A kind of preparation method of chitosan hydroxybutyl derivative

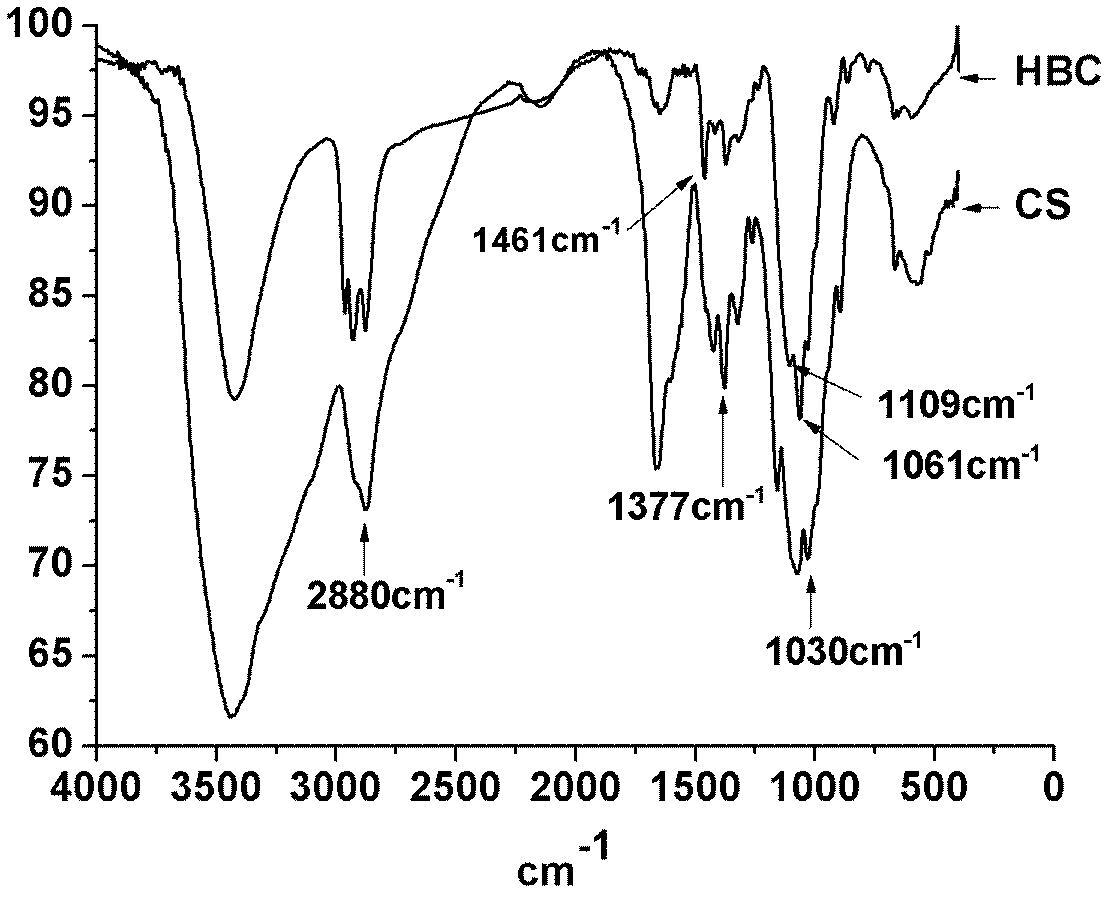

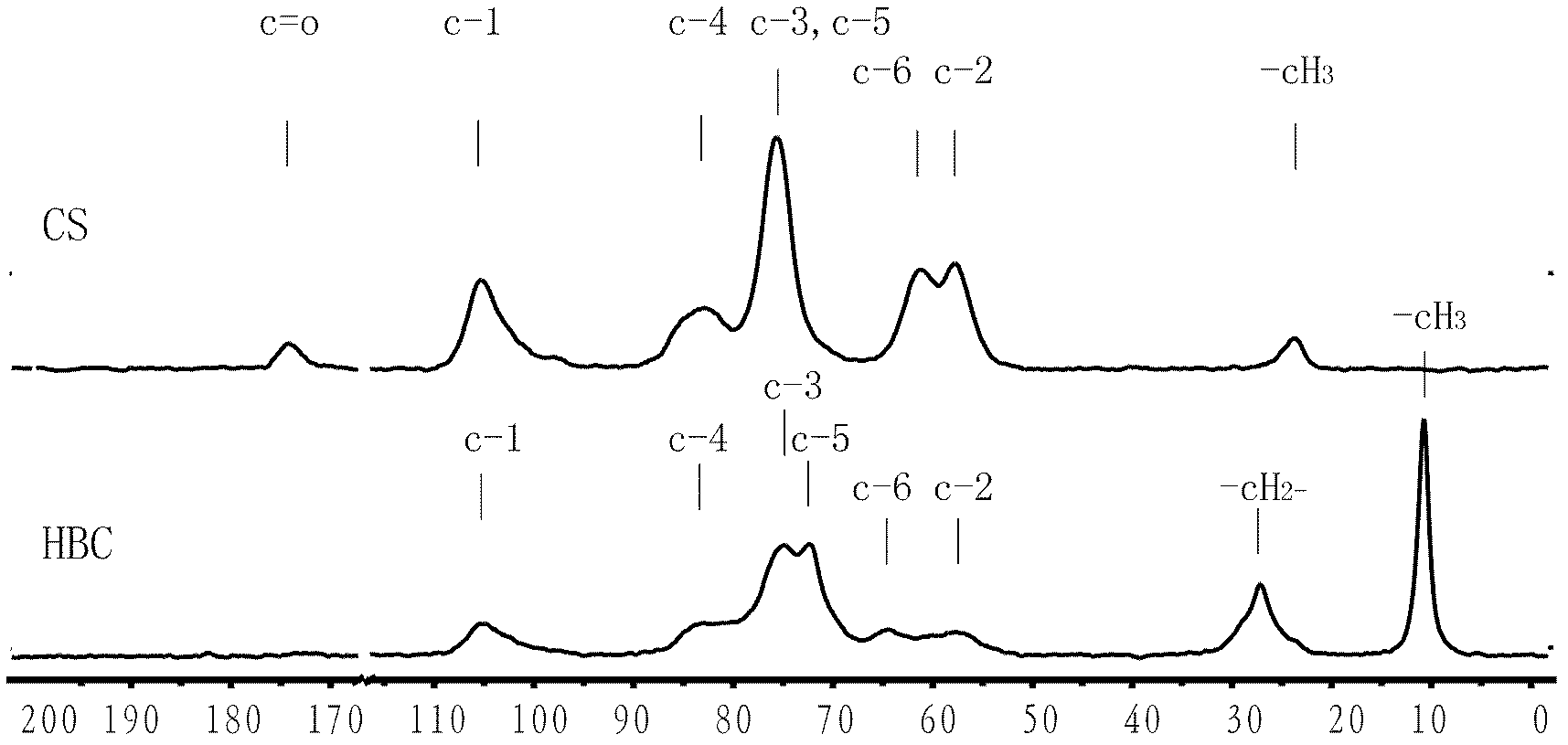

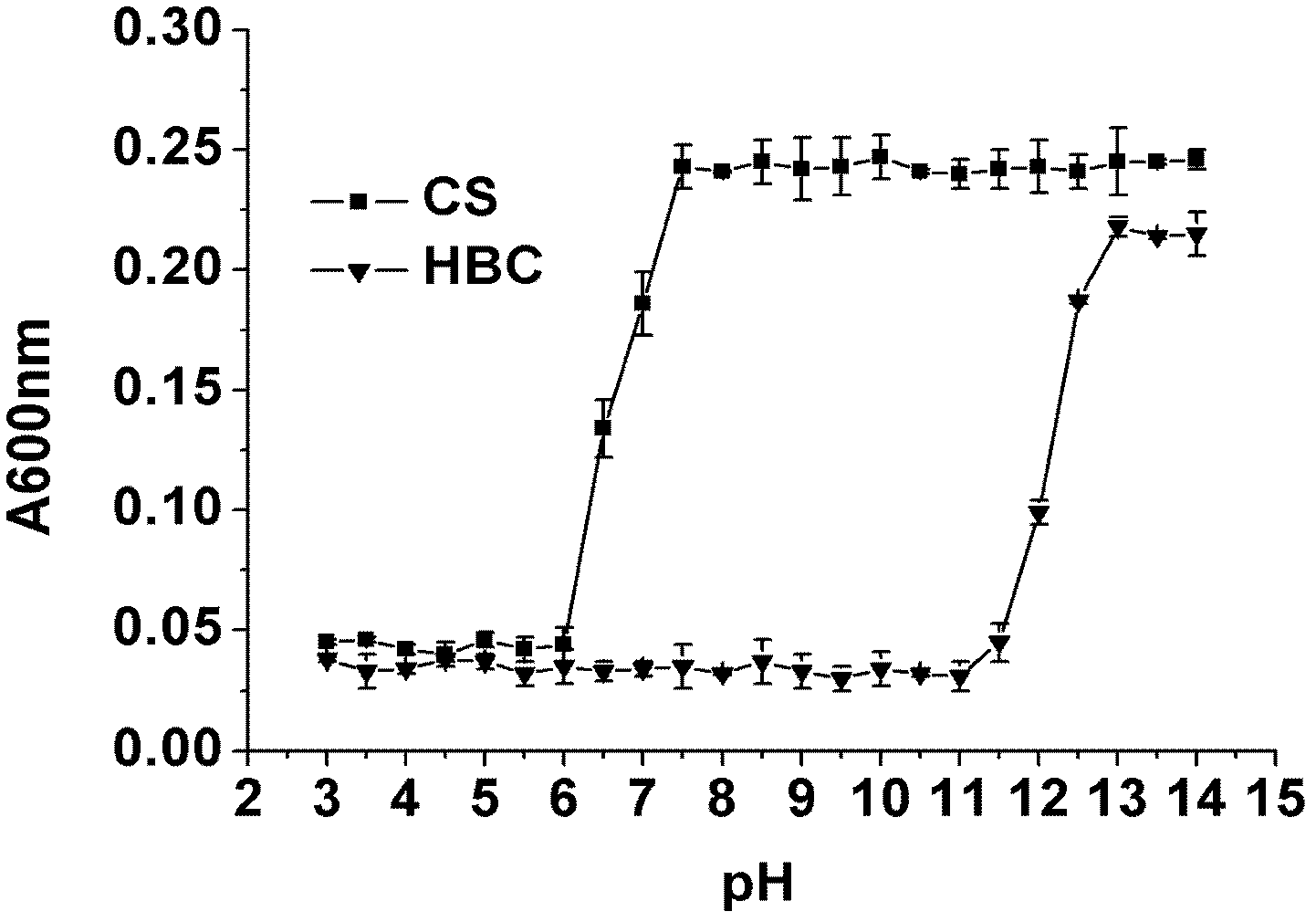

A chitosan hydroxybutyl and polysaccharide hydroxybutyl technology, which is applied in the biological field, can solve the problems of no hydroxybutyl chitosan commodity sales, limited research and application development, long preparation process cycle, etc., so as to shorten the preparation process. cycle, improved preparation efficiency, and the effect of wide pH dissolution range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Weigh 20g of chitosan, dissolve it in 1000ml of 1% HCl aqueous solution, filter, add dropwise 1mol / l NaOH solution to the filtrate to obtain a precipitate, wash with distilled water several times until neutral, desalt with 70% ethanol, and desalt with 95% ethanol Dehydrate and dry at 50°C to obtain a purified chitosan sample. Weigh 1g of purified chitosan and disperse it in 10ml of 50% NaOH aqueous solution, N 2 Protected, stirred under the power of 600W microwave for 24 hours, filtered, squeezed out the excess lye to obtain solids. Add the obtained solid to 20ml of isopropanol aqueous solution (isopropanol: water (V:V) = 19:1) and stir for 24h, add 25ml of 1,2-epoxybutane dropwise, react for 1h, and then turn on the power of 1200W Under microwave, the temperature was raised to 60°C for 48 hours. After cooling to room temperature, 10% HCl aqueous solution was added dropwise to the reaction solution to adjust the pH of the system to neutral. Filter out the insoluble m...

Embodiment 2

[0018] Weigh 20g chitosan, dissolve in 1000ml 1% HCl aqueous solution, filter, add dropwise 1mol / l NaOH solution to the filtrate to obtain a precipitate, wash with distilled water until neutral, desalt with 70% ethanol, dehydrate with 95% ethanol, Dry at 50°C to obtain purified chitosan samples. Get 1g of purified chitosan and disperse it in 10ml of 50% NaOH aqueous solution, N 2 Protected, stirred under the power of 1200W microwave for 24h, filtered, squeezed out the excess lye to obtain solids. Add the obtained solid to 20ml of isopropanol aqueous solution (isopropanol:water (V:V)=10:10) and stir for 24h, add dropwise 20ml of 1,2-epoxybutane, react for 1h, power 1000W microwave, The temperature was raised to 25°C for 72h. After cooling to room temperature, 10% HCl aqueous solution was added dropwise to the reaction solution to adjust the pH of the system to neutral. Filter out the insoluble matter, precipitate with 3 times the volume of ethanol, centrifuge (12000 rpm, 10 ...

Embodiment 3

[0020] Weigh 20g chitosan, dissolve in 1000ml 1% HCl aqueous solution, filter, add dropwise 1mol / l NaOH solution to the filtrate to obtain a precipitate, wash with distilled water until neutral, desalt with 70% ethanol, dehydrate with 95% ethanol, Dry at 50°C to obtain purified chitosan samples. Get 1g of purified chitosan and disperse it in 10ml of 50% NaOH aqueous solution, N 2 Protected, stirred under the power of 1000W microwave for 24h, filtered, squeezed out the excess lye to obtain solids. Add the obtained solid to 20ml of isopropanol aqueous solution (isopropanol: water (V:V) = 1:19) and stir for 24h, add 5ml of 1,2-epoxybutane dropwise, react for 1h, and use a microwave with a power of 600W , the temperature was raised to 80°C for 24h. After cooling to room temperature, 10% HCl aqueous solution was added dropwise to the reaction solution to adjust the pH of the system to neutral. Filter out the insoluble matter, precipitate with 3 times volume of ethanol, centrifug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com