Equal-thickness cement soil wall building machine

A technology of cement-soil and wall-making machine, which is applied in sheet pile wall, construction, infrastructure engineering and other directions, and can solve the problems of mud inclusion, weakness, and inability to form a continuous wall at the lap joint.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

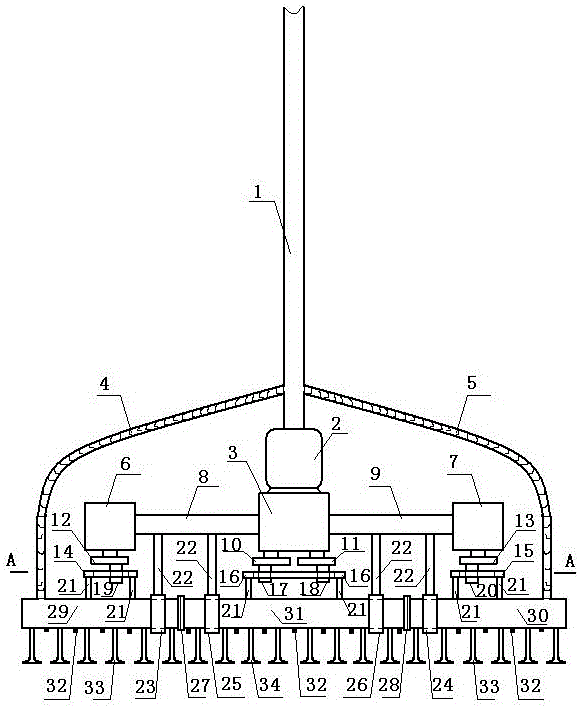

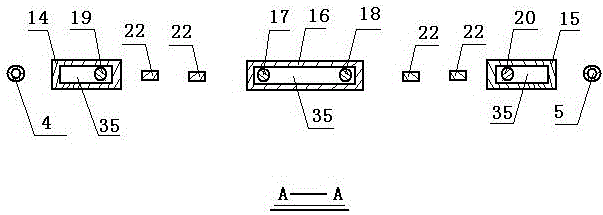

[0012] Accompanying drawing is a kind of specific embodiment of the present invention, and the bottom of drill pipe 1 of this embodiment is divided with first slurry pipe 4 to the left, and the lower end of the first slurry pipe is connected to the left end of second hollow shaft 29, and the bottom of drill pipe is divided to the right. There is a second slurry pipe 5, the lower end of the second slurry pipe is connected to the right end of the third hollow shaft 30, the lower end of the drill pipe is fixed with a motor 2, the lower end of the motor is fixed with a first transfer case 3, and the lower end of the first transfer case outputs a second A cylinder 10 and a second cylinder 11, a first axis 17 is fixed on the radius of the lower surface of the first cylinder, a second axis 18 is fixed on the radius of the lower surface of the second cylinder, and the first axis is inserted in the length of the first rectangular frame 16 The left end of the square hole, the second shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com