Modified dead axle type hydraulic automatic gear shifting with six shift gears

An automatic transmission, fixed-axis technology, applied in the direction of transmission device, fluid transmission device, belt/chain/gear, etc., can solve the problems of few shifting actuators and heavy weight, and achieve many shifting gears, simplified and compact structure, The effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

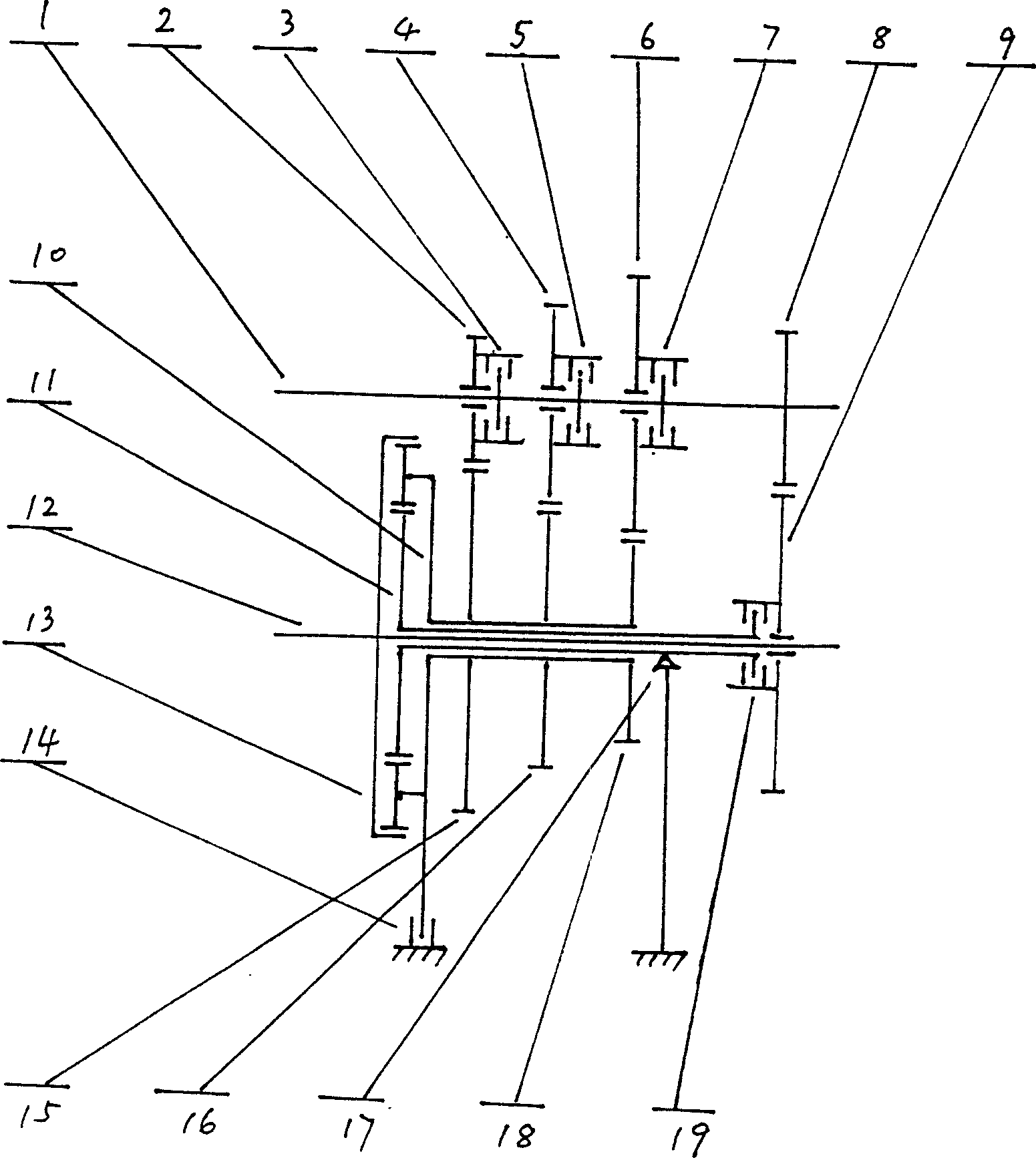

[0014] The modified fixed-shaft six-speed hydraulic automatic transmission has a main shaft 1 and a counter shaft 12, and the two shafts are parallel.

[0015] The first and second gears 2, the third and fourth gears 4, the fifth and sixth gears 6 and the main shaft gear 8 are fixedly installed on the main shaft 1, and the clutches 3, 3 and 4 are respectively installed on the sides of the gears 2, 4 and 6 Clutch 5 and Clutch 7.

[0016] A single planetary row combination gear is installed on the secondary shaft 12, and the planetary carrier 10 is successively fitted with gears 15, 16 and 18 which mesh with the gears 2, 4 and 6 on the main shaft 1, and one side of the planetary carrier 10 is fixedly installed There is a planetary carrier brake 14, and a countershaft gear 9 meshing with the main shaft gear 8 is also set on the countershaft 12, and a sun gear and a countershaft gear clutch 19 are arranged on the shaft of the sun gear 11 and on the side of the countershaft gear 9....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com