Patents

Literature

31results about How to "Torque balance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

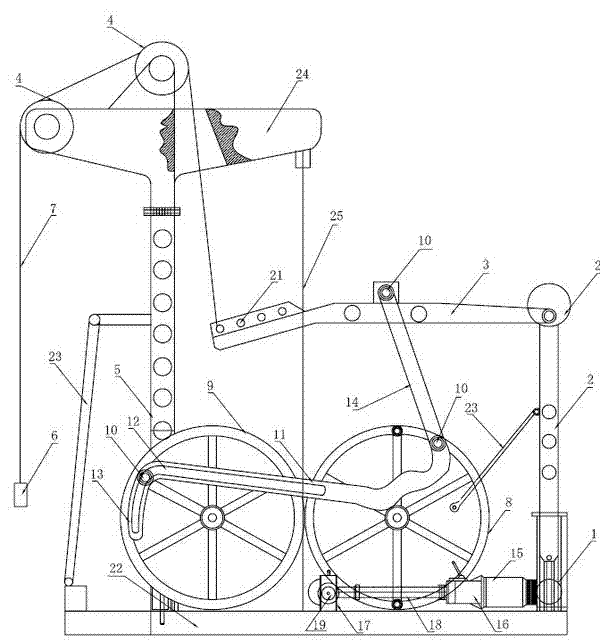

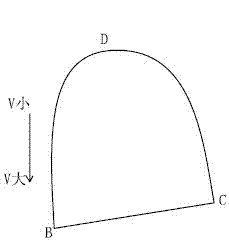

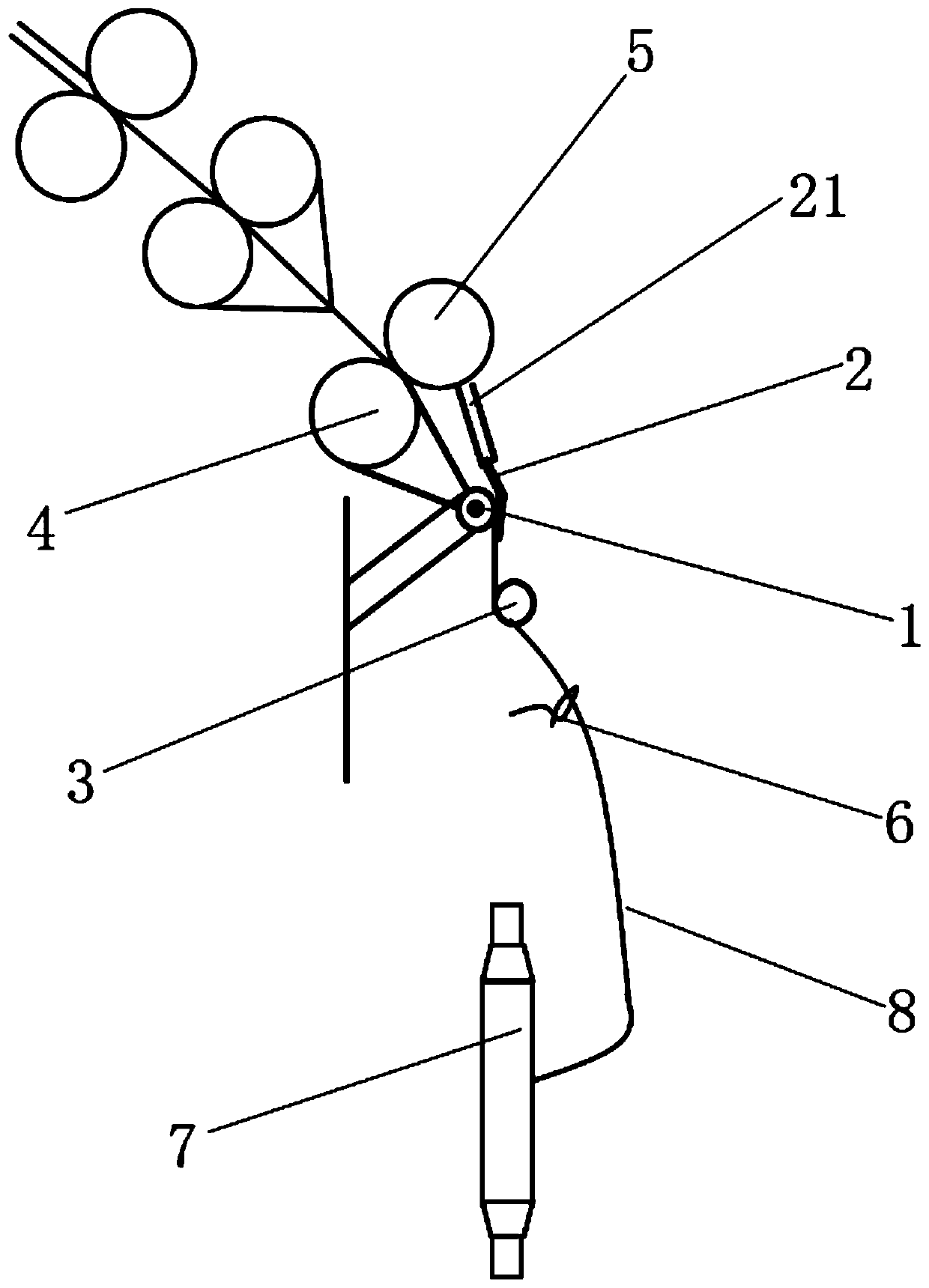

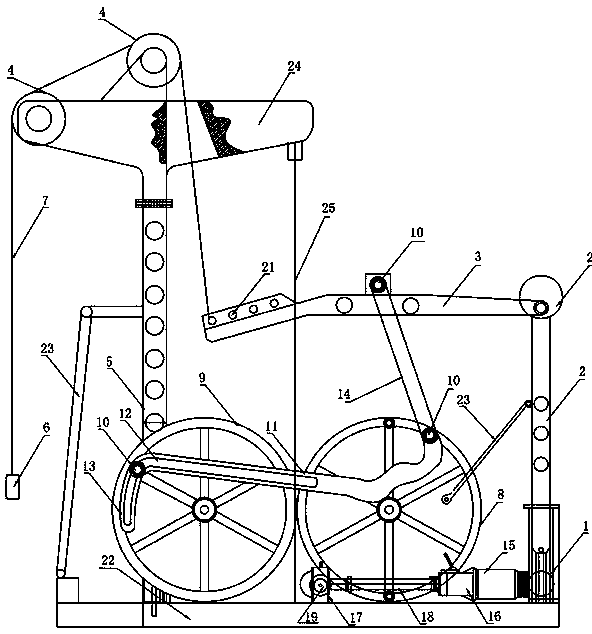

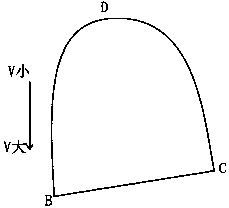

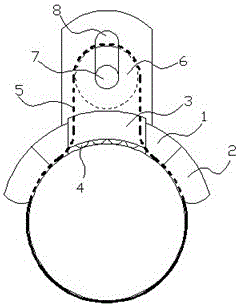

Automatic speed-changing wide-swing-angle oil pumping machine

InactiveCN102808602ASolve the oil spill problemImprove oil pumping efficiencyGearingFluid removalCrankshaftPulley

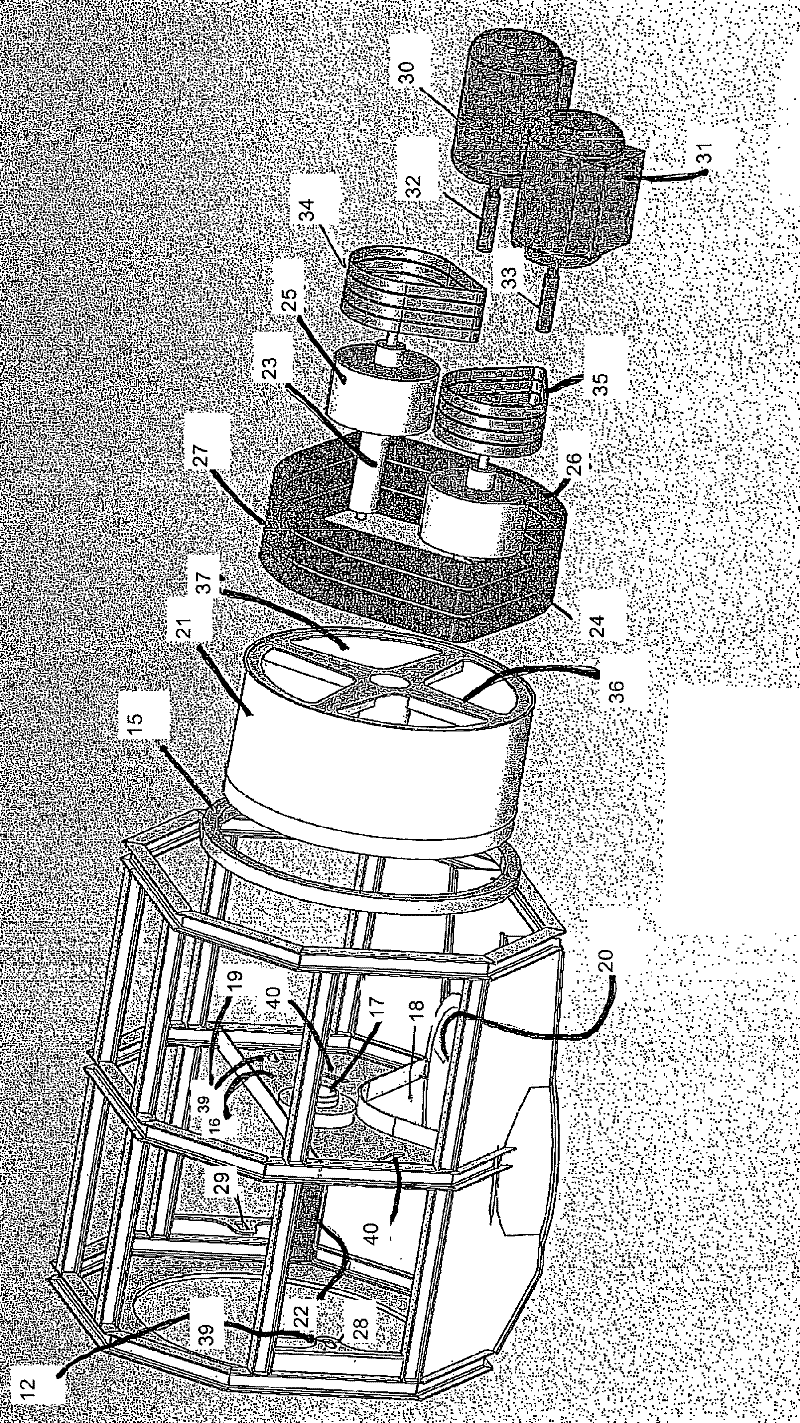

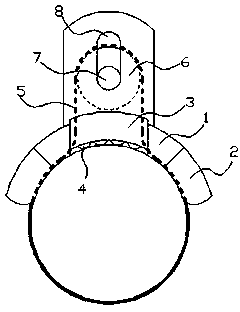

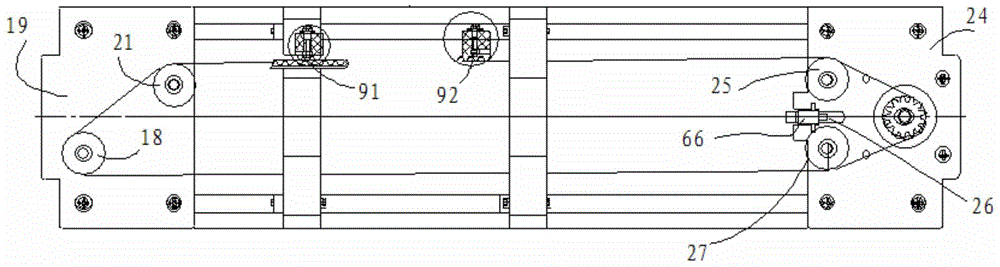

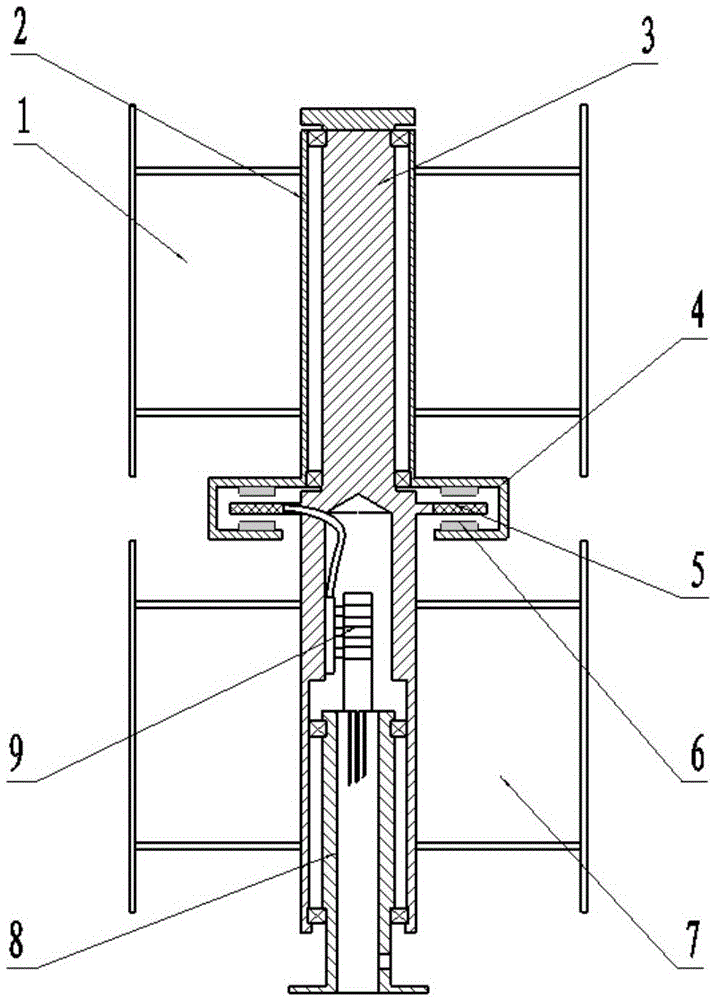

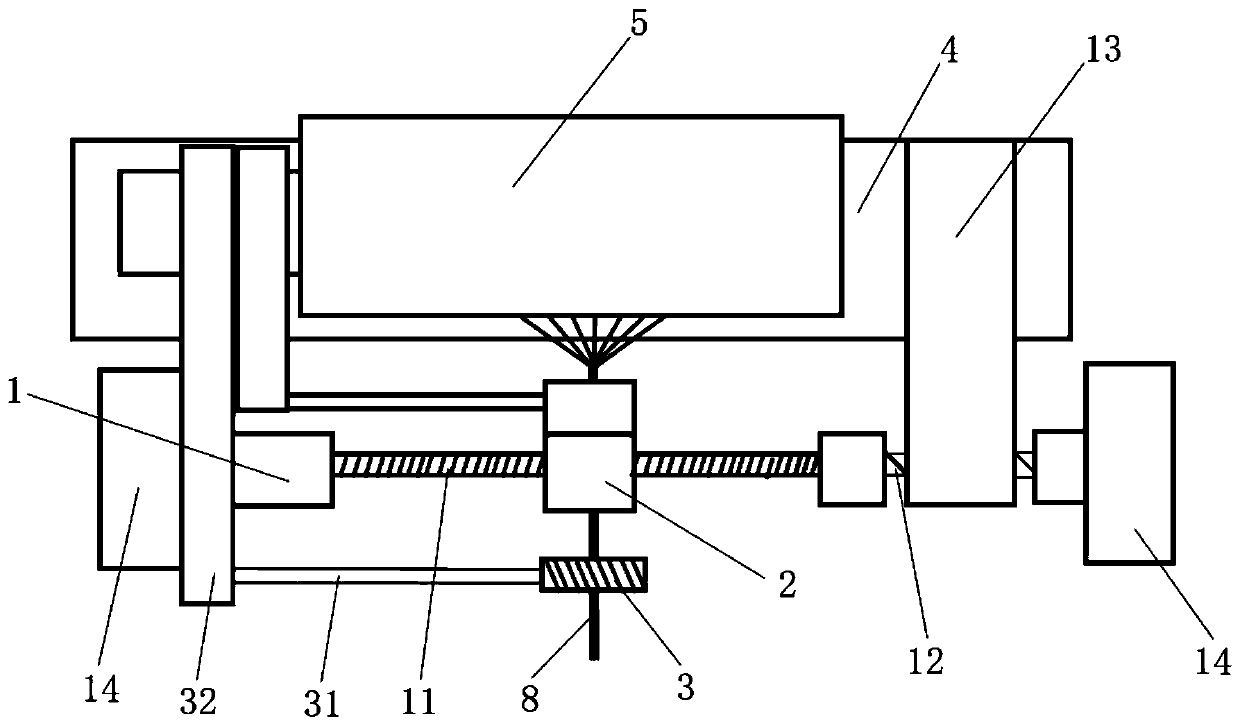

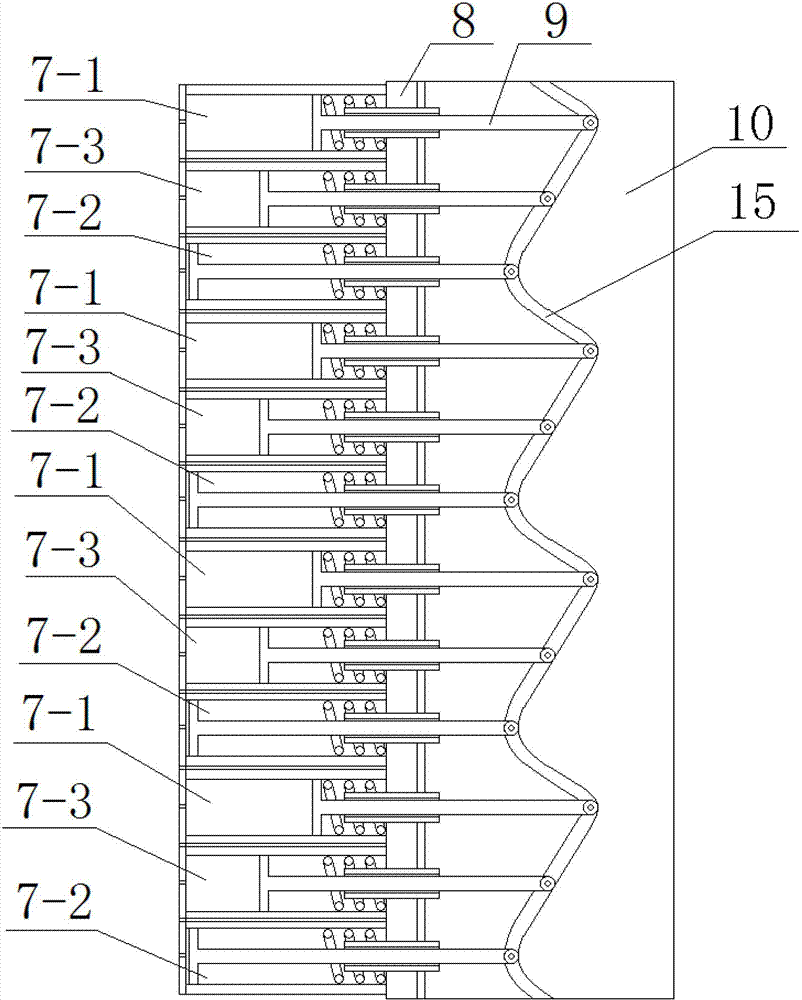

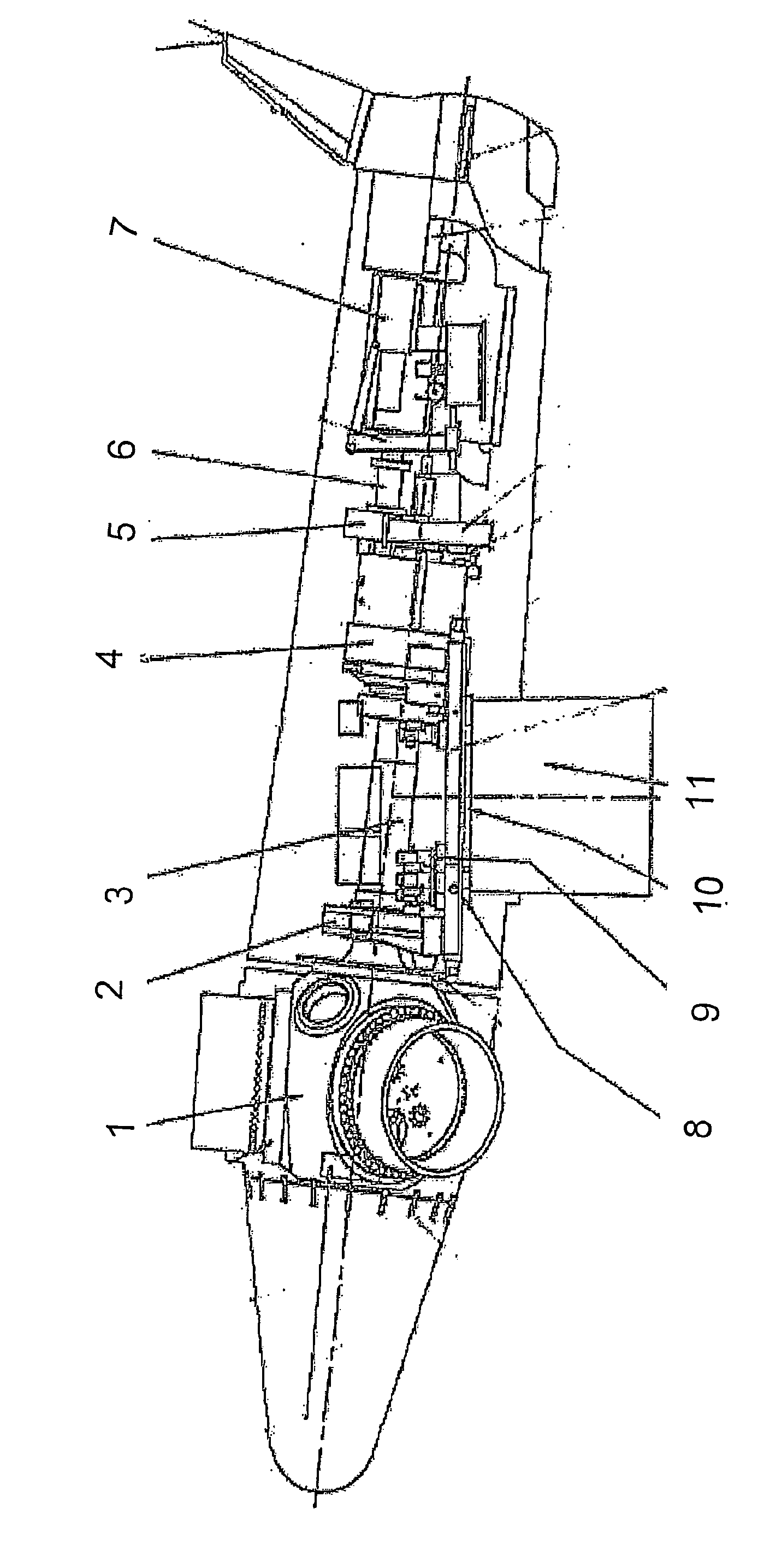

The invention relates to the technical field of oil extraction machinery, in particular to an automatic speed-changing wide-swing-angle oil pumping machine. The automatic speed-changing wide-swing-angle oil pumping machine comprises an electric motor, a speed changing mechanism, a swing arm support, a swing arm arranged on the swing arm support, a support provided with a fixed pulley and a wellhead oil pumping device, wherein the speed changing mechanism is connected with a driving crankshaft wheel, the driving crankshaft wheel is meshed with a driven crankshaft wheel, the driving crankshaft wheel is connected with a connecting piece through a bearing, one end of the connecting piece is connected with the driven crankshaft wheel, the other end of the connecting piece is connected with the swing arm through a connecting rod, a sliding chute is arranged on the connecting piece of which one end is connected with the driven crankshaft wheel, and a bearing on the driven crankshaft wheel is sleeved in the sliding chute. The automatic speed-changing wide-swing-angle oil pumping machine disclosed by the invention has the advantages that when the two crankshaft wheels are in rotation, since the position of the bearing of a driven pulley is changed, the position of the connecting piece can be also correspondingly changed, a motion trail of the connecting rod is affected by the motion of the connecting piece, the speed of the wellhead oil pumping device in the up-stroke is higher than that in the down-stroke, the oil leakage problem existing in an oil pumping process is avoided, and the oil pumping efficiency is increased.

Owner:德阳振华机械设备制造有限公司

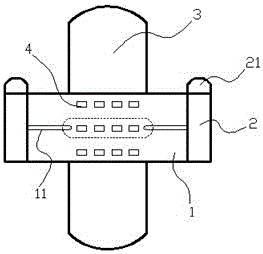

Drive device for a wind turbine

ActiveCN102308088ANot easy to corrodeReduced maintenance needsEngine fuctionsGearingTurbineElectric generator

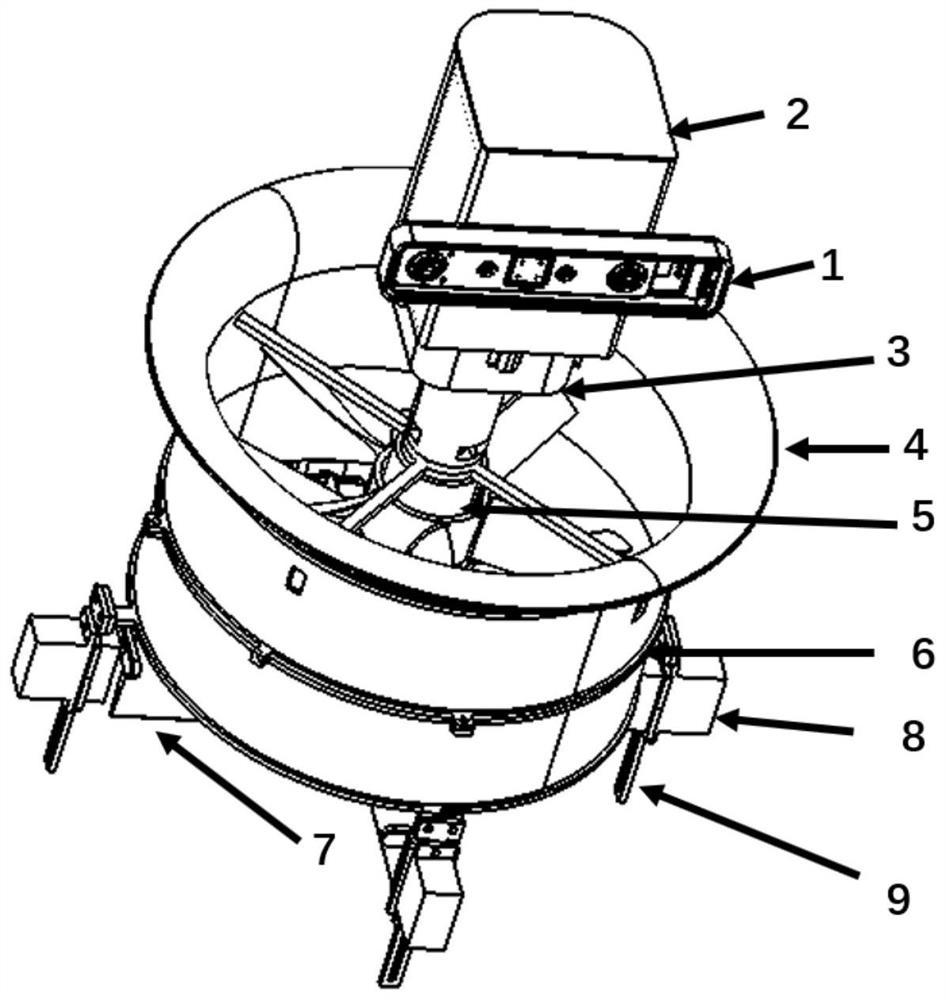

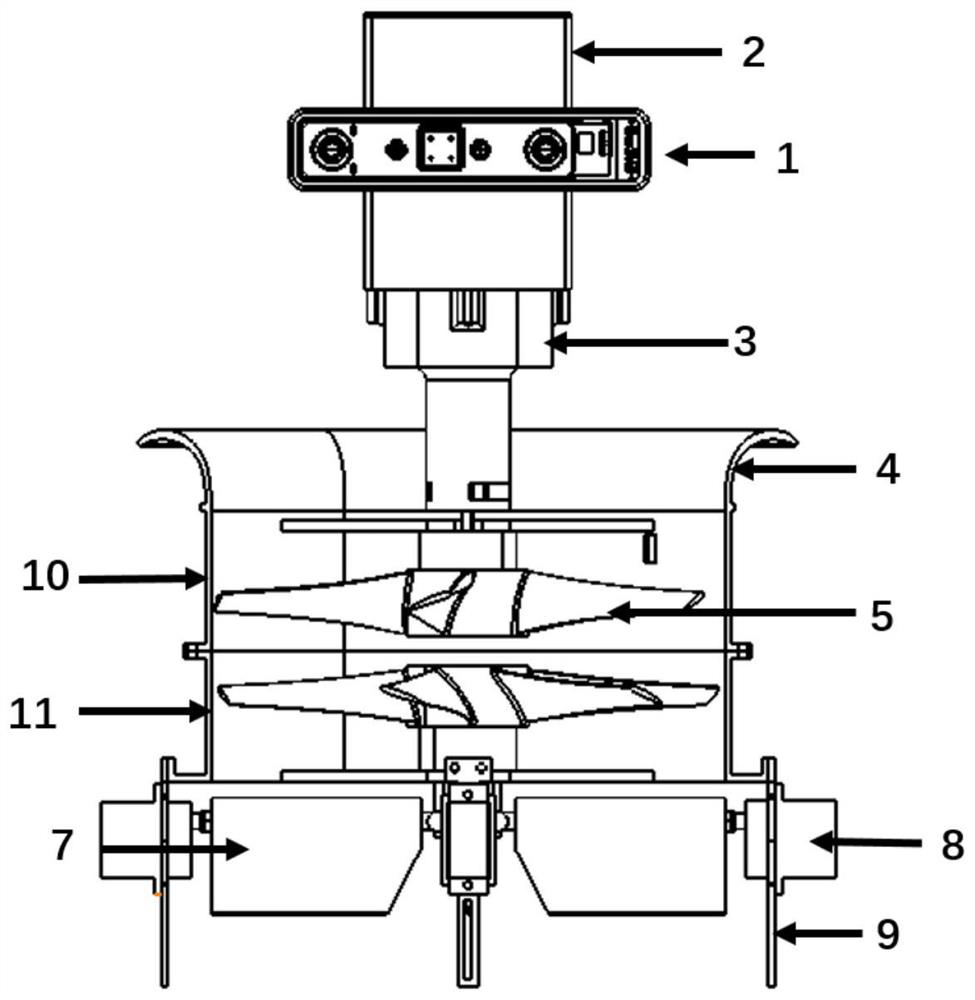

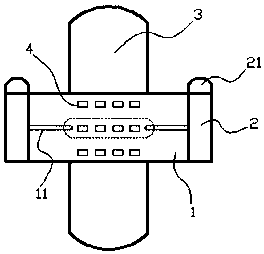

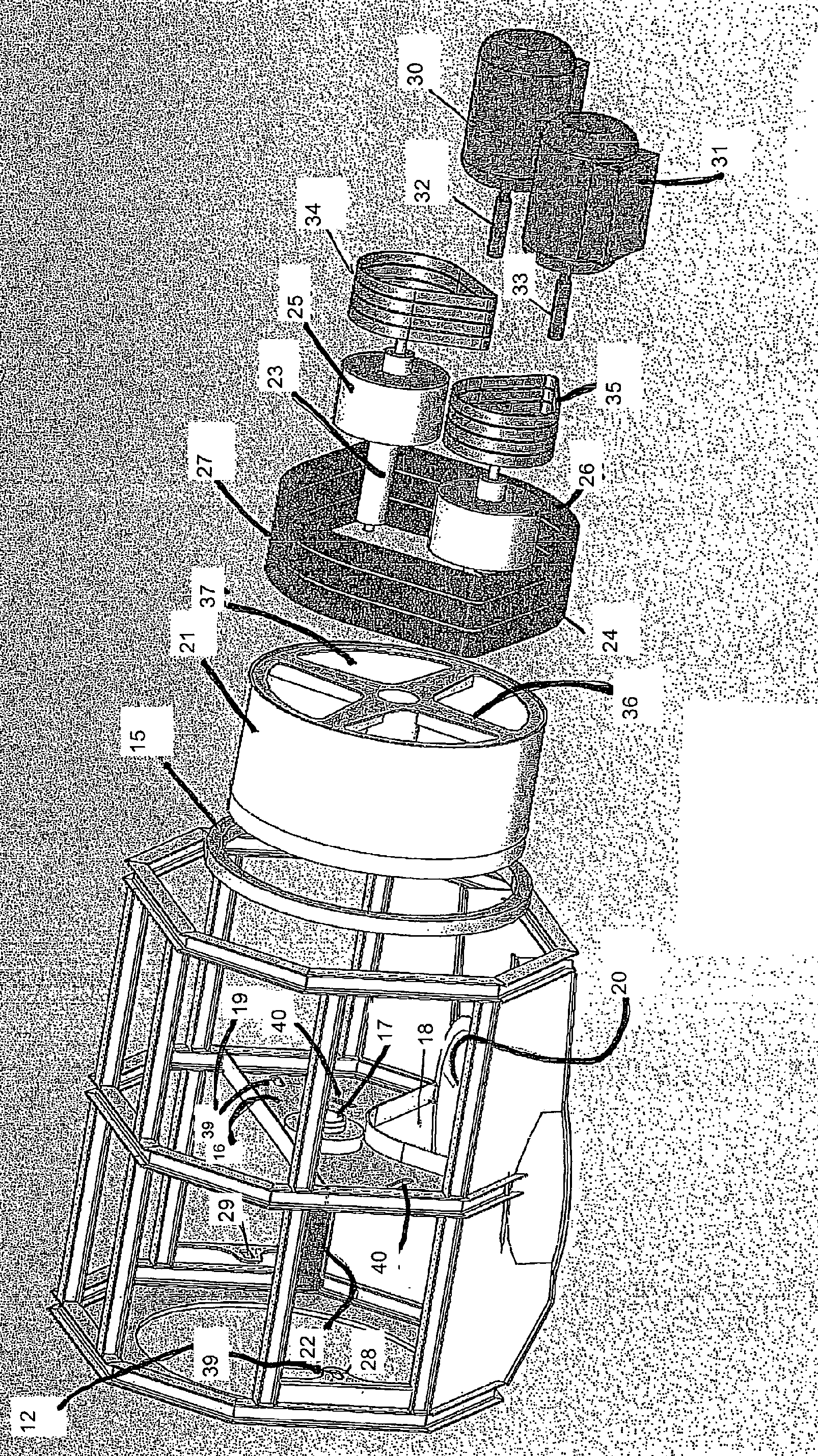

Drive device for a wind mill comprising a large pulley (21) disposed on a main shaft (22) and at least one belt (27) or chain adapted to transfer rotation from the pulley (21) to a generator (30, 31). The pulley (21) is rotationally coupled to at least two secondary shafts (23, 24), which are disposed parallel to the main shaft (22). One or more belts (27), which transfer the rotation, extend over the pulley (21) and the secondary shafts (23, 24). The secondary shafts (23, 24) are in turn rotationally coupled to at least one, preferably two, electric generators (30, 31).

Owner:VESTAS WIND SYST AS

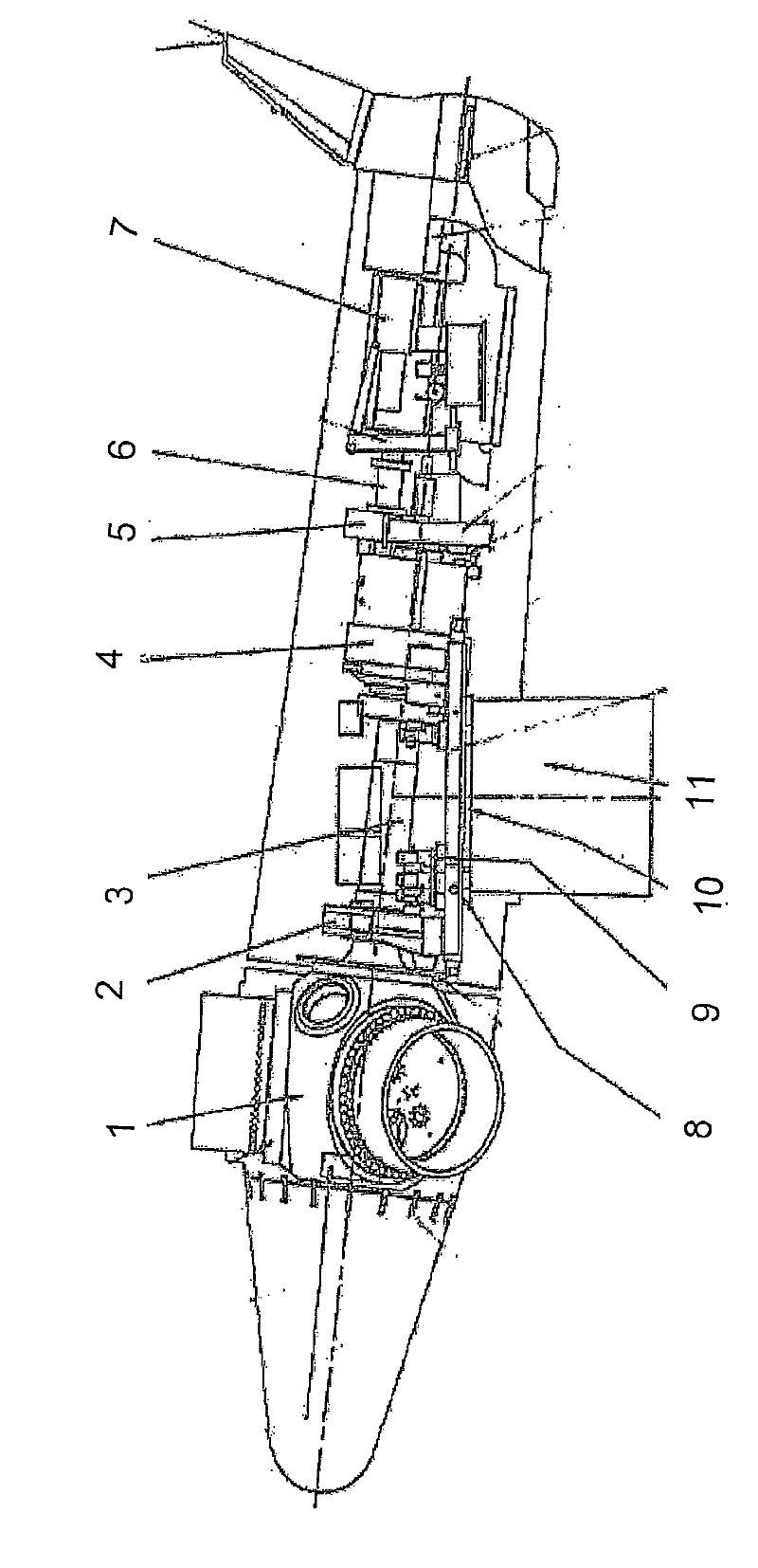

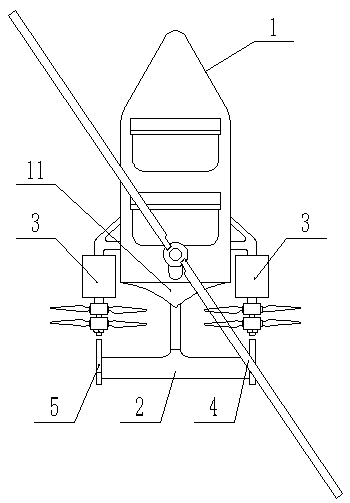

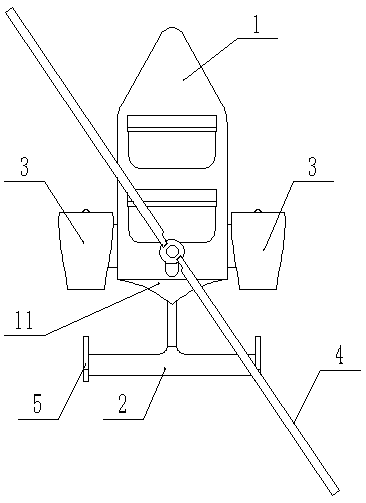

Miniaturized ducted aircraft

ActiveCN112849393AWith vertical take-off and landing functionImprove aerodynamic efficiencyPower plant cooling arrangmentsPropellersElectrical batteryVideo transmission

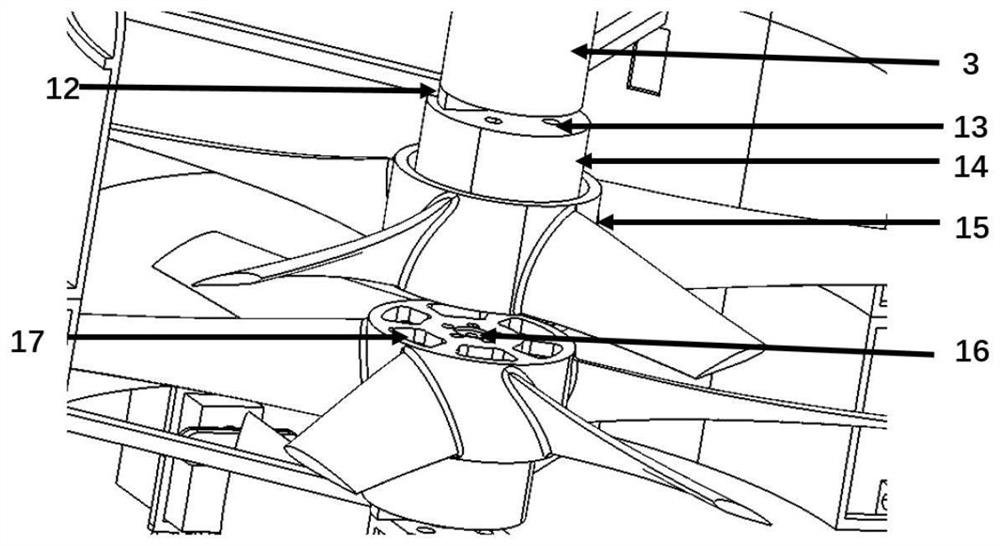

The invention relates to a miniaturized ducted aircraft. A camera is mounted right in front of a battery compartment; the battery compartment is located at the uppermost part of the aircraft, the central axis of the battery compartment coincides with the axis of the duct, and the flight control cabin is located between the battery compartment and the motor base and also coincides with the axis of the duct; a duct lip can reduce duct air inlet loss and provide extra thrust for the aircraft, and the duct lip is located over the duct and tightly connected with the duct. The installation axis of the power device coincides with the axis of the duct and is located below the flight control cabin. The control rudders change the flowing direction of airflow at the outlet of the duct, the distribution centers of the four control rudders coincide with the axis of the duct and are located at the outlet of the duct, and the four control rudder adjusting devices adjust deflection of the four control rudders correspondingly. The undercarriage is positioned at the lowermost part of the duct. According to the miniaturized design scheme of the ducted aircraft, the size of the aircraft can be fully compressed on the premise of realizing autonomous cruise and video transmission, so that the aircraft can autonomously fly in a narrower space.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

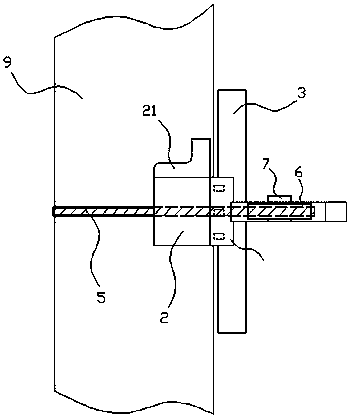

Improved power repair feet crawler

The invention relates to an improved power repair feet crawler. The improved power repair feet crawler comprises a main crawling machine; the side surface of the main crawling machine, facing an electric pole, is an arc-shaped crawling surface; universal rotating wheels are arranged at equal intervals on the crawling surface and electrically connected to a controller; a cable chute is formed in the crawling surface; a crawling cable is mounted in the cable chute, and threads are formed in the surface of the crawling cable; closed lock buckles are mounted at two ends of the crawling cable; the crawling cable is manufactured from non-stretching and bendable wearable materials; the crawling cable engages with a driving wheel; the driving wheel rotatably sleeves an adjusting shaft parallel to the electric pole; the adjusting shaft can horizontally move in an adjusting groove at the back of the main crawling machine in the radial direction of the electric pole. The feet crawler has a small size, and is convenient to carry, applicable to the electric poles of various sizes, safe and reliable, and simple to operate.

Owner:STATE GRID JIANGXI ELECTRIC POWER CO +1

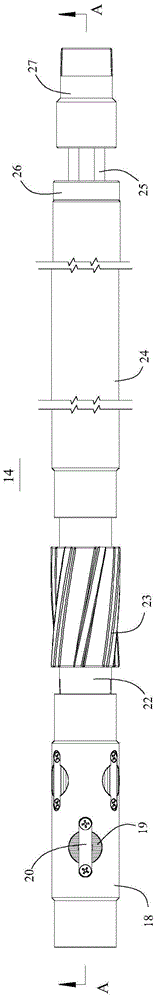

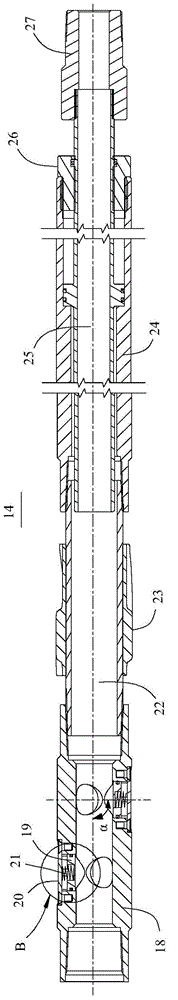

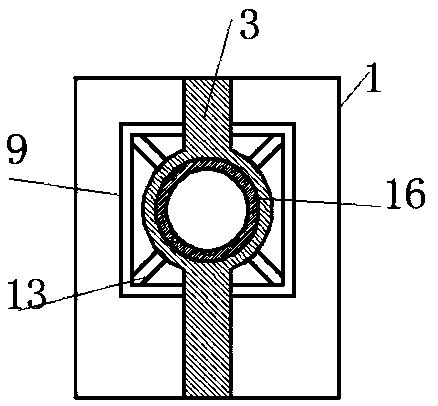

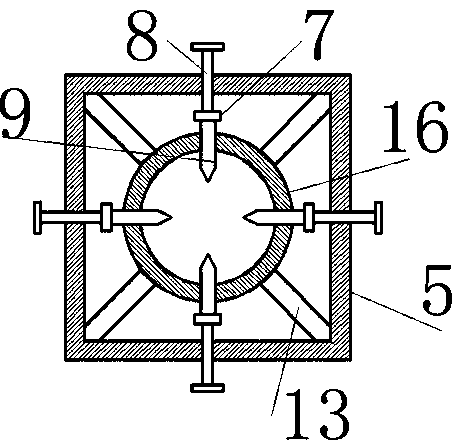

Horizontal well coiled tube drilling plug tubular column

ActiveCN106321004AEliminate the problem of blocked entrySolve the problem that is not in placeBorehole/well accessoriesAxial forcePetroleum engineering

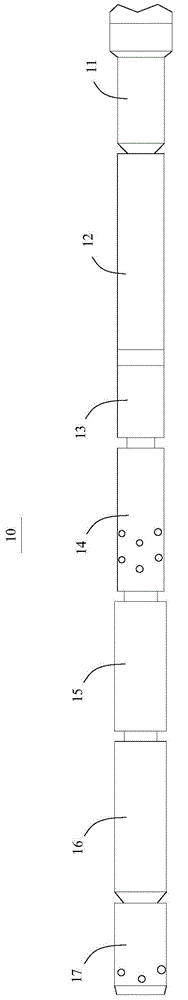

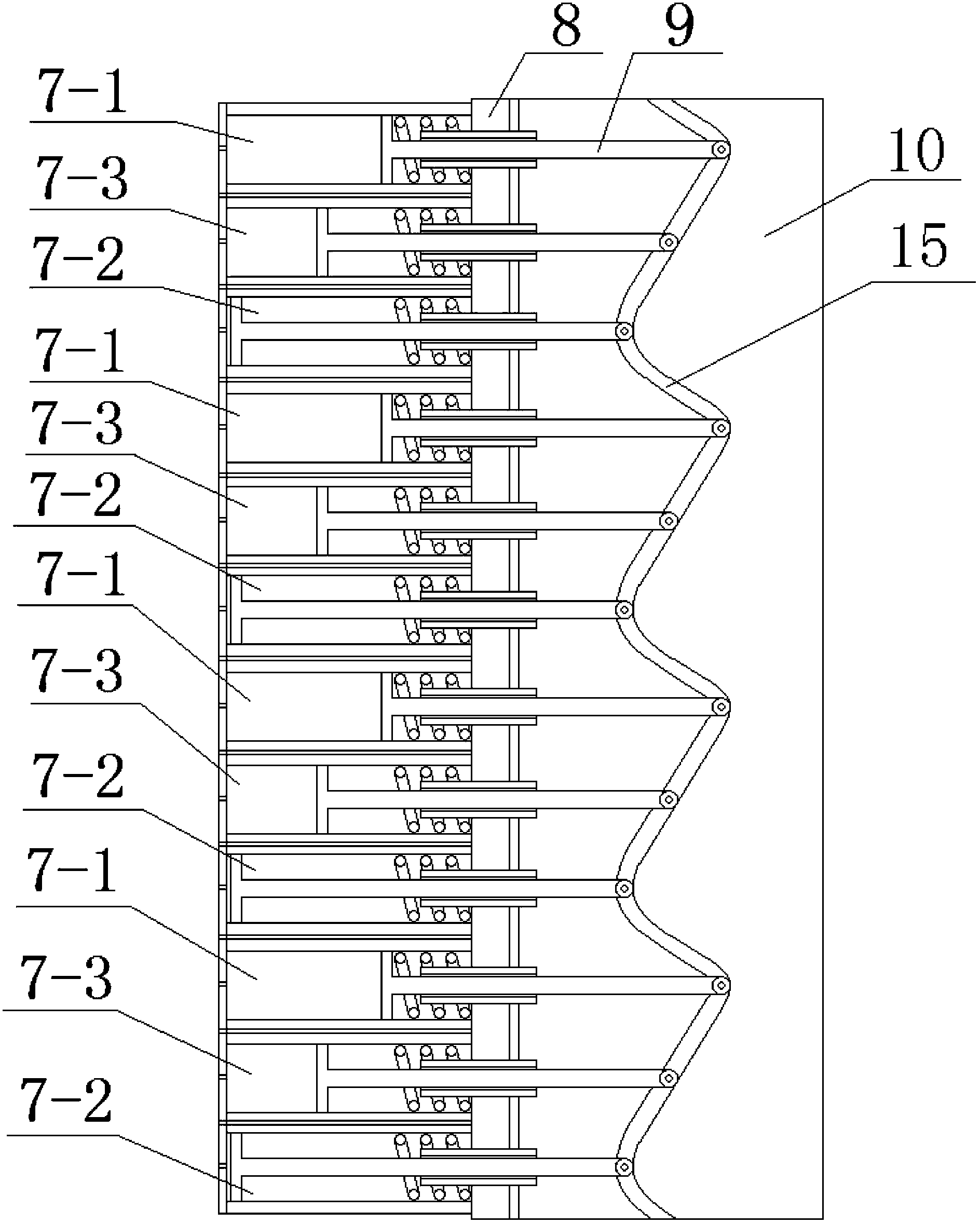

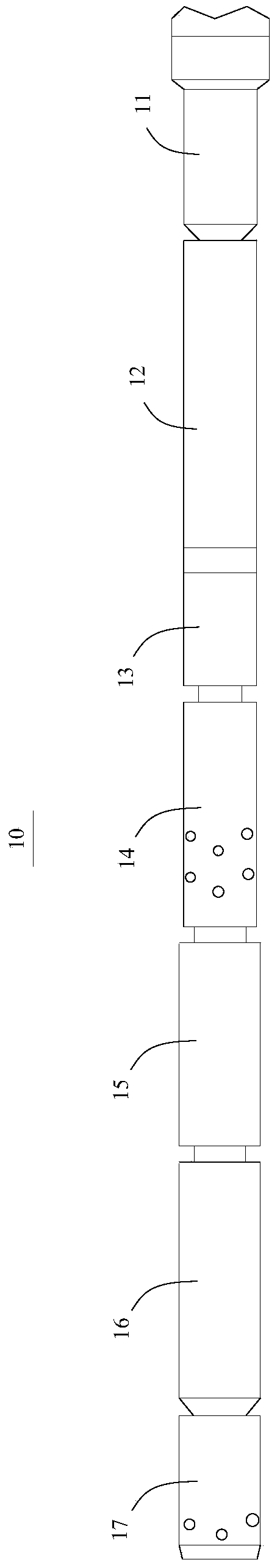

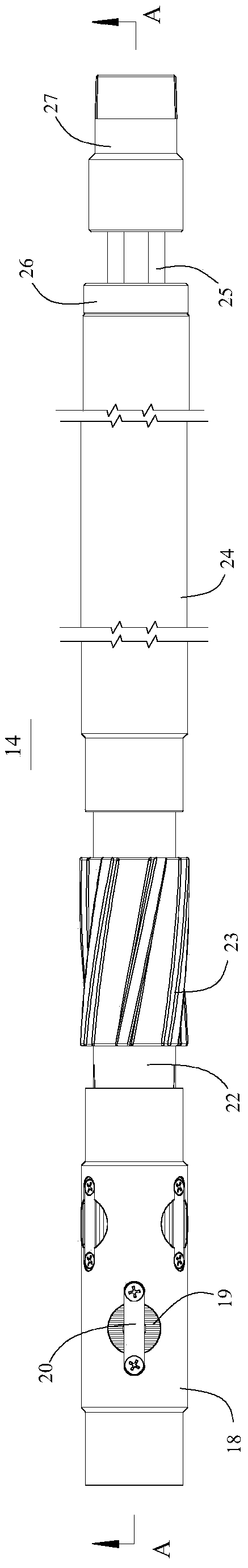

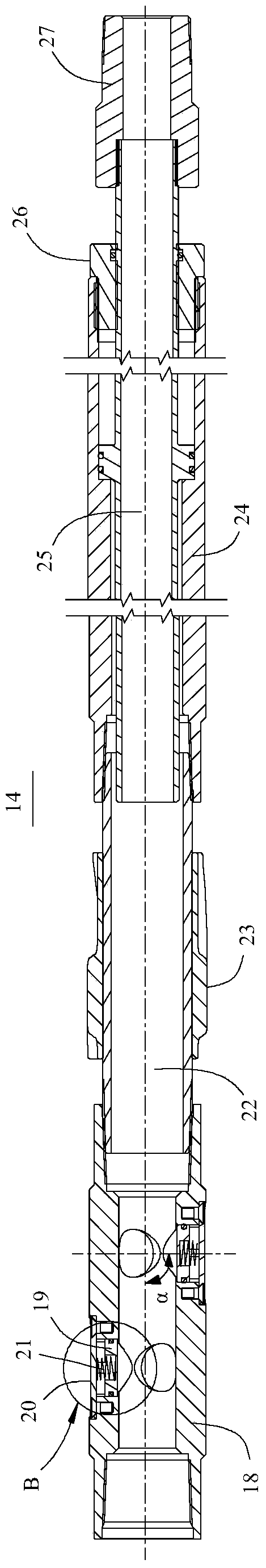

The invention provides a horizontal well coiled tube drilling plug tubular column which comprises a milling shoe, a motor, a motor head, an anchoring and pressurizing device and a jar knocker, wherein the milling shoe, the motor, the motor head, the anchoring and pressurizing device and the jar knocker are sequentially connected. The horizontal well coiled tube drilling plug tubular column comprises the anchoring and pressurizing device which can anchor a drilling plug tubular column body into a horizontal well casing tube. After the drilling plug tubular column body is anchored into the horizontal well casing tube through the anchoring and pressurizing device, the milling shoe is pressurized to guarantee the drilling pressure of the milling shoe. The anchored drilling plug tubular column can balance the axial force generated when the milling shoe drills and removes a bridge plug, and the drilling process of the milling shoe is stable. Accordingly, the efficiency of the drilling and removing of the bridge plug is improved, and the time for drilling and removing the bridge plug is shortened.

Owner:CHINA PETROLEUM & CHEM CORP +1

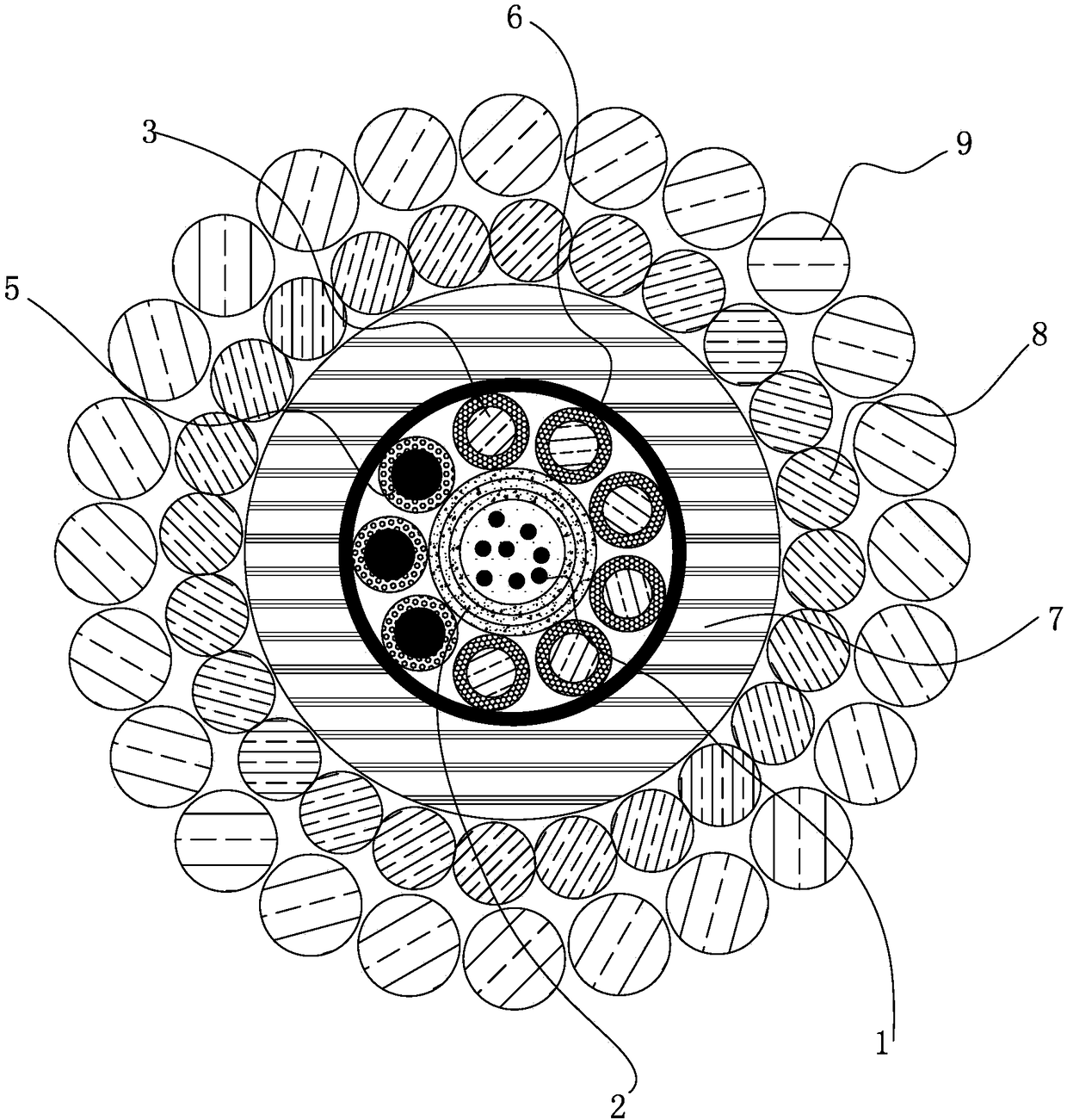

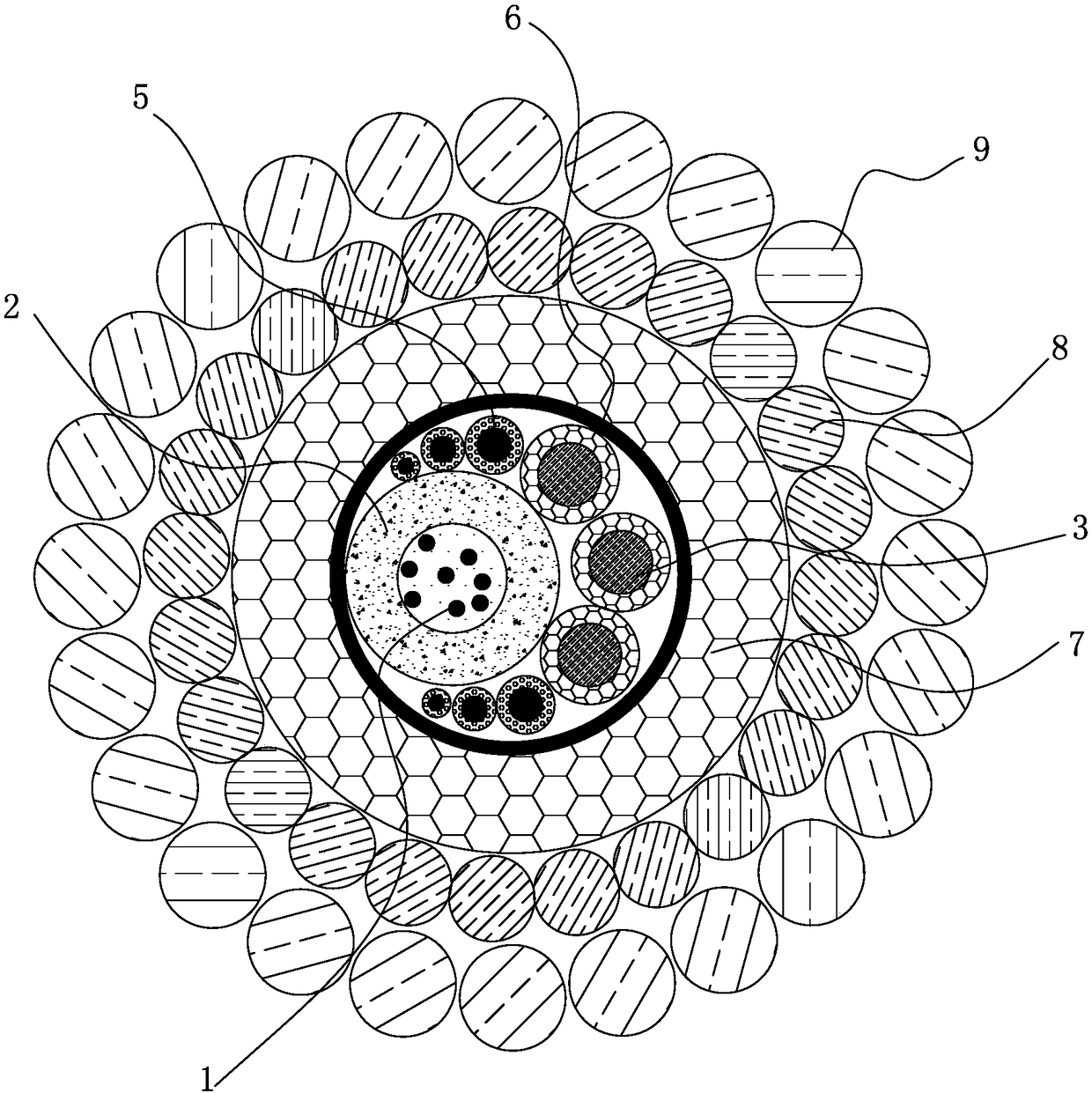

Photoelectric composite optical cable for oil well and production method thereof

PendingCN108198662AReduce lossWide operating temperature rangePlastic/resin/waxes insulatorsCommunication cablesElectrical conductorEngineering

The purpose of the invention is to provide a photoelectric composite optical cable for an oil well and a production method thereof. The method is used for solving the technical problem of improving the reliability of the photoelectric composite optical cable and facilitating the production. The cable comprises an optical fiber unit, a conductor unit, a filling unit, a covering unit and an armoringunit; the optical fiber unit is located at the middle of the composite optical cable, and comprises an optical fiber of which the outer layer is coated with polyimide and a stainless steel tube to sleeve the optical fiber; taking the stainless steel tube as the center, and the conductor unit and the filling unit with the same outer diameters are closely twisted spirally on the outer side of the stainless steel tube to form a cable core; the outer side of the cable core is respectively provided with the covering unit and the armoring unit from inside to outside; the armoring unit comprises aninner armored wire and an outer armored wire which are twisted in opposite directions. The method has the advantages of high reliability and convenient production.

Owner:SHANDONG PACIF OPTICS FIBER & CABLE CO LTD

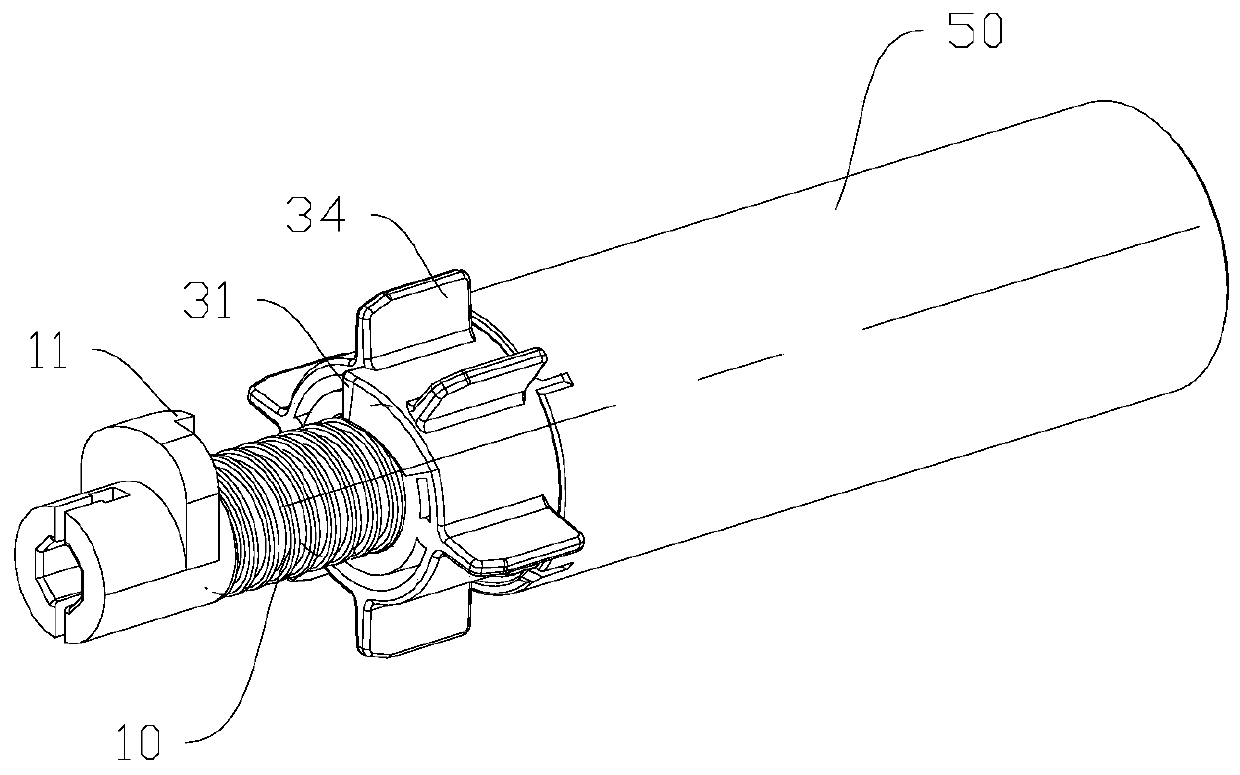

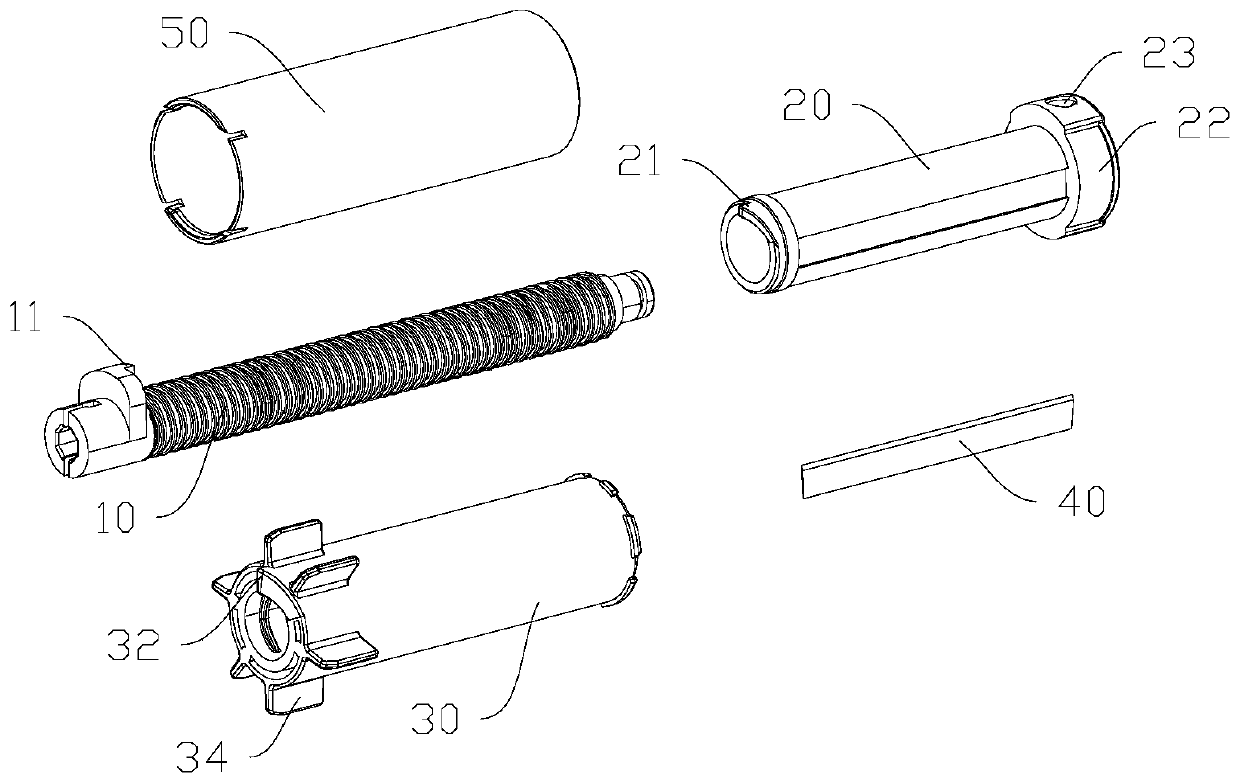

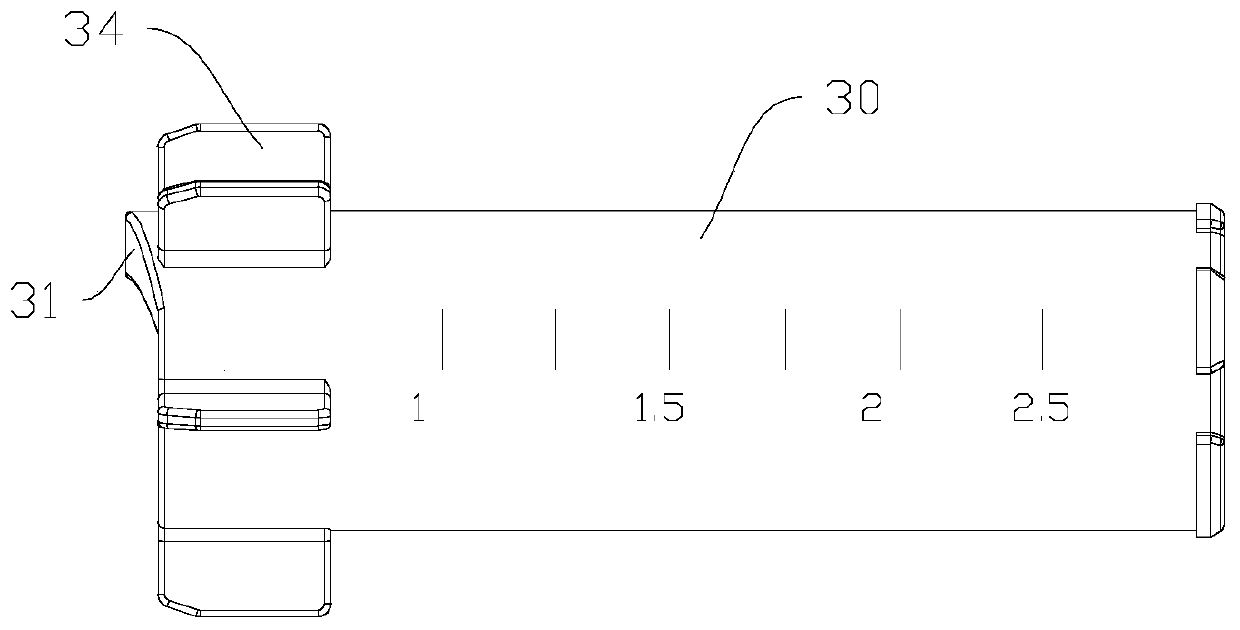

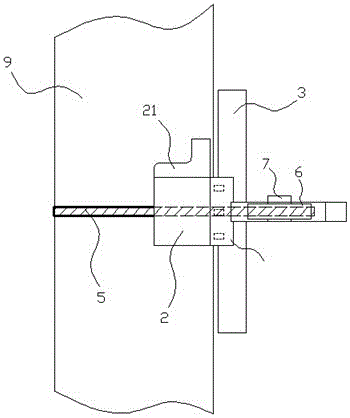

Roller blind balance regulator and roller blind with same

PendingCN110984826ATorque balanceEasy to useLight protection screensCounterweightsDynamic balanceEngineering

The invention discloses a roller blind balance regulator and a roller blind with the same. The roller blind balance regulator comprises a stepped shaft and a friction drum; the stepped shaft is provided with an external screw thread; the stepped shaft penetrates through the friction drum; the friction drum is provided with an internal screw thread; the friction drum is in threaded connection withthe stepped shaft; and a friction layer is arranged between the friction drum and the stepped shaft. The roller blind comprises a roller blind rod, fabric, two mounting members and the roller blind balance regulator, wherein a return spring is arranged in the roller blind rod. The roller blind rod drives the friction drum to rotate, the friction drum moves in the axial direction of a limiting threaded rod while the friction drum rotates, and thus the friction force between the friction drum and a friction layer is increased or decreased. When the roller blind rod rotates, the friction force between the friction drum and the friction layer can be increased or decreased along with change of torque of the return spring, and thus the function of dynamically balancing the return spring is achieved. By means of the roller blind balance regulator and the roller blind with the same, the torque of the return spring can be balanced better, the friction force between the friction drum and the friction layer can dynamically compensate the torque difference of the return spring, and the using effect is good.

Owner:GUANGZHOU JADY WINDOW COVERINGS TECH CO LTD

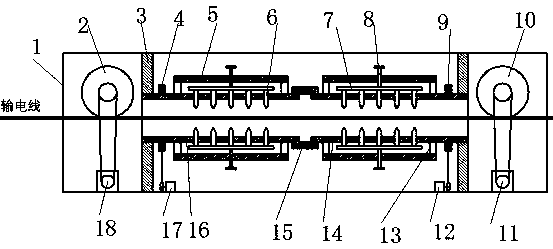

Deicing machine of single power transmission line

The invention discloses a deicing machine of a single power transmission line. The deicing machine comprises a machine body, wherein the power transmission line penetrates through the machine body, atravelling mechanism is arranged in the machine body and is arranged on the power transmission line, the machine body is driven to move an extension direction of the power transmission line, a deicingmechanism is arranged in the machine body and comprises a first cylindrical knife rest and a second cylindrical knife rest, one end of the first knife rest and one end of the second knife rest communicate with each other via a rotation connection piece so that axes of the first knife rest and the second knife rest are arranged on the same straight line, the first knife rest and the second knife rest can rotate relative to each other, a plurality of knife rows are inserted onto side walls of the two knife rests, knife row adjustment racks sleeve the first knife rest and the second knife rest,and the depth of the knife rows inserted into the side walls of the knife rests are adjusted. By the deicing machine, the cutting quantity of a cutter can be adjusted according to a thickness of an ice layer or a diameter of the power transmission line, and meanwhile, a torque applied to the power transmission line is balanced.

Owner:CHENGDU IDING IND PROD DESIGN

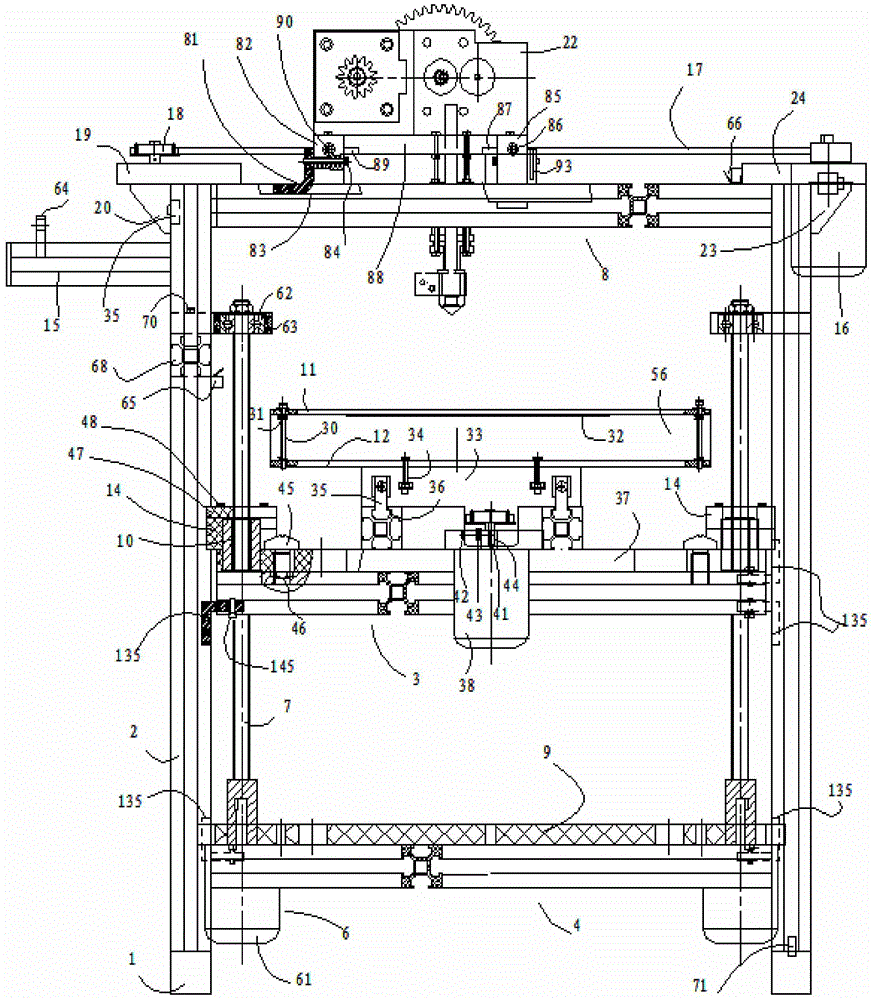

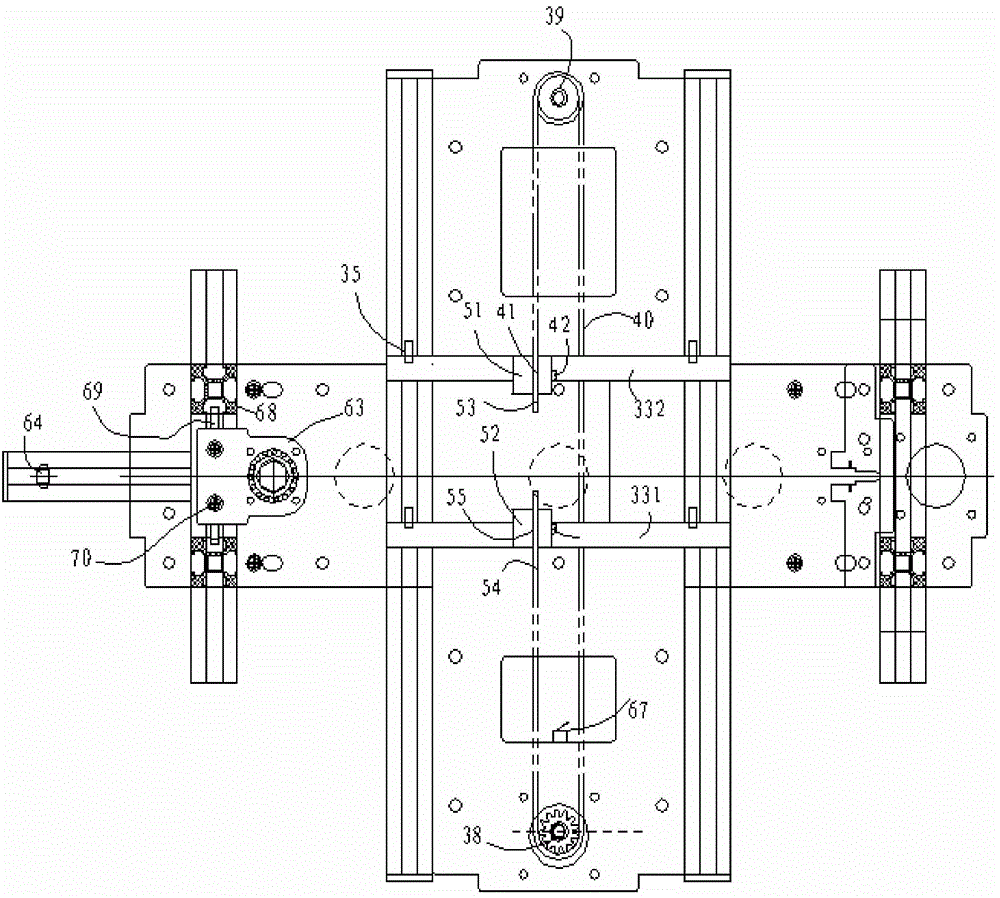

Small 3D printer

The present invention discloses a small 3D printer, which comprises a vertical column, a lower portion fixed holder, a base, a printing structure, a z-axis direction moving structure, an x-axis direction moving structure and a y-axis direction moving structure, wherein the front position and the rear position on both sides are respectively provided with the one vertical column, the base is connected with the y-axis direction moving structure, the y-axis direction moving structure is connected with the z-axis direction moving structure, the printing structure is connected with the x-axis direction moving structure, the z-axis direction moving structure comprises a z-axis direction drive motor, a vertical lead screw and a screw nut, the z-axis direction drive motor is fixedly connected on a motor connection plate, the bottom portion of the motor connection plate is connected with the lower portion fixed holder, the screw nut is nested in an axial sleeve, the end portion of the axial sleeve is provided with an axial positioning plate, the axial positioning plate is fixedly connected with the axial sleeve, the axial sleeve is connected with the first support plate of the y-axis direction moving structure, the z-axis direction drive motor is connected with the vertical lead screw, the upper end of the lead screw is provided with a bearing, and the vertical column is connected with the bottom portion horizontal support body.

Owner:UNIV OF JINAN

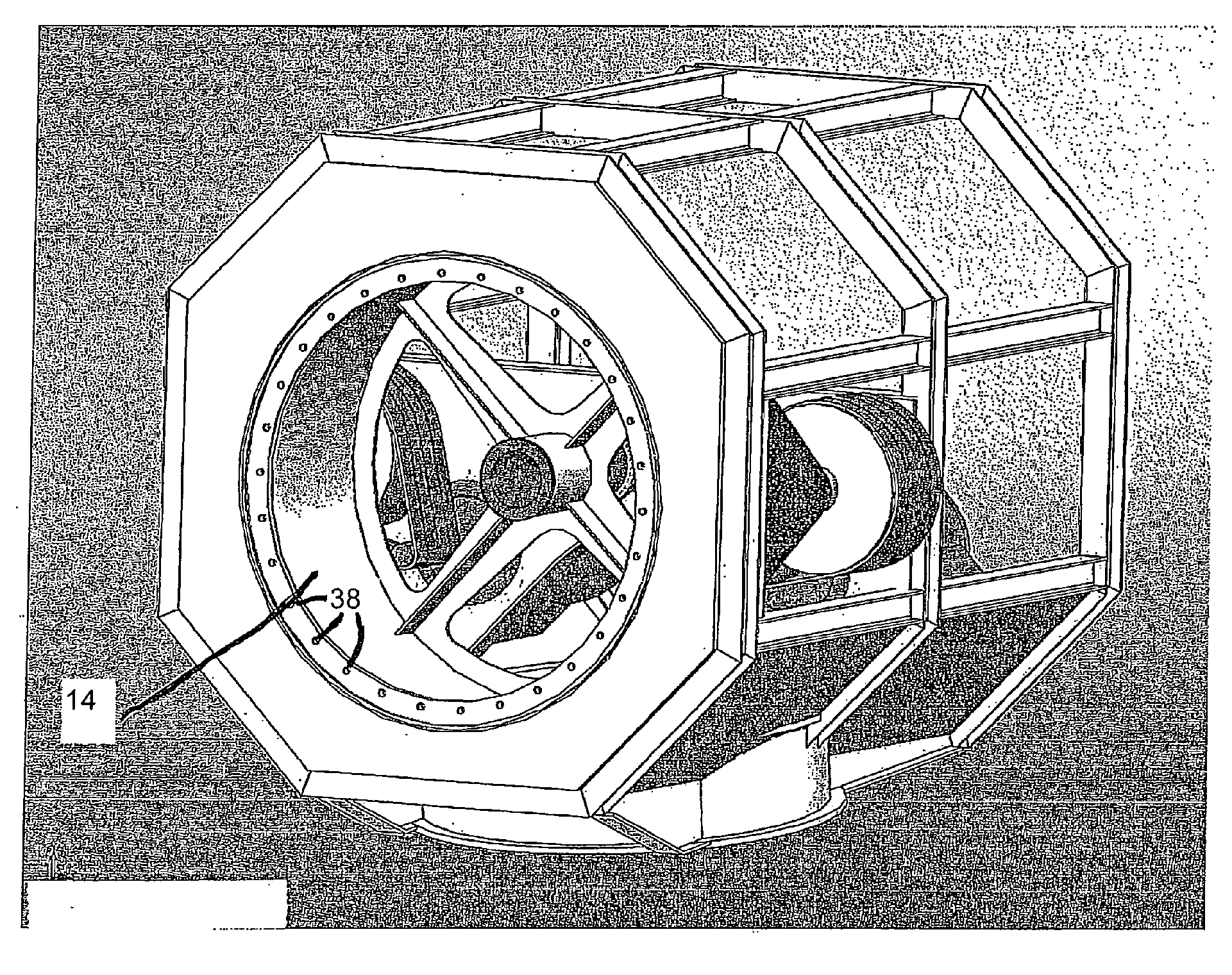

Rotor engine with boosting flywheel

InactiveCN101046156ASolve the root problem of non-continuous operationTorque balanceInternal combustion piston enginesRotary piston enginesFreewheelEngineering

The rotor engine with boosting flywheel includes one rotor engine, one driving device for the rotor engine to drive one power output device, and one boosting device driven by the rotor engine. The present invention adopts flywheel to counteract the resistance to the back assisting wheel alternately for the two rotors to rotate in the same direction, so as to realize the lasting rotation of the rotor engine.

Owner:陈维加

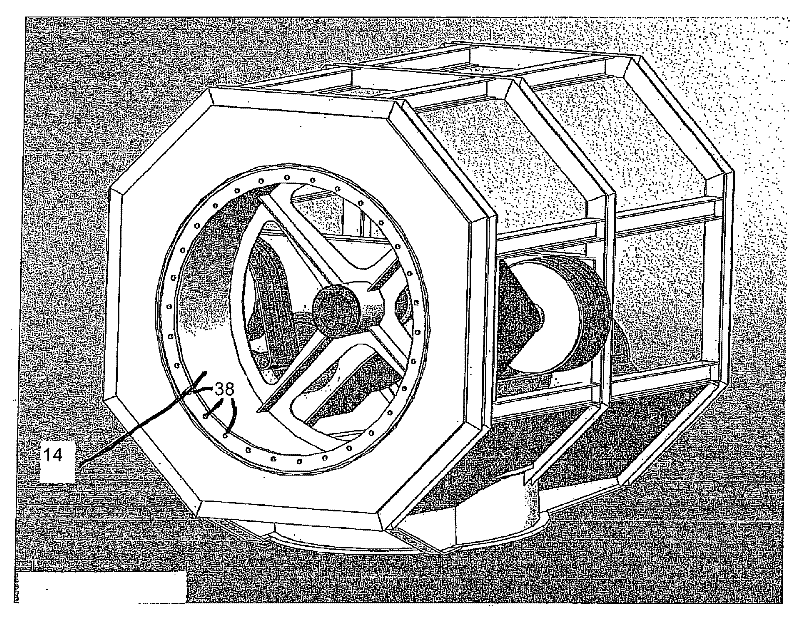

Multiplied-rotating-speed vertical-axis wind power generator and manufacturing method thereof

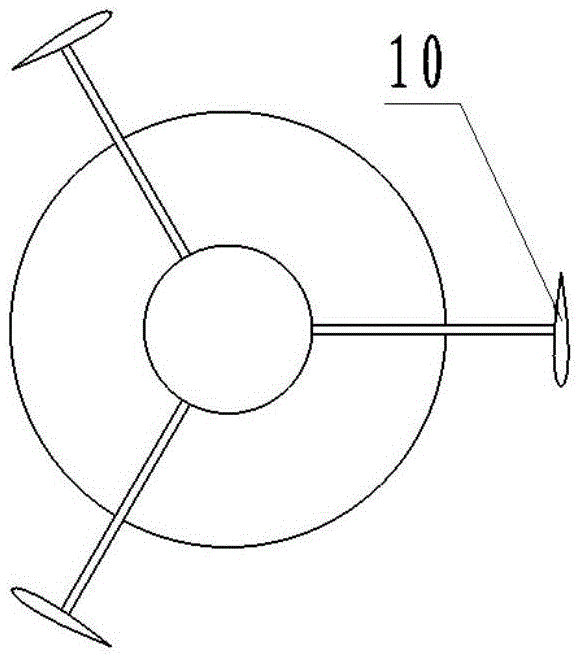

InactiveCN105569926AIncrease speedSimple structureFinal product manufactureMachines/enginesVertical axis wind turbineVertical axis

The invention discloses a multiplied-rotating-speed vertical-axis wind power generator and a manufacturing method thereof. The multiplied-rotating-speed vertical-axis wind power generator comprises a first wind turbine and a second wind turbine which are opposite in rotating direction. Blades of the first wind turbine and blades of the second wind turbine are opposite in installing direction, and it is guaranteed that the rotating direction of the first wind turbine and the rotating direction of the second wind turbine are opposite; a second pivoted lever of the second wind turbine is sleeved with a first pivoted lever of the first wind turbine, and it is achieved that the second pivoted lever moves relative to the first pivoted lever; and a fixing rod is arranged in the second pivoted lever through a bearing so that the second pivoted lever can rotate relative to the fixing rod, one end of the fixing rod is fixed, the other end of the fixing rod is fixedly connected with a collecting ring, and a power output line of an inner rotor of the power generator is connected with the collecting ring. According to the multiplied-rotating-speed vertical-axis wind power generator and the manufacturing method thereof, the two wind turbines arranged vertically are arranged, one wind turbine drives an armature disc to rotate, the other wind turbine drives a magnet to rotate in the other direction, and the rotating speed of the power generator is increased by sufficiently utilizing the relative movement of an excitation magnet and the armature disc. The whole power generator is simple in structure and high in efficiency.

Owner:SHANDONG UNIV

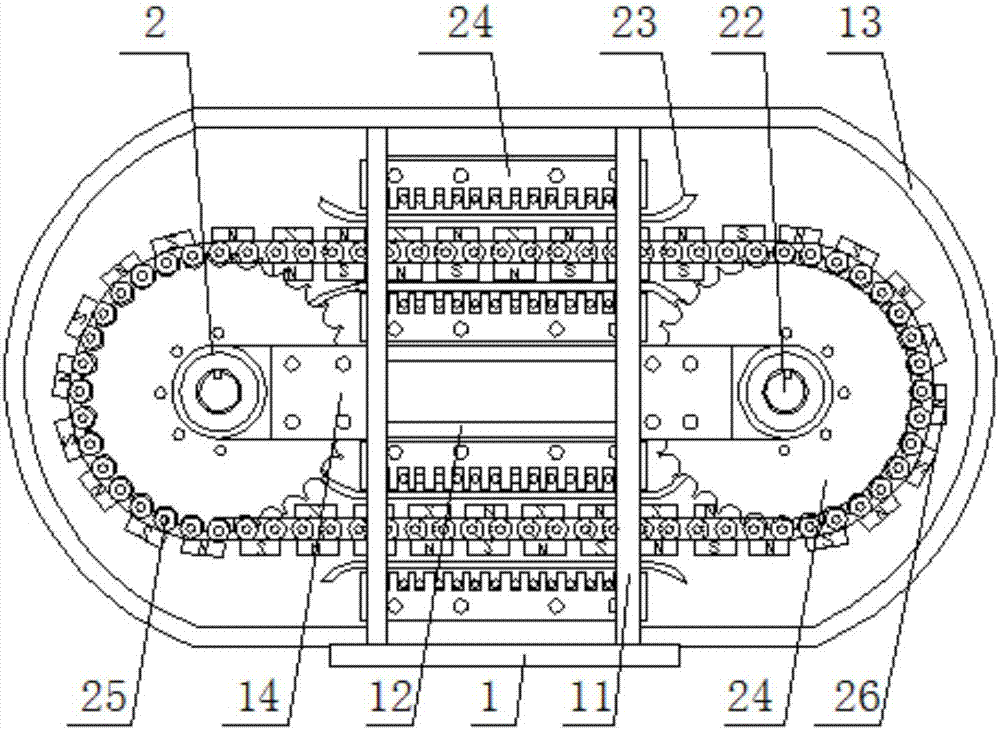

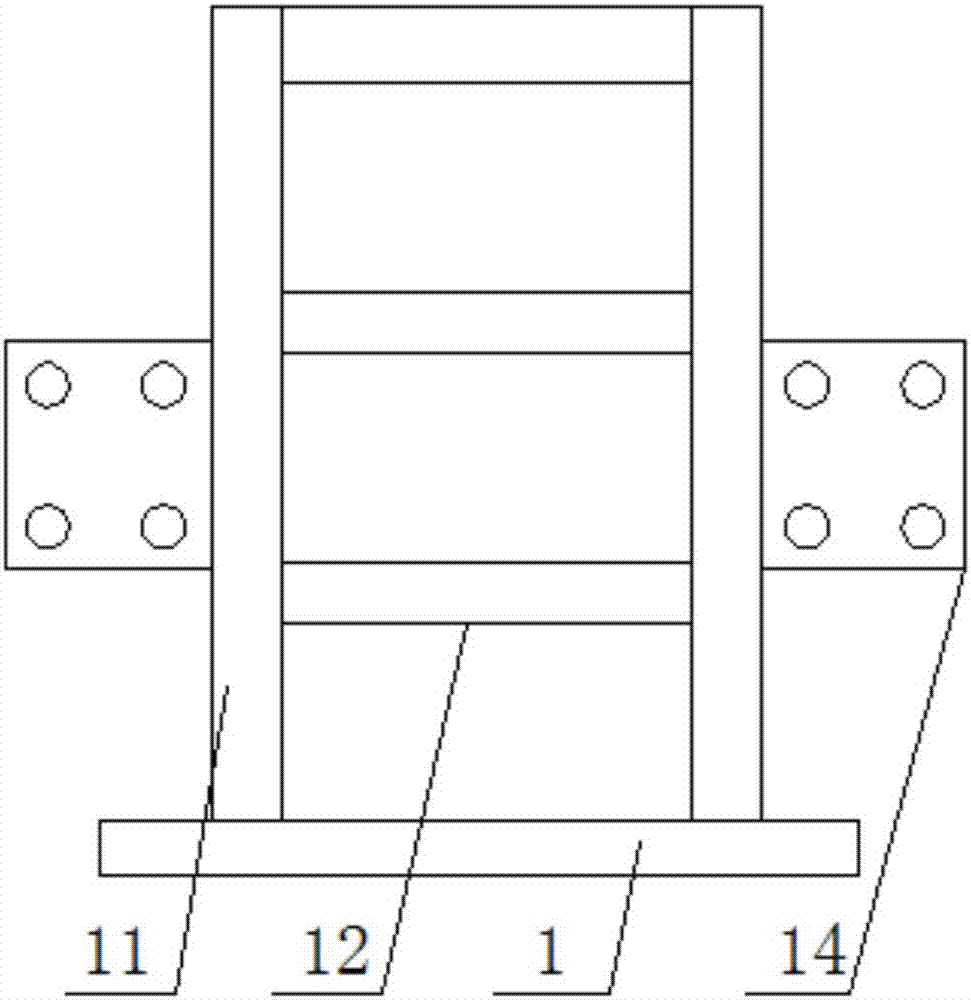

Straight stator generator of utilizing caterpillar drive excitation

PendingCN107508405ATorque balanceImprove utilization efficiencyMechanical energy handlingPropulsion systemsEngineeringDynamo

The present invention discloses a straight stator generator of utilizing caterpillar drive excitation. The straight stator generator comprises a generator installing machine pedestal, the machine body skeletons are fixedly connected at the two sides of the upper surface of the generator installing machine pedestal, and the first installing bases are fixedly connected at the two sides of the outer surfaces of the machine body skeletons. The second installing bases are fixedly connected on the surfaces at the inner sides of the first installing bases via bolts, the bearing blocks are fixedly connected on the surfaces at the outer sides of the second installing bases, and the rotating shafts are connected in the bearing blocks rotatably. The caterpillar drive chain gear flanges are fixedly connected at the two sides of the outer surfaces of the rotating shafts, the chain gear discs are fixedly installed on the outer surfaces of the caterpillar drive chain gear flanges via screws, and chains are meshed with the outer surfaces of the chain gear discs. The straight stator generator of utilizing the caterpillar drive excitation solves the difficulty of a multi-pole number low-rotating speed generator equipment production technology, and enables more effective electric energy to be outputted under the equal power.

Owner:冯树乡 +1

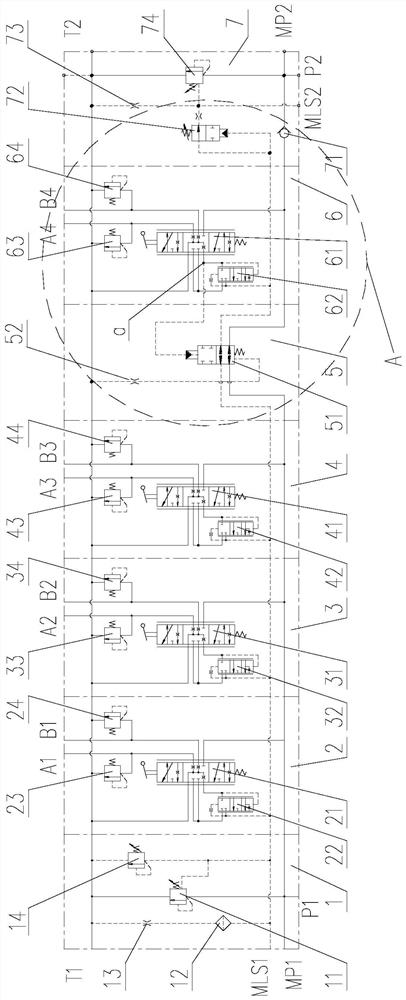

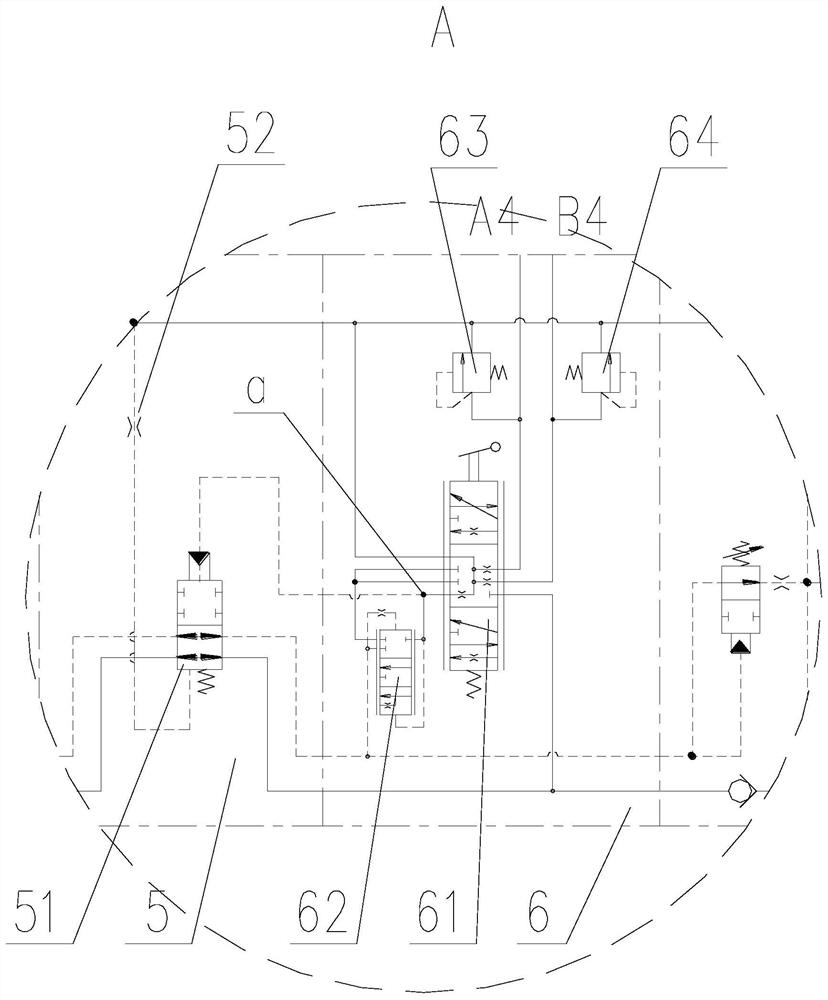

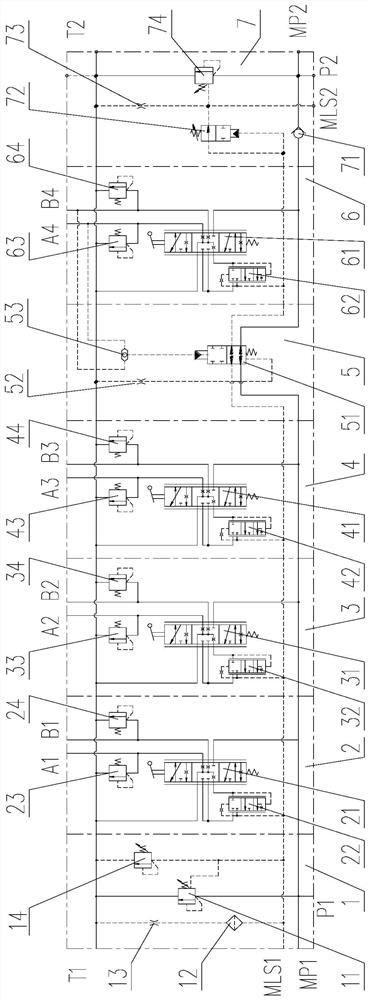

Load-sensitive multi-way valve with double-pump confluence function

PendingCN113788408ATorque balanceAvoid the phenomenon of suffocation and flameoutServomotor componentsServomotorsRotation - actionOil pump

The utility model discloses a load-sensitive multi-way valve with a double-pump confluence function, and relates to the technical field of hydraulic pressure of straight-arm lorry-mounted cranes. The load-sensitive multi-way valve comprises a first pump oil inlet control unit, a proportional reversing valve working unit, a confluence control unit, a rotation reversing unit and a second pump oil inlet control unit. The first pump oil inlet control unit is connected with a first quantitative oil pump and supplies oil to the proportional reversing valve working unit, the second pump oil inlet control unit is connected with a second quantitative oil pump and supplies oil to the rotation reversing unit, and when the rotation reversing unit does not work, the second quantitative oil pump and the first quantitative oil pump are converged through a one-way valve and a hydraulic control reversing valve of the converging control unit; the two pumps simultaneously supply oil to the proportional reversing valve working unit, so that the working efficiency is improved; and when the rotation reversing unit works, the hydraulic control reversing valve of the confluence control unit cuts off a confluence channel of the second quantitative oil pump and the first quantitative oil pump, the second quantitative oil pump independently supplies oil to the rotation reversing unit, rotation action flow matching is achieved, and energy consumption and system temperature rise are reduced.

Owner:江苏宏昌天马物流装备有限公司

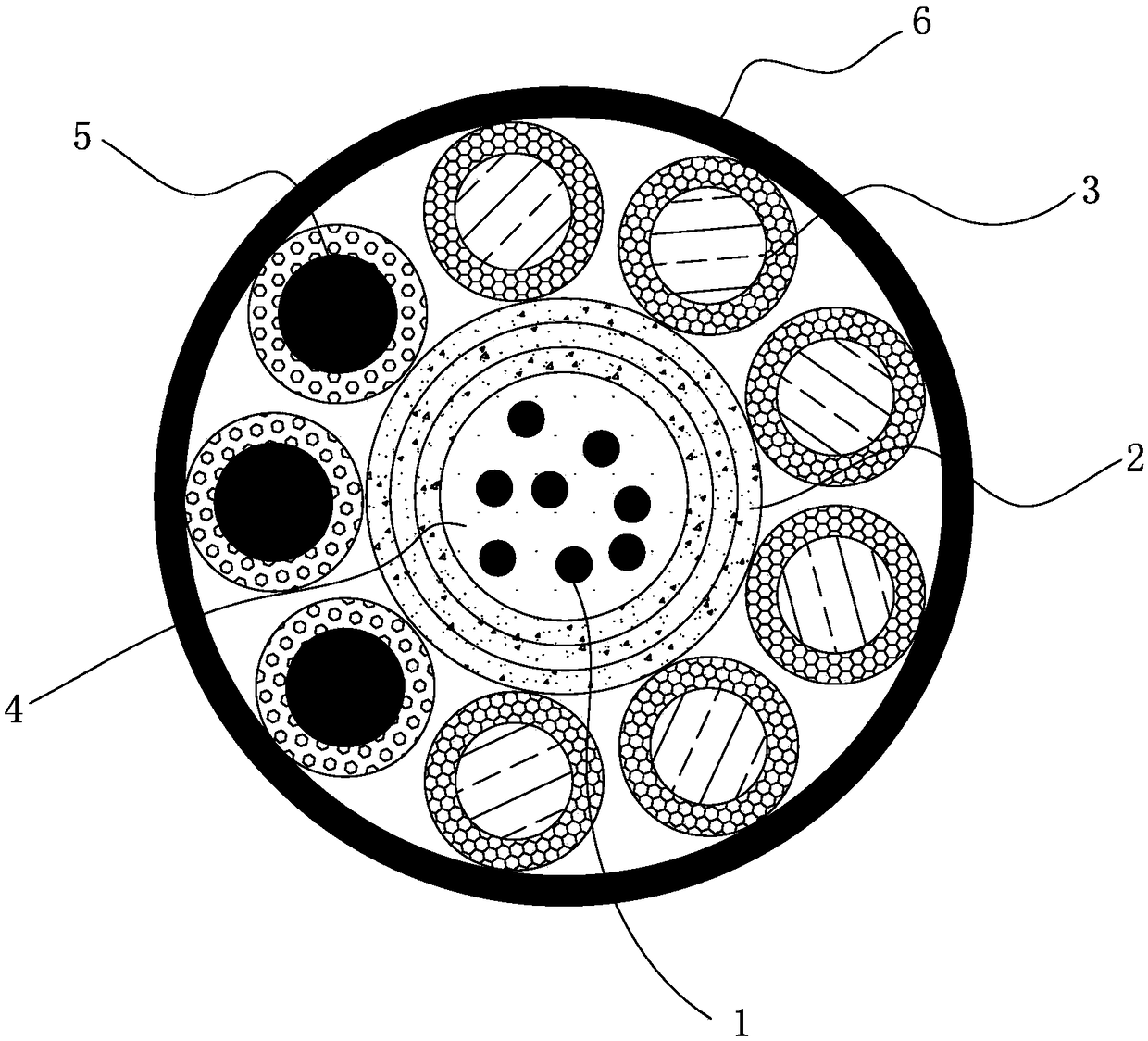

High temperature resistant photoelectric composite optical fiber for oil well and production method thereof

PendingCN108206079AReduce lossWide operating temperature rangePlastic/resin/waxes insulatorsCommunication cablesElectrical conductorHigh pressure

The invention aims at providing a high temperature resistant photoelectric composite optical fiber for an oil well and a production method thereof, used for solving the technical problem about high temperature and high voltage resistant performance and convenient production of the photoelectric composite optical fiber. The high temperature resistant photoelectric composite optical fiber for the oil well comprises an optical fiber unit, a conductor unit, a filling unit, a cladding unit and an armoring unit, wherein the optical fiber unit is positioned in a middle eccentric position of the composite optical fiber, and comprises an optical fiber of which the outer layer is coated with polyimide and a stainless steel tube for sleeving the optical fiber; the conductor unit is screwed and twisted with one side of the stainless steel tube; the filling unit is filled in a gap between the optical fiber unit and the conductor unit to jointly form a cable core; the cladding unit and the armoringunit are separately arranged on the outer side of the cable core from the inside to the outside; and the armoring unit comprises inner-layer armoring steel wires and outer-layer armoring steel wires with opposite twisting directions. The high temperature resistant photoelectric composite optical fiber for the oil well has the beneficial effect that the temperature and voltage resistant performanceof the composite optical fiber are improved.

Owner:SHANDONG PACIF OPTICS FIBER & CABLE CO LTD

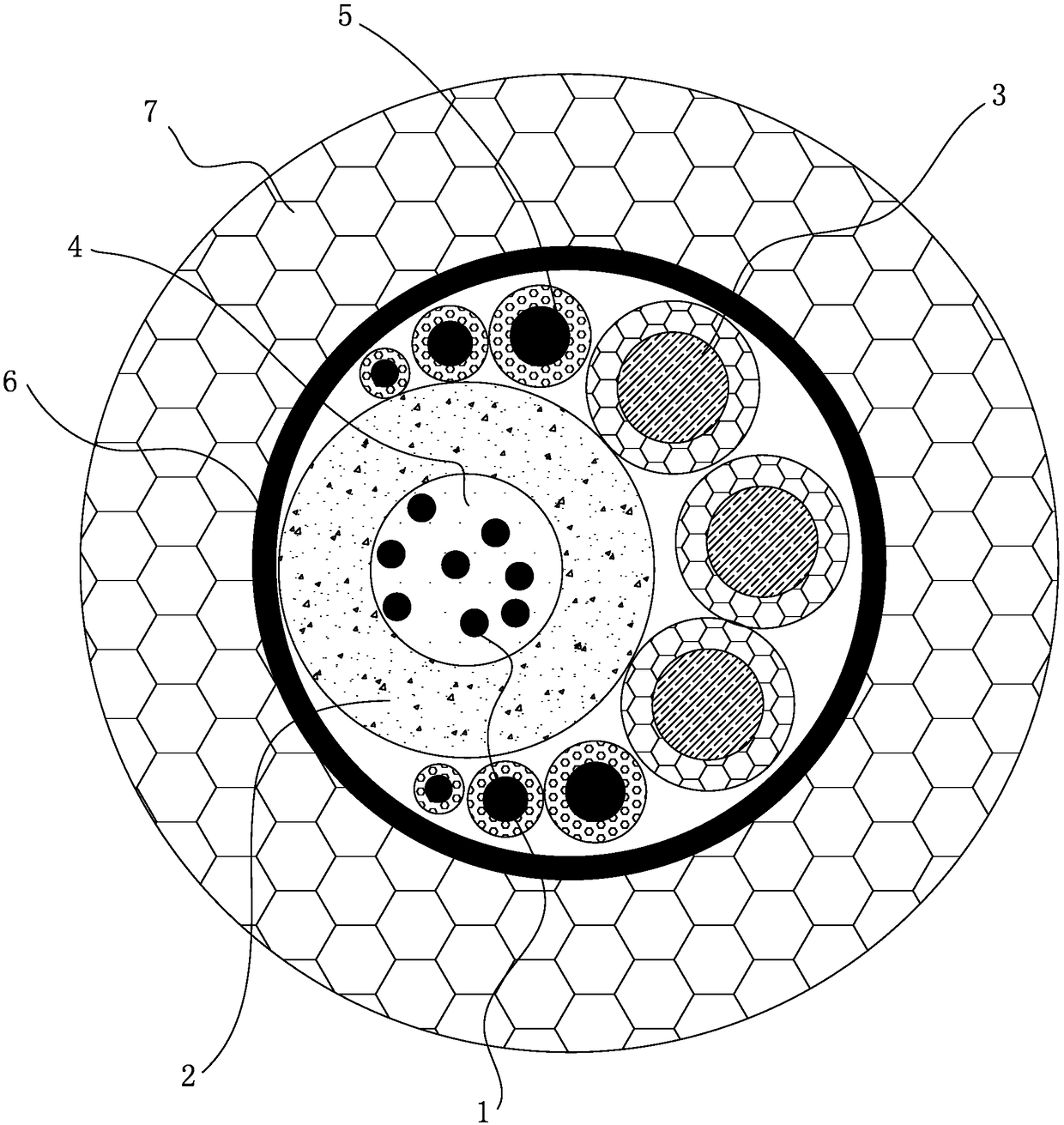

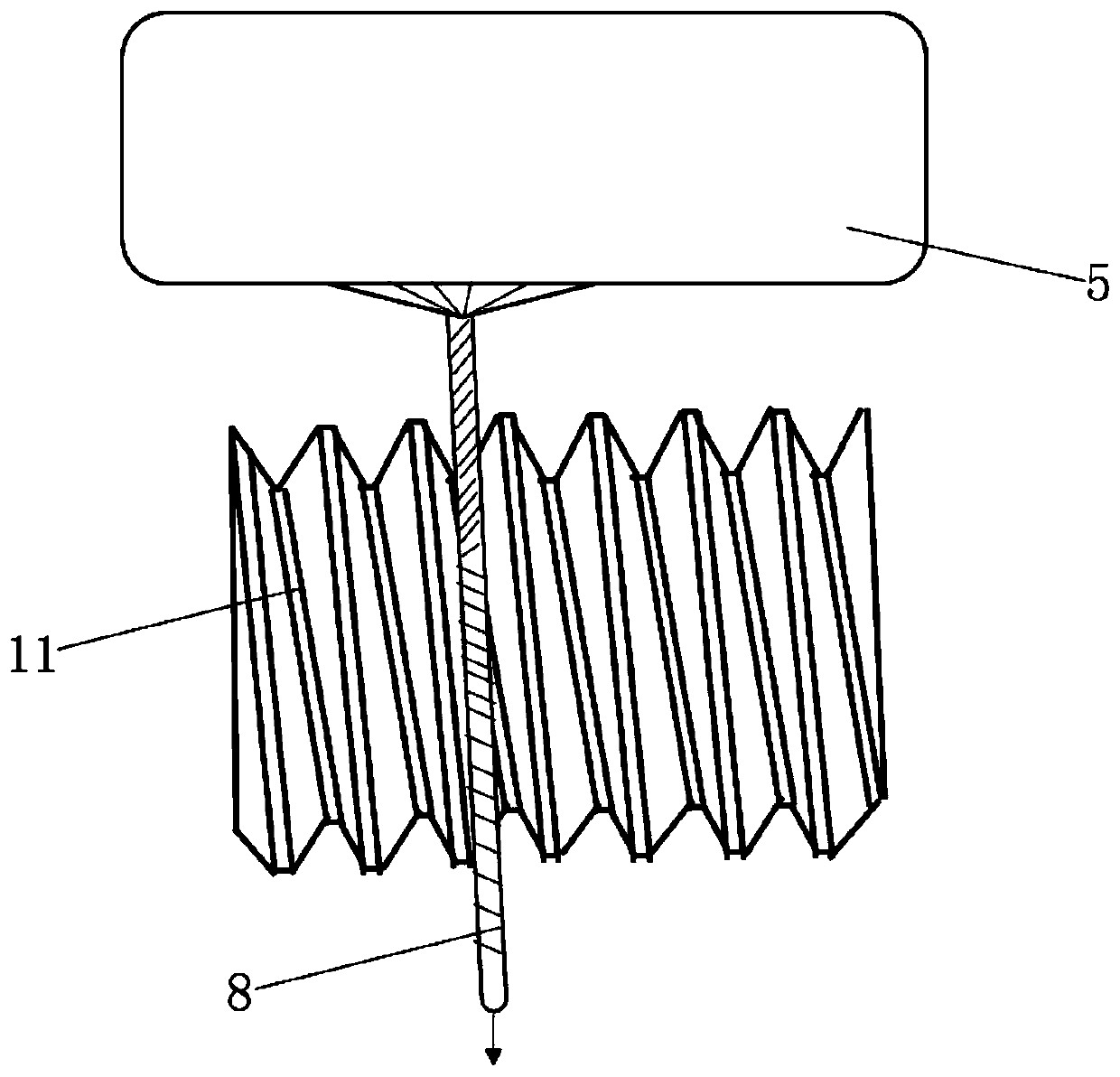

Spinning device for controlling fiber arrangement structure through synchronous rotation and spinning process thereof

The invention provides a spinning device for controlling a fiber arrangement structure through synchronous rotation. The spinning device comprises a first rotating shaft, a yarn pressing reed and a second rotating shaft, wherein the two ends of the first rotating shaft are fixed below a front jaw through bearings respectively; a fiber finishing section with a thread and a belt connecting section are arranged on the middle part of the first rotating shaft at intervals; the fiber finishing section is positioned under the front jaw; the belt connecting section is connected with a front roller through a belt; one end of the yarn pressing reed is movably pressed on the fiber finishing section; the second rotating shaft is positioned below the first rotating shaft; a thread is formed on the second rotating shaft; and the direction of the thread on the second rotating shaft is opposite to the direction of the thread in the fiber finishing section. The spinning device has the beneficial effects that the fiber structure of yarns is finished through the cooperation of the first rotating shaft and the second rotating shaft, so that the spun yarns have the advantages of being soft in hand feeling, high in strength, less in hairiness, stable in yarn levelness, small in residual torque and the like.

Owner:WUHAN TEXTILE UNIV

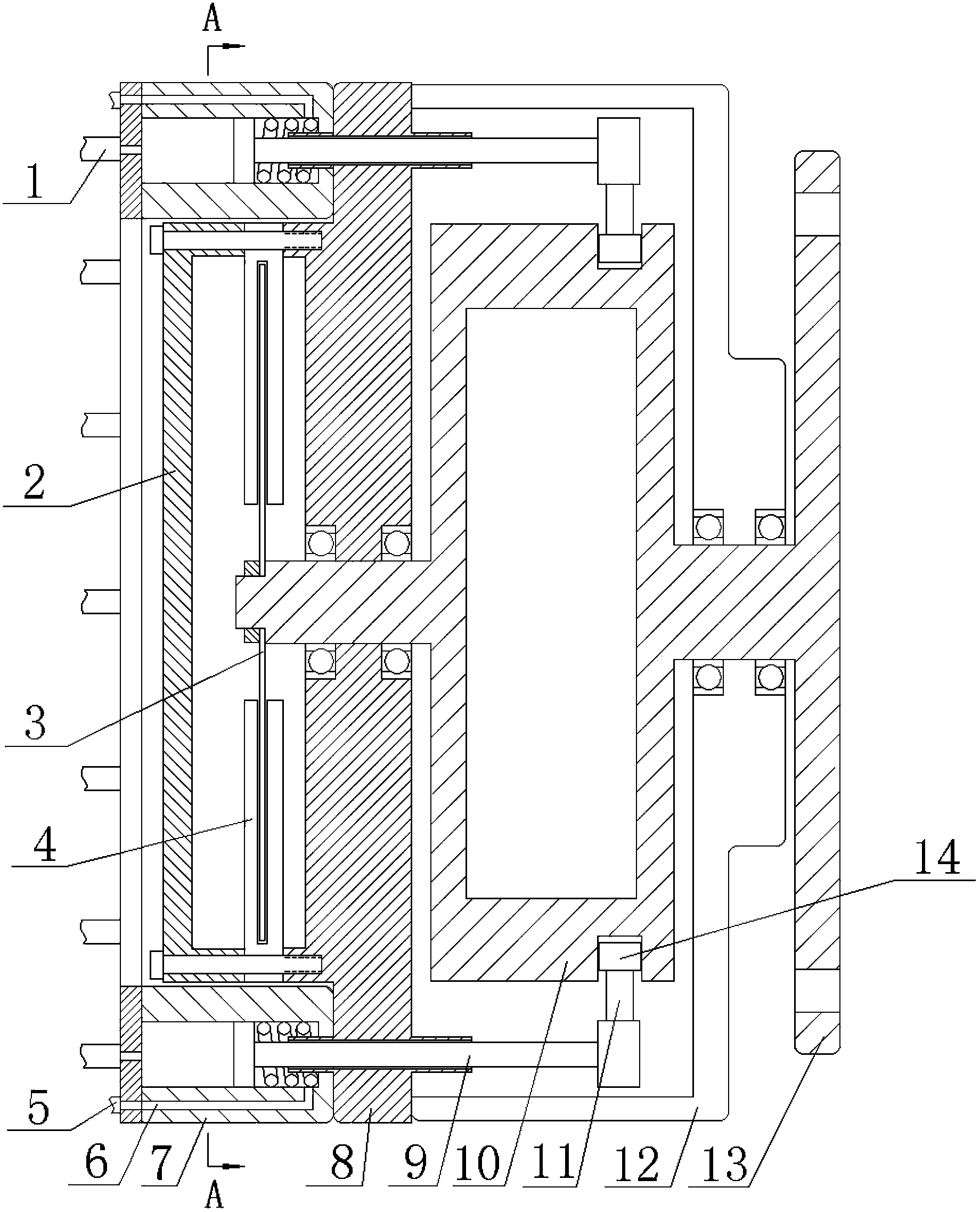

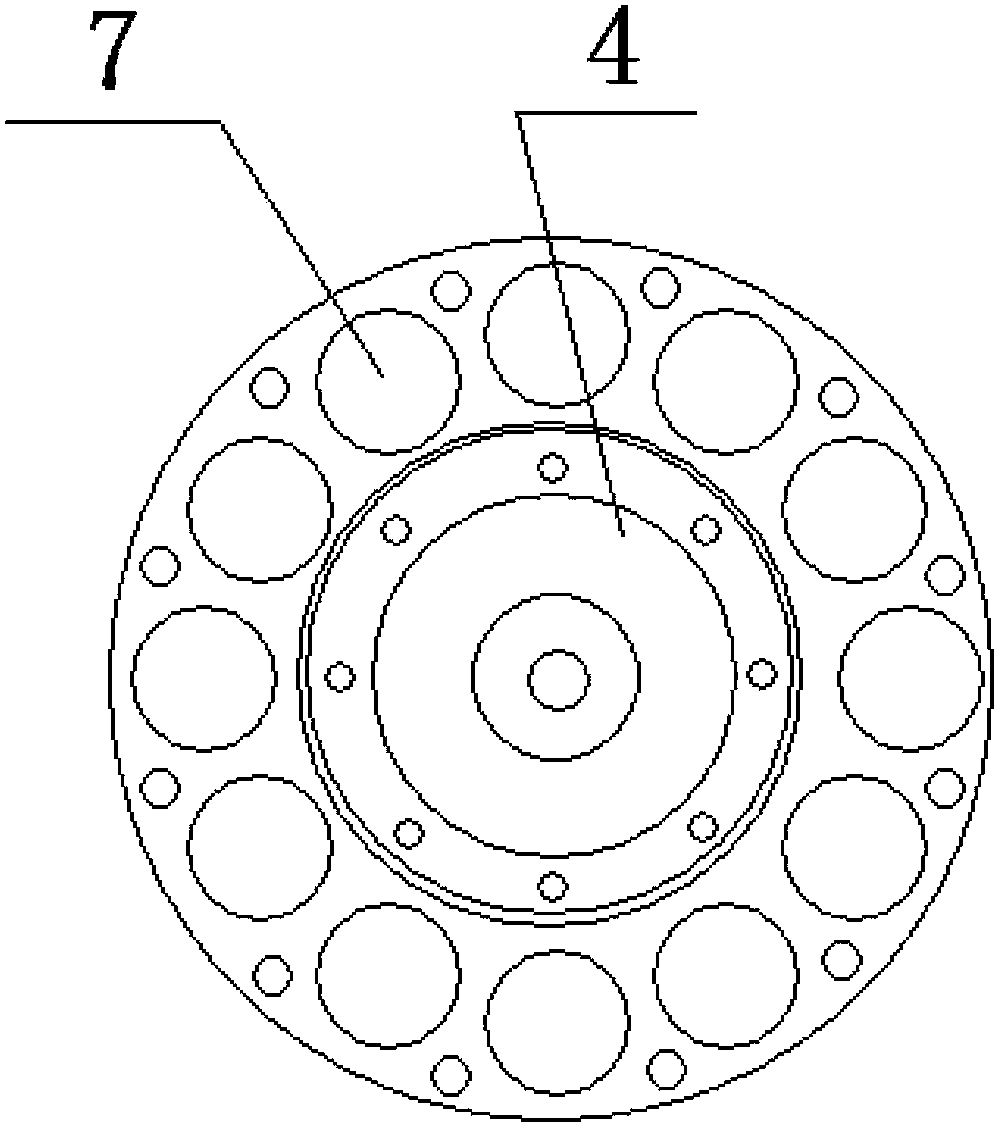

Shaft end motor of automobile electric control hydraulic independent shaft end driving system

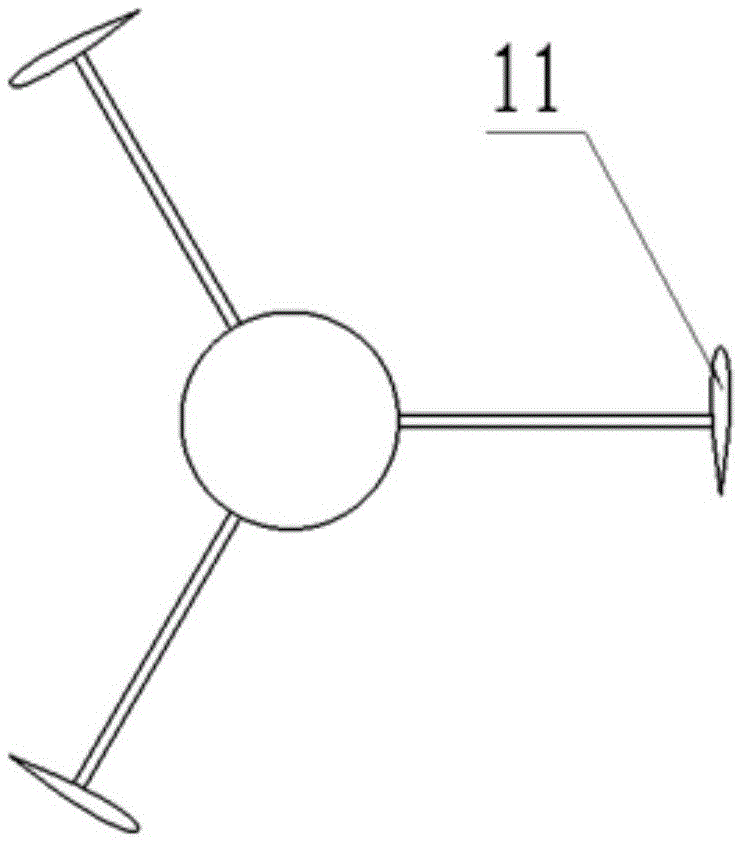

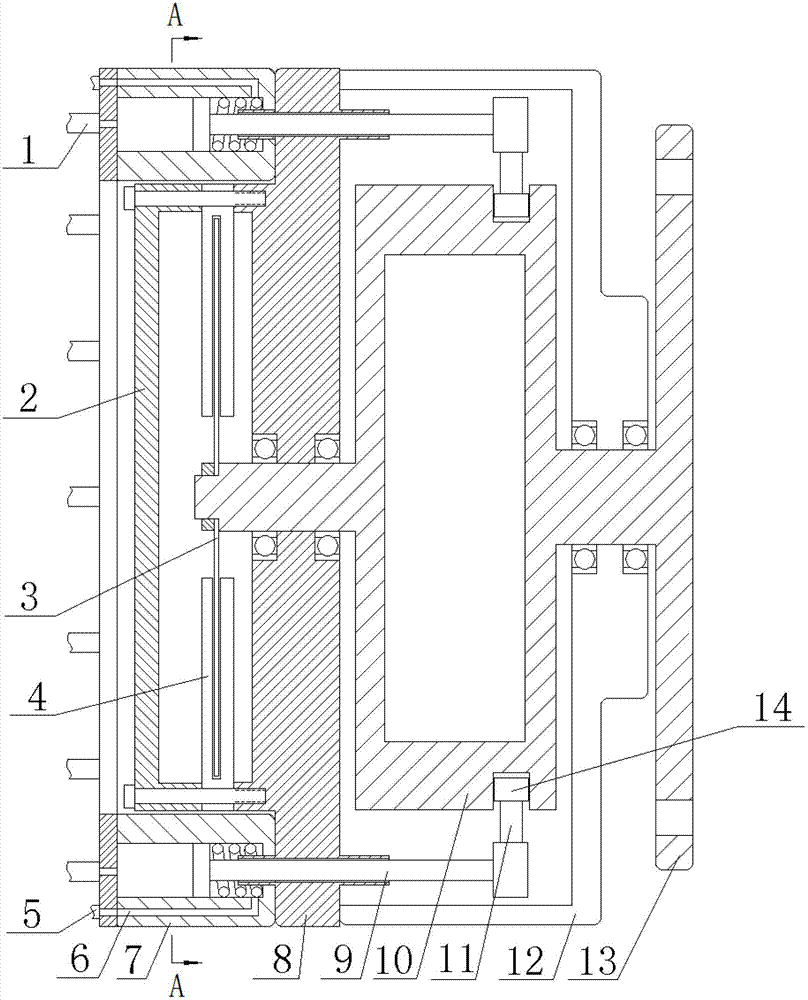

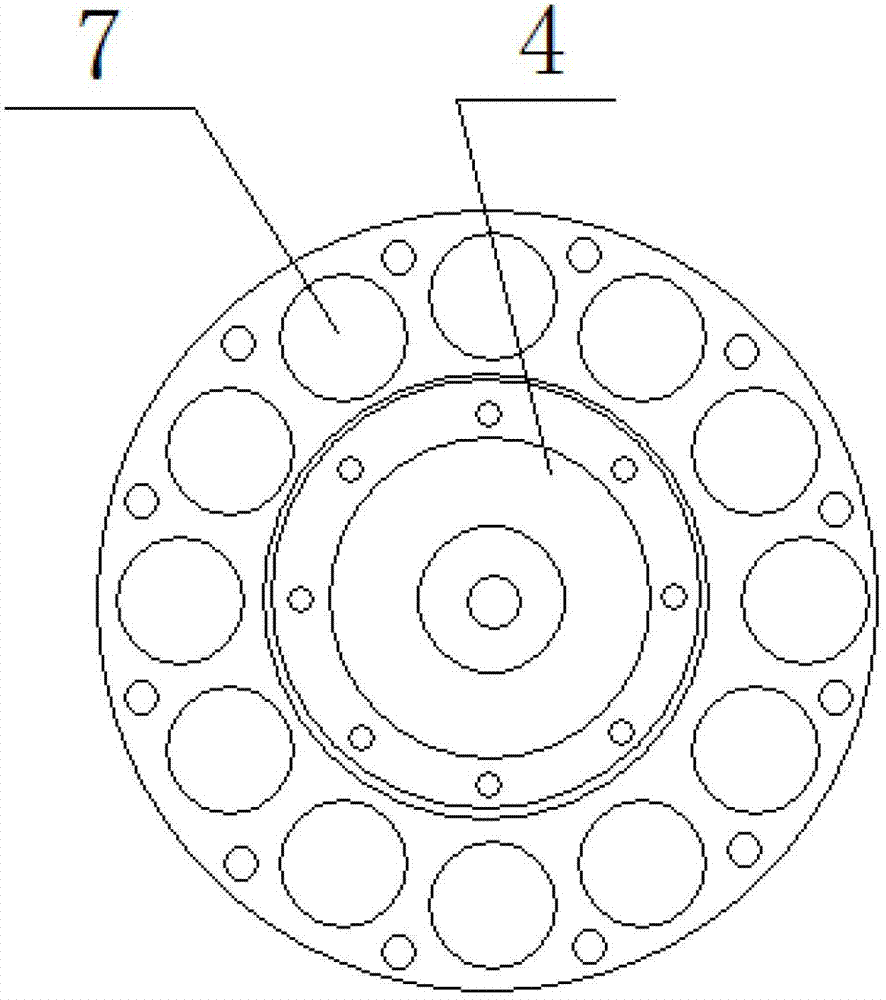

ActiveCN102900596ATorque balanceSmooth speed regulationReciprocating piston enginesHydraulic cylinderHydraulic motor

The invention provides a shaft end motor of an automobile electric control hydraulic independent shaft end driving system, aiming at solving the problems that the rotating speed and the output torque of a hydraulic motor are coordinated and matched and intelligently controlled by computer chips. The shaft end motor comprises a hydraulic oil cylinder, a host computer, an encoding disc and a sensor rest. The shaft end motor is mainly characterized in that a plurality of piston connecting rods and slide blocks of the hydraulic oil cylinder move around a rotor in a coordination manner; the straight reciprocating motion of the piston connecting rods and the slide blocks is converted into the circular motion through wave-shaped grooves arranged at the side plane of the rotor; the hydraulic oil cylinder is divided into A-phase, B-phase and C-phase which are arranged circularly; and the encoding disc connected with the rotor shaft end together and the sensor on the sensor rest transmit the position and the operation state information of the rotor to the computer chips to implement intelligent control.

Owner:吴亚利

Rotor engine with magnetic boosting

InactiveCN101046155ATorque balanceBalance energy outputInternal combustion piston enginesRotary piston enginesFlywheelEngineering

The rotor engine with magnetic boosting includes one rotor engine, one driving device for the rotor engine to drive one power output device, and one boosting device driven by the rotor engine. The present invention adopts boosting flywheel to counteract the resistance to the back assisting wheel alternately for the two rotors to rotate in the same direction and reduces the vibration and noise during operation.

Owner:陈维加

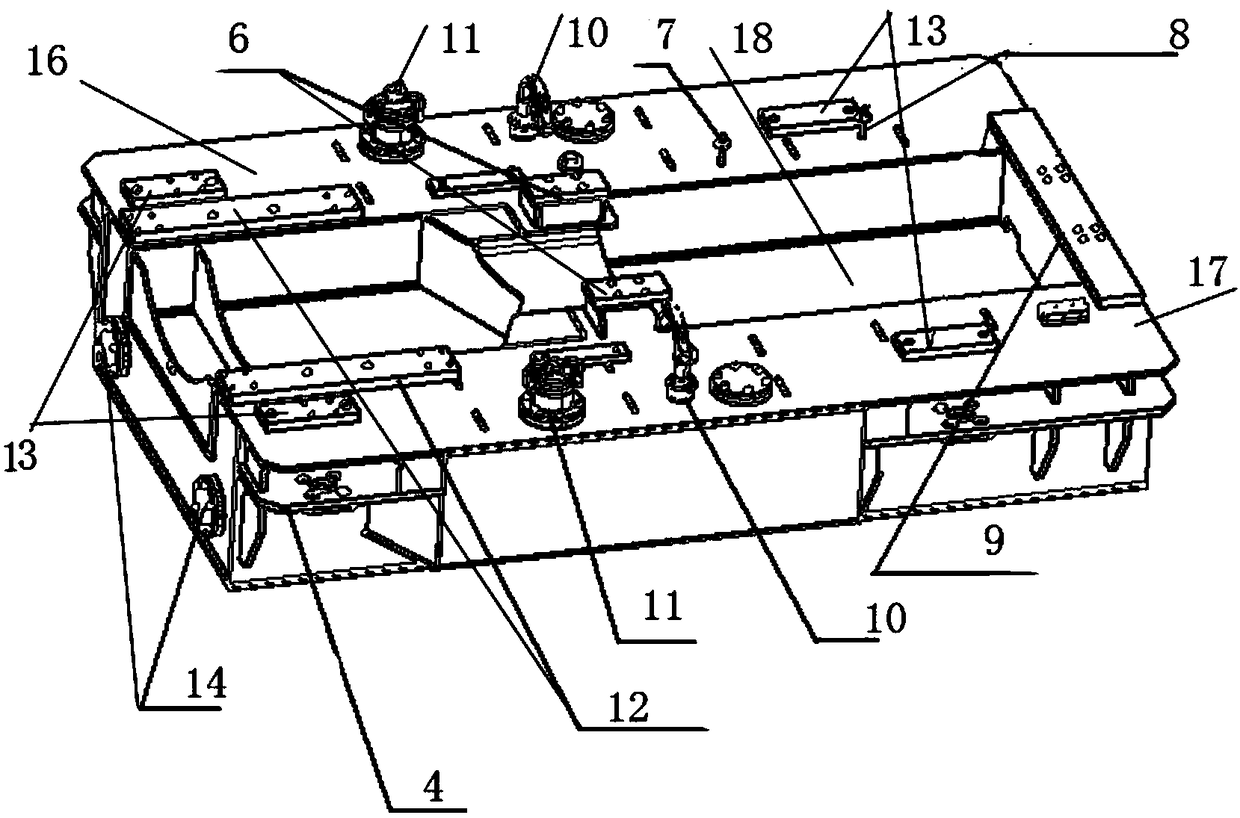

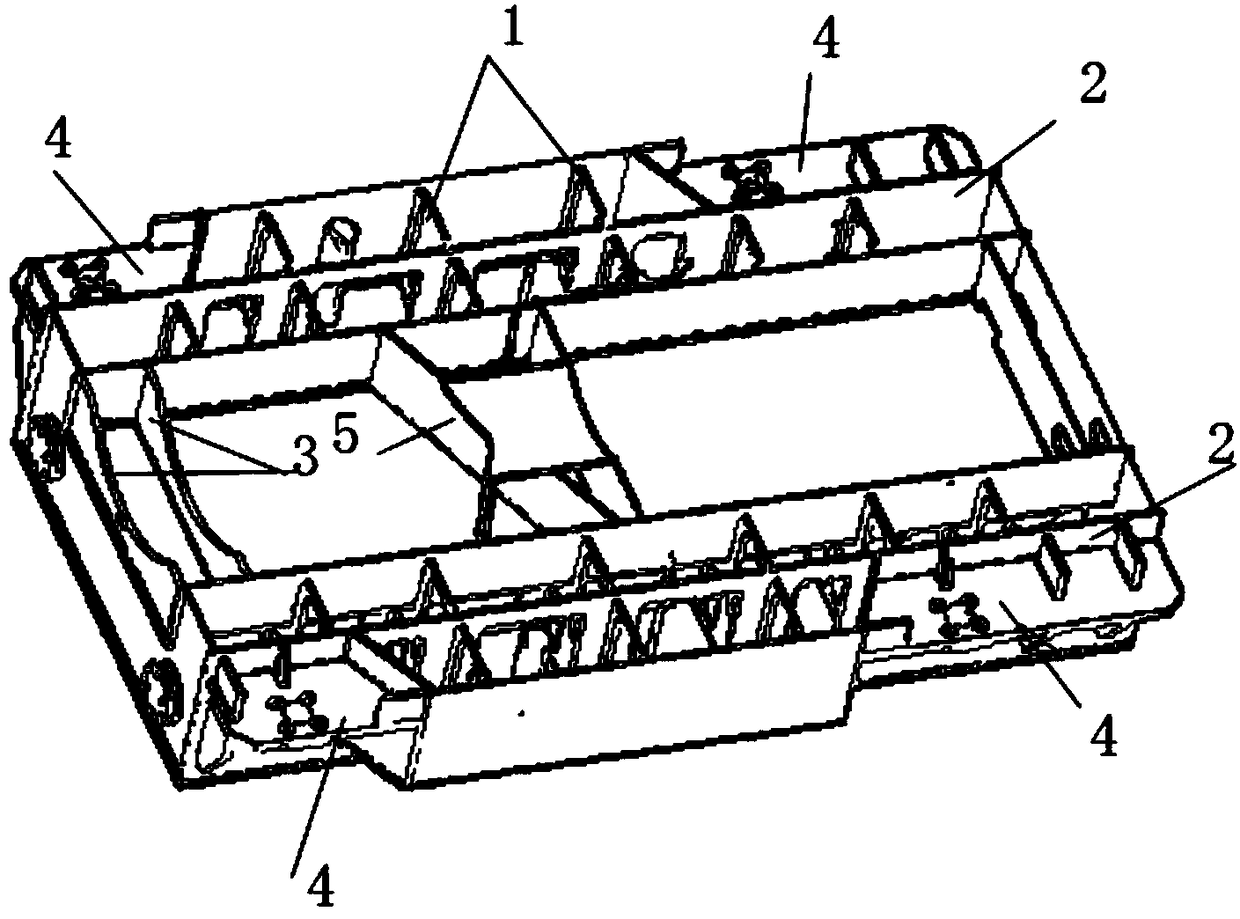

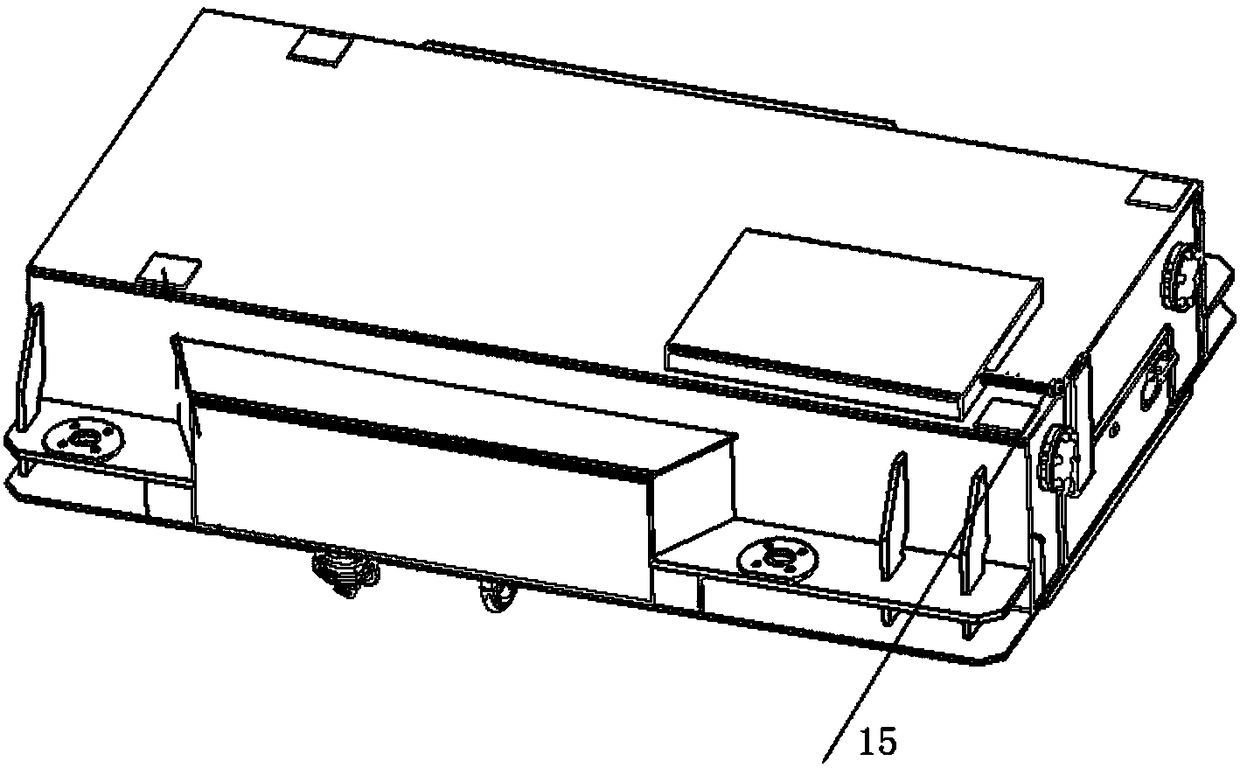

A diesel engine installation frame integrating a fuel tank

ActiveCN106428039BSave installation spaceGood for weight lossIC engine locomotivesGas turbine locomotivesFuel tankFuel oil

The invention provides a diesel engine installation frame integrated with a fuel tank. The diesel engine installation frame integrated with the fuel tank comprises a bottom plate. A fuel tank first part, a fuel tank second part, an oil collecting groove and a shock isolator installation seat are arranged on the bottom plate. The fuel tank first part and the fuel tank second part are arranged on the bottom plate oppositely, and the bottoms of the fuel tank first part and the fuel tank second part communicate with each other. The oil collecting groove is located between the fuel tank first part and the fuel tank second part. The shock isolator installation seat is located on an installation seat. A traditional fuel tank is changed into a support where a motor and a diesel engine can be placed, and the support contains fuel oil through a support inner cavity. The surface of the support is provided with an oil return port, an oil sucking port, an atmosphere communication pipe and an oil adding port universal for existing fuel engines. The supporting force of the support is increased by arranging a transverse separating frame and a longitudinal separating frame. The installation positions of a motor installation seat and a diesel engine installation seat are arranged reasonably, so that the installation frame is stressed uniformly.

Owner:CRRC ZIYANG CO LTD

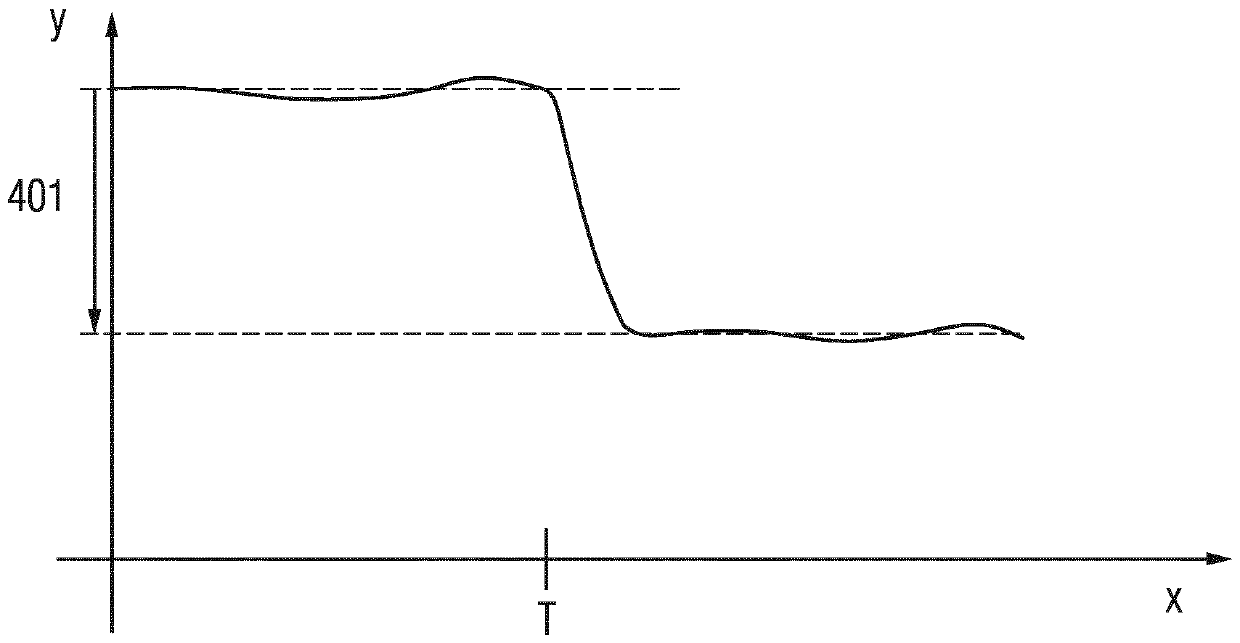

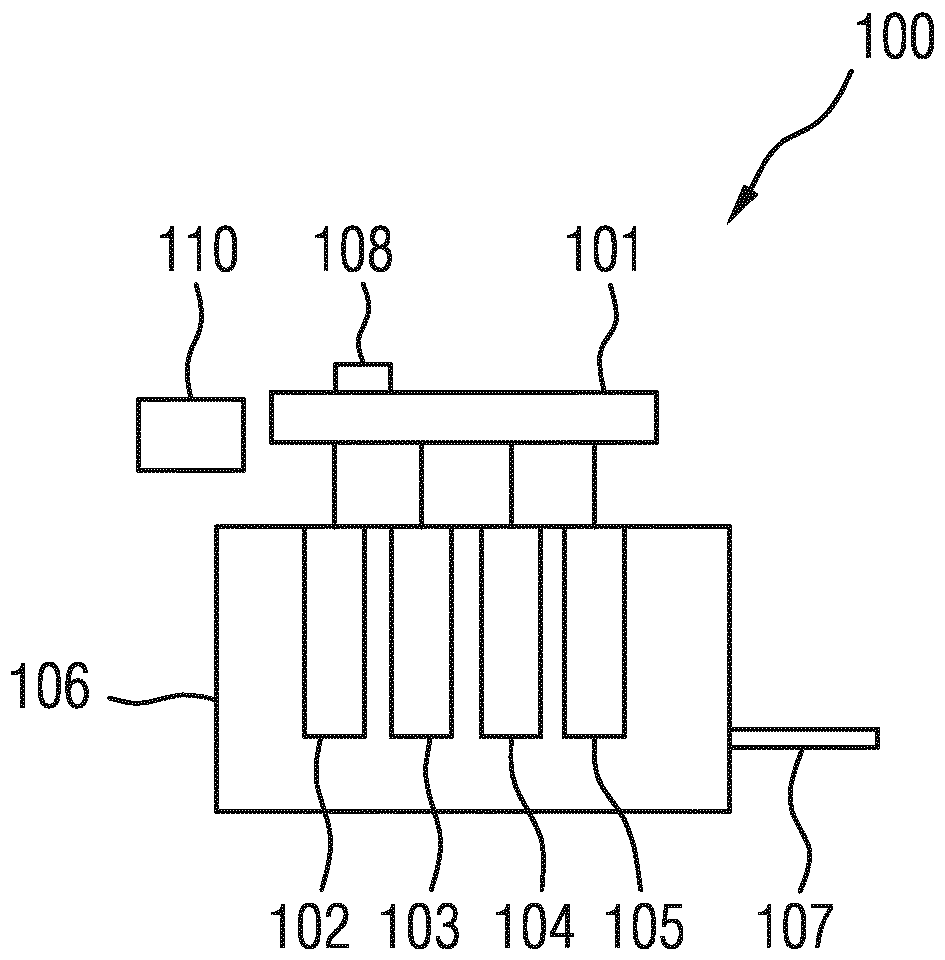

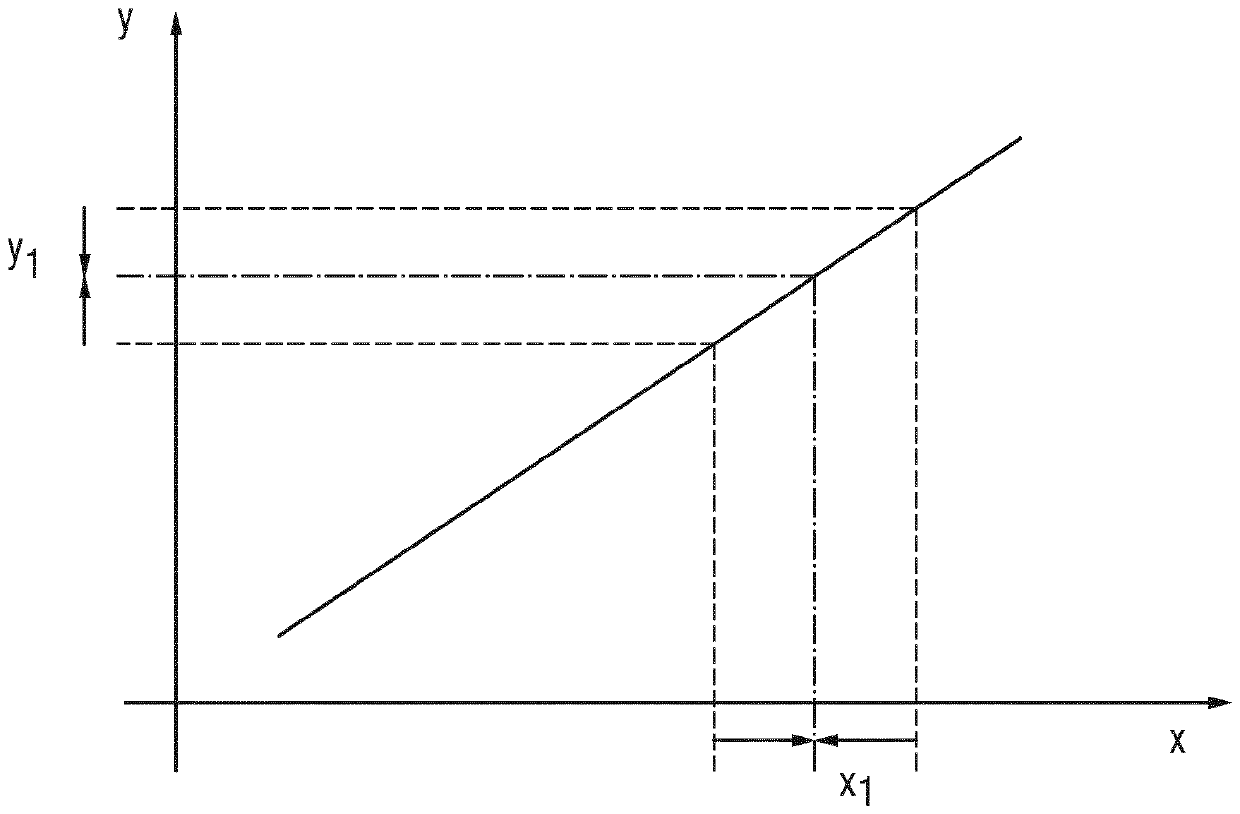

Method and device for operating an internal combustion engine

ActiveCN109964021ATorque output is obtainedTorque balanceElectrical controlInternal combustion piston enginesInternal combustion engineControl theory

The invention relates to a method for operating an internal combustion engine (106) having at least two cylinders (102, 103, 104, 105) for a motor vehicle, comprising: determining a respective torqueoutput of the cylinders (102, 103, 104, 105), which occurs due to an injection of fuel into the respective cylinder (102, 103, 104, 105), determining a difference in the torque outputs, comparing thedifference in torque outputs to a specified threshold value for the torque output, determining a respective injection mass of the respective injection into the respective cylinder (102, 103, 104, 105), determining a difference in the injection masses, comparing the difference in the injection masses to a specified threshold value for the injection mass and, if the determined differences exceed therespective associated threshold, determining whether the respective torque outputs correspond with the associated injection mass and, if the respective torque outputs are outside of a specified tolerance range for a respective corresponding injection mass, modifying an injection time (T) in at least one of the cylinders (102, 103, 104, 105).

Owner:VTESCO TECH GMBH

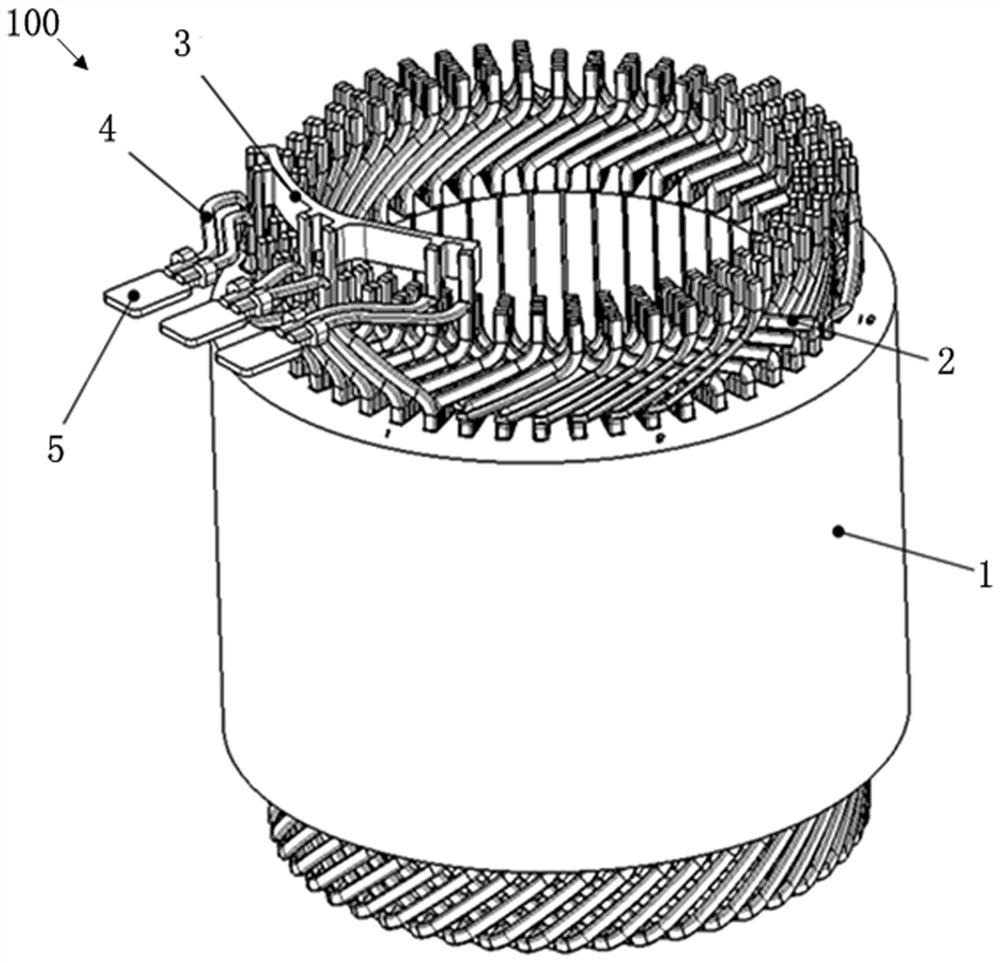

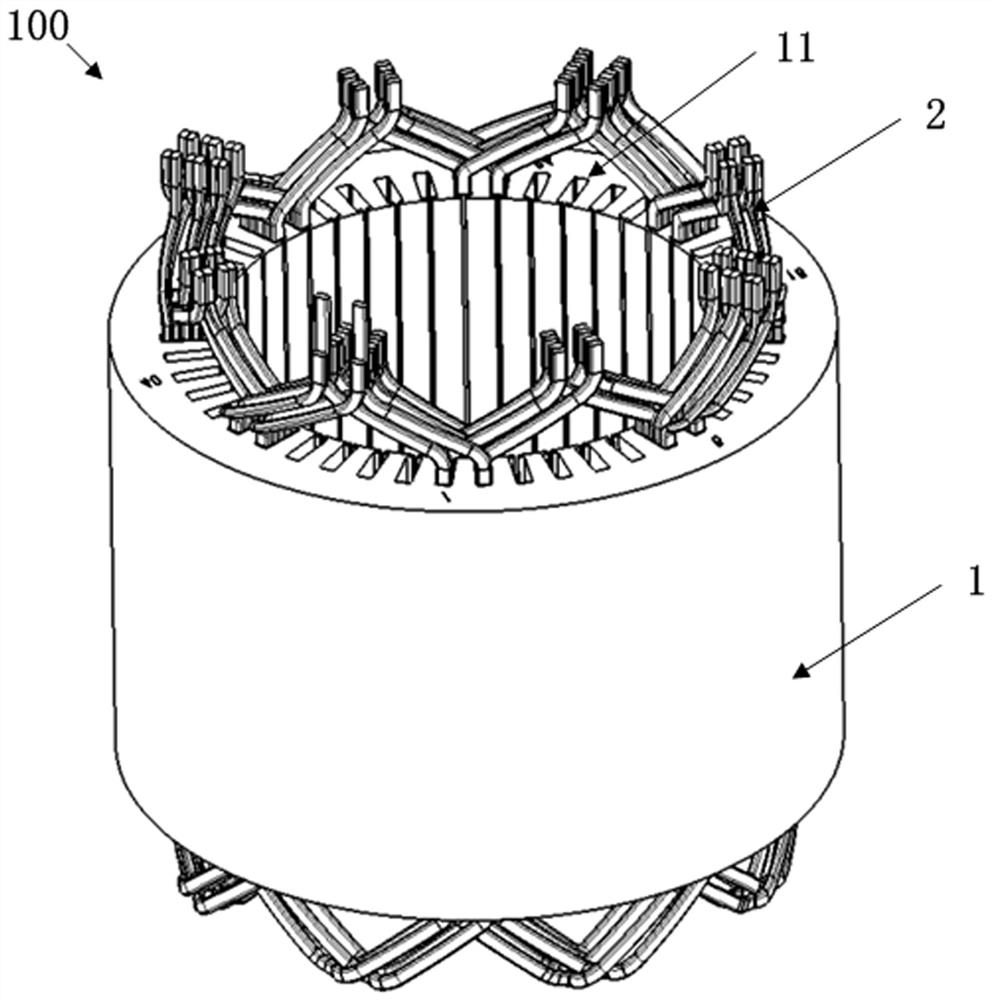

Motor stator, manufacturing method of motor stator and hairpin motor

PendingCN113629906AIncrease powerIncrease torqueMagnetic circuit stationary partsEmbedding prefabricated windingsElectrical conductorElectric machine

The invention discloses a motor stator, a manufacturing method of the motor stator and a hairpin motor. Independent loops forming the first-phase winding, the second-phase winding and the third-phase winding in the motor stator are respectively and sequentially arranged in three adjacent continuous winding grooves in a staggered manner, each independent loop is formed by alternately connecting winding coils with the span of (1+3m) winding grooves, and m is a positive integer; a repeated winding unit is contained in three adjacent winding grooves forming an independent loop and having the span of (1+3m) winding grooves, and the repeated winding unit is formed in the three adjacent winding grooves through two-time lap winding, one-time wave winding and two-time lap winding. The number of conductors in each winding groove is set to be odd number layers, the winding mode is simple, the adjustability of the number of turns of the winding is improved, the power and torque during motor design are balanced, the collector ring is simplified, and the wire outlet height is reduced.

Owner:上海伊控动力系统有限公司

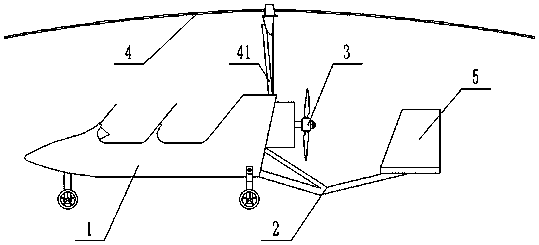

Parallel twin-type rotary-rotor aircraft

The invention discloses a parallel twin-type rotary-rotor aircraft and belongs to the technical field of aircrafts, in particular to a rotary-rotor aircraft with torque balance on both sides. The technical scheme includes that the parallel twin-type rotary-rotor aircraft comprises a fuselage, a frame, two power units, rotors and a tail; the fuselage is fixed onto the front end of the frame, the power units are symmetrically arranged on two rear sides of the fuselage, the rotors are arranged above the rear portion of the fuselage and are connected with the frame fixedly through a main column, the tail is fixed onto the rear end of the fuselage, the tail has two paired vertical tail fins, and the two tail fins of the tail are respectively arranged right behind the power units. The parallel twin-type rotary-rotor aircraft is widely applicable to the fields of searching, tourism, surveying, forest fire prevention, agricultural planting and the like.

Owner:黄鹏

Automatic speed-changing wide-swing-angle oil pumping machine

InactiveCN102808602BSolve the oil spill problemImprove oil pumping efficiencyGearingFluid removalRocker armCrankshaft

The invention relates to the technical field of oil extraction machinery, in particular to an automatic speed-changing wide-swing-angle oil pumping machine. The automatic speed-changing wide-swing-angle oil pumping machine comprises an electric motor, a speed changing mechanism, a swing arm support, a swing arm arranged on the swing arm support, a support provided with a fixed pulley and a wellhead oil pumping device, wherein the speed changing mechanism is connected with a driving crankshaft wheel, the driving crankshaft wheel is meshed with a driven crankshaft wheel, the driving crankshaft wheel is connected with a connecting piece through a bearing, one end of the connecting piece is connected with the driven crankshaft wheel, the other end of the connecting piece is connected with the swing arm through a connecting rod, a sliding chute is arranged on the connecting piece of which one end is connected with the driven crankshaft wheel, and a bearing on the driven crankshaft wheel is sleeved in the sliding chute. The automatic speed-changing wide-swing-angle oil pumping machine disclosed by the invention has the advantages that when the two crankshaft wheels are in rotation, since the position of the bearing of a driven pulley is changed, the position of the connecting piece can be also correspondingly changed, a motion trail of the connecting rod is affected by the motion of the connecting piece, the speed of the wellhead oil pumping device in the up-stroke is higher than that in the down-stroke, the oil leakage problem existing in an oil pumping process is avoided, and the oil pumping efficiency is increased.

Owner:德阳振华机械设备制造有限公司

Shaft end motor of automobile electric control hydraulic independent shaft end driving system

ActiveCN102900596BTorque balanceSmooth speed regulationReciprocating piston enginesHydraulic cylinderHydraulic motor

The invention provides a shaft end motor of an automobile electric control hydraulic independent shaft end driving system, aiming at solving the problems that the rotating speed and the output torque of a hydraulic motor are coordinated and matched and intelligently controlled by computer chips. The shaft end motor comprises a hydraulic oil cylinder, a host computer, an encoding disc and a sensor rest. The shaft end motor is mainly characterized in that a plurality of piston connecting rods and slide blocks of the hydraulic oil cylinder move around a rotor in a coordination manner; the straight reciprocating motion of the piston connecting rods and the slide blocks is converted into the circular motion through wave-shaped grooves arranged at the side plane of the rotor; the hydraulic oil cylinder is divided into A-phase, B-phase and C-phase which are arranged circularly; and the encoding disc connected with the rotor shaft end together and the sensor on the sensor rest transmit the position and the operation state information of the rotor to the computer chips to implement intelligent control.

Owner:吴亚利

A horizontal well coiled tubing drill string

ActiveCN106321004BEliminate the problem of blocked entrySolve the problem that is not in placeBorehole/well accessoriesCoiled tubingDrill pipe

The invention provides a horizontal well coiled tube drilling plug tubular column which comprises a milling shoe, a motor, a motor head, an anchoring and pressurizing device and a jar knocker, wherein the milling shoe, the motor, the motor head, the anchoring and pressurizing device and the jar knocker are sequentially connected. The horizontal well coiled tube drilling plug tubular column comprises the anchoring and pressurizing device which can anchor a drilling plug tubular column body into a horizontal well casing tube. After the drilling plug tubular column body is anchored into the horizontal well casing tube through the anchoring and pressurizing device, the milling shoe is pressurized to guarantee the drilling pressure of the milling shoe. The anchored drilling plug tubular column can balance the axial force generated when the milling shoe drills and removes a bridge plug, and the drilling process of the milling shoe is stable. Accordingly, the efficiency of the drilling and removing of the bridge plug is improved, and the time for drilling and removing the bridge plug is shortened.

Owner:CHINA PETROLEUM & CHEM CORP +1

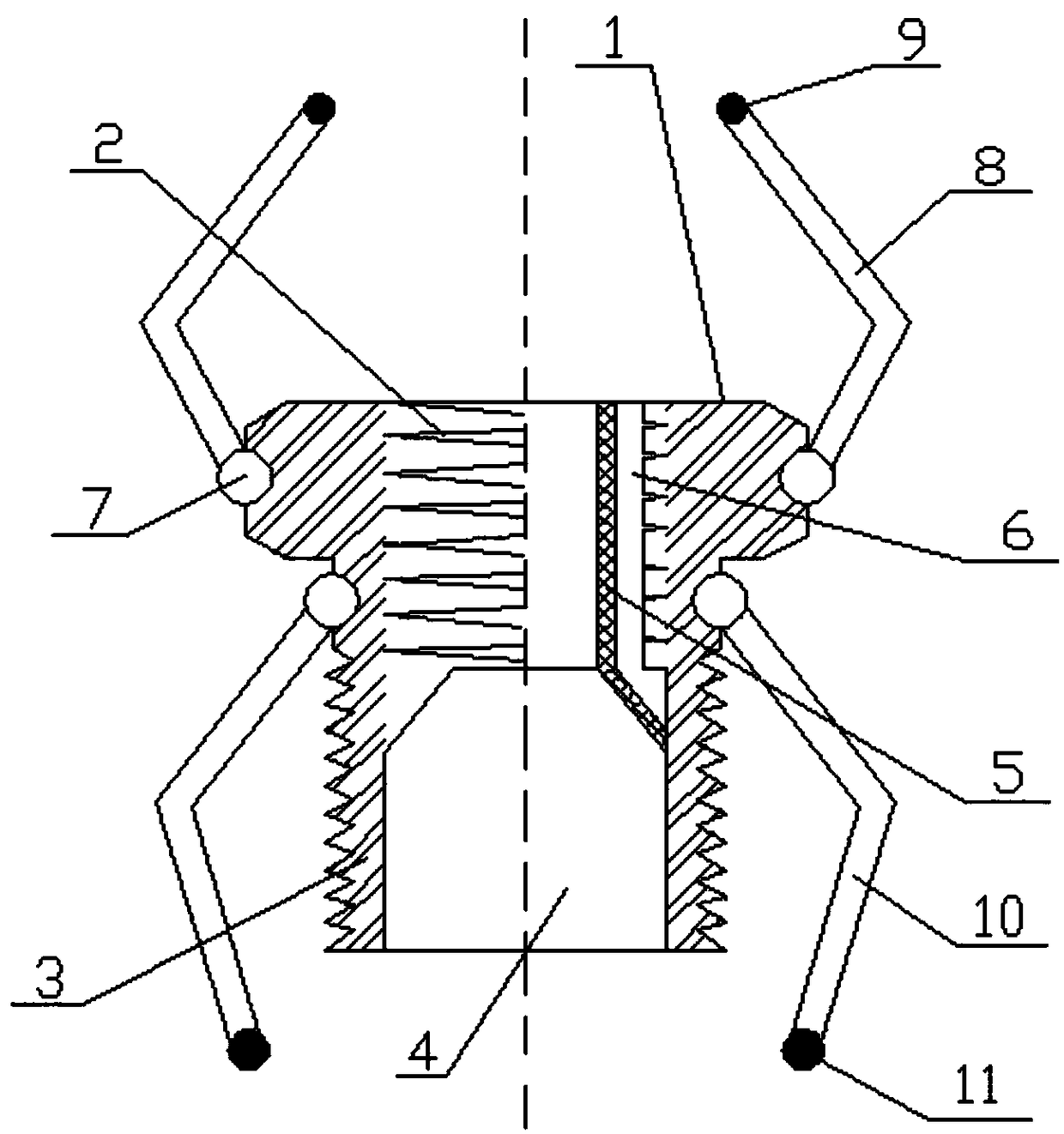

Wear-resistant reinforced reducer joint

The invention discloses a wear-resistant reinforced reducer joint, which comprises a reducer joint body. The top of the reducer joint body is provided with an inner wire, the bottom of the reducer joint body is provided with an outer wire, a passage axially penetrates through the middle of the reducer joint body, the top of the passage is provided with an inner sleeve, a connecting slot is formedbetween the inner sleeve and the inner wire, a plurality of first pressure arms are arranged on the top of the outer surface of the reducer joint body and are rotatably connected to the reducer jointbody by torsion springs, and the free ends of the first pressure arms are provided with first pressure heads; the middle part of the outer surface of the reducer joint body is provided with a plurality of second pressure arms, the second pressure arms are rotatably connected with the reducer joint body through torsion springs, the free ends of the second pressure arms are provided second pressureheads, the first pressure arms applies pressure to the top of the reducer joint body, and the second pressure arms applies pressure to the bottom of the reducer joint body. The wear-resistant reinforced reducer joint has good wear resistance, is unlikely to loose, and has good structural stability.

Owner:江苏迪威高压科技股份有限公司

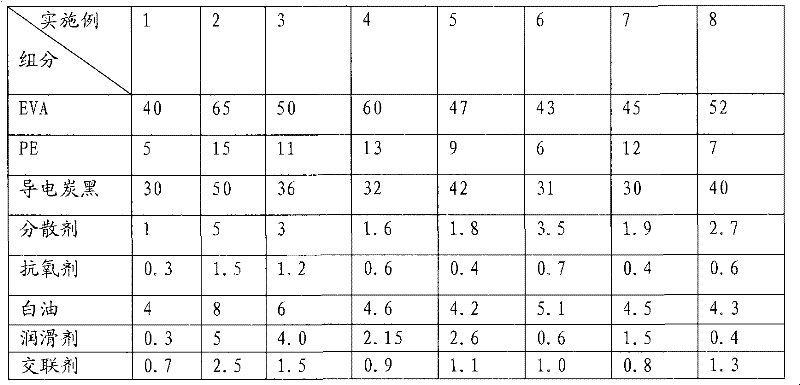

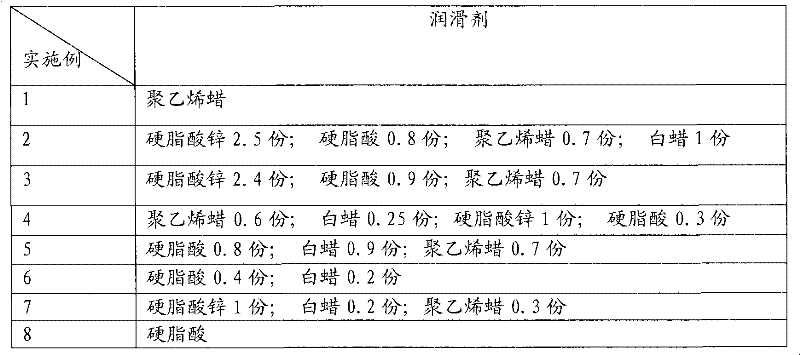

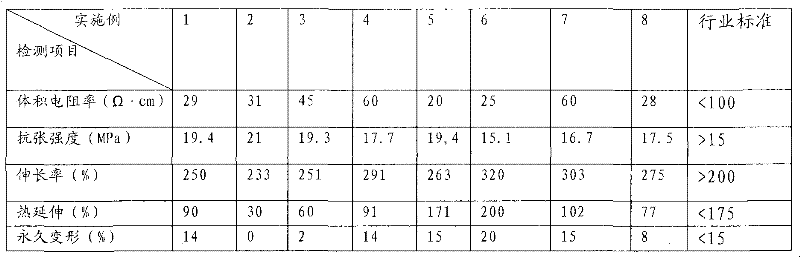

Screen material for 35kV grade high/medium voltage crosslinked cable conductor layer and preparation method thereof

ActiveCN101817950BEvenly dispersedLittle fluctuation in wire diameterPower cables with screens/conductive layersNon-conductive material with dispersed conductive materialCross-linkElectrical conductor

Owner:ENLEMAN INSTR (XUZHOU) CO LTD

Improved Power Maintenance Foot Climb

The invention relates to an improved power repair feet crawler. The improved power repair feet crawler comprises a main crawling machine; the side surface of the main crawling machine, facing an electric pole, is an arc-shaped crawling surface; universal rotating wheels are arranged at equal intervals on the crawling surface and electrically connected to a controller; a cable chute is formed in the crawling surface; a crawling cable is mounted in the cable chute, and threads are formed in the surface of the crawling cable; closed lock buckles are mounted at two ends of the crawling cable; the crawling cable is manufactured from non-stretching and bendable wearable materials; the crawling cable engages with a driving wheel; the driving wheel rotatably sleeves an adjusting shaft parallel to the electric pole; the adjusting shaft can horizontally move in an adjusting groove at the back of the main crawling machine in the radial direction of the electric pole. The feet crawler has a small size, and is convenient to carry, applicable to the electric poles of various sizes, safe and reliable, and simple to operate.

Owner:STATE GRID JIANGXI ELECTRIC POWER CO +1

Drive device for wind turbine

Drive device for a wind mill comprising a large pulley (21) disposed on a main shaft (22) and at least one belt (27) or chain adapted to transfer rotation from the pulley (21) to a generator (30, 31). The pulley (21) is rotationally coupled to at least two secondary shafts (23, 24), which are disposed parallel to the main shaft (22). One or more belts (27), which transfer the rotation, extend over the pulley (21) and the secondary shafts (23, 24). The secondary shafts (23, 24) are in turn rotationally coupled to at least one, preferably two, electric generators (30, 31).

Owner:VESTAS WIND SYST AS

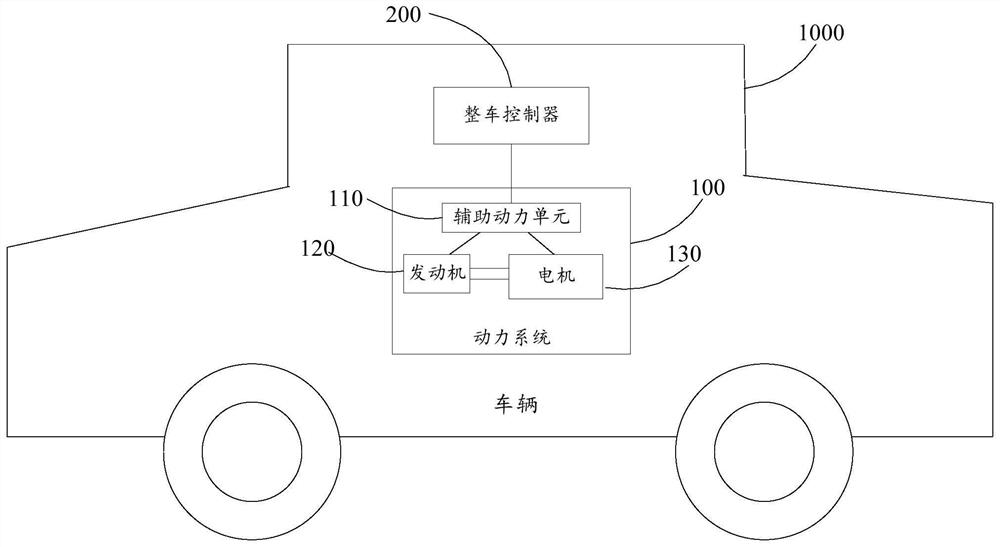

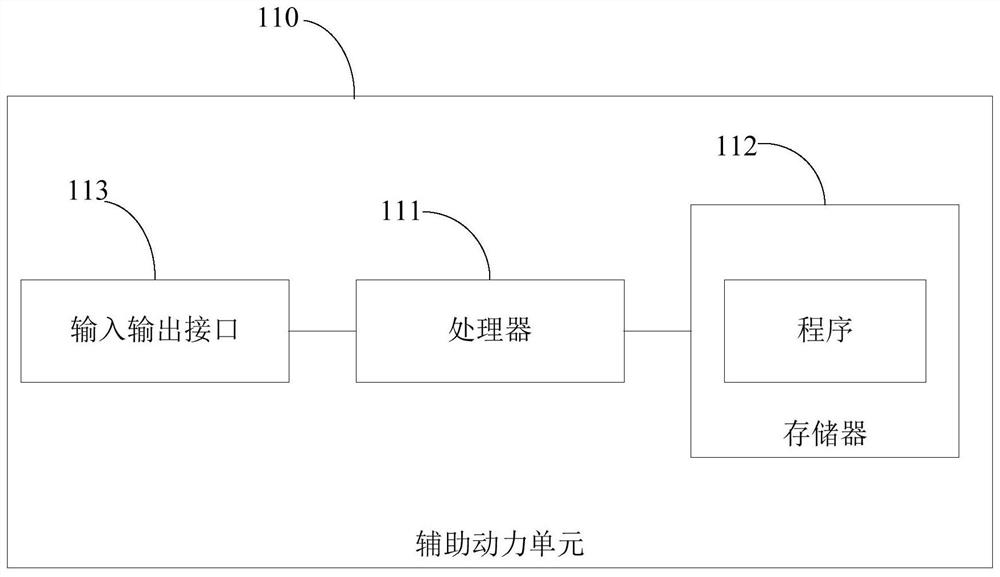

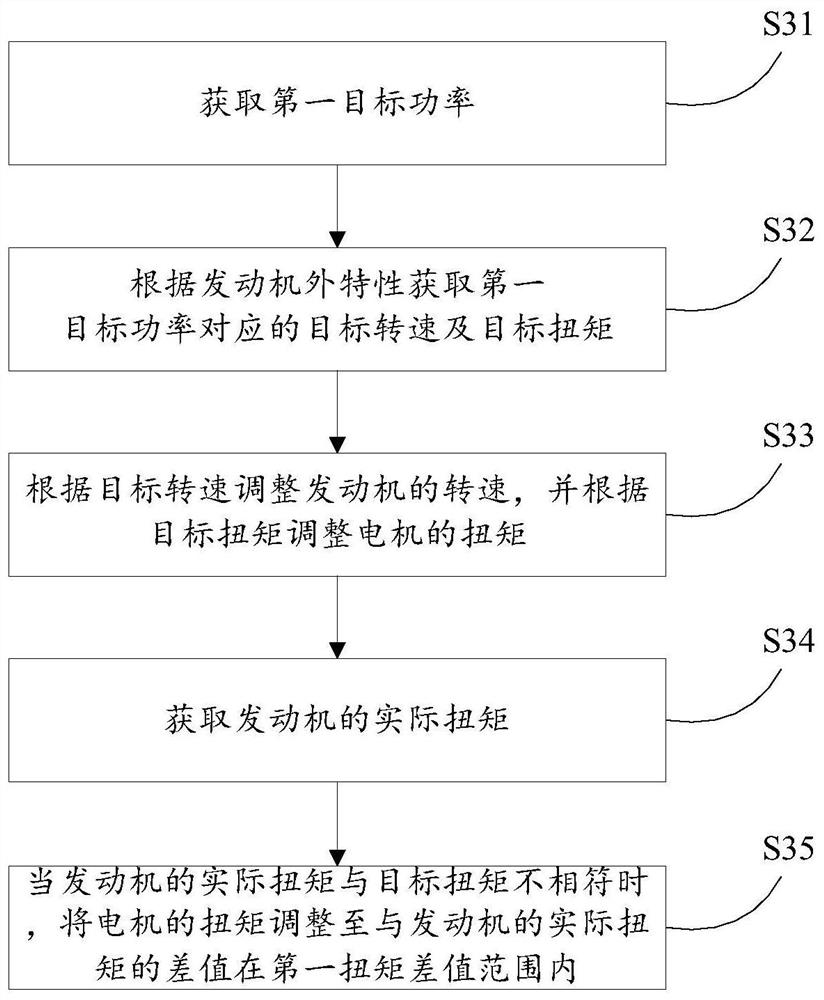

Control methods and related products

ActiveCN110962832BOperational controlShort response timeHybrid vehiclesElectric machineryControl theory

Owner:重庆长安工业(集团)有限责任公司深圳分公司

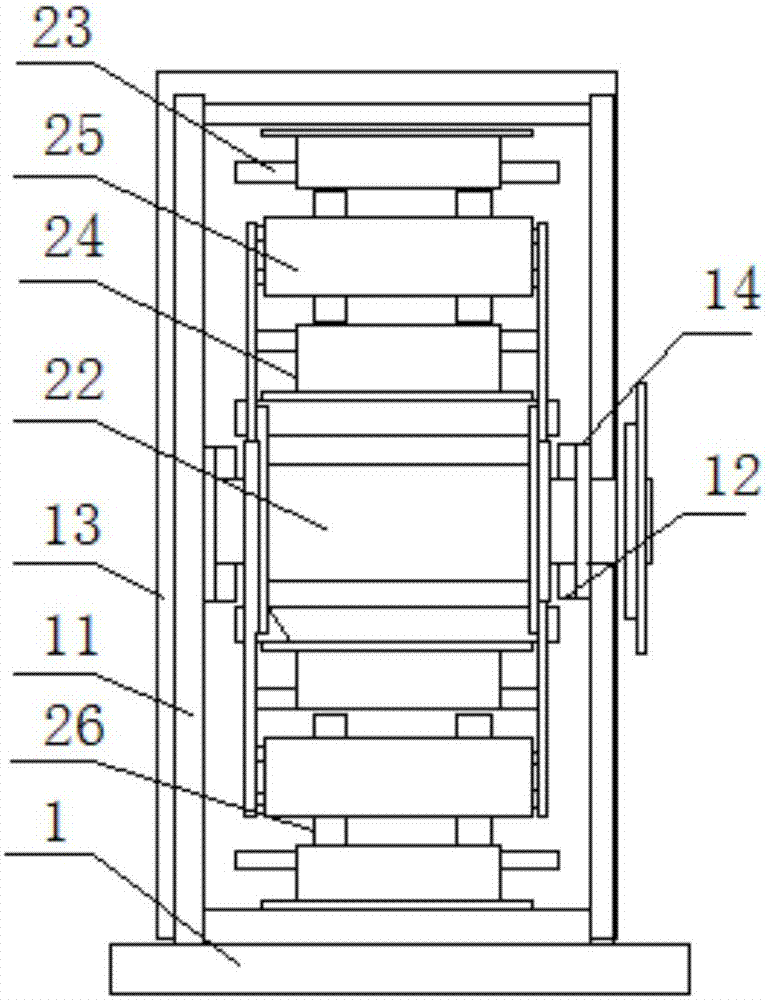

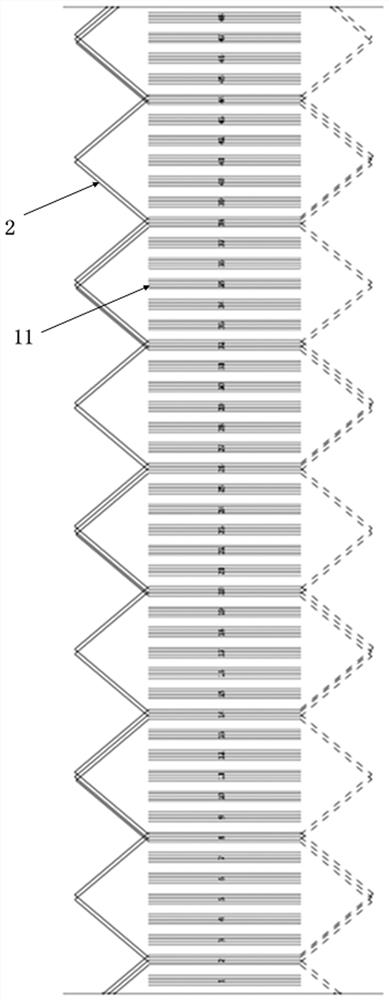

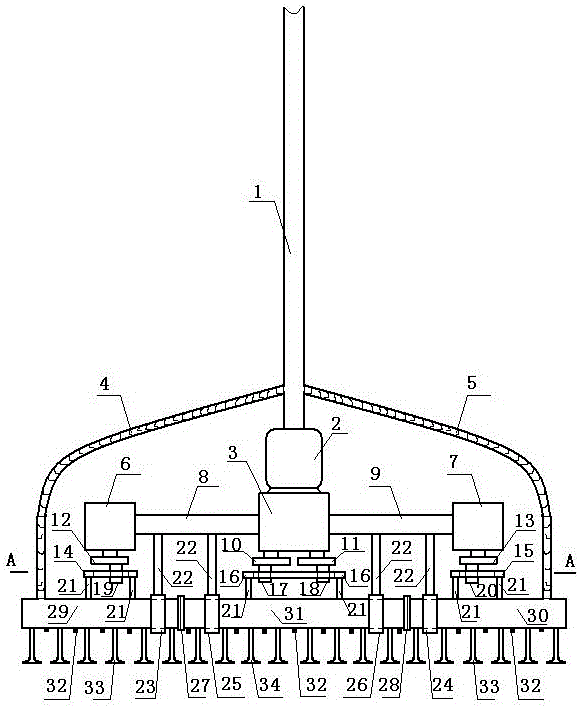

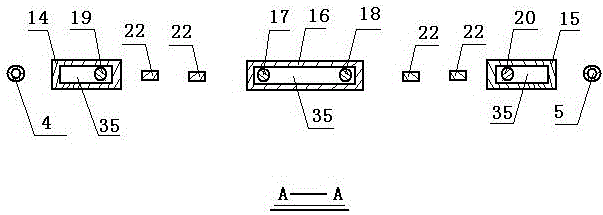

Equal-thickness cement soil wall building machine

Provided is an equal-thickness cement soil wall building machine. A first cylinder and a second cylinder are output at the lower end of a first transfer case. A first shaft is fixed to the lower surface of the first cylinder within the radius range and inserted into the left end of a rectangular hole of a first rectangular frame. A second shaft is fixed to the lower surface of the second cylinder within the radius range and inserted into the right end of the rectangular hole of the first rectangular frame. A second transfer case is arranged on the left side of the first transfer case and connected with the first transfer case through a first link arm. A third cylinder is output at the lower end of the second transfer case. A third shaft is fixed to the lower surface of the third cylinder within the radius range and inserted into the right end of a rectangular hole of a second rectangular frame. A third transfer case is arranged on the right side of the first transfer case and connected with the first transfer case through a second link arm. A fourth cylinder is output at the lower end of the third transfer case. A fourth shaft is fixed to the lower surface of the fourth cylinder within the radius range and inserted into the left end of a rectangular hole of a third rectangular frame.

Owner:宋姝娴

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com