Novel method for manufacturing short shell ring flange sections of offshore wind power tower barrel

A technology of offshore wind power and flange sections, which is applied in the field of offshore wind power generation, can solve the problems of long production cycle, general production accuracy, and the inability to quickly and safely use the short tube flange section of the roller frame, so as to save the time of assembly , The cutting area is small, the effect of shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings and embodiments.

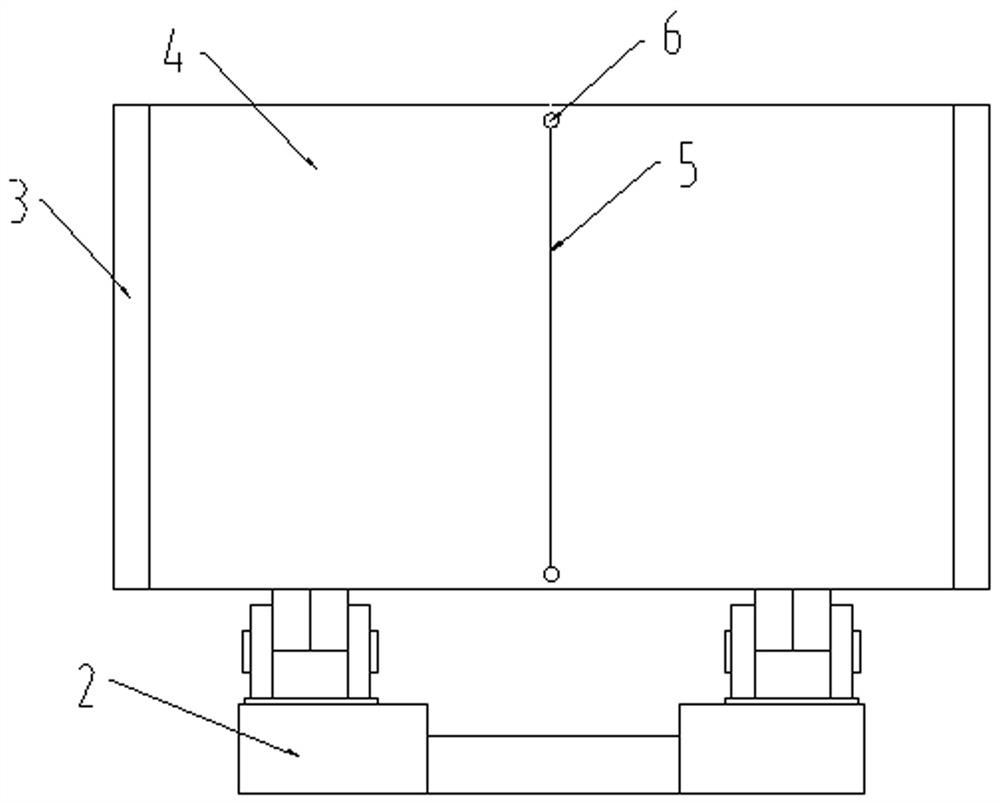

[0023] Please refer to figure 1 with figure 2 As shown, the new method for making the flange section of the short tube section of the offshore wind power tower in this embodiment, the specific method is as follows:

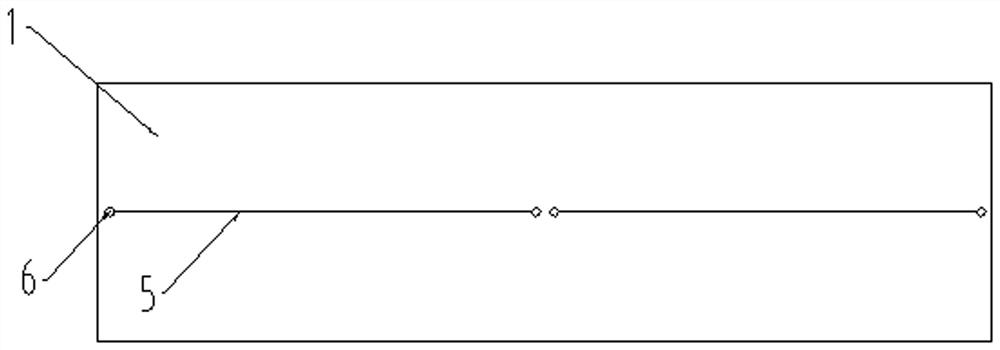

[0024] Step 1. The two short tube sections are blanked as a whole. Use a CNC machine tool to cut out two equal-length gaps 5 at intervals of about 2 horizontally at a cutting speed of 280-320 mm / min at the middle position of the blanked steel plate 1 using a CNC machine tool. , the bridge nodes 6 are left at both ends of the gap 5, and the length direction of the gap 5 is perpendicular to the length direction of the long tube flange section 4 to be fabricated;

[0025] Step 2. Use a semi-automatic flame cutting machine to cut the bevel, and polish and clean it with a grinder;

[0026] Step 3: St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com