Method for large-size workpiece processing vertical placement

A vertical placement, large-volume technology, used in metal processing equipment, metal processing mechanical parts, positioning devices, etc., can solve the problem that large-volume workpieces cannot be placed vertically

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

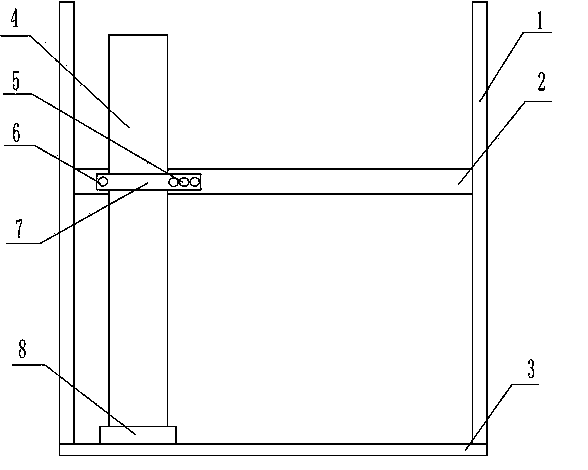

[0014] Example: such as figure 1 As shown, a method for vertical placement of large-volume workpiece processing includes the following steps. First, the installation of the fixing device, the fixing device includes a base 3, a column 1, and a fixing rod 2, and the column 1 is vertically arranged at the center of both ends of the base 3 , the fixed rod 2 is horizontally arranged between the two columns 1, and the fixed rod 2 is provided with a fixed piece 7, which is used to fix the workpiece 4. One end of the fixed piece 7 is provided with a threaded hole 6, and the fixed rod 2 is provided with a threaded hole 6 Cooperating threaded hole I, fix one end of the fixed plate 7 on the fixed rod 2 by screws, the other end of the fixed plate 7 is provided with at least three threaded holes II5, and the fixed rod 2 is provided with threaded holes matching the threaded hole II5 Ⅲ. Secondly, select the fixture 8 that matches the end of the workpiece 4, put the workpiece 4 into the fixtu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com