Reciprocating inverse-pushing type garbage incinerator

A waste incinerator, reverse push technology, applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problems of small effect of stirring and loosening, small effect of crushing effect, no boss on the head of the grate, etc. Achieve the effect of avoiding garbage bridging phenomenon, stable and reliable operation, simple and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

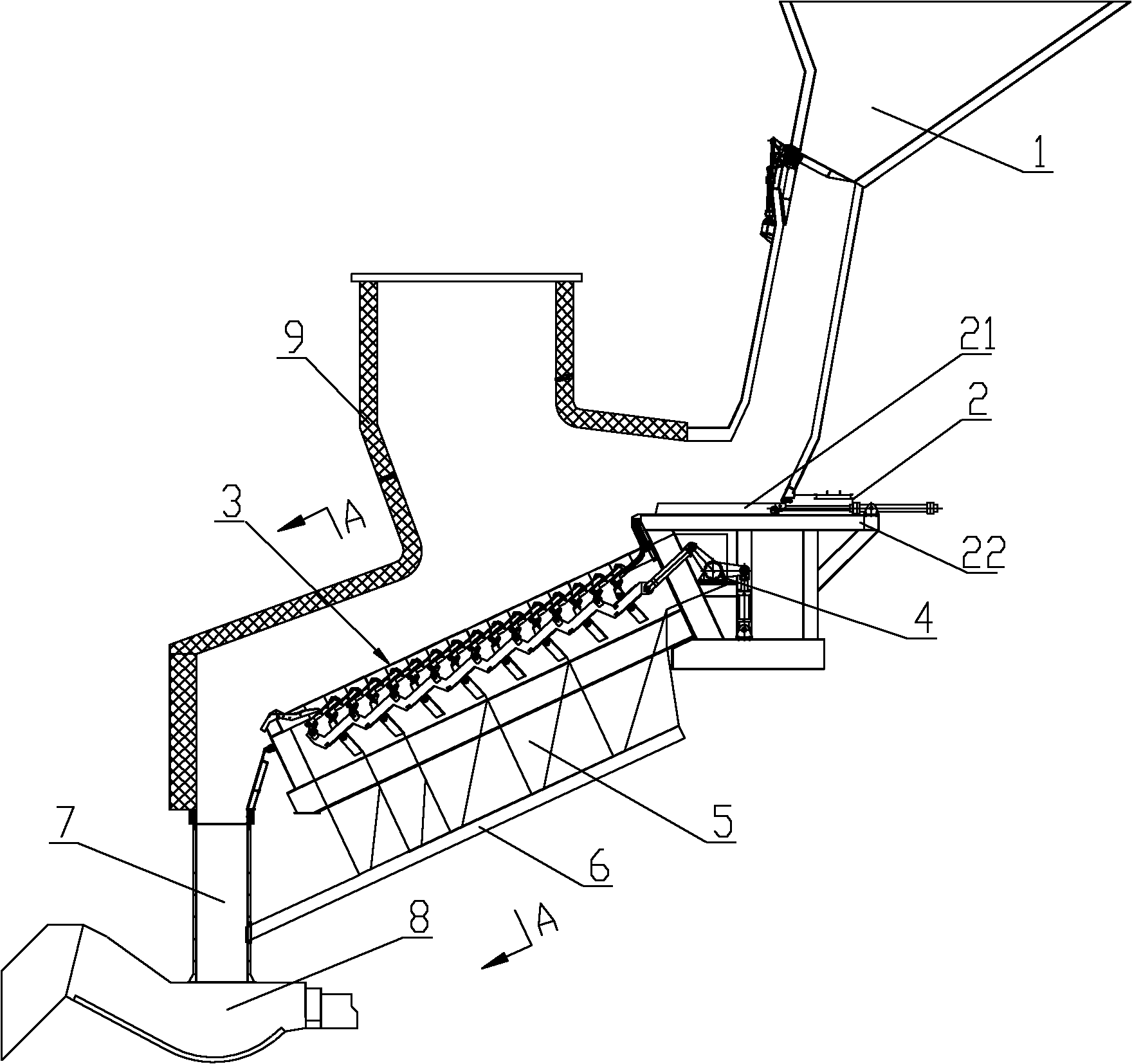

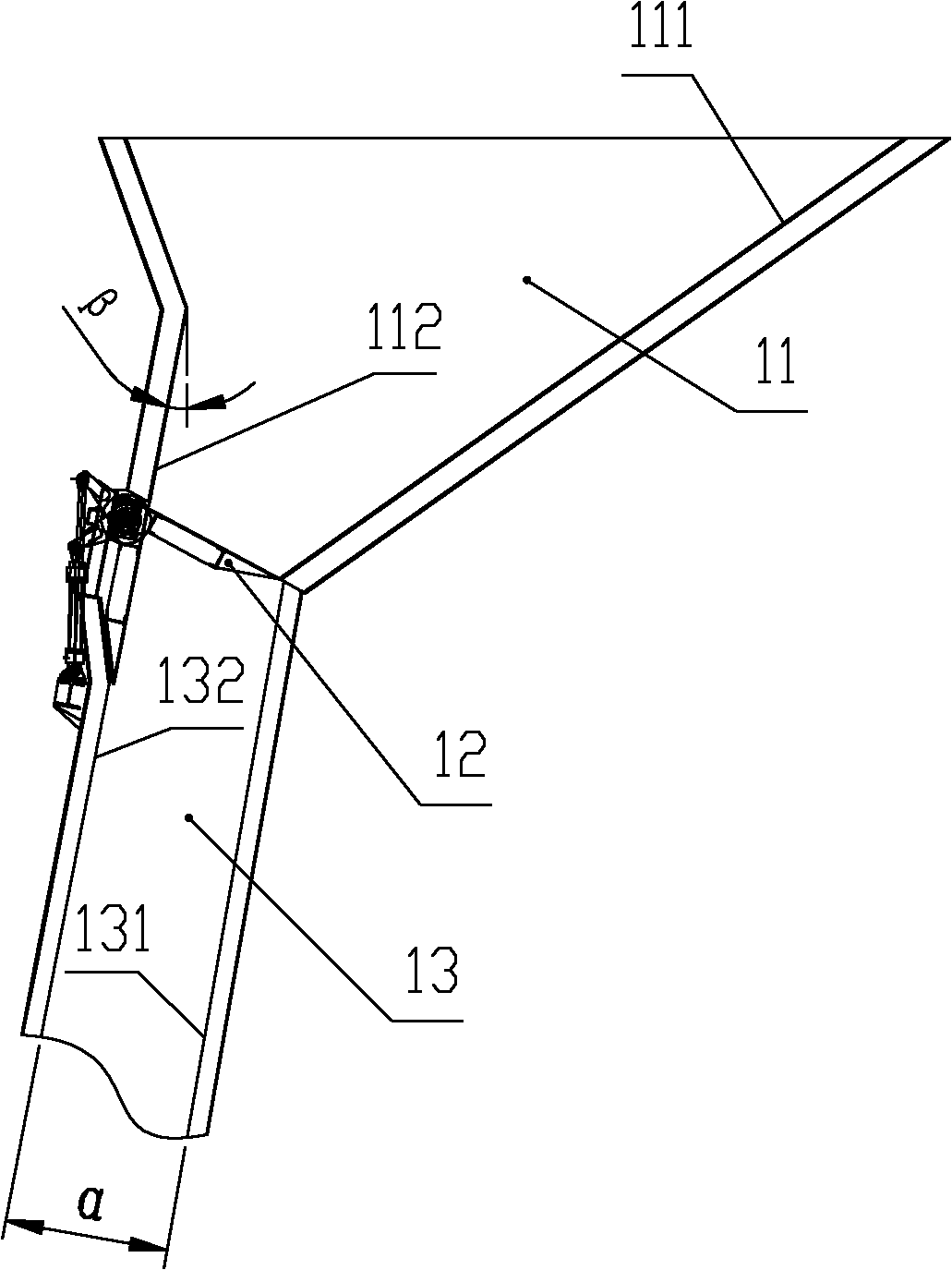

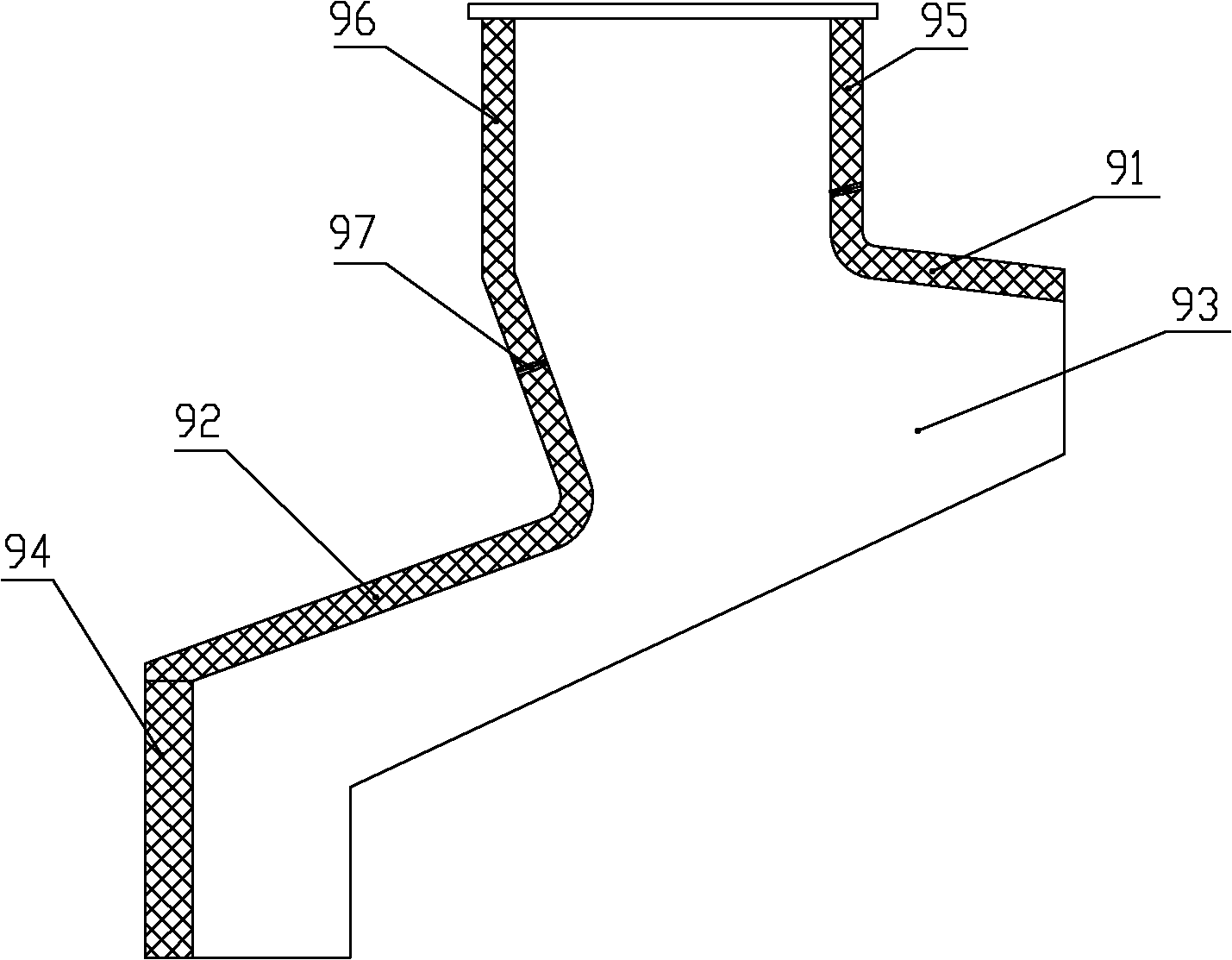

[0036] Please refer to figure 1 , the reciprocating reverse push type garbage incinerator of the present embodiment includes a furnace wall 9, a hopper device 1 installed on the upper port of the furnace wall 9 and a feeding device 2 located below the hopper device 1, and a lower port installed on the furnace wall 9. The slag drop tank 7 and the slag extractor 8 located below the slag drop tank 7; the reciprocating and reverse push type fire grate 3 is installed in the furnace wall 9, and the primary air chamber 5 and the ash discharge device 6 are arranged in turn below the fire grate 3 to provide An airtight shaft driving device 4 is also arranged below the material device 2, and the grate 3 is arranged in a downward slope along the forward direction of the garbage, and the grate 3 is divided into 2 to 6 rows of grate units alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com