Rotor engine with boosting flywheel

A technology of rotary engine and gear transmission mechanism, applied in the direction of rotary piston engine, rotary or swing piston engine, combustion engine, etc., can solve the problem that the force in the same direction cannot be generated, and achieve the effect of balanced torque energy output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

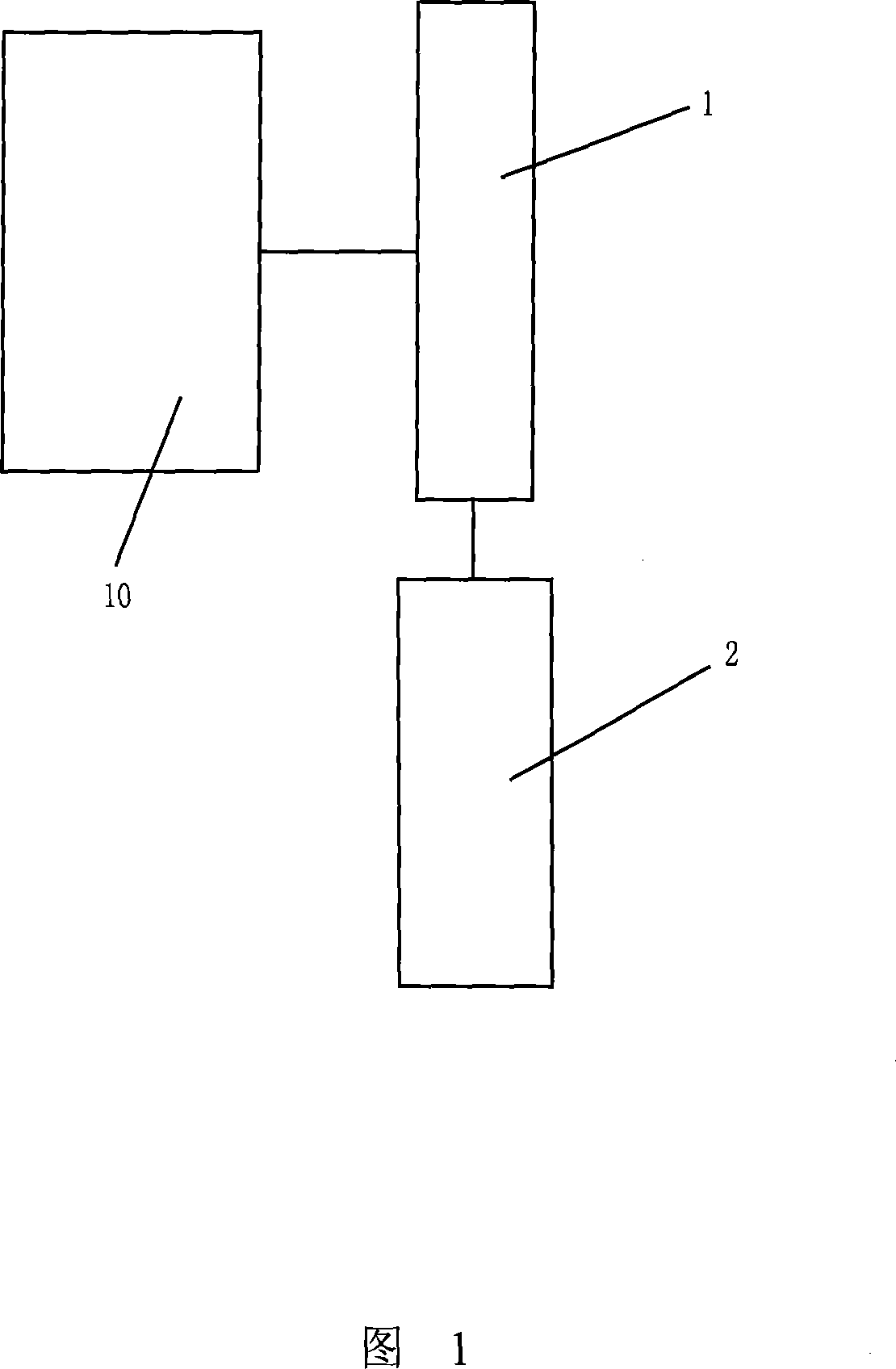

Embodiment 1

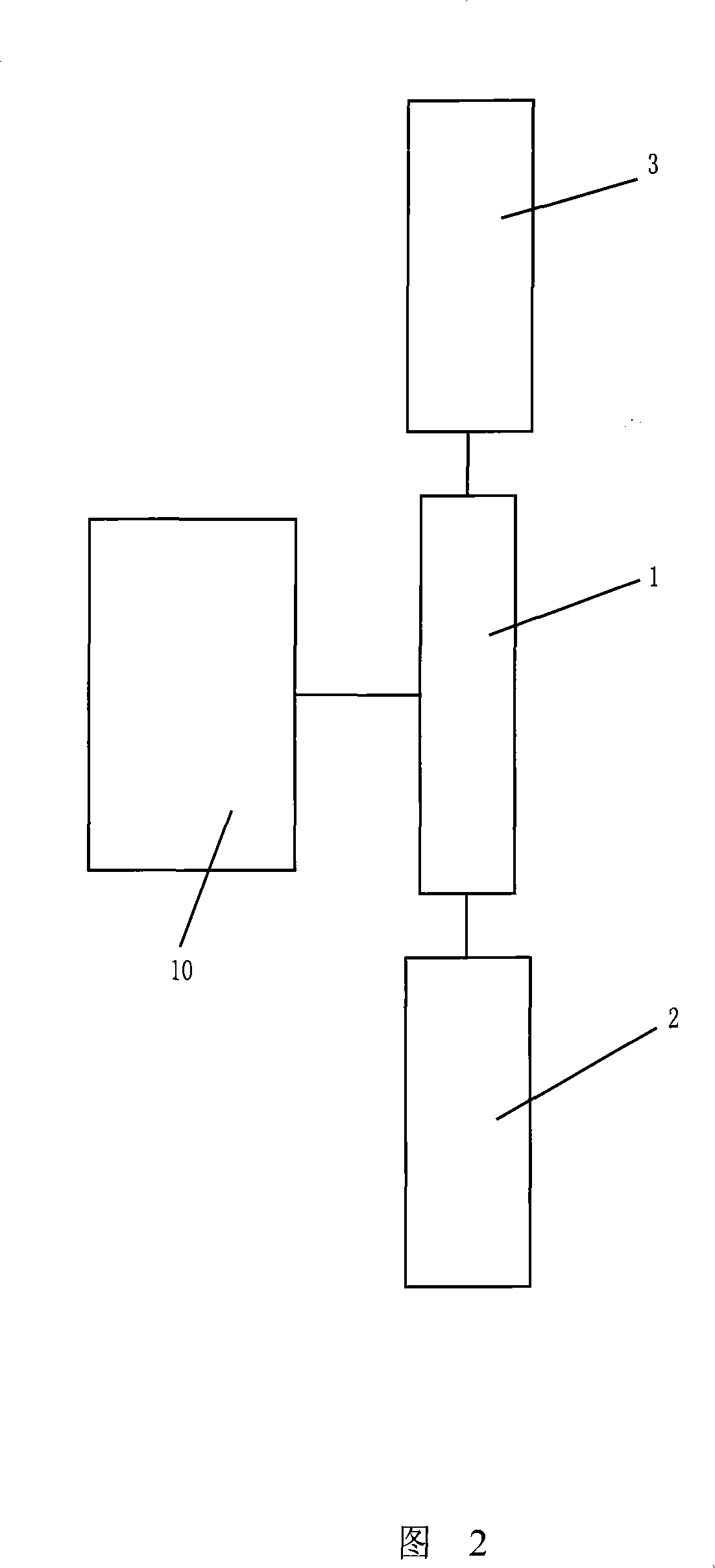

[0019] Embodiment 1: As shown in Figures 2 and 4, a rotary engine with a booster flywheel includes a rotary engine 10, and a transmission 1 is installed on the output shafts 5 and 51 of the two rotors 4 and 41 of the rotary engine, respectively. , the transmission device 1 includes a driving gear 81, two driven gears 82 meshing with the driving gear 81 respectively, and the two driven gears 82 drive the booster device 3 and the power output device 2 respectively; the booster device 3 is the booster flywheels 6 and 61, The booster flywheels 6 and 61 are arranged on the passive transmission shafts 7 and 71 ; the other two passive transmission shafts 72 and 73 of the two transmission devices 1 are arranged coaxially and are provided with an output flywheel 9 coaxially.

Embodiment 2

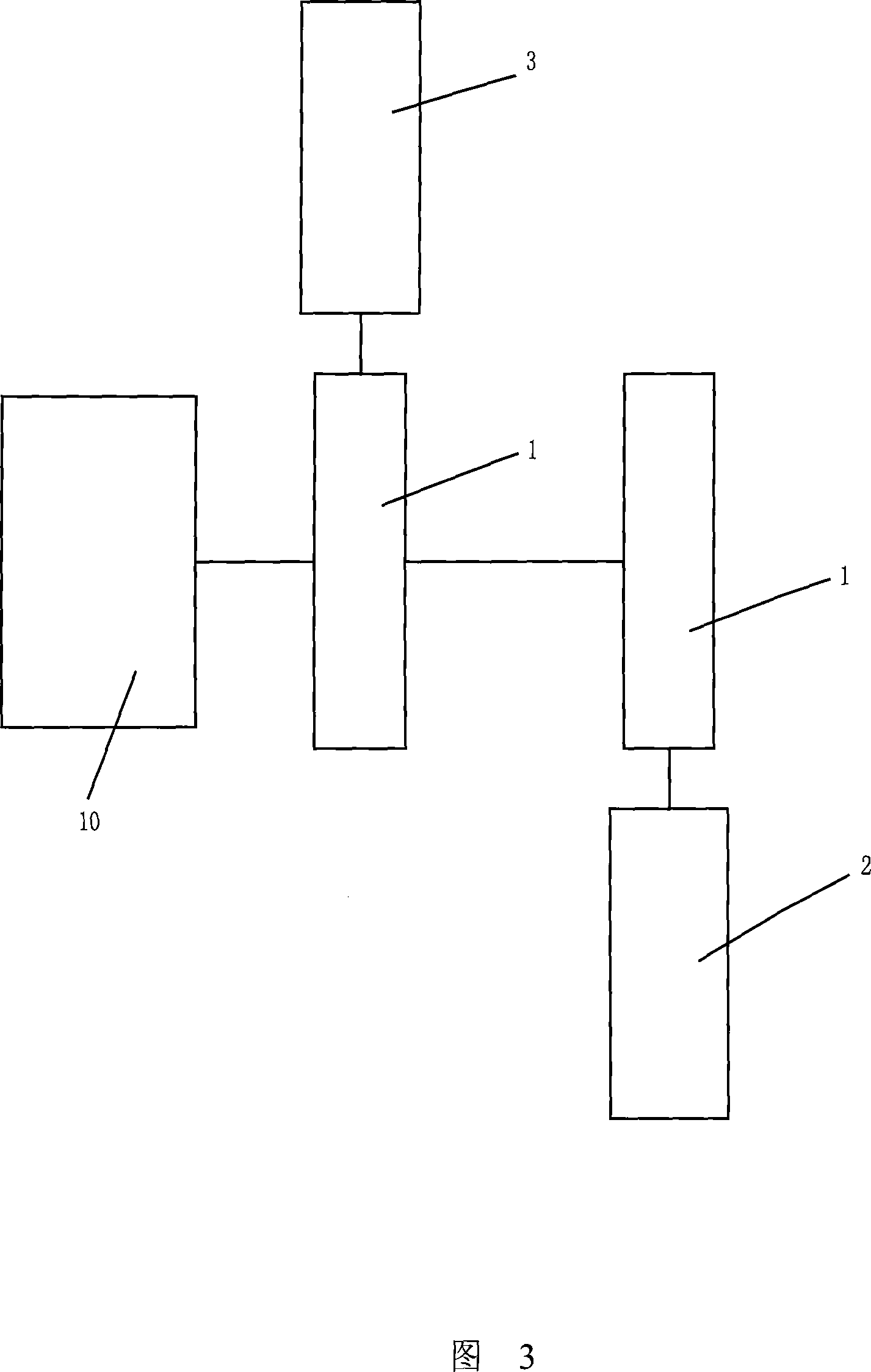

[0020] Embodiment 2: As shown in Figures 3 and 5, a rotary engine with a booster flywheel includes a rotary engine 10, and a transmission 1 is installed on the output shafts 5 and 51 of the two rotors 4 and 41 of the rotary engine, respectively. , the transmission device 1 comprises two coaxial first-stage gear transmission mechanisms 83 and 84 respectively, and the two groups of coaxial first-stage gear transmission mechanisms 83 and 84 drive the booster device 3 and the power output device 2 respectively; the booster device 3 is The booster flywheels 6 and 61 are arranged on the corresponding passive transmission shafts 7 and 71; the other two passive transmission shafts 72 and 73 of the two transmission devices 1 are arranged coaxially and are coaxially provided with an output flywheel 9 .

[0021] The above-mentioned transmission device 1 can also be a multi-stage gear transmission mechanism, and the booster flywheels 6 and 61 are arranged on the last-stage transmission sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com