Bicycle sprocket and bicycle sprocket assembly

A bicycle and combination technology, applied in the direction of wheels, belts/chains/gears, vehicle parts, etc., can solve the problem of not being able to move, not the root of the teeth of another rear sprocket, etc., and achieve the effect of improving the speed change performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 approach

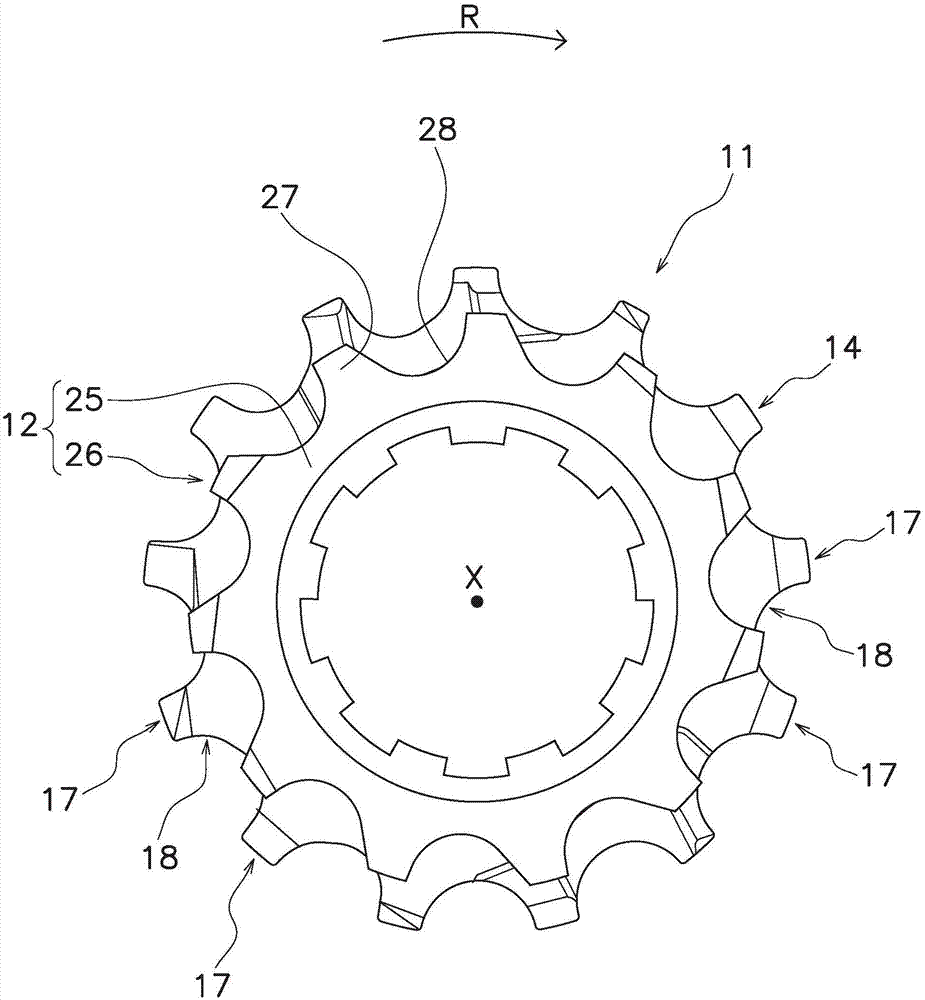

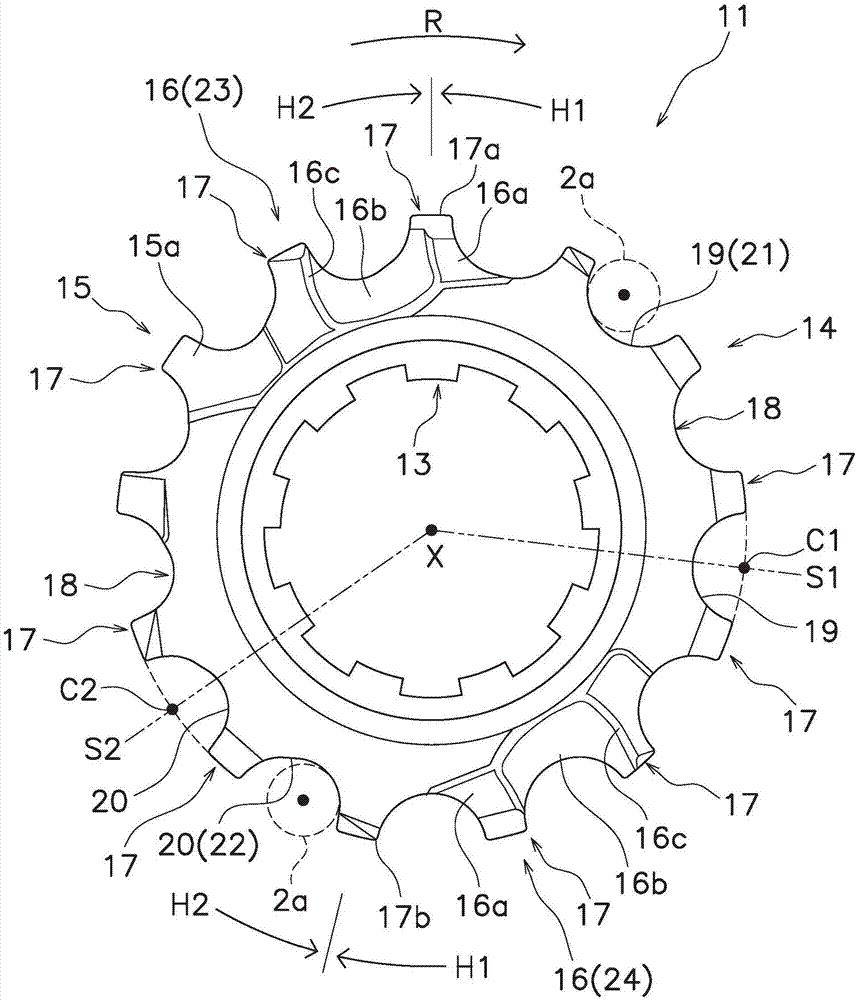

[0116] Instead of the large-diameter rear sprocket 11 and the small-diameter rear sprocket 12 of the first embodiment, for Figure 7 The present invention can also be applied to the illustrated large-diameter rear sprocket 111 and small-diameter rear sprocket 112 (an example of a bicycle sprocket).

[0117] In the second embodiment, the dedendum portion 118 of the large-diameter rear sprocket 111 is composed of dedendum portions having the same shape over the entire circumference. In addition, the dedendum portion 128 of the small-diameter rear sprocket 112 is composed of a dedendum portion having a different shape.

[0118] In addition, in the second embodiment, descriptions of substantially the same configurations as those in the first embodiment are omitted. In addition, about the substantially same structure as 1st Embodiment, the same code|symbol as 1st Embodiment is attached|subjected.

[0119] (large diameter rear sprocket)

[0120] The large-diameter rear sprocket 111...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com