Multi-point flexibly-driven stepless speed change winding device

A technology of continuously variable speed and hoisting device, which is applied in the field of continuously variable speed hoisting device and multi-point flexible drive, which can solve problems such as inability to adjust in place in time, overall weight increase, and stepless speed regulation, etc., to achieve improved Reel variable speed performance, simple overall structure, and the effect of prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with drawings and embodiments.

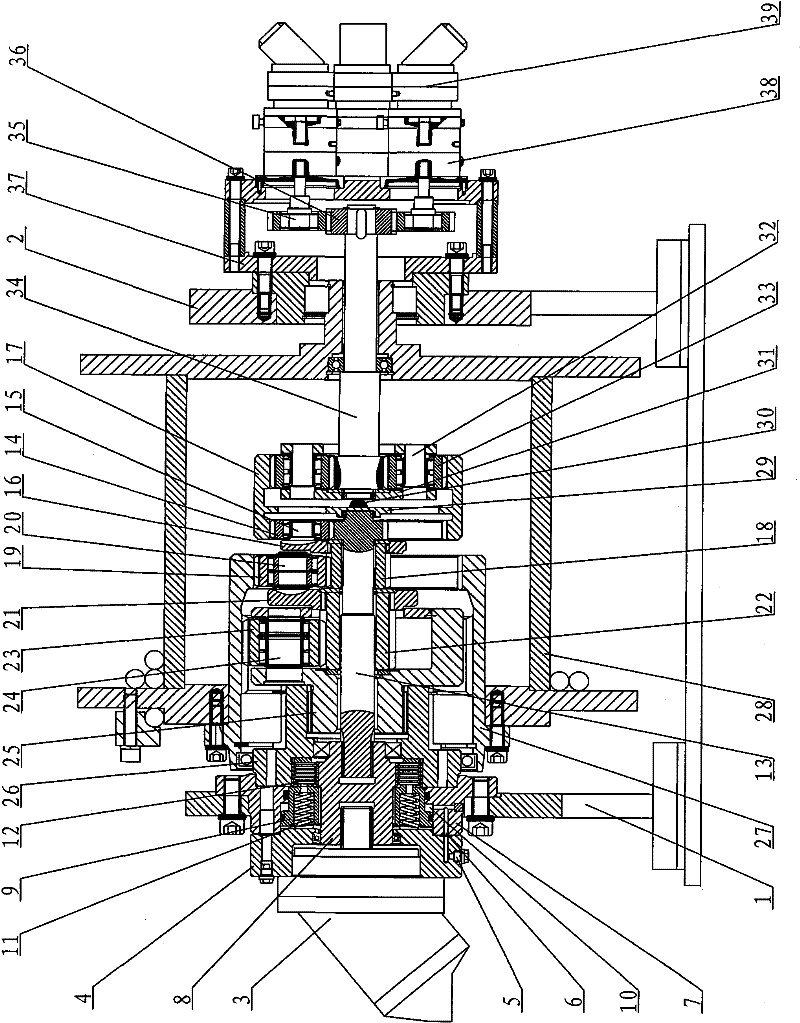

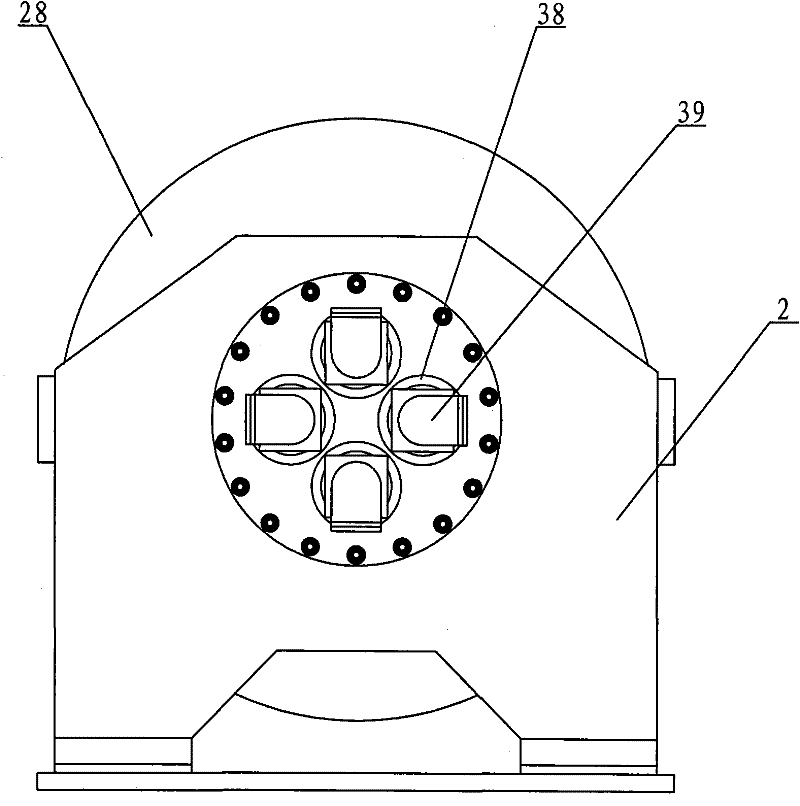

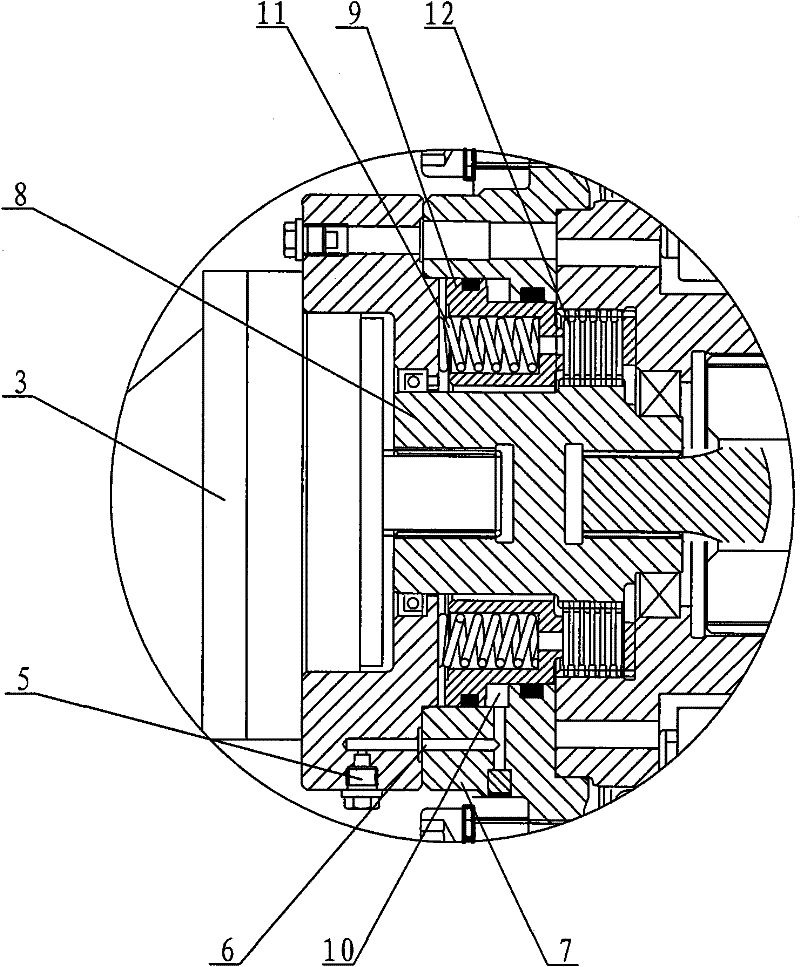

[0025] figure 1 , 2As shown, the multi-point flexible drive continuously variable speed winch device mainly includes left and right brackets 1, 2, reel 28, main drive motor 3, flange 4, main drive controller, main input center wheel 13, auxiliary input center Wheel 34, drive ring gear 27, floating ring gear 17, many auxiliary drive controllers 38 and many auxiliary drive motors 39. The main drive controller is installed on the left bracket 1 through the cylinder body 7, the main drive motor 3 is connected to one end of the main drive controller spline sleeve 8 through the flange 4, and the other end of the spline sleeve 8 is splined to one end of the main input center wheel 13. The other end of the input sun gear 13 is connected to the main input planetary gear 14 by transmission. The main input planetary gear 14 meshes with one end of the floating ring gear 17. The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com