mechanism is used for driving the diamond wires in the cutting tool bits to move to achieve cutting action, and the walking drive assembly is used for moving the cutting tool bits; and a plurality of cutting tool bits are arranged and sequentially arranged in the length direction of the workpieces, and the distances between the cutting tool bits and the workpieces are different. According to the multi-cutter cutting machine produced through the scheme, the cutting process is smooth, the phenomena of edge breakage and the like are avoided, the whole operation process can be rapidly finished by one person, multi-person cooperative operation is not needed, the cut workpieces can be separated, the efficient multi-cutter cutting machine can be used for single-cutter cutting and can also achieve multi-cutter cutting, and applicability and expansibility are very high.

Owner:QINGDAO GAOCE TECH CO LTD

Novel method for manufacturing short shell ring flange sections of offshore wind power tower barrel

The invention discloses a novel method for manufacturing short shell ring flange sections of an offshore wind power tower barrel. The method comprises the steps of steel plate cutting, groove processing, steel plate edge rolling and assembling, longitudinal seam welding, flange assembling, circular seam welding and integral cutting, and during steel plate cutting, a left gap and a right gap are respectively and horizontally cut at the middle position at an interval, broken bridge nodes are reserved at the two ends of each gap, and during integral cutting, the broken bridge nodes are cut off along the gaps, so that two short shell ring flange sections are separately manufactured. The manufacturing period of the short shell ring flange section is greatly shortened, the working efficiency is improved, and meanwhile the cutting accuracy is guaranteed.

Owner:JIANGSU HAILING HEAVY IND EQUIP TECH

Dust collecting device

ActiveCN111844480AEasy to handleImprove protectionUsing liquid separation agentWorking accessoriesEngineeringStructural engineering

The invention discloses a dust collecting device. The dust collecting device comprises a shell, two sliding grooves are formed in one side of the shell, cutting blades for cutting raw stone are arranged in the two sliding grooves respectively, one side of each cutting blade is connected with an angle adjusting part, the angle adjusting parts are connected into the shell, the angle adjusting partsare connected with driving parts in an ejecting mode, and the driving parts are connected with the shell; the top of the shell is connected with a collecting part for collecting raw stone dust, and the two ends of the collecting part are located at the tops of two cutting blades. According to the dust collecting device, the arranged shell is placed at a jade position to be cut, the cutting angle between the two cutting blades is adjusted through the arranged angle adjusting parts, the two cutting blades are driven at the same time through the driving parts; the two cutting blades can be conveniently driven to cut jade raw stone, the collecting part is started to adsorb the jade dust cut off from the tops of the two cutting blades, the jade dust is absorbed in time, and the situation that the jade dust adheres to the cutting blades is reduced.

Owner:山东安和安全技术研究院有限公司

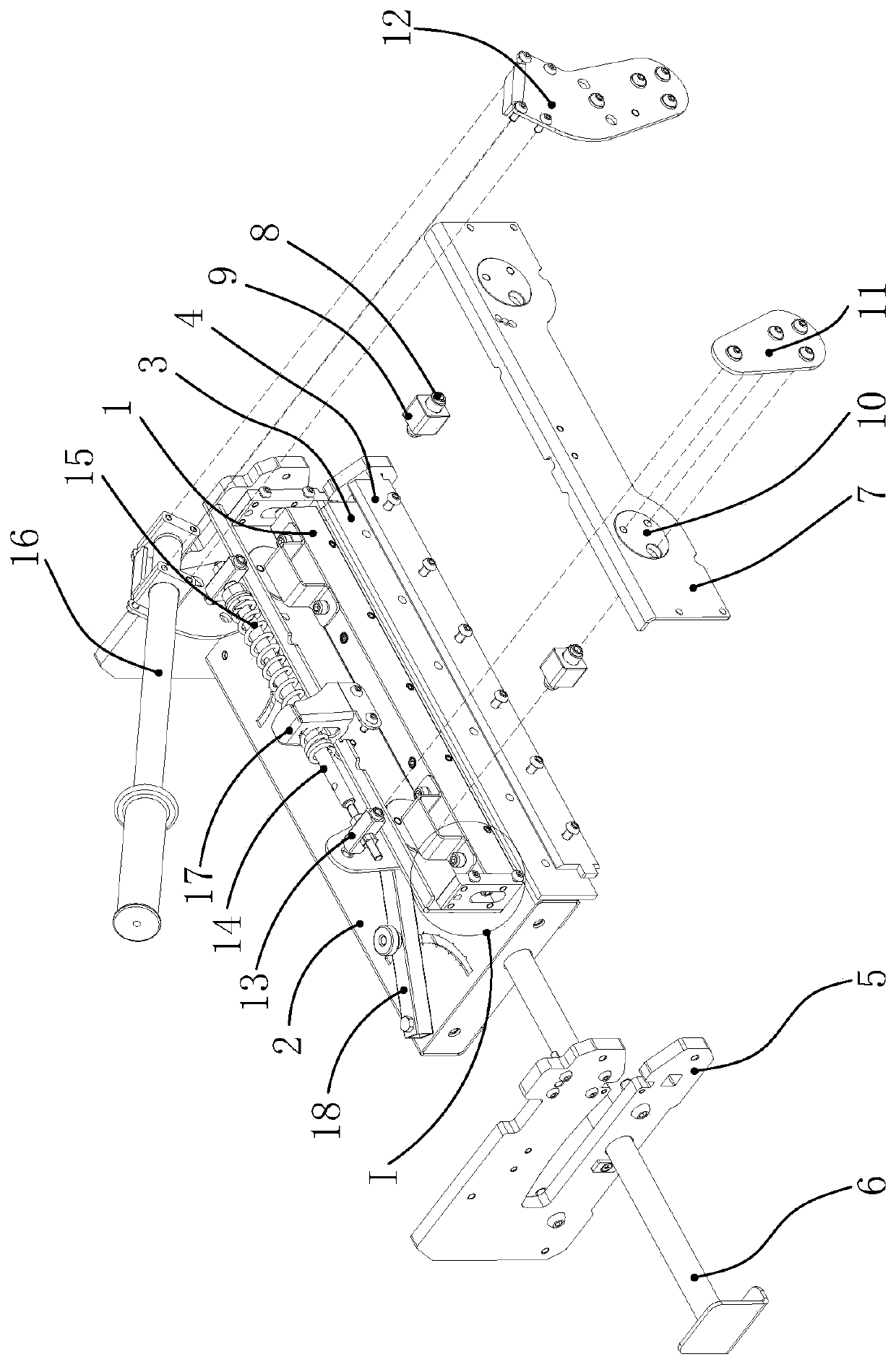

Movement mechanism for synchronization action of cutters and cutting knife

The invention discloses a movement mechanism for synchronization action of cutters and a cutting knife. The movement mechanism comprises rocker mechanisms, a transmission mechanism and eccentric rotating mechanisms, wherein the eccentric rotating mechanisms are used for driving cutter components to move up and down; at least two sets of rocker mechanisms and eccentric rotating mechanisms are arranged, and multiple sets of rocker mechanisms realize the synchronization action through the transmission mechanism; each eccentric rotating mechanism comprises an eccentric wheel and a rotation shaft,and the rotation shaft passes through the eccentric wheel and then is connected with the corresponding rocker mechanism; the eccentric wheel is arranged on a support and is fixedly connected with thecorresponding rocker mechanism; and the eccentric wheel can rotate on the support by the swing of the corresponding rocker mechanism. According to the movement mechanism, the eccentric wheel rotatingmechanisms are matched with the rocker mechanisms and the transmission mechanism, the cutter components are arranged on the eccentric wheel rotating mechanisms, the eccentric wheels and the rotation shafts connected with the cutter components are arranged in the eccentric wheel rotating mechanisms, and the cutter components are synchronously driven to move up and down to cut plates.

Owner:QINGDAO CHENBA IND & TRADE CO LTD

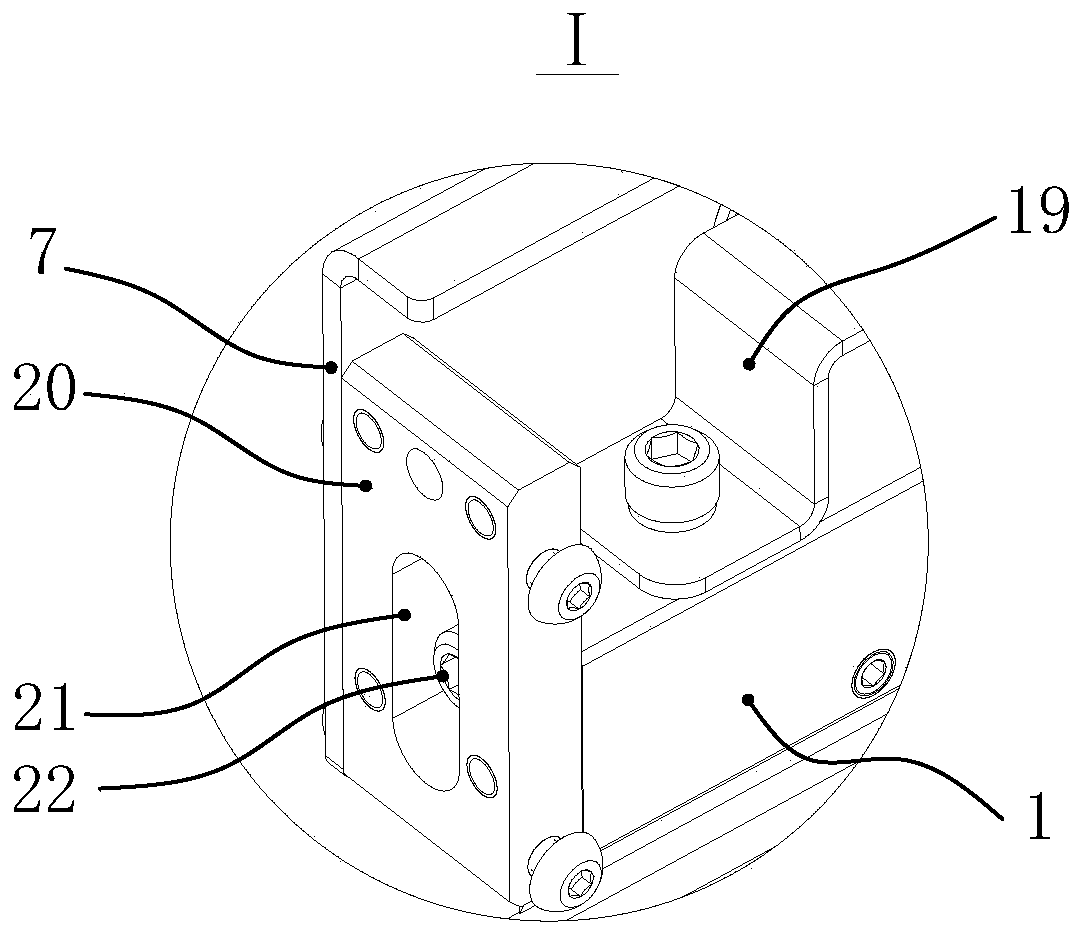

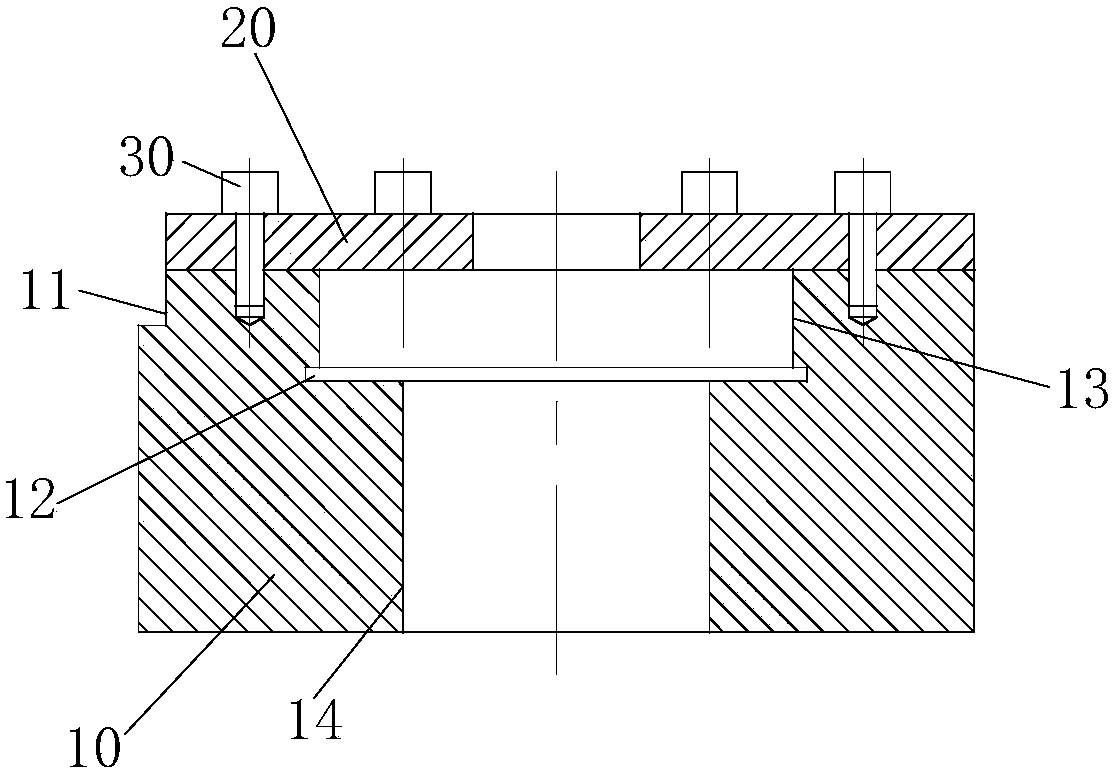

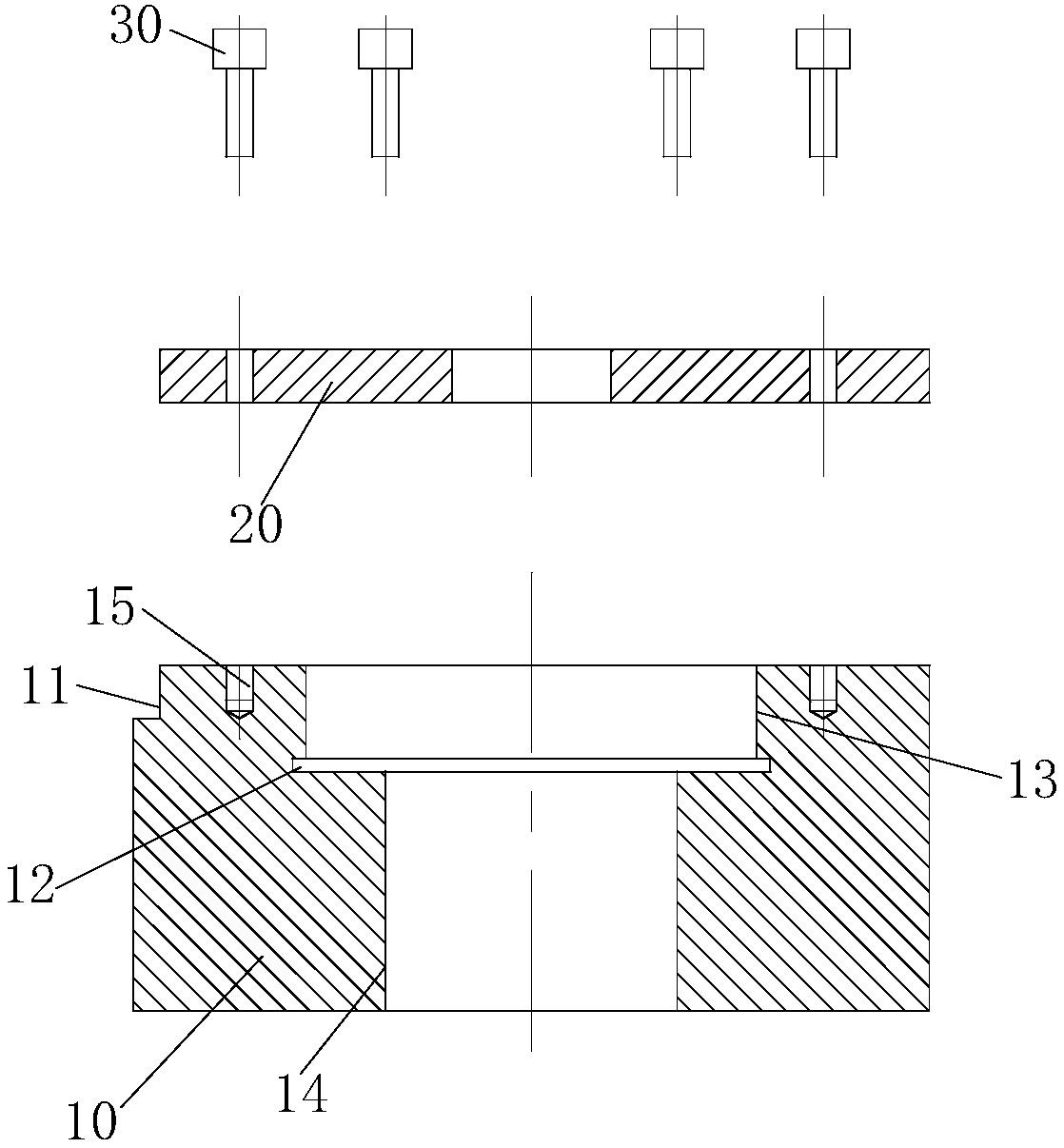

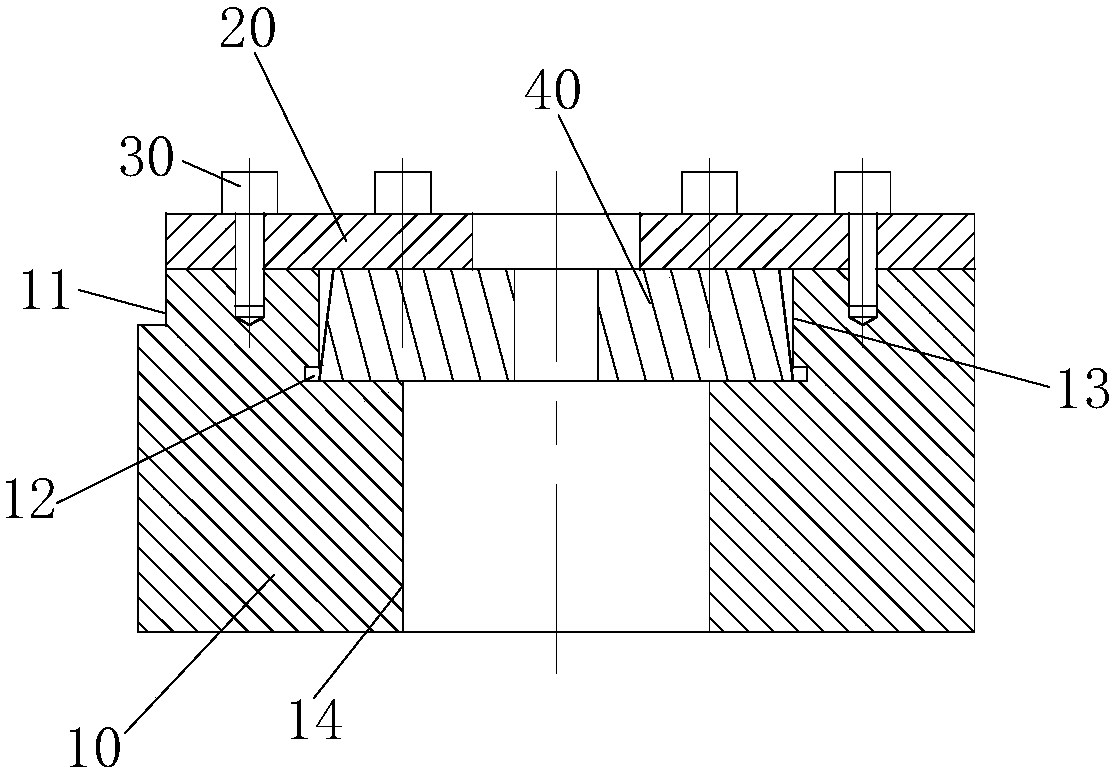

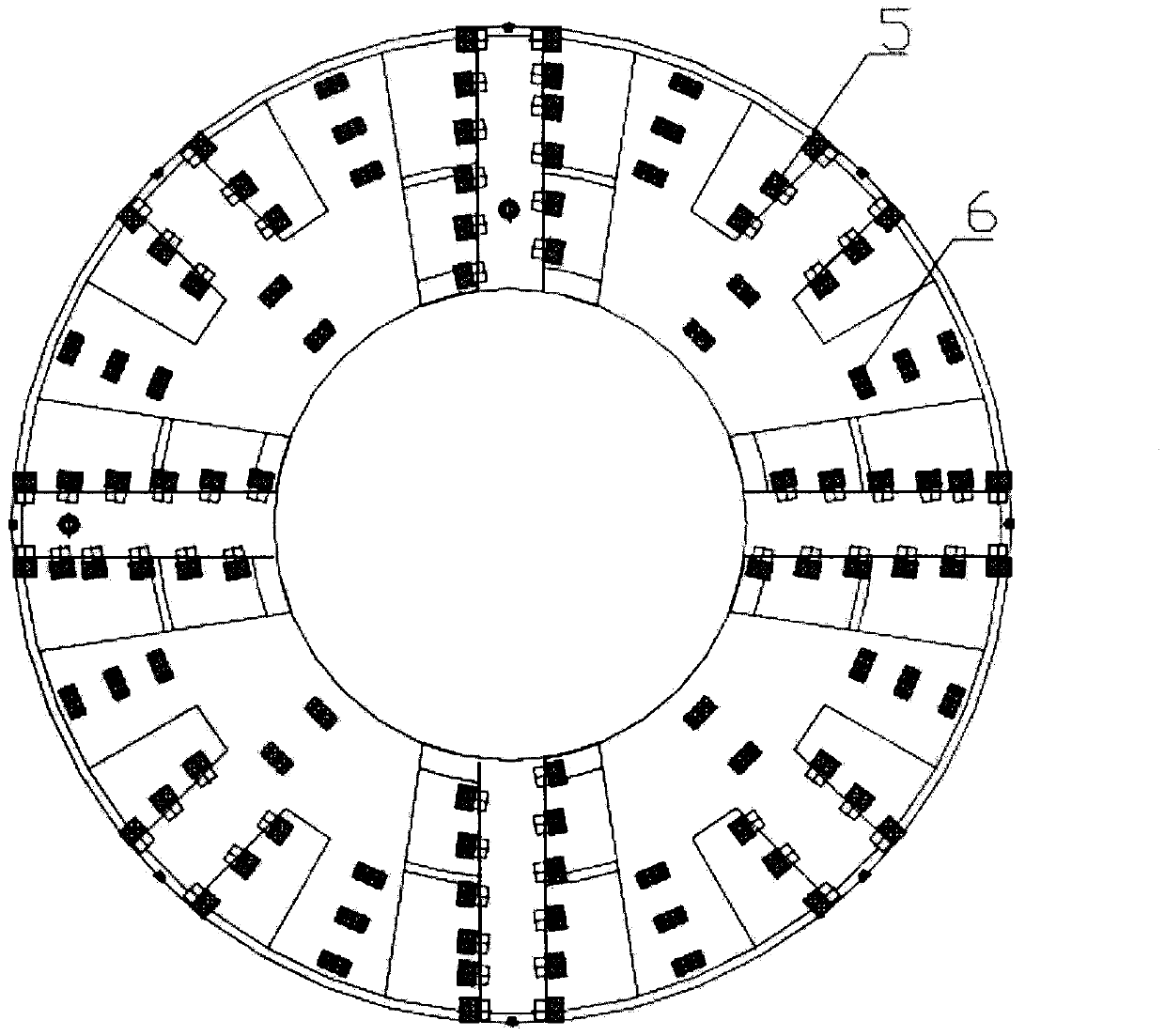

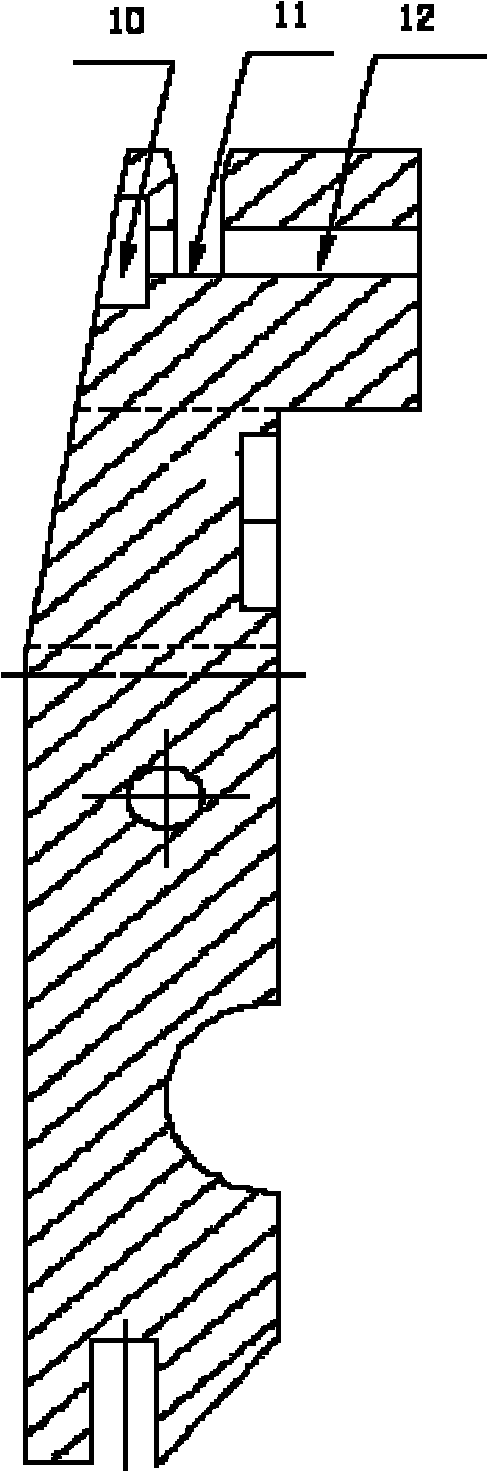

Nut cover die machining jig and nut cover die machining machine tool

PendingCN108393550AReduce cutting areaReduce the amount of cuttingElectrical-based auxillary apparatusEngineeringMachine tool

The invention provides a nut cover die machining jig and a nut cover die machining machine tool with the nut cover die machining jig, and relates to the technical field of nut machining die manufacturing. The nut cover die machining jig comprises a clamp base and a clamp cover detachably arranged on the clamp base. The clamp base is provided with a first clamping surface, and the first clamping surface is the inner end face of a first hole in the surface of the clamp base. The clamp cover is provided with a second clamping surface, and the first clamping surface and the second clamping surfaceare used for clamping a nut cover die. The nut cover die machining jig and the nut cover die machining machine tool can solve the technical problem that in the prior art, the nut cover sleeve machining side face angle error exists.

Owner:周志容

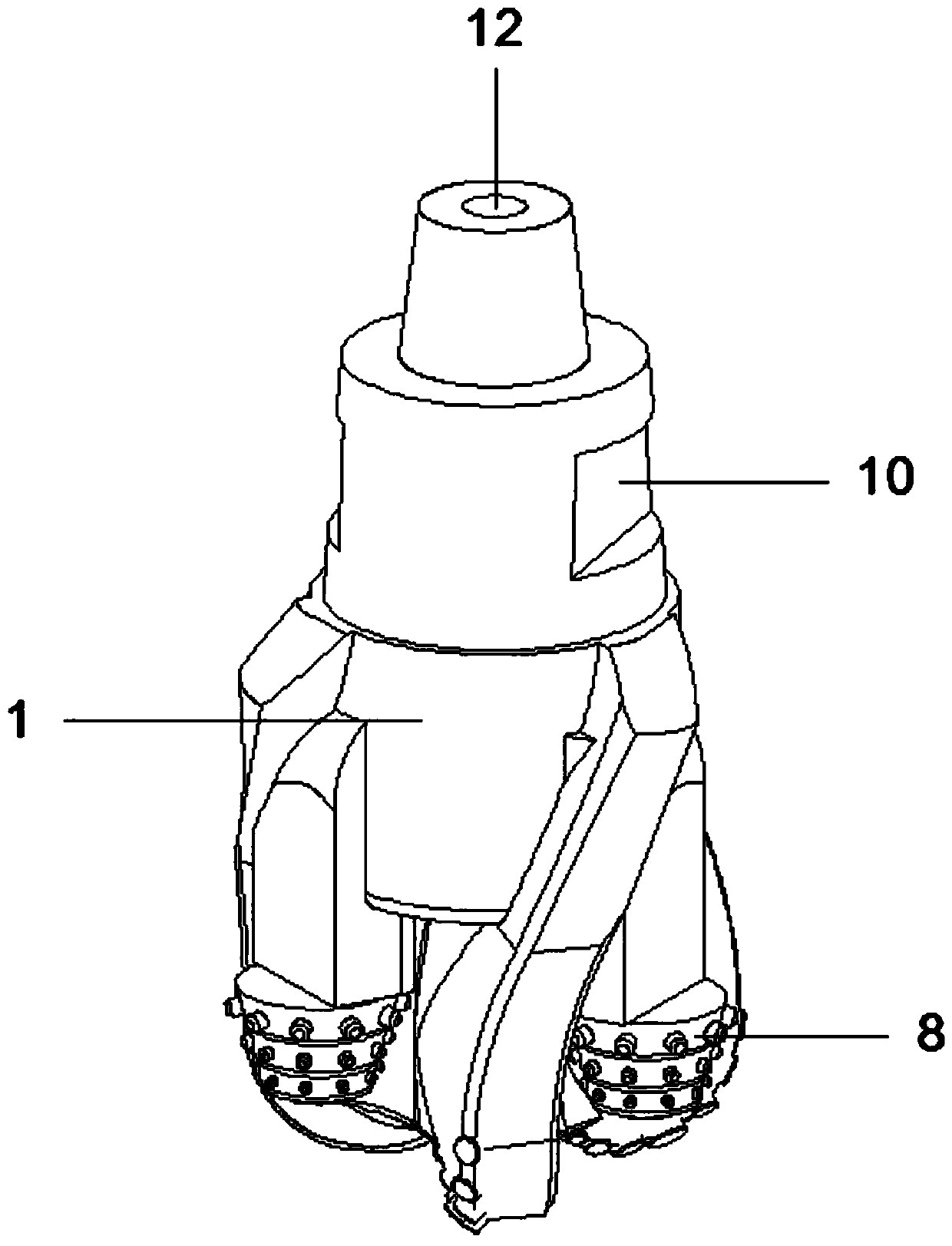

Coring shield mechanism of tunnel boring machine

The invention discloses a coring shield mechanism of a tunnel boring machine. The coring shield mechanism comprises a pushing device, a converting device and a rotating fixed base, wherein the converting device is matched with the pushing device, the rotating fixed base is arranged on one side of the converting device in a matched mode to be driven, one side of the rotating fixed base is further connected with supporting legs, and a cutter head is connected to one end of each supporting leg. The coring shield mechanism of the tunnel boring machine serves as a cutting mechanism of the tunnel boring machine, and the coring shield mechanism not only is high in efficiency, safe and reliable, but also prolongs service life of a cutting component and reduces production cost.

Owner:江苏银旭隧道机械有限公司

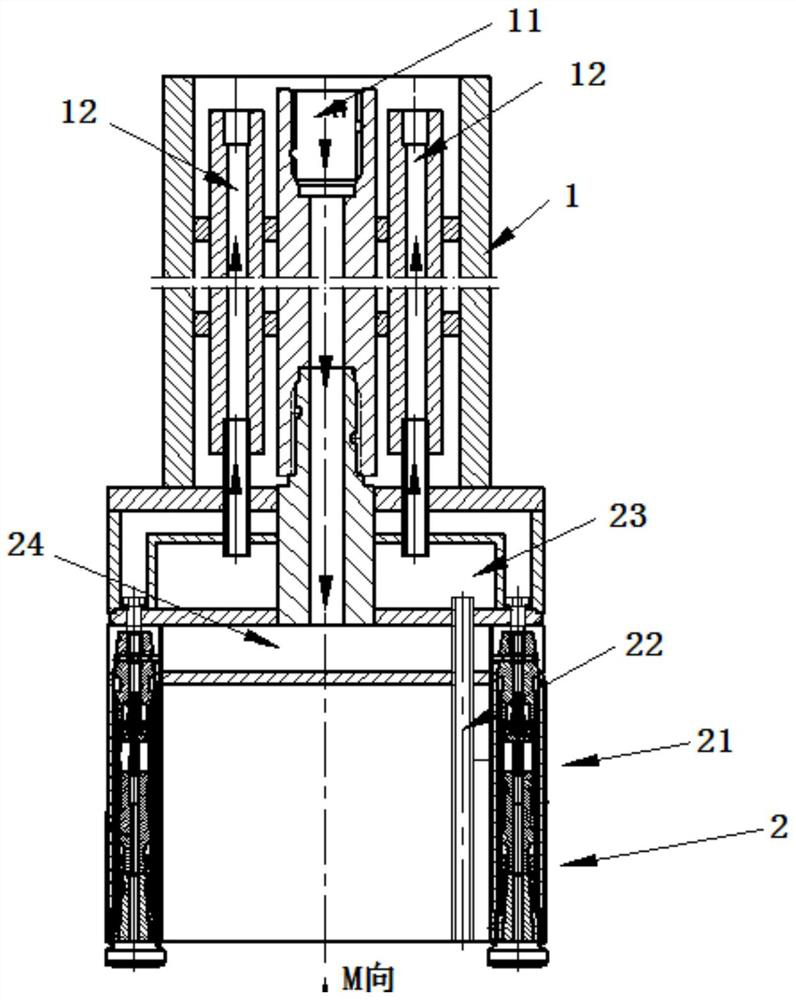

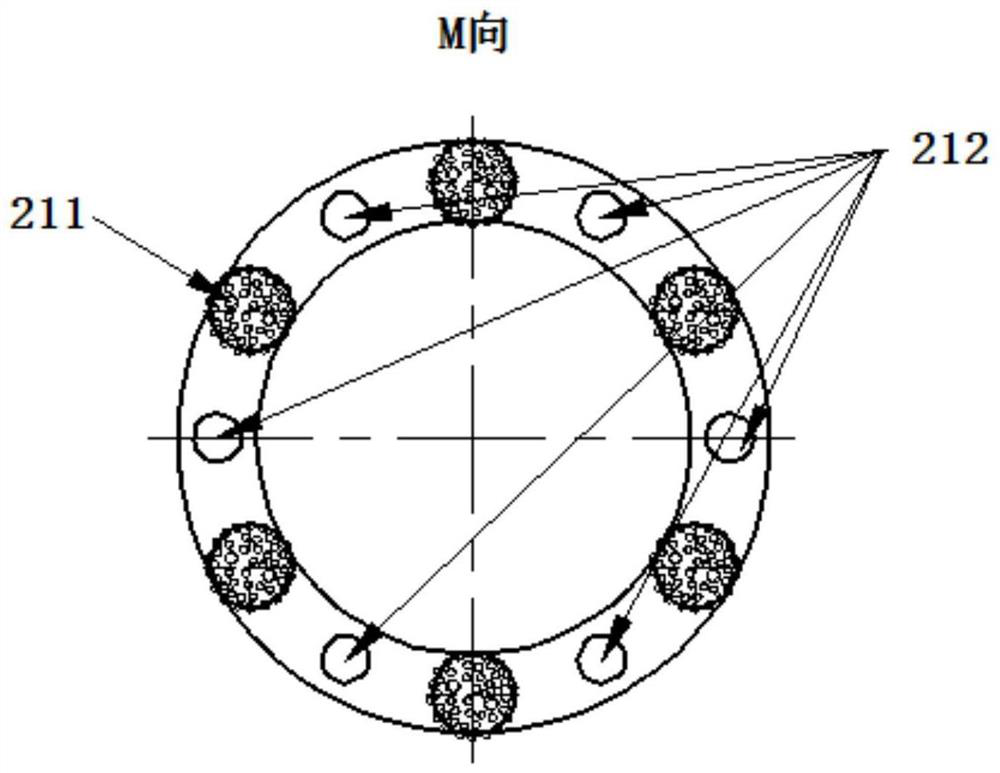

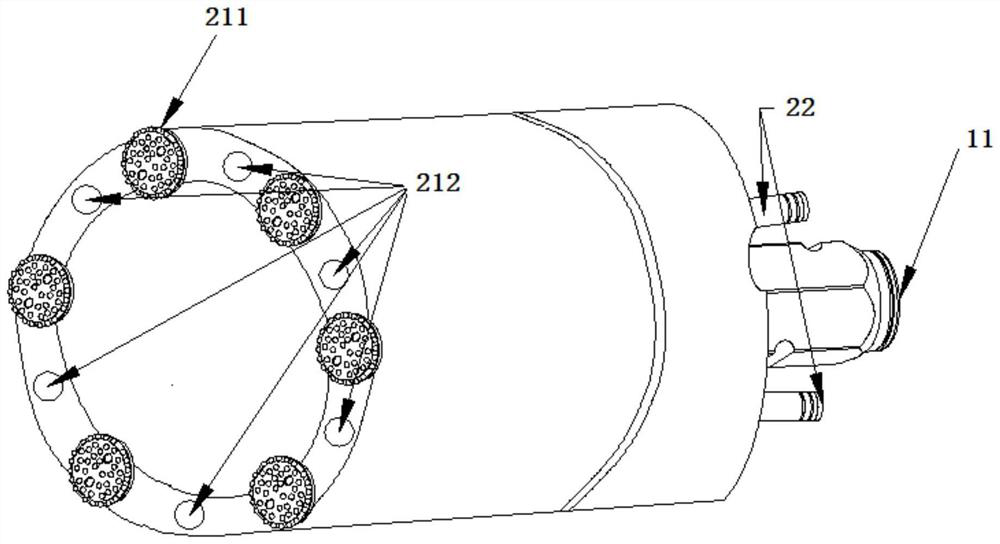

Reverse circulation impactor and system

PendingCN114016896AReduce cutting areaLow costConstructionsBorehole drivesStructural engineeringPetroleum engineering

The invention discloses a reverse circulation impactor and system. The reverse circulation impactor comprises a drill rod component and a coring component. The drill rod component and the coring component are integrally formed, and the drill rod component is arranged above the coring component; the coring component comprises a coring impactor; the bottom of the coring impactor cylinder is in a circular ring shape, and multiple positive circulation sub down-the-hole hammers are arranged on the circular ring at intervals; the drill rod component is used for providing a high-pressure air channel for the coring impactor. The device and the system are simple in structure, safe, effective, reliable and easy and convenient to operate, the drilling efficiency of the large-diameter impactor can be effectively improved, and the cost consumed by a drilling tool is reduced.

Owner:CHANGSHA HEIJINGANG IND CO LTD

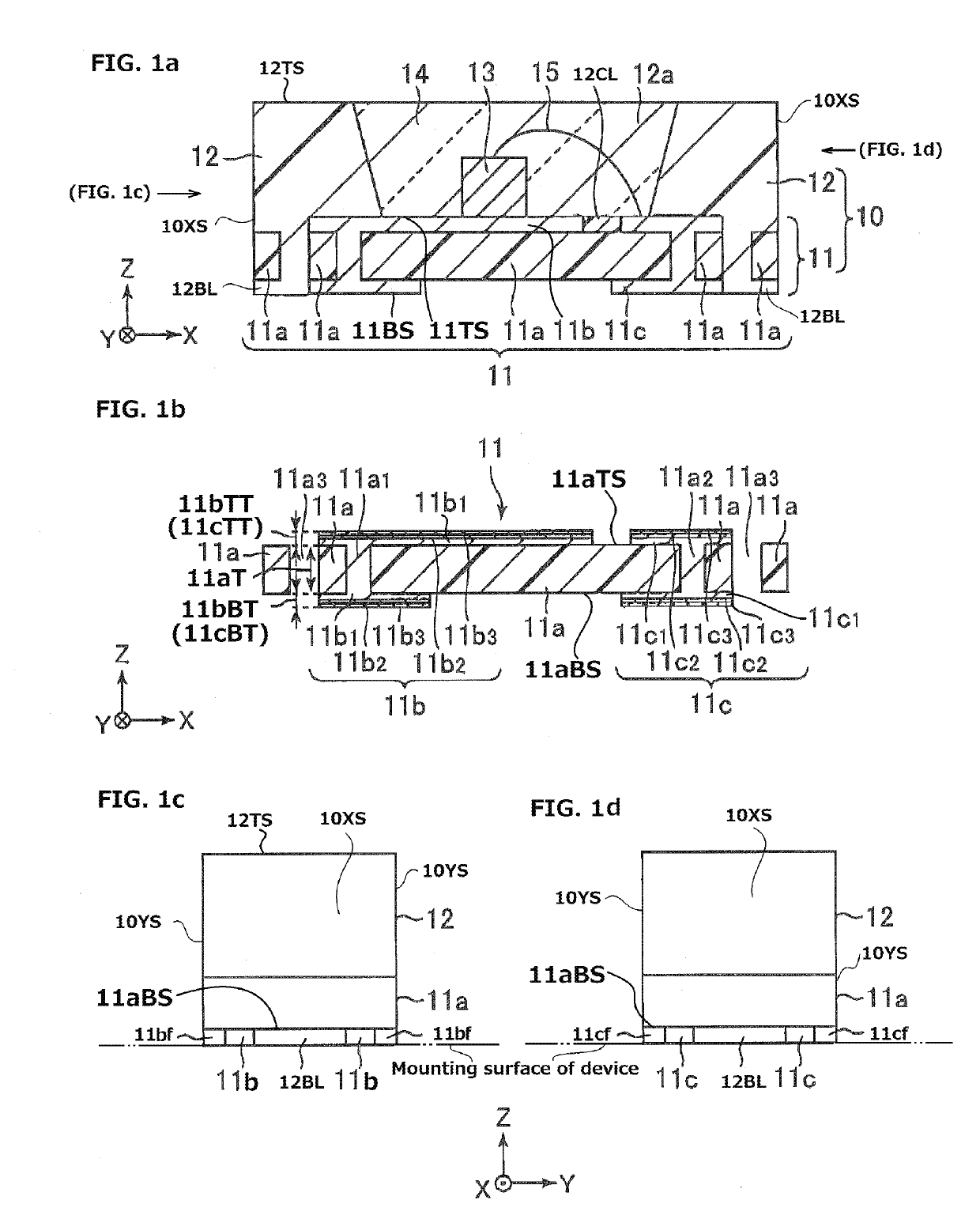

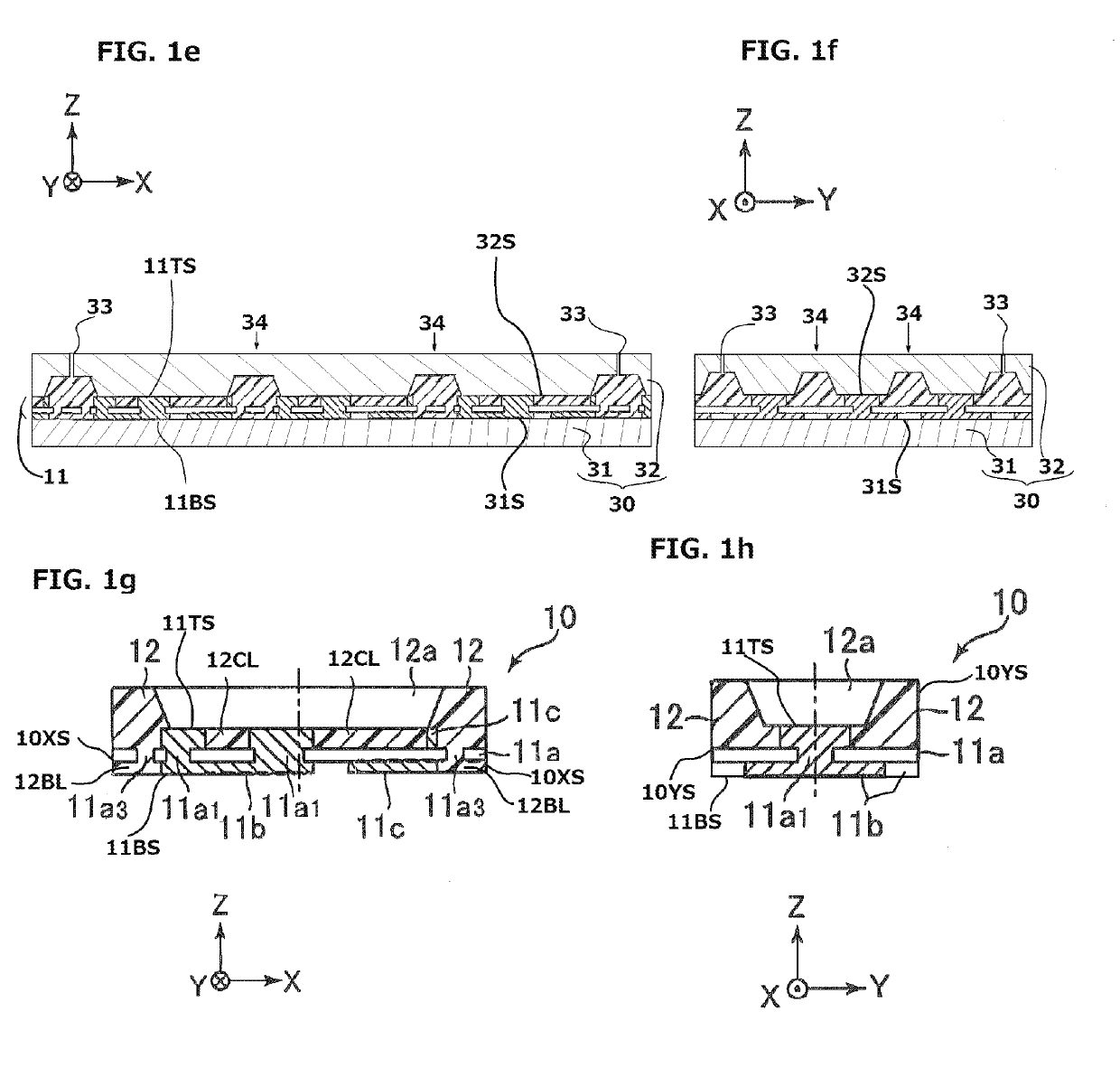

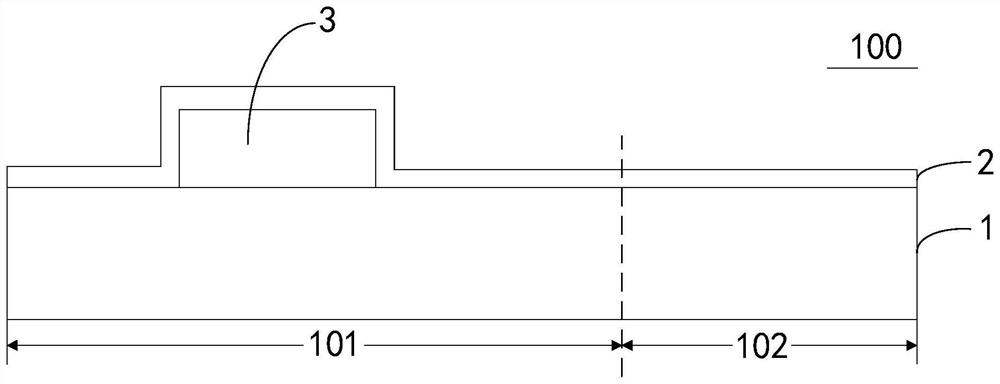

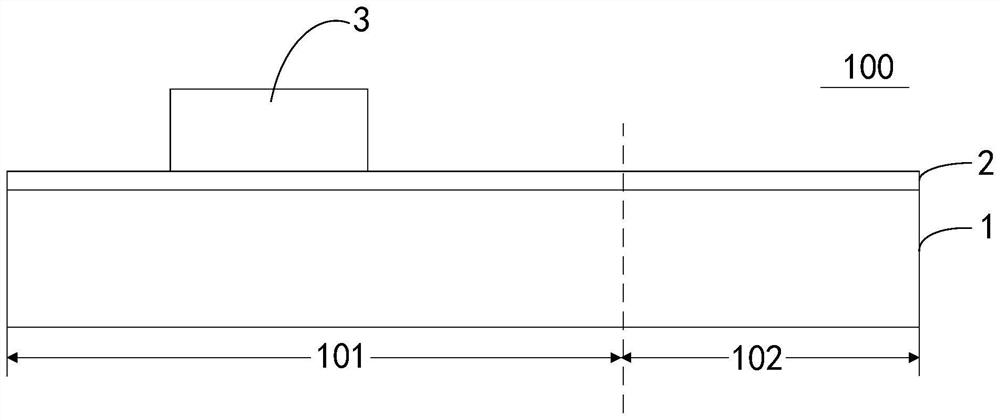

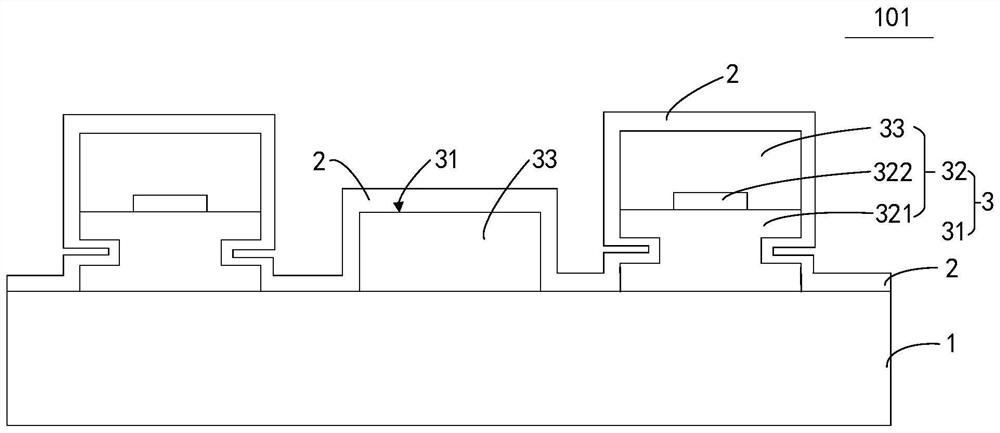

Resin package and semiconductor light-emitting device

ActiveUS20190198731A1Improve reliabilityImprove efficiencyPrinted circuit aspectsCasings/cabinets/drawers detailsEngineeringPrinted circuit board

Reliable resin packages and semiconductor light-emitting devices using the resin package can include a printed circuit board including a resin layer, metallic layers formed on a top surface of the resin layer and underneath a bottom surface of the resin layer and a frame arranged from a top surface of the printed circuit board toward a bottom surface of the printed circuit board. The semiconductor light-emitting device using the resin package can prevent the printed circuit board from warping toward the frame when forming the frame incorporating the printed circuit board because a total of each thickness of the metallic layers formed on the top surface and underneath the bottom surface of the resin layer can be thicker than a thickness of the resin layer. Thus, the present invention can provide the semiconductor light-emitting devices having high reliability, which can be used as a light source for vehicle lamps, etc.

Owner:STANLEY ELECTRIC CO LTD

Implantation tool for fixation of orthopaedic prosthesis

The invention discloses an implantation tool for fixation of orthopaedic prosthesis, and particularly relates to the technical field of implantation tools. The implantation tool comprises a recovery compartment. A punching mechanism and a polishing mechanism are arranged at the top of the recovery compartment. The punching mechanism comprises a first motor compartment that is internally provided with a partition plate. A first double-shaft motor is fixedly arranged on one side of the partition plate. A sleeve is arranged on one side of the first motor compartment. A power shaft is fixedly arranged on one side of the sleeve. A hollow pipe is arranged on the other side of the sleeve. and a sawtooth ring is fixedly arranged at one end of the hollow pipe. According to the present invention, the punching mechanism is arranged, and the first double-shaft motor is used to drive rotation of the power shaft and the sleeve, thereby driving rotation of a transmission rod and the hollow pipe. The sawtooth ring at one end of the hollow pipe rotates and then makes direct contact with the outer end of a bone for cutting the bone. A hole is formed after a round bone is cut off. The implantation tool of the present invention has advantages of less cutting area, few fragments, and convenience in cleaning.

Owner:XIANGYA HOSPITAL CENT SOUTH UNIV

Marc preventing juice extractor

The invention relates to a juice extractor, in particular to a marc preventing juice extractor. The invention discloses the marc preventing juice extractor which comprises a machine body, a cover body, a discharge pipe, a cutter rack, a cutter, a fixed part, a filter screen and a power device, wherein the cover body is arranged on the machine body, the machine body is conical, a discharge pipe is connected with the bottom of the machine body and tilts down, the filter screen is arranged in the discharge pipe, the cutter is arranged on the cutter frame and is saw-toothed, the fixed part is fixed at the upper part of the cutter, the cutter rack is arranged at the bottom inside the machine body, the power device is provided with a rotating bar, and the rotating bar is connected with a cutter rack. The marc preventing juice extractor has the benefits as follows: through the serrated cutter, the cutting area is reduced, through the conical machine body, the clearance between the cutter and the inner wall of the machine body is reduced and a sufficient cutting effect is played; through filtering to vegetable and fruit juice by the filter screen, the effect of reducing the marc containing quantity of the vegetable and fruit juice is played.

Owner:黄健

Shielding device, processing method and equipment, semiconductor equipment

ActiveCN102573429BSolve high temperatureReduce eddy currentElectric discharge tubesMagnetic/electric field screeningPower semiconductor deviceEngineering

The invention provides a shielding apparatus, a processing method and a device, and a semiconductor device. The shielding apparatus comprises a shell, the shell is provided with a plurality of through holes, and a sidewall curve of the shell is parallel to a magnetic line of force in a magnetic field where the shell is located. The technical scheme of the invention can reduce the cutting area of the magnetic field and the shielding apparatus, thereby reducing the vortex in the shielding apparatus, and reducing, even eliminating the conversion from magnetic field energy to heat, so that the loss of the magnetic field energy can be reduced, and the problem of higher temperature of the shielding apparatus also can be solved completely.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

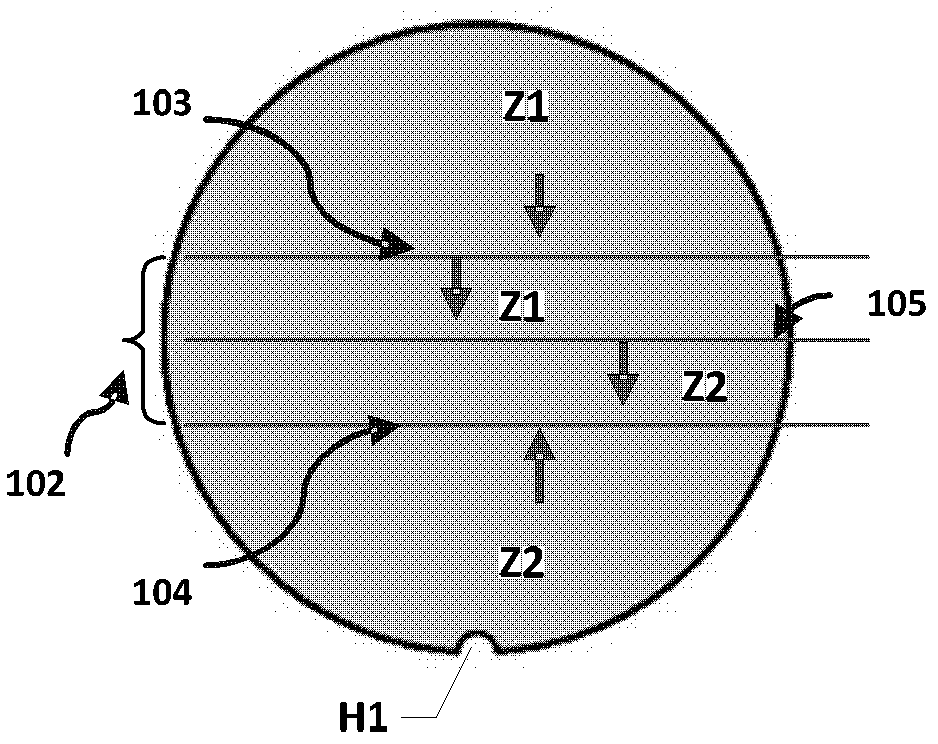

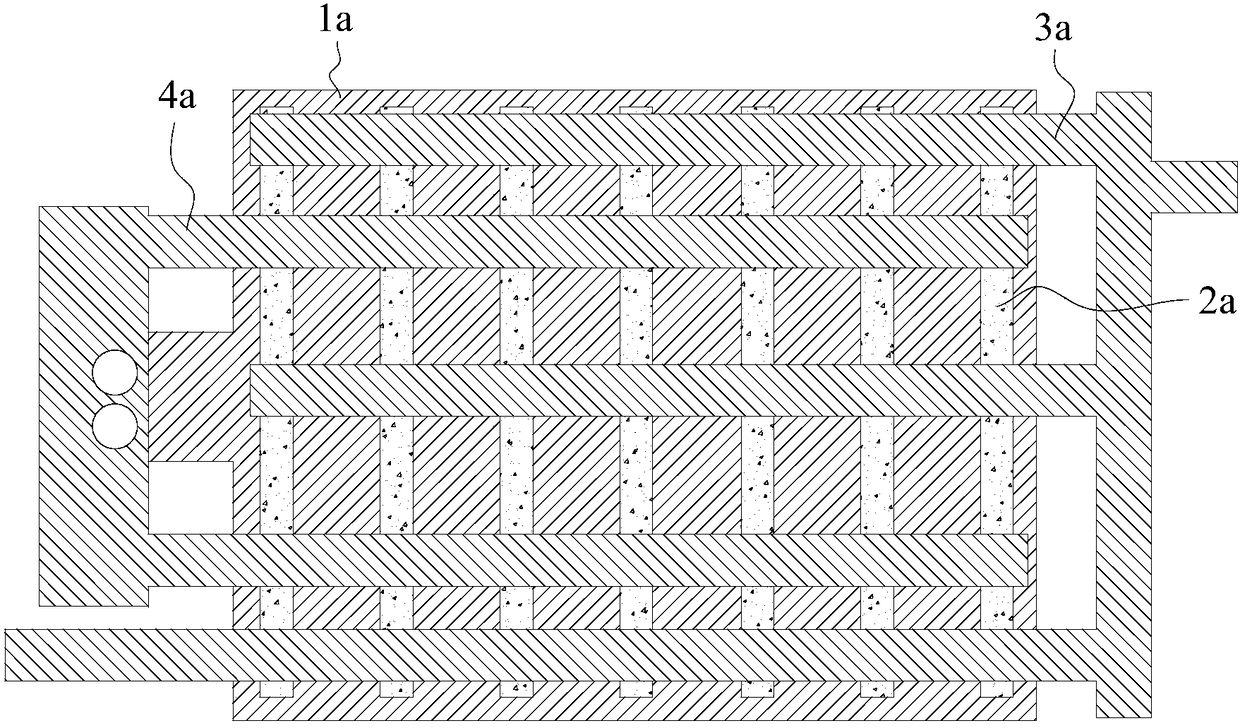

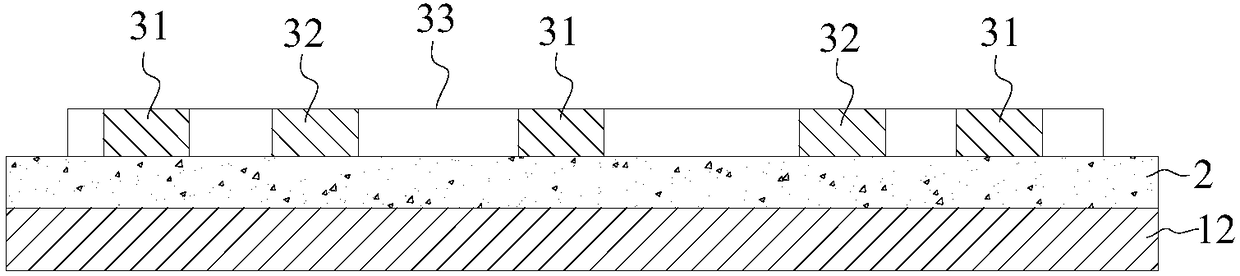

Display panel and display equipment

PendingCN114843425AReduce or eliminate cracksGuaranteed encapsulation effectSolid-state devicesSemiconductor/solid-state device manufacturingStructural engineeringComposite material

The embodiment of the invention provides a display panel and display equipment. The display panel comprises a substrate, a packaging layer and a barrier structure, the packaging layer comprises an inorganic packaging layer, the inorganic packaging layer is arranged on one side of the substrate, and the inorganic packaging layer is a continuous film layer; the barrier structure comprises a stress release structure, the stress release structure is arranged on the side, close to or away from the substrate, of the inorganic packaging layer, the elastic modulus of the stress release structure is smaller than that of the inorganic packaging layer, and the stress release structure is used for releasing the cutting stress of the inorganic packaging layer. The barrier structure is arranged in the peripheral area, and the elastic modulus of the stress release structure in the barrier structure is smaller than the elastic modulus of the inorganic packaging layer, so that when the inorganic packaging layer is cut, the cutting stress is released by the stress release structure, cracks of the inorganic packaging layer can be reduced or eliminated, and the yield of the packaging layer is improved. Therefore, the packaging effect of the display area can be ensured, and the packaging reliability and the cutting yield of the display panel can be improved.

Owner:HEFEI BOE ZHUOYIN TECH CO LTD +1

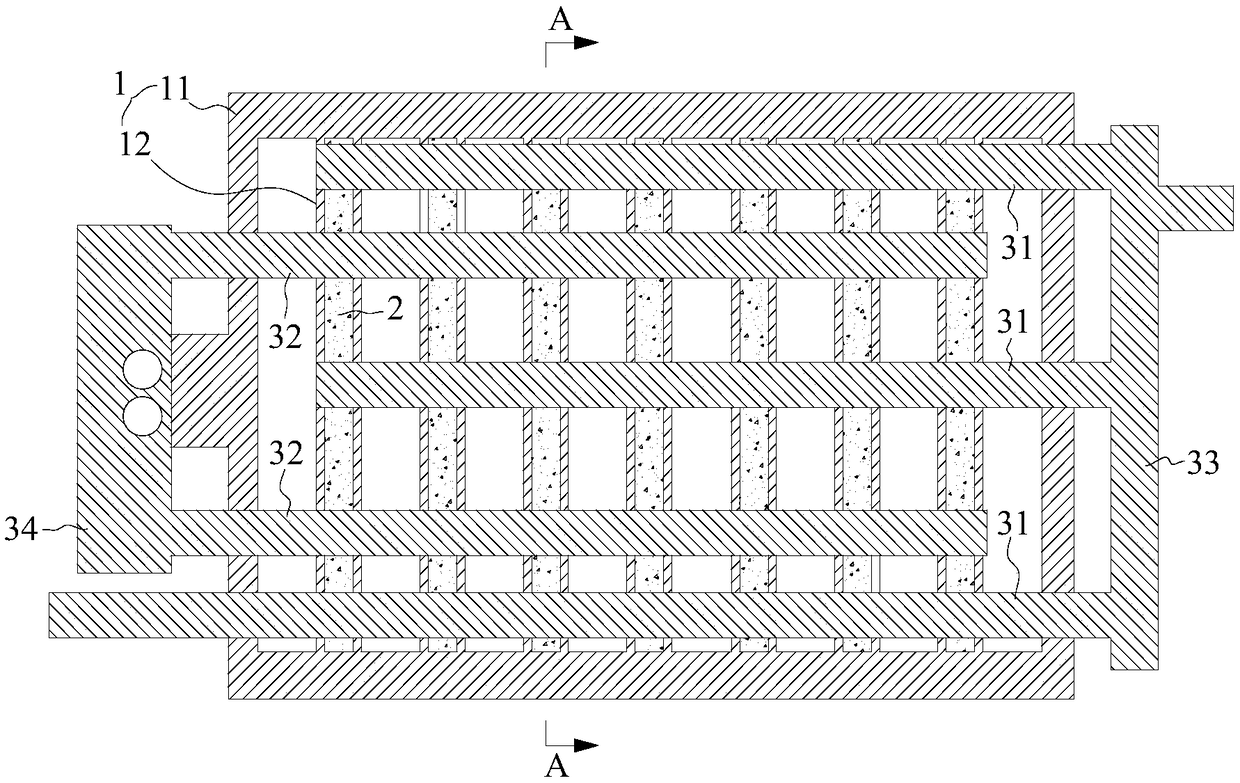

Display device, array substrate, gate drive circuit, transistor and manufacturing method thereof

InactiveCN108231756AEliminate short circuitAvoid cutsSolid-state devicesIdentification meansDisplay deviceActive layer

The present invention discloses a display device, an array substrate, a gate drive circuit, a transistor and a manufacturing method thereof, and relates to the technical field of reality. The transistor is used for a gate drive circuit, and the gate drive circuit is arranged at a non-display area of an array substrate. The transistor comprises a gate layer, an active layer and a source and drain layer. The gate layer comprises a plurality of gate lines distributed in a first direction and connected to one another. The active layer is arranged on the gate layer. The source and drain layer is arranged on the active layer and comprises a plurality of source lines and a plurality of drain lines which are distributed at intervals in a second direction, the source lines are connected to one another, the drain lines are connected to one another, and the second direction is different from the first direction.

Owner:BOE TECH GRP CO LTD +1

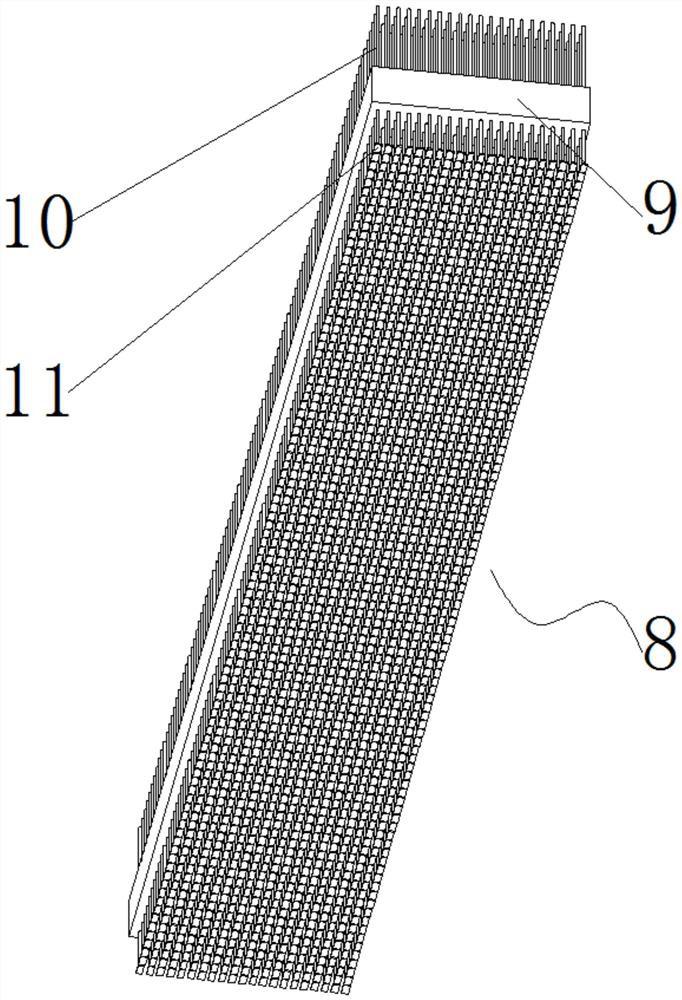

Efficient and consumption-reducing stone cutting machine

InactiveCN114102871ARealize automatic cuttingSmall footprintWorking accessoriesStone-like material working toolsSTONE CUTTERFriction force

The invention discloses an efficient and consumption-reducing stone cutting machine which comprises a stone conveying mechanism and a stone cutting mechanism, the stone cutting mechanism is arranged above the stone conveying mechanism, the stone cutting mechanism comprises a rack and a saw belt type cutting device arranged on the rack, and the saw belt type cutting device drives a saw belt to cut stone. Compared with the prior art, the method has the beneficial effects that the material loss can be reduced, the cost can be reduced, the quarry stone can be cut into more stone plates, and the yield and the production benefit can be improved. The saw band is in a tangent state with the stone during cutting, and the cutting point of the saw band is always one point, so that the cutting area of the saw band is reduced, the cutting pressure and friction force of the cutting point are increased, the saw band can cut the stone more powerfully, the cutting efficiency is improved, and the cutting time is shortened.

Owner:福建省久冈传动科技有限公司

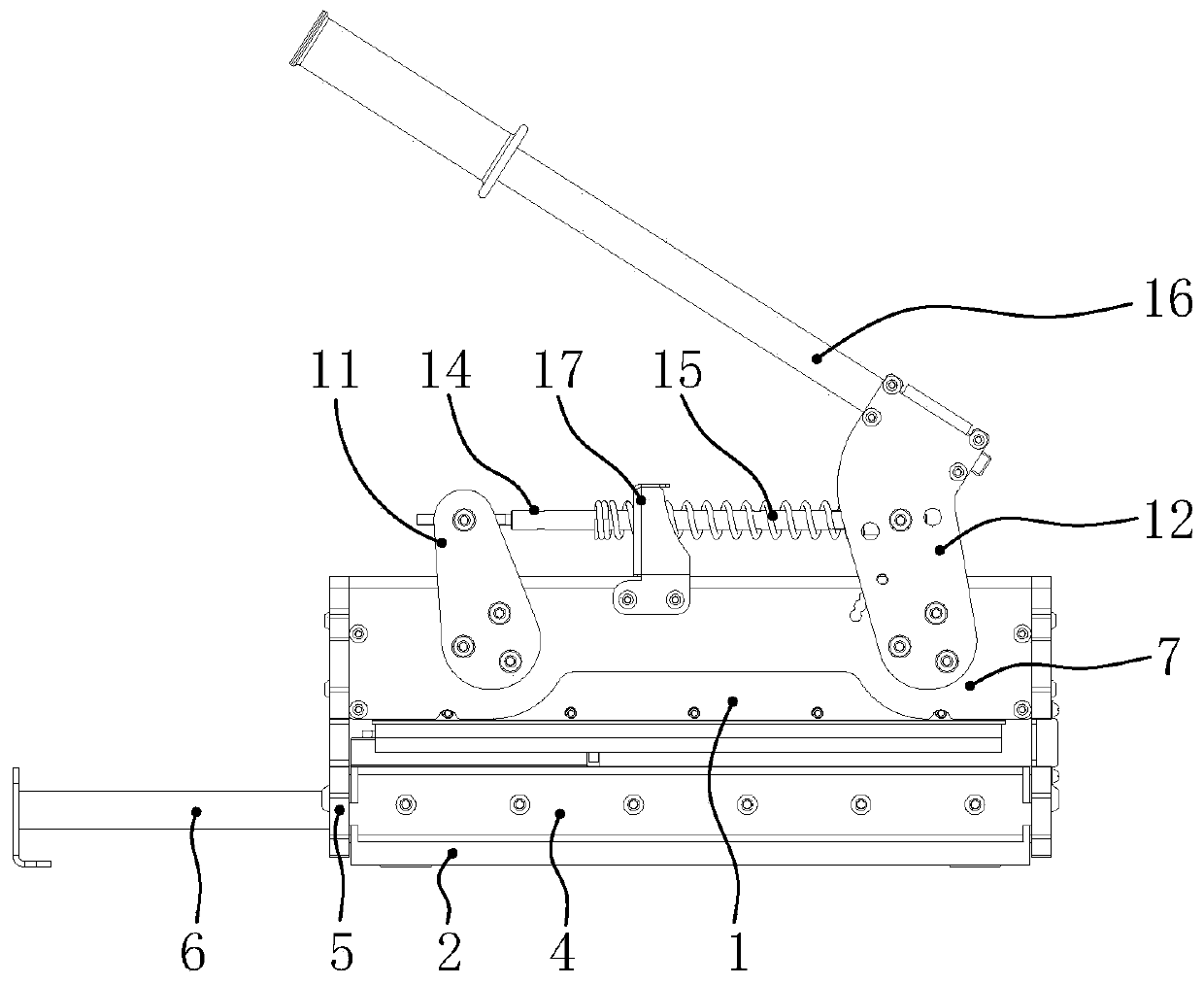

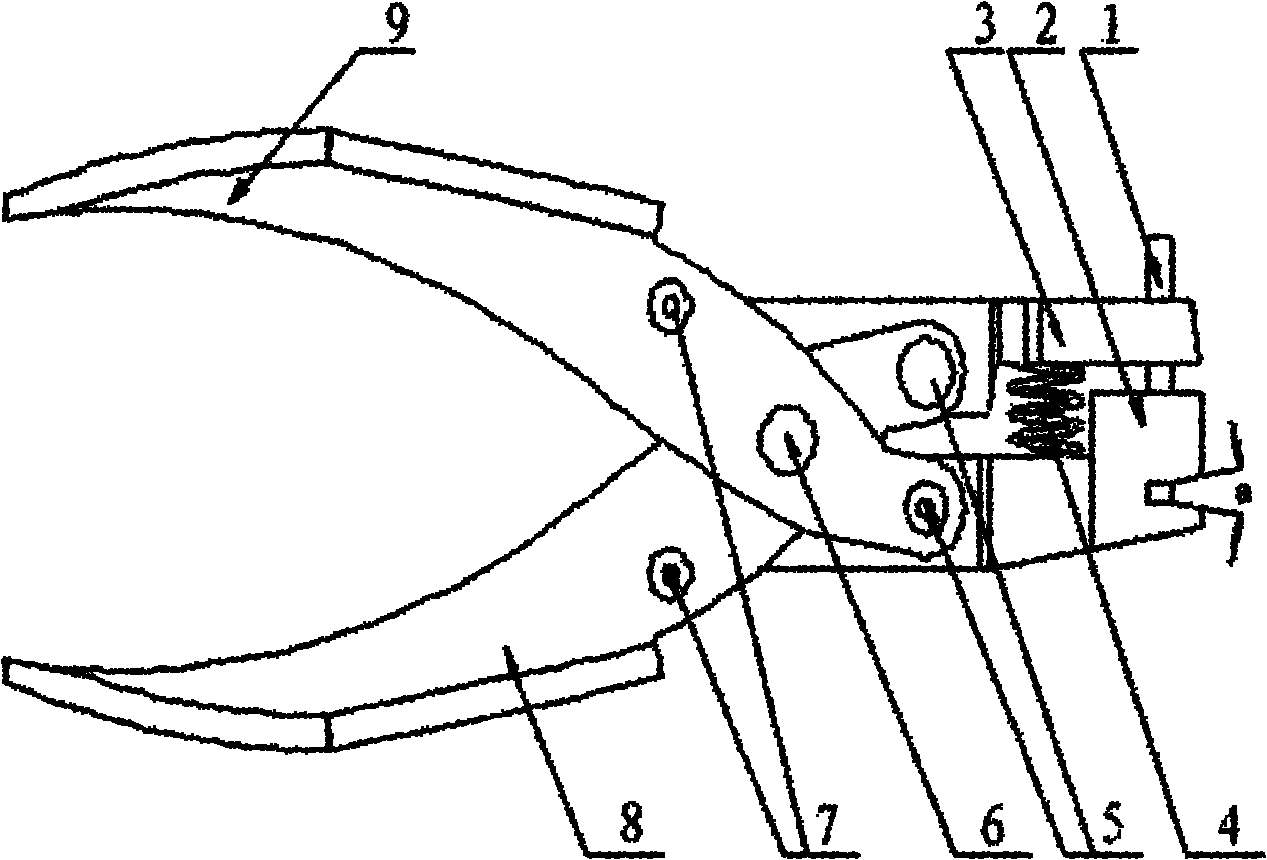

Processing device for intensive bus insulating film pin notch and operation method

The invention relates to a processing device for an intensive bus insulating film pin notch and an operation method, belonging to the technical field of electrical equipment. In the processing device, a notch cutter (convex die), a power knife rest, a notch knife rest (concave die), an upper operating handle, a lower operating handle, hollow rivets, a rotating shaft and guide positioning shafts are organically combined together. Due to adoption of the device, the technique for processing the existing insulating film notch is improved, the waste of human resources is reduced and the production efficiency is improved; in addition, the invention provides a control tooling of the bus pin notch, which is simple and accurate in control and flexible to operate, and saves time and labor; and the invention has the advantages that the operation is simple due to portable operation, the processing is convenient and the operation space is small.

Owner:吉林龙鼎电气股份有限公司

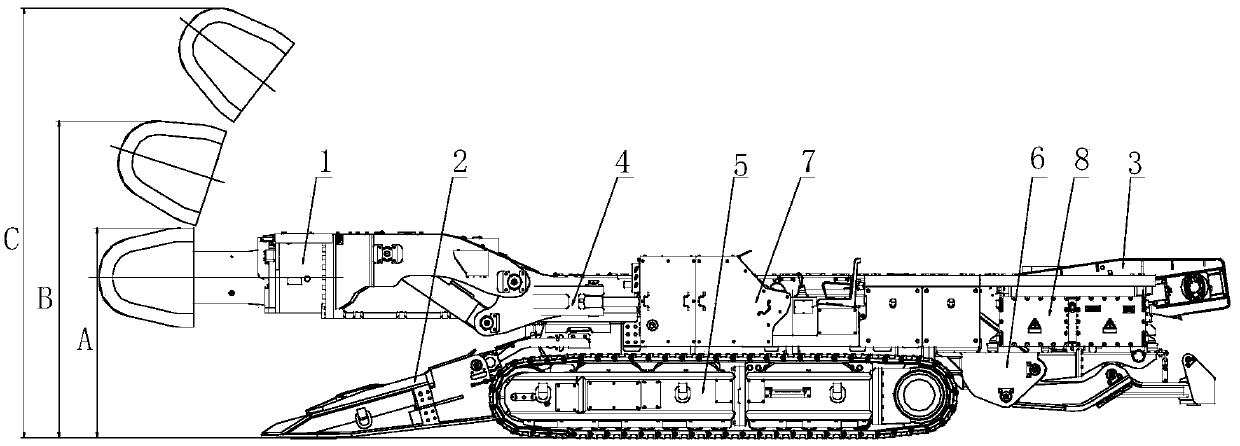

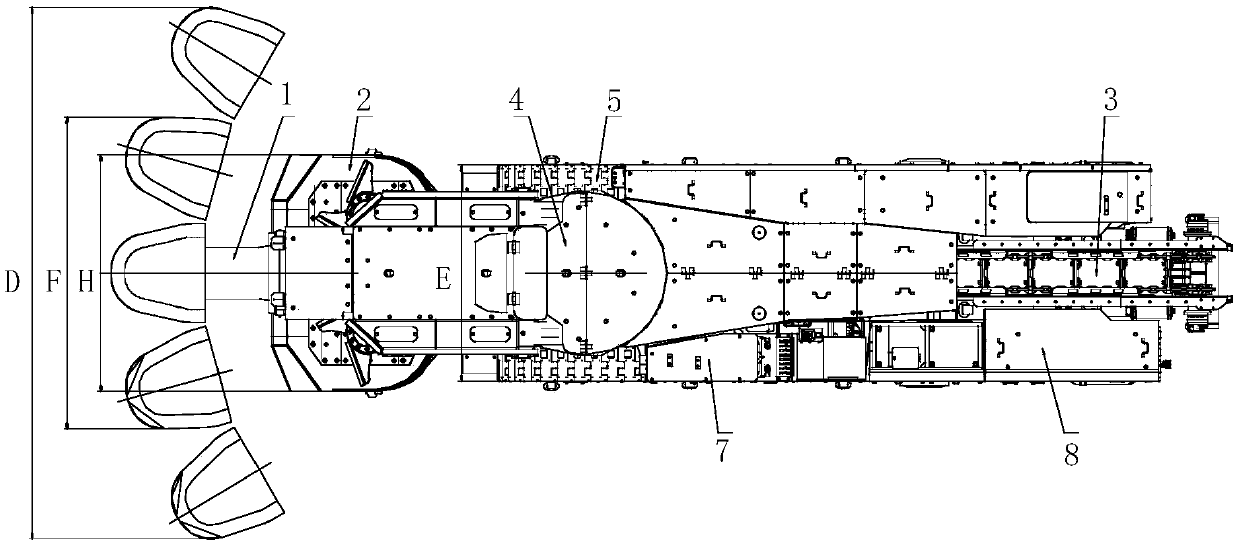

Heading machine for rock roadway with small cross section

The invention discloses a heading machine for a rock roadway with a small cross section and belongs to the technical field of heading machines. A walking part is mounted on the lower part of a body part, a hydraulic system is mounted on the middle of the body part, a cutting part and a shovel plate part are mounted in the front of the body part, the shovel plate part is located below the cutting part, an electrical part is mounted on the rear part of the body part, an intermediate conveyor is mounted on the middle of the body part in an inserted mode, and a rear supporting part is mounted on the lower part of the electrical part. The heading machine for the rock roadway with the small cross section is characterized in that theoutline dimension of the whole machine is small and the headingmachine can pass through the small section, the rock roadway with high hardness can further be cut, a cutting area can be reduced, the cost is saved, and the heading machine for the rock roadway withthe small cross section is applicable to a rock roadway of a mine and a tunnel, namely the working condition is a rock roadway, and the required cutting section of the roadway is small.

Owner:无锡华瀚能源装备科技有限公司

Band saw machine capable of adjusting the cutting angle of the band saw

Owner:EVERISING MACHINE

An implant tool for orthopedic prosthesis fixation

The invention discloses an implant tool for orthopedic prosthesis fixation, specifically relates to the technical field of implant tools, including a recovery cabin, the top of the recovery cabin is provided with a punching mechanism and a grinding mechanism, and the punching mechanism includes a first A motor compartment, the inside of the first motor compartment is provided with a partition, one side of the partition is fixed with a first biaxial motor, one side of the first motor compartment is provided with a sleeve, and one side of the sleeve is A power shaft is fixedly provided, a hollow tube is provided on the other side of the sleeve, and a serrated ring is fixedly provided at one end of the hollow tube. The present invention uses the first double-axis motor to drive the power shaft and the sleeve to rotate by setting the punching mechanism, thereby causing the transmission rod and the hollow tube to rotate. After the sawtooth ring at one end of the hollow tube rotates, it directly contacts the outer end of the bone and cuts the bone. The hole is formed after cutting a round bone, the cutting area is small, the debris is less, and it is easy to clean up.

Owner:XIANGYA HOSPITAL CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com