Rotor engine

A rotary engine, rotor technology, applied in combustion engines, machines/engines, internal combustion piston engines, etc., to achieve the effect of balancing energy output and balancing torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

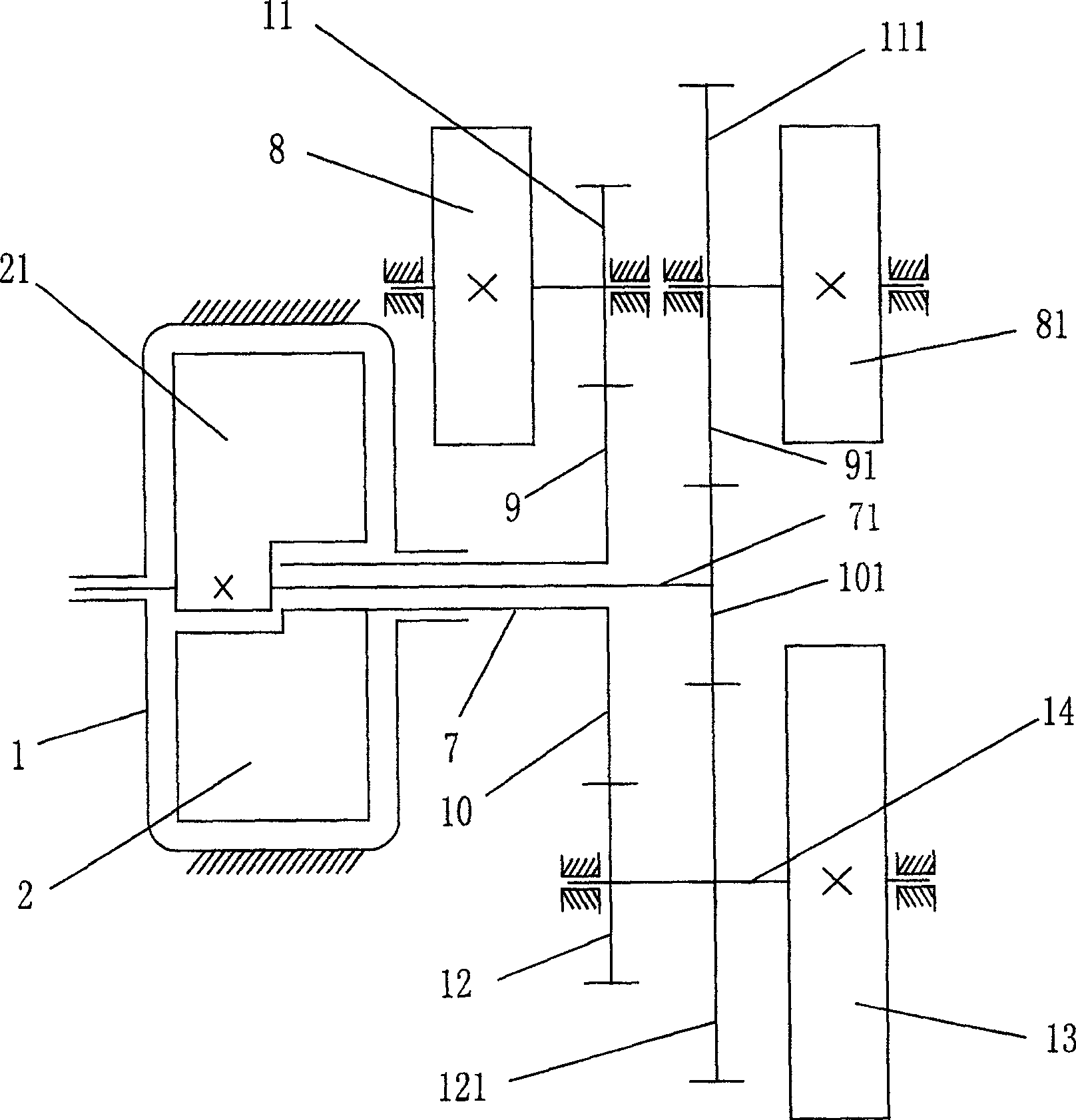

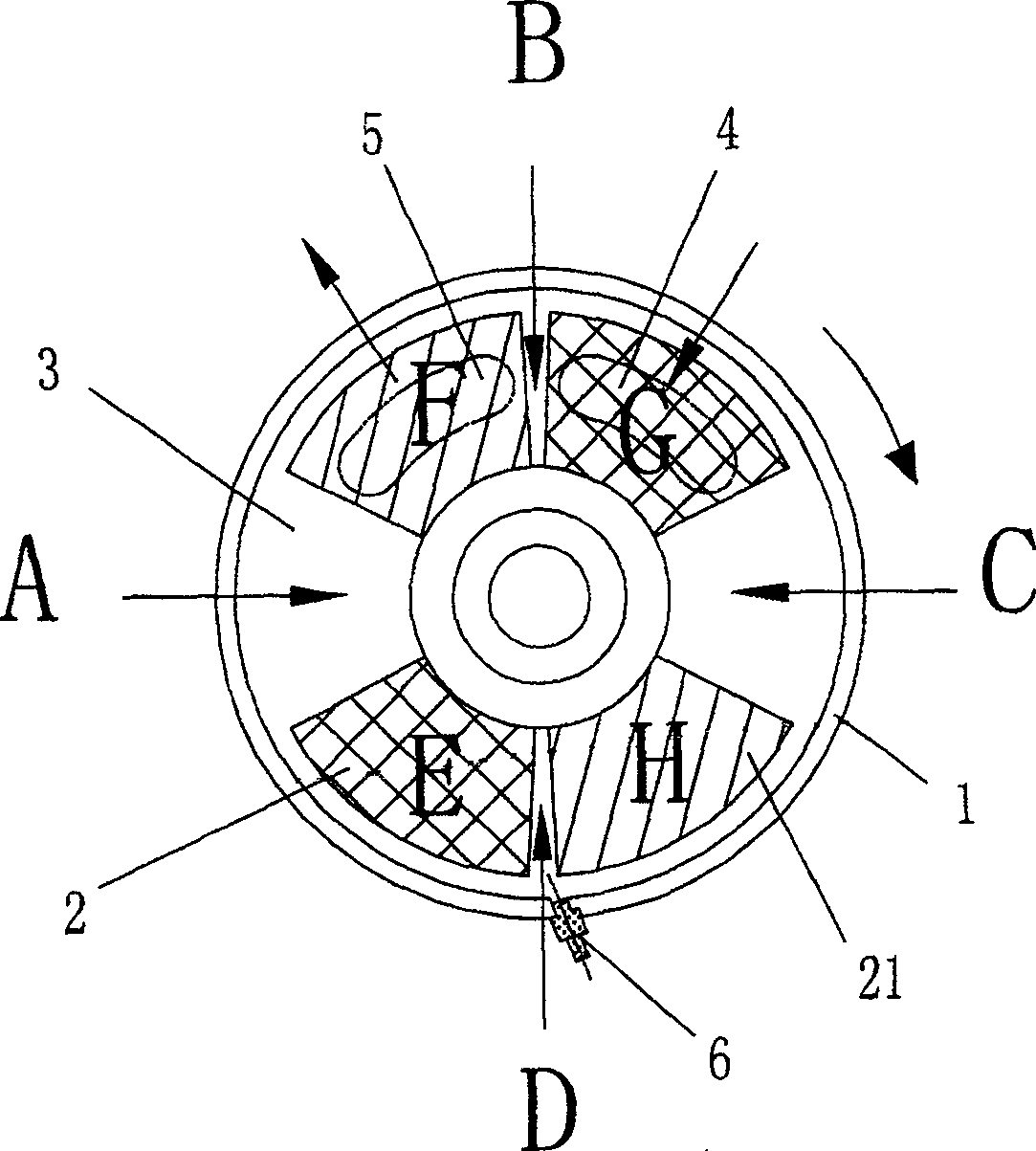

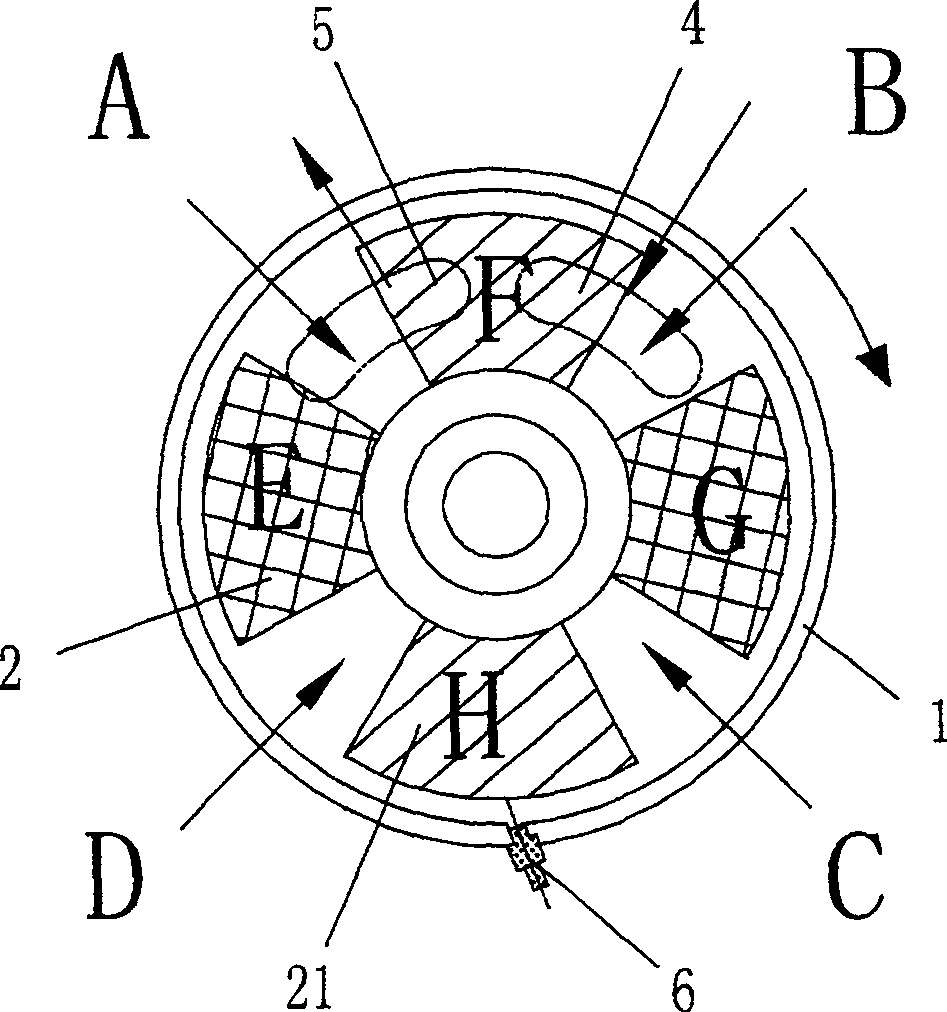

[0016] Example: such as figure 1 As shown, a rotary engine includes a cylinder block 1, and two vane rotors 2 and 21 are arranged in the cylinder block 1, and the two rotors 2 and 21 and the cylinder block 1 form at least four sealed chambers 3 through elastic sealing sheets , Cylinder block 1 is provided with intake port 4, exhaust port 5 and ignition or nozzle device 6, rotor output shaft 7 and 71 of two rotors 2 and 21 is connected with rotor flywheel 8 and 81 through speed change device 9 and 91.

[0017] Speed change devices 9 and 91 include rotor oval gears 10 and 101 fixed on rotor output shafts 7 and 71, rotor flywheel oval gears 11 and 111 meshed with rotor oval gears 10 and 101, rotor flywheels 8 and 81 and rotor flywheel oval gears 11 and 111 are coaxially fixed respectively, and the two rotor oval gears 10 and 101 are respectively meshed with output flywheel oval gears 12 and 121, and the two output flywheel oval gears 12 and 121 are arranged on the engine output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com