Air floating and pulse type automatic quantitative valve bag packing machine

A quantitative valve, packaging machine technology, applied in the direction of packaging, transportation and packaging, packaging item types, etc., can solve the problems of difficult replacement, dead corners of air flotation devices and tanks, and easy to run ash.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

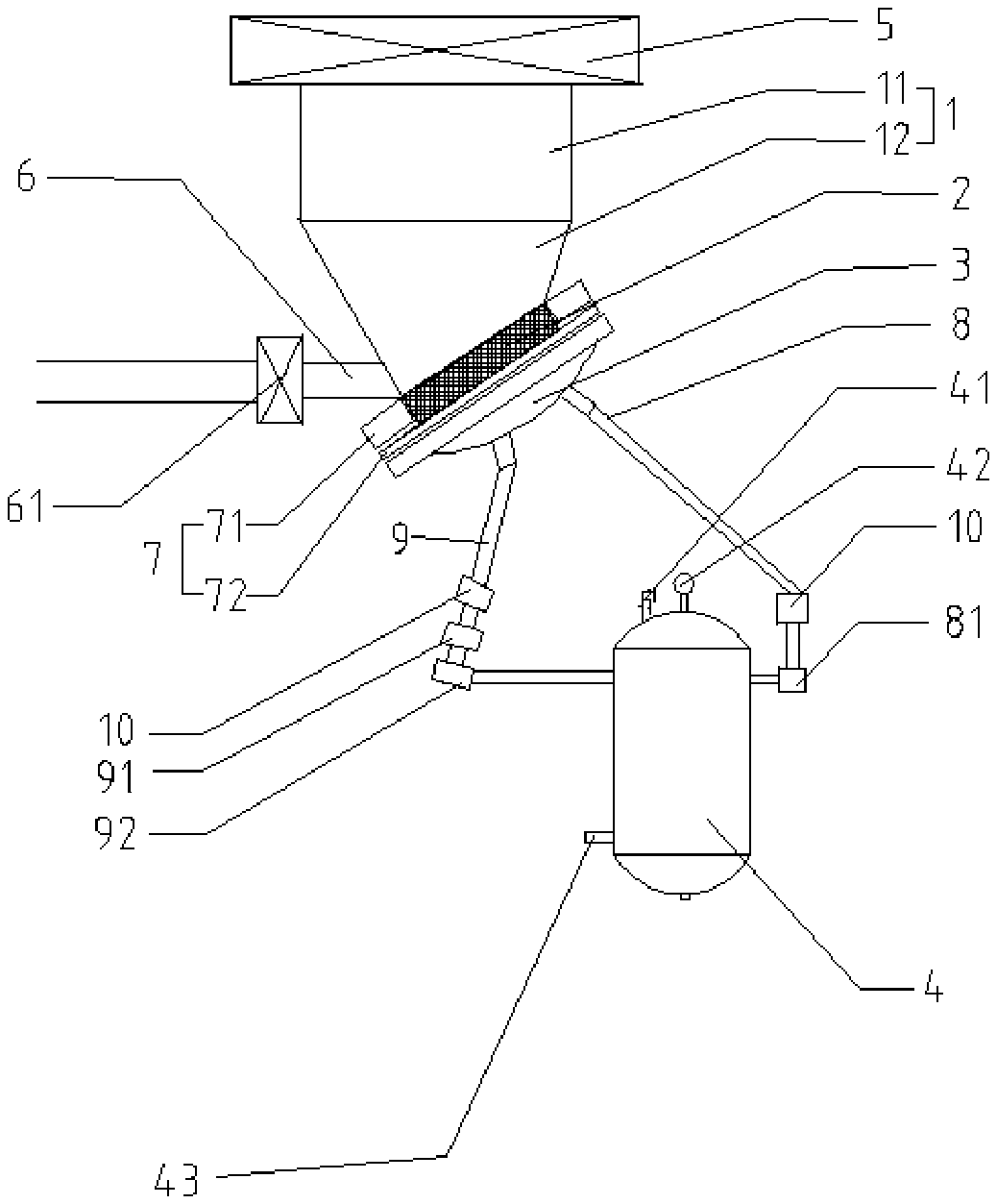

[0025] figure 1 A schematic diagram of the structure of the air-floating pulse automatic quantitative valve pocket packaging machine provided in the first embodiment of the present invention; such as figure 1 As shown, the air-floating pulse automatic quantitative valve bag packaging machine provided in the first embodiment of the present invention includes a tank body 1, a ventilation plate 2, a sealing cover 3 and an air storage tank 4;

[0026] The top of the tank body 1 is provided with a butterfly valve 5 , the side wall of the tank body 1 is provided with a discharge port 6 , the bottom of the tank body 1 is provided with an oblique opening, and the ventilation plate 2 is installed on the said tank body through a flange assembly 7 . On the inclined port, the sealing cover 3 is arranged under the ventilation plate 2 and is connected with the flange assembly 7;

[0027] Compressed air is stored in the air storage tank 4, and the air storage tank 4 is communicated with the...

Embodiment 2

[0053] The air flotation pulse automatic quantitative valve pocket packaging machine provided in the second embodiment is a further improvement of the air flotation pulse automatic quantitative valve pocket packaging machine provided in the first embodiment. figure 1 On the basis of , the air flotation pulse automatic quantitative valve bag packaging machine provided in the second embodiment includes a tank body 1, a ventilation plate 2, a sealing cover 3 and an air storage tank 4;

[0054] The top of the tank body 1 is provided with a butterfly valve 5 , the side wall of the tank body 1 is provided with a discharge port 6 , the bottom of the tank body 1 is provided with an oblique opening, and the ventilation plate 2 is installed on the said tank body through a flange assembly 7 . On the inclined port, the sealing cover 3 is arranged under the ventilation plate 2 and is connected with the flange assembly 7;

[0055] Compressed air is stored in the air storage tank 4, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com