Patents

Literature

84results about How to "Increase gear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

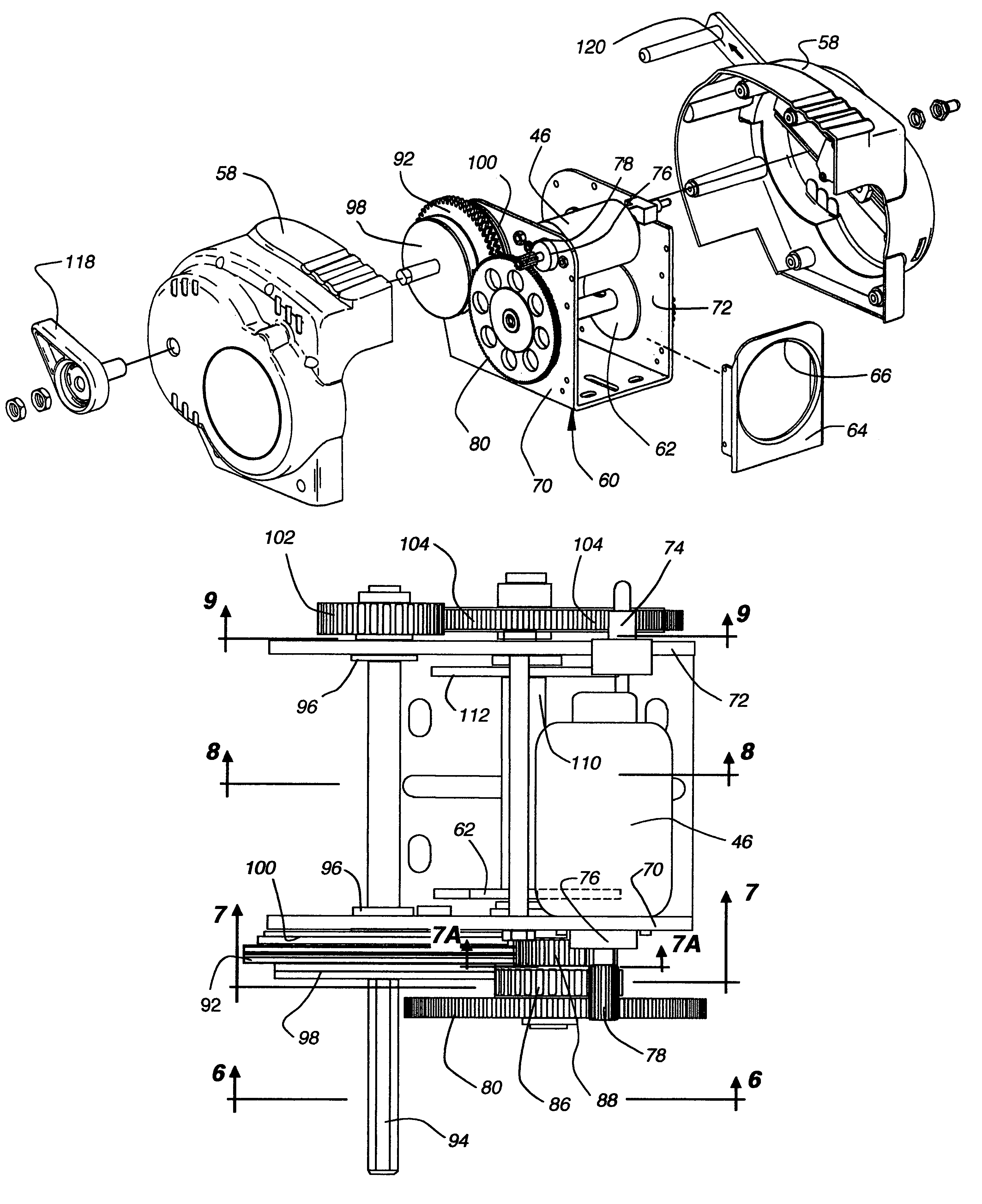

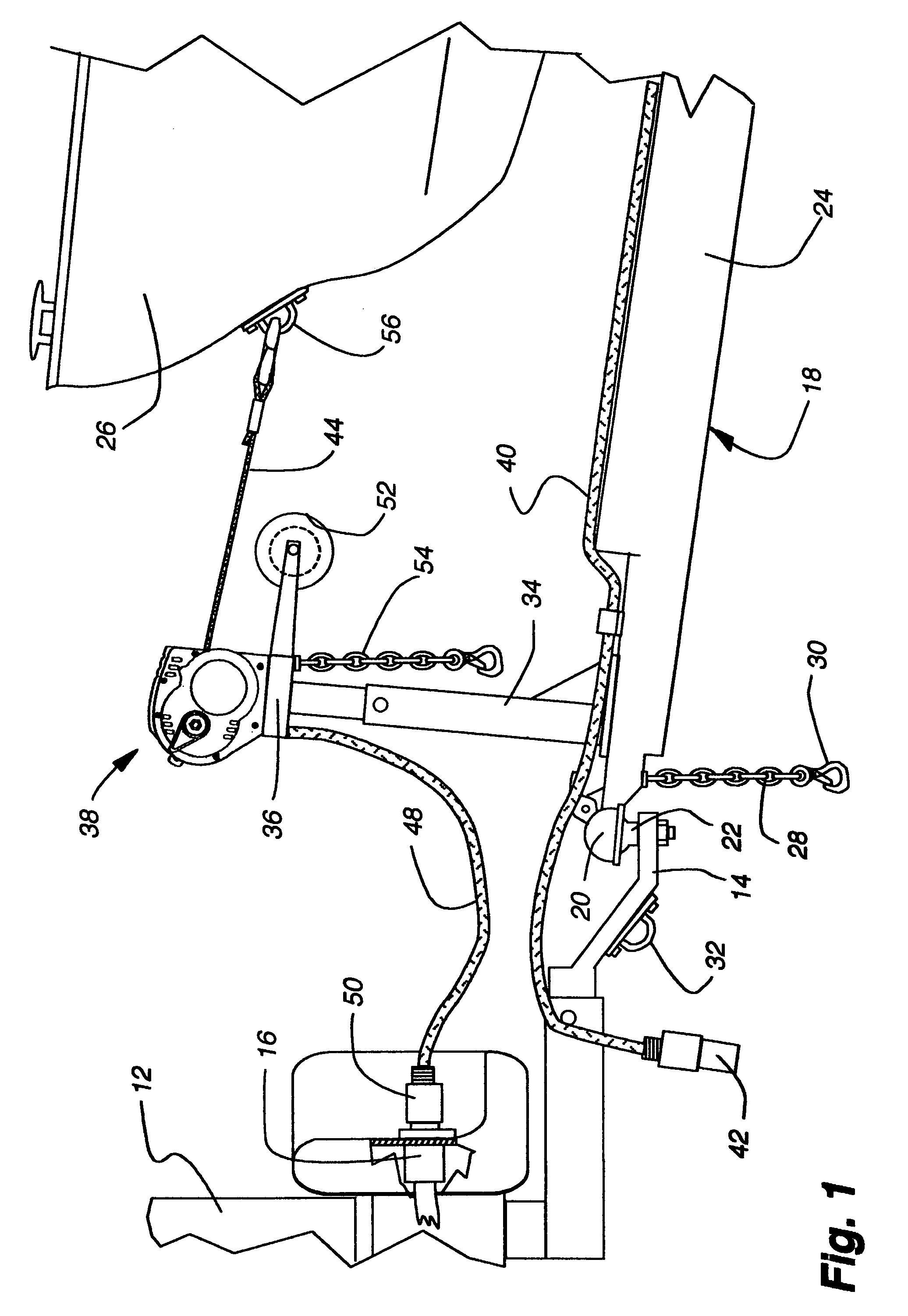

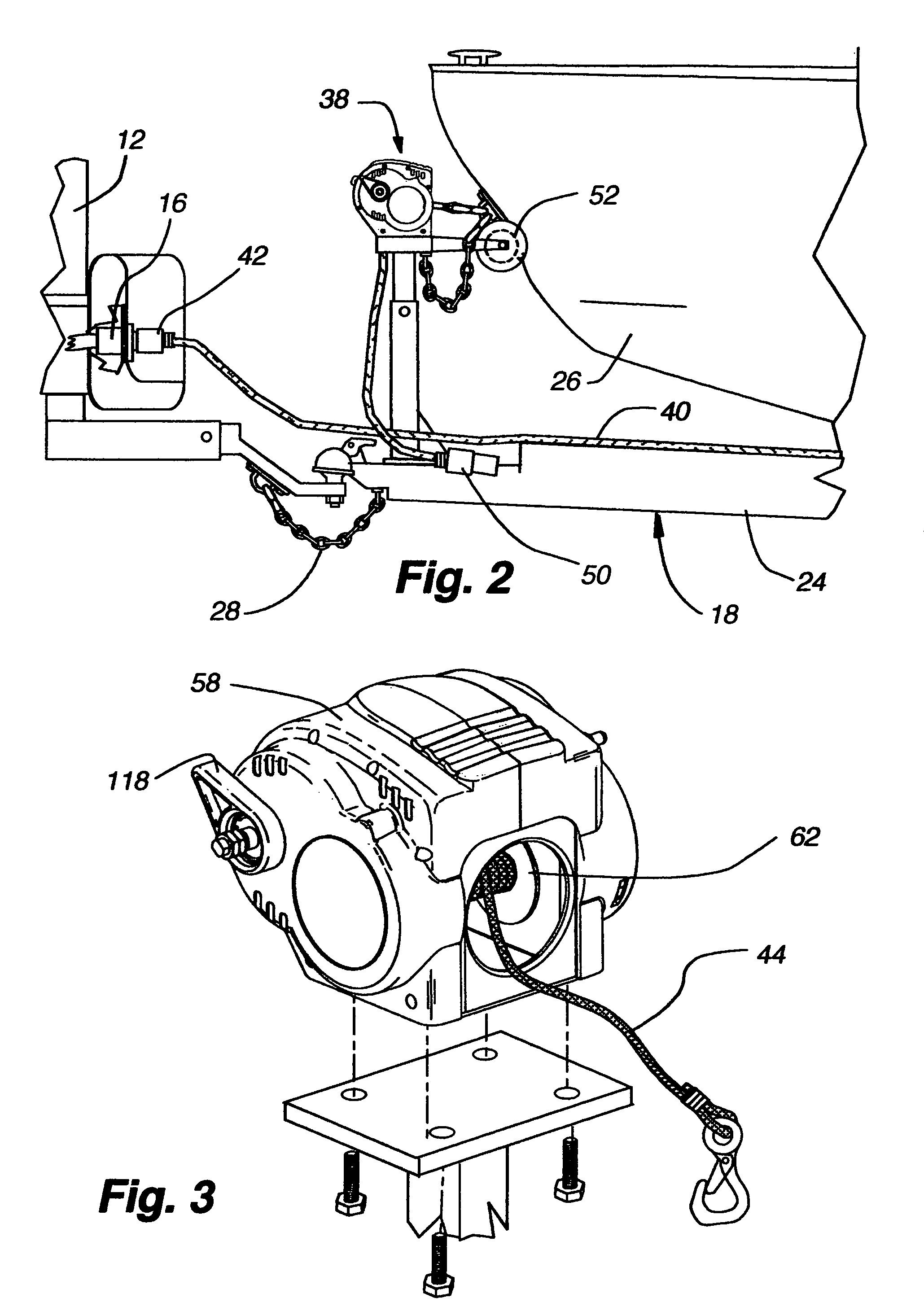

Winch for boat trailer

InactiveUS7017887B1Total current dropCurrent drawDifferential gearingsWinding mechanismsGear wheelEngineering

A low-amp winch for use on boat trailers is provided with a higher gear reduction than conventional winches and with a winch cable made of a softer material and shorter length than conventional boat winches to reduce the current draw from the motor. The winch is capable of operating off a seven-pin RV socket which provides 12 volts of DC power at no greater than 30 amps.

Owner:FUJIFILM HEALTHCARE CORP +1

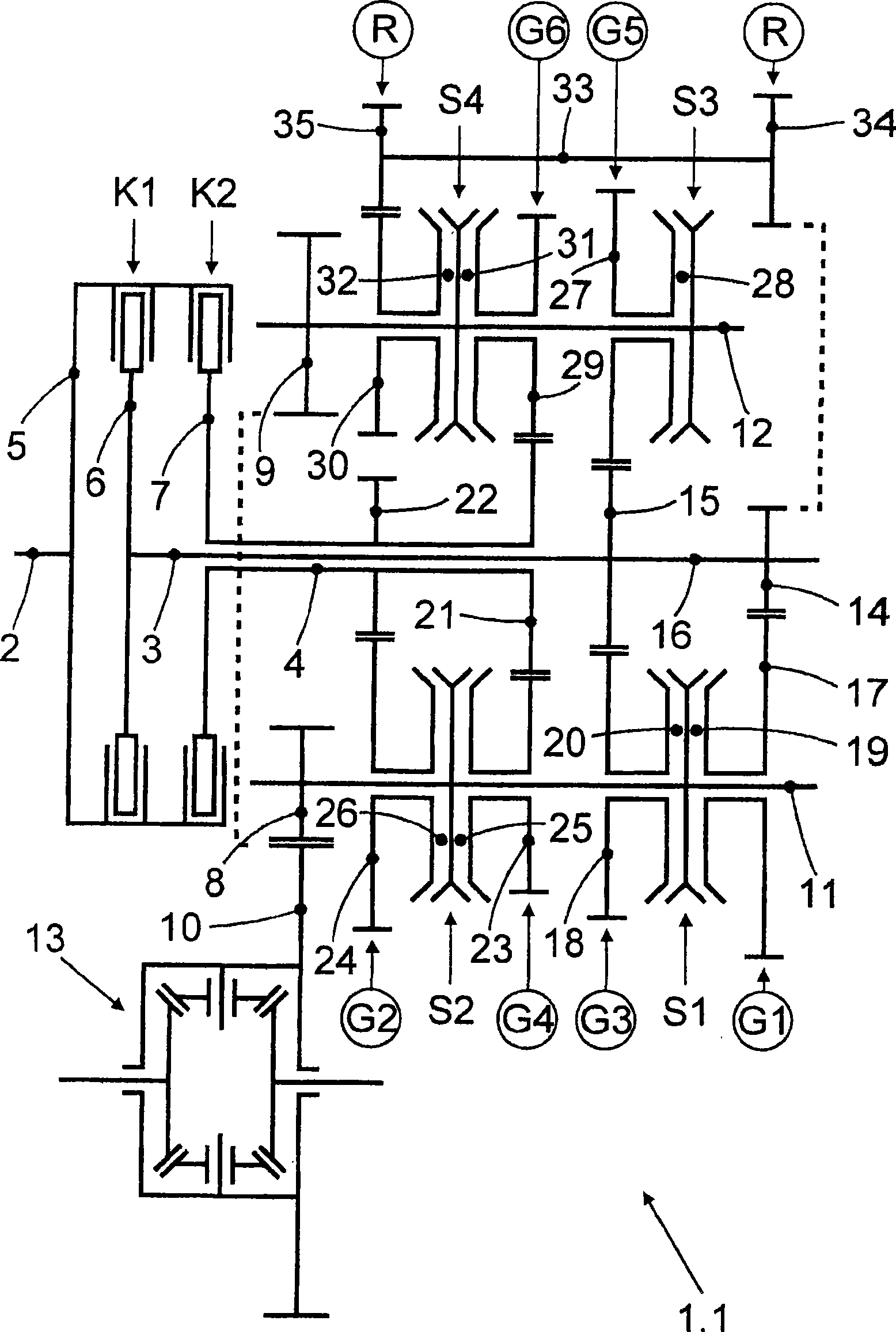

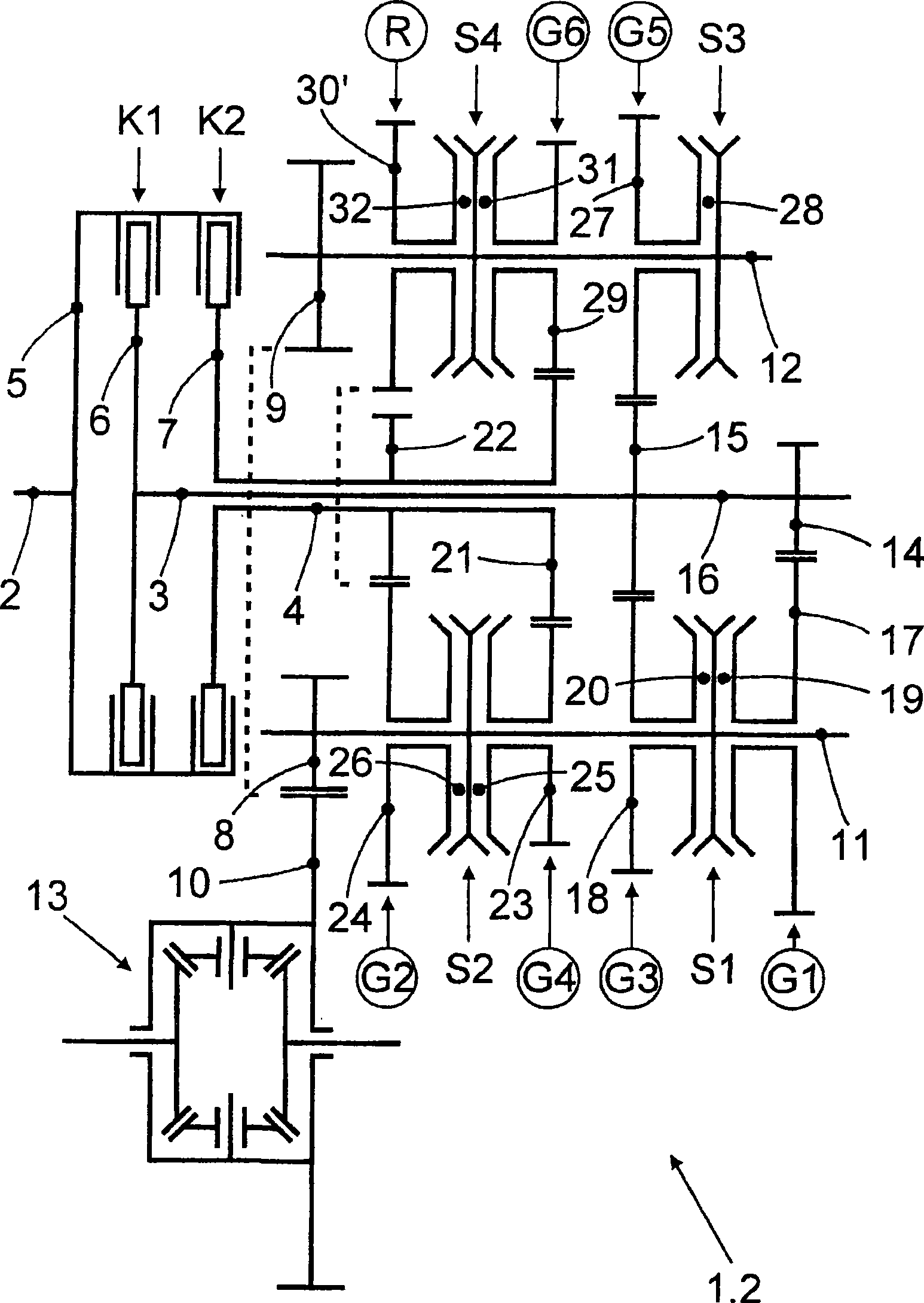

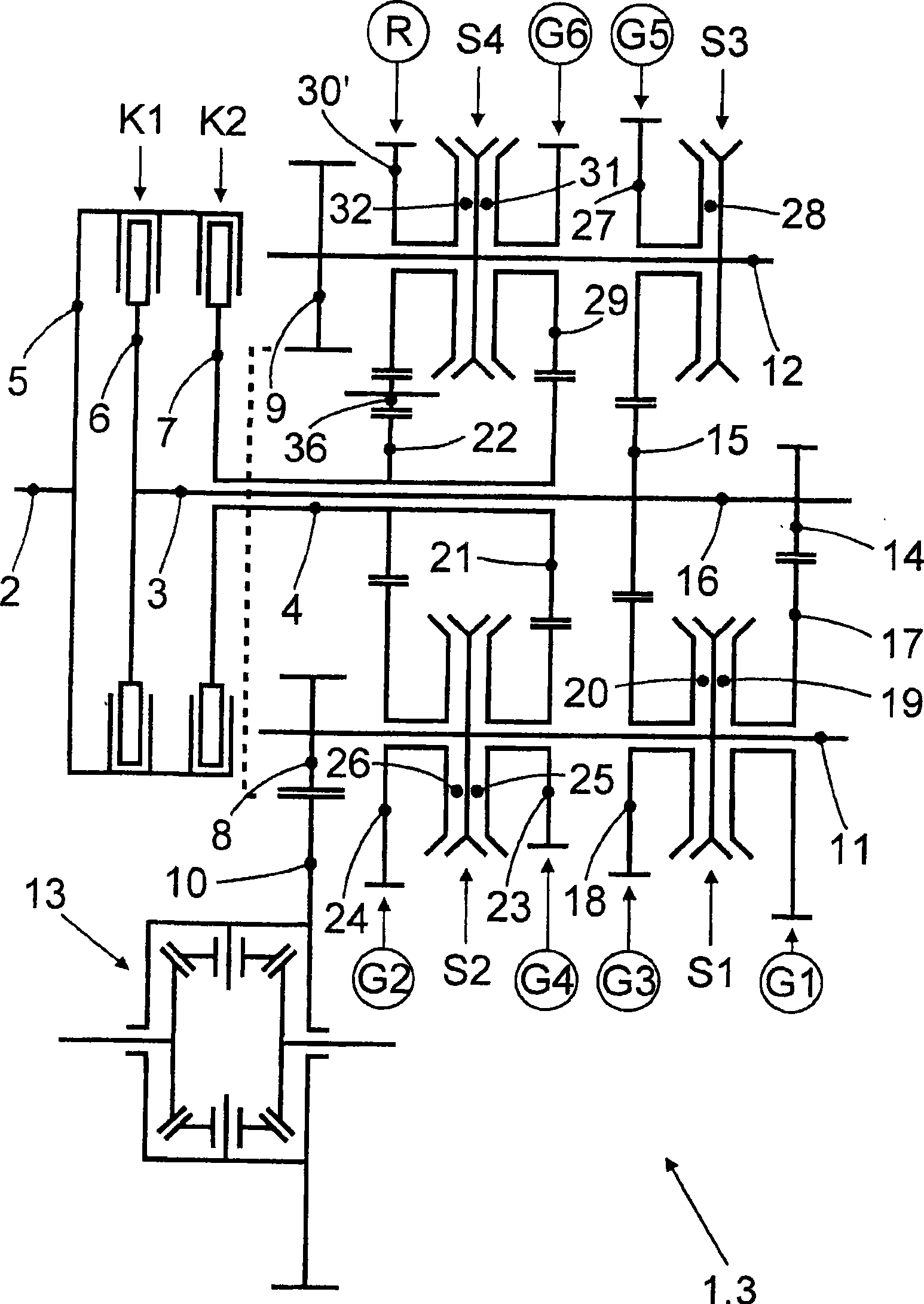

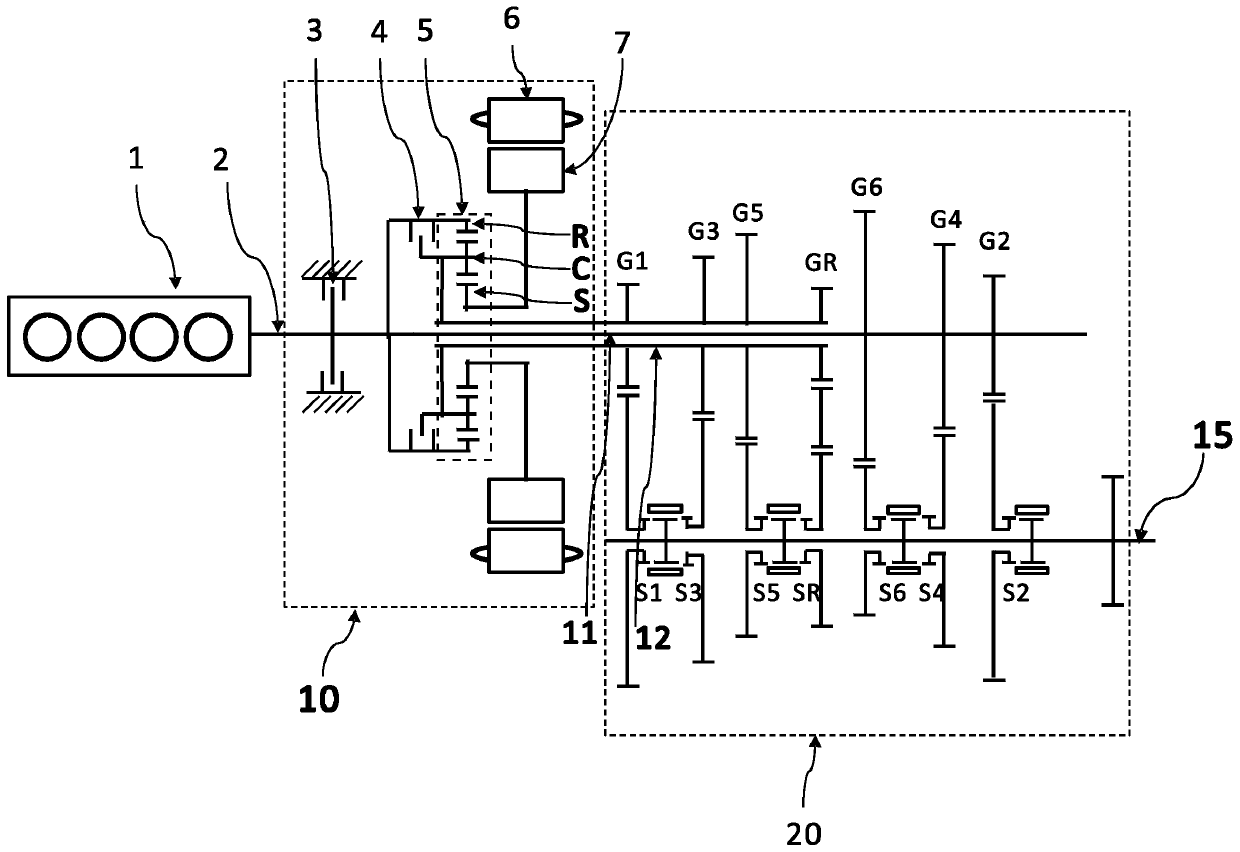

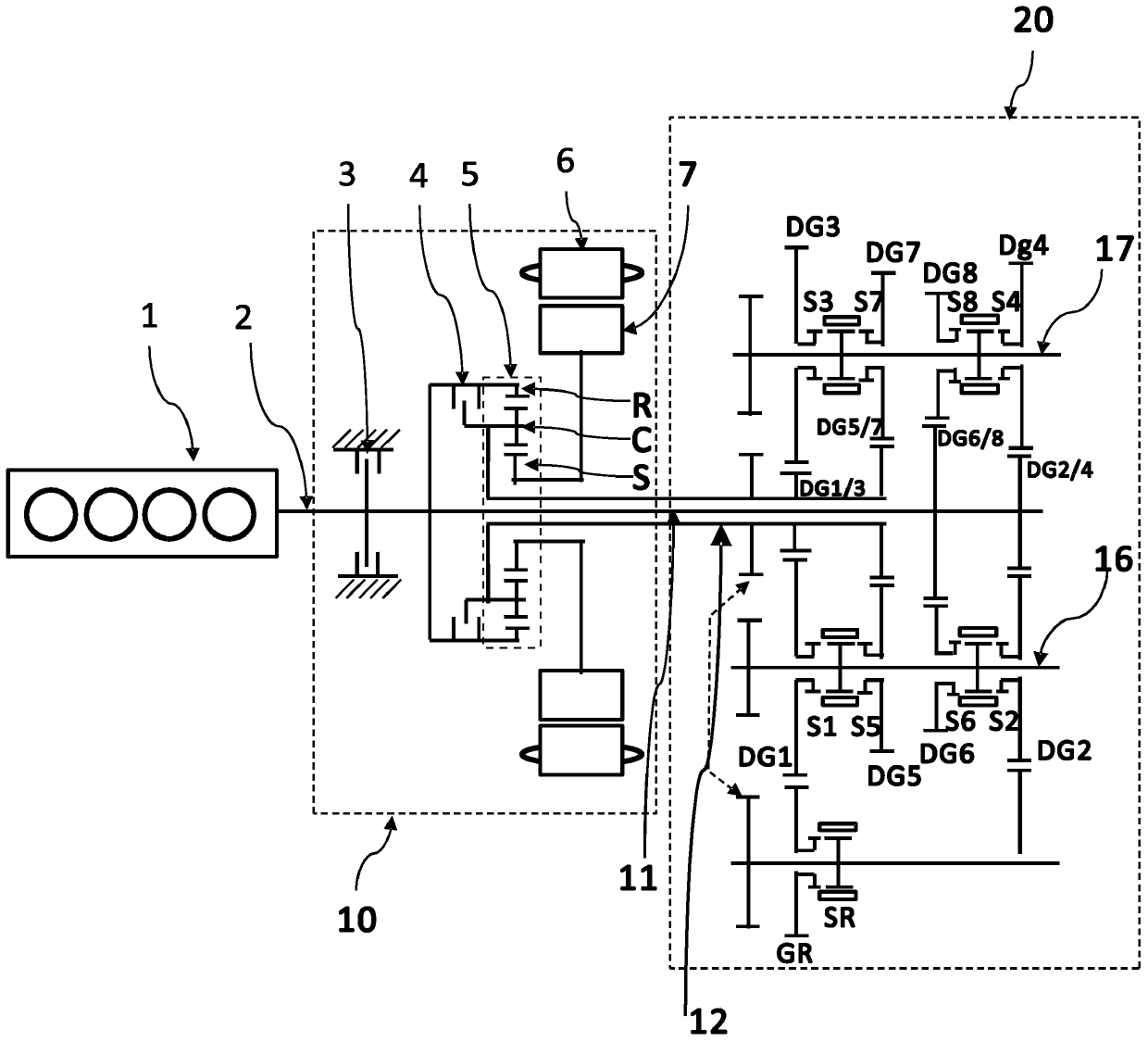

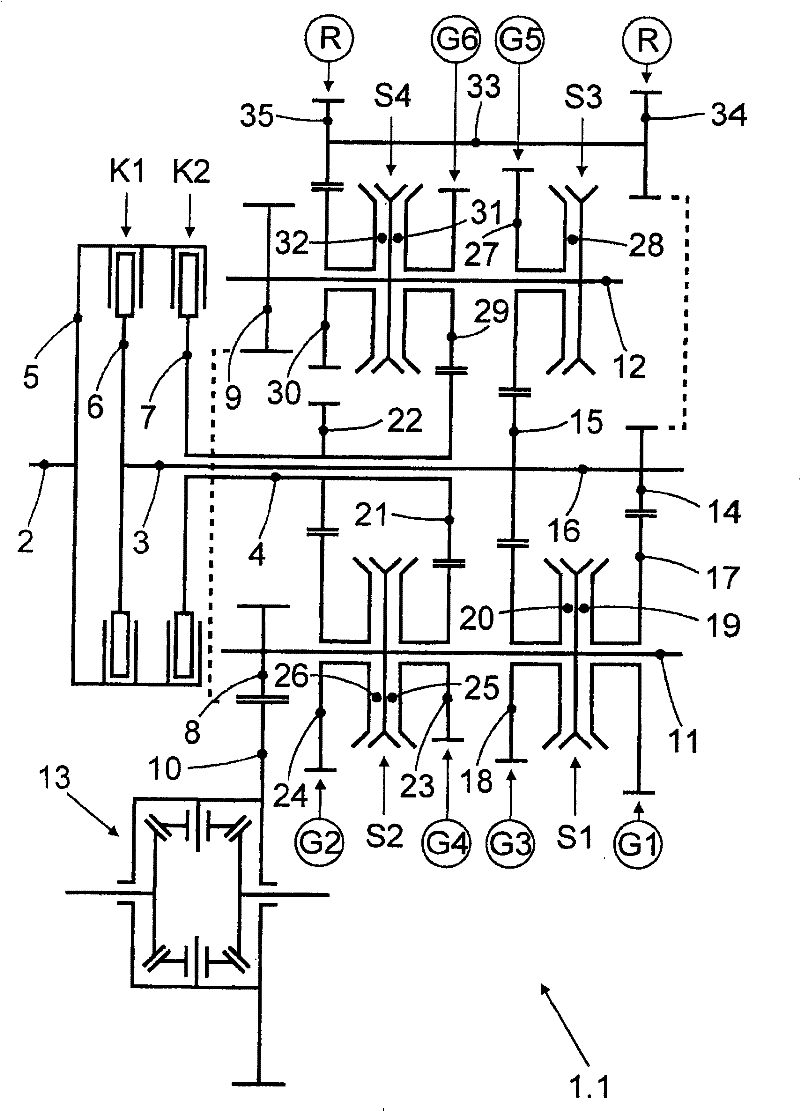

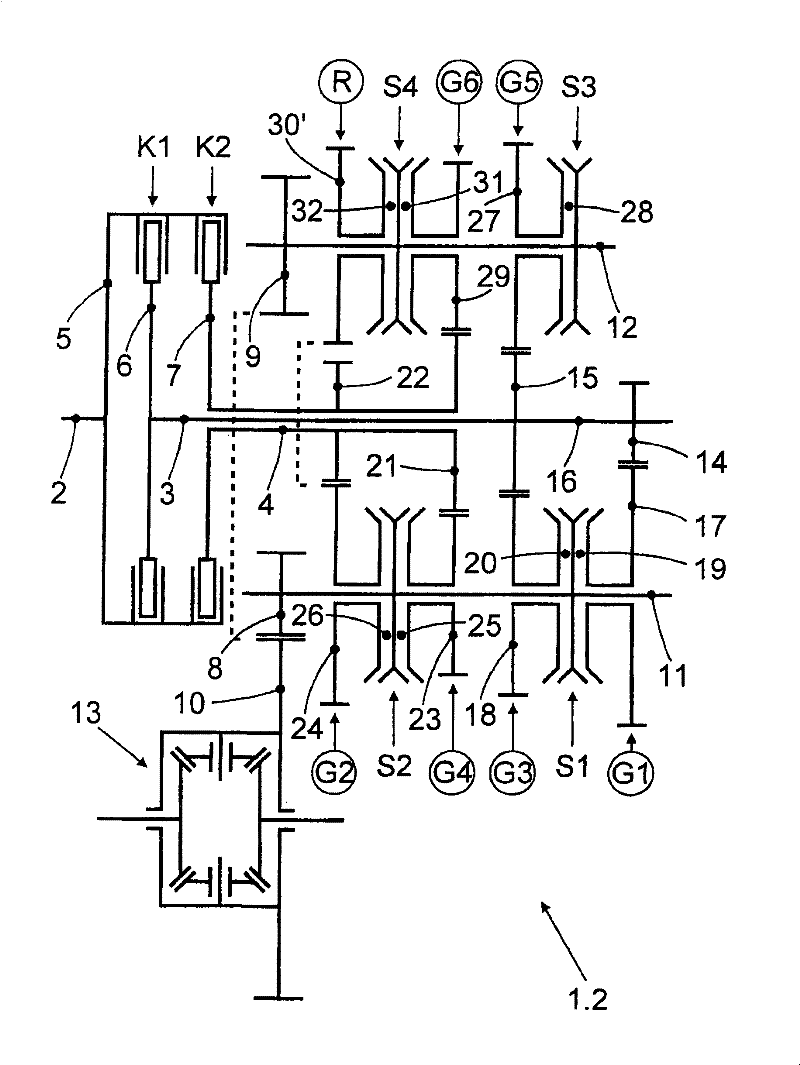

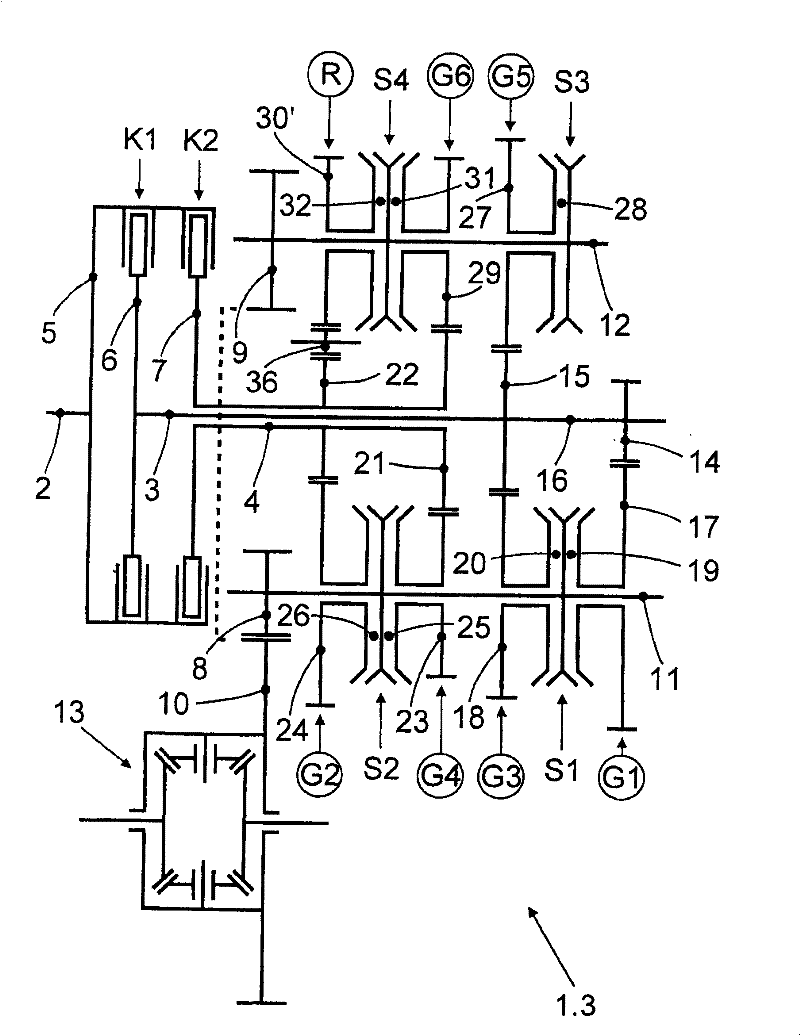

Double clutch transmission of a motor vehicle

InactiveCN101535679ALow costFew stallsToothed gearingsTransmission elementsMobile vehicleDrive wheel

The invention relates to a double clutch transmission of a motor vehicle, comprising two input shafts (3, 4), which are disposed coaxially to each other and can be connected to the drive shaft (2) of a driving motor via a separate clutch (K1, K2). The invention further comprises two countershafts (11, 12), which are arranged parallel to the axis next to the input shafts (3, 4) and are connected and driven via a driven wheel (8, 9) by a common output element (10). The invention further comprises a plurality of gear wheel sets, comprising a plurality of toothed wheels, amongst others one fixed wheel and one loose wheel, wherein at least two wheels are in engagement with each other. The fixed wheels thereof are distributed on the two input shafts (3, 4) and are arranged rotationally fixed on the associated input shaft (3, 4). The loose wheels are distributed on the two countershafts (11, 12), are rotationally arranged on the associated countershaft (11, 12) and can be connected thereto in a rotationally fixed manner by an associated clutch. Each of the two input shafts (3, 4) comprises at least one fixed wheel, which is associated with two gear wheel sets and engages with loose wheels arranged on different countershafts (11, 12). A double clutch transmission of this type, having six forward gears (G1 to G6) and one reverse gear (R), is proposed as a basic transmission, which has an uncomplicated and space-saving design and can be reduced by one gear to form a five speed transmission and be expanded by one gear to form a seven speed transmission in a simple and cost-effective manner.

Owner:ZF FRIEDRICHSHAFEN AG

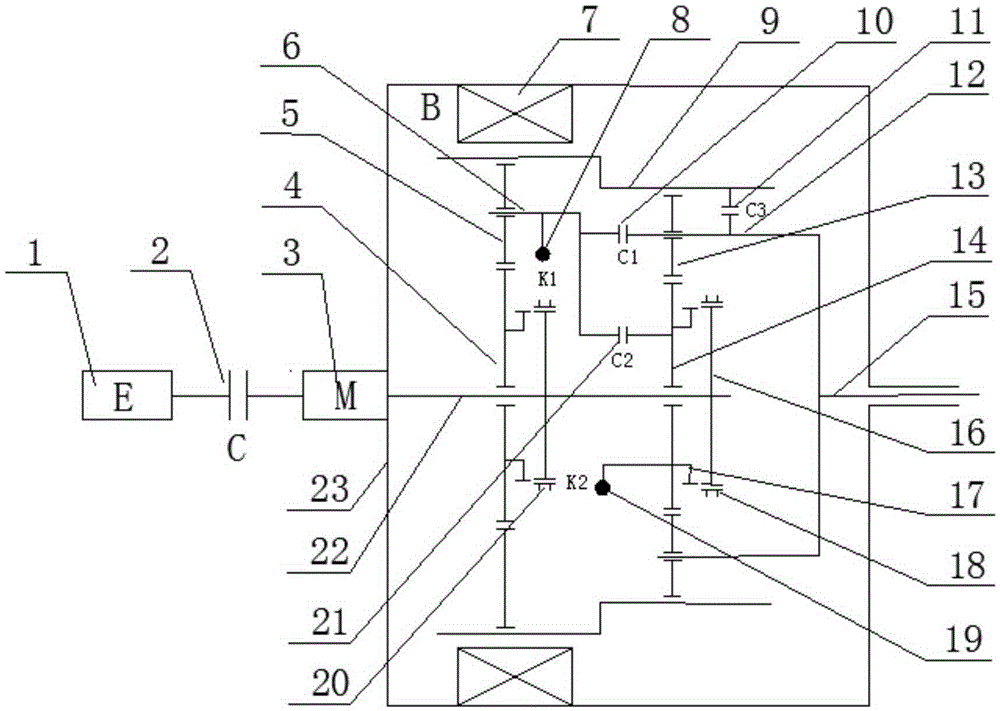

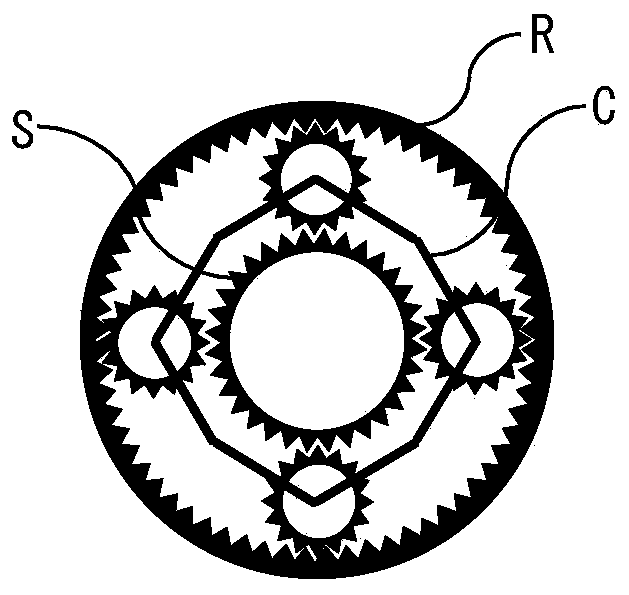

Four-gear mechanical automatic transmission power assembly system based on planetary gear mechanisms

ActiveCN105402334ASmall sizeReduce processing difficultyToothed gearingsAutomatic transmissionGear wheel

The invention discloses a four-gear mechanical automatic transmission power assembly system based on planetary gear mechanisms. The four-gear mechanical automatic transmission power assembly system comprises an engine, a main clutch, a motor, a first planet row, a second planet row, two engagement devices, three auxiliary clutches, an electromagnetic brake, two brakes, a gear ring, and a transmission input shaft as well as a transmission output shaft; the first planet row, the second planet row and a splined hub are orderly arranged on the transmission input shaft; the splined hub is engaged with an engagement sleeve; and switching of four forward gears, a neutral gear and a reverse gear is realized by means of mutual cooperation of the engagement sleeve, the electromagnetic brake and the clutches. Compared with a traditional mechanical transmission, the four-gear mechanical automatic transmission power assembly system based on the planetary gear mechanisms is provided with no synchronizer, and instead, the motor is adopted for accurate speed regulation to realize smooth gear shifting, and two planetary gear mechanisms are used to take the place of traditional a plurality of pairs of gear mechanism; as a result, the overall mechanism is simple, small in volume, low in cost and easy to manufacture.

Owner:包头北奔重汽桥箱有限公司

2,3-dichloropyridine synthesis method

InactiveCN1807414ASuppress generationLow reaction temperatureOrganic chemistry3-AminopyridineCopper chloride

A Synthesis of 2, 3-dichloro-pyridine, including steps as follows: 1)liquating the raw material of 3-aminopyridine in decuple-twelvefold mass thick alcaine at the condition of mixing, cooling to 4-5 deg C, adding equal mol mass hydroperoxide as raw material, controlling reaction temperature between 6-8deg Cand mixing for 1-2h at the same temperature after adding the things; 2) cooling the solution below 0deg C, adding equal mol mass erinitrit solution as raw material and then preserving heat for 0. 5-1h; 3) controlling the reaction temperature below 0deg C, adding miscible liquids of 0. 15 times mol mass copper chloride as the raw material and duple mass as thick alcaine, then preserving heat for a half hour at least; 4) Returning reactant to ambient temperature and doing extraction by dichloromethane; 5) vacuum distilling the tobacco extract to dry will get product. The intermediate products of the invention are never purified and moved, all the procedures can be done in the same reaction pot and the three step reaction only uses alcaine which contains reactant as solution.

Owner:南京广通医药化工有限责任公司

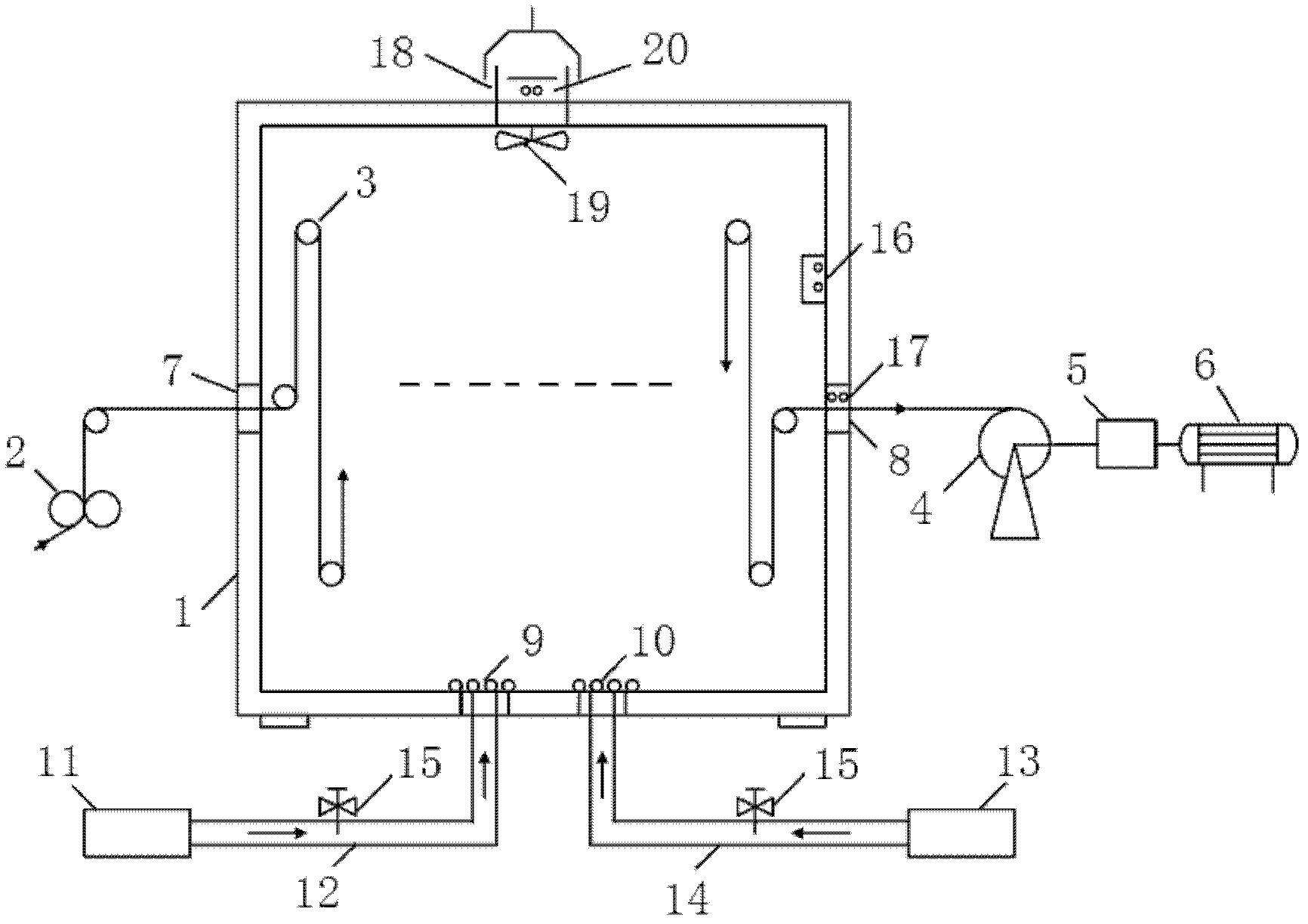

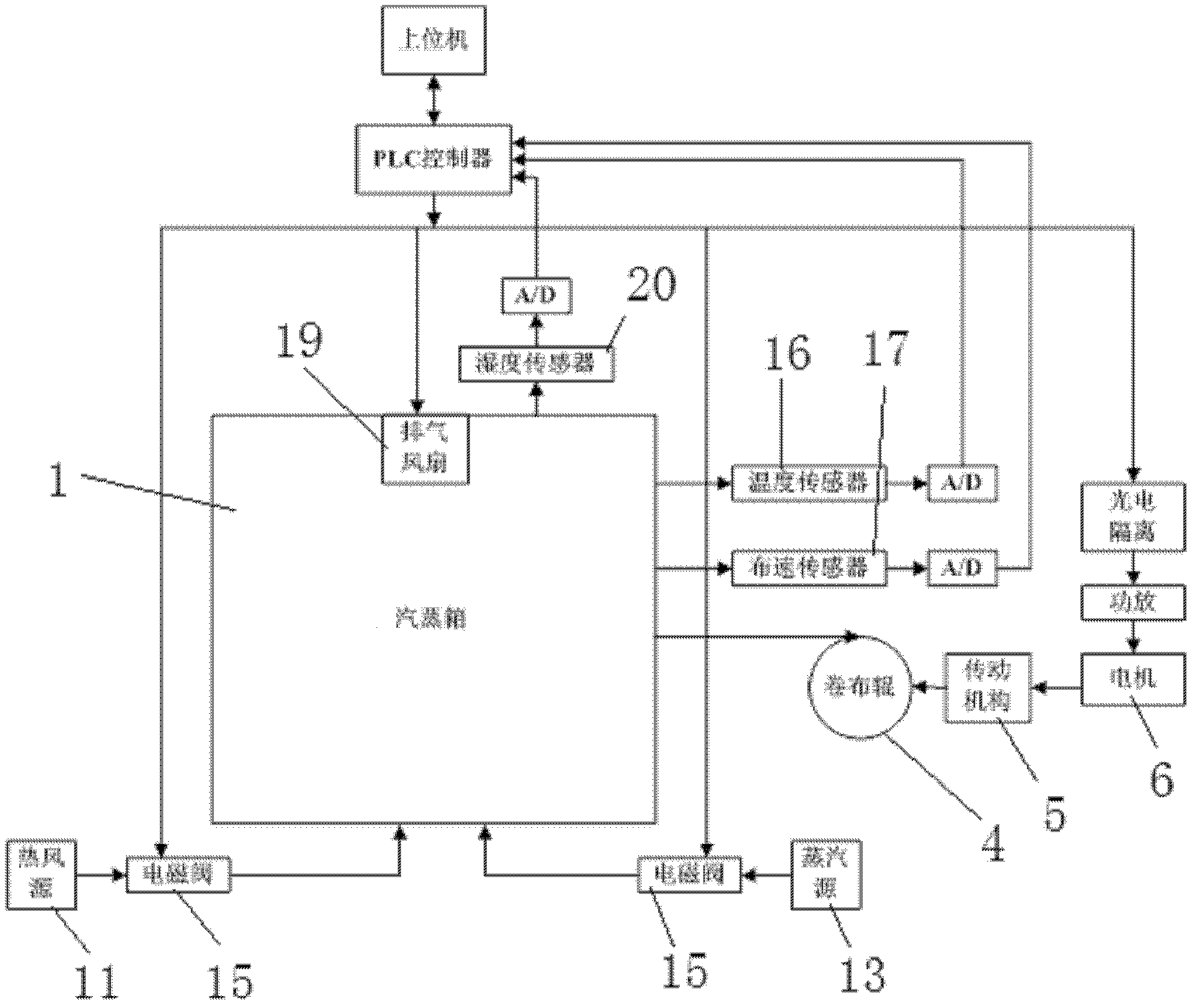

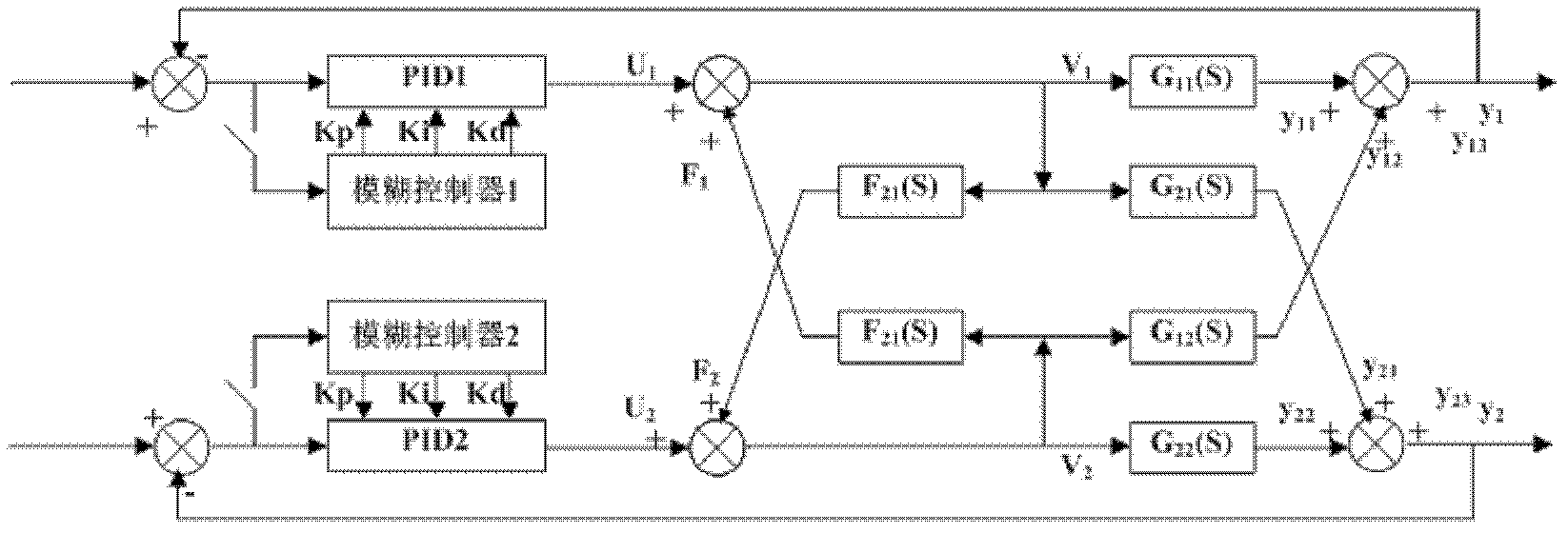

Steaming device for textile printing and dyeing and steaming method thereof

InactiveCN102443989ASolve problems such as chromatic aberration and defectsEasy to detectTextile treatment carriersLiquid/gas/vapor textile treatmentTemperature controlTextile printer

The invention disloses a steaming device for textile printing and dyeing and a steaming method thereof. The steaming device comprises a steaming box, a padder, a cloth guide roll, a cloth winding roll and a motor, wherein the motor controls the cloth winding roll by a transmission mechanism; the steaming box is provided with a cloth inlet and a cloth outlet; the box wall of the steaming box is provided with a hot air inlet and a steam inlet; the hot air inlet is communicated with a hot air pipeline connected with a hot air source; and the steam inlet is communicated with a steam pipe connected with a steam source. The steaming method of the device comprises the following steps of: mixing dry-hot air and saturated steam entering the steam inlet, using the generated high-temperature steam to carry out steaming on textile, and controlling the temperature and the humidity in the steaming box. By adopting the structure and the method, the steaming device and the steaming method have the following advantages that: 1) the extensive-form operating situation of the traditional steaming machine is changed, and online detection and intelligent control of parameters of a steaming process are realized; and 2) decoupling control is adopted for respectively compensating a temperature control loop and a humidity control loop, and automatic control can be carried out on two strong-coupling parameters such as temperature and humidity simultaneously.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Electric coupling assembly of double-row planet gear apparatus of mixed dynamic vehicle

The invention consists of a motor, three clutches, three brakes, a pair of constant mesh gears, four front and back planet rows, an output shaft and an engine. The output shaft of the motor is connected with the front and back solar wheels. The engine is connected with the driving gear via the clutch of the engine, and the driven gear is integrated with the front planet frame and the back gear ring. The output shaft is connected with the front gear ring or the back planet frame via the front gear ring clutch and the back planet frame clutch. Using the different state combination of three clutches and three brakes can realize many kinds of working modes of the motor vehicles.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

2,3-dichloropyridine synthesis method

InactiveCN100357272CSuppress generationLow reaction temperatureOrganic chemistry3-AminopyridineCopper chloride

A Synthesis of 2, 3-dichloro-pyridine, including steps as follows: 1)liquating the raw material of 3-aminopyridine in decuple-twelvefold mass thick alcaine at the condition of mixing, cooling to 4-5 deg C, adding equal mol mass hydroperoxide as raw material, controlling reaction temperature between 6-8deg Cand mixing for 1-2h at the same temperature after adding the things; 2) cooling the solution below 0deg C, adding equal mol mass erinitrit solution as raw material and then preserving heat for 0. 5-1h; 3) controlling the reaction temperature below 0deg C, adding miscible liquids of 0. 15 times mol mass copper chloride as the raw material and duple mass as thick alcaine, then preserving heat for a half hour at least; 4) Returning reactant to ambient temperature and doing extraction by dichloromethane; 5) vacuum distilling the tobacco extract to dry will get product. The intermediate products of the invention are never purified and moved, all the procedures can be done in the same reaction pot and the three step reaction only uses alcaine which contains reactant as solution.

Owner:南京广通医药化工有限责任公司

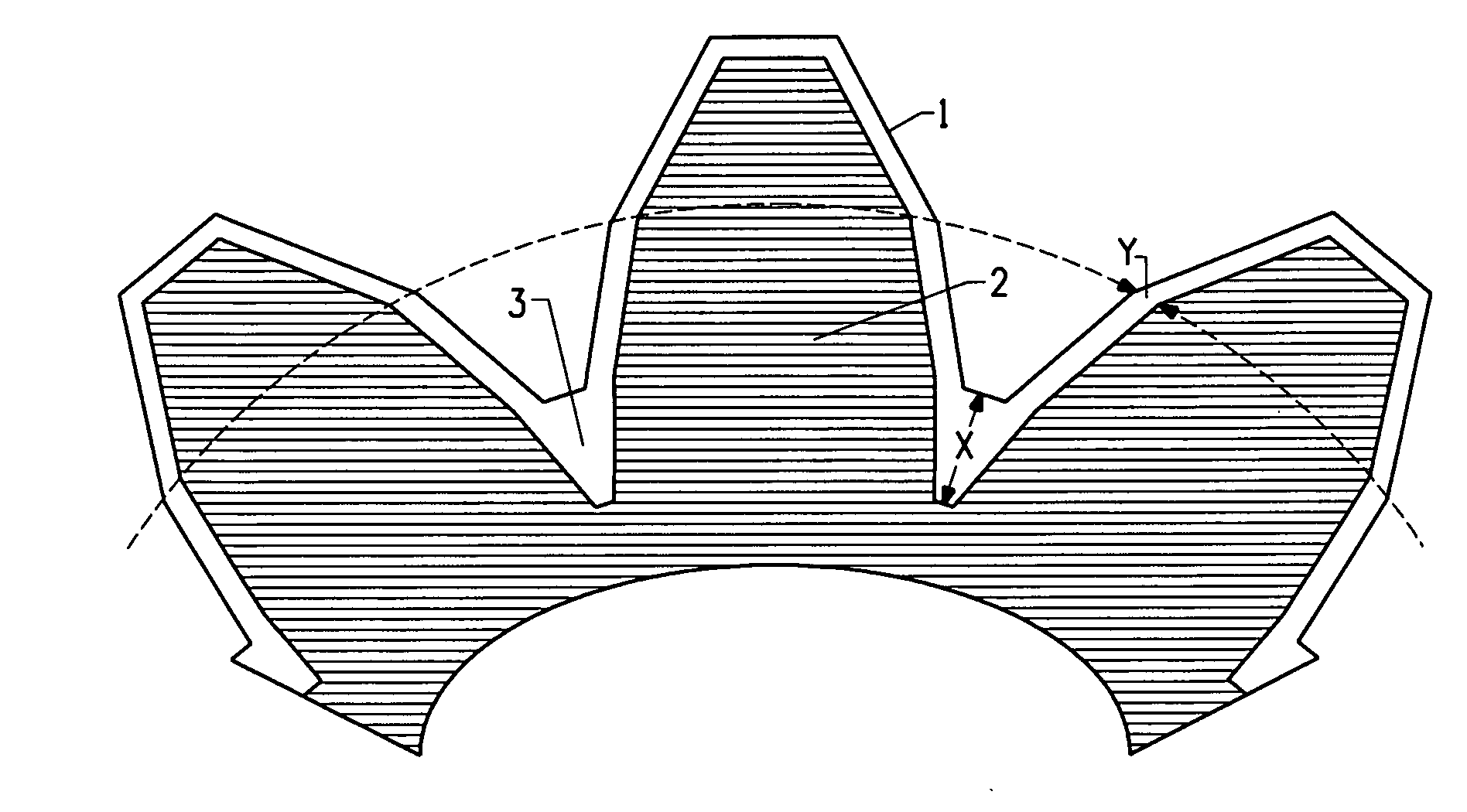

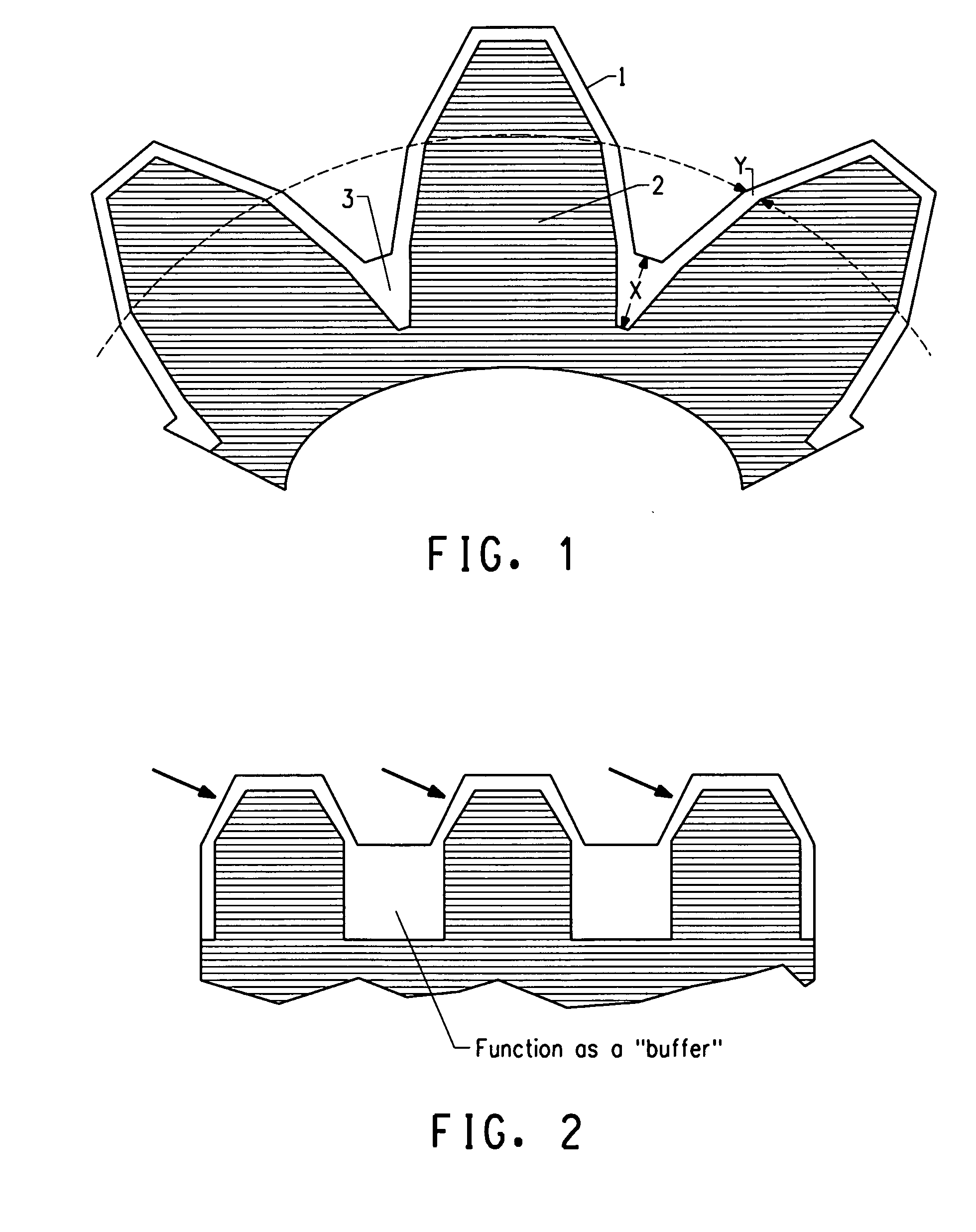

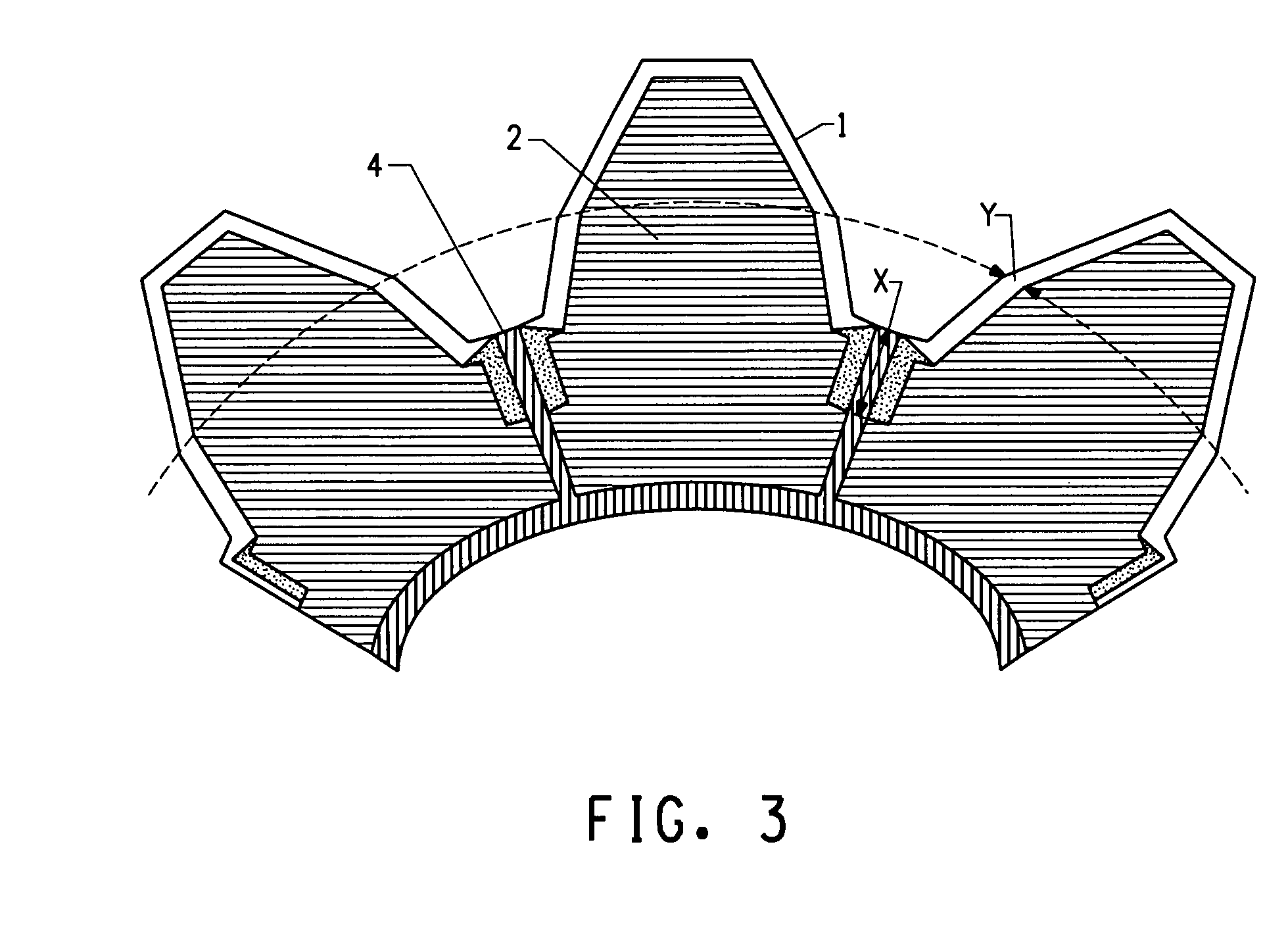

Composite gear

InactiveUS20090081402A1High elongationLarge strainLayered productsCeramic shaping apparatusGear wheelBiomedical engineering

The gear wheel of the present invention comprises a core, and teeth, in which said core comprises a first material, said teeth comprising the first material of the core together with a second material molded thereon as a skin, wherein the thickness of said skin at root of the teeth is more than the thickness of said skin at pitch line of the teeth.

Owner:EI DU PONT DE NEMOURS & CO

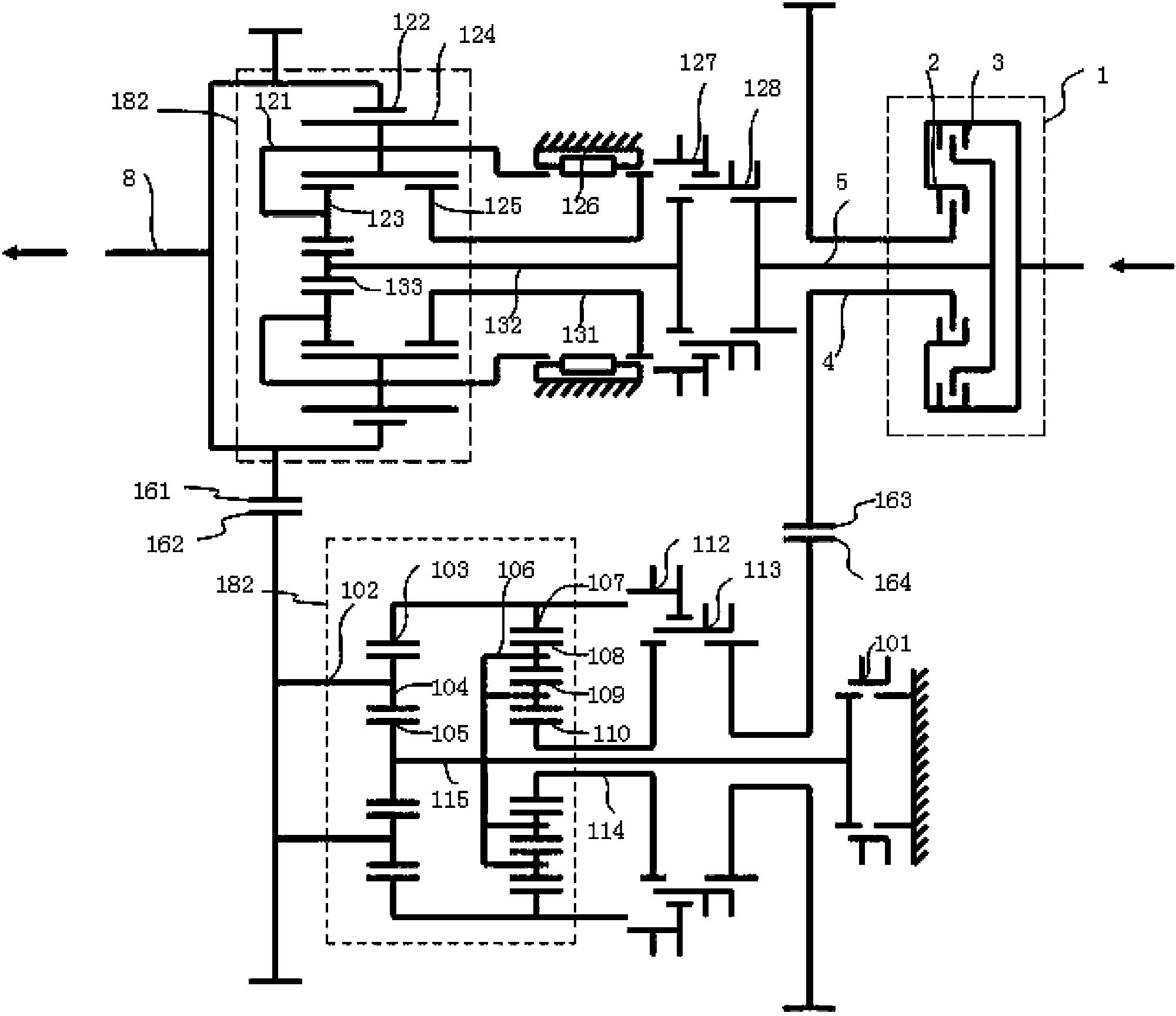

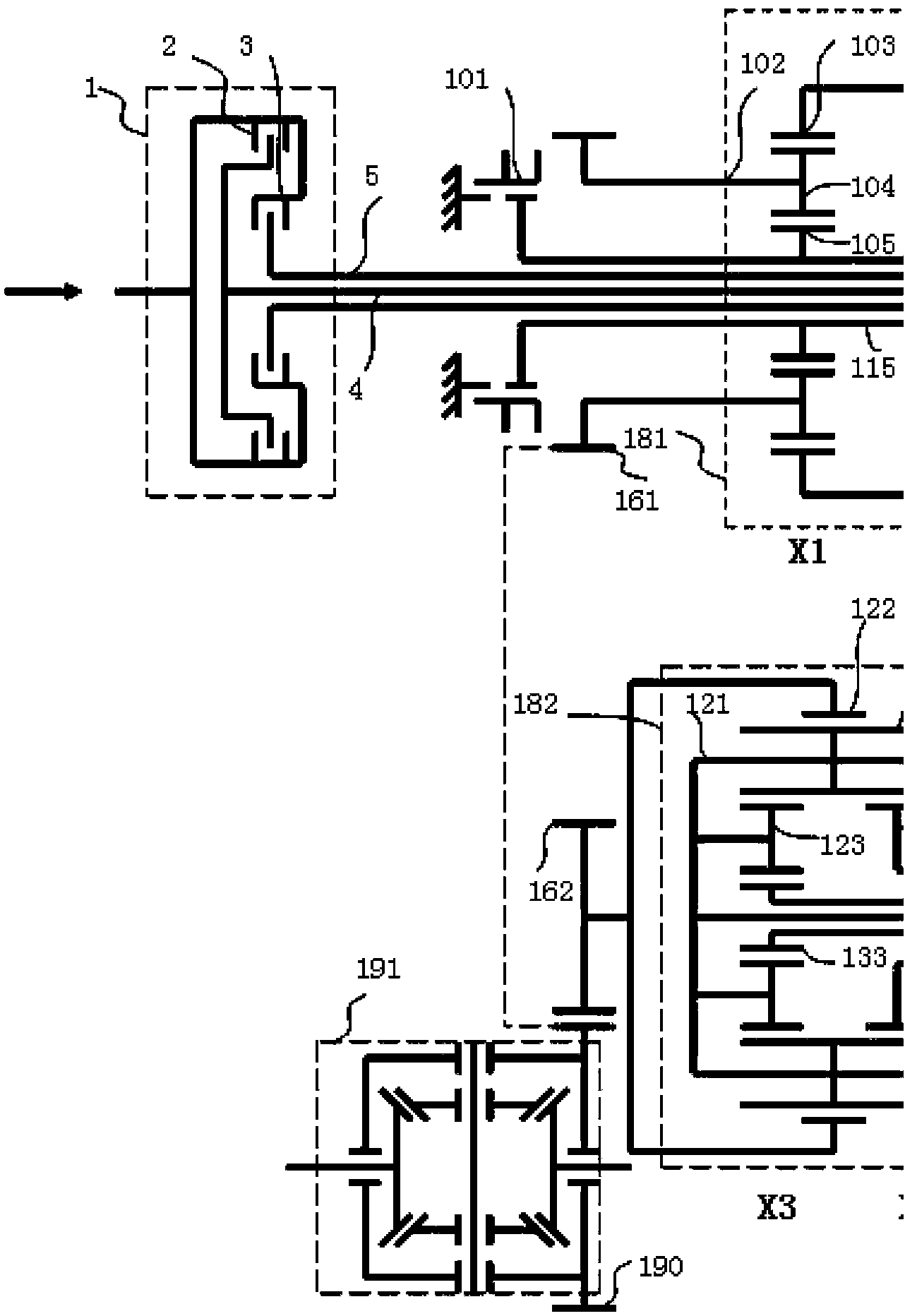

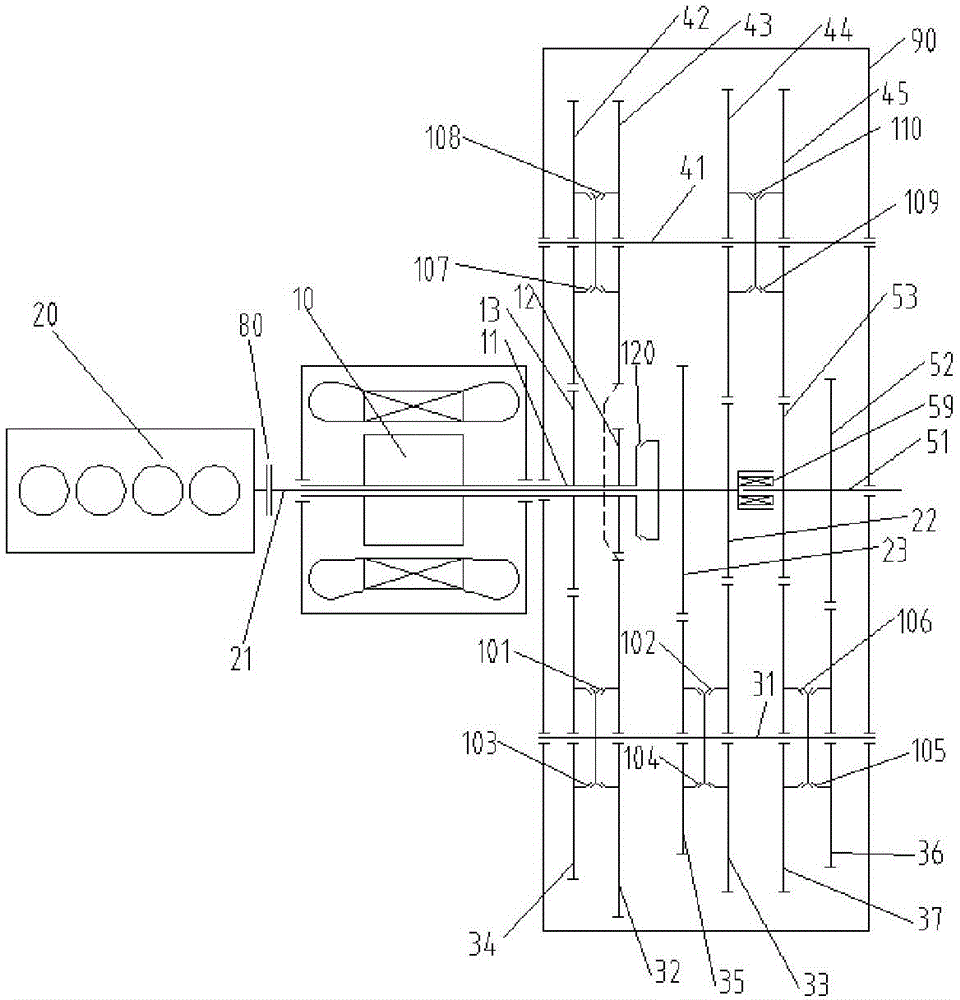

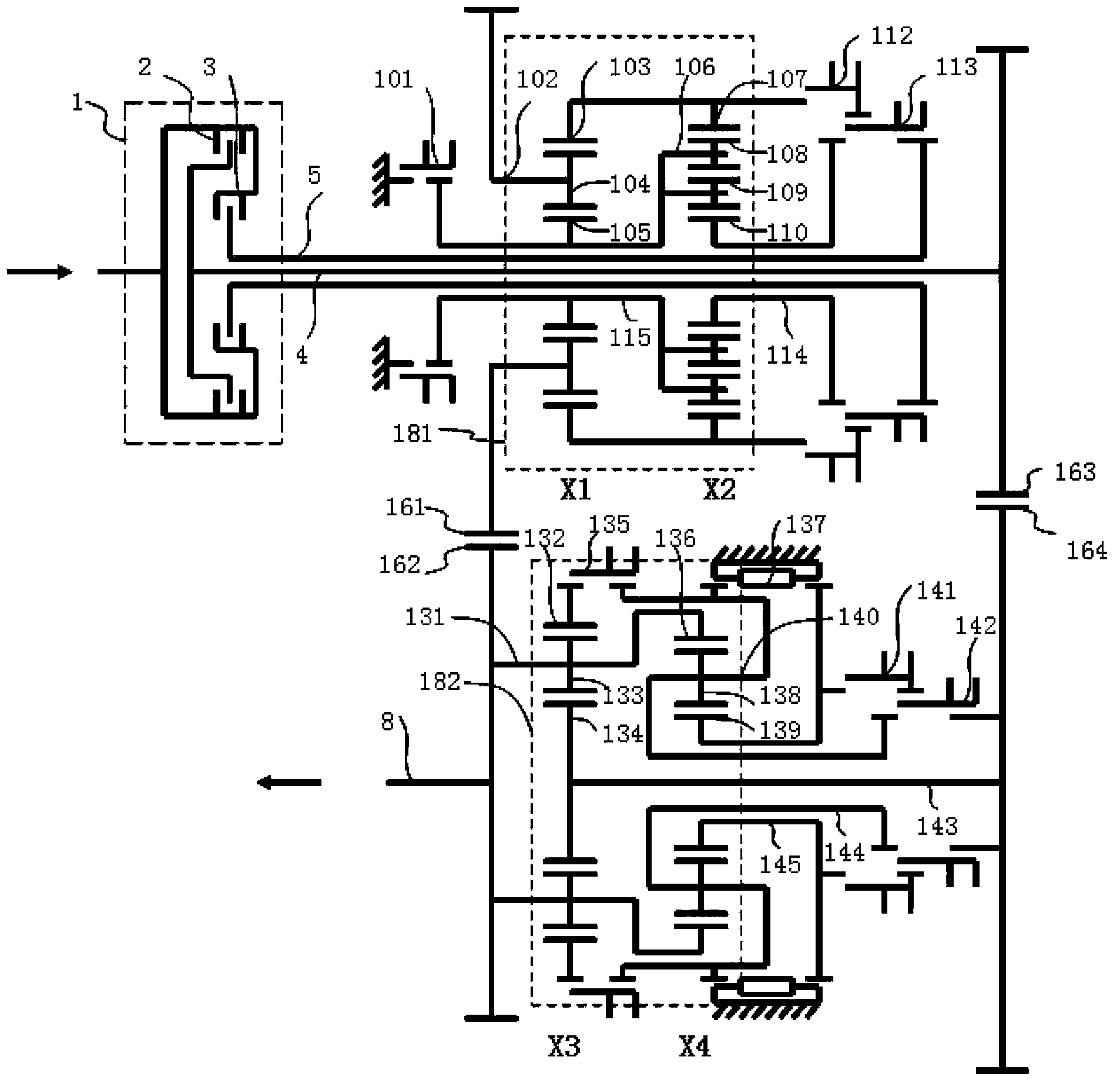

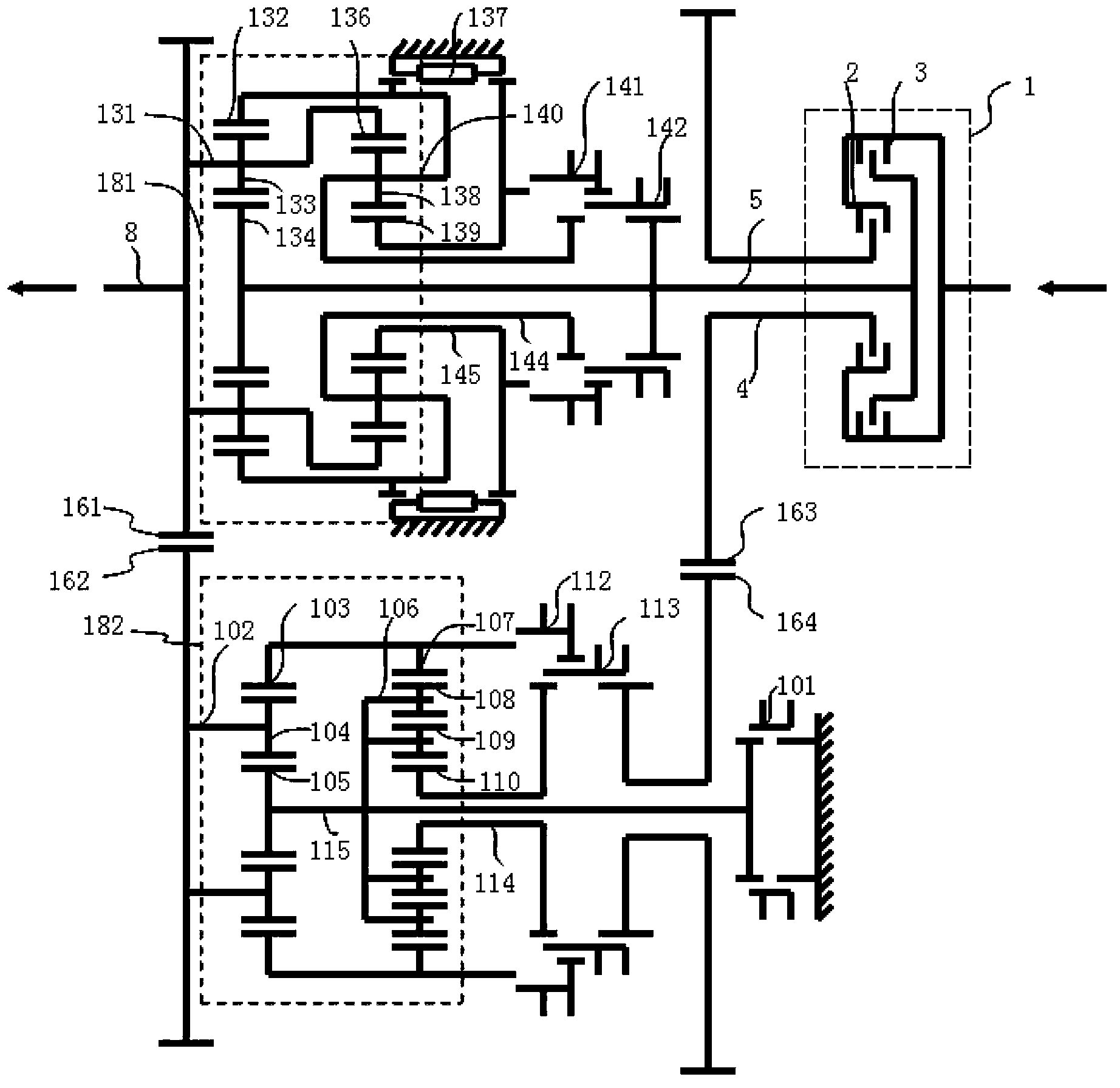

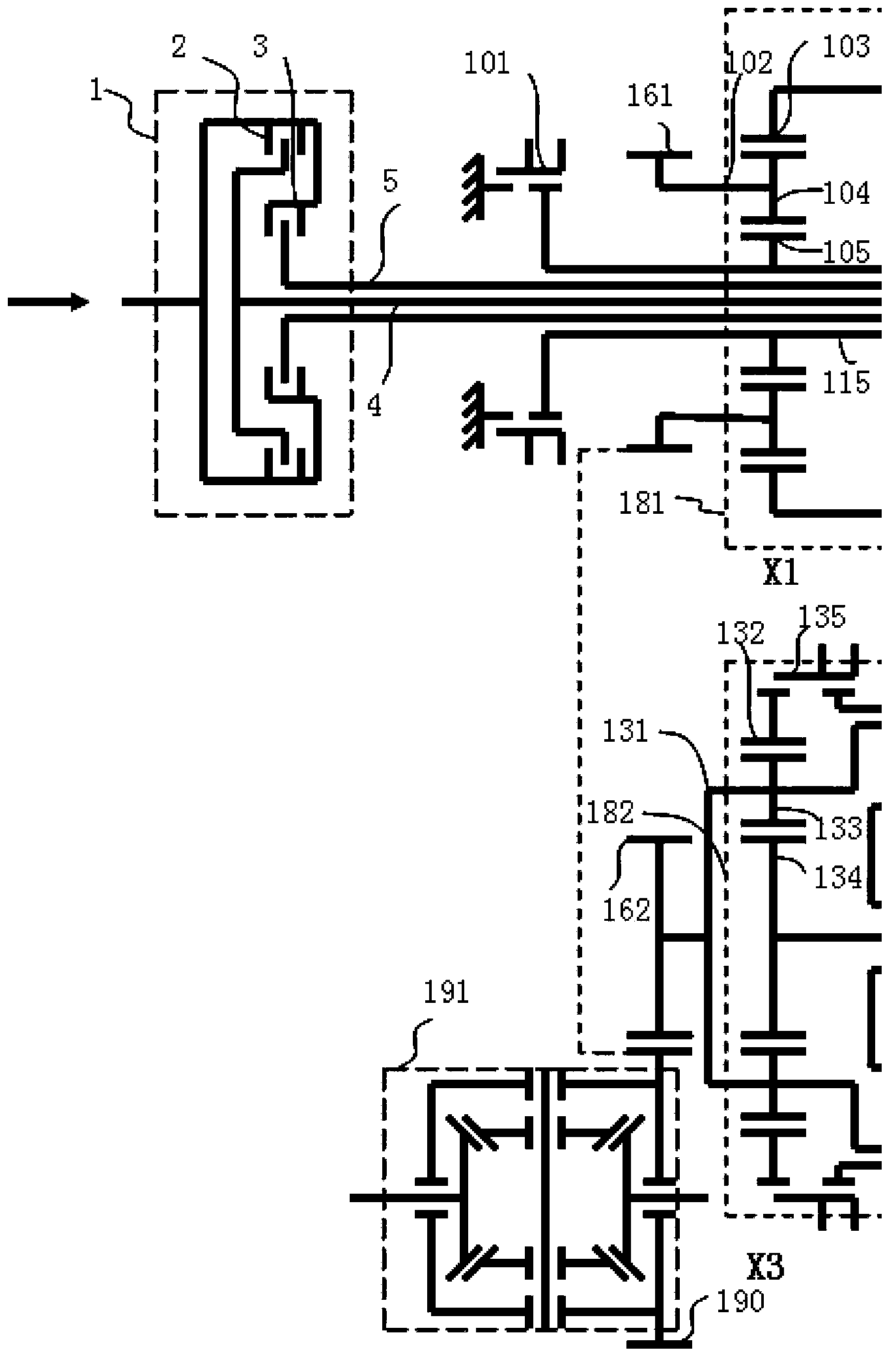

Vehicle hybrid power system and control method thereof

ActiveCN110525191AAdjust torqueTorque balanceHybrid vehiclesGas pressure propulsion mountingElectric machineGear wheel

The invention discloses a vehicle hybrid power system and a control method thereof. The system involves an engine, a hybrid power module and a double-input-shaft speed change mechanism, wherein the hybrid power module is composed of a motor, a planetary gear train and a first clutch, the planetary gear train is provided with at least three rotating shafts, the three rotating shafts comprise a rotating shaft X1, a rotating shaft X2 and a rotating shaft X3, axes of the three rotating shafts are on one straight line, the rotating speed of the rotating shaft X2 is between the rotating speed of therotating shaft X1 and the rotating speed of the rotating shaft X3, a first clutch is arranged between any two of the three rotating shafts, a power output shaft of the engine is connected with the rotating shaft X3 or the rotating shaft X1 of the planetary gear train and a second input shaft of the double-input-shaft speed change mechanism, a rotor of the motor is connected with the rotating shaft X1 or the rotating shaft X3, and the rotating shaft X2 is connected with a first input shaft of a double-input-shaft gearbox. According to the system and the method, the transmission efficiency is high, multiple gears are provided, the three-axis double-freedom-degree planetary gear train is introduced, a vehicle is driven to start by the differential between the engine and the motor, starting of the vehicle is stable, the smoothness of gear shifting is good, and the impact of gear shifting is small.

Owner:段志辉

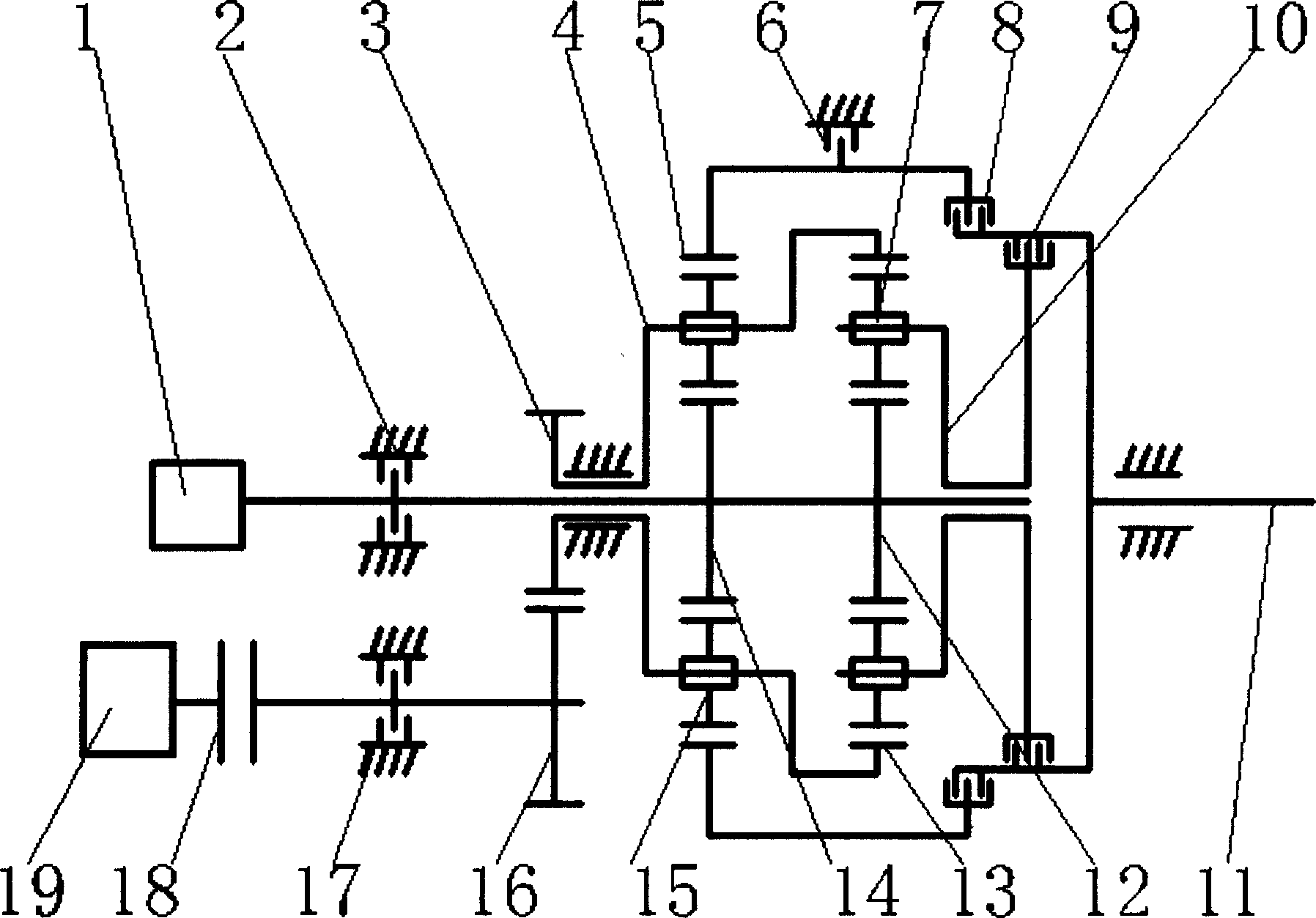

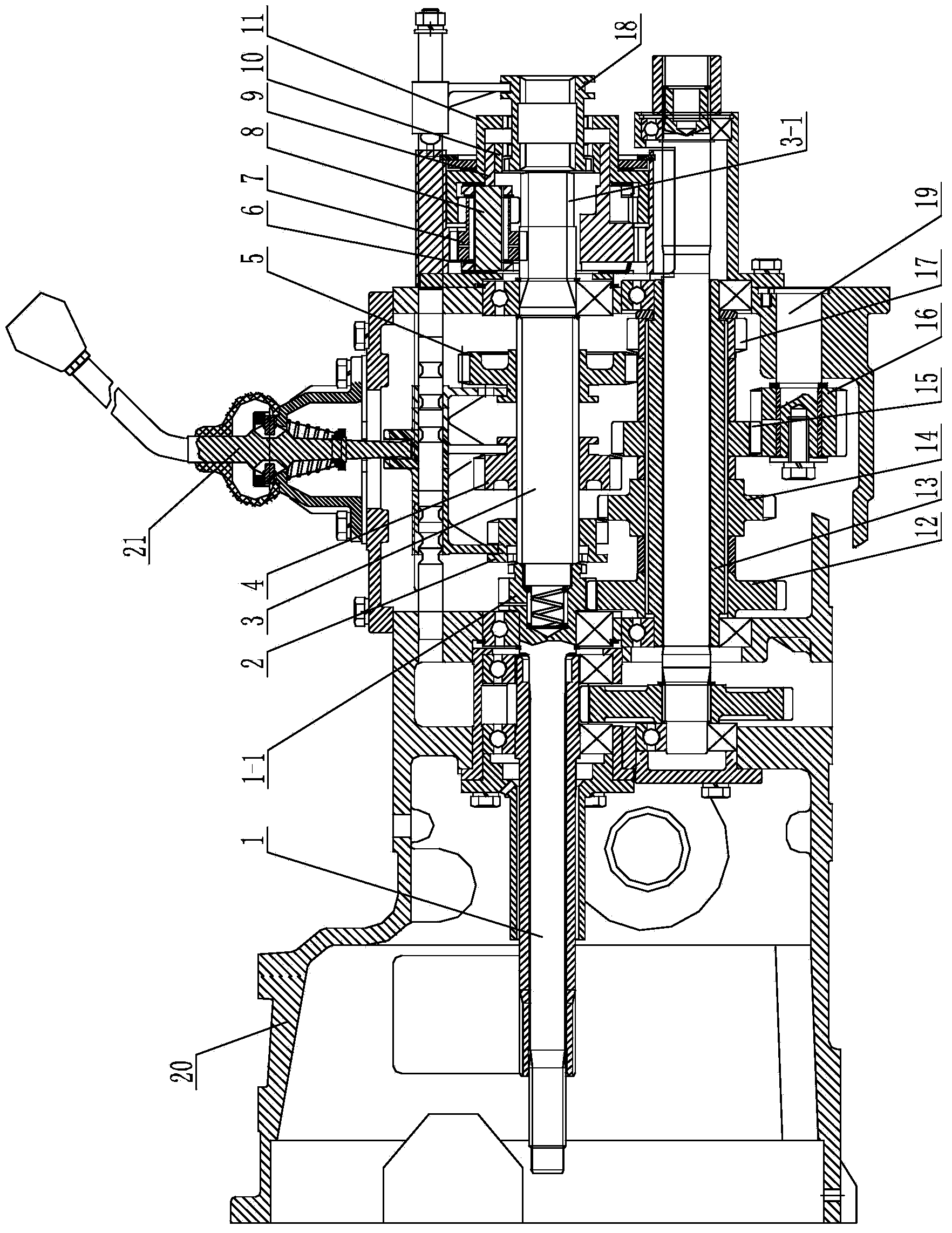

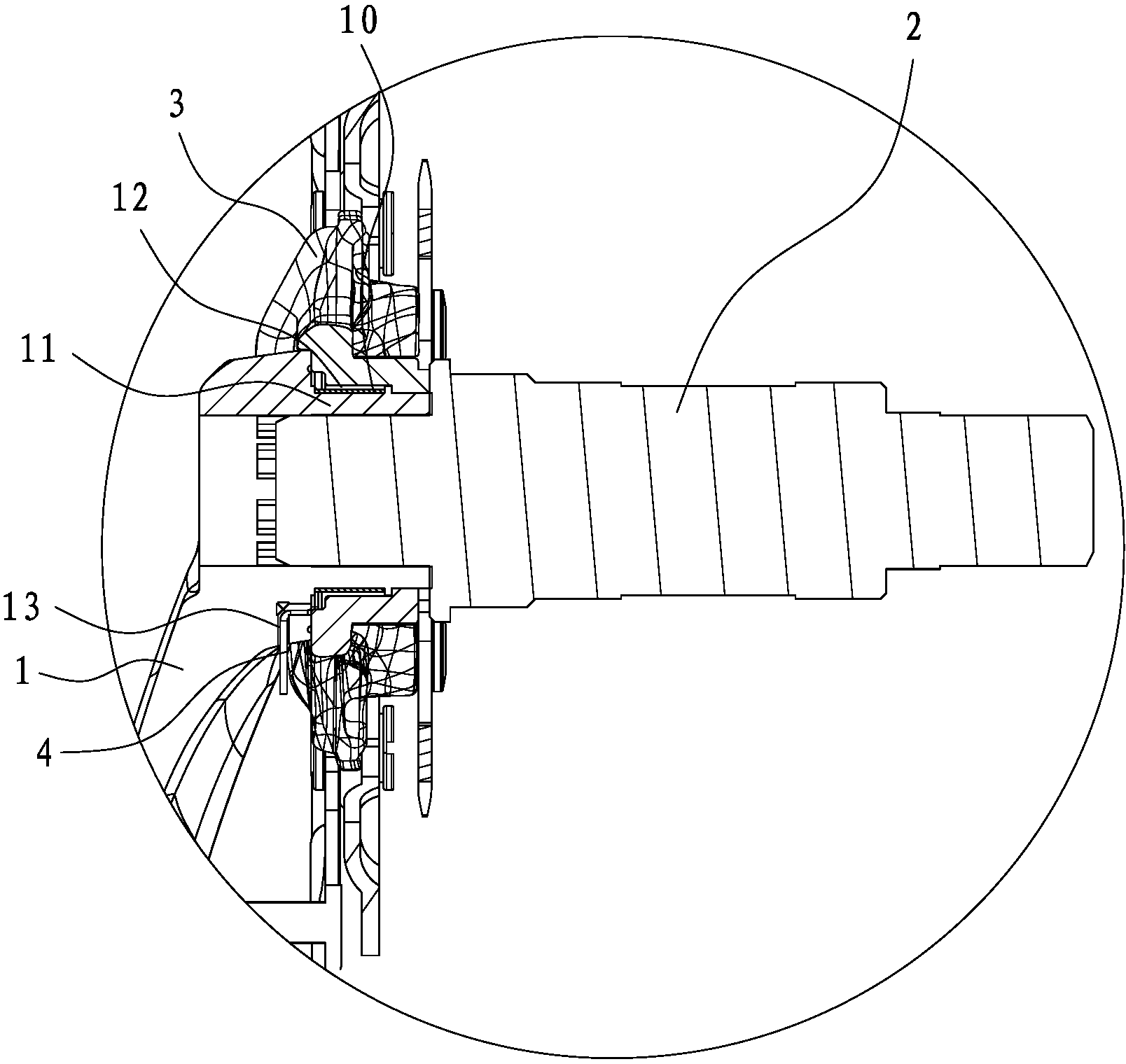

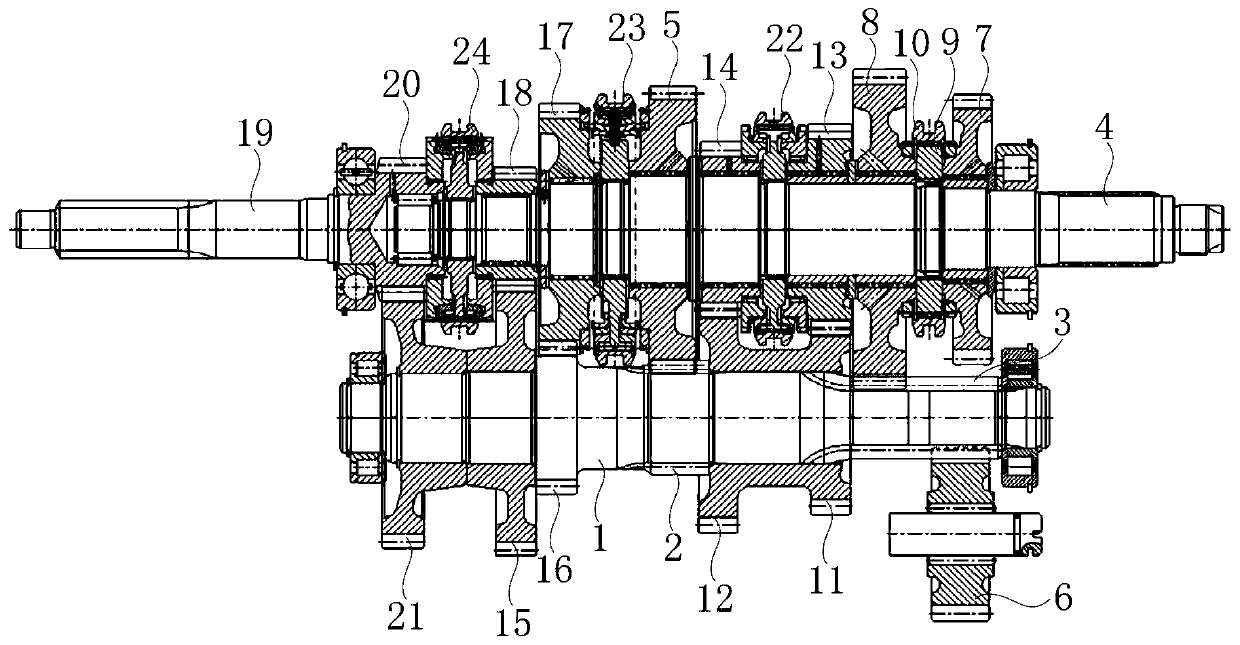

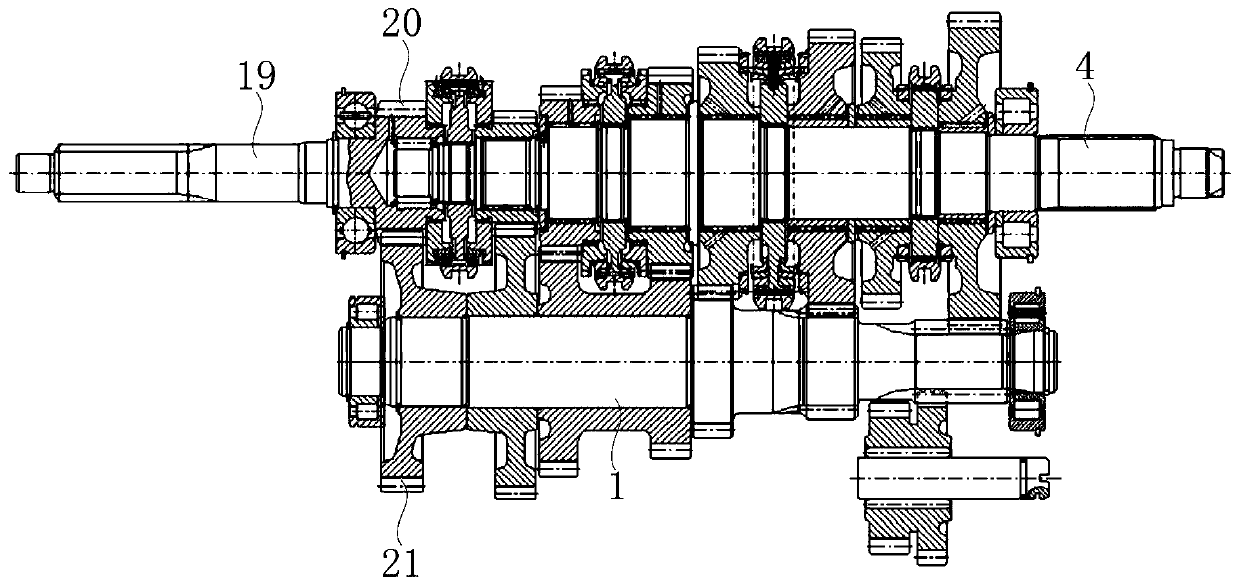

Tractor gearbox

InactiveCN103939538AIncrease gearGood inheritanceToothed gearingsTransmission elementsEngineeringTractor

The invention discloses a tractor gearbox which comprises a box body, a main operating device, a main speed change mechanism and a subsidiary speed change mechanism. The main speed change mechanism comprises a first shaft as a power input shaft, an intermediate shaft parallel to the first shaft, a second shaft coaxial with the first shaft and a reverse gear shaft. The subsidiary speed change mechanism comprises a planetary gear device capable of adjusting a high gear, a low gear and a creeper gear of the rotating speed output by the main speed change mechanism. The planetary gear device comprises a planetary gear spline ring, a creeper gear ring and a joint gear sleeve used for being connected with an output shaft. The joint gear sleeve moves to be in meshing transmission with a gear shaft of the second shaft, the planetary gear spline ring and the creeper gear ring to achieve conversion between the high-gear rotating speed, the low-gear rotating speed and the creeper-gear rotating speed. According to the tractor gearbox, on the premise that the transmission part of an existing gearbox body is kept unchanged, speed change gears of the gearbox can be increased, the successiveness is good, the using demands of users are better met, and the tractor gearbox is compact in structure, convenient to operate and high in practicability.

Owner:常州市武进俊云机械配件厂(普通合伙)

Multi-speed planetary gear type double-clutch gearbox

The invention discloses a multi-speed planetary gear type double-clutch gearbox which comprises a first clutch, a first input shaft corresponding to the first clutch, a second clutch, a second input shaft corresponding to the second clutch, a plurality of synchronizers and an output shaft, wherein the first input shaft and the second input shaft are arranged in a sleeving way; the multi-speed planetary gear type double-clutch gearbox also comprises a first double-row planetary gear train, a second double-row planetary gear train, a first gear, a second gear, a third gear and a fourth gear, wherein the first gear is meshed with the second gear; the third gear is meshed with the fourth gear; one of the first double-row planetary gear train and the second double-row planetary gear train is formed by two planet rows; in the front planet row, a front sun gear is connected with a rear planet carrier into a whole, and is fixed with a shell by the first constant mesh synchronizer or the clutches; the rear planet row adopts a double-planet wheel structure; a front gear ring is connected with a rear gear ring into a whole; the power is transmitted into a rear sun gear or the rear gear ring by the second synchronizer, the third synchronizer or the clutches through a first rear outer shaft, and is output by a front planet carrier. The multi-speed planetary gear type double-clutch gearbox can realize more speed ratio gears by fewer gear pairs, reduces the size of the gearbox, and enables the structural layout design of an automobile to be more flexible.

Owner:FOSHAN SHUNDE BELIEVE ELECTRICAL APPLIANCES CO LTD

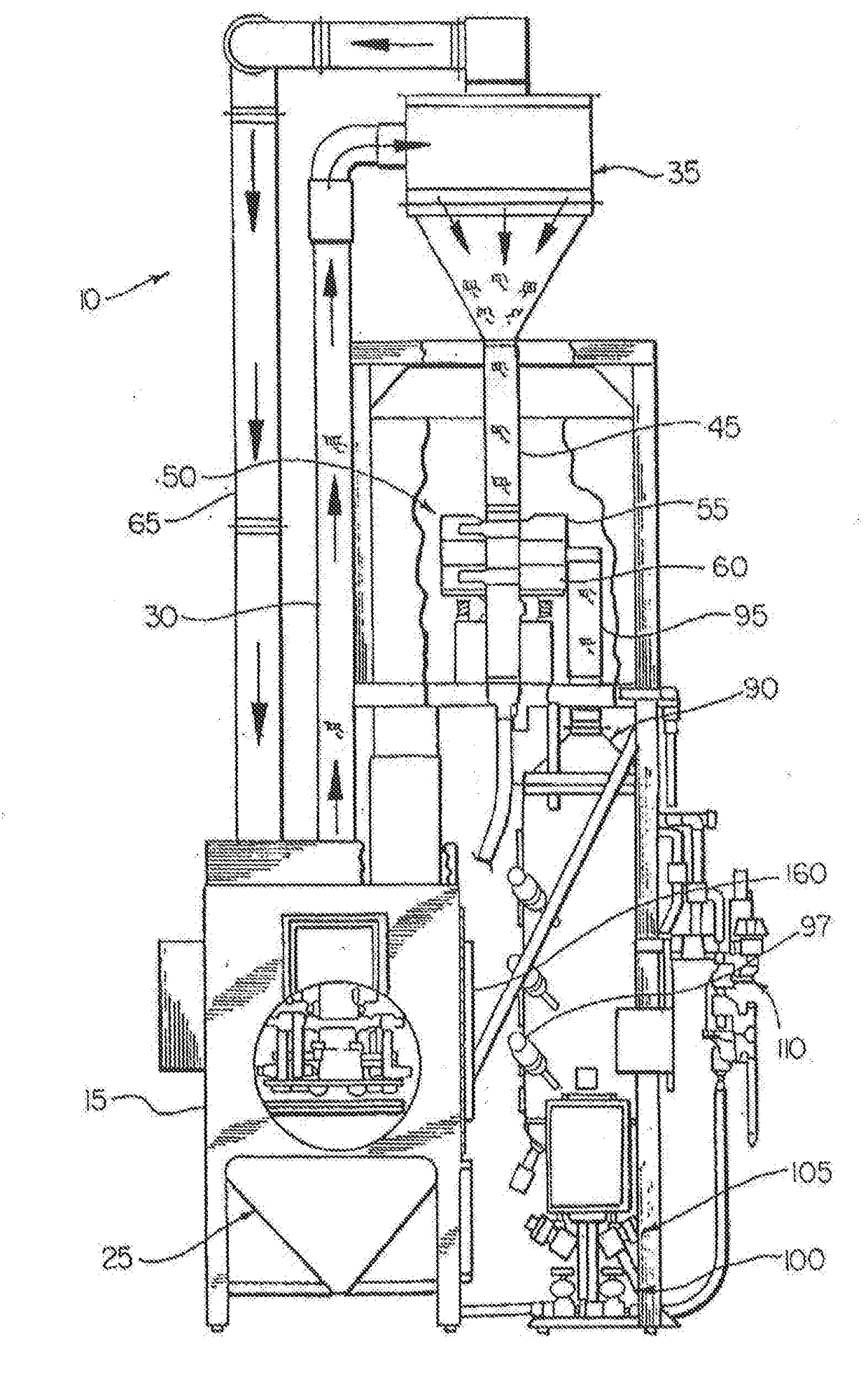

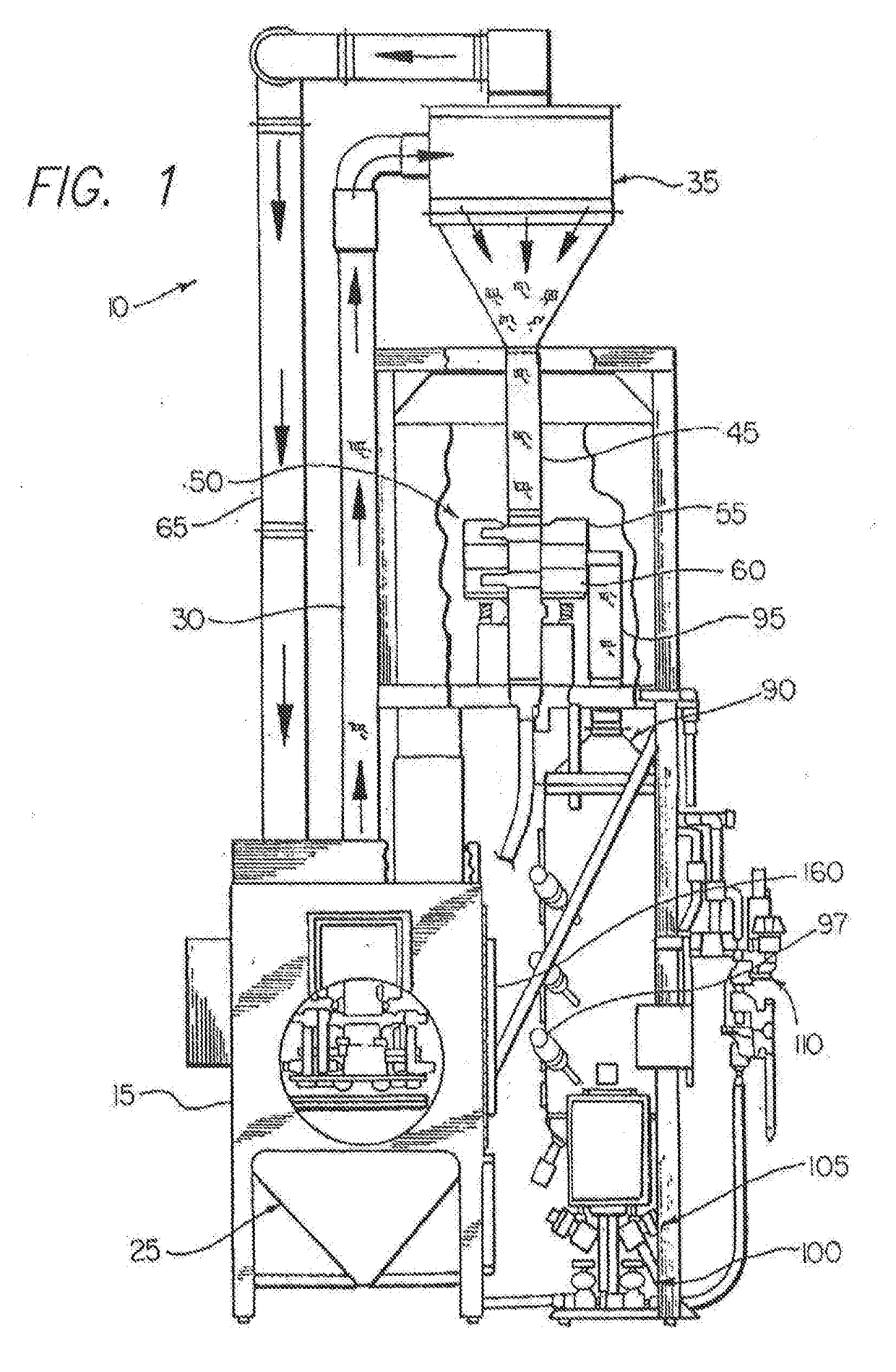

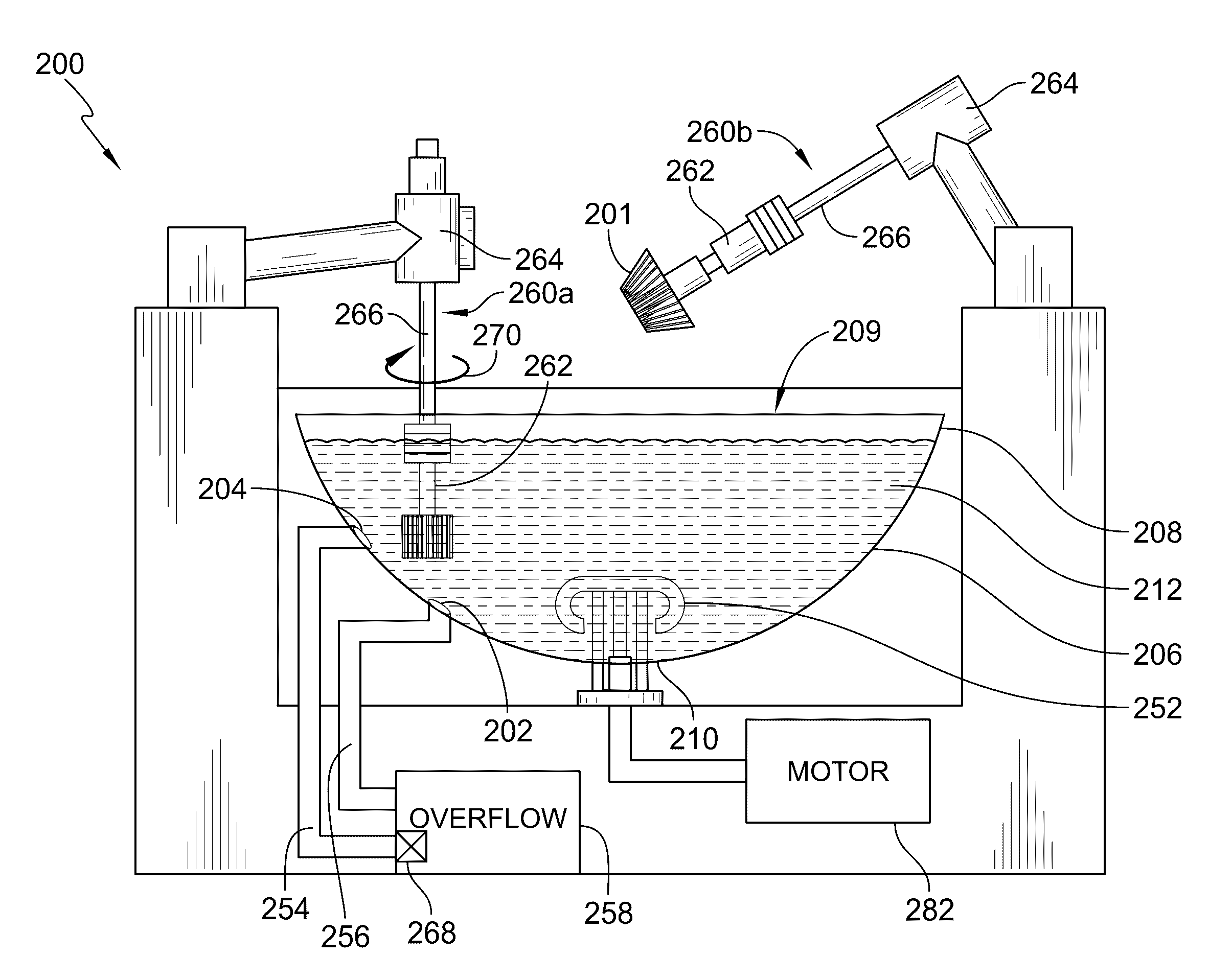

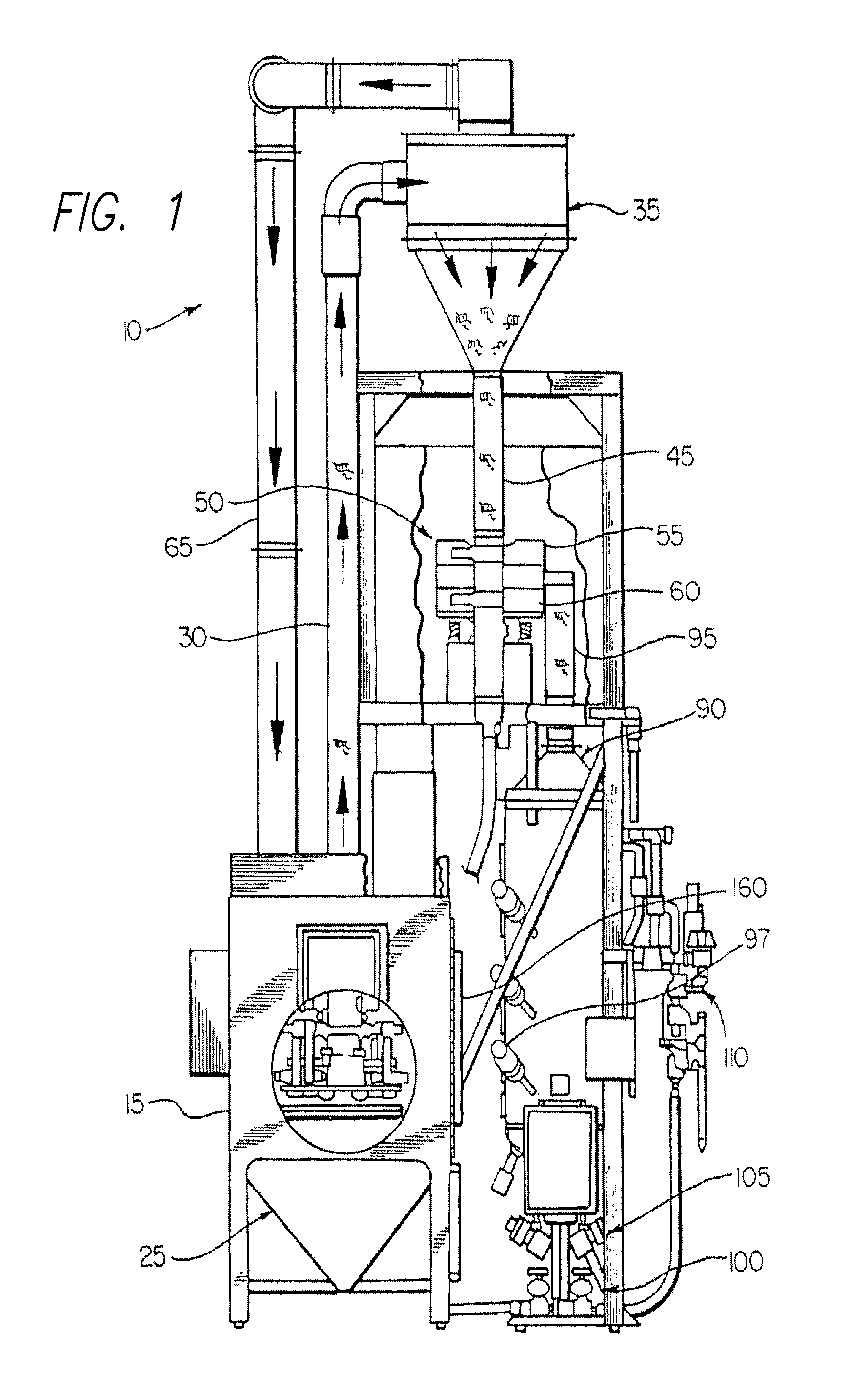

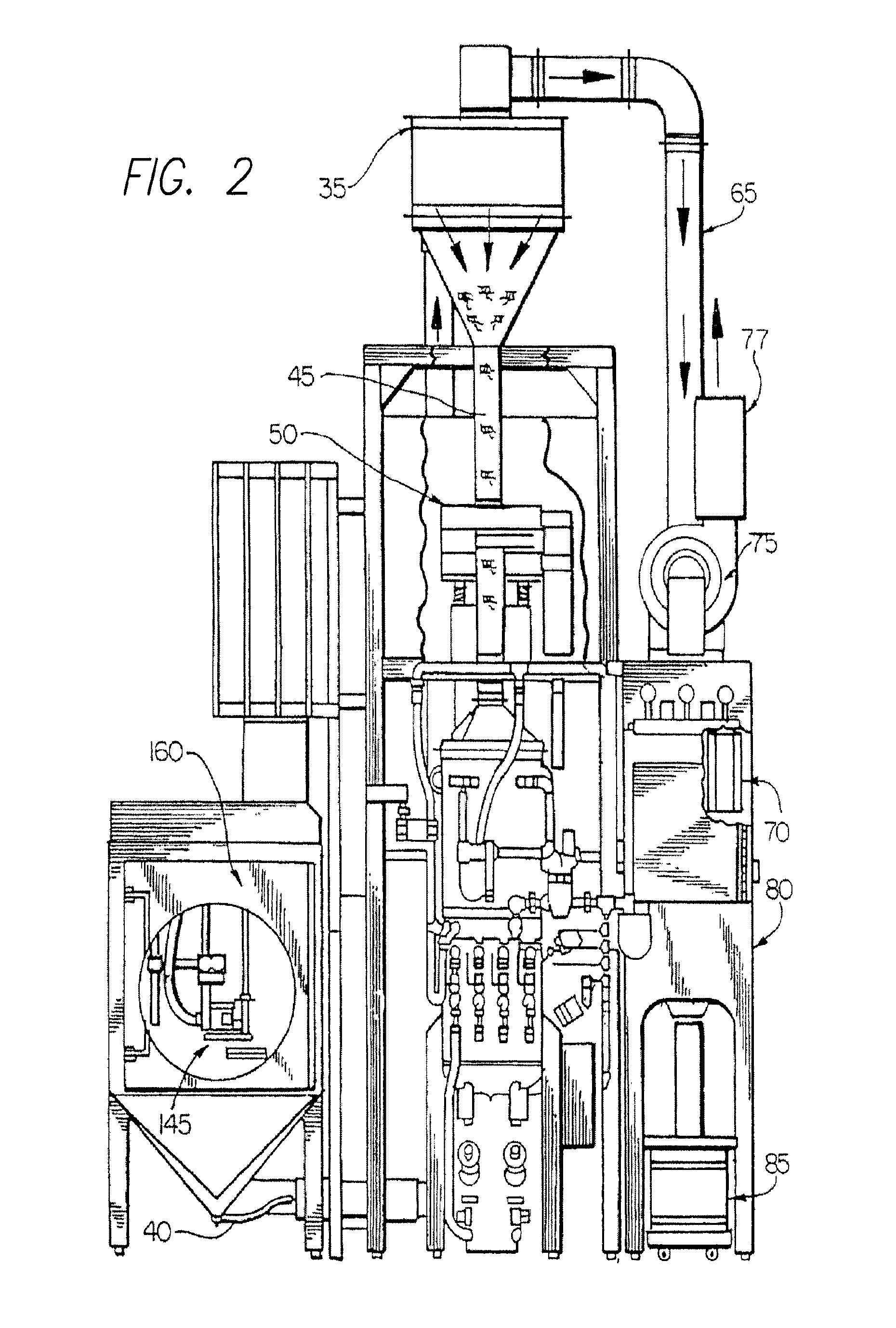

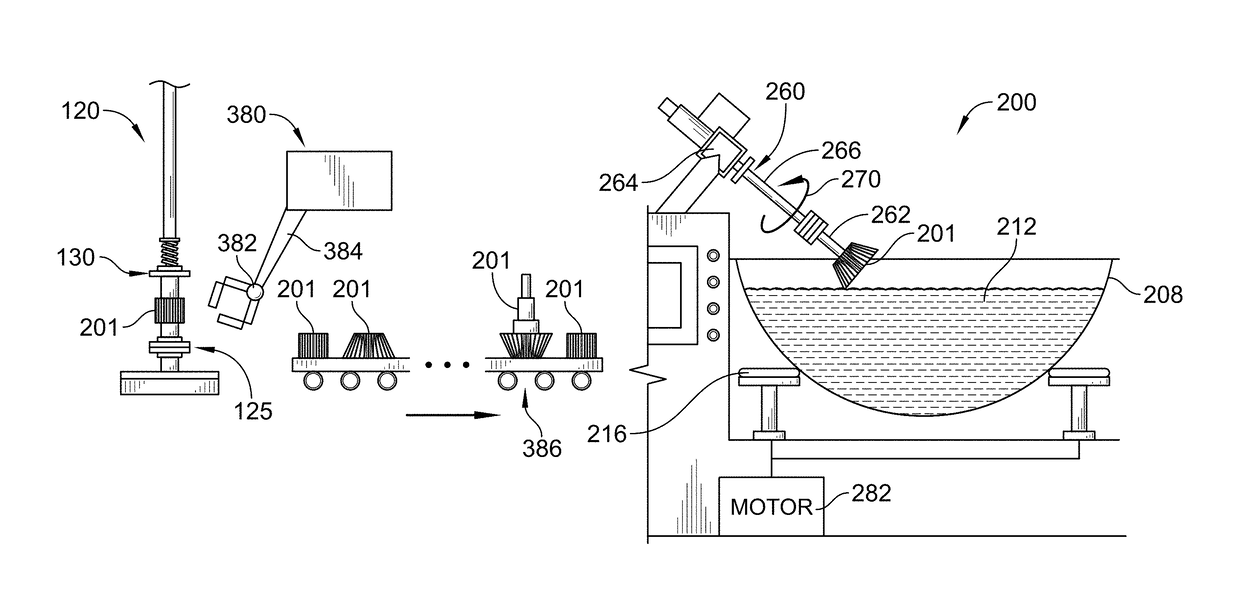

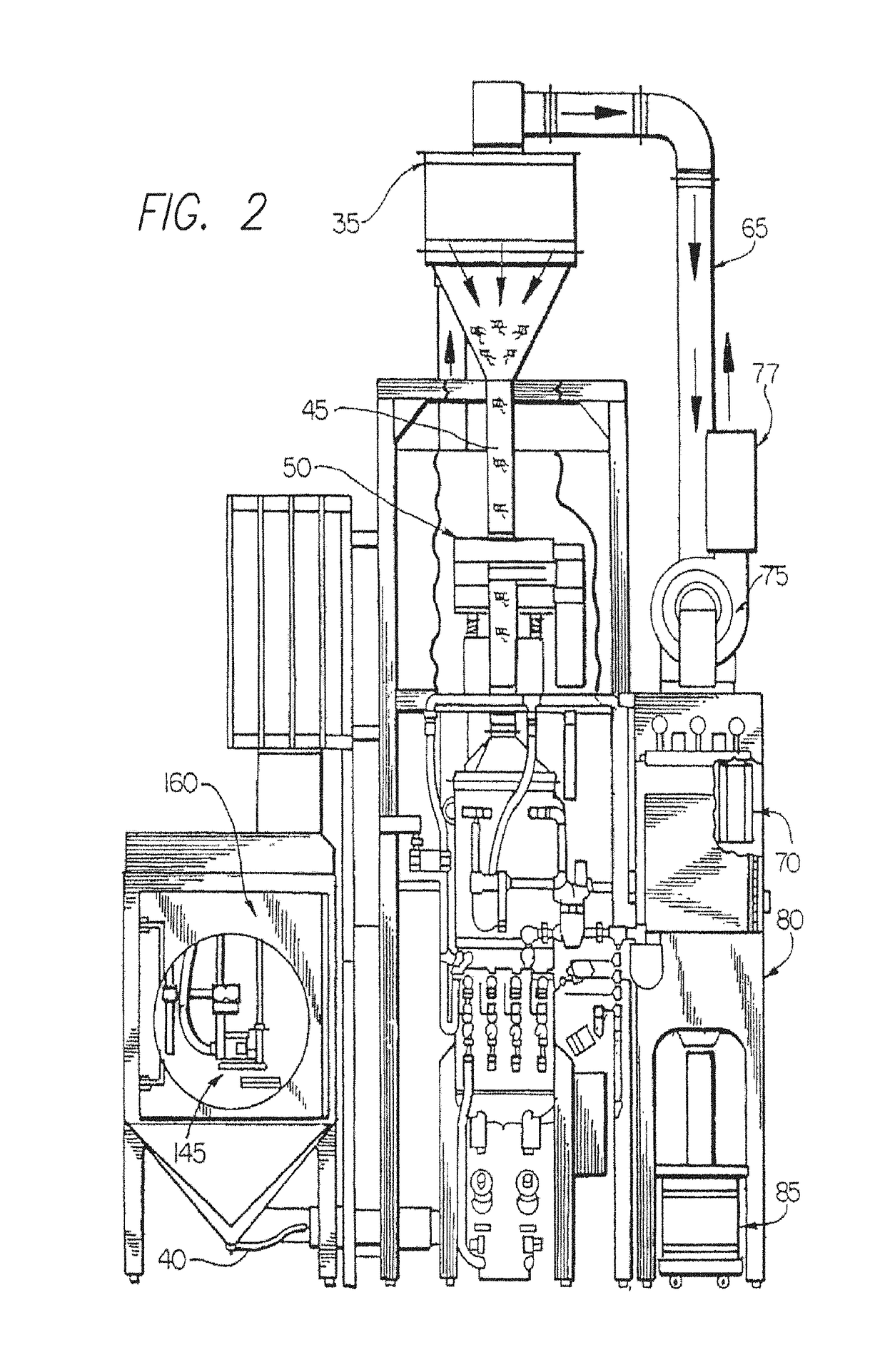

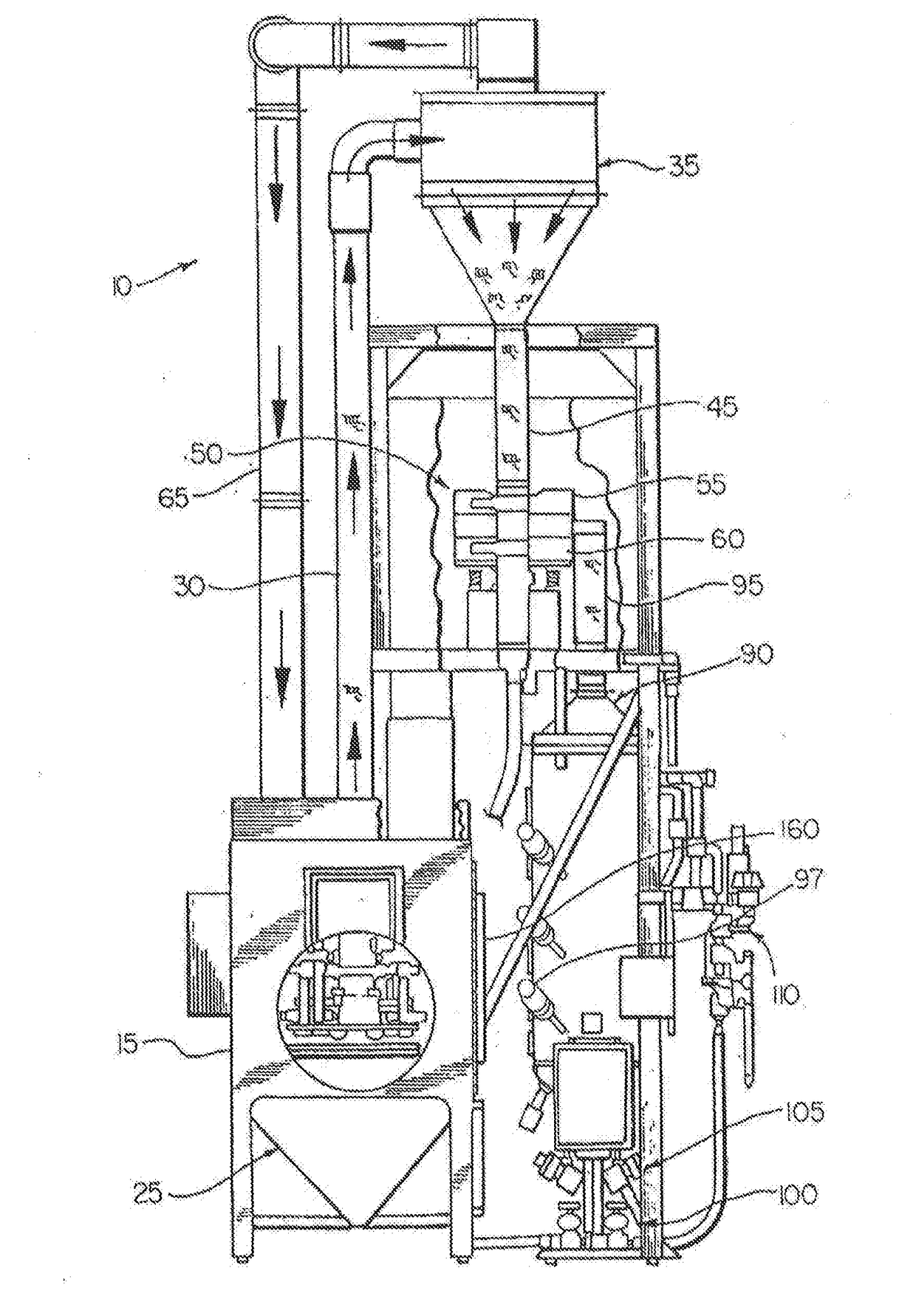

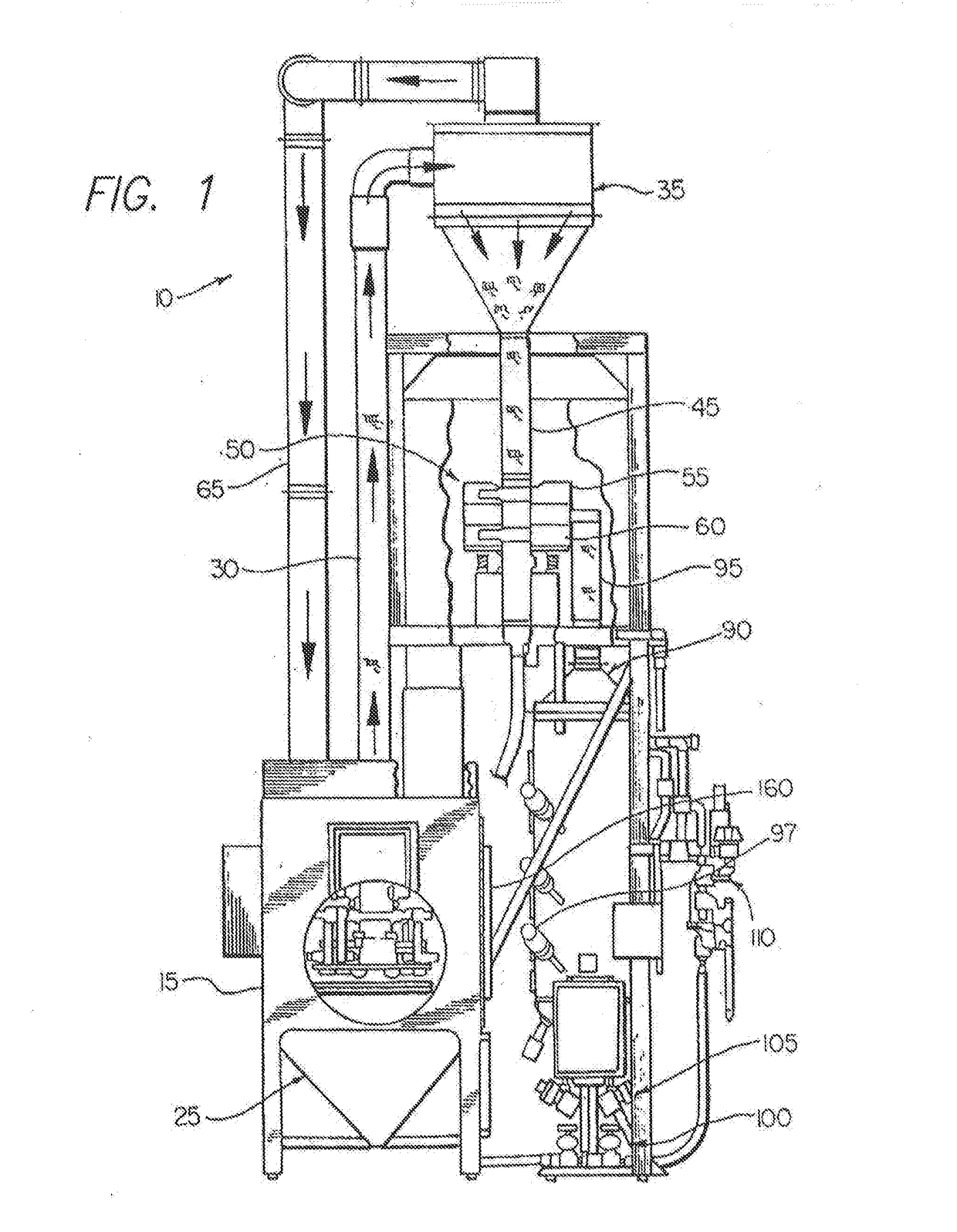

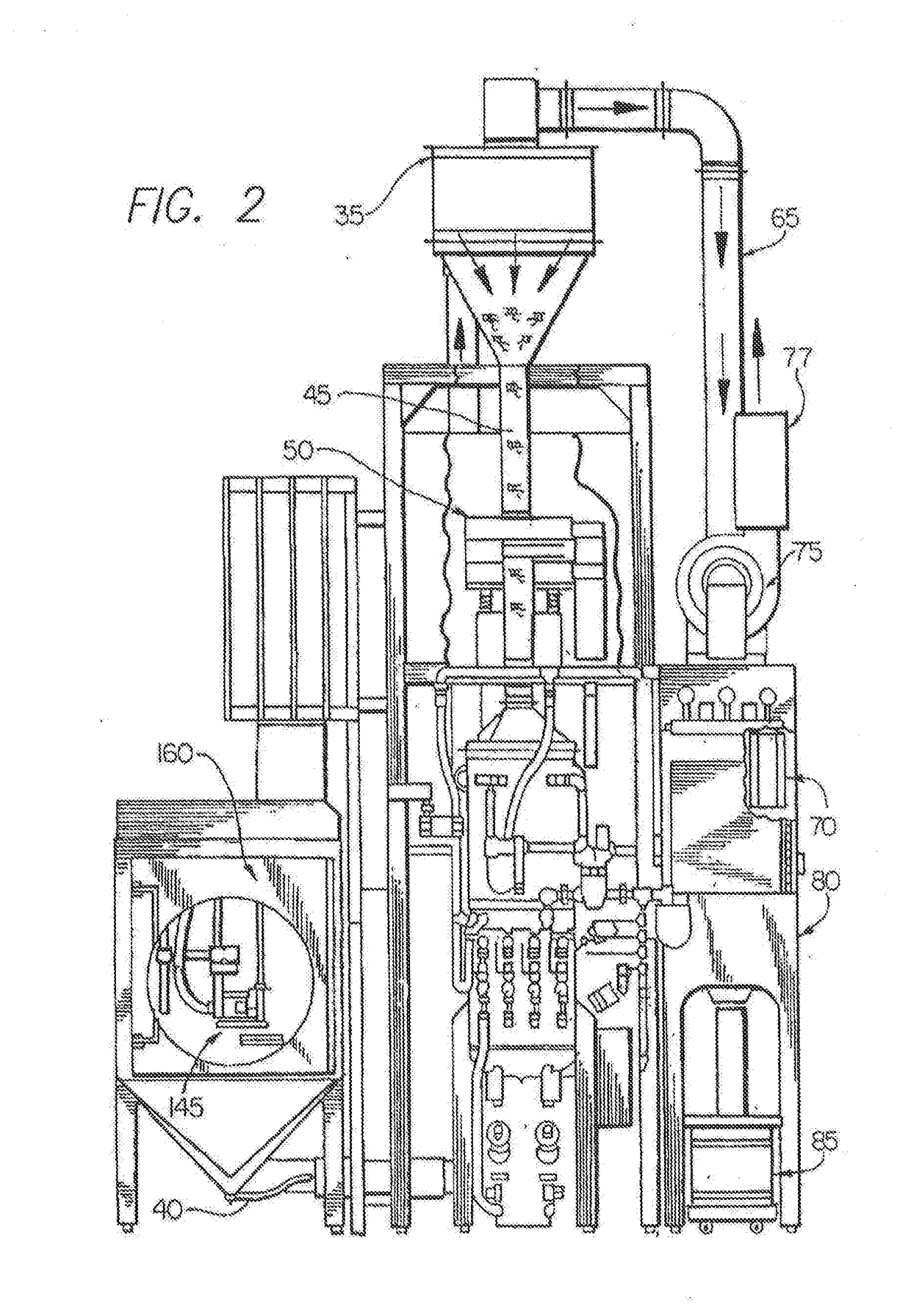

Part processing and cleaning apparatus and method of same

ActiveUS20170129073A1ToughenProvide roughnessAbrasive machine appurtenancesCleaning using liquidsSurface cleaningMegasonic cleaning

A part processing apparatus and method is disclosed that includes a media-blasting apparatus and a cleaning apparatus. The media-blasting apparatus is configured to blast a stream of media against a surface of a part, and the cleaning apparatus is configured to clean debris or particles from the surface of the part. The cleaning apparatus includes a first spray-and-wash unit, a first ultrasonic wash unit, a second ultrasonic wash unit, and a second spray-and-wash unit, which may be arranged in the listed order. Each of the units may be configured to utilize hot liquid or water to clean the part being processed. The first ultrasonic wash unit is configured to ultrasonically vibrate a liquid in the first ultrasonic wash unit at a first frequency, and the second ultrasonic wash unit is configured to ultrasonically vibrate a liquid in the second ultrasonic wash unit at a second frequency. The first and second frequencies may be different from each other, such that vibration at the second frequency causes additional debris or particles to be removed from the surface of the part that were not, or could not be, removed from exposure to vibration at the first frequency. The apparatus and method may further include a drying and / or inspection unit for the part after being processed in the cleaning apparatus.

Owner:ENGINEERED ABRASIVES

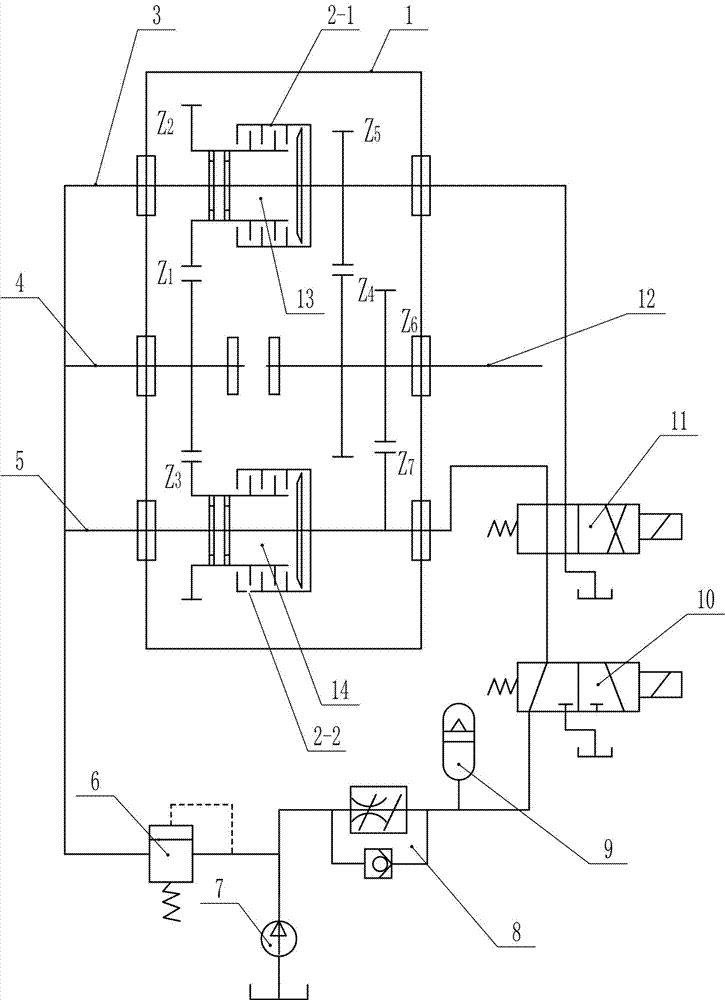

Modified dead axle type hydraulic automatic gear shifting with six shift gears

InactiveCN1687614AImprove gear shifting performanceIncrease usageFluid gearingsAutomatic transmissionVariator

The present invention relates to a modified dead axle type hydraulic automatic gear shift with six axle gears, which is characterized in that a single row star arrange on an additional axle of the double-shaft dead axle type hydraulic gear shift having not reverse gear, and the simple structure only with four clutches, an arrester, a single direction clutch has excellent capacity of six advancing gears, a reverse gear. The invention has many shifting gears, high shifting ratio, which is suitable for various military use, civilian use vehicles, particularly for diesel motor vehicle having small shifting range.

Owner:付宪生

Machining system, apparatus and method

ActiveUS20160375531A1Remove and reduce effectProvide roughnessEdge grinding machinesPolishing machinesAbrasive blastingGear wheel

A method and apparatus for processing a metallic workpiece with defined edges (e.g., a gear) comprises media blasting of the workpiece by directing a first media against exposed surfaces on the workpiece to increase the root strength of the gear, the blasting causing the defined edges to be radiused or mushroomed, ceasing the media blasting, loading the workpiece into a finishing apparatus, and subjecting the workpiece to a finishing process with a second media, the exposed surfaces on the workpiece being subjected to the finishing process to reduce the radiused edges on the workpiece created from the media blasting. The process of moving the workpiece to the spindle-finishing apparatus from the media blasting may be performed automatically by a machine. Once the workpiece has been subjected to the finishing process with the second media, it may be removed from the spindle-finishing machine, washed, and rinsed with rust inhibitor whereby wear properties of the workpiece are enhanced.

Owner:ENGINEERED ABRASIVES

Speed changing system of mini-tiller

The invention discloses a speed changing system of a mini-tiller. The speed changing system comprises a box body, wherein the box body is internally provided with a main shaft, a secondary shaft and an output shaft, which are parallel to one another, wherein a first main gear and a second man gear sleeve the main shaft; the first main gear and the second main gear are fixedly connected to form a main shaft duplicate gear; a first secondary gear, a second secondary gear, a third secondary gear, a fourth secondary gear and a fifth secondary gear sequentially sleeve the secondary shaft; a first output gear, a second output gear and a third output gear sequentially sleeve the output shaft; and all the gears are engaged through the axial sliding of the main shaft duplicate gear to realize gear shifting and speed changing. With the adoption of the speed changing system of the mini-tiller, gears of an existing mini-tiller are increased; and the selection range is relatively wide in a use process so that the mini-tiller has relatively high practicability and the requirements of actual production are met.

Owner:WEIMA AGRI MACHINERY CO LTD

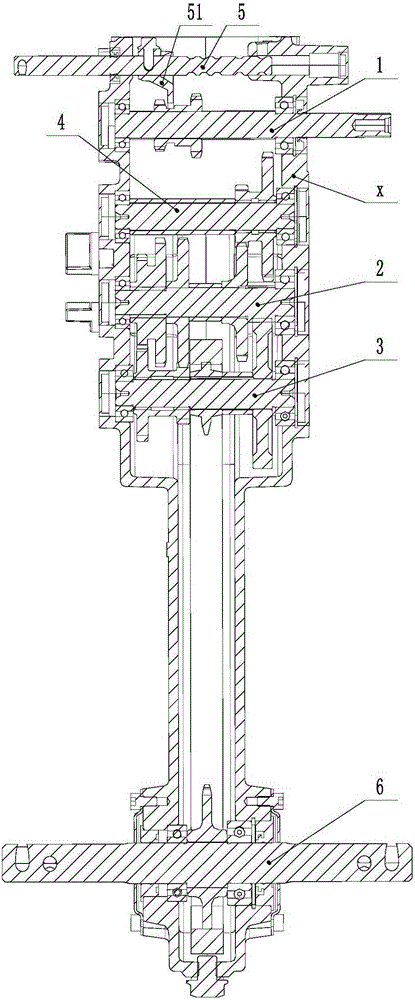

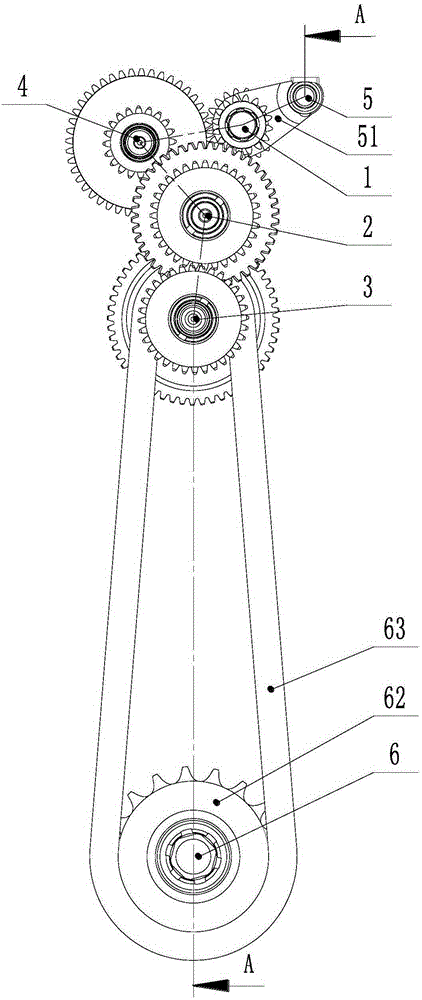

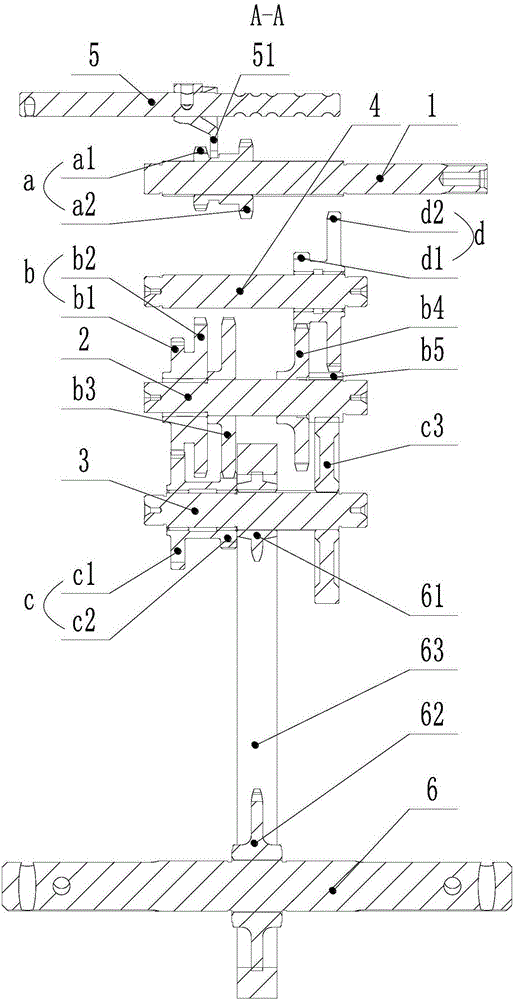

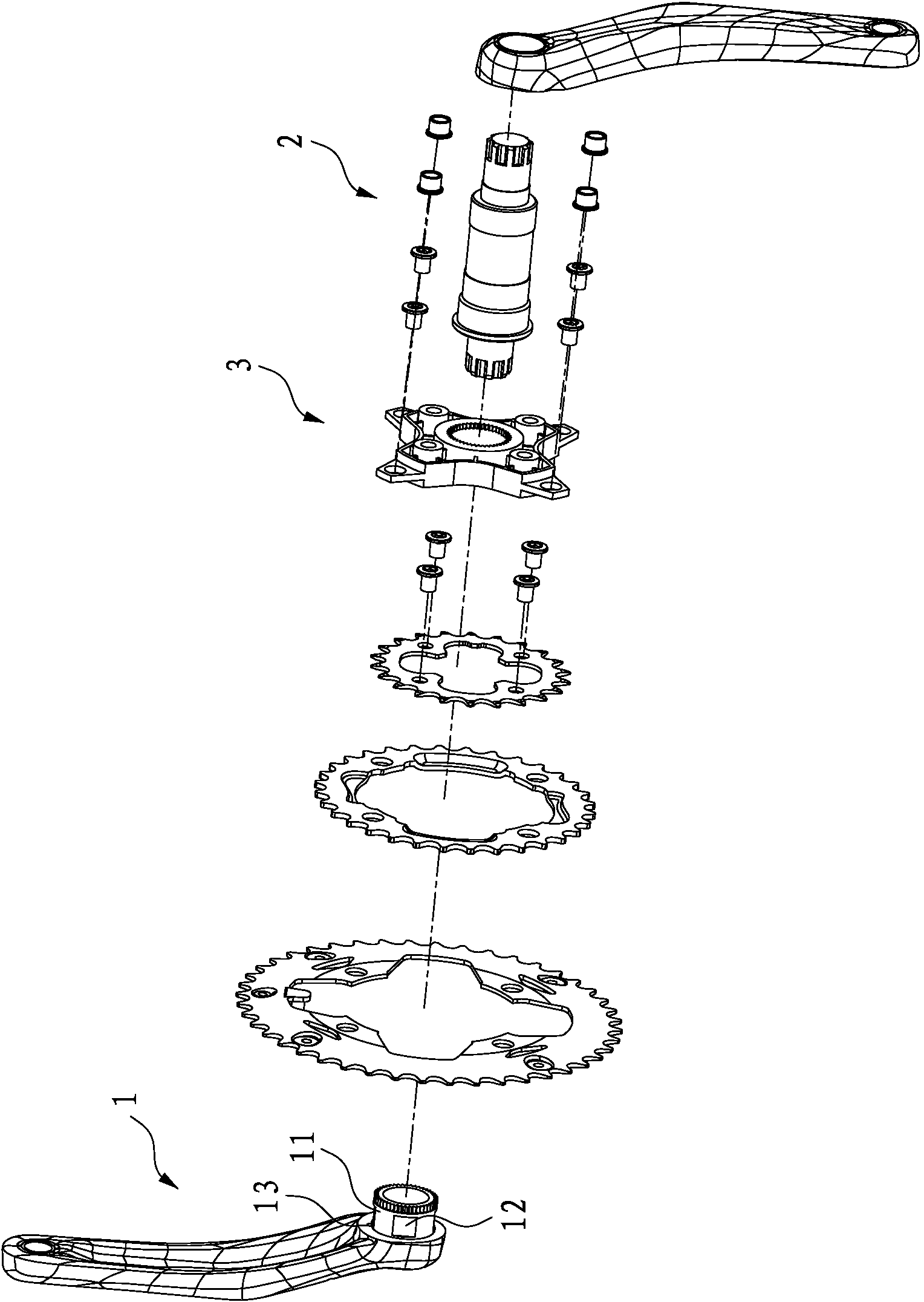

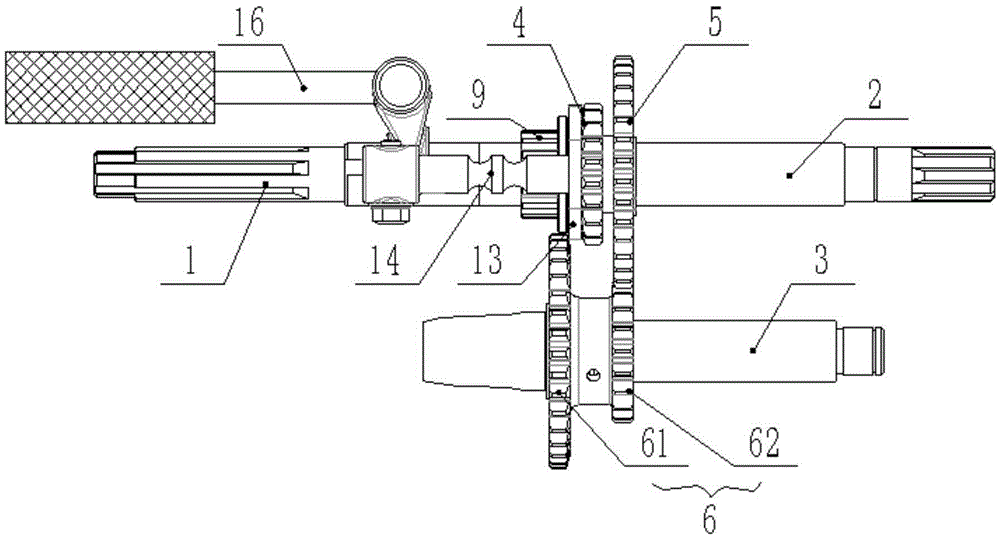

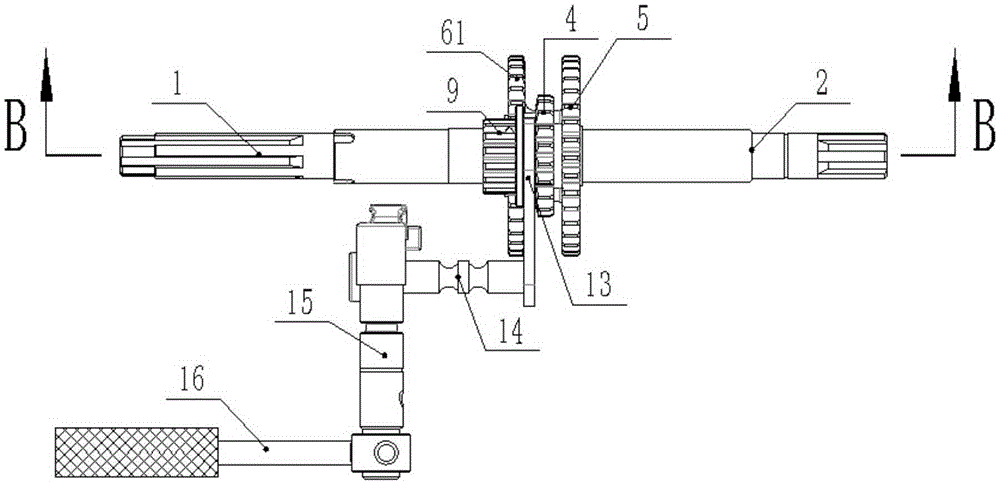

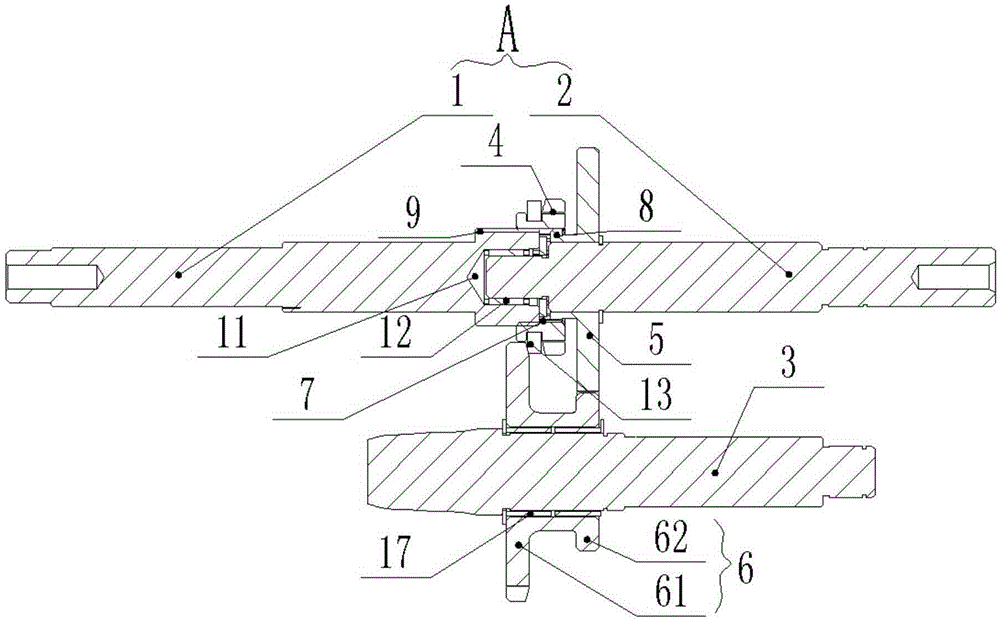

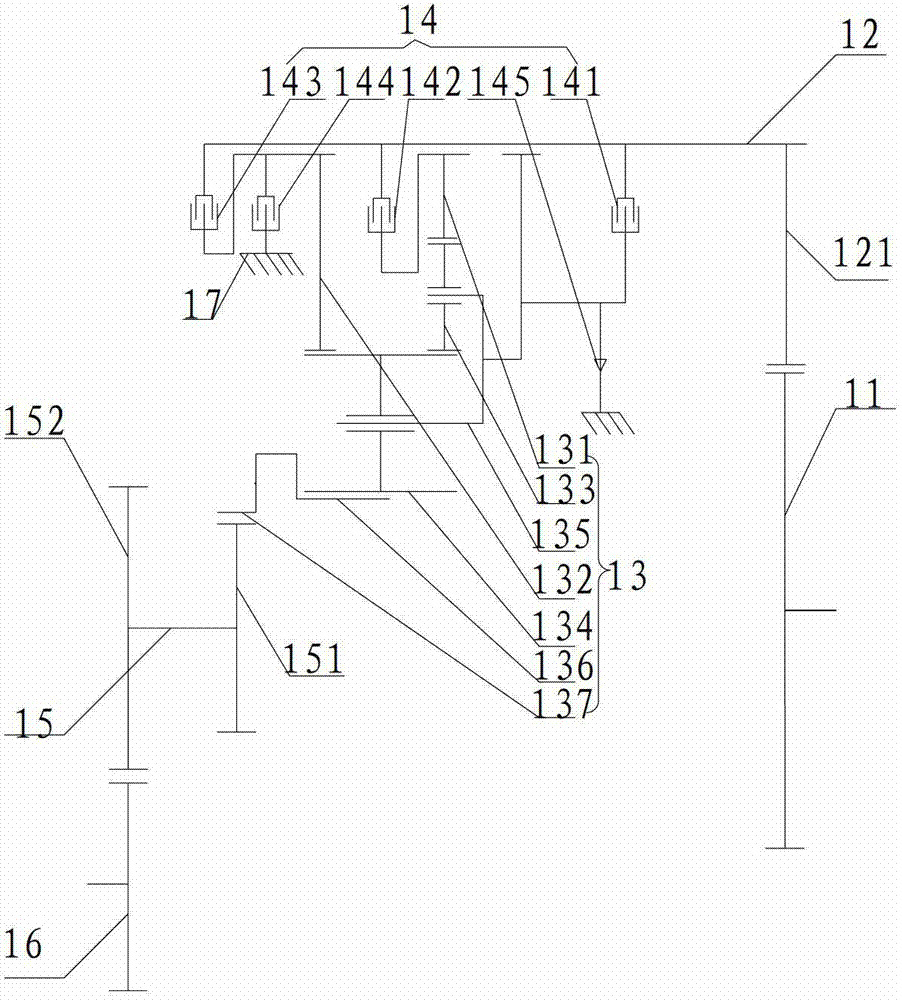

Measuring device for power of bicycle

InactiveCN103487185ADoes not affect the installation spaceRemove restrictionsWork measurementTorque measurementStructural engineeringMechanical engineering

The invention discloses a measuring device for power of a bicycle. The measuring device for the power of the bicycle comprises torsion sensors and a microprocessor chip, wherein one end, fixed to a middle shaft, of a crank extends to form a shaft sleeve, the middle shaft is sleeved with the shaft sleeve, a gap is reserved between the shaft sleeve and the middle shaft, installing positions are arranged on the shaft sleeve, the torsion sensors are fixed to the installing positions, and are connected with the microprocessor chip, the number of the installing positions is four, each torsion sensor is fixed to each installing position, the four torsion sensors are connected in series to form a Wheatstone bridge, the Wheatstone bridge is connected with the microprocessor chip, and the torsion sensors and the microprocessor chip are arranged in a separated mode. The measuring device for the power of the bicycle is convenient to install, maintain and replace, more stable in signal sensing, and more accurate in measurement, and cost is reduced.

Owner:卢泽仲

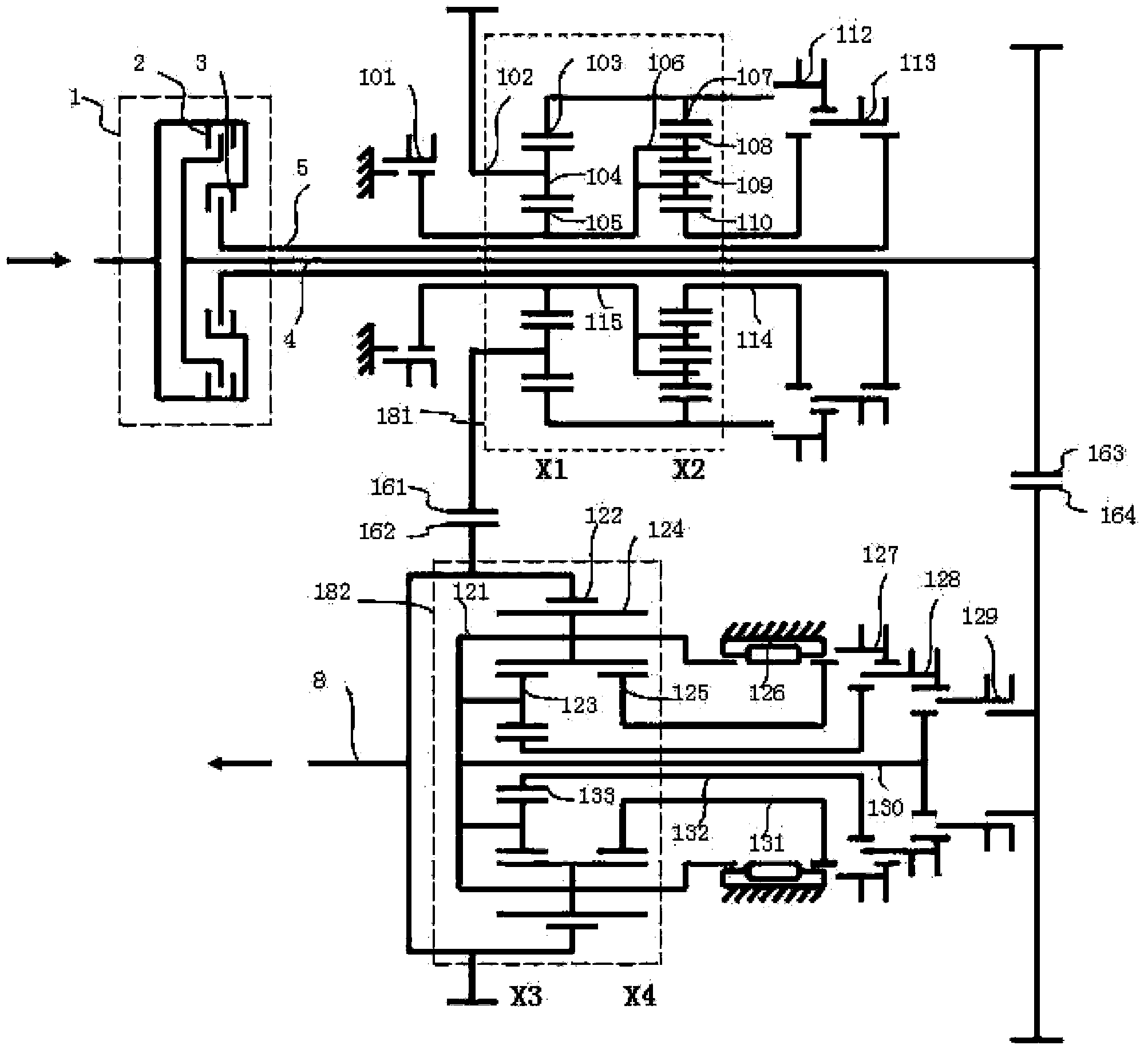

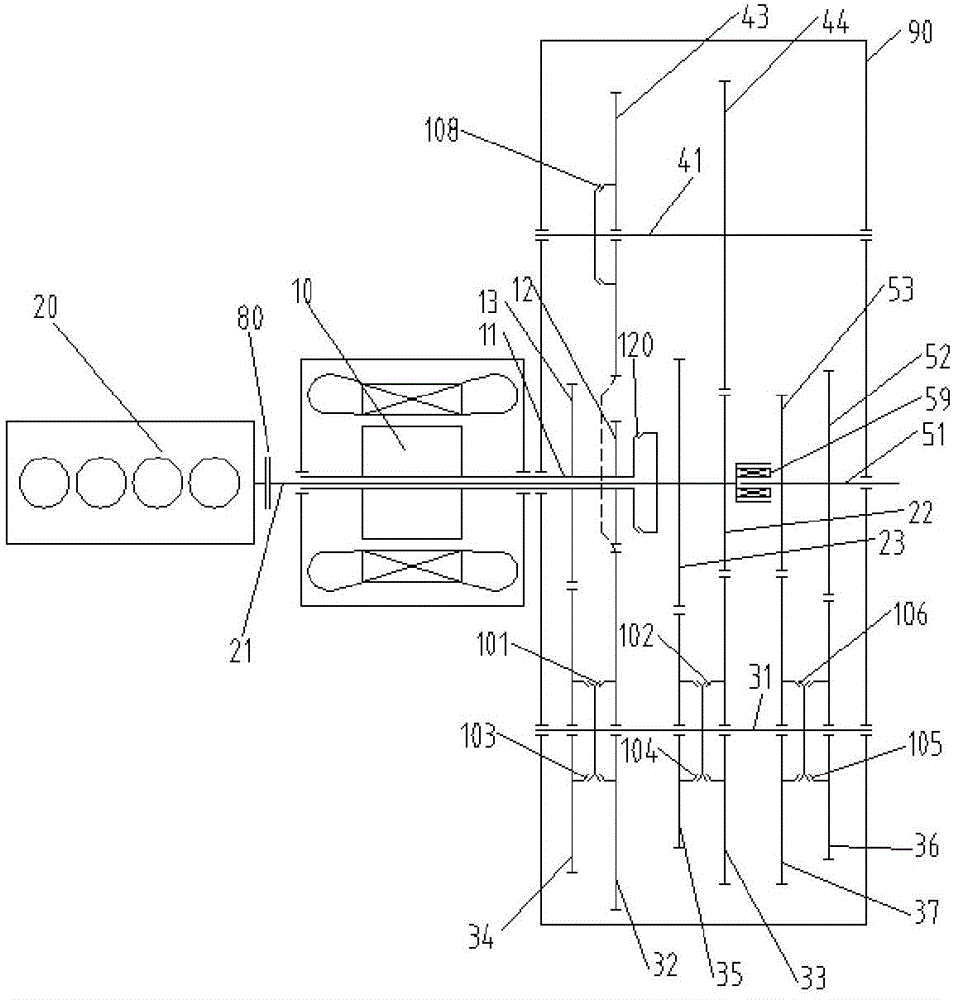

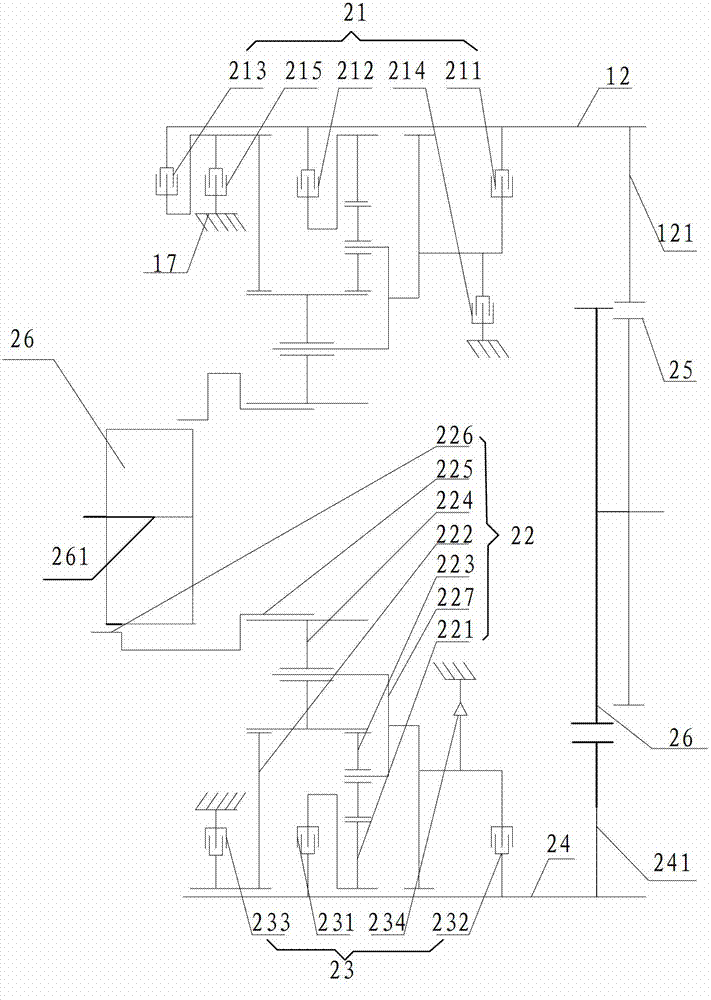

Hybrid power system

InactiveCN104816622AAchieve vertical placementIncrease gearHybrid vehiclesGas pressure propulsion mountingIn vehicleEngineering

The invention discloses a hybrid power system. The hybrid power system comprises a first driving motor, an engine, a clutch and a speed change device; the speed change device comprises a gear box body, a first input shaft, a first clutch transmission unit, a third clutch transmission unit, a second input shaft, a second clutch transmission unit, a fourth clutch transmission unit, an intermediate shaft, a fifth clutch transmission unit, a sixth clutch transmission unit, a gear reversing shaft, a seventh clutch transmission unit, an eighth clutch transmission unit, a ninth clutch transmission unit and an output shaft; the first input shaft is arranged in the gear box body; the first clutch transmission unit and the third clutch transmission unit are corresponding to the first input shaft; the second clutch transmission unit and the fourth clutch transmission unit are corresponding to the second input shaft; the fifth clutch transmission unit and the sixth clutch transmission unit are corresponding to the intermediate shaft; the seventh clutch transmission unit, the eighth clutch transmission unit and the ninth clutch transmission unit are corresponding to the gear reversing shaft. According to the hybrid power system, the longitudinal arrangement of the power system can be implemented, gears under the driving conditions are greatly increased, the engine can participate in vehicle reversing or can be used for independently driving the vehicle reversing, and accordingly the possibility of the operation of the engine in the high efficiency area is greatly improved and the application rage of a vehicle is greatly extended.

Owner:安徽易佳斯动力科技有限公司

Mini-tiller high-low-speed gearshift

InactiveCN105351456ANovel structureIncrease gearControlled membersAgricultural machinesLow inputEngineering

The invention discloses a mini-tiller high-low-speed gearshift which comprises a main shaft and an auxiliary shaft arranged in parallel, wherein the main shaft comprises a first main shaft and a second main shaft which are arranged on the same straight line; an input gear is mounted on the first main shaft in a sleeving manner; a first main gear is fixedly mounted on the second main shaft in a sleeving manner; an auxiliary shaft duplicate gear is movably mounted on the auxiliary shaft in a sleeving manner; a shifting fork mechanism enables the input gear to slide on the first main shaft so as to realize conversion of high and low input speeds. With adoption of the structure which is novel, the situation that the main shaft provides high and low input speeds for a mini-tiller gearbox is realized to double the gears, in other words, the selectable output speed options are doubled; the mini-tiller high-low-speed gearshift is suitable for various farming production situations and environments and meets the practical demands of production.

Owner:WEIMA AGRI MACHINERY CO LTD

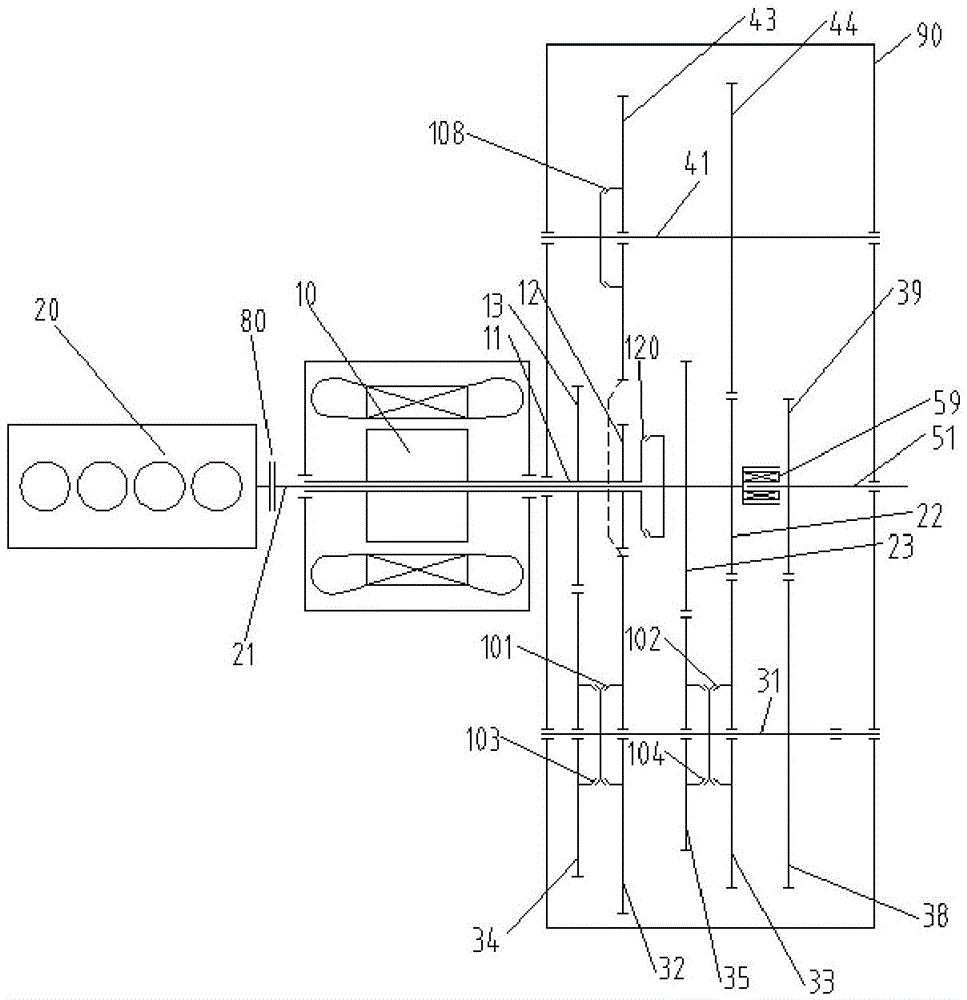

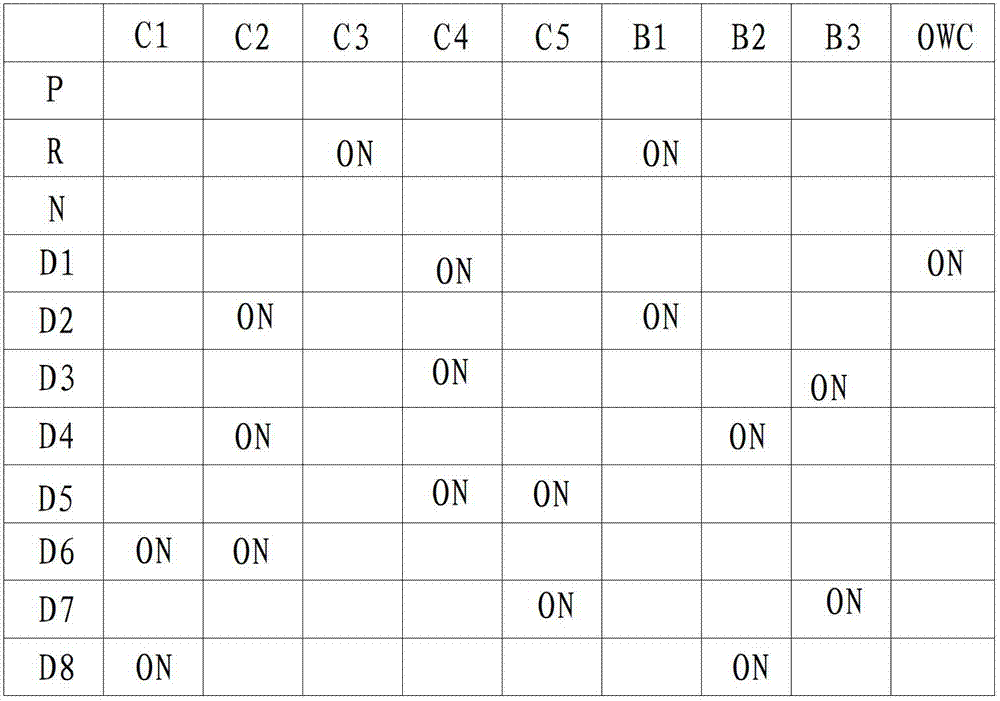

Automatic transmission and vehicle applying same

InactiveCN102927221AIncrease gearMeet the needs of different dynamicsToothed gearingsVehicle dynamicsAutomatic transmission

The embodiment of the invention discloses an automatic transmission and a vehicle applying the same, relating to the technical field of vehicle fittings and solving a problem that the vehicle has poor gear-shifting smoothness and low power performance when a traditional four-gear transmission is used. The automatic transmission disclosed by the invention comprises a second input shaft, a second planetary gear mechanism and a second transmission mechanism, wherein the second transmission mechanism is properly selected to operate when the second input shaft acts, so that a second planetary gear forms transmission ratio of four advance powers; the second input shaft is matched with the first input shaft, so that a first planetary gear and the second planetary gear jointly form transmission ratio of eight advance powers, the gears of the vehicle are increased, and a speed ratio of the gears is reduced; moreover, the first input shaft and the second input shaft operate independently, when one input shaft operates, the other input shaft can achieve pre-shifting, thereby reducing the gear-shifting time and improving the gear-shifting smoothness; simultaneously, the requirements of the vehicle under different powers are satisfied, thereby greatly bringing the vehicle dynamic performance into effect furthest, and improving the dynamic performance and economic performance of the vehicle.

Owner:GREAT WALL MOTOR CO LTD

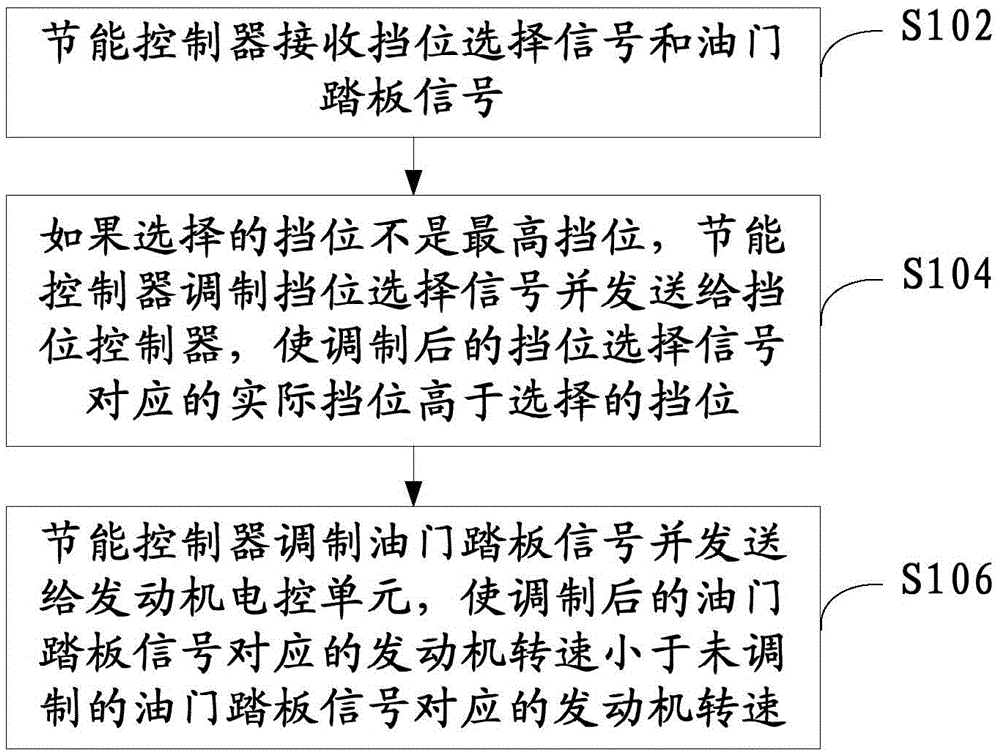

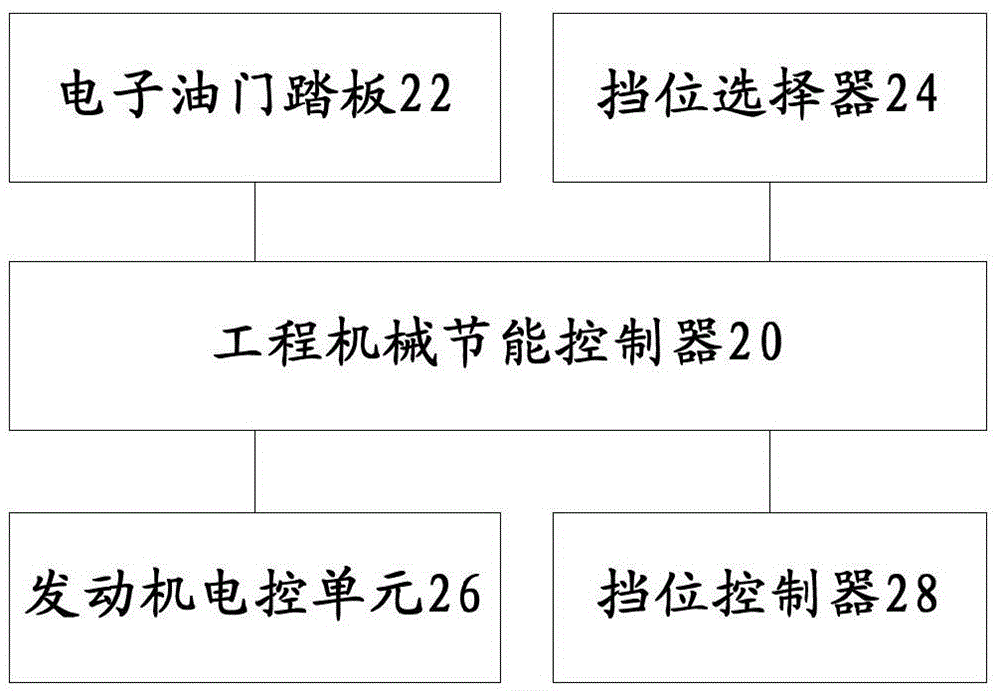

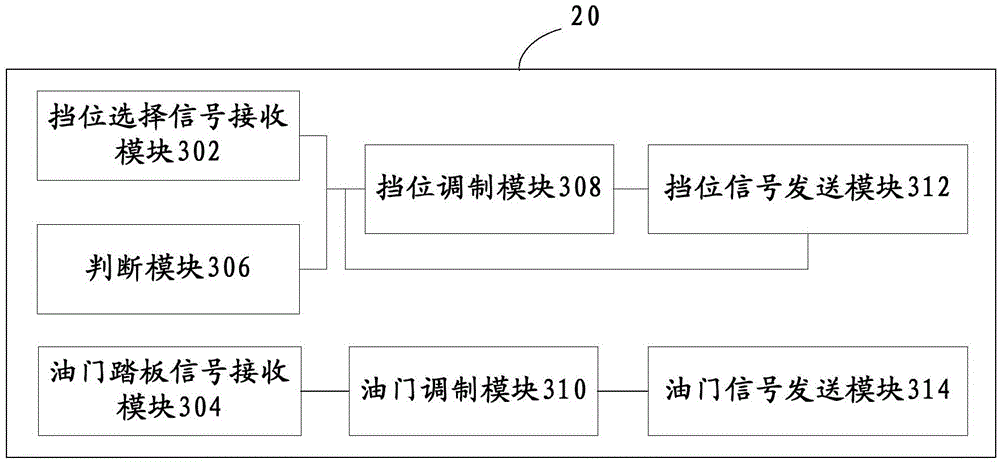

Energy-saving method, controller and system for engineering machinery and land leveler

PendingCN106499527AReduce speedReduce fuel consumptionMechanical machines/dredgersSpeed sensing governorsControl engineeringHeavy load

The invention discloses an energy-saving method, controller and system for engineering machinery and a land leveler and relates to the field of energy saving of engineering machinery. The energy-saving method for the engineering machinery includes the steps that the energy-saving controller receives a gear position selecting signal and an accelerator pedal signal; if the selected gear position is not a highest gear position, the energy-saving controller modulates the gear position selecting signal and sends the gear position selecting signal to a gear position controller, and an actual gear position corresponding to the modulated gear position selecting signal is made to be higher than the selected gear position; and the energy-saving controller modulates the accelerator pedal signal and sends the accelerator pedal signal to an engine electronic control unit, and the engine rotating speed corresponding to the modulated accelerator pedal signal is made to be smaller than the engine rotating speed corresponding to an non-modulated accelerator pedal signal. The engine rotating speed is decreased while the gear position is improved, the engineering machinery can achieve the speed expected by a driver, the oil consumption of the engineering machinery is reduced, and the energy-saving method for the engineering machinery is applicable to the common non-limit heavy load work conditions.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

Dual-clutch automatic hydraulic clutch

InactiveCN103032545AIncrease gearKeep driving funGearing controlFluid gearingsAutomatic transmissionGear wheel

The invention relates to a dual-clutch automatic hydraulic clutch. A second gear and a fifth gear are respectively mounted on a clutch shaft I; a third gear and a seventh gear are respectively mounted on a clutch shaft II; an input shaft is also mounted in a box, and a first gear is mounted on the input shaft, and is respectively engaged with the second gear and the third gear; an output shaft is also mounted in the box, a fourth gear and a sixth gear are mounted on the output shaft, the fourth gear is engaged with the fifth gear, and the sixth gear is engaged with the seventh gear. For a manual transmission, the dual-clutch automatic hydraulic clutch realizes multi-gear shifting, and solves the problem of cooperation between the clutch and an accelerator in the process of gearing and gear shifting and the problems of difficult gear-shifting operation on a snowy ground, difficult hill start and the like. For an automatic transmission, the dual-clutch automatic hydraulic clutch solves the problem that a passenger vehicle with the multi-gear automatic transmission cannot coast at the neutral position.

Owner:王云高

Apparatus and method for processing a workpiece

ActiveUS10086483B2Remove and reduce effectProvide roughnessEdge grinding machinesPolishing machinesUltimate tensile strengthMaterials science

Owner:ENGINEERED ABRASIVES

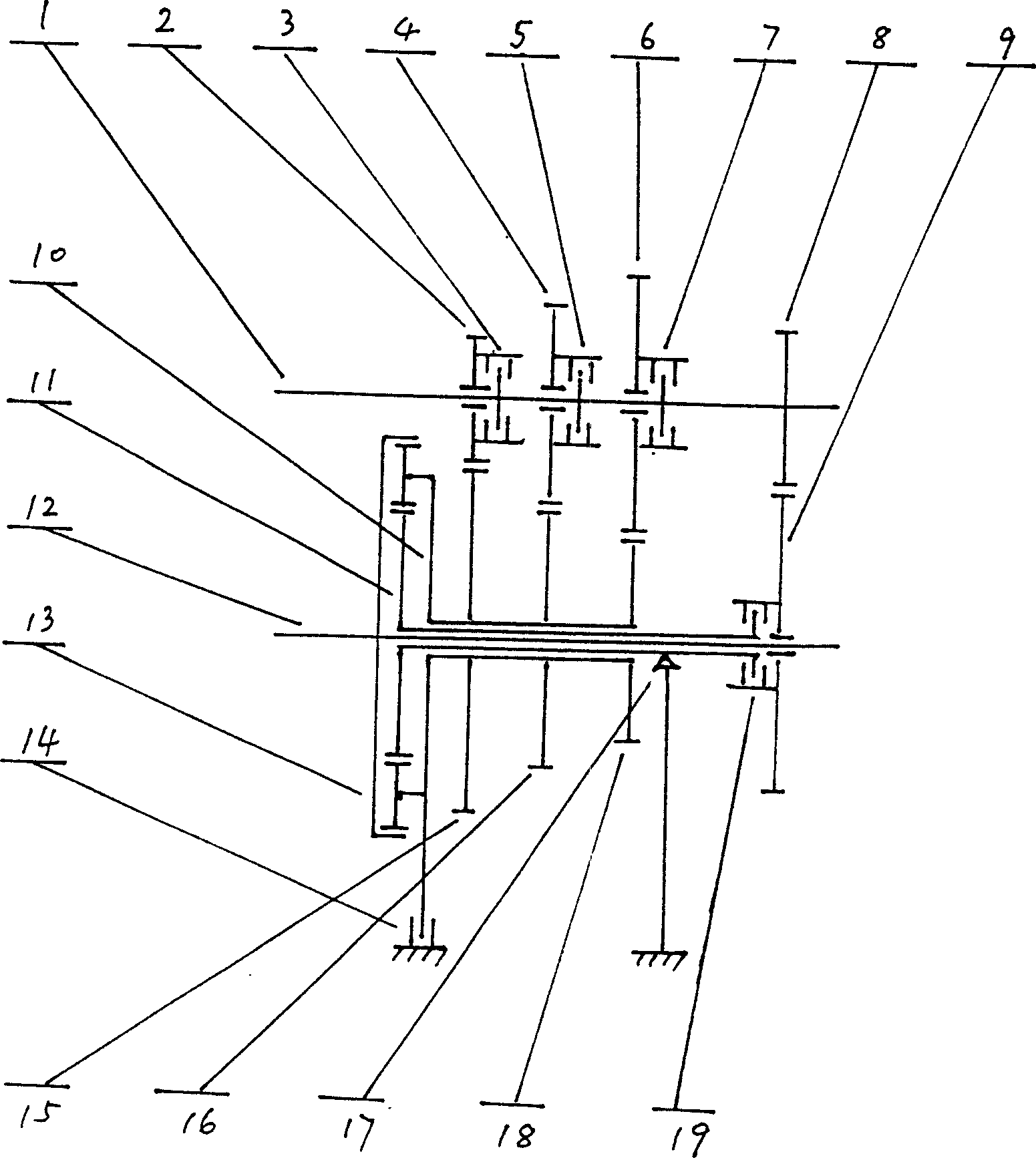

Double clutch transmission of a motor vehicle

The invention relates to a double clutch transmission of a motor vehicle, comprising two input shafts (3, 4), which are disposed coaxially to each other and can be connected to the drive shaft (2) of a driving motor via a separate clutch (K1, K2). The invention further comprises two countershafts (11, 12), which are arranged parallel to the axis next to the input shafts (3, 4) and are connected and driven via a driven wheel (8, 9) by a common output element (10). The invention further comprises a plurality of gear wheel sets, comprising a plurality of toothed wheels, amongst others one fixed wheel and one loose wheel, wherein at least two wheels are in engagement with each other. The fixed wheels thereof are distributed on the two input shafts (3, 4) and are arranged rotationally fixed onthe associated input shaft (3, 4). The loose wheels are distributed on the two countershafts (11, 12), are rotationally arranged on the associated countershaft (11, 12) and can be connected thereto in a rotationally fixed manner by an associated clutch. Each of the two input shafts (3, 4) comprises at least one fixed wheel, which is associated with two gear wheel sets and engages with loose wheels arranged on different countershafts (11, 12). A double clutch transmission of this type, having six forward gears (G1 to G6) and one reverse gear (R), is proposed as a basic transmission, which has an uncomplicated and space-saving design and can be reduced by one gear to form a five speed transmission and be expanded by one gear to form a seven speed transmission in a simple and cost-effective manner.

Owner:ZF FRIEDRICHSHAFEN AG

Rotary-screen flicker printing method on pure wax printing cloth

InactiveCN101332727AImprove printing effectIncrease added valueScreen printersOther printing apparatusScreen printingWax

The invention provides a flash printing process which uses a rotary screen printing machine and applies the flash printing process to the real wax dyeing cloth printing. In detail, the flash printing process uses the rotary screen printing machine to print the mixture of flash sheets and adhesive on the real wax dyeing cloth and carries out the baking subsequently; wherein, the rotary screen printing machine is a cylinder-typed rotary screen printing machine; the grain specification of the flash sheet is ranging from 1 / 64 to 1 / 512; the meshes of the cylinder-typed rotary screen printing machine are 30-80; the adhesive viscosity is ranging from 30-50dPaS; the mass ratio of the flash sheet and the adhesive is 15%:85%; the vehicle speed of the rotary screen printing machine is controlled at 20-45m / min; the baking temperature is 120-150 DEG C and the baking time is 2-4min. Correspondingly, according to the flash printing process, the flash printing is effectively realized by using the rotary screen printing machine on the real wax dyeing cloth.

Owner:王港生

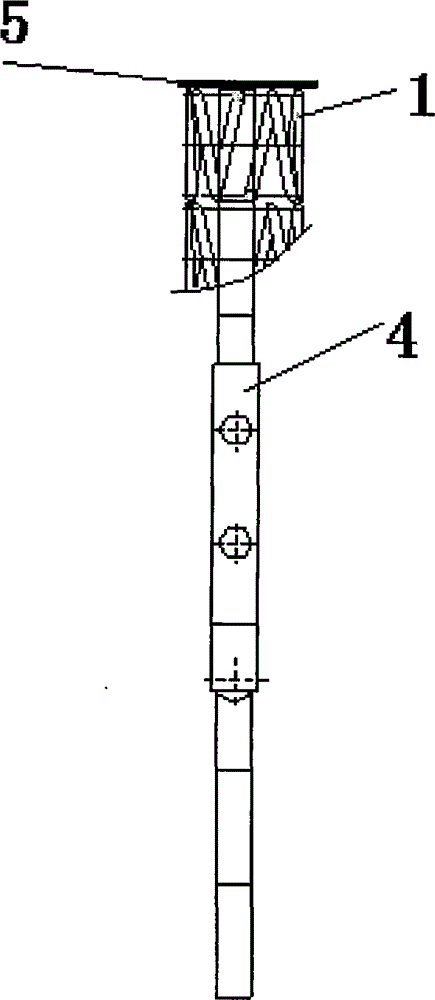

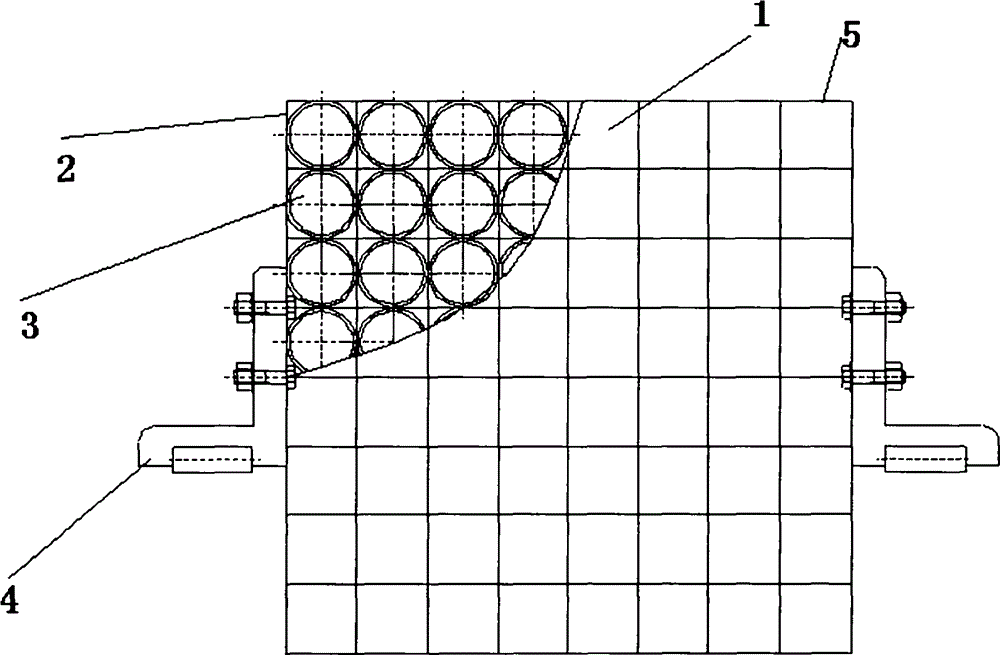

Reusable elastic pressure filtration plate

The invention discloses a reusable elastic pressure filtration plate belonging to the technical field of deep dehydration of sludge. The elastic pressure filtration plate adopts the structure that elastic body mounting grooves are formed in a filtration plate support, elastic bodies are arranged in the elastic body mounting grooves, and filtration plate travelling mechanisms are arranged at two ends of the filtration plate support. The elastic pressure filtration plate is simple and convenient to process, mount and maintain, saves materials, and can effectively prolong the service life of equipment and reduce the failure rate of the equipment; the elastic bodies have good rebound resilience and high fatigue resistance and are resistant to compression.

Owner:KANGTAI JIANGSU ENVIRONMENTAL PROTECTION LTD BY SHARE LTD

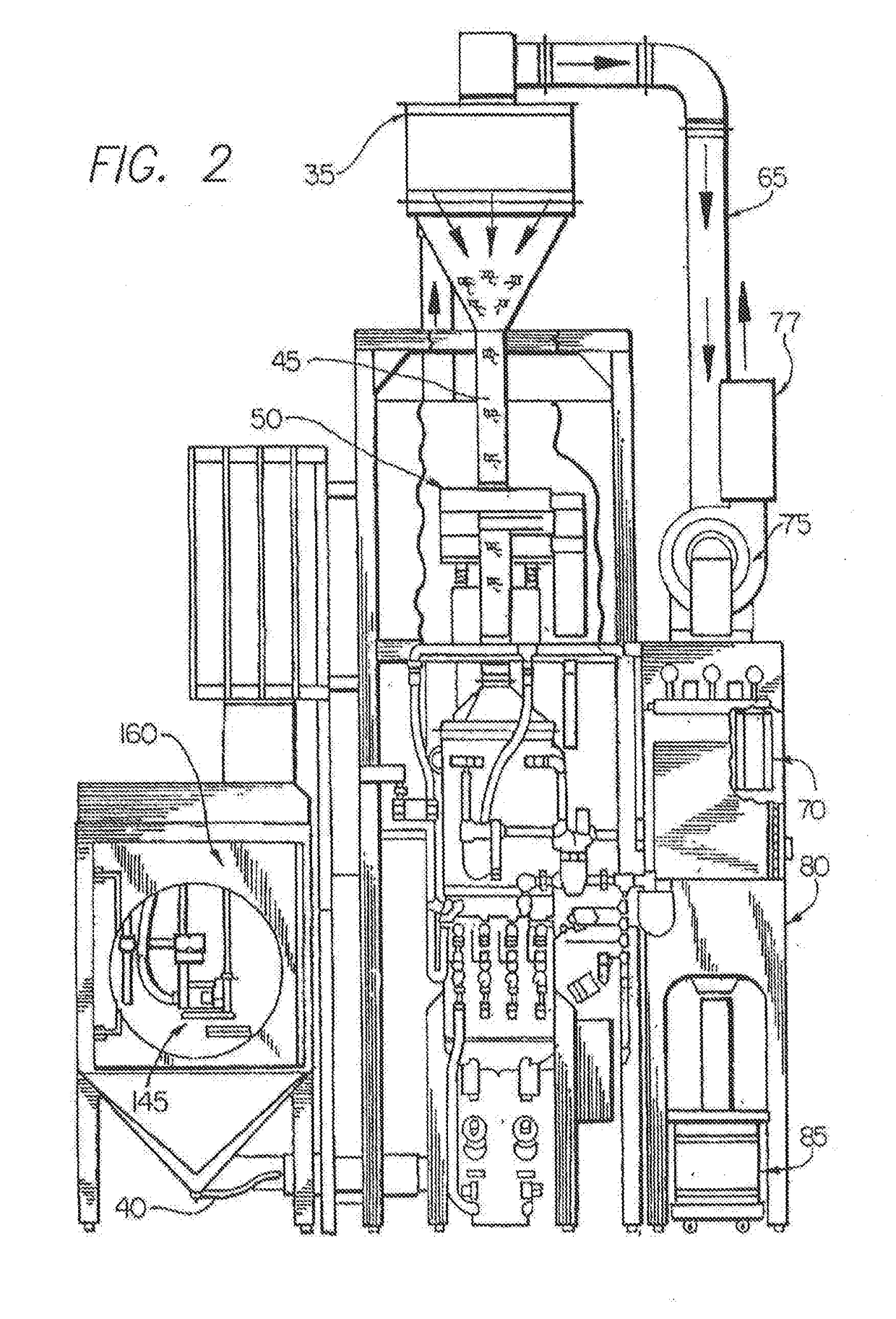

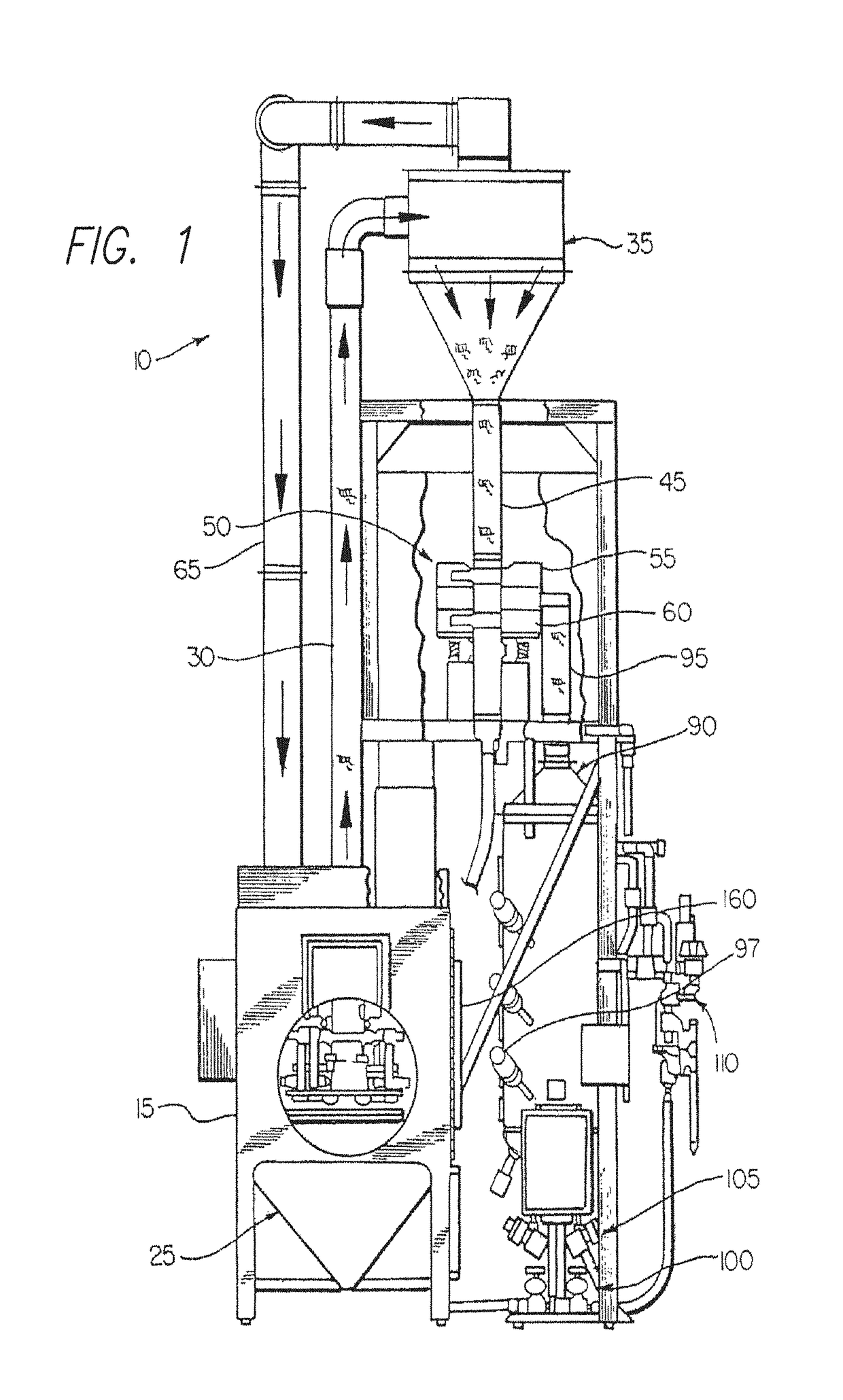

Part processing and cleaning apparatus and method of same

ActiveUS20180222015A1Provide roughnessIncrease gearAbrasive machine appurtenancesCleaning using liquidsSurface cleaningEngineering

A part processing apparatus and method is disclosed that includes a media-blasting apparatus and a cleaning apparatus. The media-blasting apparatus is configured to blast a stream of media against a surface of a part, and the cleaning apparatus is configured to clean debris or particles from the surface of the part. The cleaning apparatus includes a first spray-and-wash unit, a first ultrasonic wash unit, a second ultrasonic wash unit, and a second spray-and-wash unit. The first ultrasonic wash unit is configured to ultrasonically vibrate a liquid in the first ultrasonic wash unit at a first frequency, and the second ultrasonic wash unit is configured to ultrasonically vibrate a liquid in the second ultrasonic wash unit at a second frequency. The first and second frequencies may be different from each other, such that vibration at the second frequency causes additional debris or particles to be removed from the surface of the part.

Owner:ENGINEERED ABRASIVES

Method for manufacturing high quality recombinant bamboo

InactiveCN104875249AHeating evenlyHigh speedLaminationLamination apparatusEngineeringEnergy consumption

The invention belongs to the field of fire doors, and particularly relates to a method for manufacturing high quality recombinant bamboo. The method comprises steps of firstly, selecting bamboo wood, secondly, uniformly paving the bamboo wood and applying glue on the bamboo wood to form a bamboo plate to be pre-pressed, thirdly, pushing the pre-pressed bamboo plate into a high frequency hot press, fourthly, pre-pressing the bamboo plate to be pre-pressed, fifthly, starting the high frequency hot press to manufacture a bamboo plate through high frequency hot pressing for 6 to 45 minutes, and sixthly, unloading pressure which is applied on the bamboo plate by an upper pressing plate and a side pressing plate after high frequency hot pressing, and sending the bamboo plate from the high frequency hot press. The high frequency hot press comprises a lower support board used for supporting a bamboo plate to be pre-pressed, an upper pressing plate used for pressing on the bamboo plate to be pre-pressed and a side pressing plate applying pressure on a side of the bamboo plate to be pre-pressed. The high frequency voltage is characterized in that a high frequency electric field can penetrate a base plate, so that the inner and the outer of the base plate can be synchronously and uniformly heated, the method is quick in speed and low in energy consumption, so the method is particularly suitable for hot-press gluing a bamboo plate with a large section.

Owner:ZHEJIANG YONGYU FURNITURE CO LTD

Multi-speed gearbox transmission mechanism

InactiveCN103438164AAchieve shifting performanceReduce axial sizeToothed gearingsGear wheelEngineering

The invention discloses a multi-speed gearbox transmission mechanism which comprises a first clutch, a first input shaft corresponding to the first clutch, a second clutch, a second input shaft corresponding to the second clutch, a plurality of synchronizers, a first double-row planetary gear train and a second double-row planetary gear train, wherein one of the first double-row planetary gear train and the second double-row planetary gear train is formed by a front planet row and a rear planet row; in the front planet row, a front sun gear is connected with a rear planet carrier into a whole, and is fixed with a shell by the first constant mesh synchronizer or the clutches; the rear planet row adopts a double-planet wheel structure; a front gear ring is connected with a rear gear ring into a whole; the power is transmitted into a rear sun gear or the rear gear ring by the second synchronizer, the third synchronizer or the clutches through a first rear outer shaft, and is output by a front planet carrier. The multi-speed gearbox transmission mechanism combines a CR-CR type gear speed change mechanism and a novel double-planet row gear speed change mechanism, and the two clutches and the plurality of synchronizers are matched for use, so that the gear shift performance of a double-clutch gearbox can be realized, the size of the gearbox is reduced, and the gear shift smoothness is also improved.

Owner:SHUNDE POLYTECHNIC

Gearbox and vehicle

PendingCN111043253AImprove rigidityShorten the axial lengthToothed gearingsGearing detailsGear wheelGear tooth

The invention provides a gearbox and a vehicle provided with the same. The gearbox comprises a middle shaft assembly. The middle shaft assembly comprises a middle shaft and an intermediate speed transmission gear assembly arranged on the middle shaft in a sleeving manner. The middle shaft comprises a one-gear tooth and a reversing gear tooth. The intermediate speed transmission gear assembly is located between the one-gear tooth and the reversing gear tooth. A tool withdrawal groove is formed in one side of the reversing gear tooth. A part of the intermediate speed transmission gear assembly is arranged on the tool withdrawal groove. In the scheme, due to the fact that the intermediate speed transmission gear assembly does not need to avoid the tool withdrawal groove, the tool withdrawal groove is buried in the intermediate speed transmission gear assembly, thus the axial length of a shaft body is reduced, rigidity of the middle shaft is improved, the axial structure is more compact, under the circumstance of increasing gears of the gearbox, the size of the gearbox is basically the same as the axial installing size of a gearbox in the related technology, and thus the gearbox with the gears increased can fit multiple vehicles beneficially.

Owner:ZHEJIANG WANGLIYANG TRANMISSION CO LTD

Method for rapidly manufacturing recombinant bamboo

InactiveCN104875269ACool evenlyUniform and further rapid coolingWood working apparatusFlat articlesEngineeringEnergy consumption

The invention belongs to the field of fire doors, and particularly relates to a method for rapidly manufacturing recombinant bamboo, wherein the method is uniform in heating process, quick in speed and low in energy consumption. The method comprises steps of firstly, selecting bamboo wood, secondly, uniformly paving the bamboo wood and applying glue on the bamboo wood to form a bamboo plate to be pre-pressed, thirdly, pushing the pre-pressed bamboo plate into a high frequency hot press, fourthly, pre-pressing the bamboo plate to be pre-pressed, and fifthly, starting the high frequency hot press to manufacture a bamboo plate through high frequency hot pressing for 6 to 45 minutes. The high frequency hot press comprises a lower support board used for supporting a bamboo plate to be pre-pressed, an upper pressing plate used for pressing on the bamboo plate to be pre-pressed and a side pressing plate applying pressure on a side of the bamboo plate to be pre-pressed. The high frequency voltage is characterized in that the high frequency electric field can penetrate a base plate, so that the inner and the outer of the base plate can be synchronously and uniformly heated, the method is quick in speed and low in energy consumption, so the method is particularly suitable for hot-press gluing a bamboo plate with a large section.

Owner:ZHEJIANG YONGYU FURNITURE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com