Hybrid power system

A technology of hybrid power system and clutch transmission, applied in the field of vehicle transmission system, can solve the problems that the engine cannot participate or be driven independently, reduce the overall efficiency of the hybrid power system, limit the use range of the whole vehicle, etc., and achieve shortened radial layout space, The effect of improving the range of use and enriching the axial space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

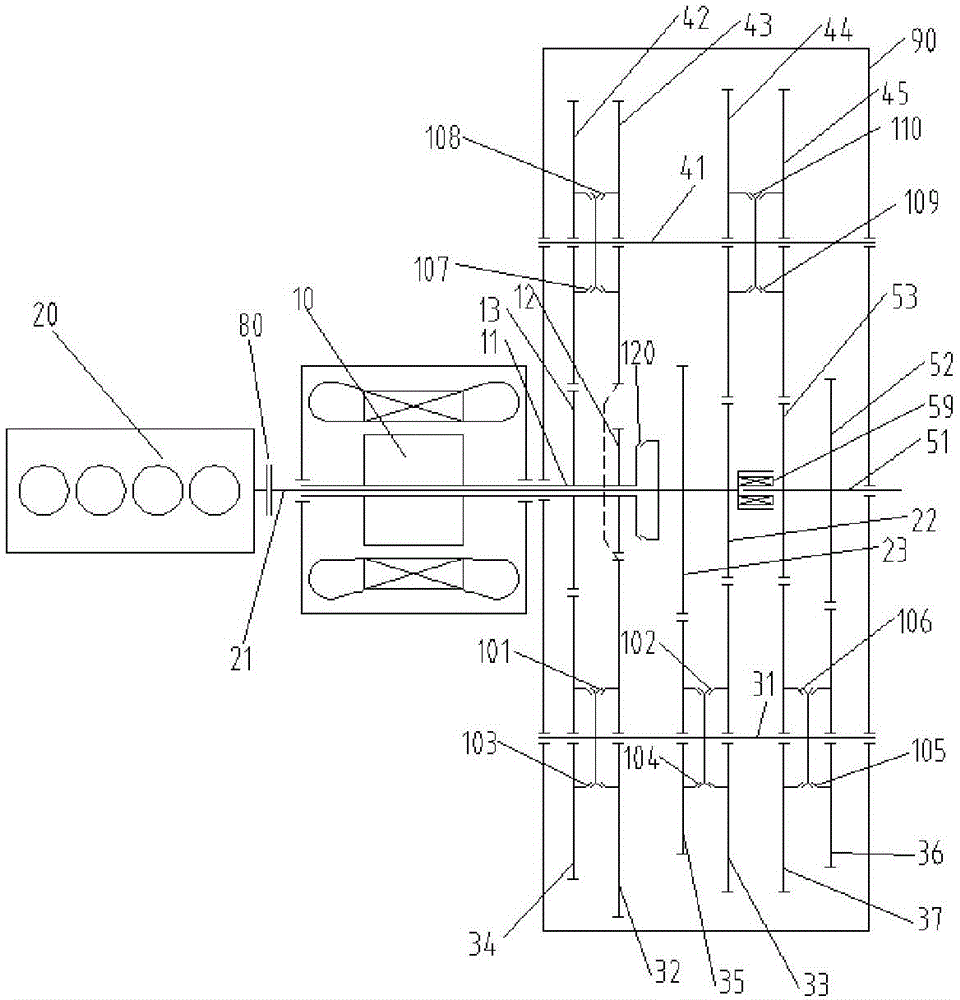

[0031] Such as figure 1 As shown, a hybrid power system includes a first drive motor 10, an engine 20, a clutch 80, and a transmission device.

[0032] The speed change device includes a gearbox body 90 and a first input shaft 11 located in the gearbox body, a first clutch transmission unit corresponding to the first input shaft and a third clutch transmission unit, a second input shaft 21, and a second input shaft 21 corresponding to the first input shaft. A second clutch transmission unit and a fourth clutch transmission unit of the shaft, an intermediate shaft 31, a fifth clutch transmission unit corresponding to the intermediate shaft, a sixth clutch transmission unit, a reverse gear shaft 41, a first clutch transmission unit corresponding to the reverse gear shaft Seven clutch transmission units, an eighth clutch transmission unit, a ninth clutch transmission unit, a tenth clutch transmission unit and an output shaft 51 .

[0033] The first clutch transmission unit inclu...

Embodiment 2

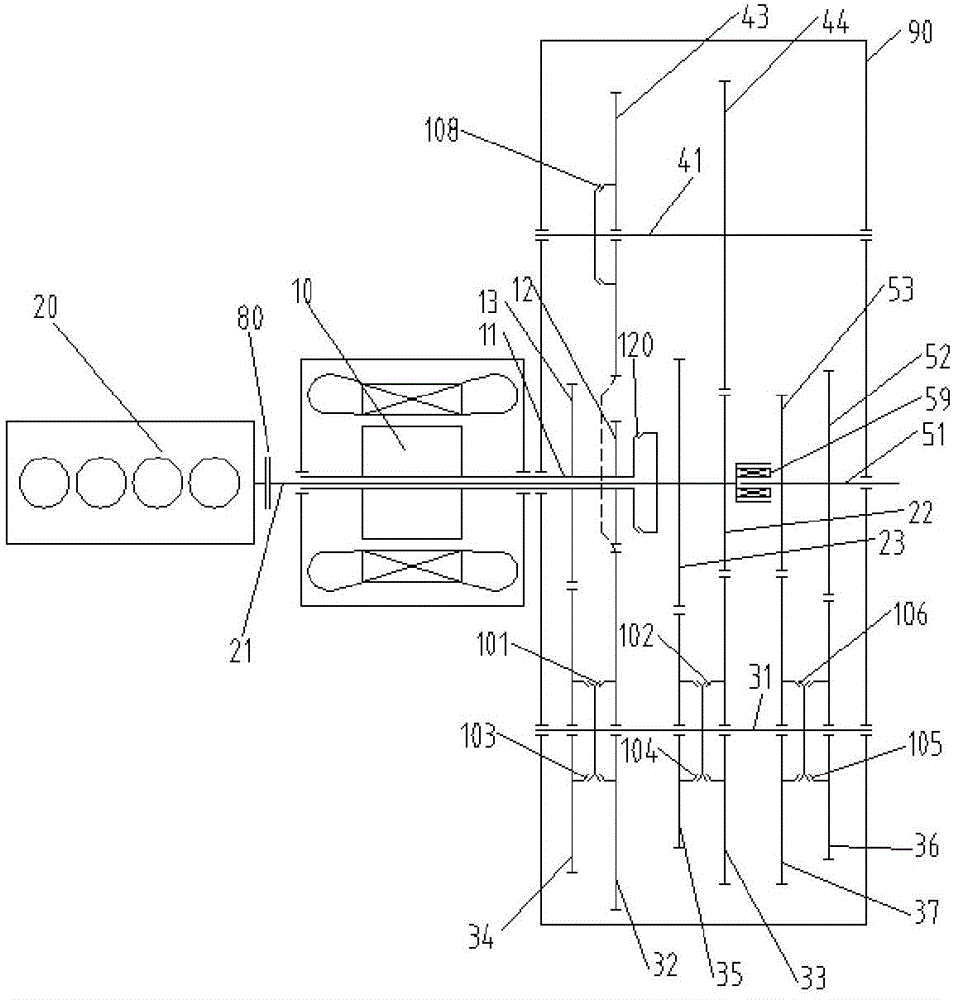

[0184] Such as figure 2 As shown, this embodiment 2 includes some technical features in embodiment 1, the difference is that the seventh clutch transmission unit and the ninth clutch transmission unit are canceled for the corresponding reverse gear shaft, and the tenth clutch transmission unit connects with the reverse gear shaft through one The driven gear that is fixedly connected and meshed with the fifth driven gear 52 or the sixth driven gear 53 is replaced (the tenth driven gear 44) to realize the power connection between the second input shaft and the reverse shaft. The scheme eliminates the possibility of establishing a power connection between the reverse gear shaft 41 and the output shaft 51, and switches the power of the intermediate shaft from the fifth clutch transmission unit to the output shaft 51 to the sixth clutch transmission unit to the output shaft. 51 There will be power interruption during the process of outputting power. Compared with the technical sol...

Embodiment 3

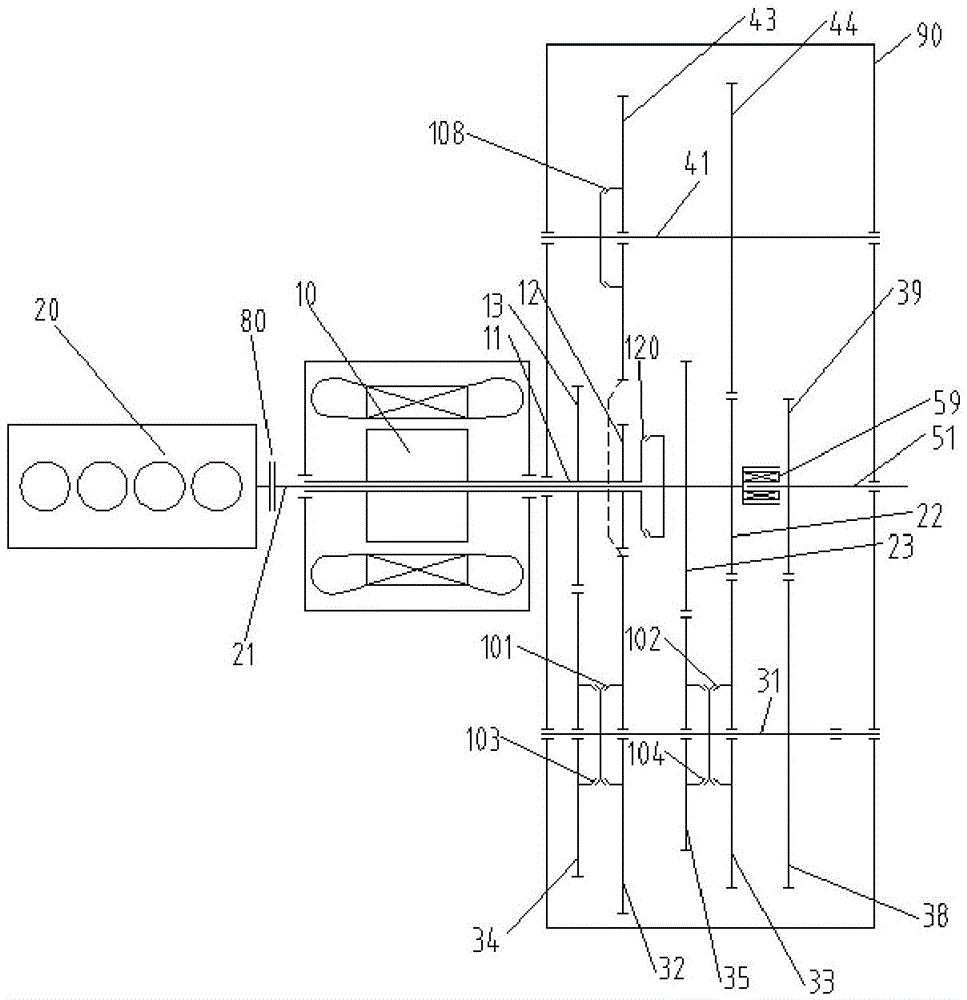

[0186] Such as image 3As shown, the third embodiment includes some technical features of the first embodiment, the difference is that the fifth and sixth clutch transmission units are omitted, and the intermediate shaft 31 is driven to the output shaft 51 through gear meshing. During specific implementation, an intermediate gear 38 is coaxially fixed on the intermediate shaft 31, an output gear 39 is coaxially fixed on the output shaft 51, and the intermediate gear meshes with the output gear. Compared with the technical solution of the embodiment 2, the advantage of the embodiment 3 is that two clutch transmission units can be reduced, which reduces the cost of the hybrid power system, and the disadvantage is that the gears are reduced. Compared with the prior art, this embodiment 2 increases the reverse gear of the engine, so that the engine can participate in or independently drive the whole vehicle to reverse, which greatly improves the range of use of the whole vehicle. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com