Rotor engine

A technology of rotor engines and rotors, which is applied to combustion engines, machines/engines, internal combustion piston engines, etc., and can solve problems such as inability to generate forces in the same direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

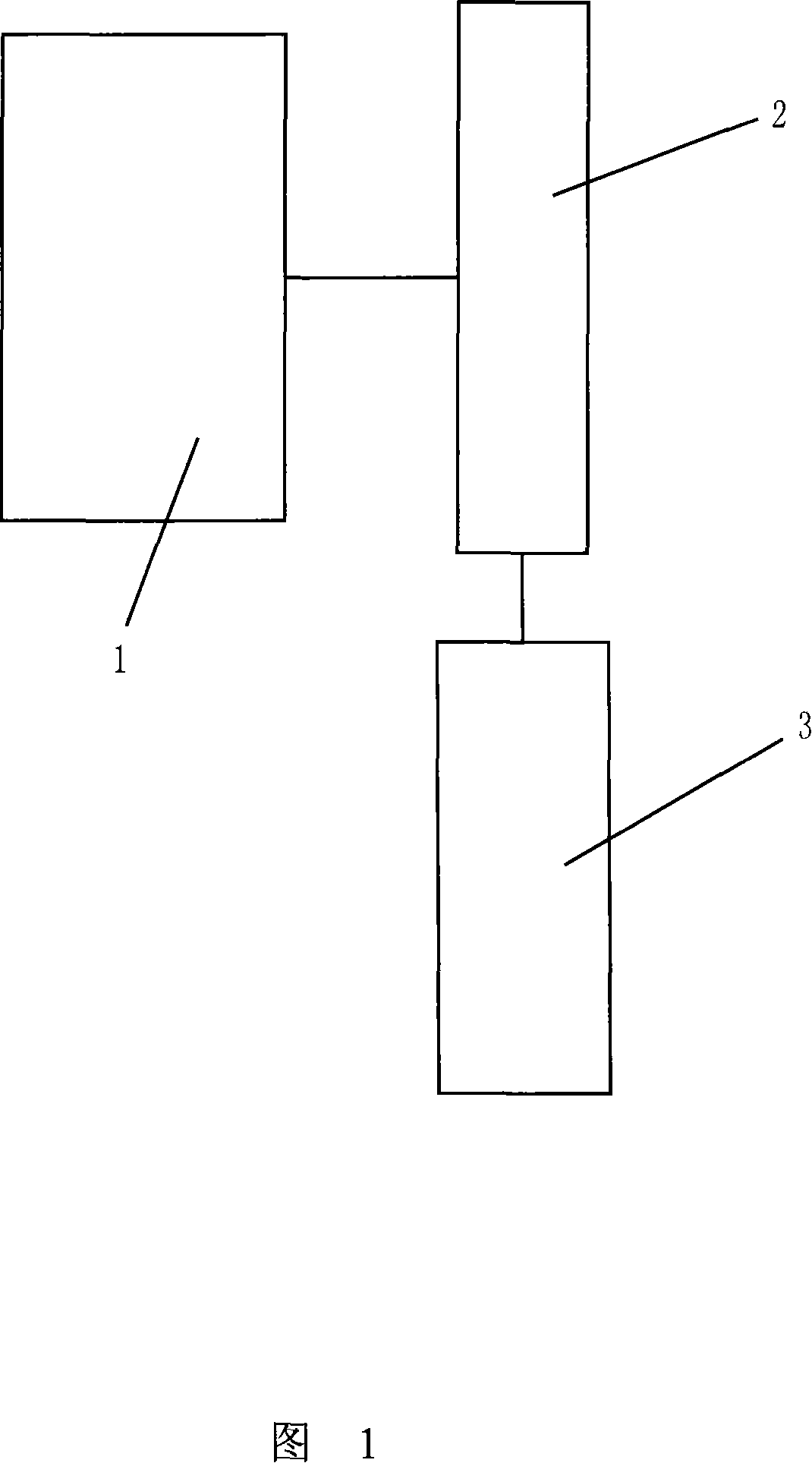

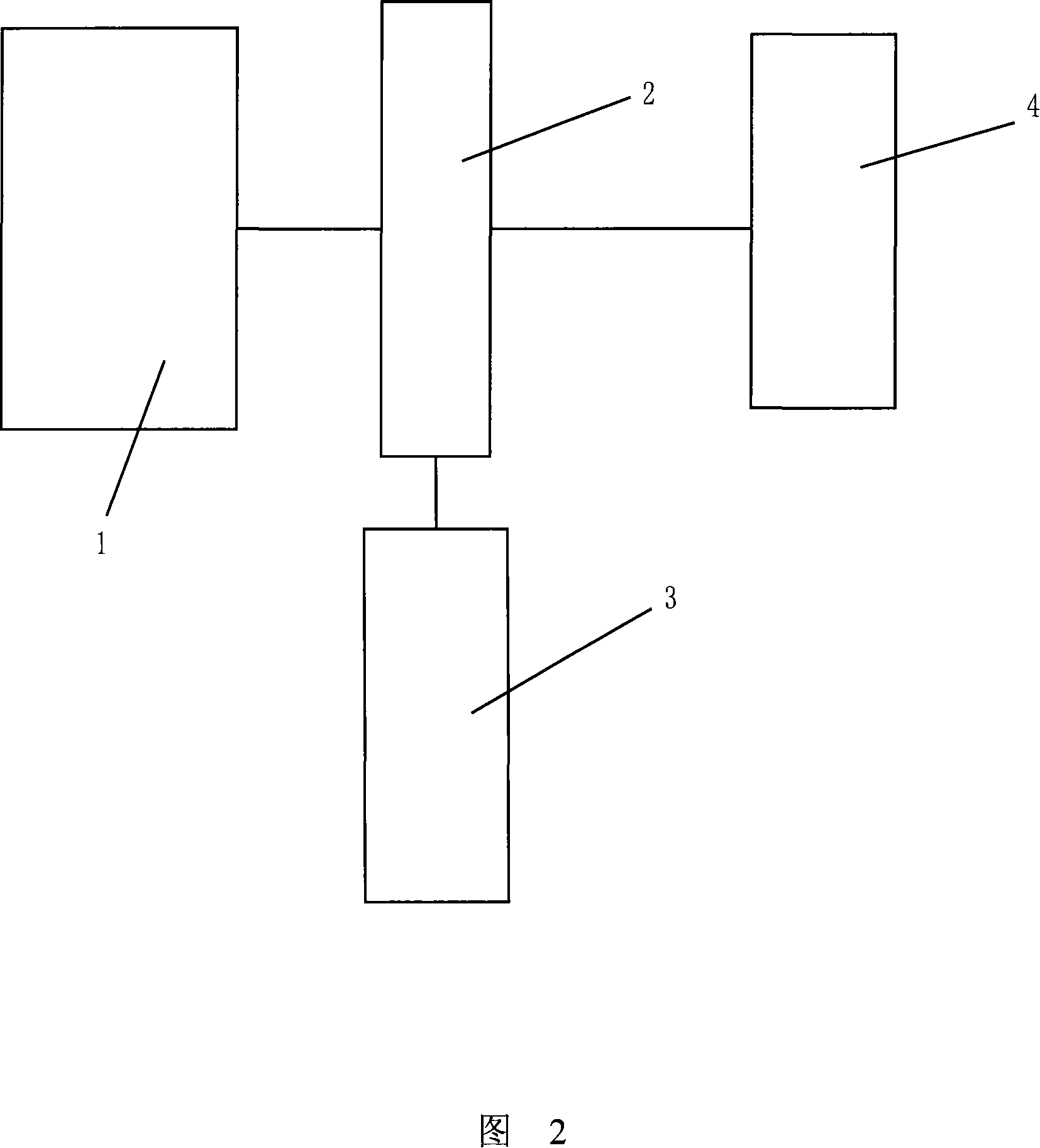

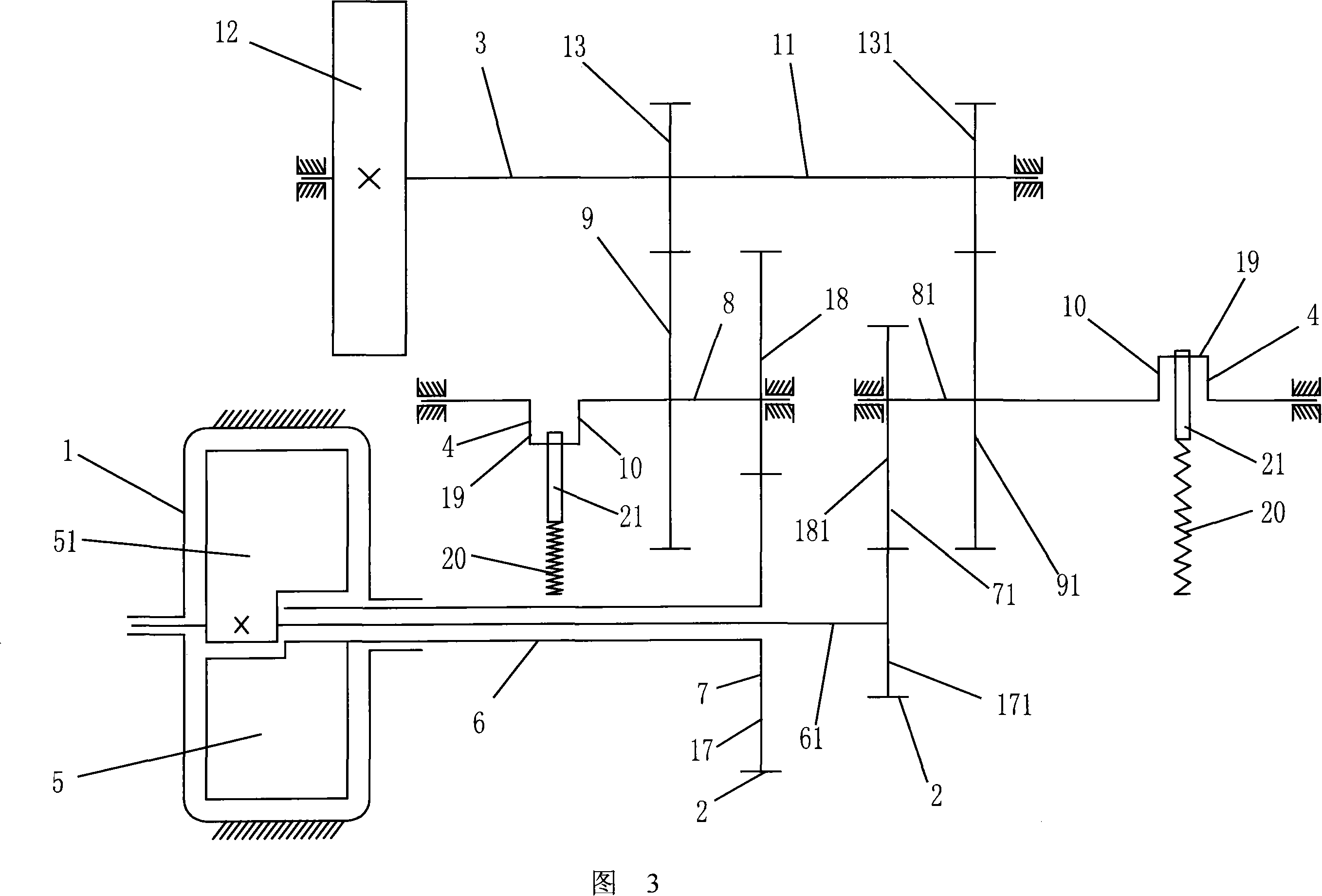

[0023] Embodiment: as shown in Fig. 2 and Fig. 3, a kind of rotary engine comprises rotary engine 1, and the output shafts 6, 61 of two rotors 5, 51 of rotary engine 1 are installed with transmission device 2 respectively, and rotary engine 1 is passed transmission The device 2 is driven by a power take-off 3 and a booster 4 .

[0024] Transmission device 2 comprises the primary gear transmission mechanism 7,71 that is installed on the output shaft 6,61 respectively, and it comprises active elliptical gear 17,171 and passive eccentric gear 18,181, and the major axes of two active elliptical gears 17,171 are opposite Set vertically, when the far point of one of the active oval gears 17 cooperates with the near point of the passive eccentric gear 18 (as shown in Figure 4), the near point of the other active oval gear 171 cooperates with the far point of the passive eccentric gear 181 (as shown in Figure 4). Figure 5).

[0025] The booster device 4 includes rotating parts 10, 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com