LiFePO4/C nano composite positive pole material and preparation method thereof

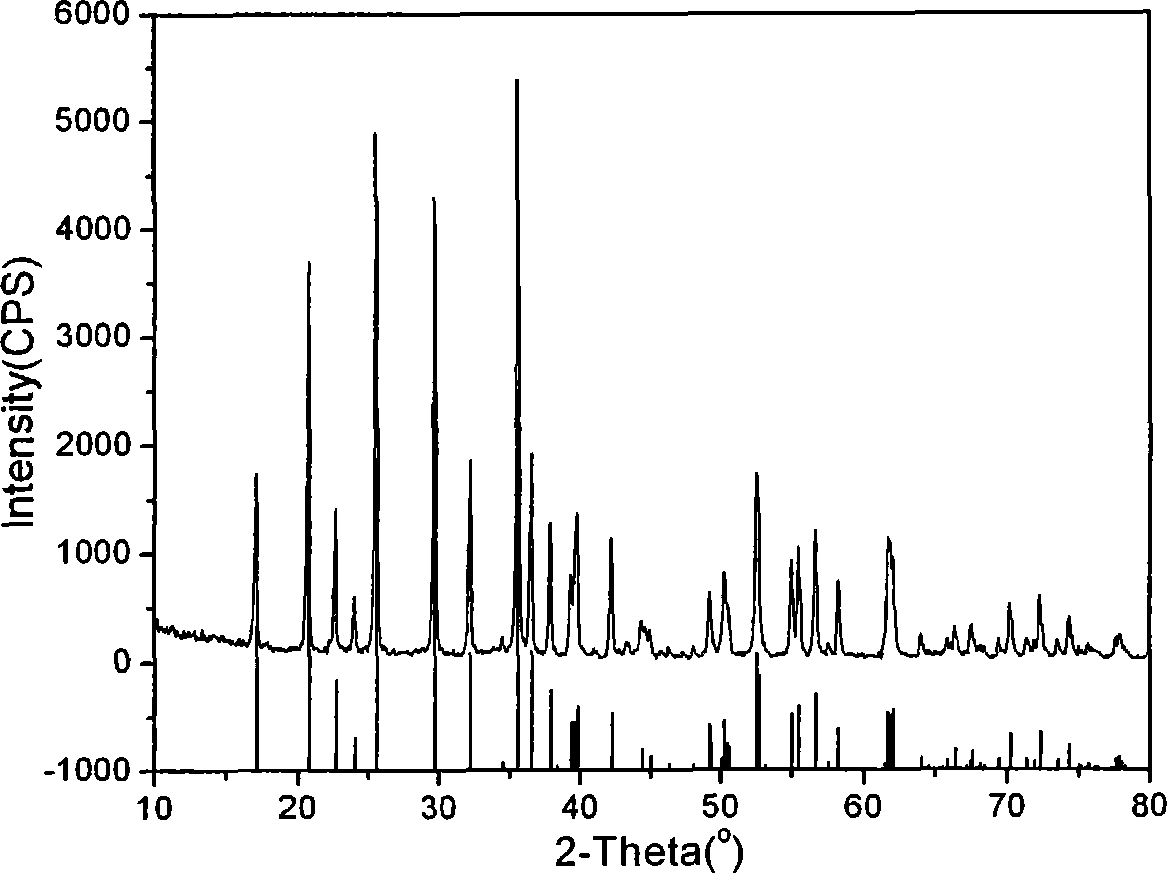

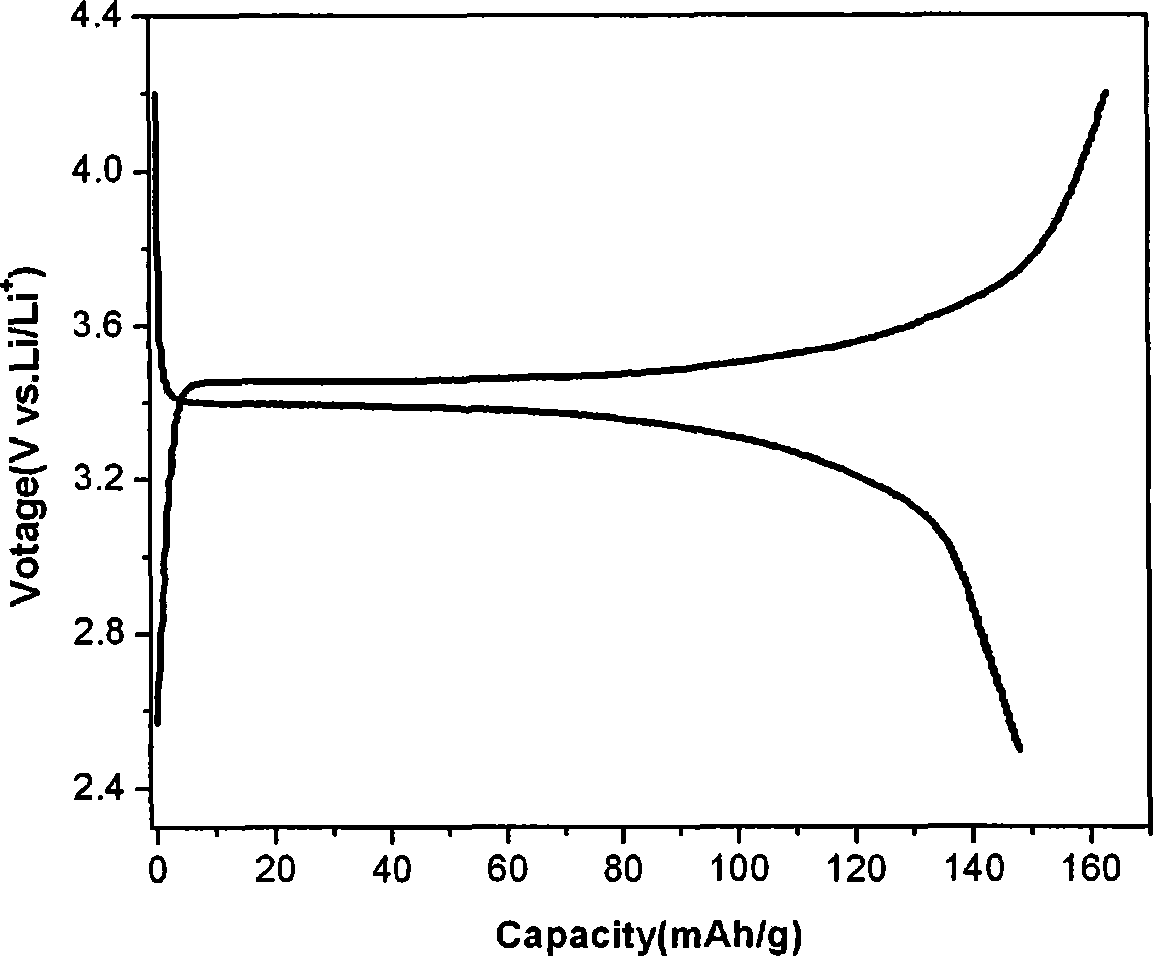

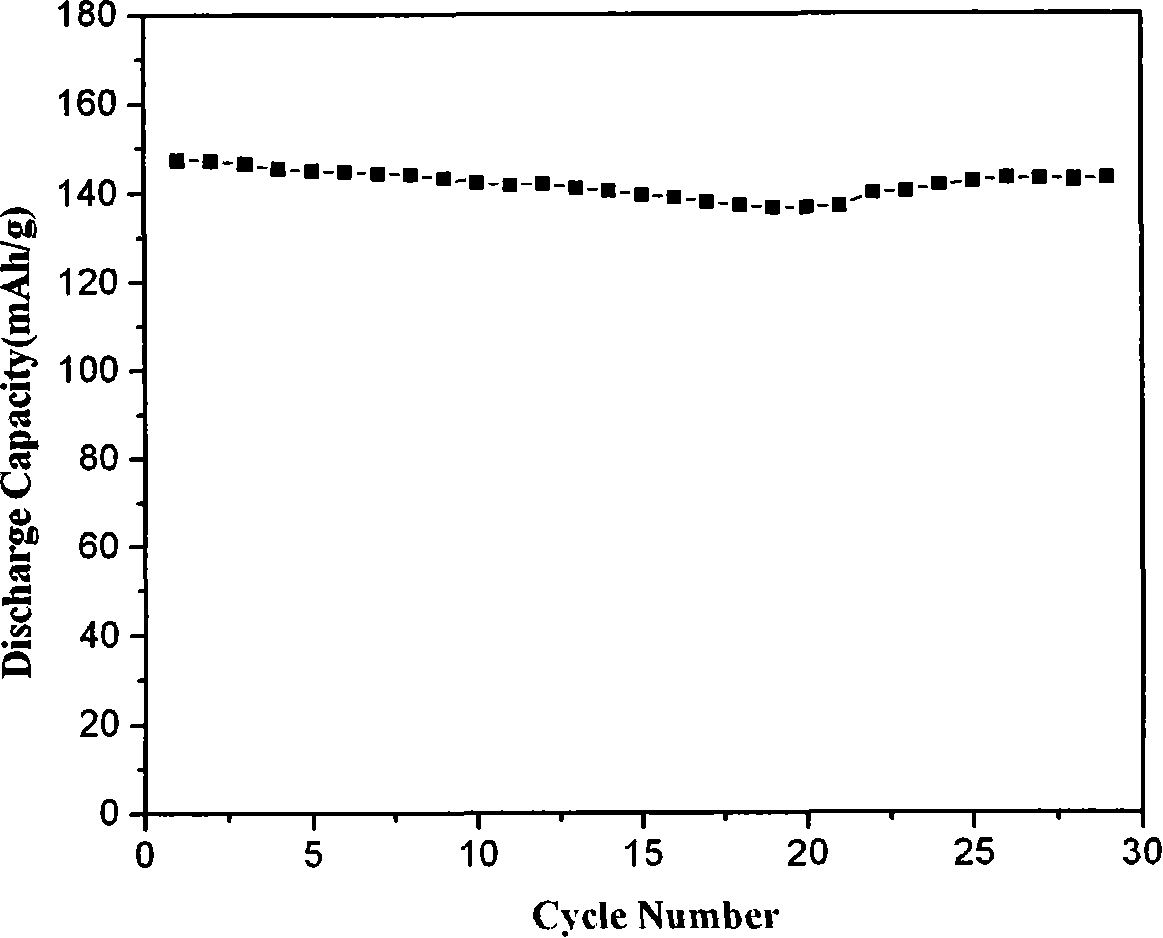

A cathode material and nanocomposite technology, which is used in electrode manufacturing, chemical instruments and methods, phosphorus compounds, etc., can solve the problems such as the inability to effectively control the particle size and distribution of the product, and the inability to achieve uniform dispersion of carbon sources, and achieve the preparation cycle. The effect of short, stable structure and pure crystal phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 2.308g of lithium hydroxide monohydrate, 0.079g of high specific surface area activated carbon, and 80ml of PEG (average molecular weight: 400) into 100ml of distilled water, and fully stir for 0.5h to obtain a uniform mixture; mix 6.951g of ferrous sulfate heptahydrate and 2.859g One piece of lithium dihydrogen phosphate was dissolved in 100ml of distilled water, and stirred for 10 minutes to obtain a suspension. Under an argon atmosphere, the LiH 2 PO 4 and FeSO 4 Quickly drop the suspension of LiOH into the LiOH mixture. After the dropwise addition, age for 0.5h to obtain the precursor gel, and then perform centrifugation, wash the precipitate with deionized water several times, filter it with suction, and then heat it at 75°C 1. Drying in a vacuum oven replaced with argon for 8 hours to obtain the precursor powder. Then the dried precursor powder was pressed into tablets at 15MPa, put into a crucible filled with activated carbon, put the crucible in a microwa...

Embodiment 2

[0029] Add 4.196g lithium hydroxide monohydrate, 0.395g high specific surface area acetylene black, 79ml PEG (average molecular weight 400), 3.944g CTAB into 100ml distilled water, and fully stir for 1h to obtain a homogeneous mixture; 13.901g ferrous sulfate heptahydrate Dissolve 5.200g of lithium dihydrogen phosphate in 100ml of distilled water and stir for 15min to obtain a suspension. Under an argon atmosphere, the LiH 2 PO 4 and FeSO 4Quickly drip the suspension of LiOH into the LiOH mixture. After the dropwise addition, age for 10 minutes to obtain the precursor gel, and then perform centrifugation, wash the precipitate with deionized water several times, filter it with suction, and then store it at 70°C, Dry in a vacuum oven replaced with argon for 12 hours to obtain the precursor powder. Then the dried precursor was pressed into tablets at 20 MPa, put into a crucible with graphite powder, placed in a microwave oven, and the microwave power was controlled to 600W to ...

Embodiment 3

[0031] Add 4.196g of lithium hydroxide monohydrate, 0.1580g of high specific surface area graphite powder, and 15.776g of CTAB into 100ml of distilled water, and stir thoroughly for 1 hour to obtain a uniform mixture; mix 13.901g of ferrous sulfate heptahydrate and 5.200g of lithium dihydrogen phosphate Dissolve in 100ml distilled water and stir for 15min to obtain a suspension. Under an argon atmosphere, the LiH 2 PO 4 and FeSO 4 Quickly drip the suspension of LiOH into the LiOH mixture. After the dropwise addition, age for 15 minutes to obtain the precursor gel, and then perform centrifugation, wash the precipitate with deionized water several times, filter it with suction, and then store it at 80°C, Dry in a vacuum oven replaced with argon for 10 h to obtain precursor powder. Then the dried precursor was pressed into tablets at 25 MPa, put into a crucible with activated carbon, placed in a microwave oven, and heated at 500W for 7 minutes to obtain LiFePO 4 / C nanocompos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com