Direct on-line molding apparatus for long fiber-reinforced thermal plastics

A molding equipment and long fiber technology, applied in the field of direct online molding equipment for long fiber reinforced thermoplastics, can solve the problems of increased machine maintenance, maintenance, uneven glass fiber content, unstable glass fiber content, etc., to reduce maintenance and maintenance. cost, increase the content of glass fiber, and save electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the specific embodiments and the accompanying drawings.

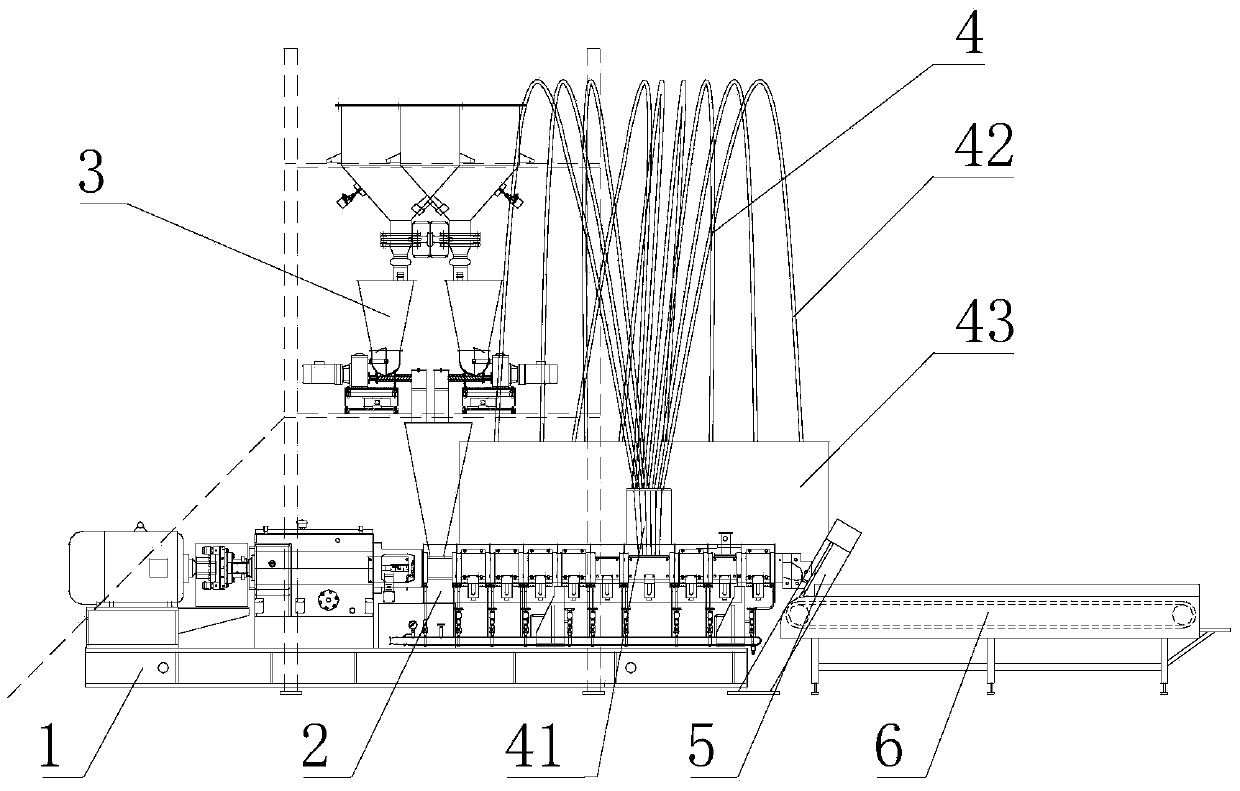

[0027] figure 2 It is a front structural view of the long-fiber reinforced thermoplastic direct-on-line molding equipment of the present invention.

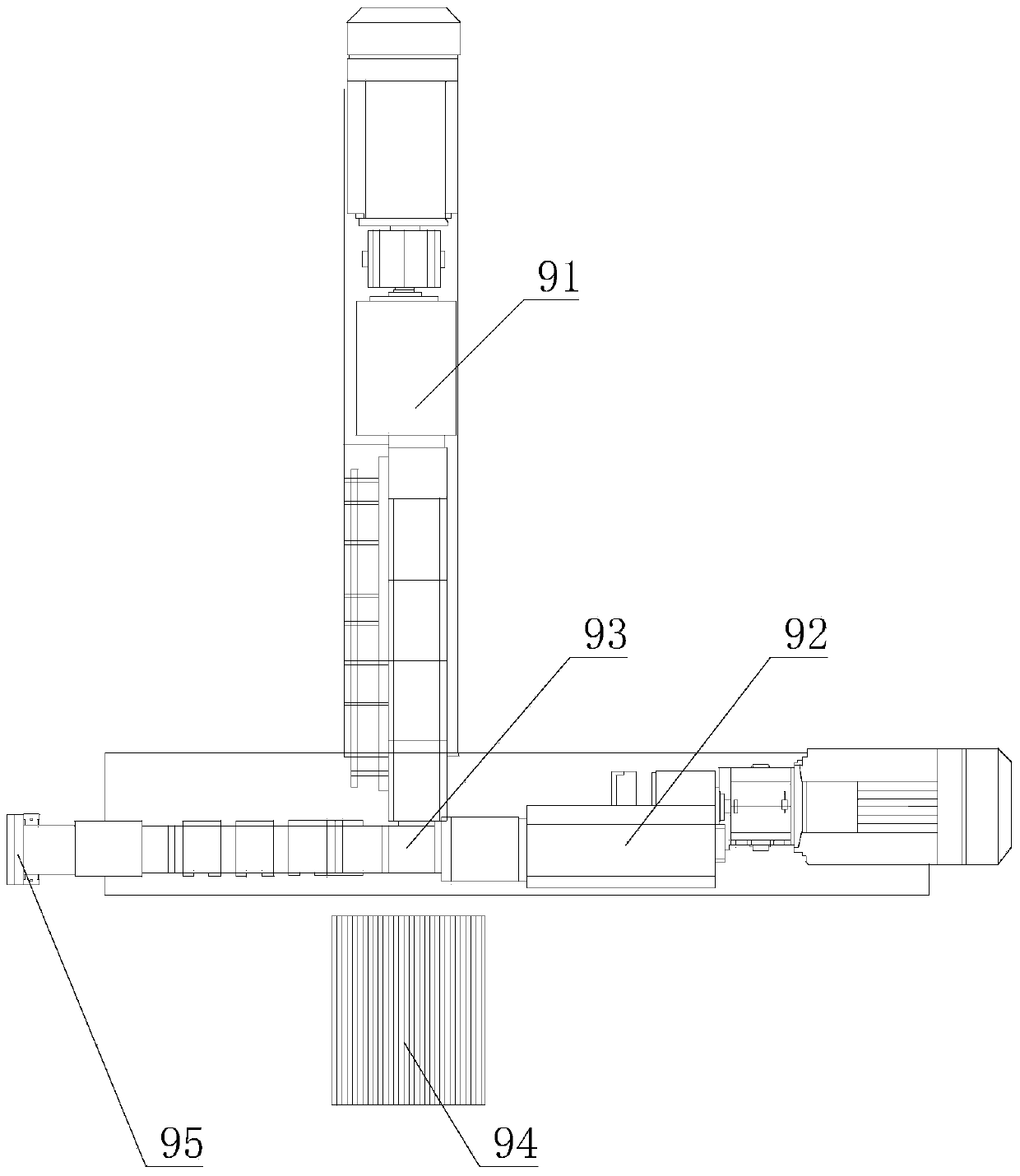

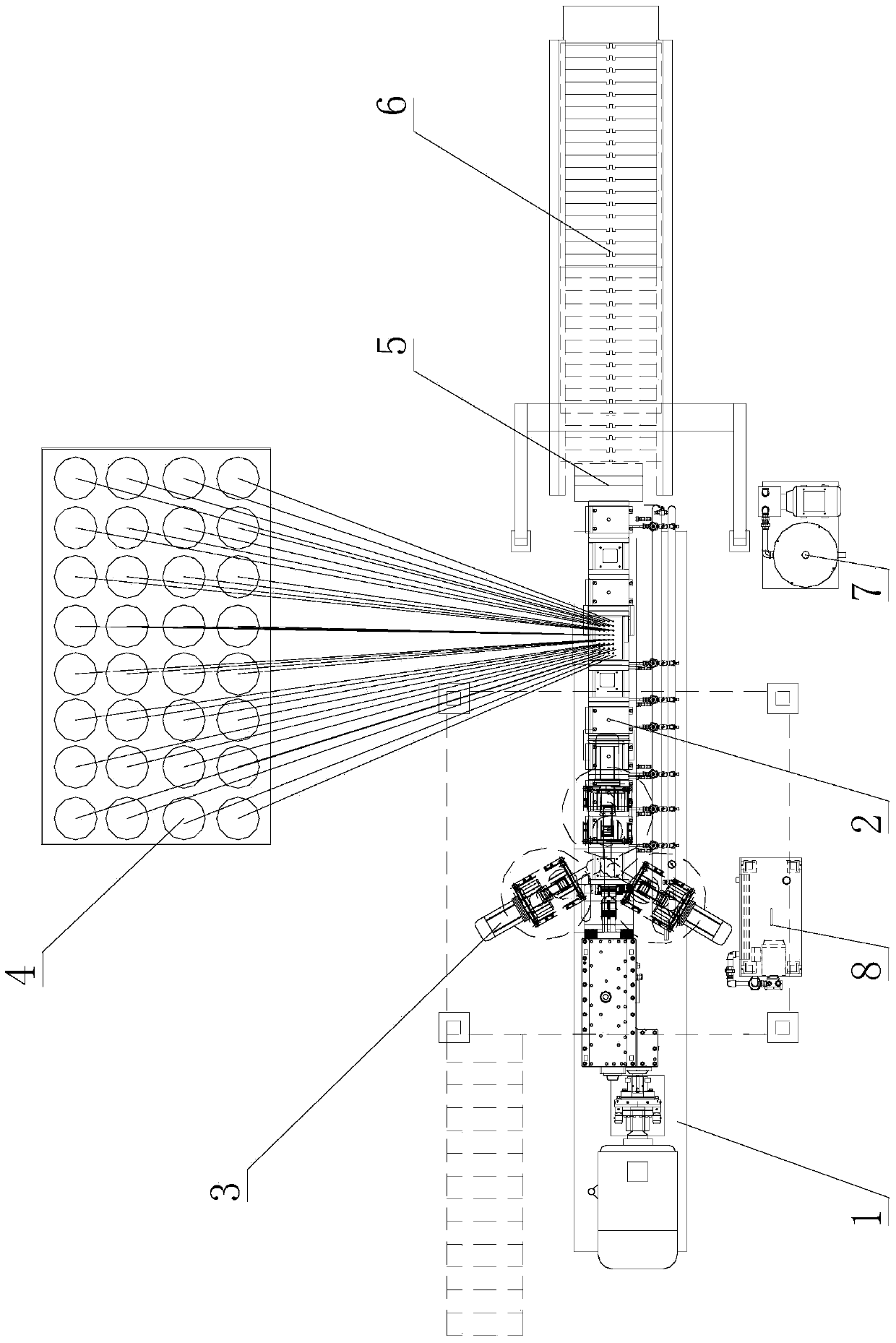

[0028] image 3 It is a top view of the direct on-line molding equipment for long fiber reinforced thermoplastics of the present invention.

[0029] Figure 4 It is a schematic diagram of the structure of the extrusion device of the present invention.

[0030] like Figure 2 to Figure 4 As shown, the long-fiber reinforced thermoplastic direct on-line molding equipment of the present invention mainly includes a steel platform 1, which is arranged under the steel platform 1 for heating the master batch (generally plastic), shearing glass fibers and mixing the two, softening Milled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com