Reusable elastic pressure filtration plate

A pressure filter plate, elastic technology, applied in the field of deep sludge dewatering, can solve the problems of complex manufacturing process, short service life and high cost of the filter plate, and achieve the effect of material saving, simple and convenient maintenance, and high fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

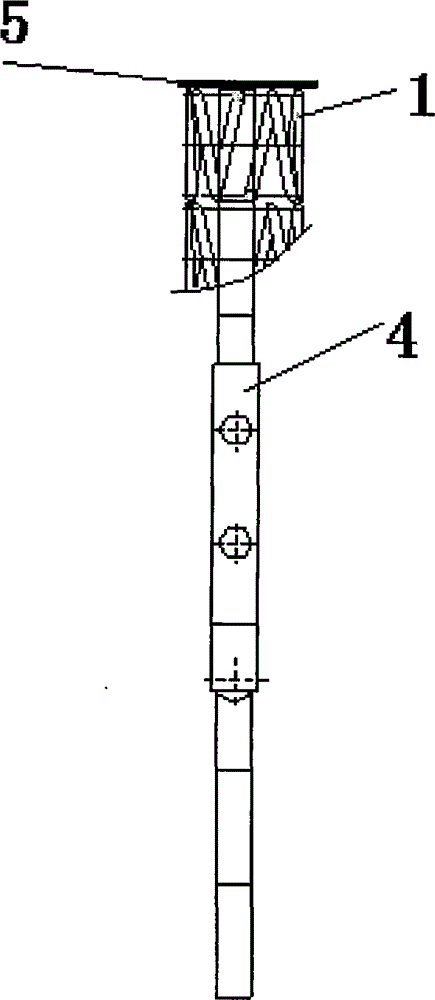

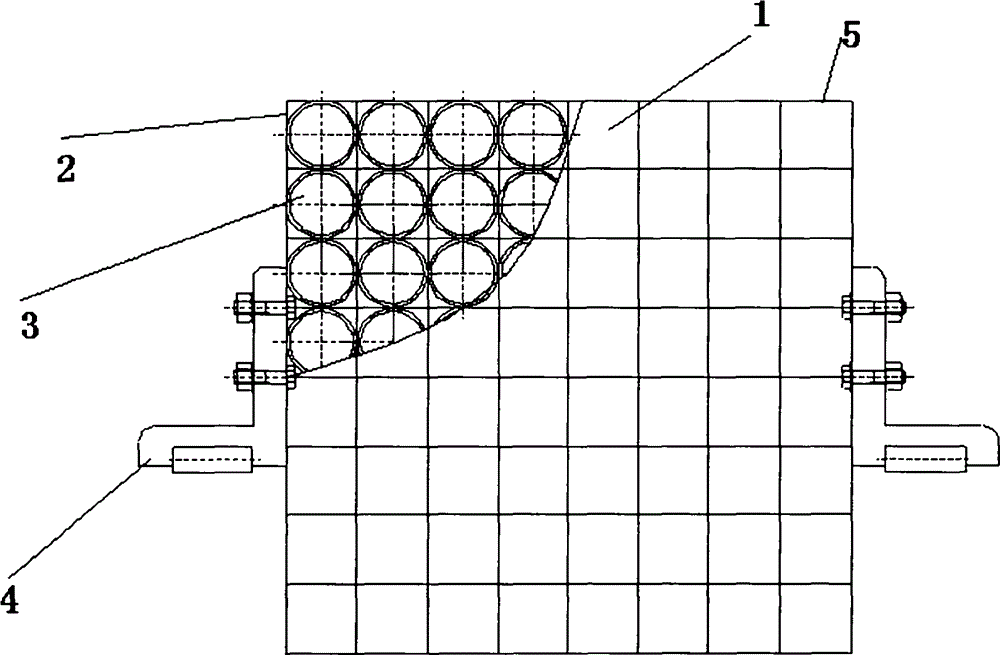

[0013] A reusable elastic filter press plate, such as figure 1 and figure 2 As shown, the filter plate support 1 is provided with an elastic body installation groove 2, and the elastic body installation groove 2 is provided with an elastic body 3, and the two ends of the filter plate support 1 are provided with a filter plate traveling mechanism 4.

[0014] Filter cloths 5 are also provided at both ends of the elastic filter press plate.

[0015] The elastic body installation groove 2 is formed by criss-cross strip plates.

[0016] The elastic body is a spring, and the surface of the spring is coated with a protective layer.

[0017] The elastic body in this embodiment is fixed in the elastic body installation groove, and the elastic body installation groove is formed of a honeycomb shape by criss-cross strip plates to form a filter plate support to improve the compression resistance of the filter plate. The filter cloth is covered on both ends of the filter plate, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com