Patents

Literature

39results about How to "Change running speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

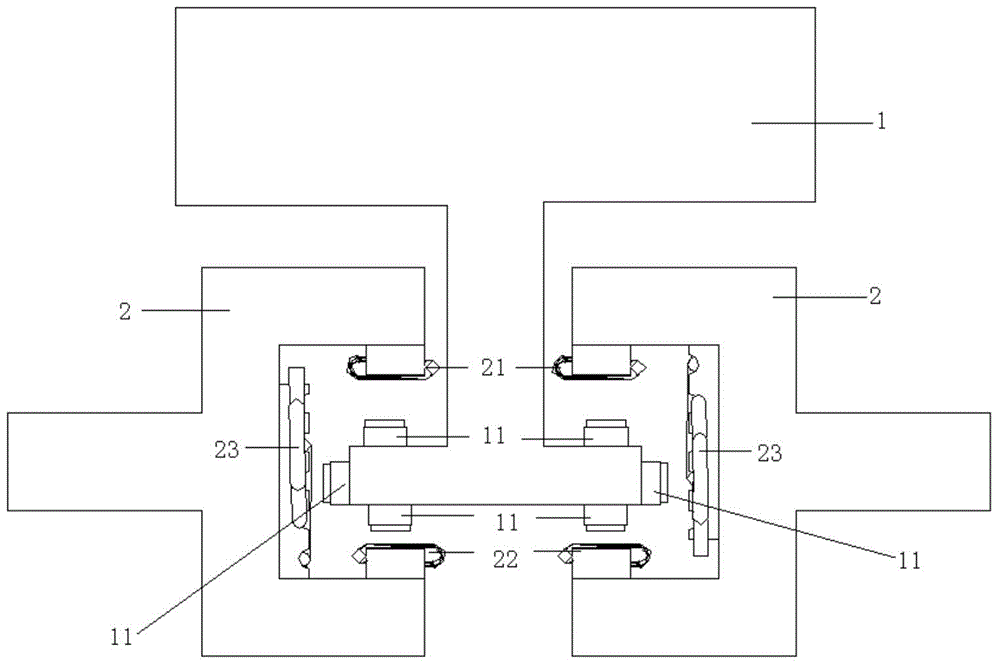

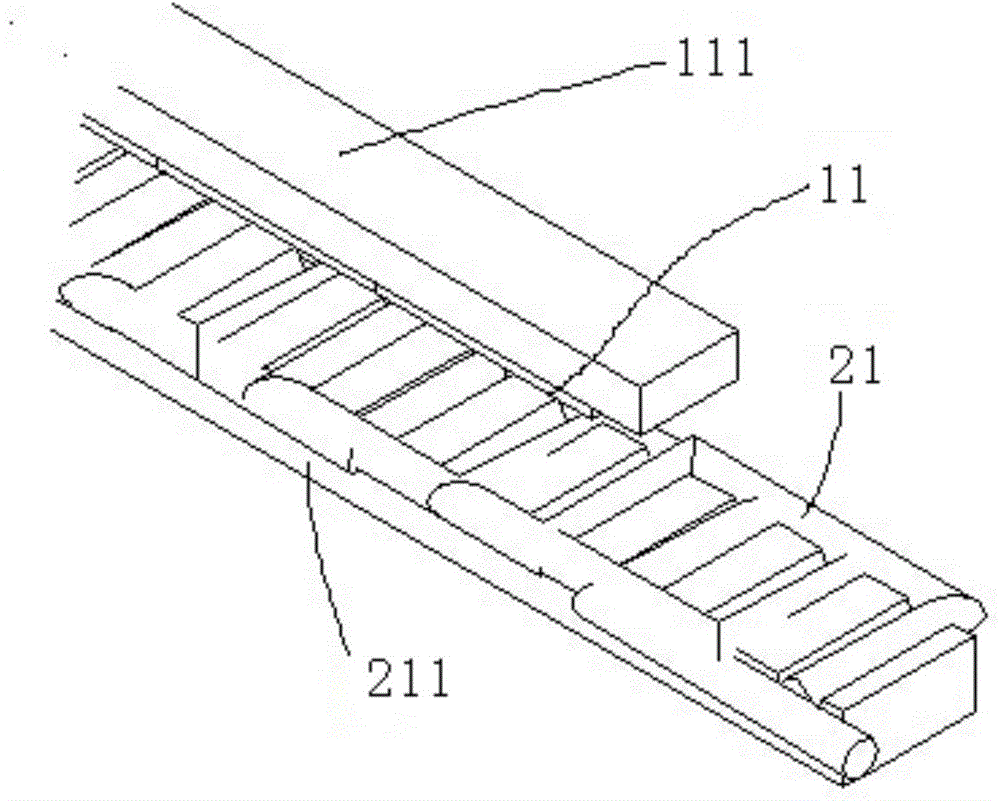

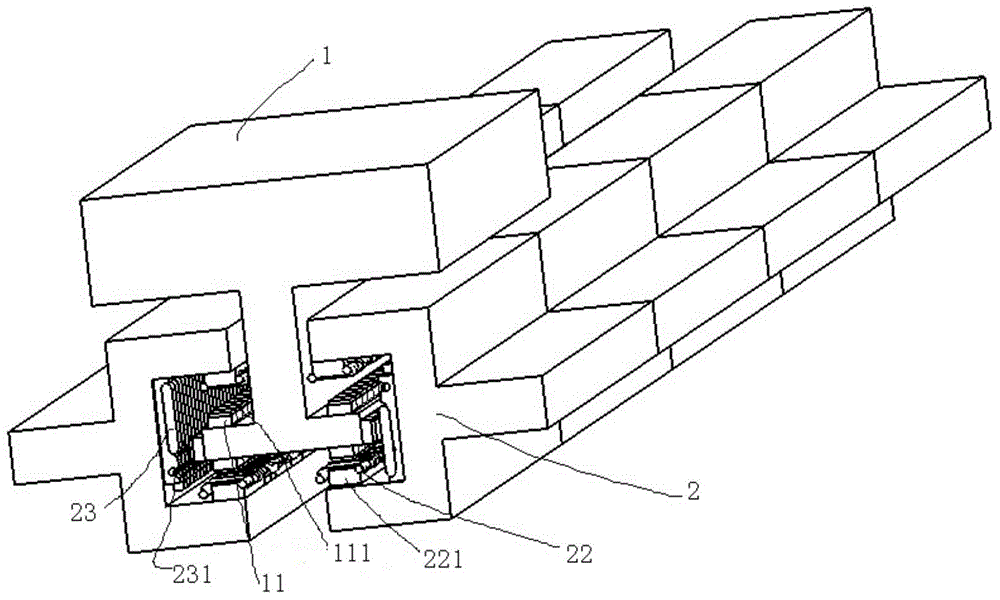

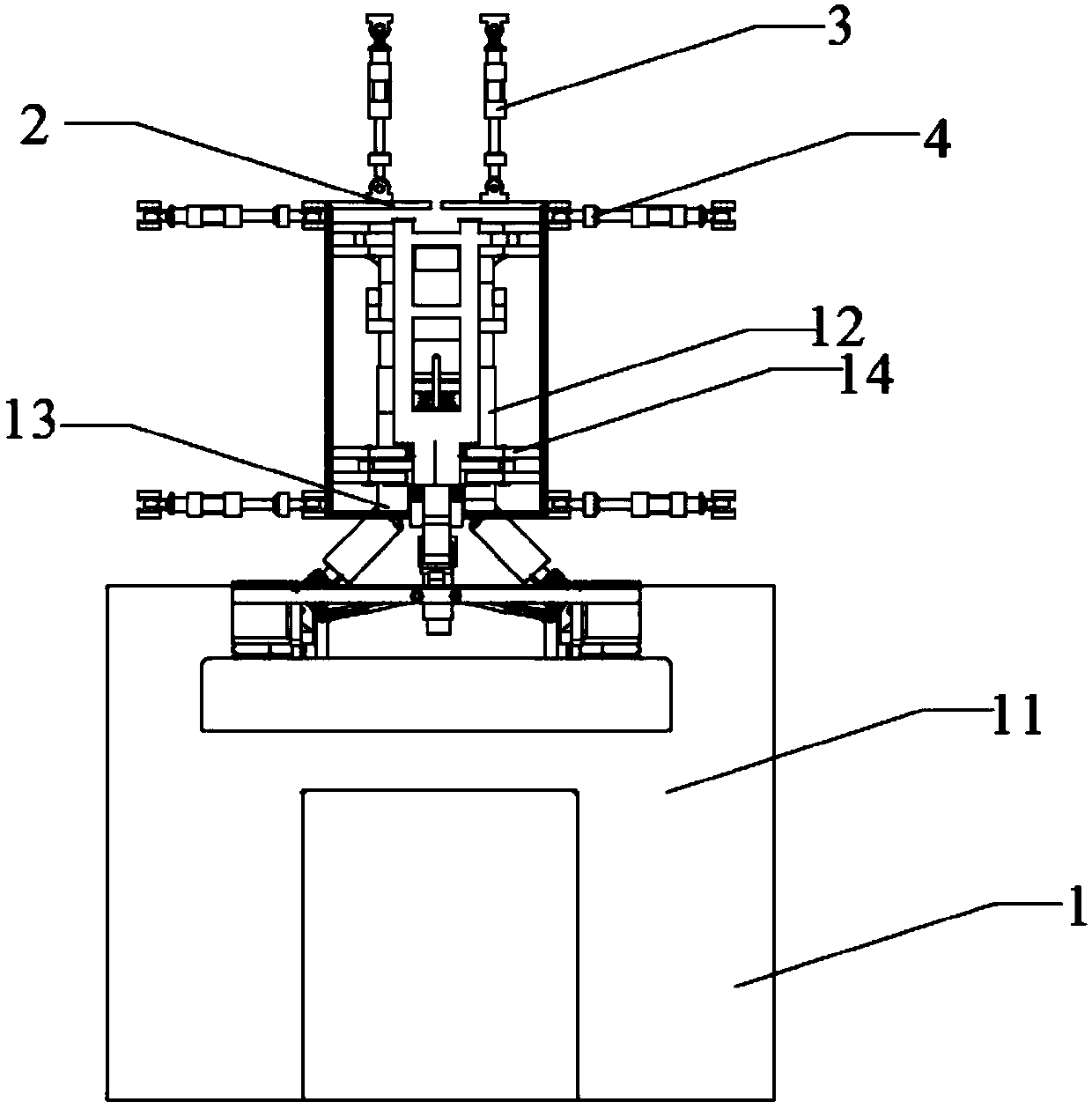

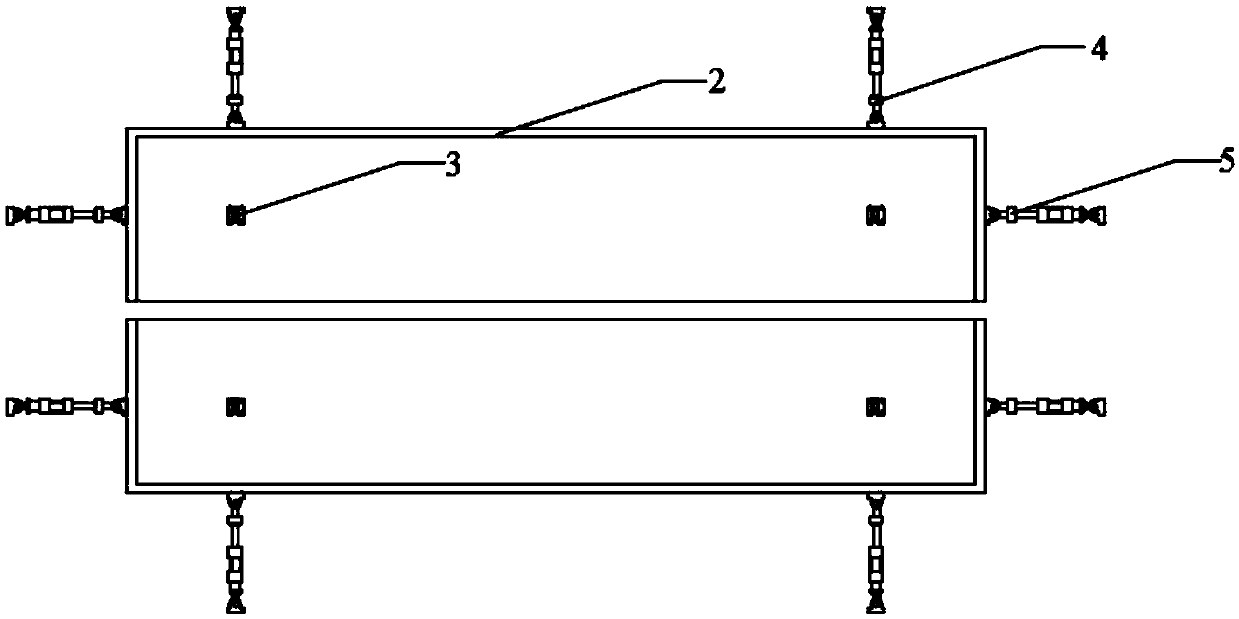

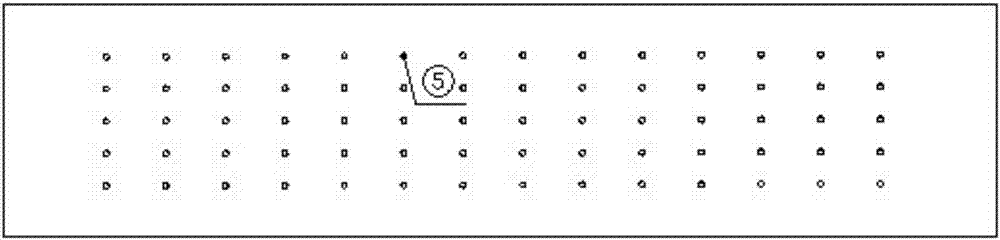

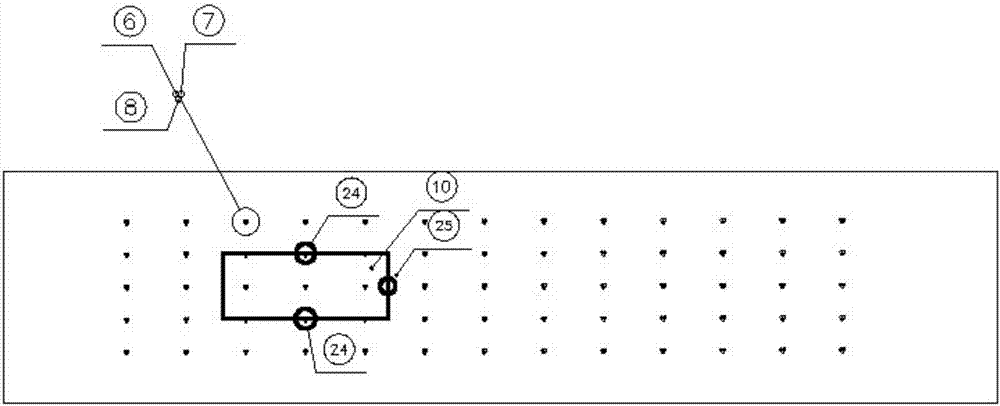

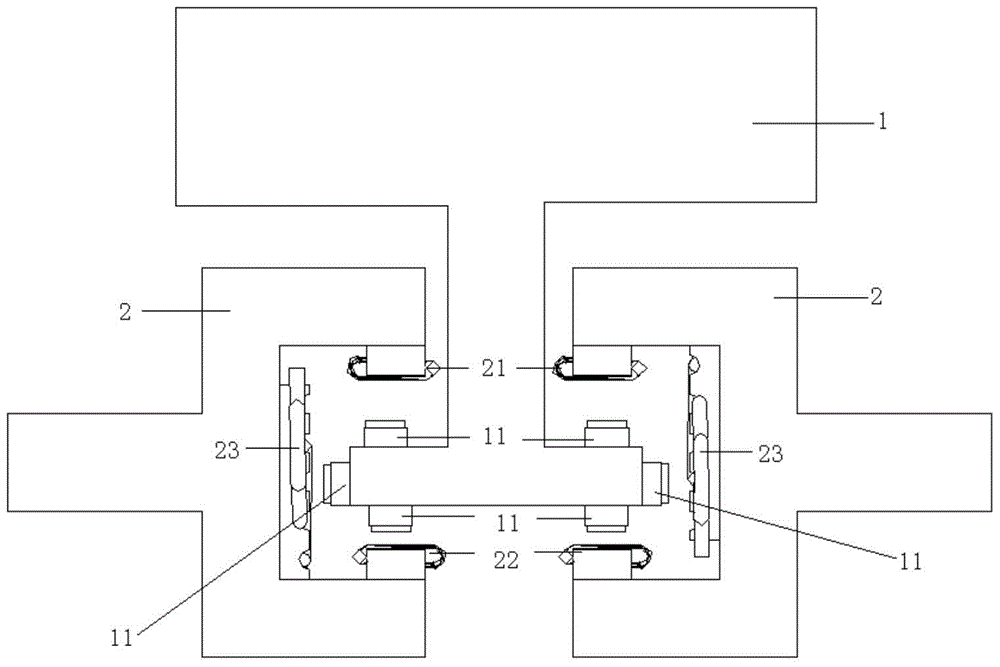

Symmetrical permanent-magnet linear synchronous motor

ActiveCN104617741ASuspension control is simple and effectiveChange running speedPropulsion systemsPermanent magnet synchronous motorLinear motor

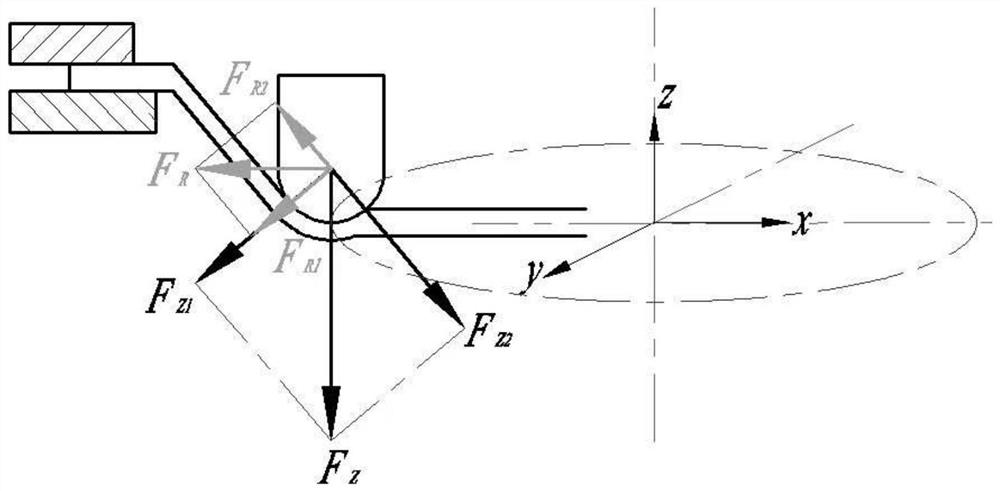

The invention discloses a symmetrical permanent-magnet linear synchronous motor. The motor comprises a rotor and a plurality of stator guide rails symmetrically arranged on both sides of the rotor, wherein the plurality of stator guide rails forms a movement track where the rotor moves; both sides of the bottom of the rotor are symmetrically provided with three groups of array permanent magnets respectively, each stator guide rail includes an U-shaped structure, and open ends of the U-shaped structures of the stator guide rails on both sides are oppositely arranged; the upper and lower positions of the open ends of the U-shaped structures are respectively fixed with a traction force coil, and a suspension force coil is fixedly installed inside the bottom of the U-shaped structure; the suspension force coil inside the bottom of the U-shaped structure interacts with the array permanent magnet at the corresponding position of the bottom of the rotor, and the traction force for upwardly suspending the rotor and the normal force are simultaneously generated; the suspension force coils on the stator guide rails symmetrically arranged on two sides of the rotor interact with the normal force generated by the array permanent magnet, so that the rotor of the linear motor always moves at the center of the guide rail.

Owner:江苏希太芯科技有限公司

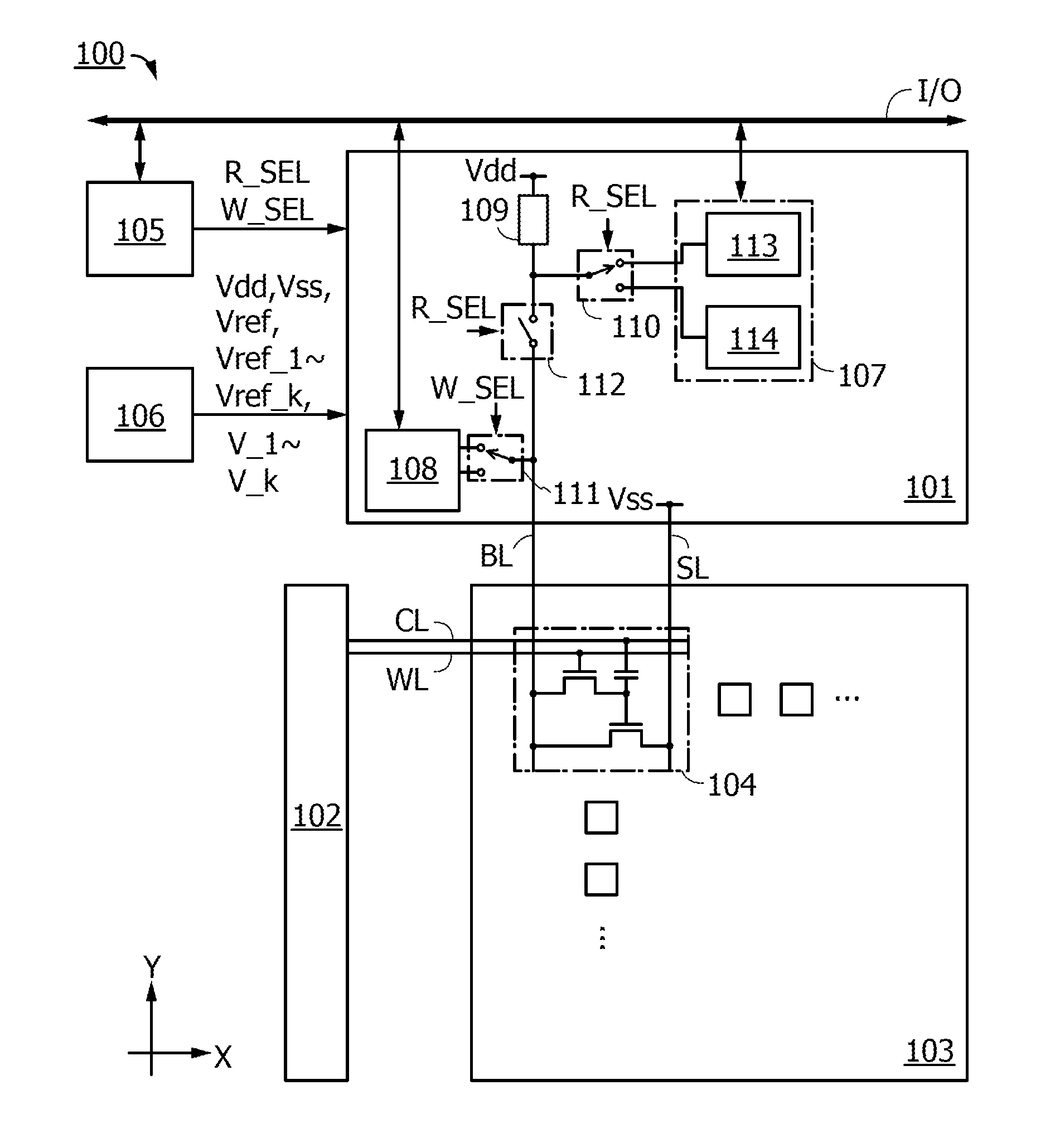

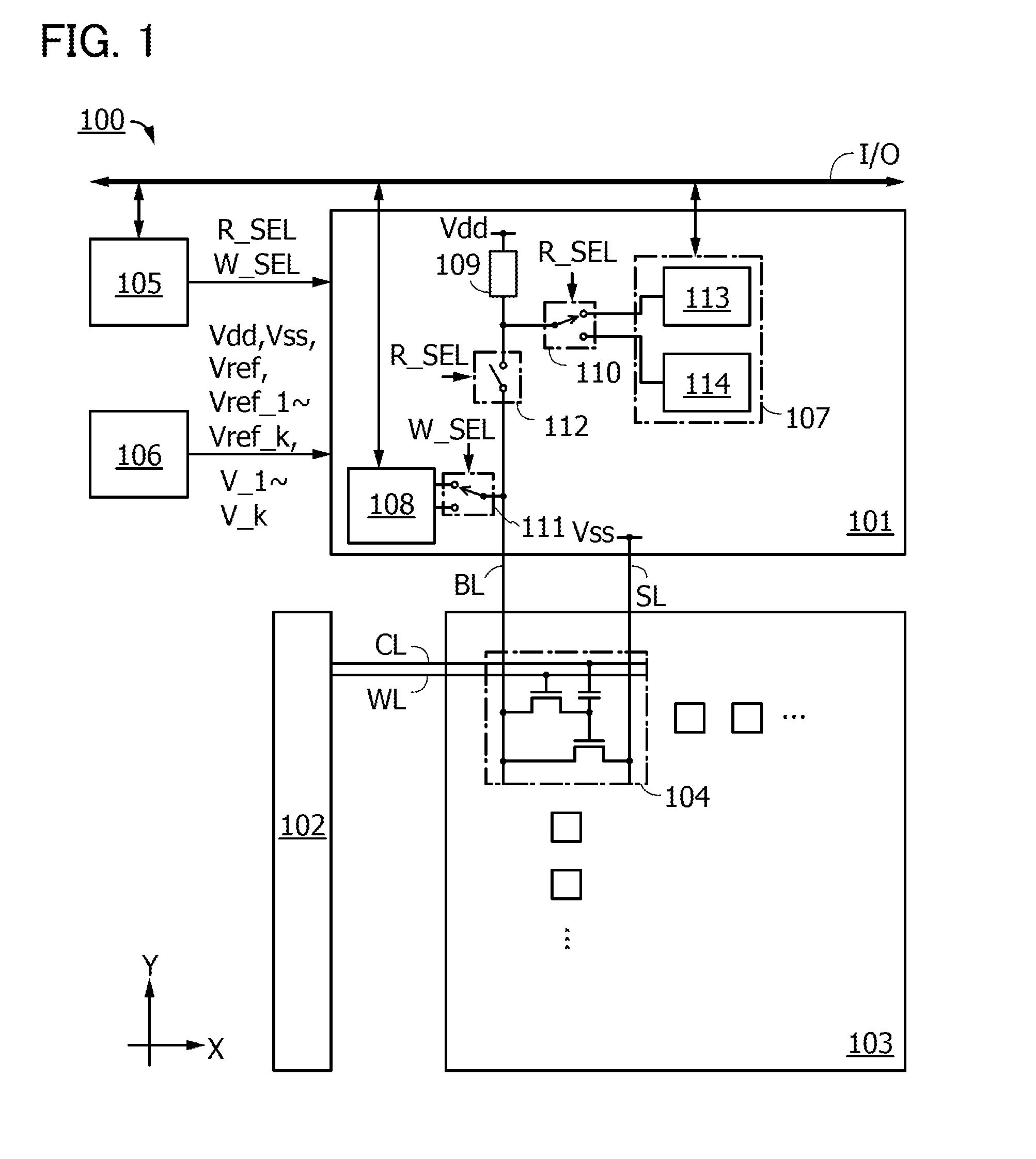

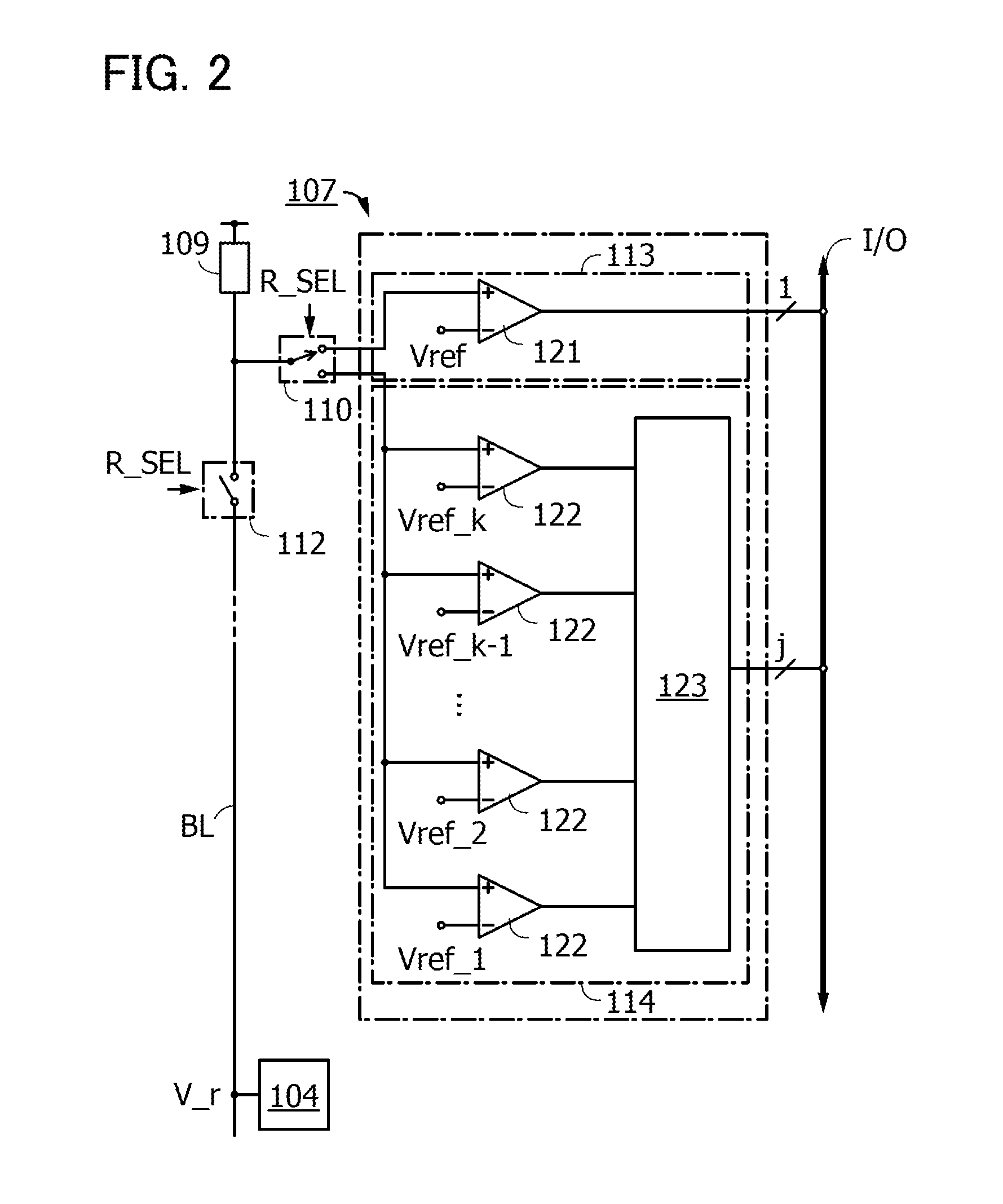

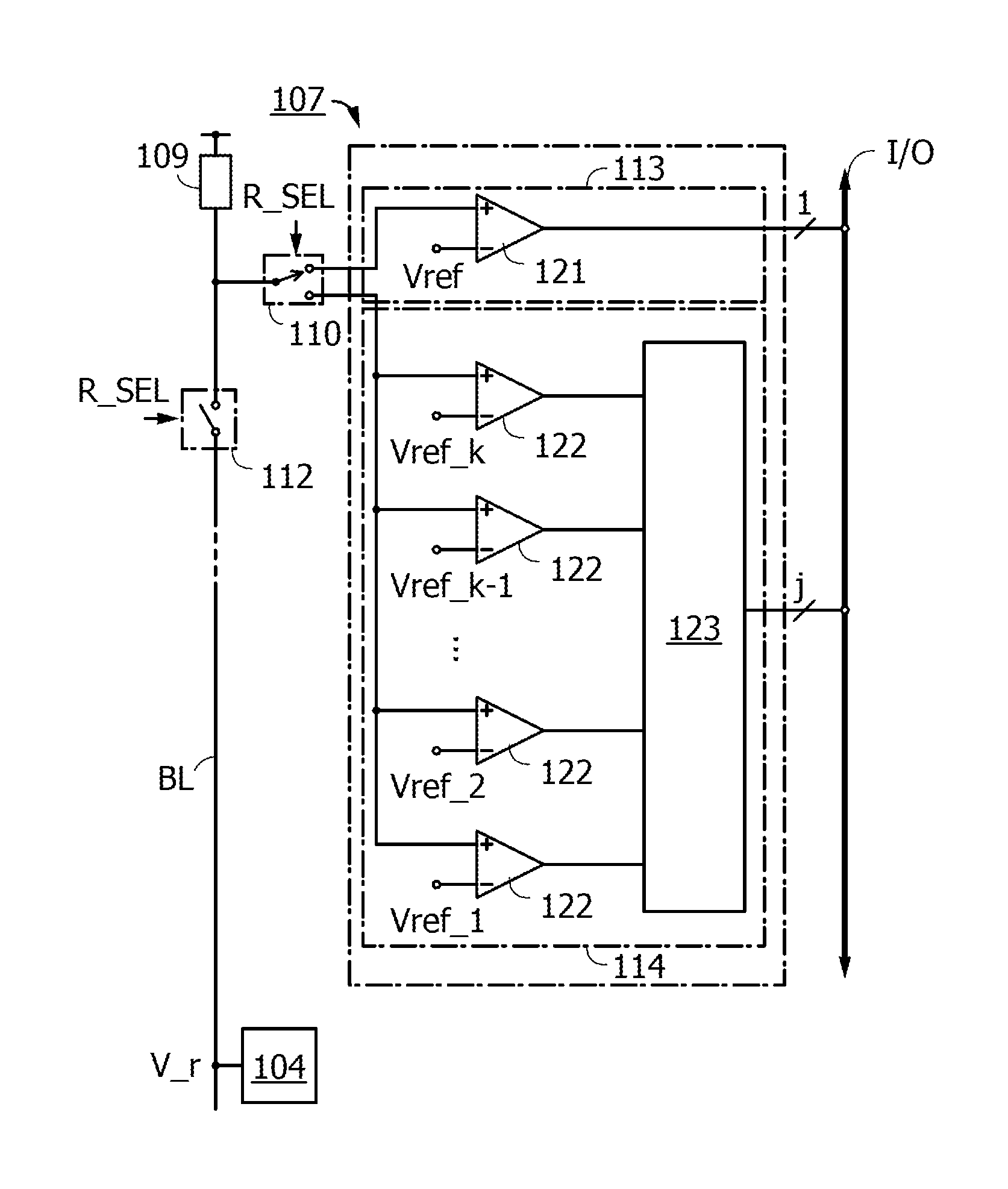

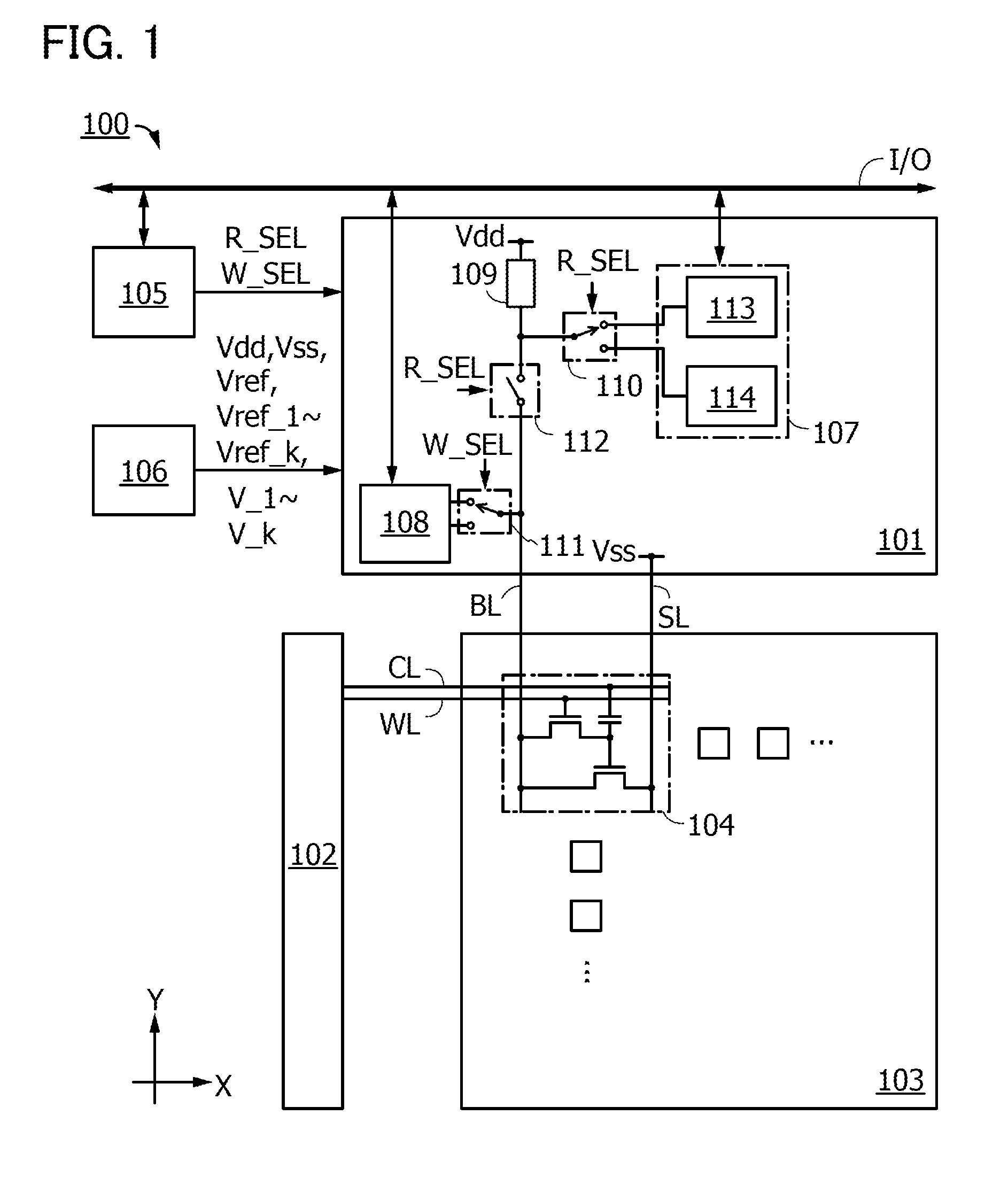

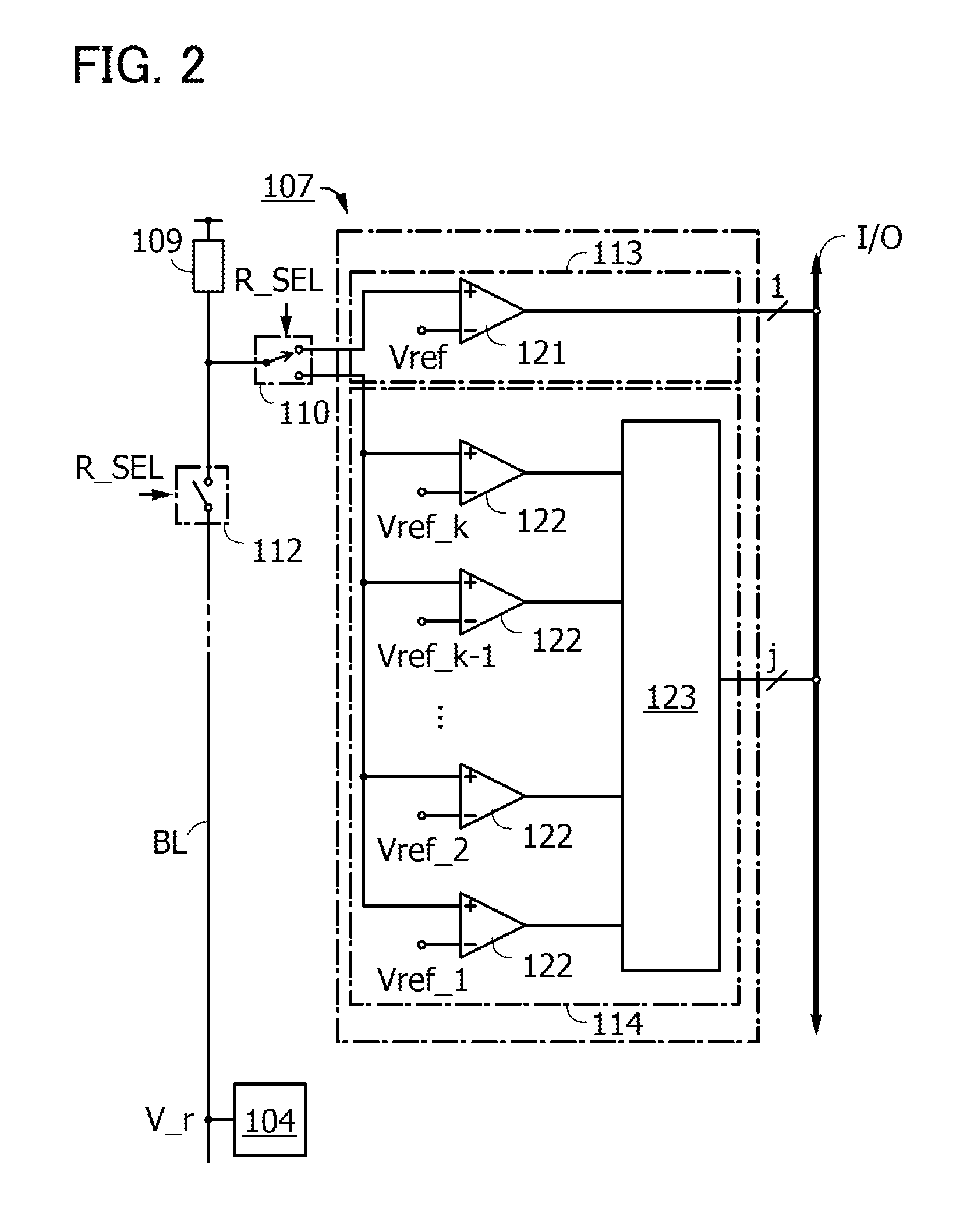

Semiconductor device

ActiveUS20140177345A1Novel structureImprove convenienceDigital storagePower semiconductor deviceData storing

To provide a semiconductor device that has a novel structure and achieves a higher degree of convenience, the semiconductor device is configured to include a memory cell that stores binary data or multilevel data, and a reading circuit that reads the data stored in the memory cell and transfers the data to the outside. The reading circuit includes a first reading circuit for reading binary data and a second reading circuit for reading multilevel data.

Owner:SEMICON ENERGY LAB CO LTD

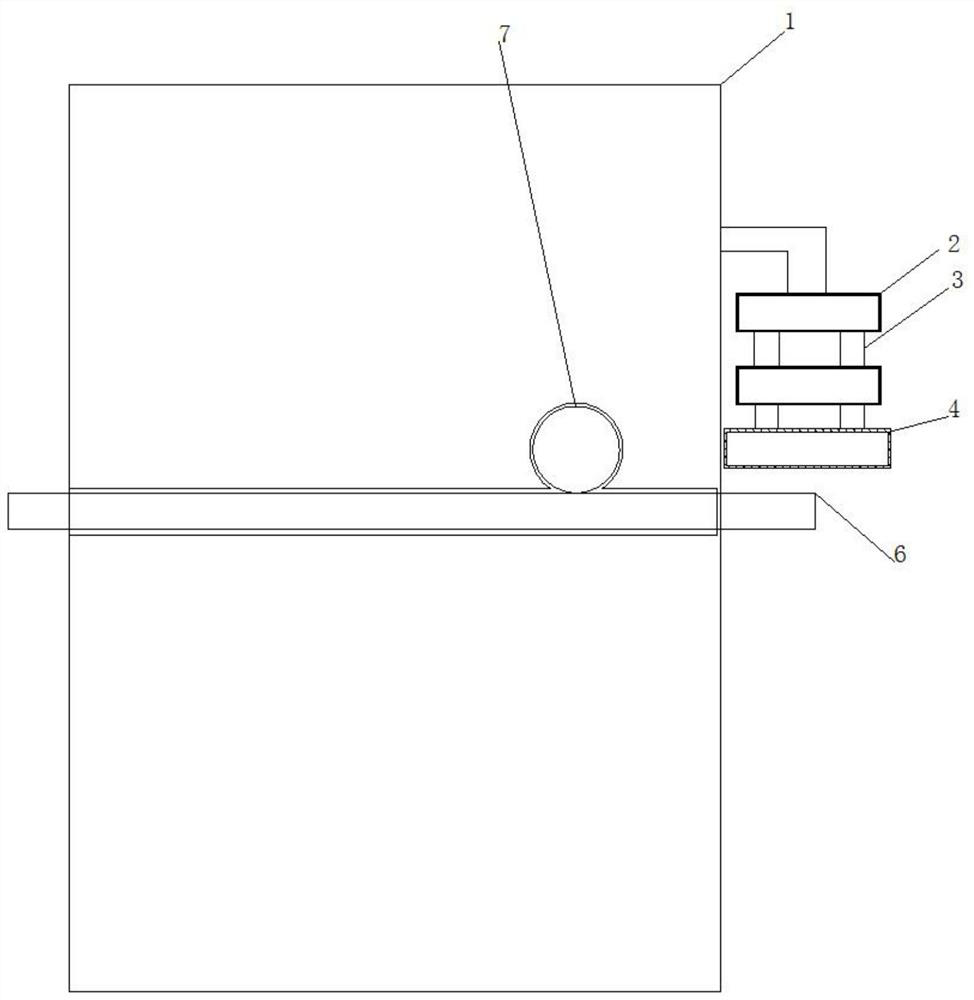

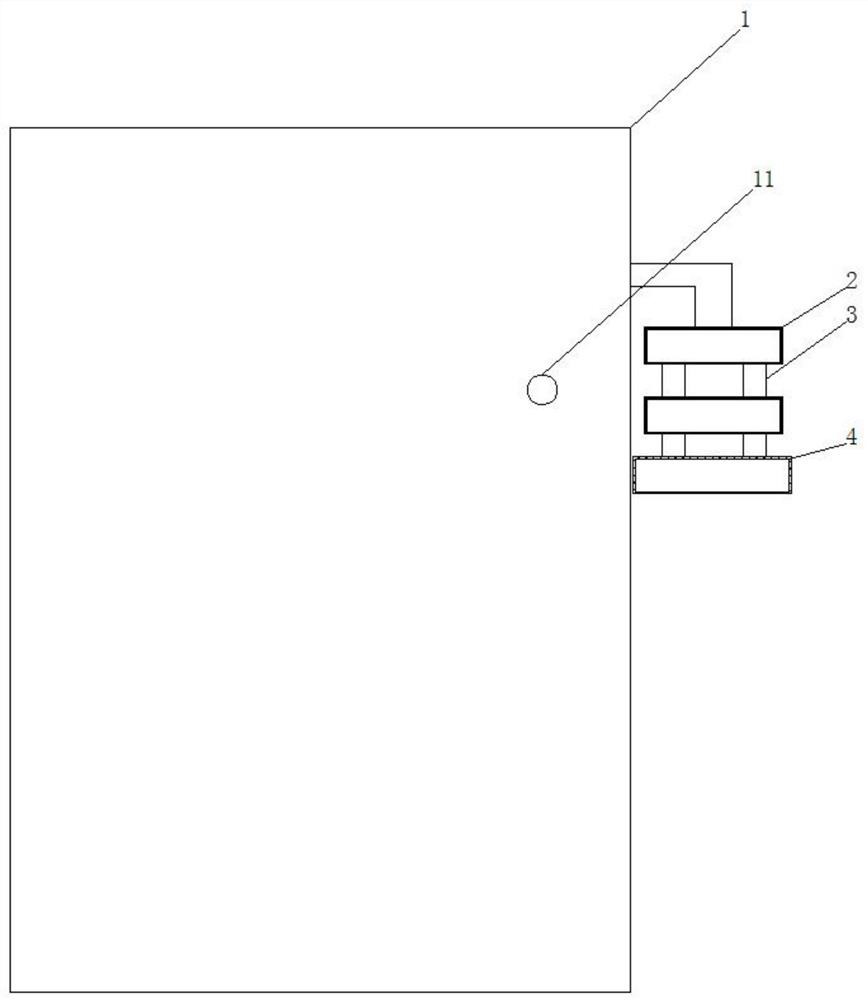

Automatic-rise-fall computer display device bracket

PendingCN106020366AControlled riseControl distanceDigital data processing detailsStands/trestlesDisplay deviceHemt circuits

The invention relates to an automatic-rise-fall computer display device bracket which comprises a support unit, a lifting device, a control unit and a power supply unit, wherein the lifting device is arranged in the support unit; the control unit comprises a position detection circuit and a singlechip for controlling the lifting device to rise and fall; the power supply unit is connected with the control unit and lifting device; the position detection circuit comprises a U-shaped resistor and two position sensing elastic needles; the U-shaped resistor is fixed to the support unit; the position sensing elastic needles are fixed to the lifting device; and the two position sensing elastic needles communicate with each other and are movably connected with both ends of the U-shaped resistor. By adopting the singlechip and position detection circuit to control the rise and fall process, the rise and fall distance can be accurately controlled, and the rise and fall stop time can be accurately controlled; and the rise or fall speed can be accurately changed by changing the transmission ratio of the worm and gear.

Owner:叶建新

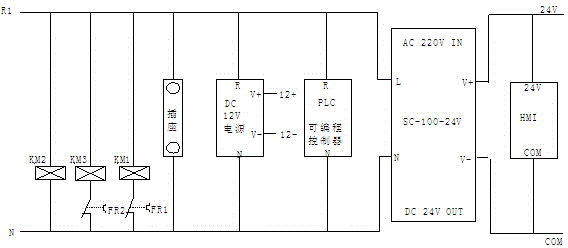

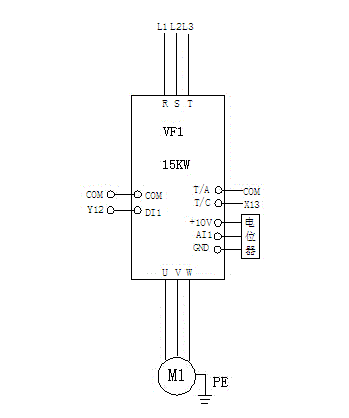

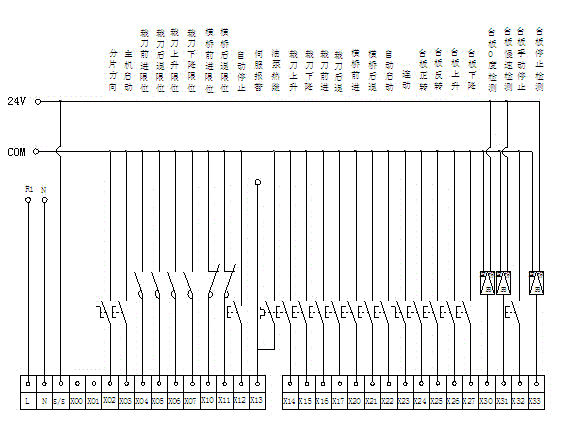

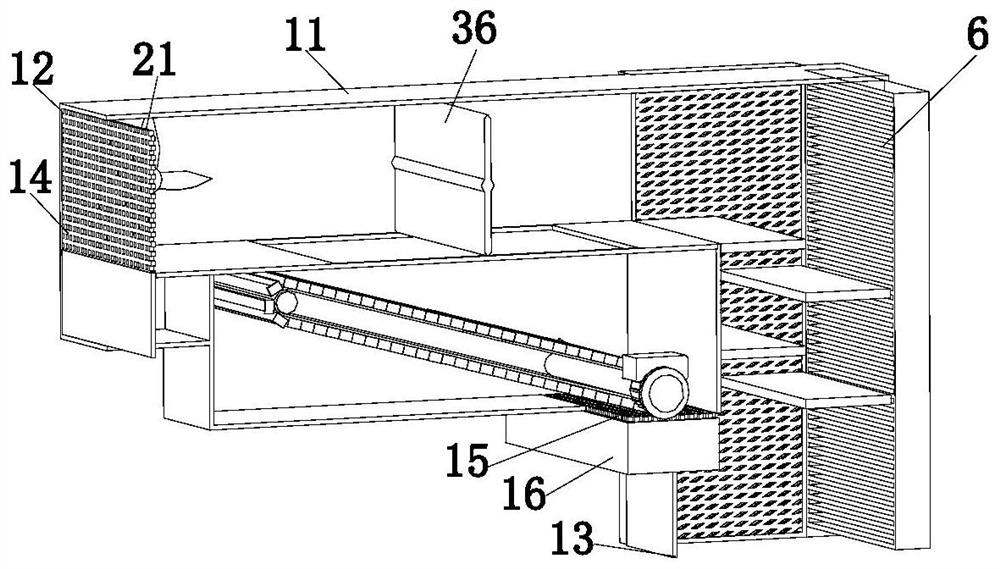

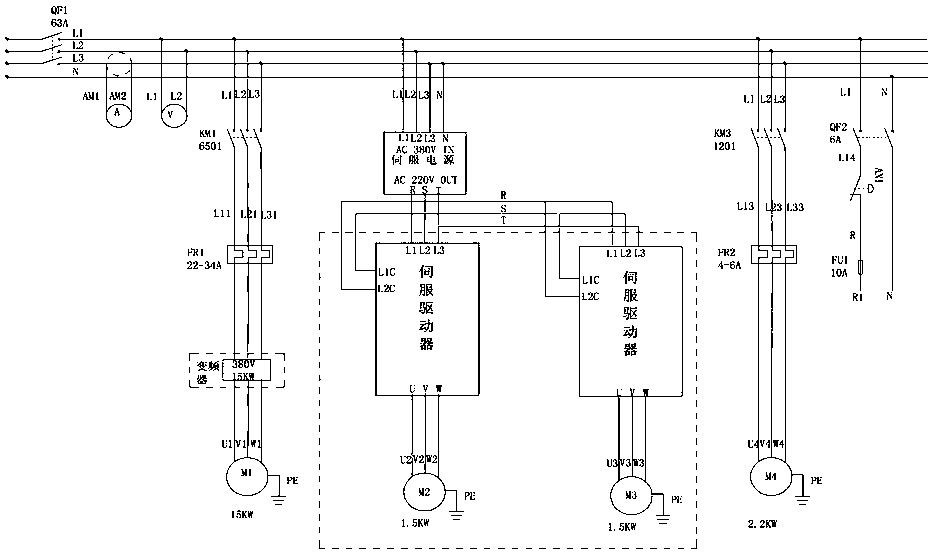

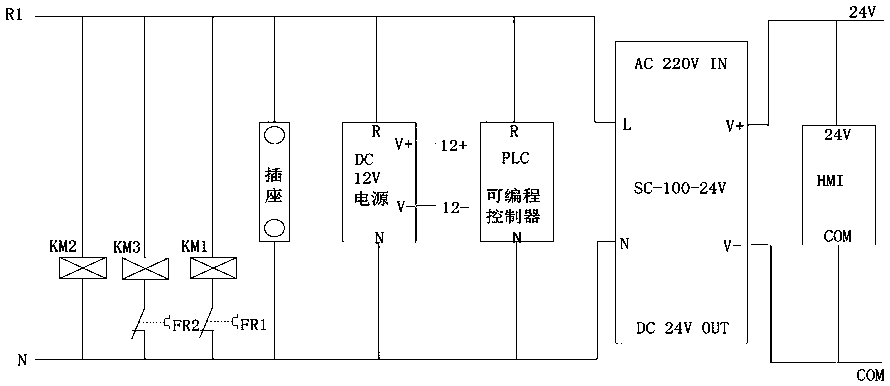

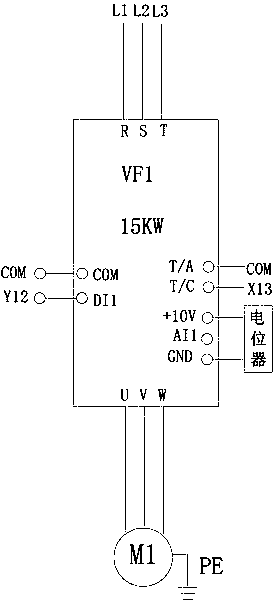

Infrared servo bridge type cutter control system

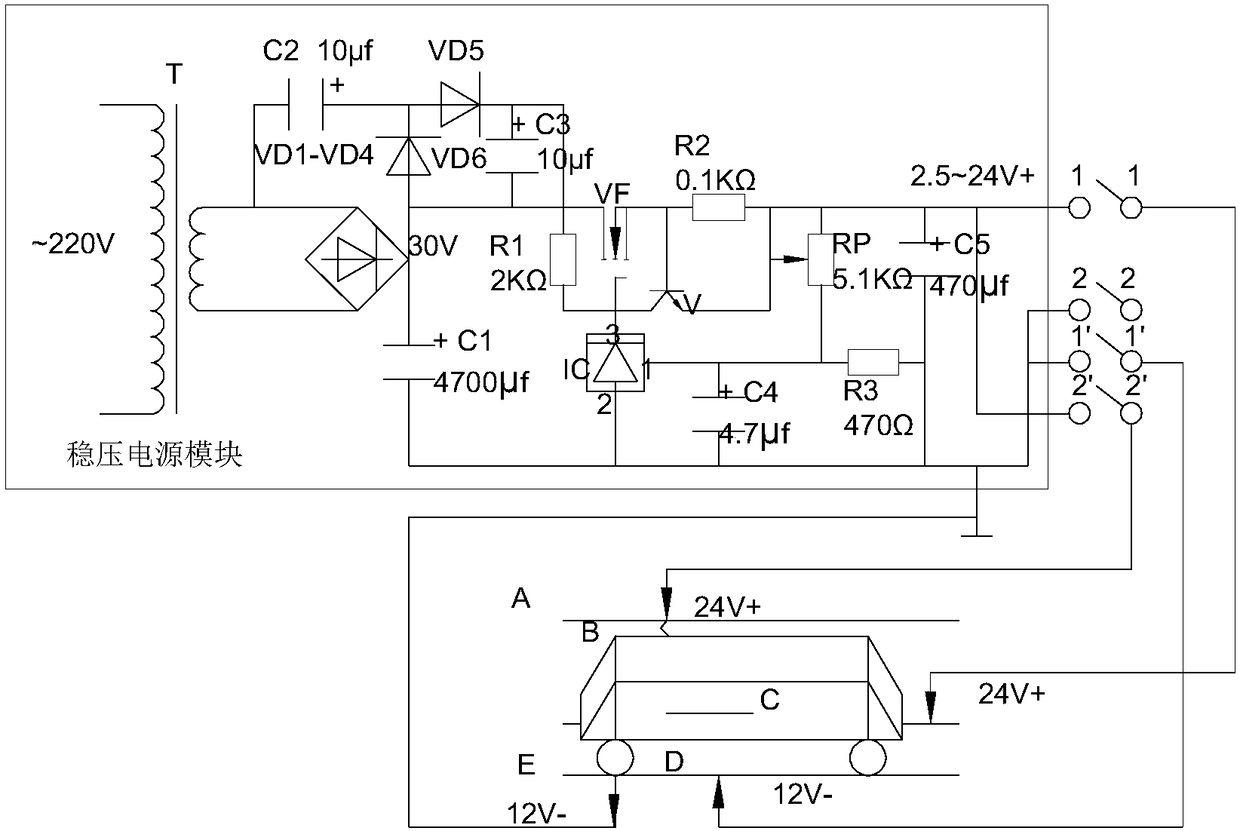

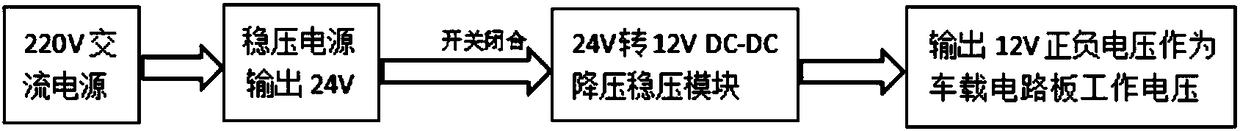

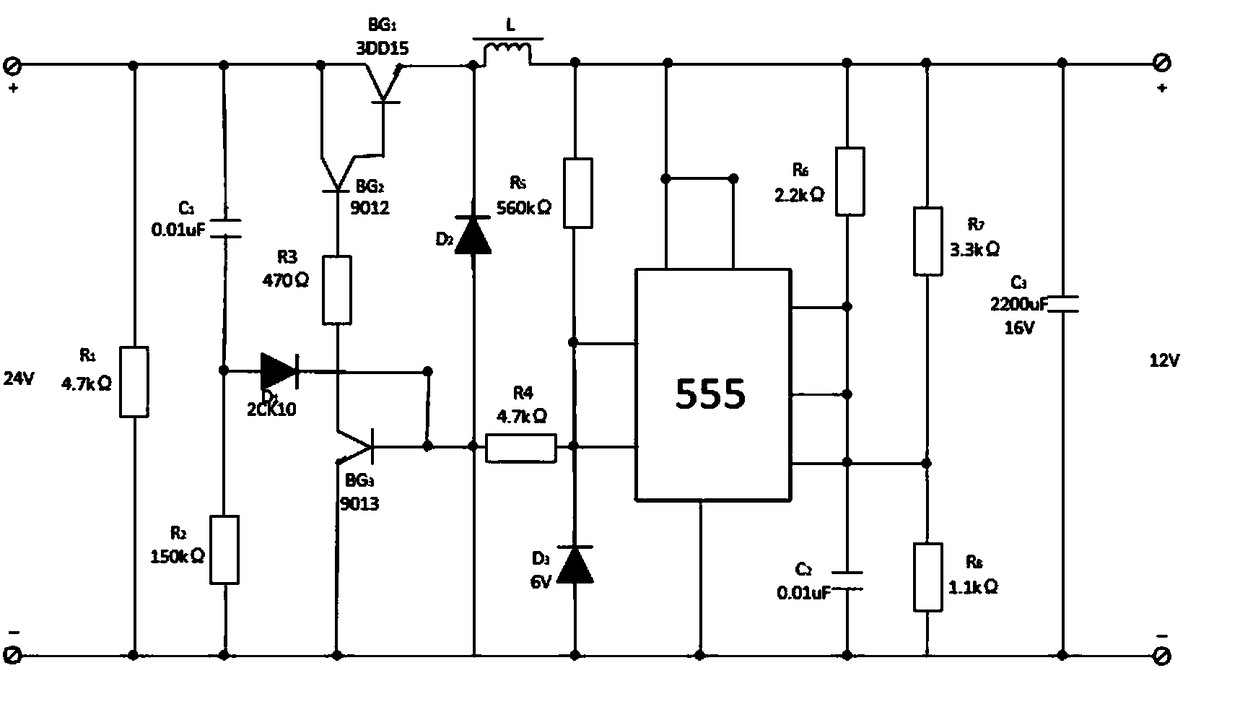

The invention provides an infrared servo bridge type cutter control system. The system comprises a main control circuit, a power control circuit and a PLC control circuit; the main control circuit is connected with the power control circuit; the power control circuit is connected with the PLC control circuit; the main control circuit comprises a power supply circuit which is of a three-phase four-wire system power supply mode, a main power supply switch, an ampere meter, a voltage meter and a motor driving device; the main power supply switch, the ampere meter, the voltage meter and the motor driving device are arranged on the power supply circuit; the main power supply switch is arranged at the input end of the power supply circuit; two ends of the voltage meter are respectively connected to two of three phase lines, and the rest phase line is connected in series with the ampere meter; the motor driving device comprises a main cutter circuit, a servo motor circuit and an oil pump motor circuit. According to the system, the PLC controller and the servo drive are adopted to control a travelling motor and a slicing motor, so that the control precision is high, the electricity energy loss is reduced, and the production efficiency is increased; the utilization efficiency of a water source can be improved through a water valve switch.

Owner:QUANZHOU XINHAI ENERGY TECH

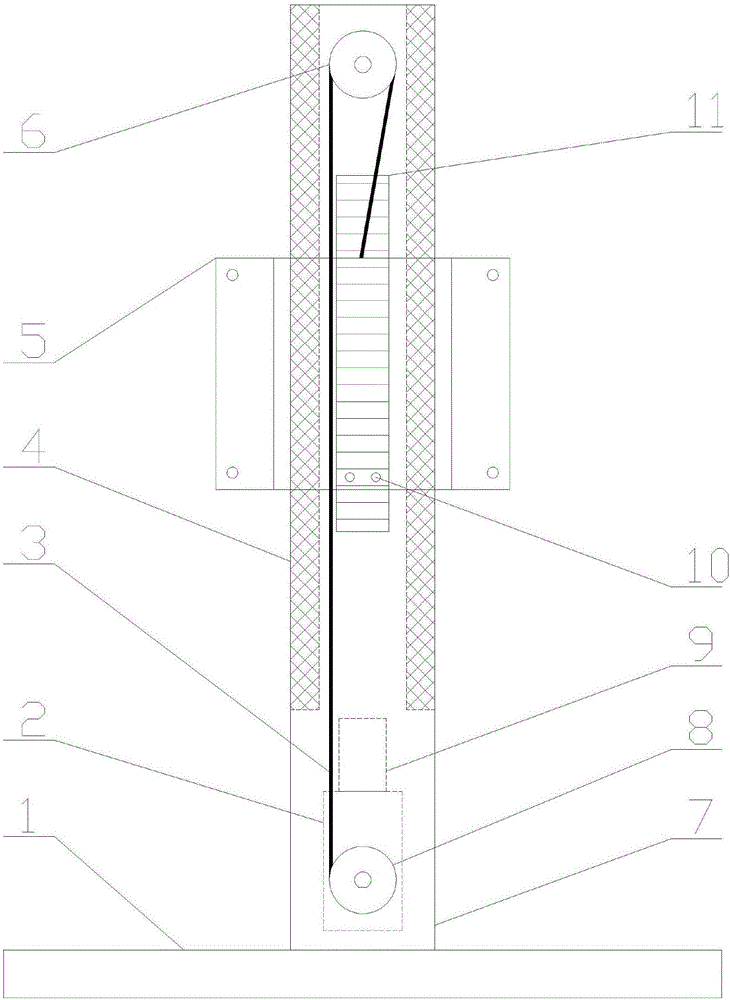

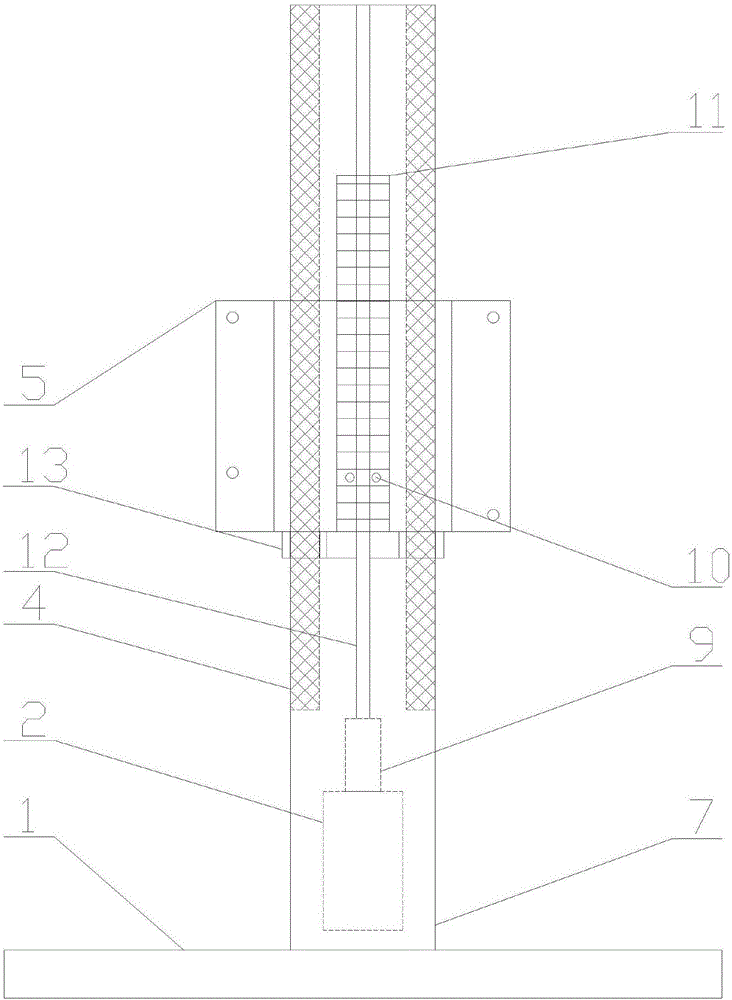

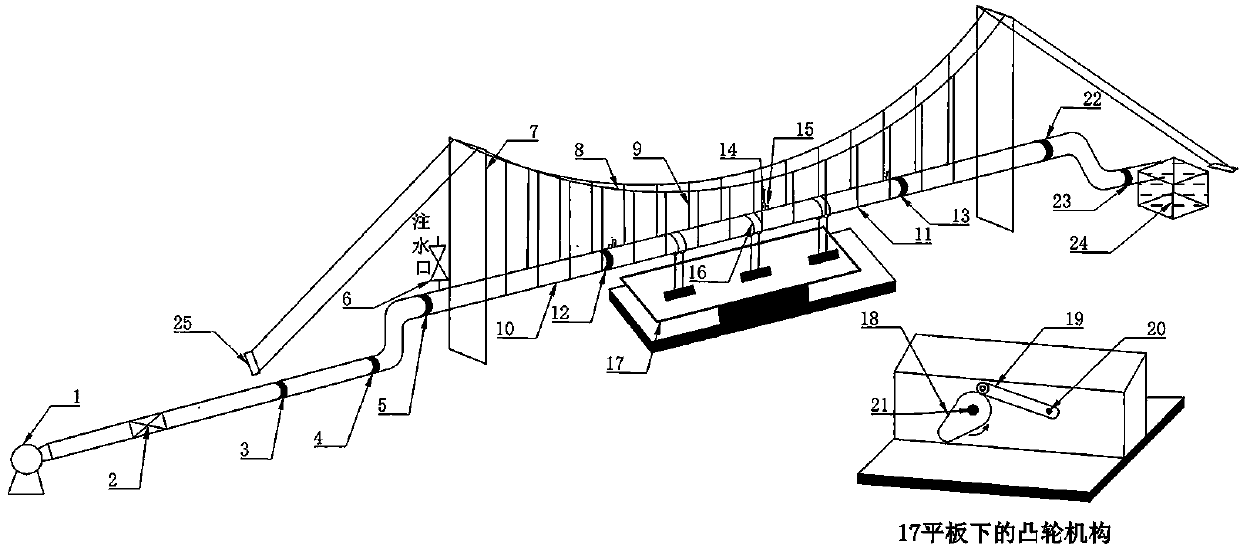

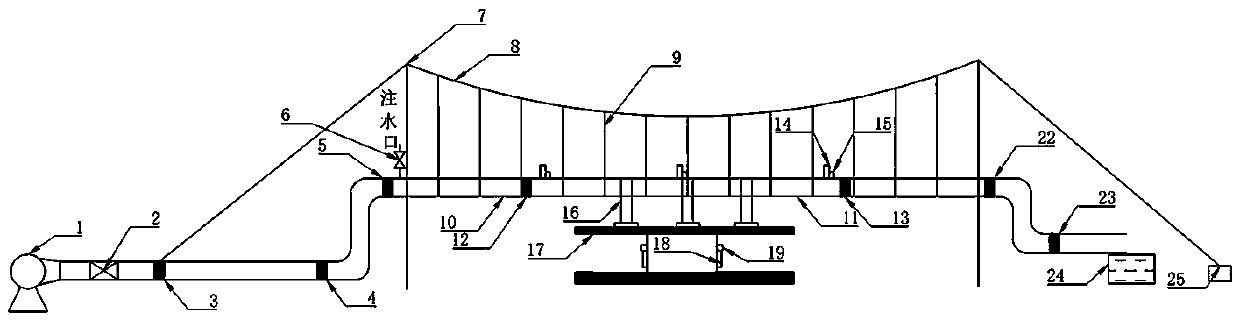

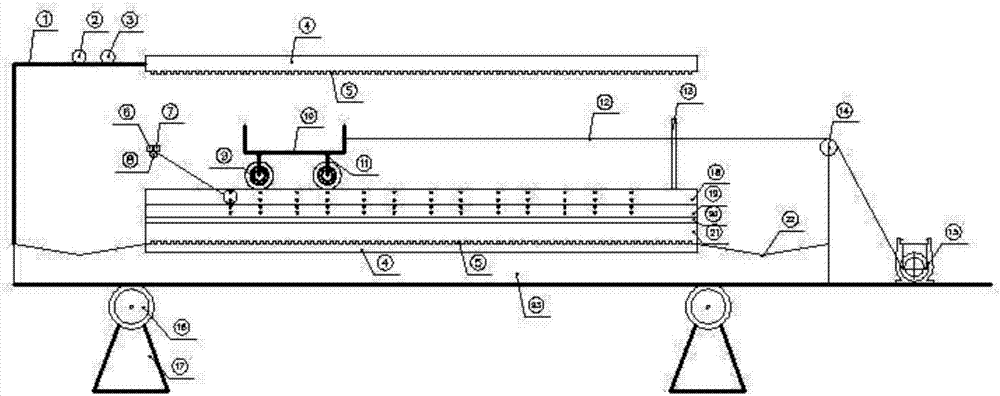

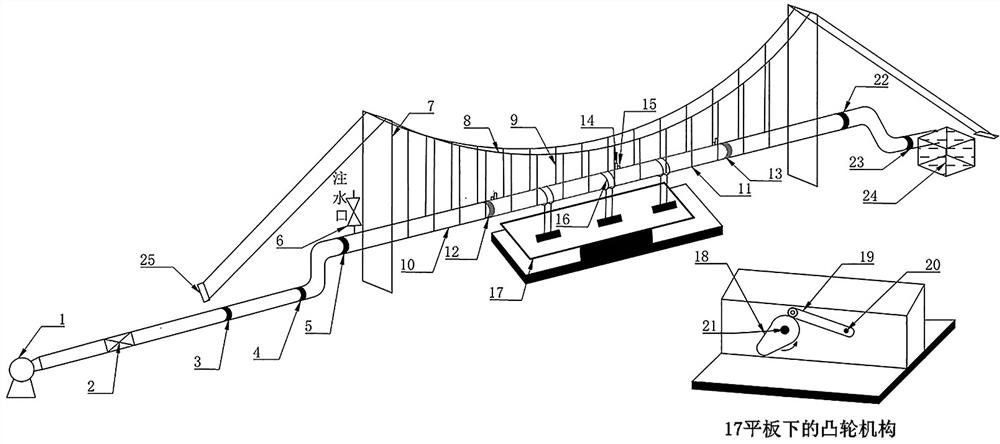

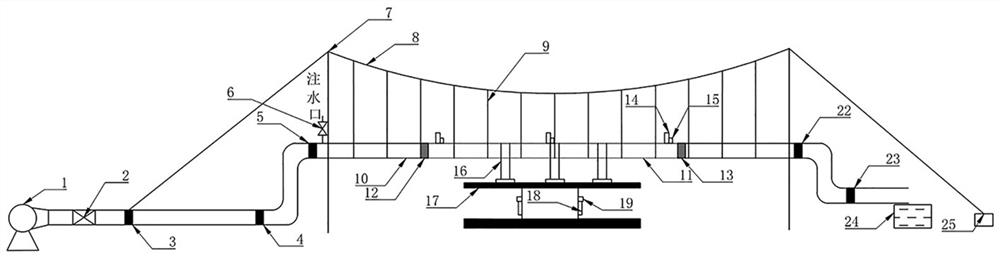

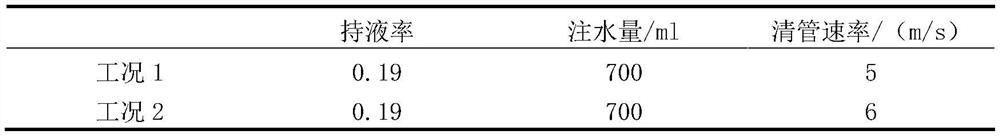

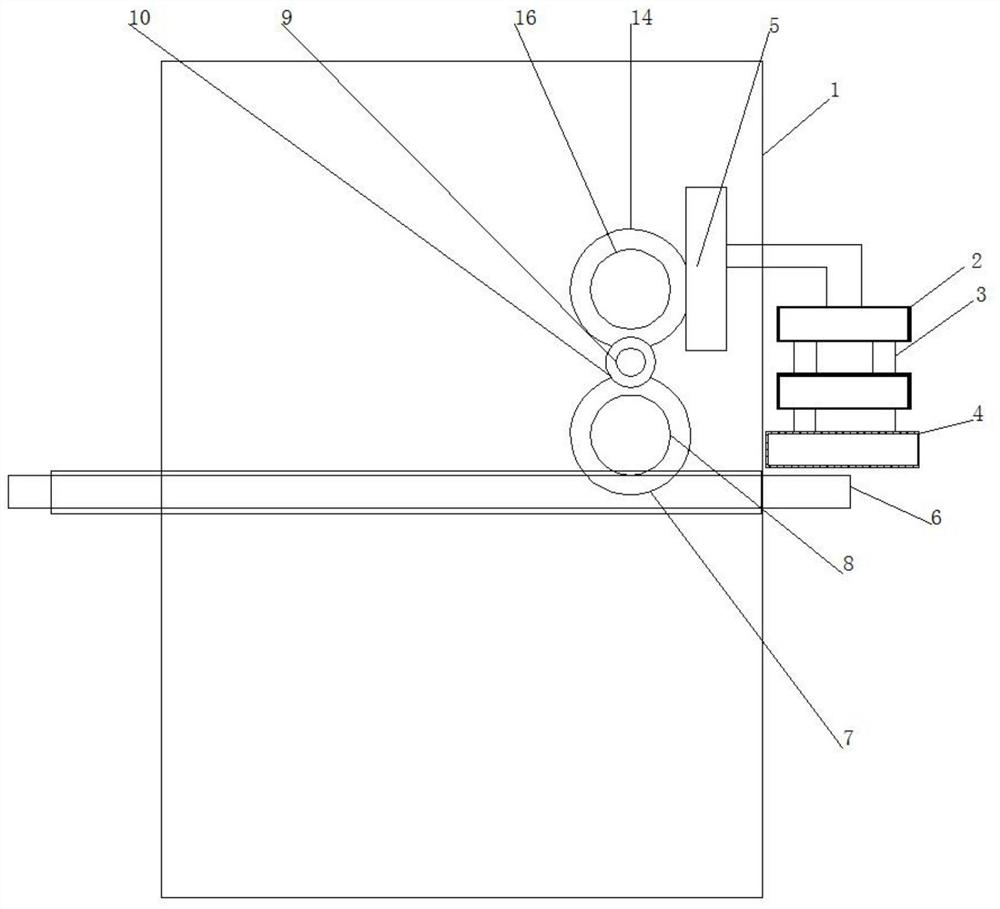

Device for carrying out pigging dynamic response experiment on natural gas pipeline cable-suspension structure

ActiveCN110726529AChange running speedGuaranteed vibration accelerationHydrodynamic testingVibration testingVibration accelerationPigging

The invention provides a device for carrying out a pigging dynamic response experiment on a natural gas pipeline cable-suspension structure. A transparent toughened glass pipe is connected with seamless steel pipes through flanges; a main cable is connected with towers as a main bearing component; fixing brackets can be used for fixing the seamless steel pipes, and are placed on a flat plate; a connecting rod can be driven to move up and down through the rotation of a cam below the flat plate in order to drive the flat plate to move up and down, thereby realizing upward and downward vibrationof a pipeline; and an acceleration sensor and a displacement sensor of a signal testing device can be arranged at corresponding positions of the seamless steel pipes according to testing needs. The device is mainly designed for researching the dynamic response and the influence on the two-phase flow of pigging during pigging of the natural gas pipeline cable-suspension structure, and can acquire the vibration acceleration, vibration displacement and the like of the pipeline cable-suspension structure under different pigging conditions, and simulate the influences of the pipeline on the two-phase flow pattern of pigging under different vibration conditions.

Owner:SOUTHWEST PETROLEUM UNIV

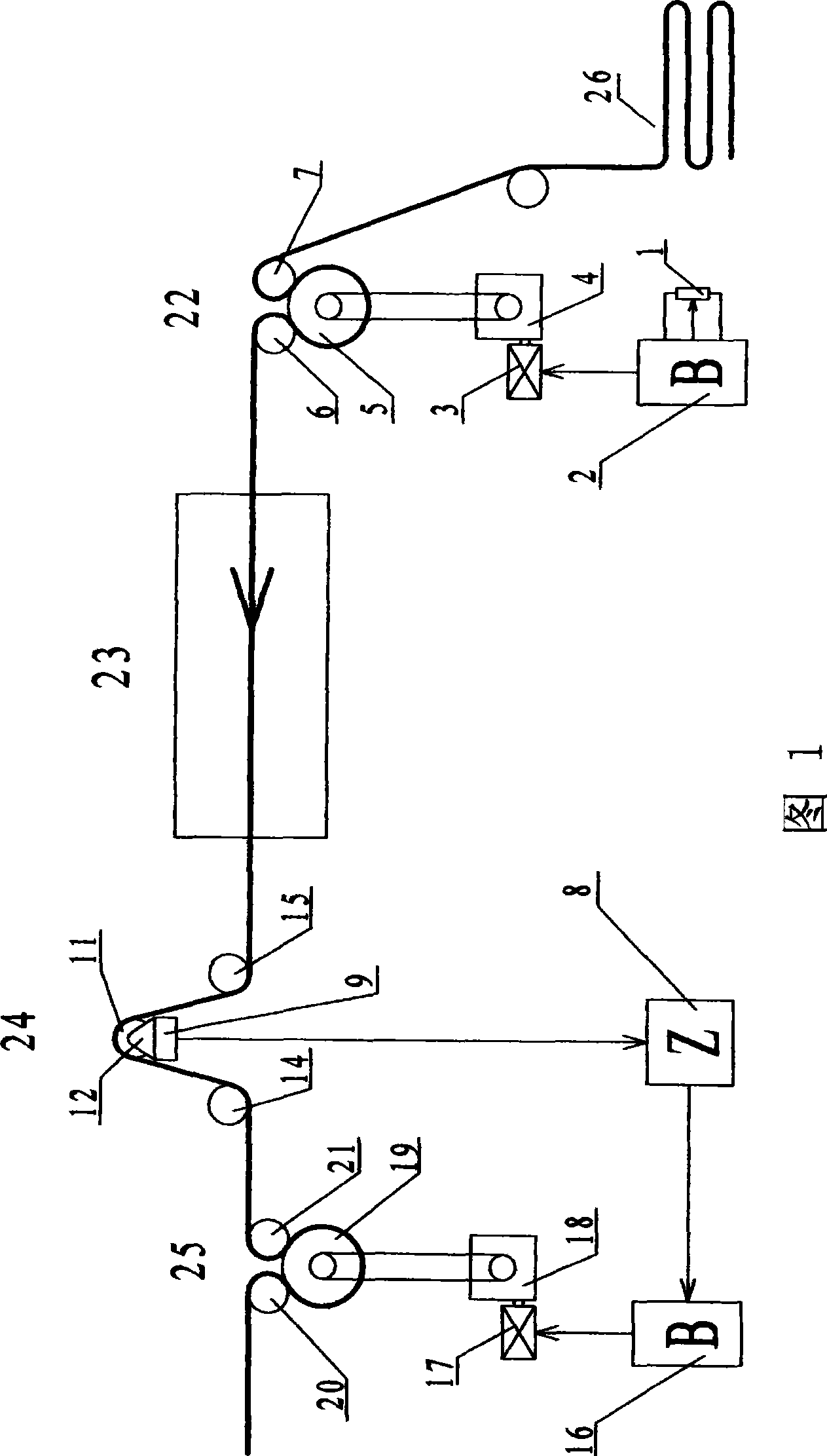

Carbon cloth tension automatic control device in low temperature carbonization furnace system

InactiveCN101419472AChange running speedChange speedHeating/cooling textile fabricsMechanical pressure/force controlFuel cellsAutomatic control

The invention relates to an automatic carbon cloth tension controlling device in a carbon cloth low-temperature carbide furnace system used by a fuel battery in the automatic control field. The device comprises a potentiometer, an inlet frequency variation controller, an inlet driving roller, a tension controller, a tension roller, an outlet frequency variation controller and an outlet driving roller. The inlet driving roller is positioned in front of a low-temperature carbide furnace; the inlet frequency variation controller, the potentiometer and the inlet driving roller form a closed loop feedback chain; the tension roller and the outlet driving roller are sequentially positioned behind the low-temperature carbide furnace; the tension controller is respectively connected with the tension roller and the outlet frequency variation controller; and the outlet frequency variation controller is connected with the outlet driving roller to output the carbon cloth. A tension sensor in the invention measures and obtains an instant tension value of the carbon cloth and is controlled by a feedback closed loop so that the carbon cloth tension control achieves high accuracy, satisfactory stability and fast response. Manual adjustment of the potentiometer can stabilize the invention in a new and balanced feedback loop so as to perform fine adjustment to the carbon cloth of different materials and to facilitate technical operations.

Owner:SHANGHAI SXCARBON TECH

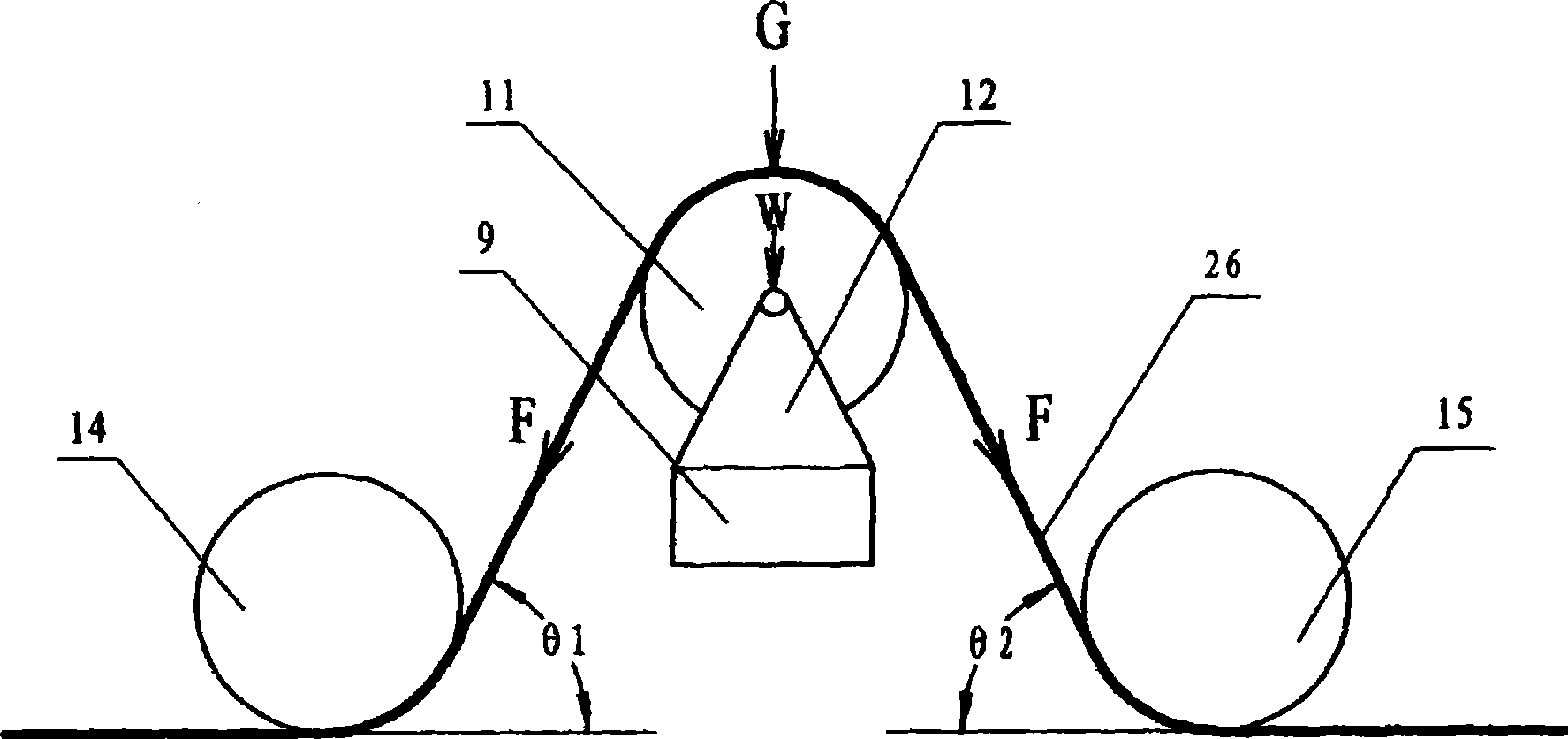

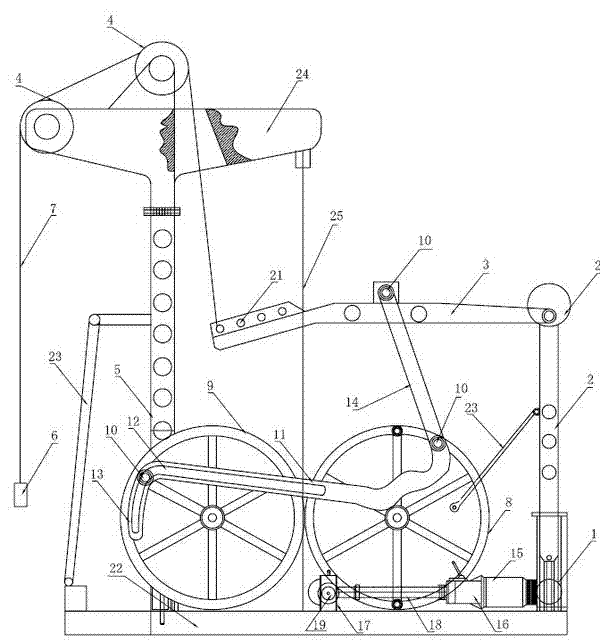

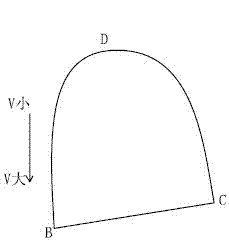

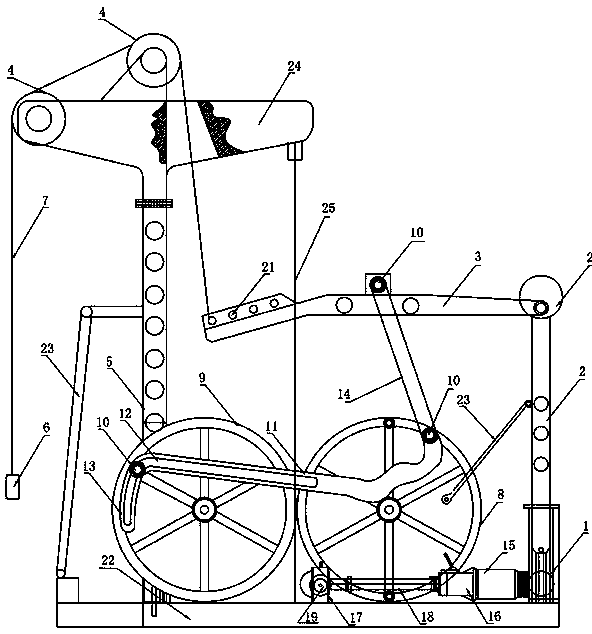

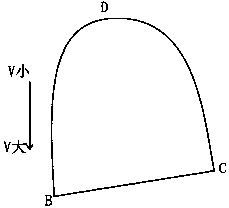

Automatic speed-changing wide-swing-angle oil pumping machine

InactiveCN102808602ASolve the oil spill problemImprove oil pumping efficiencyGearingFluid removalCrankshaftPulley

The invention relates to the technical field of oil extraction machinery, in particular to an automatic speed-changing wide-swing-angle oil pumping machine. The automatic speed-changing wide-swing-angle oil pumping machine comprises an electric motor, a speed changing mechanism, a swing arm support, a swing arm arranged on the swing arm support, a support provided with a fixed pulley and a wellhead oil pumping device, wherein the speed changing mechanism is connected with a driving crankshaft wheel, the driving crankshaft wheel is meshed with a driven crankshaft wheel, the driving crankshaft wheel is connected with a connecting piece through a bearing, one end of the connecting piece is connected with the driven crankshaft wheel, the other end of the connecting piece is connected with the swing arm through a connecting rod, a sliding chute is arranged on the connecting piece of which one end is connected with the driven crankshaft wheel, and a bearing on the driven crankshaft wheel is sleeved in the sliding chute. The automatic speed-changing wide-swing-angle oil pumping machine disclosed by the invention has the advantages that when the two crankshaft wheels are in rotation, since the position of the bearing of a driven pulley is changed, the position of the connecting piece can be also correspondingly changed, a motion trail of the connecting rod is affected by the motion of the connecting piece, the speed of the wellhead oil pumping device in the up-stroke is higher than that in the down-stroke, the oil leakage problem existing in an oil pumping process is avoided, and the oil pumping efficiency is increased.

Owner:德阳振华机械设备制造有限公司

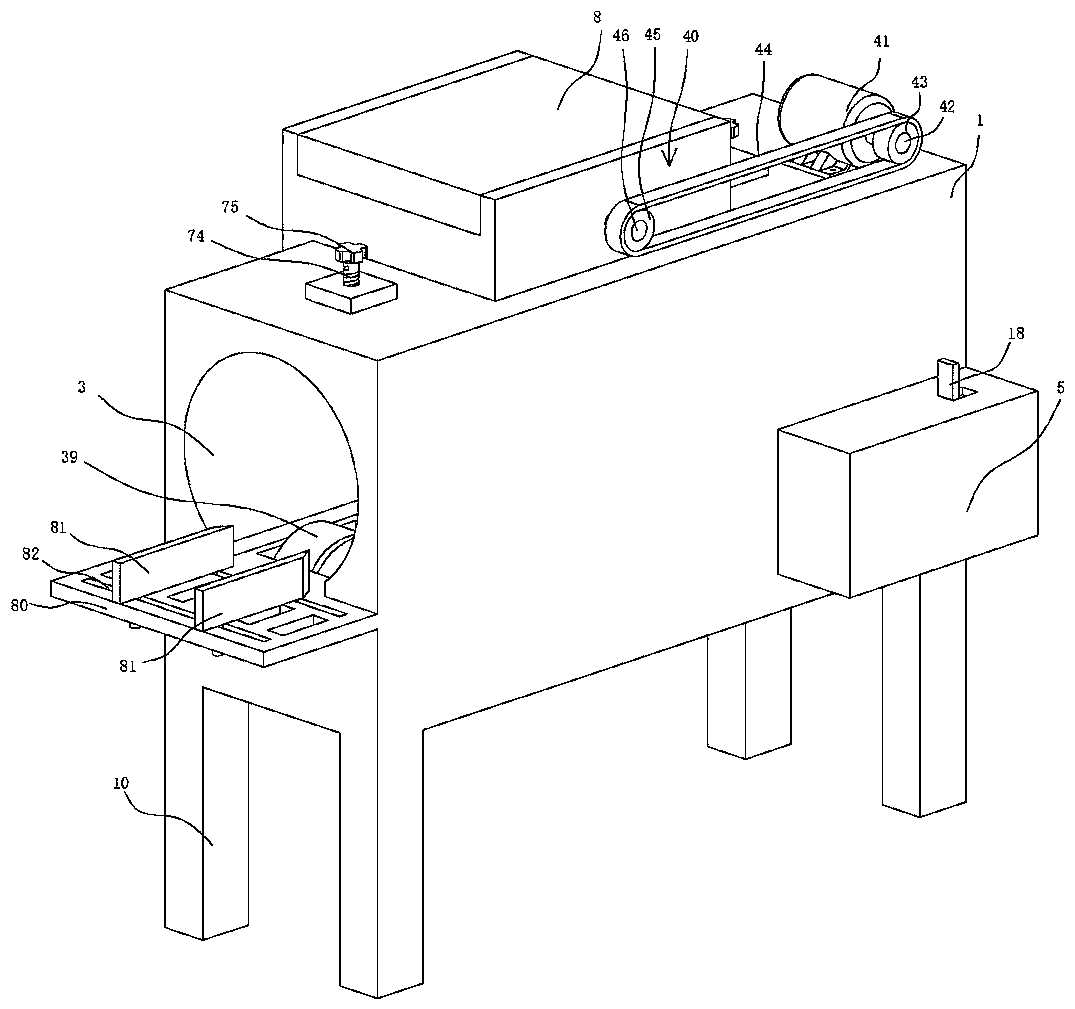

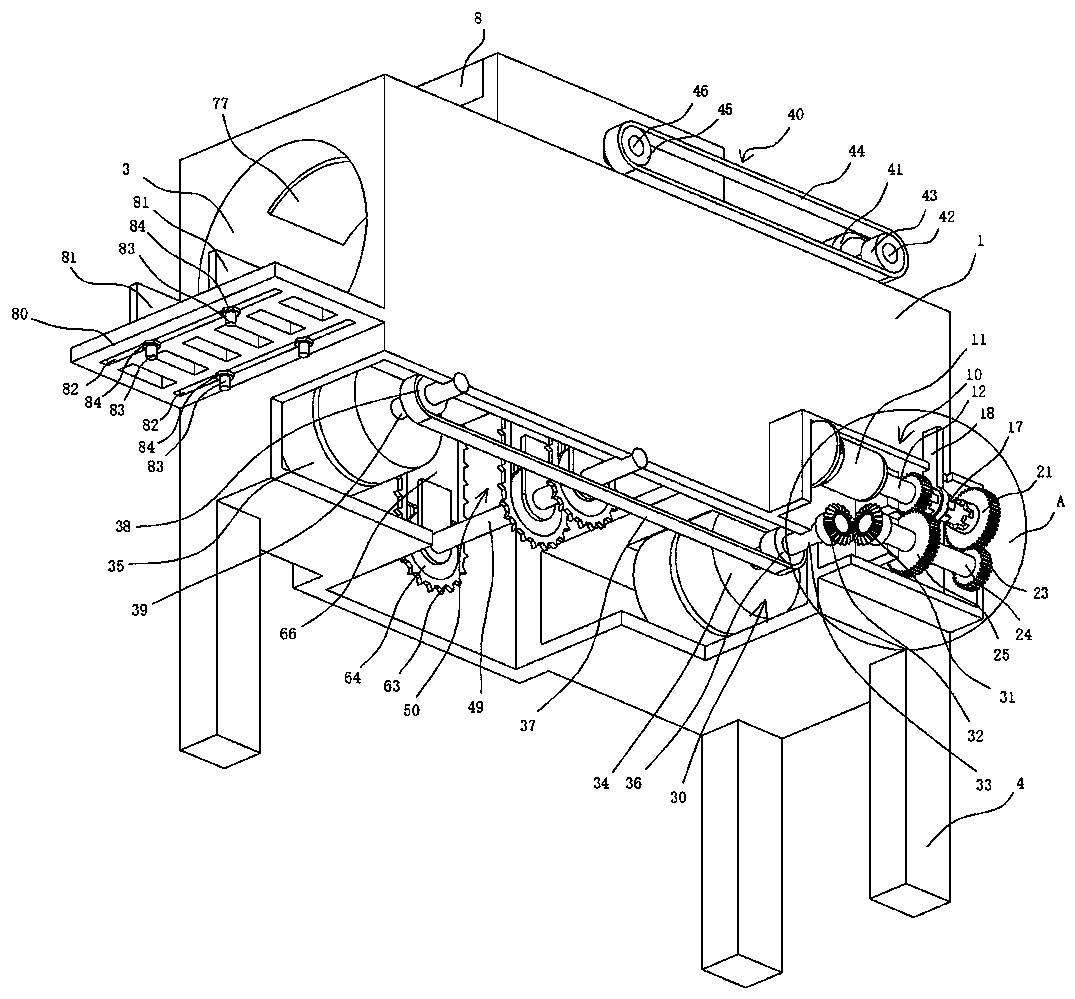

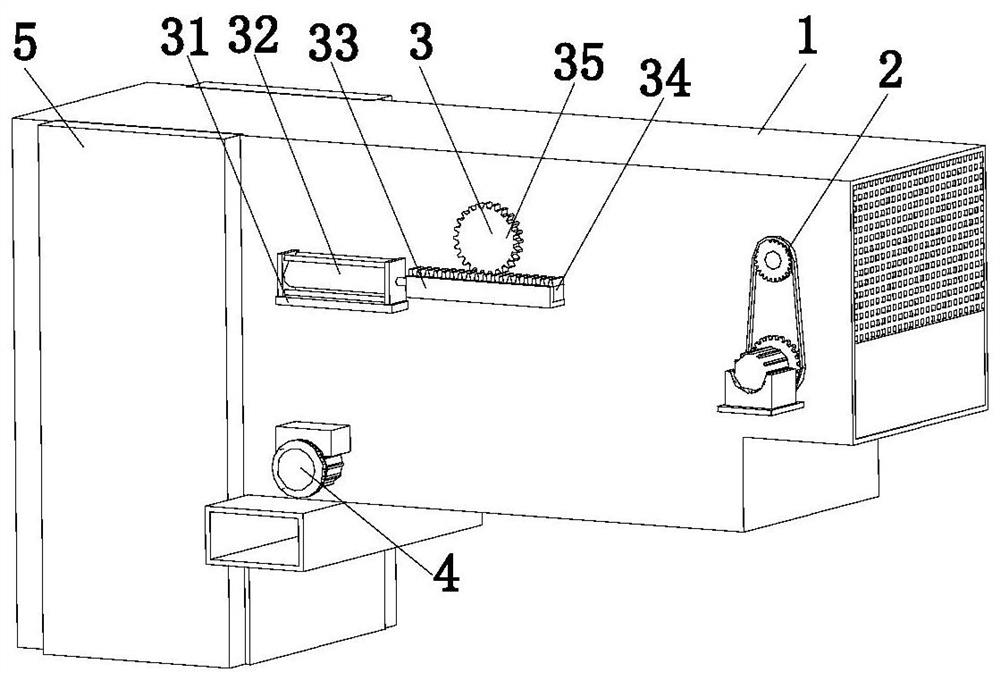

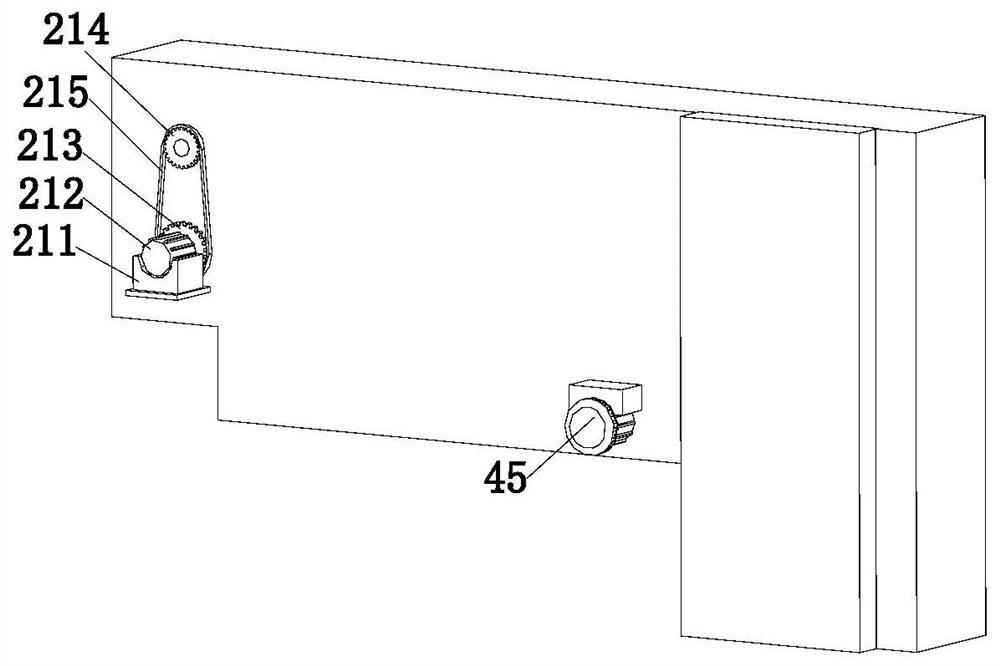

Wood cutting machine with adjustable cutting thickness

InactiveCN110666888AChange running speedImprove cutting efficiencyFeeding devicesChain sawsClutchAgricultural engineering

The invention discloses a wood cutting machine with the adjustable cutting thickness. The wood cutting machine with the adjustable cutting thickness includes a machine body, one end of the machine body is provided with a feeding port, the other end of the machine body is provided with a discharge port, and the bottom end of the machine body is provided with a plurality of uniformly-distributed landing legs. The wood cutting machine is characterized in that one side of the machine body is provided with a clutch mechanism having two-gear rotating speeds, one end of the clutch mechanism is provided with a transport mechanism for transporting wood, one side of the machine body is provided with a power mechanism, the power mechanism is provided with a plurality of uniformly-distributed cuttingmechanisms capable of moving, and the two ends of the machine body are each provided with a fixing mechanism for fixing the wood. The wood cutting machine has the beneficial effects that the wood withthe larger diameter can be cut, meanwhile, the wood cutting thickness can be adjusted according to the processing requirements, the adjustment method is simple, the wood diameter application scope ofthe wood cutting machine is increased, and the practicability of the wood cutting machine is improved.

Owner:杭州易岚永道景观设计有限公司

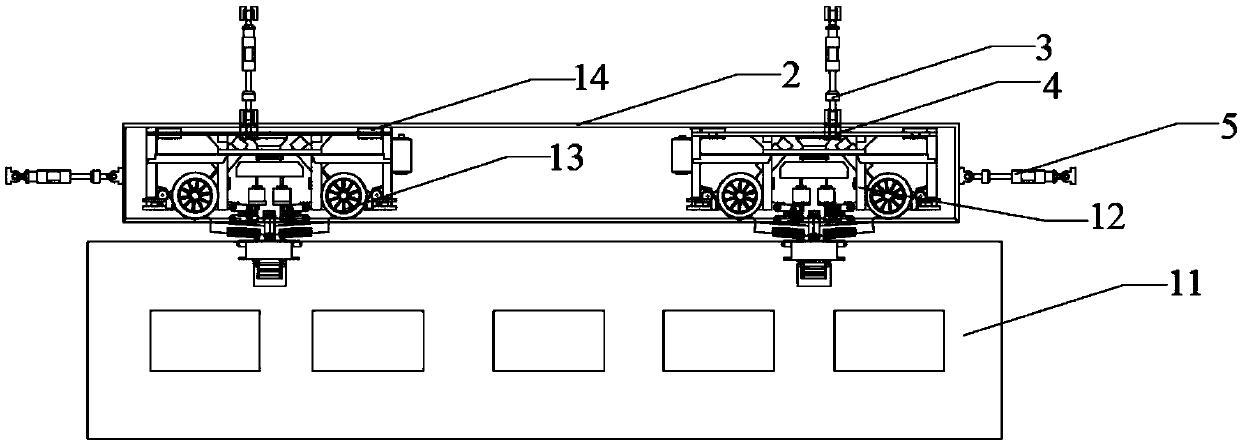

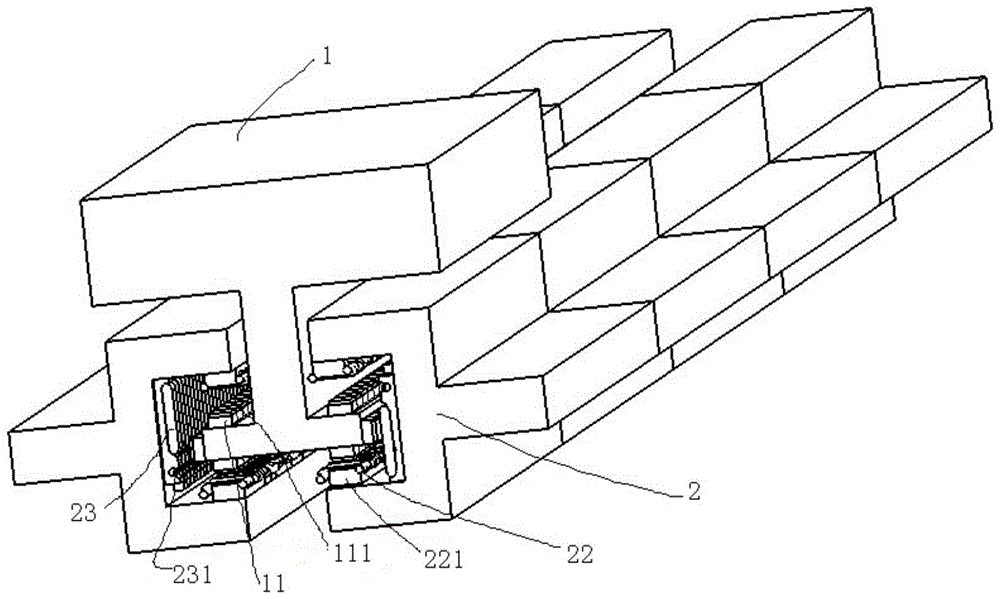

Hanging type single track vehicle rolling vibration test device

PendingCN109612749ASimulation running statusAccurate and reliable simulation operation dataRailway vehicle testingVibration testingBogieSingle vehicle

The invention discloses a hanging type single track vehicle rolling vibration test device. The hanging type single track vehicle rolling vibration test device comprises a single track vehicle, the single track vehicle comprises a vehicle body and a bogie, the vehicle body is arranged on the bogie through a shock absorber, the bogie is movably arranged in a track beam, a plurality of vertical actuators are symmetrically arranged above the track beam, two symmetric transverse actuators are transversely and separately arranged on the two sides of the track beam, and two longitudinal actuators aresymmetrically and separately arranged at two ends of the track beam. Caterpillar band conveyor belts are arranged on the two sides of the lower surface of the side surfaces of the track beam, a plurality of walking wheels are movably arranged on the caterpillar band conveyor belts of the lower surface of the track beam, and a plurality of guide pulleys are movably arranged on the caterpillar bandconveyor belts of the side surfaces. According to the hanging type single track vehicle rolling vibration test device, through the combination of the actuators in a plurality of directions, meanwhile, shock excitation is carried out on the track beam in the various directions, the operating state of a hanging type single track vehicle is effectively simulated, and the problems that the test device cannot effectively simulate vehicle operating state, cannot simulate test working condition as much as possible, and the cost is higher are solved.

Owner:SOUTHWEST JIAOTONG UNIV

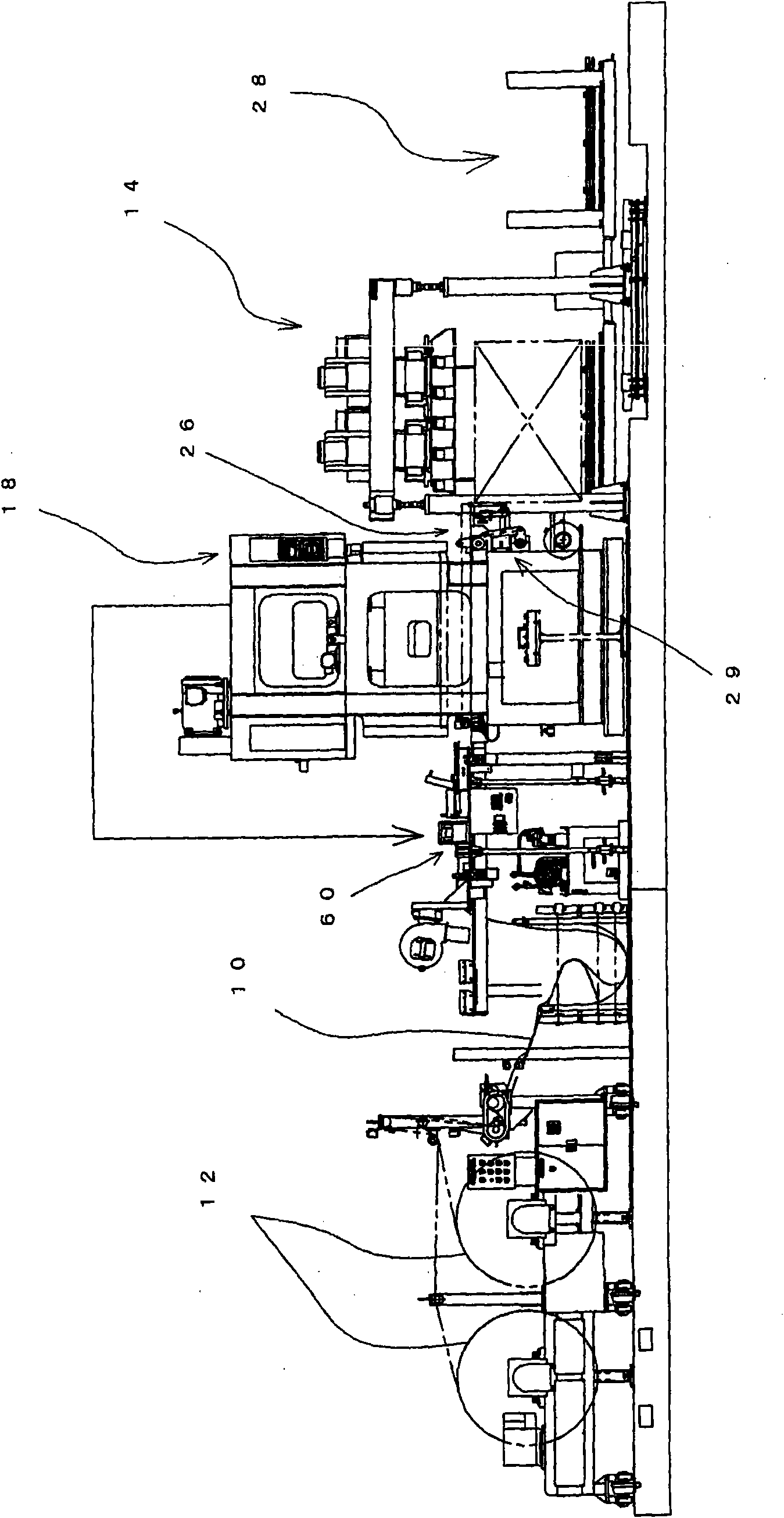

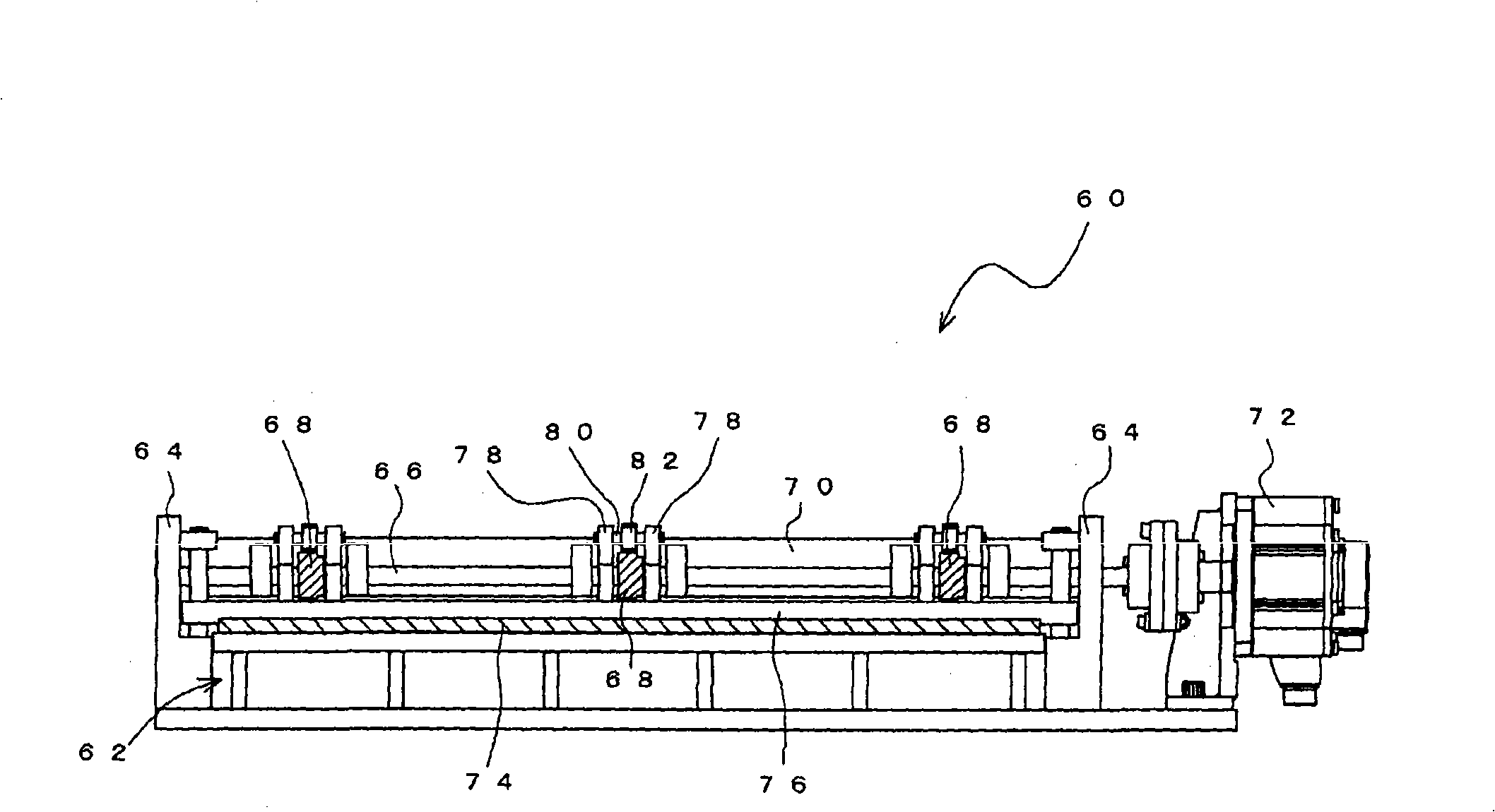

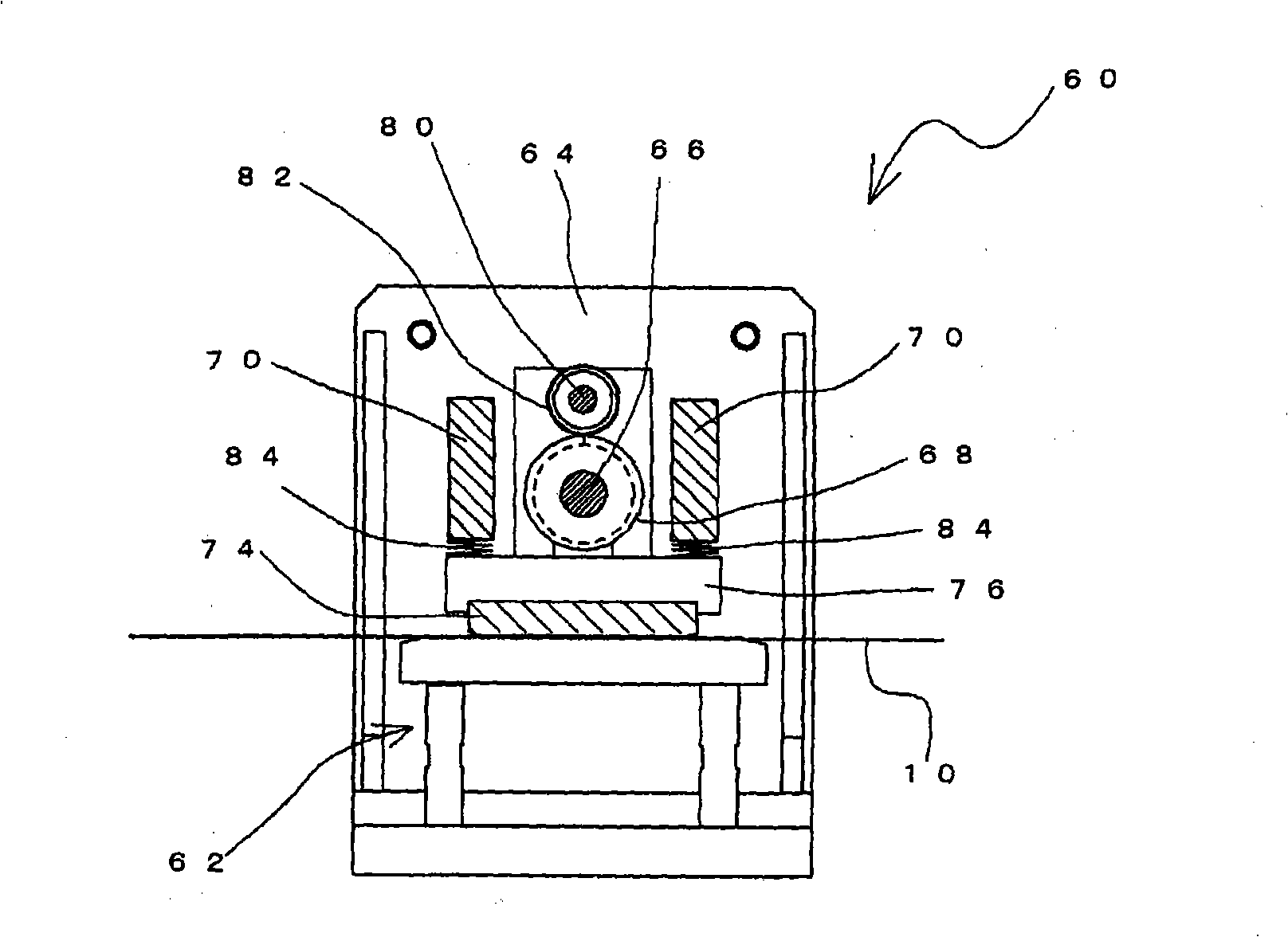

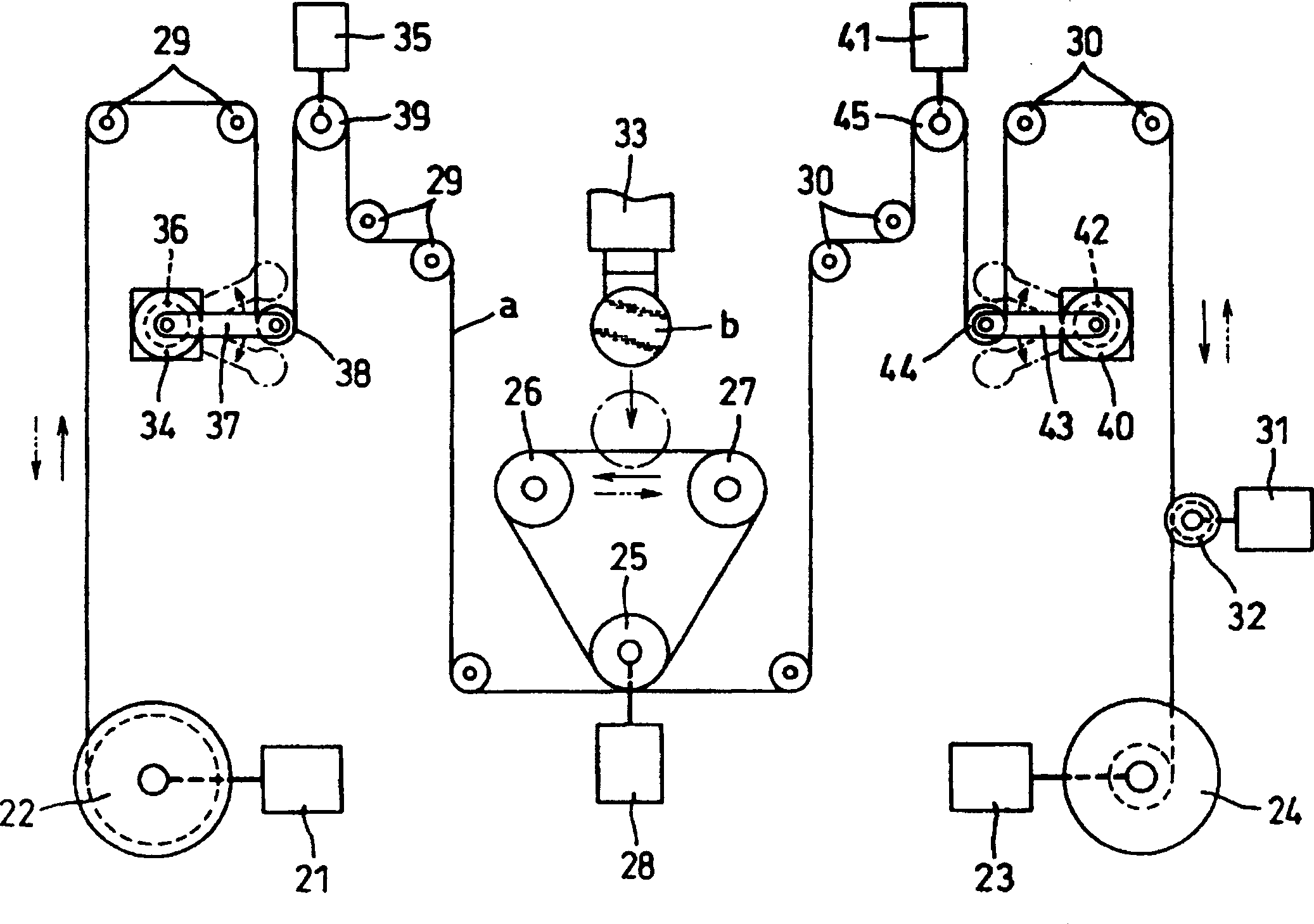

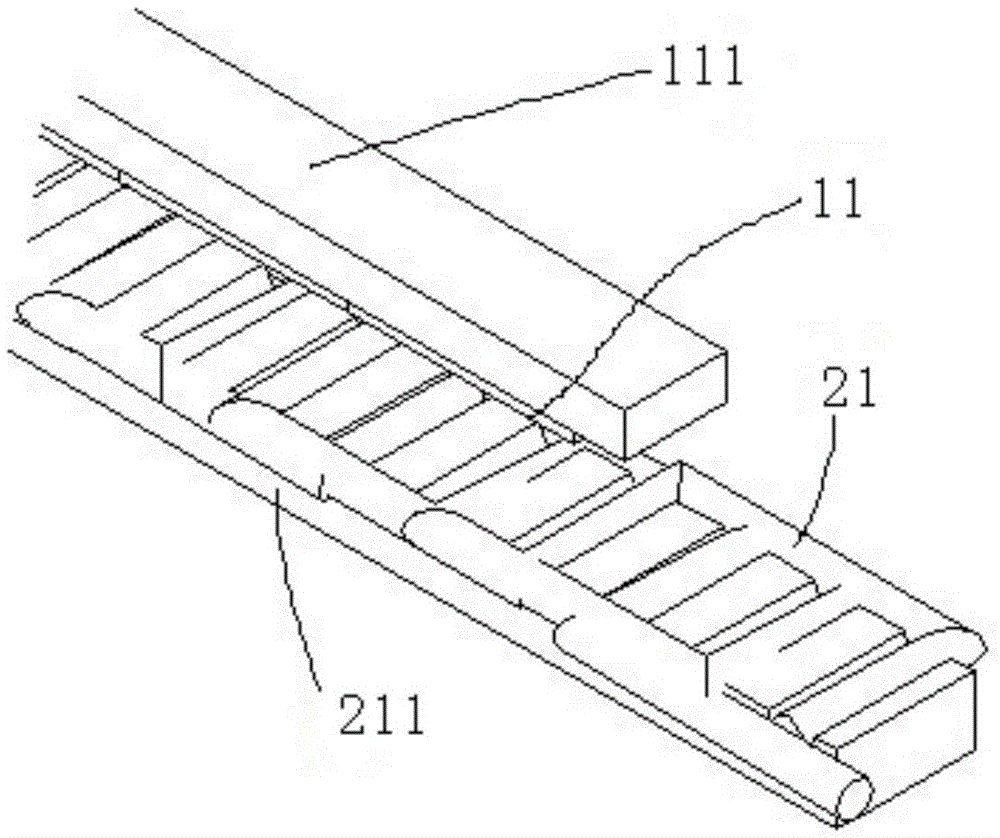

Tension device and heat exchange fin manufacturing machine

InactiveCN101537462AAvoid deformationChange running speedMetal-working feeding devicesHeat exchange apparatusBand shapeMechanical engineering

The tension device comprises: a feeding unit for feeding a band-shaped metal plate to a press unit; and a holding unit for applying tension to the band-shaped metal plate. The feeding unit is constituted by a moving member and a feeding pin. The front end of the feeding pin has a slope face so as to engage with a collared through-hole of the band-shaped metal plate when the moving member moves in a feeding direction of the band-shaped metal plate and so as to disengage therefrom when the moving member stops and moves in the reverse direction. The holding unit has a holding member, which holds and applies prescribed tension to the band-shaped metal plate when the moving member stops and which releases the band-shaped metal plate when the moving member starts to move in the feeding direction.

Owner:HIDAKA SEIKI KK

Asphalt and recycled concrete pavement testing apparatus

The invention discloses an asphalt and recycled concrete pavement testing apparatus which comprises an asphalt and recycled concrete pavement module, a loading traction device, a dip angle adjusting device, a measurement device and a rainwater device. The asphalt and recycled concrete pavement module includes an asphalt and recycled concrete layer, a recycled concrete type rubble layer, a cushion layer and an earth filling layer which are arranged from top to bottom. The loading traction device comprise a roller, a weight-bearing supporting plate, a connecting piece, a traction rope, an anti-collision plate, a guiding wheel and a variable-frequency and variable-speed motor. The dip angle adjusting device comprises a scale rotating wheel, an extensible support and a working platform. The measurement device comprises a thermometer, a flowmeter, a pressure meter, a horizontal displacement meter, a vertical displacement meter, a shake sensor and a rate meter. The rainwater device comprises a water guiding frame and a water distributor. The water distributor is arranged on the earth filling layer, and the earth filling layer is arranged on the working platform. Different situations are systematically researched, a corresponding relation between the situations and pressure, displacement and shake is established, technical support is provided for road project application of building waste, and meanwhile the utilization rate of the testing apparatus is improved.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

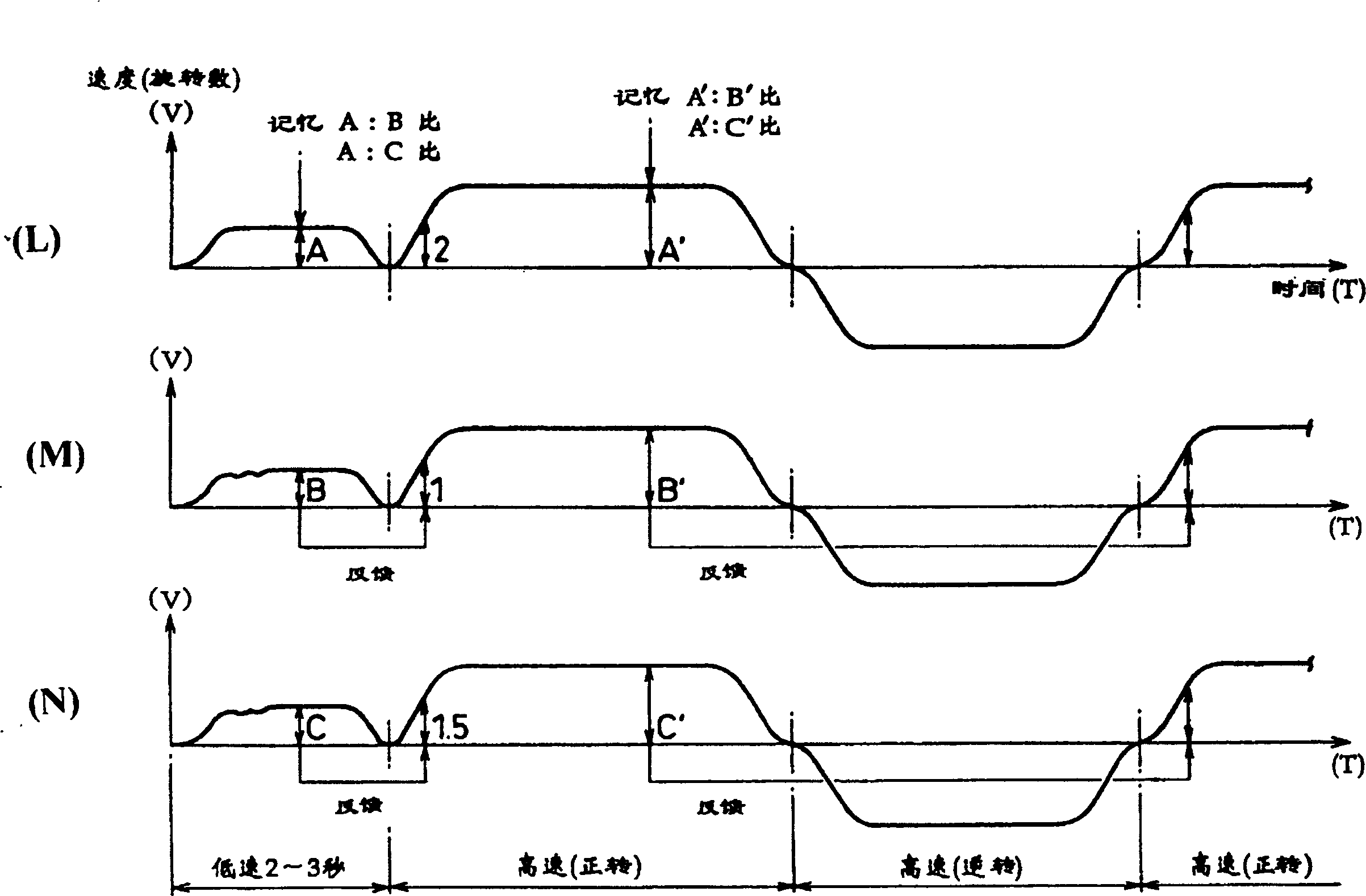

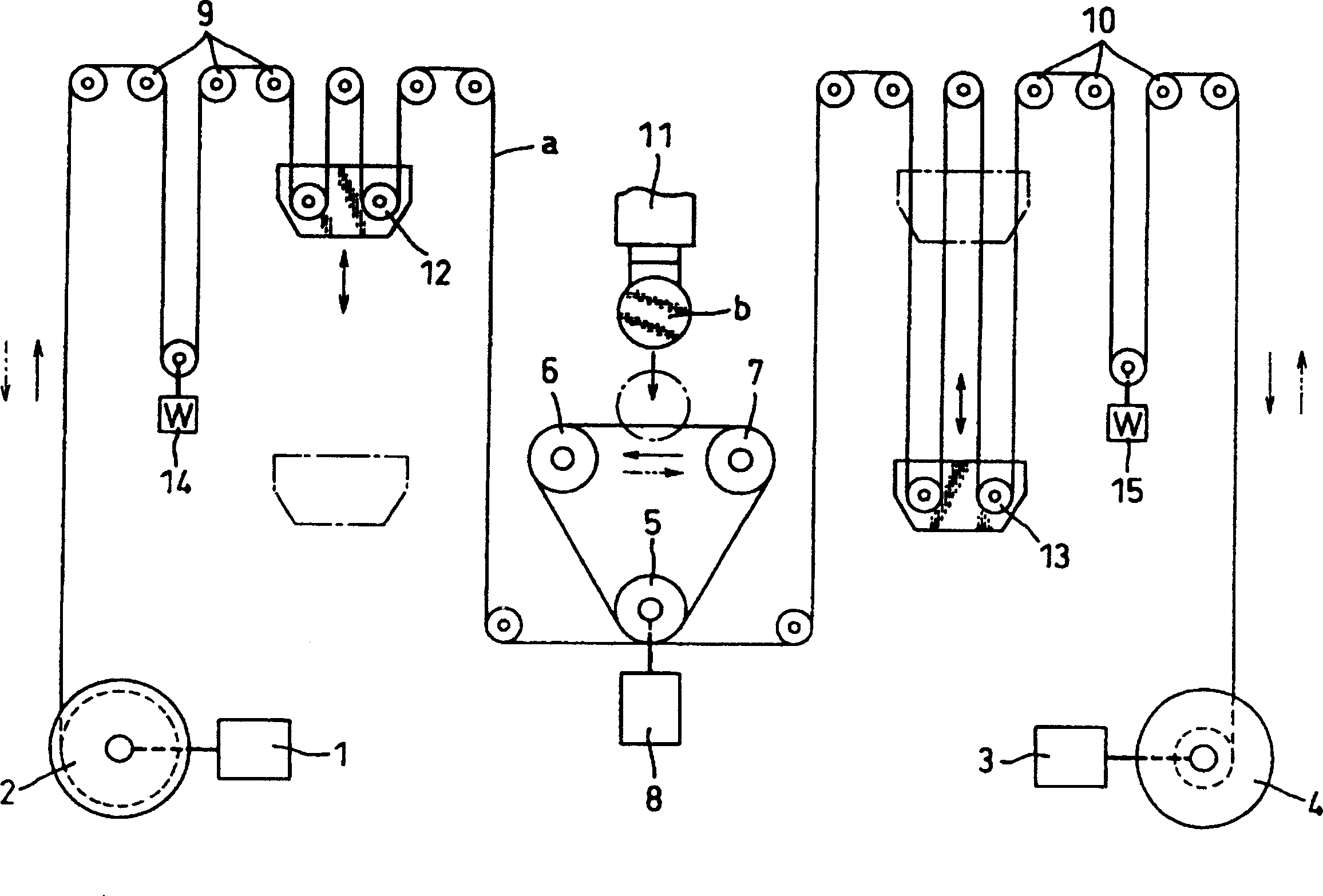

Method for wire-cutting controlling metal wire moving

InactiveCN1116953CRun fastChange running speedFilament handlingElectrical-based machining electrodesLow speedElectric machinery

The present invention relates to a wire traveling control method. A wire is wrapped on the multislot roller between a supply roller and a recovery roller, at start of operation, the three rollers are normally rotated and a wire is traveled at a low speed. A correlative speed ratio is calculated at a time when traveling of the wire is stabilized. The respective driving motors are simultaneously started at a high speed on the basis of the speed ratio. Next, the speed ratio of the supply roller driving motor and the recovery roller driving motor with respect to the multislot roller driving motor at the high speed traveling is stored. The respective driving motors are controlled to reversely rotate with the stored speed ratio at returning traveling of the wire, which is repeated at reciprocating traveling of the wire thereafter, thereby to realize the control to a metal wire. The structure of the application device of the present invention is simple and wire additional tension is steady.

Owner:TAKATORI

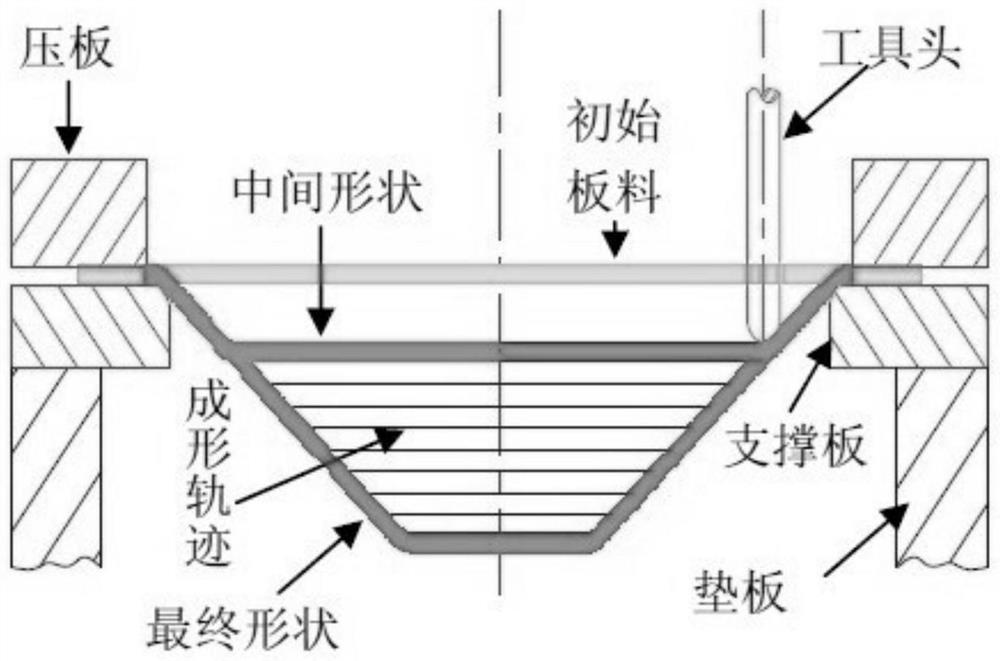

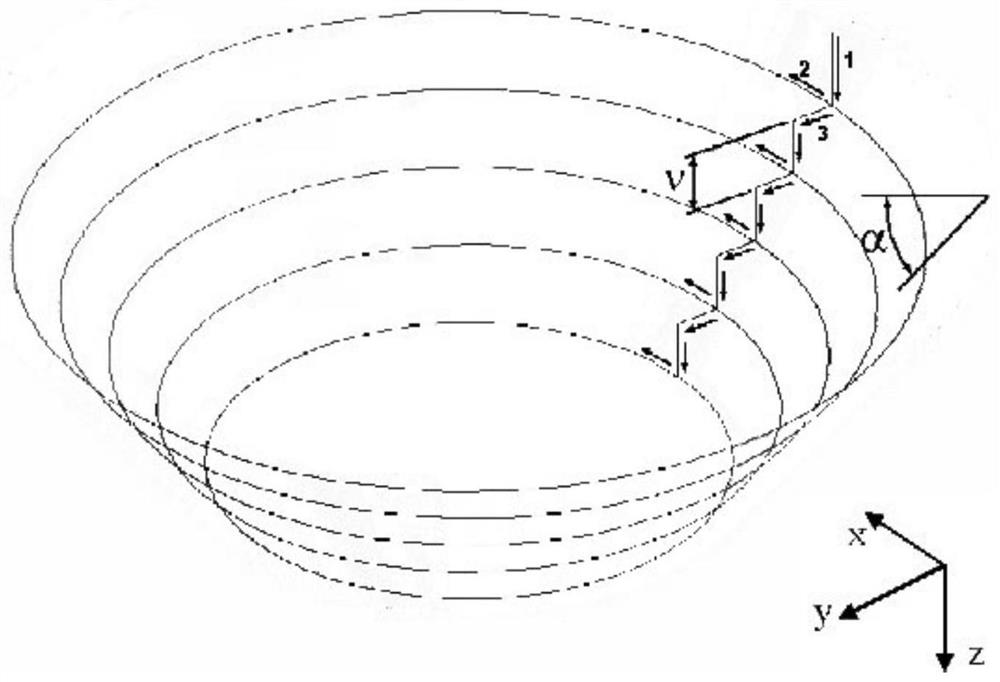

Self-adaptive control incremental forming method

ActiveCN112517746AReal-time detectionGood forming precisionMachining processUltimate tensile strength

The invention discloses a self-adaptive control incremental forming method. According to the method, machining parameters are changed according to local strain, change of the machining parameters comprises the steps of changing the diameter of a tool head, the running speed of the tool head and the layer-by-layer feeding amount in real time, the forming precision and forming quality of machined parts are improved within the shortest machining time, and the flexibility and operability of an incremental forming machining process are fully utilized; and according to the method, different self-adaptive incremental forming machining schemes are formulated by referring to different forming materials, and basic parameters of the schemes comprise the tensile strength and the shear strength of thematerials.

Owner:SOUTHEAST UNIV

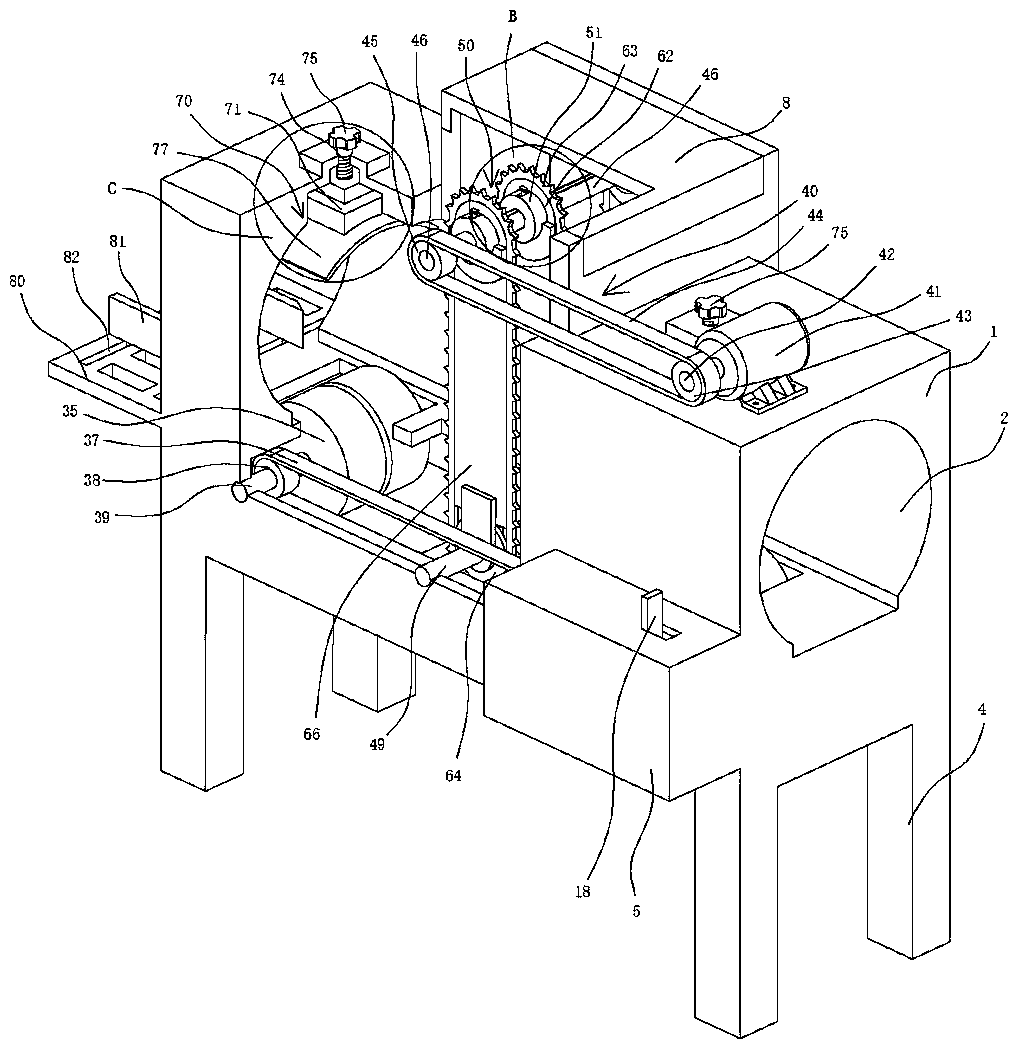

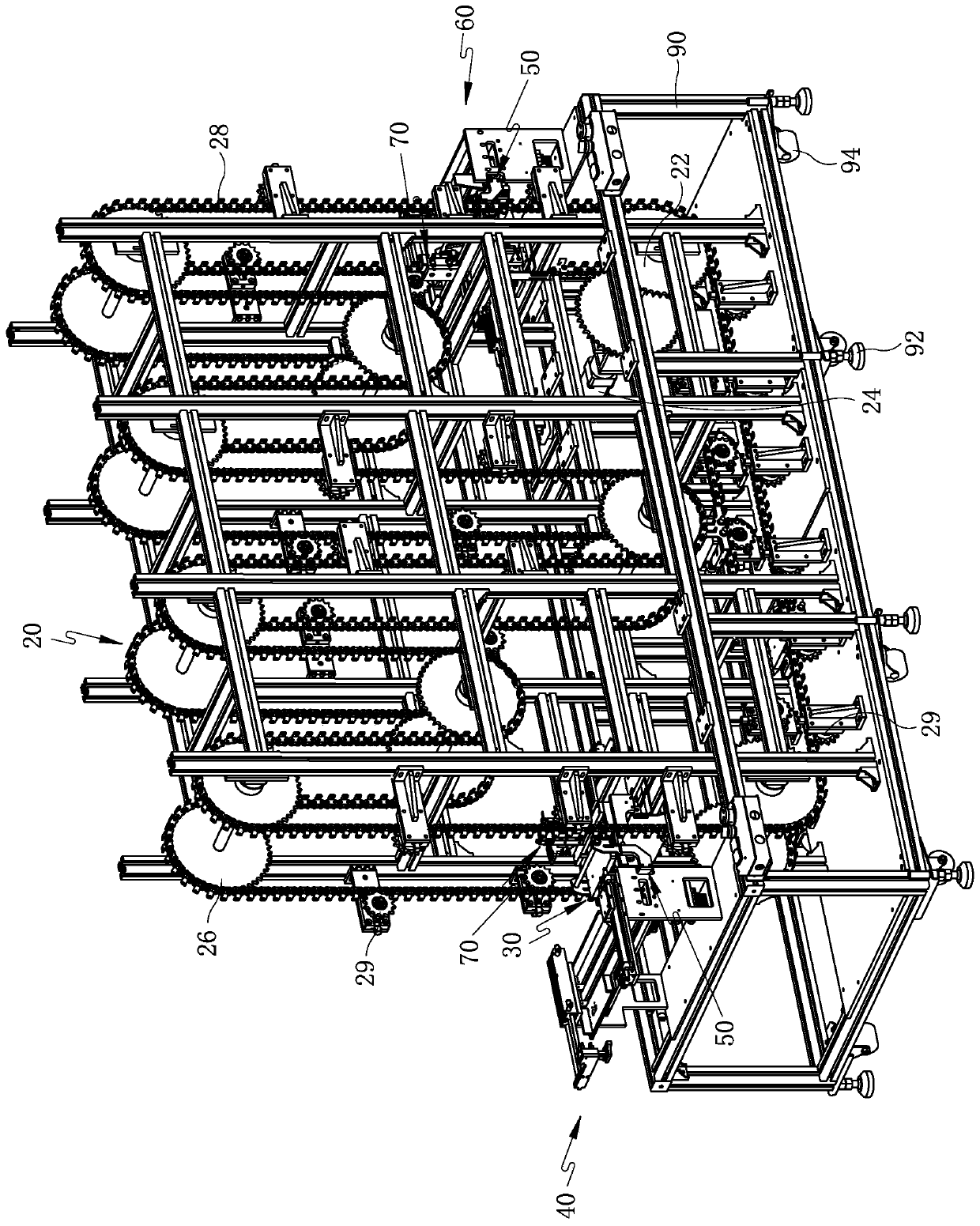

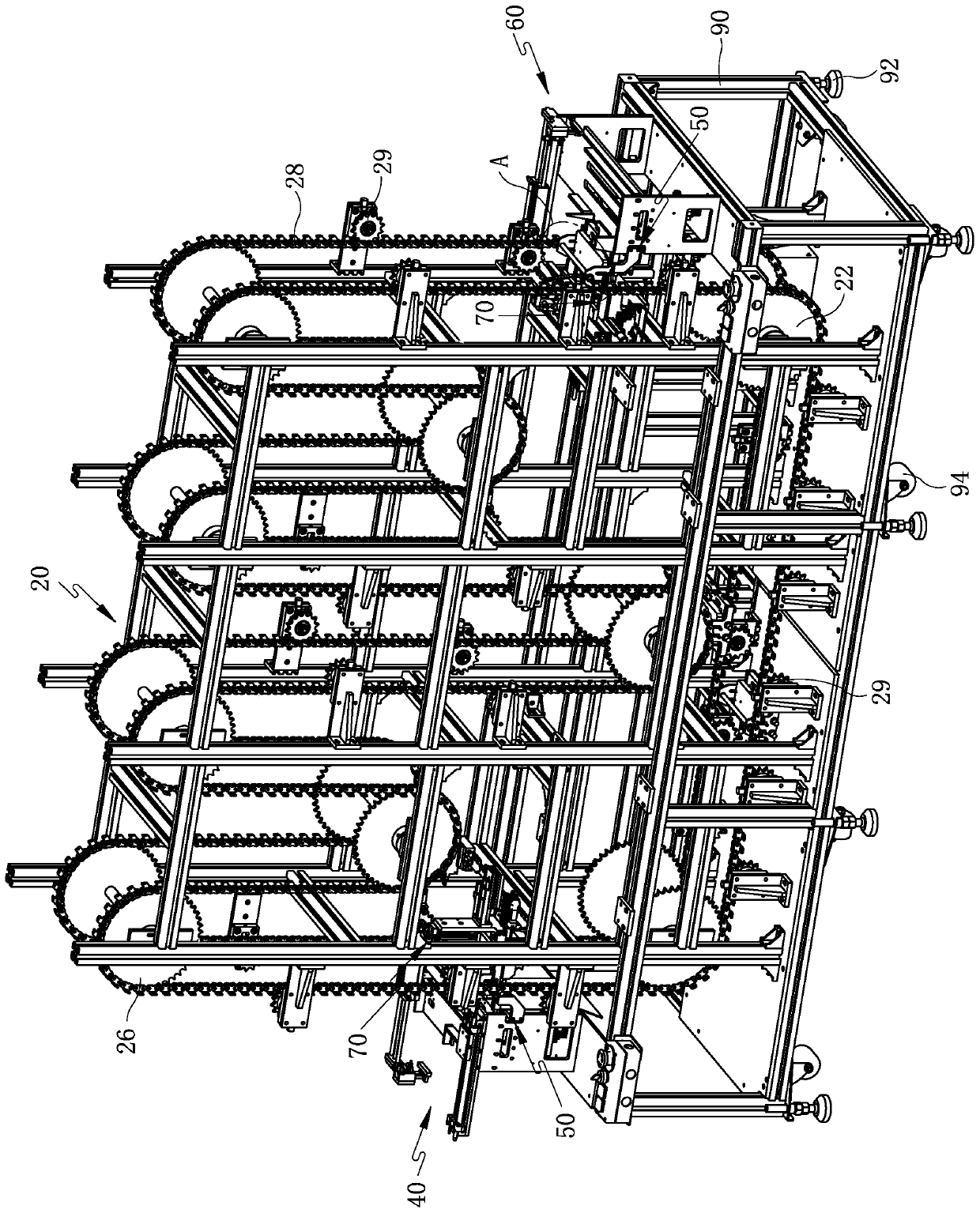

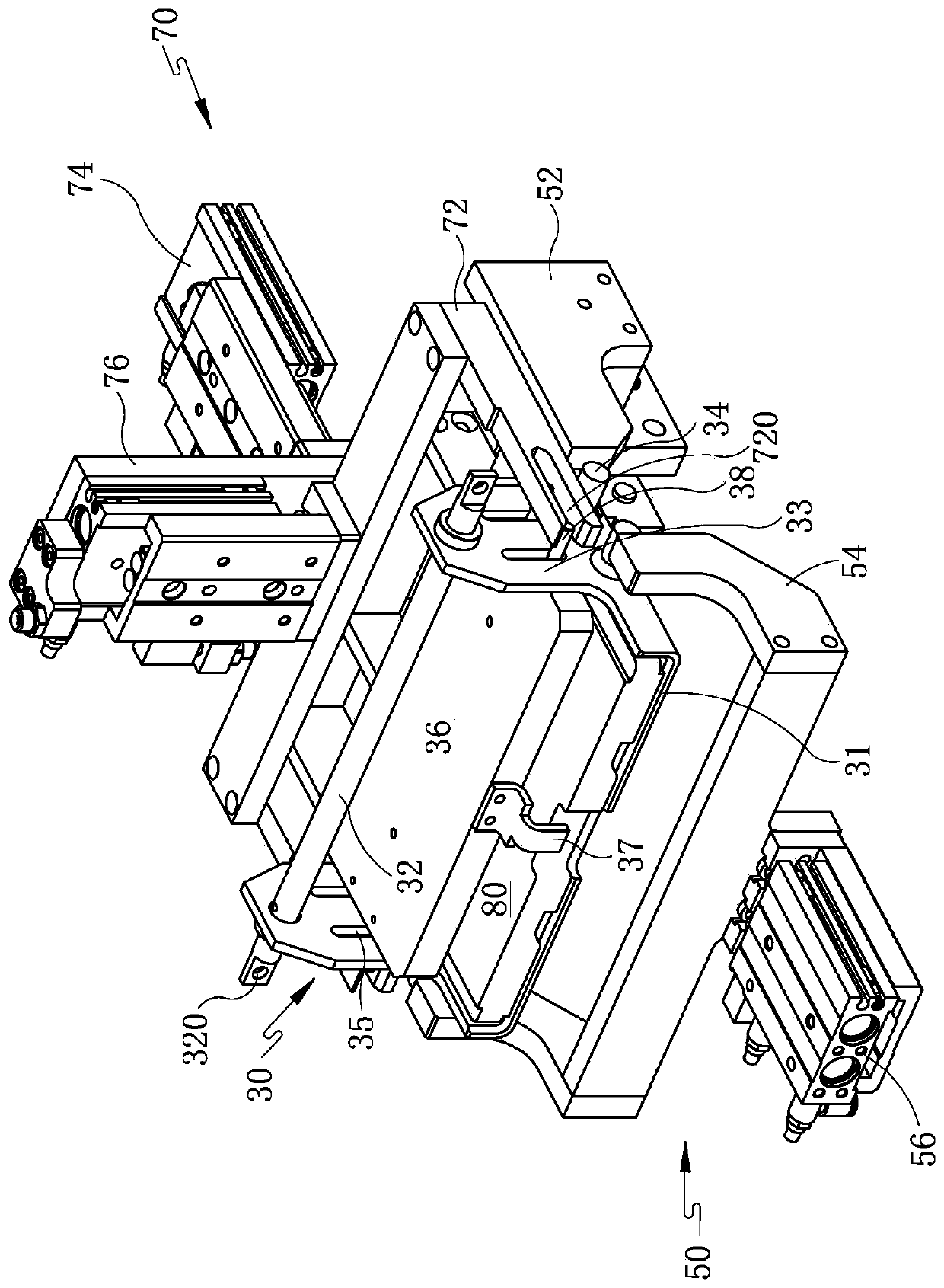

Tool pressure maintaining time-delay equipment

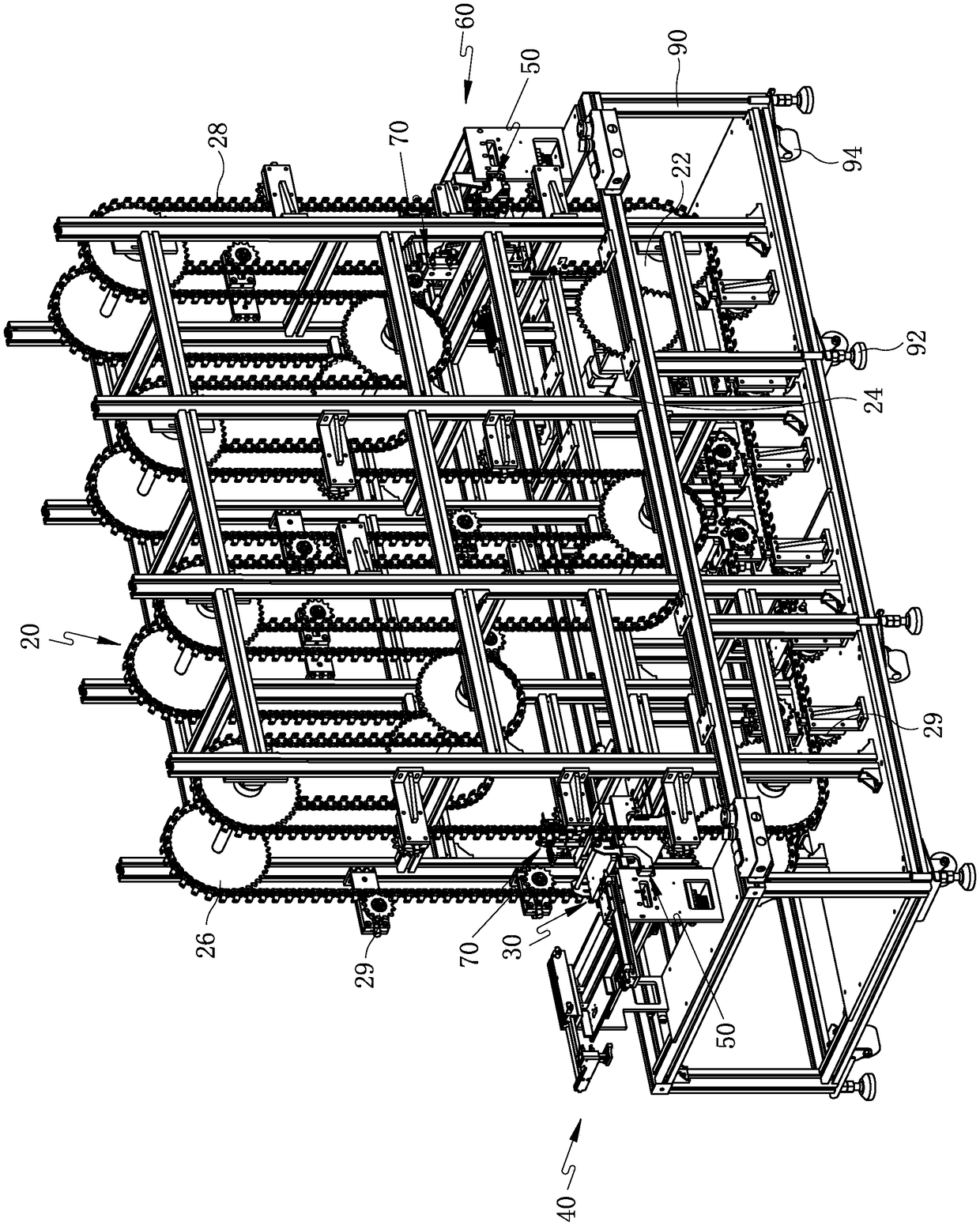

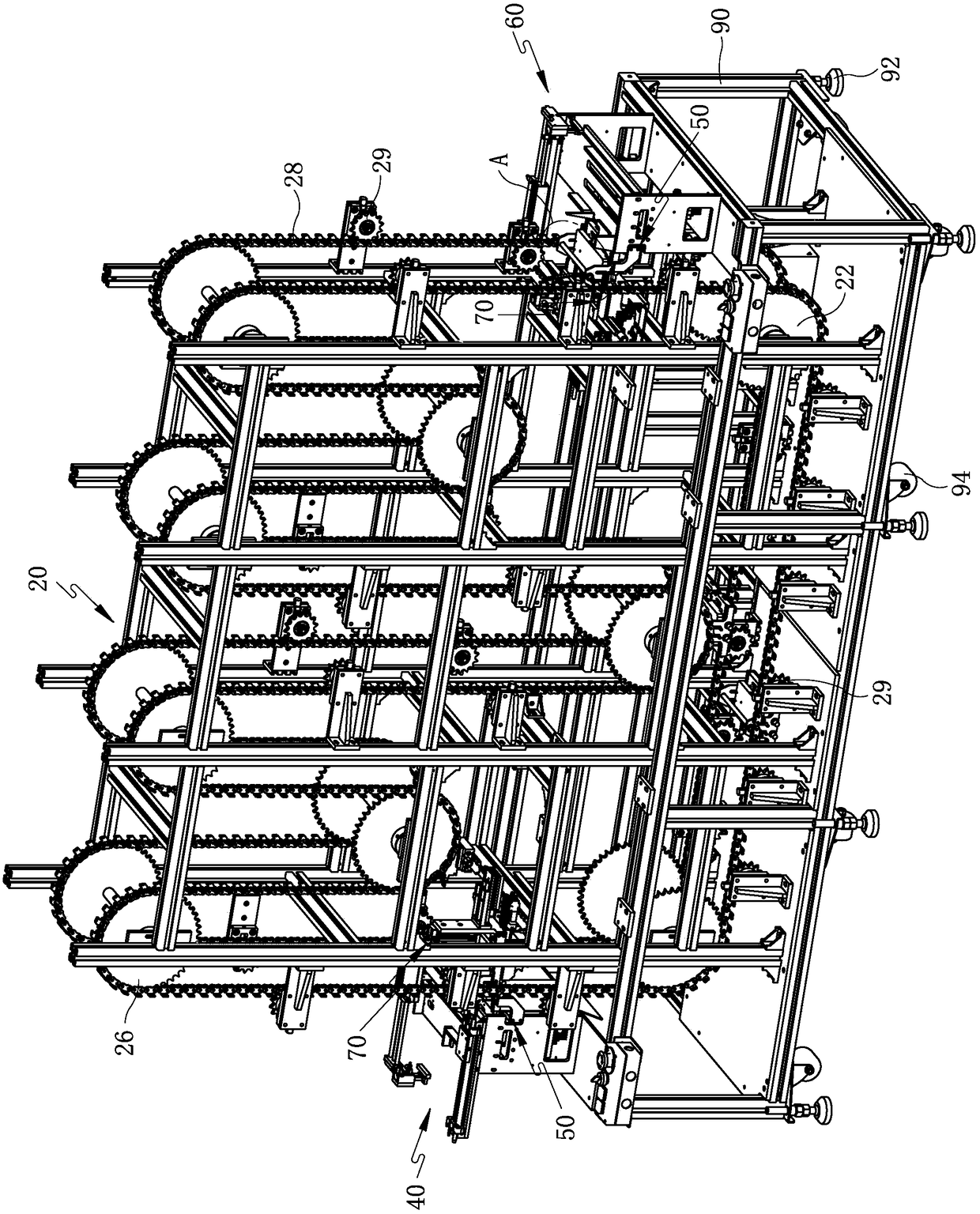

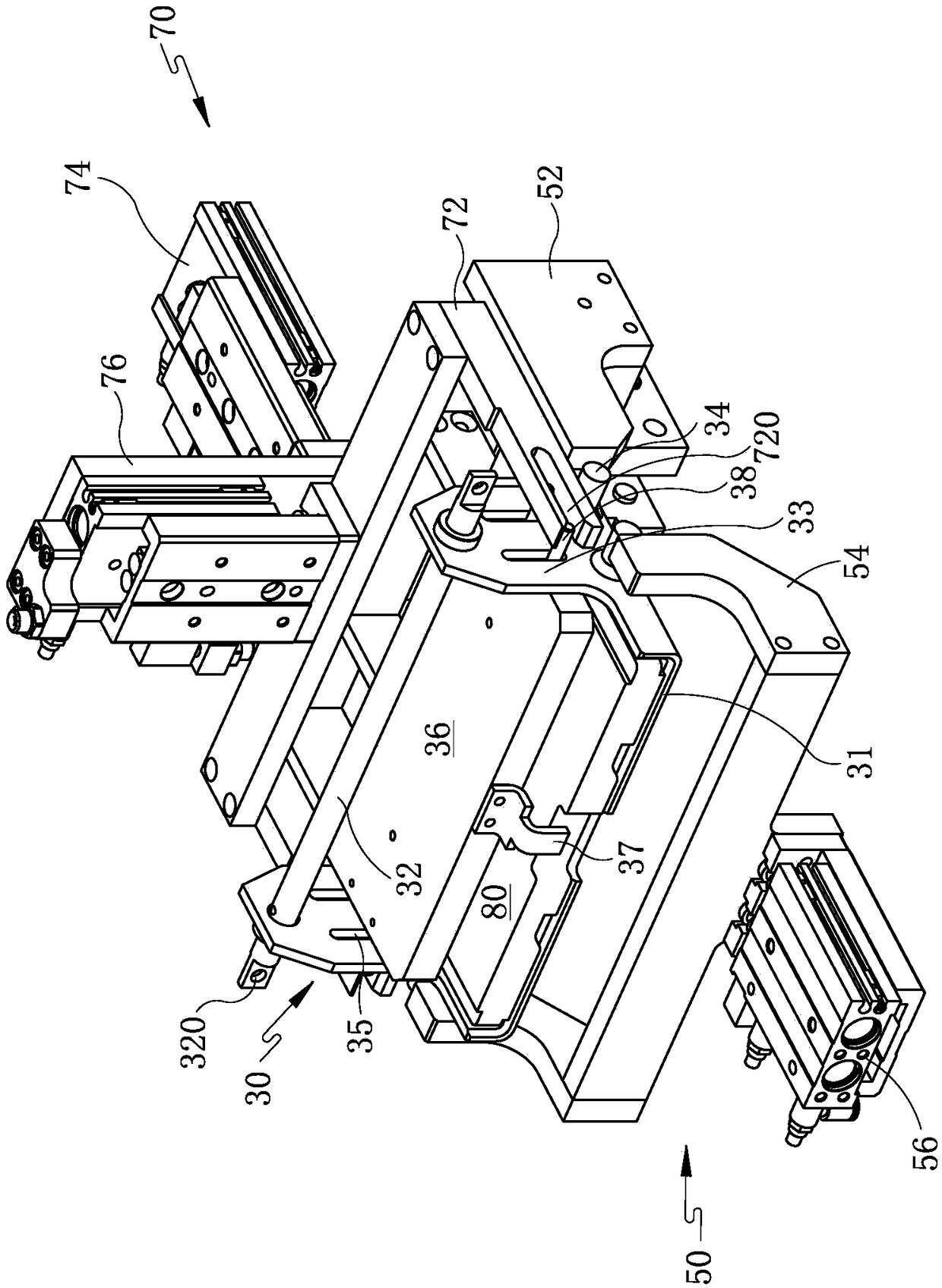

ActiveCN109230231AEasy to lift the counterweightRealization of holding pressure delayConveyorsSupporting framesTime delaysDelayed time

The invention discloses tool pressure maintaining time-delay equipment and relates to the technical field of electronic product production equipment. The tool pressure maintaining time-delay equipmentincludes a rack, multiple chain wheel groups are installed on the rack, each chain wheel group includes two chain wheels which are arranged coaxially, and all the chain wheels on the same side in each chain wheel group are surrounded by a chain; all the chain wheel groups are staggered vertically, and correspondingly the two chains form a structure which is folded several times; a hanging basketwhich is used for placing tools and moves along with the chains is hung between the two chains, and counter weights used for maintaining the pressure of the tools are arranged in the hanging basket; afeeding mechanism used for placing the tools into the hanging bracket and a discharge mechanism used for taking the tools out of the hanging basket are arranged at the two ends of the rack respectively; the two ends of the rack are both provided with a hanging basket positioning mechanism and a counter weight lifting mechanism, wherein each hanging basket positioning mechanism can position the hanging basket after the hanging basket moves in place, and each counter weight lifting mechanism is used for lifting up the counter weights after positioning in order to provide convenience for feedingby the feeding mechanism and discharge by the discharge mechanism. The tool pressure maintaining time-delay equipment in a small size meets the requirement for long pressure maintaining delay time.

Owner:WEIFANG LOKOMO PRECISION IND

Novel traction power supply system based on rail traffic sand table model

InactiveCN108273272AChange running speedPower stabilityEducational modelsModel railwaysElectricitySimulation

The invention discloses a novel traction power supply system based on a rail traffic sand table model. The two traction power supply modes of an overhead contact line and a contact rail are adopted, wherein according to the power supply mode of the overhead contact line, a semi-compensation suspending device and a full-compensation suspending device are adopted, the combination of soft and hard crossing is adopted by a station, soft crossing is adopted by a vehicle section, the line is provided with equipment like a segmented insulator, an anchoring section joint, a center anchoring section, afeeder line, an electric connector and a return line and various lines, and the signal marks are complete, and are completely identical to those in the actual operating situations. The basic principle and the working operating scene of a rail traffic or railway power supply system can be truly restored to achieve the purpose of educating and teaching students of relevant universities and majors of railway and rail traffic, the purpose of training staff by rail traffic and railway construction and operation units can also be achieved, and the original intention of the design of a sand table istruly embodied.

Owner:SHIJIAZHUANG INST OF RAILWAY TECH

Semiconductor device

ActiveUS9437273B2Novel structureImprove convenienceRead-only memoriesDigital storagePower semiconductor deviceData transmission

Owner:SEMICON ENERGY LAB CO LTD

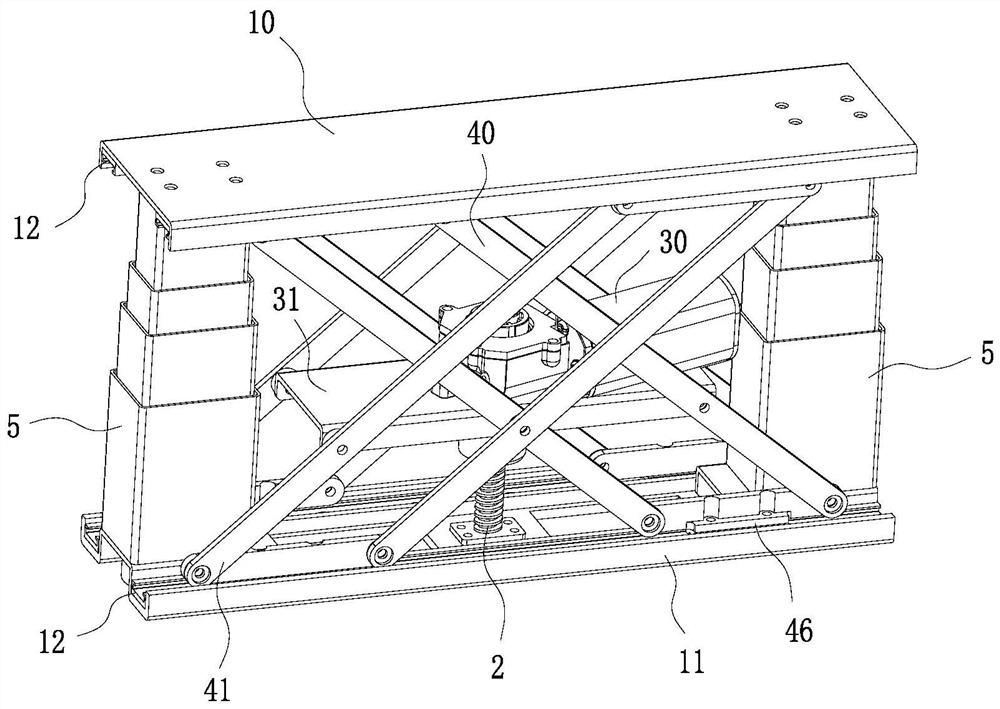

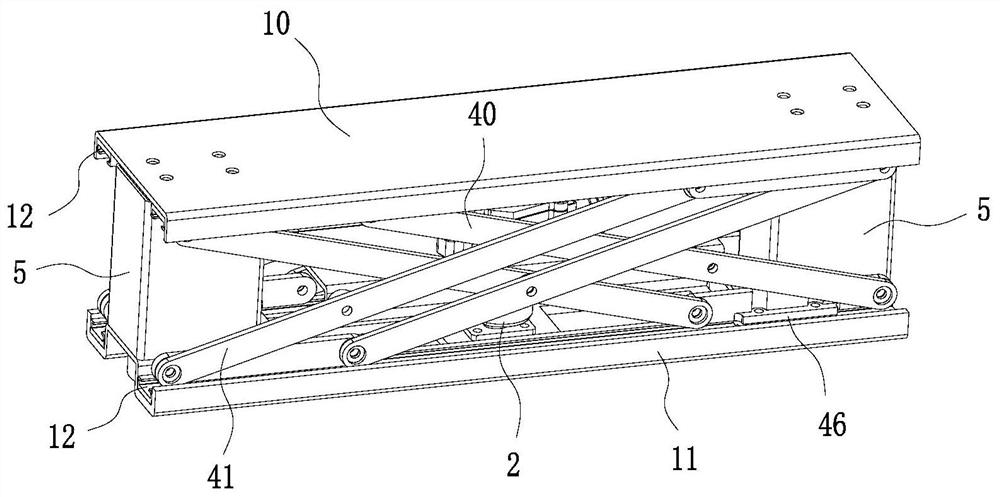

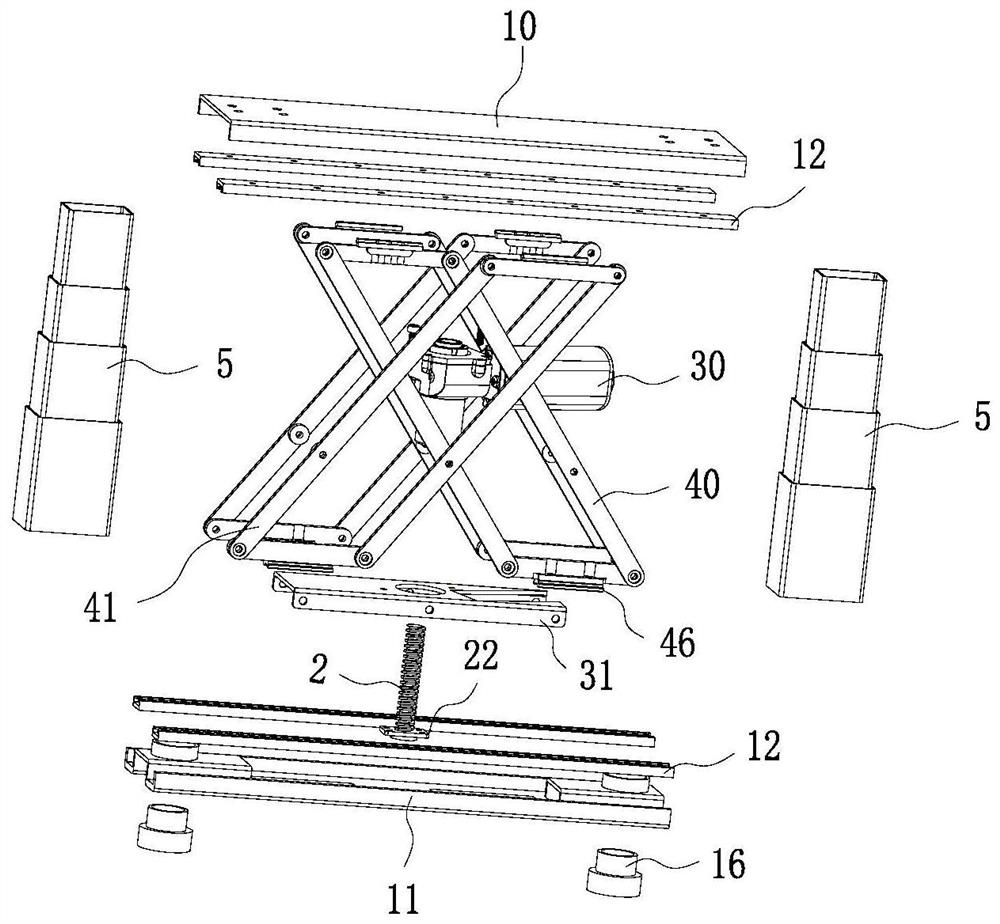

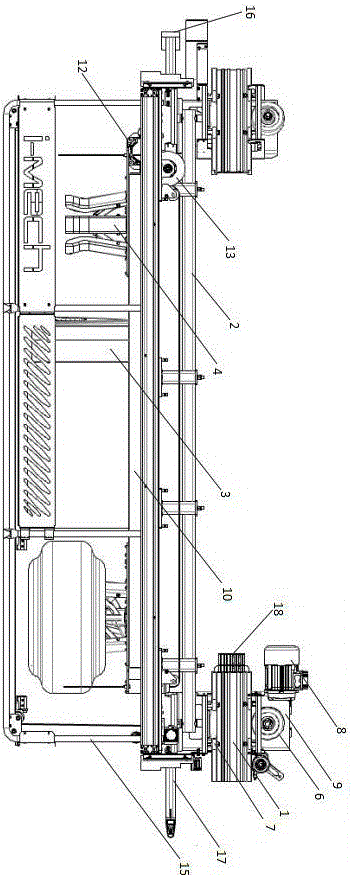

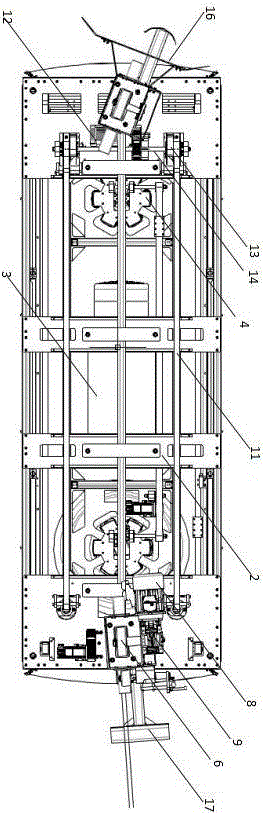

Lifter with short mounting distance and large stroke

PendingCN112062037AReduce the number of meshesImprove transmission efficiencyLifting framesElectric machineryStructural engineering

The invention provides a lifter with a short mounting distance and a large stroke. The lifter comprises a top plate, a bottom plate and a driving device used for controlling the top plate to ascend and descend, wherein the driving device comprises a driving motor and a lead screw, a lead screw nut is arranged on the lead screw, the driving device is fixed between the top plate and the bottom plate, a connecting plate is arranged on the driving device, connecting rod sets are arranged between the top plate and the bottom plate, the two ends of each connecting rod set are slidably connected withthe bottom plate and the top plate respectively, the middle of each connecting rod set is rotatably connected with the side face of the connecting plate, the driving device controls the connecting plate to ascend and descend, and the connecting plate drives the connecting rod set to move for ascending and descending of the top plate. The lifter has the advantages that the stroke of the lifter canbe increased by changing the connecting rod sets while the mounting distance is not increased.

Owner:ZHEJIANG JIECHANG LINEAR MOTION TECH

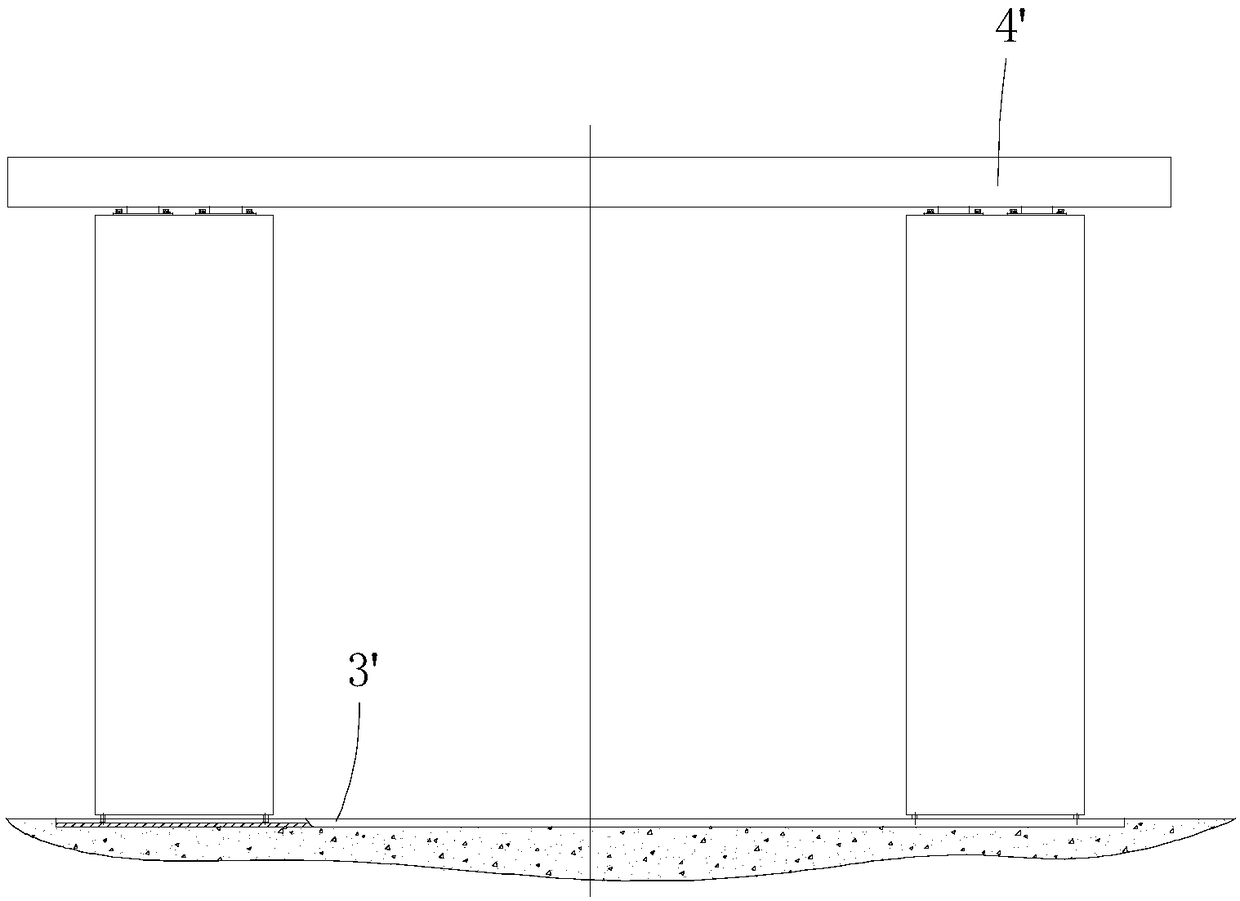

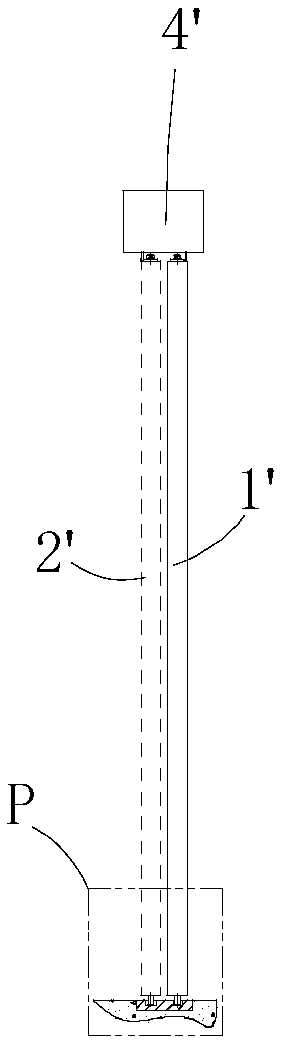

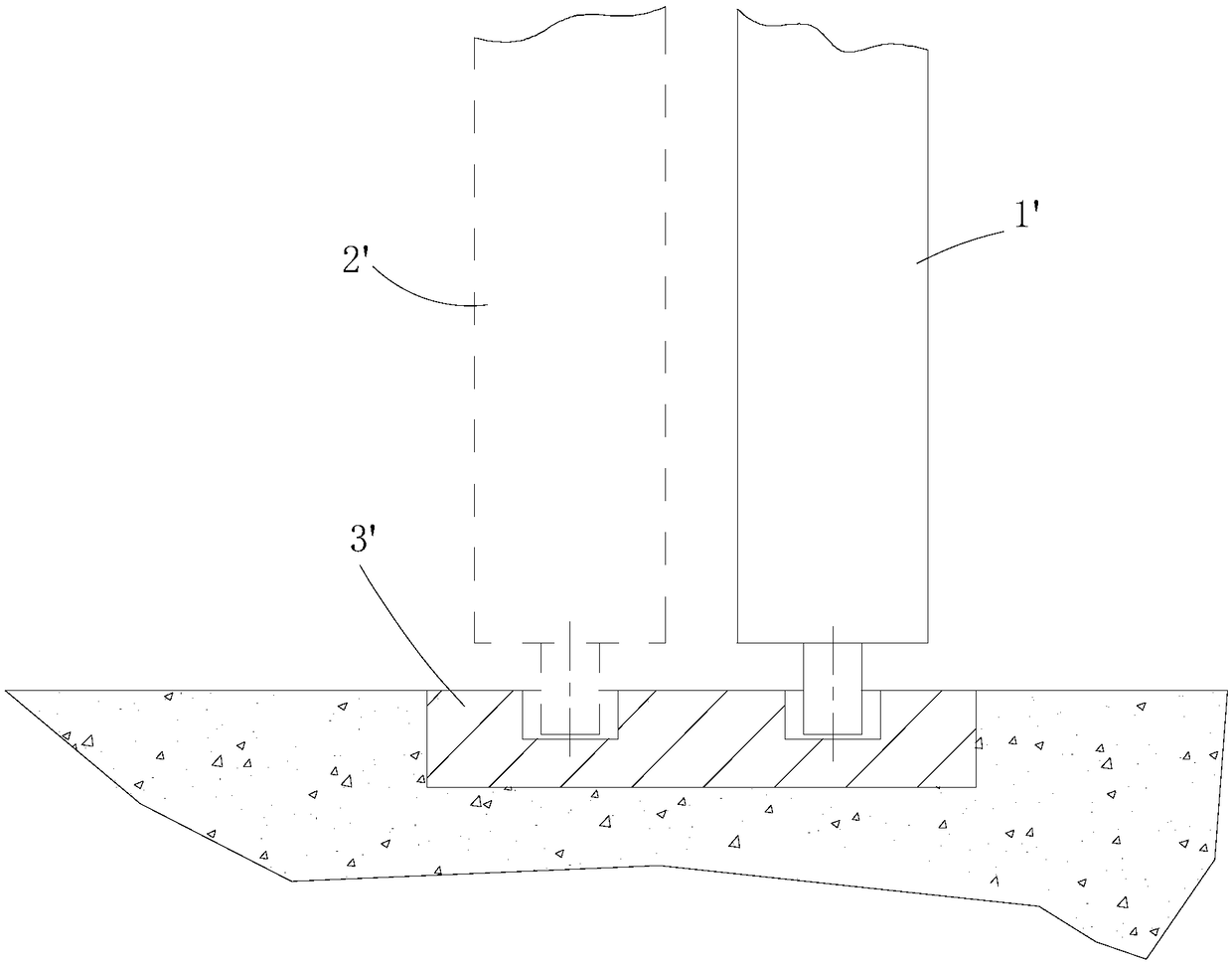

Door without sill and stereo garage thereof

InactiveCN109505492AGuaranteed uptimeGuaranteed to be verticalPower-operated mechanismDoor/window applicationsPulley

The invention relates to a door without a sill. The door comprises an outer door panel and an inner door panel. The bottom end of the door is installed on the ground or the floor surface, and the topend is suspended on a horizontal frame. Fixed guide wheels are arranged on the ground or the floor surface. A guide wheel mounting plate with moving guide wheels is disposed on the outer door panel. An outer door track and an inner door track are disposed on the horizontal frame, and the outer door panel and the inner door panel respectively slide on the outer door track and the inner door track through a door panel hanging pulley block. An inner driving motor, a driving wheel assembly, an inner door belt pulley, an outer door belt pulley, an inner belt and an outer belt are also disposed on the horizontal frame. An inner lower belt connecting frame and an outer lower belt connecting frame are respectively disposed on down sections of the inner belt and the outer belt and connected with the door panel hanging pulley block. A stereo garage using the door is further disclosed. The door has the advantages of door opening and closing quick response, high operation efficiency and low maintenance cost.

Owner:ZIGONG INNOVATION CENT OF ZHEJIANG UNIV +2

A device for pigging response experiment of natural gas pipeline suspension cable spanning structure

ActiveCN110726529BChange running speedGuaranteed vibration accelerationHydrodynamic testingVibration testingVibration accelerationPigging

The invention provides a device for carrying out a pigging dynamic response experiment of a natural gas pipeline suspension cable across a structure, wherein a transparent tempered glass tube and a seamless steel tube are connected through a flange, and a main cable is connected to a tower as a main load-bearing component. The fixed bracket can fix the seamless steel pipe and place it on the flat plate. The rotation of the cam under the flat plate can drive the connecting rod to move up and down, which makes the flat plate move up and down, so as to realize the vertical vibration of the pipe. The signal test device acceleration sensor and displacement sensor can be installed in the corresponding position of the seamless steel pipe according to the test requirements. The device is mainly designed to study the dynamic response of the natural gas pipeline suspension cable spanning structure and its influence on the pigging two-phase flow, and can obtain the vibration acceleration and vibration displacement of the pipeline suspension cable spanning structure under different pigging conditions etc., and simulate the influence of the pipeline on the pigging two-phase flow pattern under different vibration conditions.

Owner:SOUTHWEST PETROLEUM UNIV

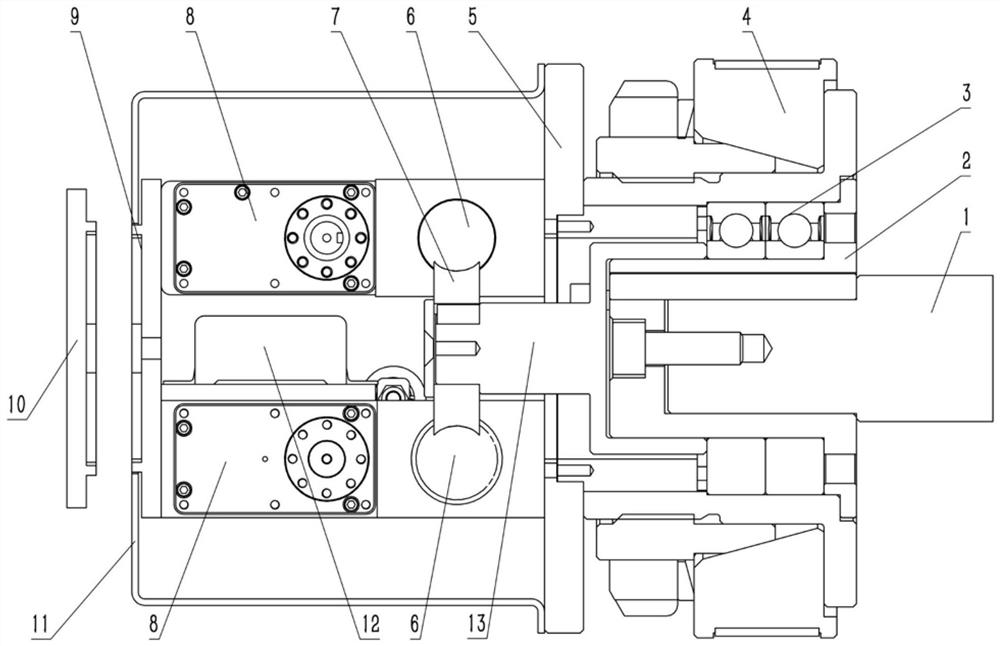

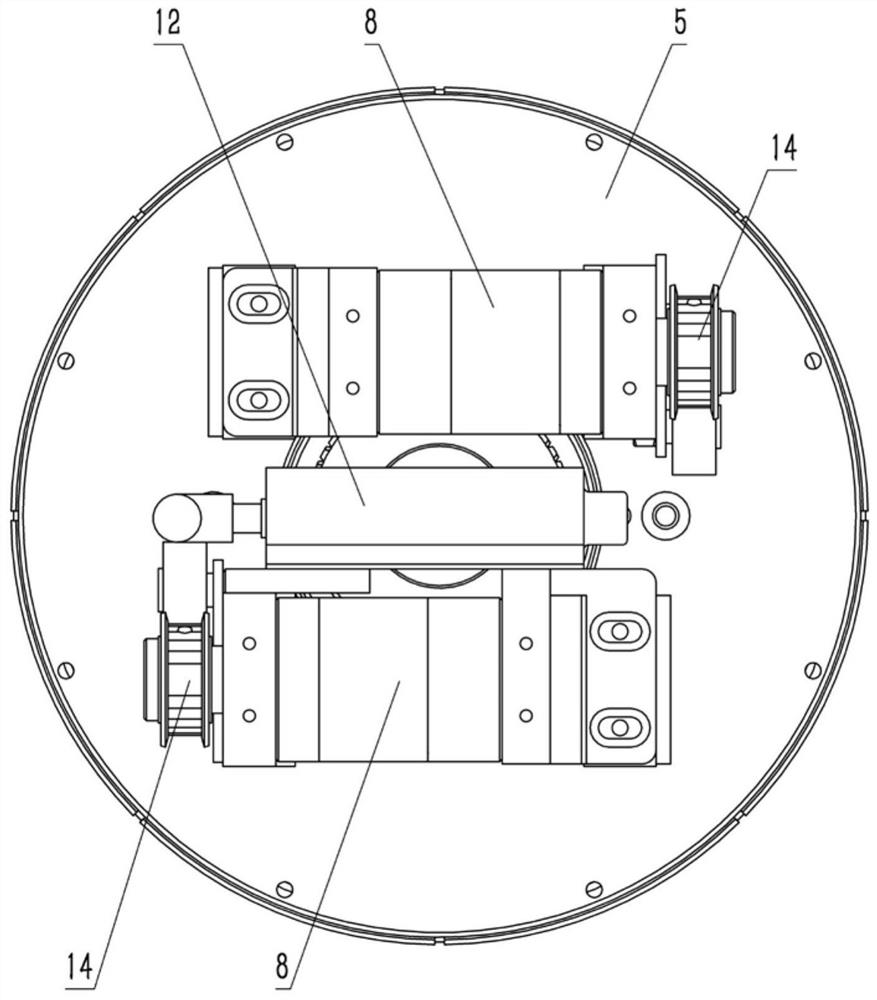

A Machine Tool Fixture Structure with Adjustable Feeding Speed

ActiveCN111975410BAdjustable feeding speedTo achieve the effect of fixing the workpiecePositioning apparatusMetal working apparatusDrive shaftGear wheel

The invention relates to the technical field of machine tool processing, and discloses a machine tool fixture structure that can adjust the feeding speed, including a shell, the right side of the shell is movably connected with a clamp body, and the top of the clamp body is fixedly connected with a gear The inside of the housing is provided with a feeding track, the top of the feeding track is provided with a pulley, the back side of the pulley is keyed to a power column, and the top of the power column is provided with a rotating shaft, and the rotating shaft The outer side of the rotating shaft is movably connected with a running wheel, the right side of the rotating shaft is provided with a transmission shaft, the outside of the transmission shaft is movably connected with a bracket, the back side of the transmission shaft is fixedly connected with a handle, and the upper side of the rotating wheel engages There is a transmission column, the back side key of the transmission column is connected with a motor, and the front key of the transmission column is connected with a gear. By turning the handle to change the position of the bracket, the bracket drives the runner to move left and right, and by adjusting the position of the runner on the power column and transmission column on the upper and lower sides, the effect of changing the running speed of the feeding track is achieved.

Owner:平湖市成功机械有限公司

Automatic speed-changing wide-swing-angle oil pumping machine

InactiveCN102808602BSolve the oil spill problemImprove oil pumping efficiencyGearingFluid removalRocker armCrankshaft

The invention relates to the technical field of oil extraction machinery, in particular to an automatic speed-changing wide-swing-angle oil pumping machine. The automatic speed-changing wide-swing-angle oil pumping machine comprises an electric motor, a speed changing mechanism, a swing arm support, a swing arm arranged on the swing arm support, a support provided with a fixed pulley and a wellhead oil pumping device, wherein the speed changing mechanism is connected with a driving crankshaft wheel, the driving crankshaft wheel is meshed with a driven crankshaft wheel, the driving crankshaft wheel is connected with a connecting piece through a bearing, one end of the connecting piece is connected with the driven crankshaft wheel, the other end of the connecting piece is connected with the swing arm through a connecting rod, a sliding chute is arranged on the connecting piece of which one end is connected with the driven crankshaft wheel, and a bearing on the driven crankshaft wheel is sleeved in the sliding chute. The automatic speed-changing wide-swing-angle oil pumping machine disclosed by the invention has the advantages that when the two crankshaft wheels are in rotation, since the position of the bearing of a driven pulley is changed, the position of the connecting piece can be also correspondingly changed, a motion trail of the connecting rod is affected by the motion of the connecting piece, the speed of the wellhead oil pumping device in the up-stroke is higher than that in the down-stroke, the oil leakage problem existing in an oil pumping process is avoided, and the oil pumping efficiency is increased.

Owner:德阳振华机械设备制造有限公司

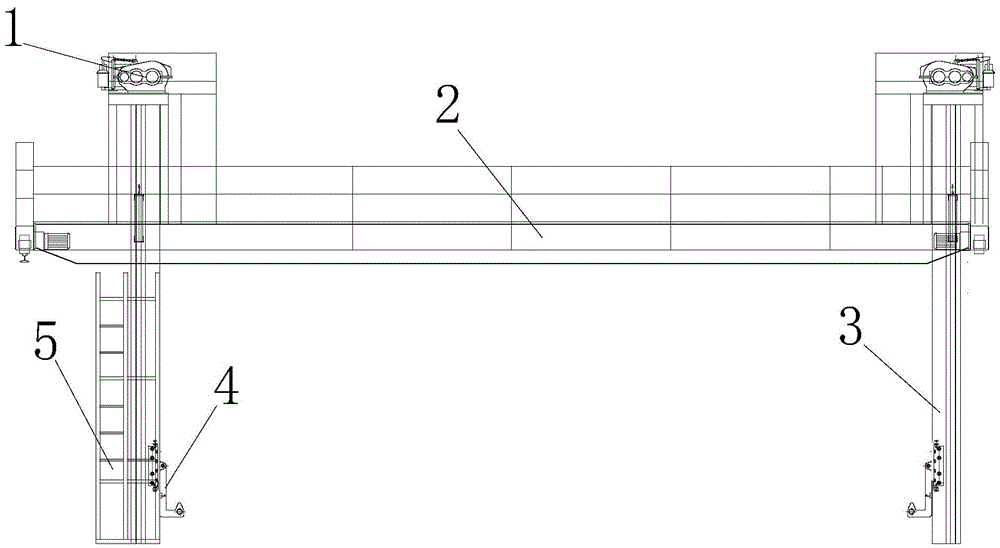

Monorail air intelligent transport vehicle

InactiveCN106743261AGuaranteed uptimeChange running speedMechanical conveyorsLogistics managementMonorail

The invention relates to a monorail air intelligent transport vehicle. The monorail air intelligent transport vehicle comprises a driving system, a vehicle body chassis, a vehicle body, a lifting device and an anti-collision system. The driving system is divided into a master driving mechanism and a slave driving mechanism. The driving system is mounted on an air rail. The vehicle body chassis is mounted on the driving system. The lifting device and a PLC control device are arranged inside the vehicle body. The lifting device is mounted on the vehicle body chassis and provided with a gripper. A power collector is mounted on the driving system. Anti-collision devices are mounted in the front of and on the back of the vehicle body. By means of the monorail air intelligent transport vehicle, efficient and automatic conveying of engineering logistics is achieved; air transportation can be achieved, and in addition, gripping operation is achieved in the transporting process; and the limited space is reasonably utilized, and work efficiency is improved.

Owner:艾马工业工程(大连)有限公司

Tooling pressure holding delay equipment

ActiveCN109230231BEasy to lift the counterweightRealization of holding pressure delayConveyorsSupporting framesHanging basketSprocket

The invention discloses tool pressure maintaining time-delay equipment and relates to the technical field of electronic product production equipment. The tool pressure maintaining time-delay equipmentincludes a rack, multiple chain wheel groups are installed on the rack, each chain wheel group includes two chain wheels which are arranged coaxially, and all the chain wheels on the same side in each chain wheel group are surrounded by a chain; all the chain wheel groups are staggered vertically, and correspondingly the two chains form a structure which is folded several times; a hanging basketwhich is used for placing tools and moves along with the chains is hung between the two chains, and counter weights used for maintaining the pressure of the tools are arranged in the hanging basket; afeeding mechanism used for placing the tools into the hanging bracket and a discharge mechanism used for taking the tools out of the hanging basket are arranged at the two ends of the rack respectively; the two ends of the rack are both provided with a hanging basket positioning mechanism and a counter weight lifting mechanism, wherein each hanging basket positioning mechanism can position the hanging basket after the hanging basket moves in place, and each counter weight lifting mechanism is used for lifting up the counter weights after positioning in order to provide convenience for feedingby the feeding mechanism and discharge by the discharge mechanism. The tool pressure maintaining time-delay equipment in a small size meets the requirement for long pressure maintaining delay time.

Owner:WEIFANG LOKOMO PRECISION IND

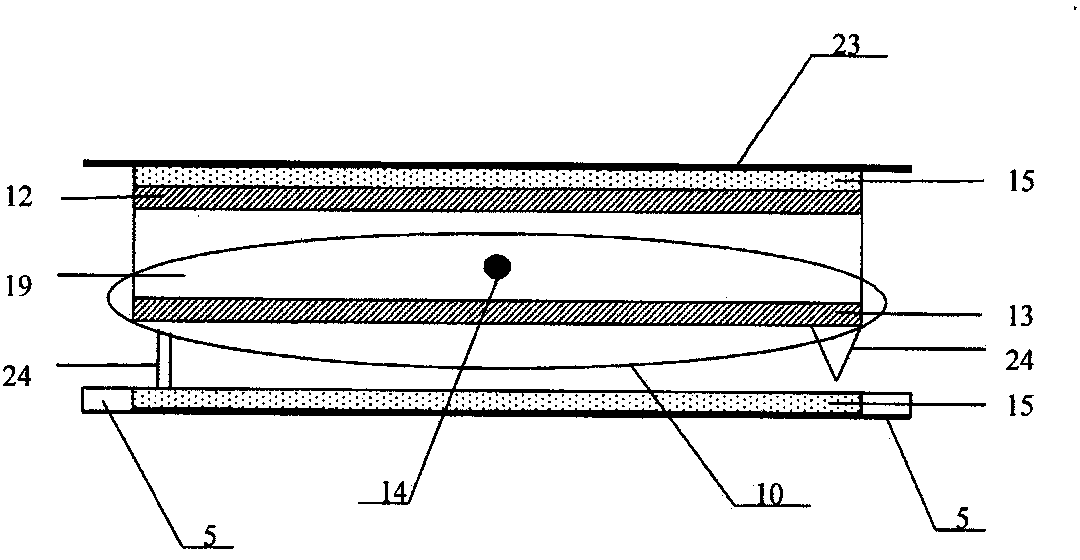

Symmetrical permanent magnet synchronous linear motor

ActiveCN104617741BSuspension control is simple and effectiveChange running speedPropulsion systemsPermanent magnet synchronous motorLinear motor

The invention discloses a symmetrical permanent-magnet linear synchronous motor. The motor comprises a rotor and a plurality of stator guide rails symmetrically arranged on both sides of the rotor, wherein the plurality of stator guide rails forms a movement track where the rotor moves; both sides of the bottom of the rotor are symmetrically provided with three groups of array permanent magnets respectively, each stator guide rail includes an U-shaped structure, and open ends of the U-shaped structures of the stator guide rails on both sides are oppositely arranged; the upper and lower positions of the open ends of the U-shaped structures are respectively fixed with a traction force coil, and a suspension force coil is fixedly installed inside the bottom of the U-shaped structure; the suspension force coil inside the bottom of the U-shaped structure interacts with the array permanent magnet at the corresponding position of the bottom of the rotor, and the traction force for upwardly suspending the rotor and the normal force are simultaneously generated; the suspension force coils on the stator guide rails symmetrically arranged on two sides of the rotor interact with the normal force generated by the array permanent magnet, so that the rotor of the linear motor always moves at the center of the guide rail.

Owner:江苏希太芯科技有限公司

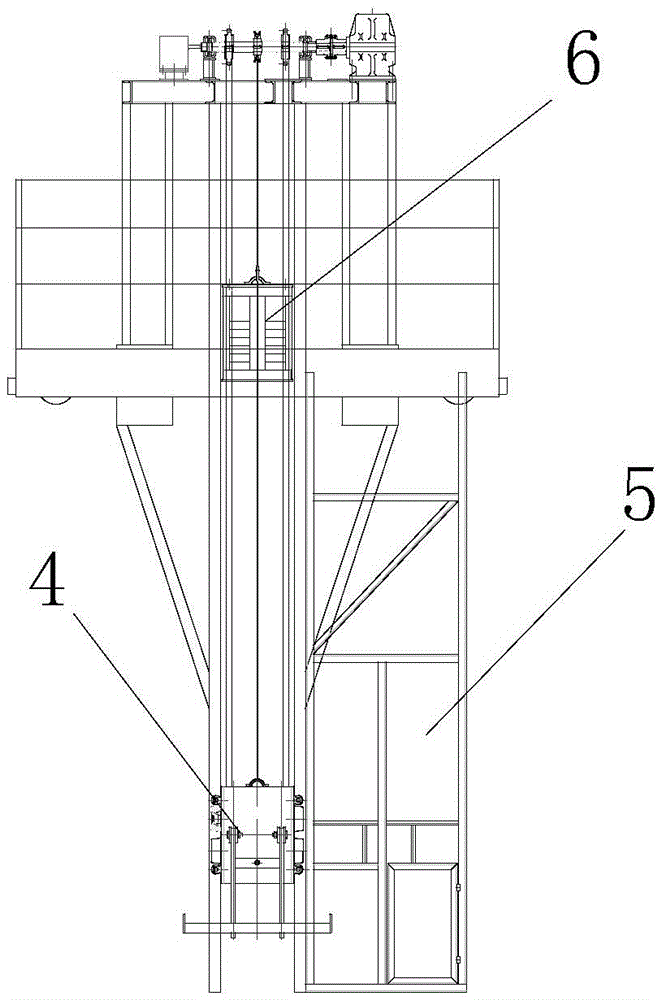

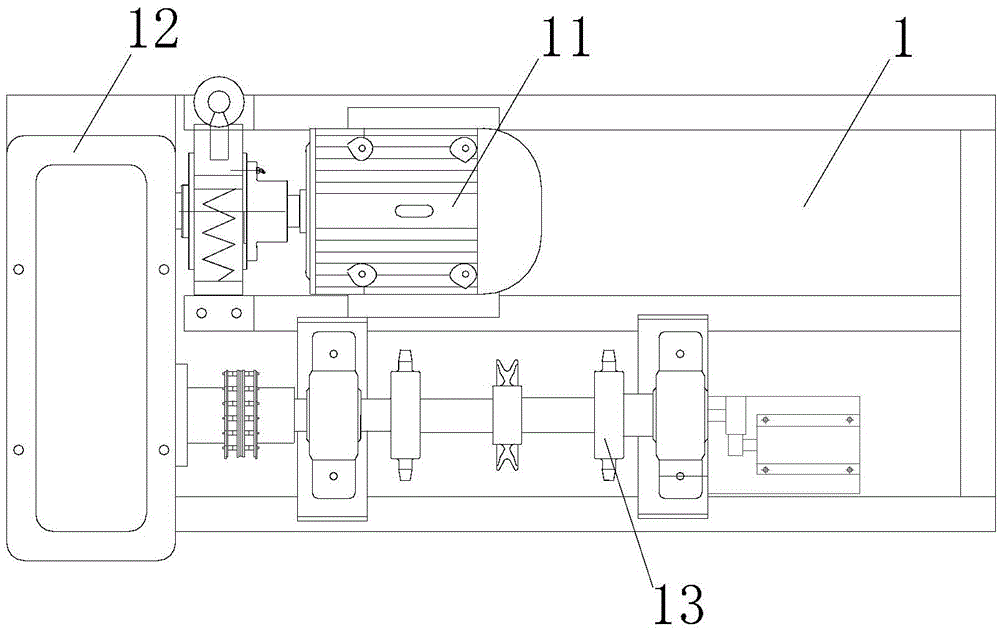

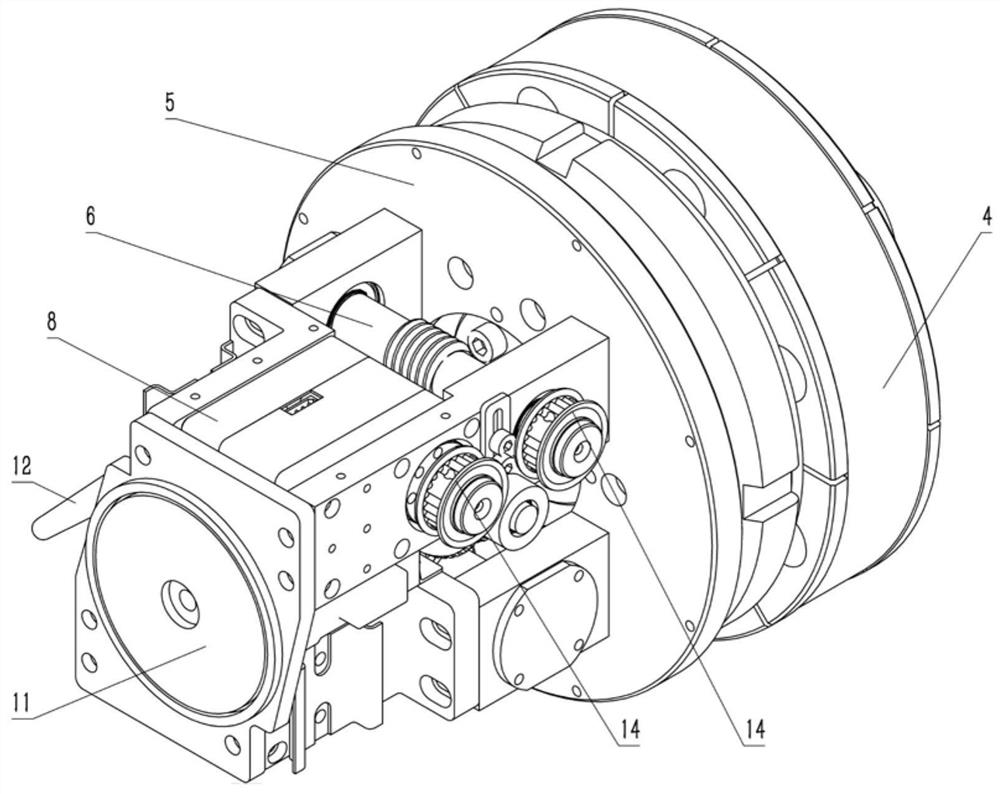

A special crane for the production of aluminum profiles

ActiveCN104192724BSmall starting currentReduce the temperatureTrolley cranesWork timeIndustrial engineering

Owner:广东南桂起重机械有限公司

Cigarette bar conveying speed adjusting device and adjusting method thereof

PendingCN112021646AChange running speedCigarette manufactureAutomotive engineeringElectrical and Electronics engineering

The invention relates to a cigarette bar conveying speed adjusting device and an adjusting method thereof. The cigarette bar conveying speed adjusting device comprises a motor, a power source and a cloth belt wheel used for conveying cigarette bars. The power source is connected with the motor through a wireless power supply module or a wired electric connector, and the motor can drive the cloth belt wheel to change the rotating speed through a connecting device. The device has the advantages that in the cigarette bar moving process, a cigarette bar can deviate front and back possibly, patterns on the cigarette can not be located at the set position, at the moment, the motor is started to change the running speed of the cloth belt wheel, and the patterns of the cigarette are adjusted to the set position.

Owner:云南远足科技有限公司

Drying and ventilating device for ocean engineering living cabin

PendingCN113184157AEasy accessPrevent getting involvedDispersed particle filtrationAuxillariesPhysicsEngineering

The invention discloses a drying and ventilating device for an ocean engineering living cabin, and belongs to the technical field of ocean engineering. The drying and ventilating device for the ocean engineering living cabin comprises a fixing device, an air inducing device, a blocking device, a conversion device, a drying device and a sound reducing device, the fixing device is vertically arranged on a living cabin, and the air inducing device is horizontally arranged on the side wall of the fixing device; the blocking device is horizontally arranged on the side wall of the fixing device, the conversion device is horizontally arranged on the inner side wall of the fixing device, the drying device is vertically arranged on the side wall of the fixing device, and the sound reduction device is vertically arranged on the inner side wall of the fixing device. The air speed entering the living cabin is controlled through the blocking device, and air entering the living cabin is dried through the drying device.

Owner:胡太为

An infrared servo bridge cutting machine control system

Owner:QUANZHOU XINHAI ENERGY TECH

Multifunctional automatic sesame seed cake roasting furnace

InactiveCN104336117AFurnace temperature constantImprove qualityFood processingBaking ovenFurnace temperatureEngineering

The invention discloses a multifunctional automatic sesame seed cake roasting furnace, and the stove has the characteristics of heat-insulating protection, semi-enclosed furnace chamber, constant furnace temperature, continuous operation without manual intervention, environmental protection, and energy and labor saving, thus the roasted sesame seed cake is steady in quality, excellent in uniformity and high in efficiency. According to specific conditions of each user, the heater power and the conveyer belt running speed are changed, and the production capacity and the efficiency can be also changed. The multifunctional automatic sesame seed cake roasting furnace is used to roast different-type and different-taste sesame seed cakes by different-scale sesame seed cake roasting merchants. The roasting furnace is a novel roasting machine which isn't specially nursed by a person, the sesame seed cake no less than that roasted by the traditional way can be roasted by the furnace, and the roasting furnace has the advantages of energy saving, high efficiency, quickness, cleanness and easy operation. The roasting furnace can roast large batches of sesame seed cakes by one person, and the roasted sesame seed cakes are very steady in color.

Owner:陈彬然

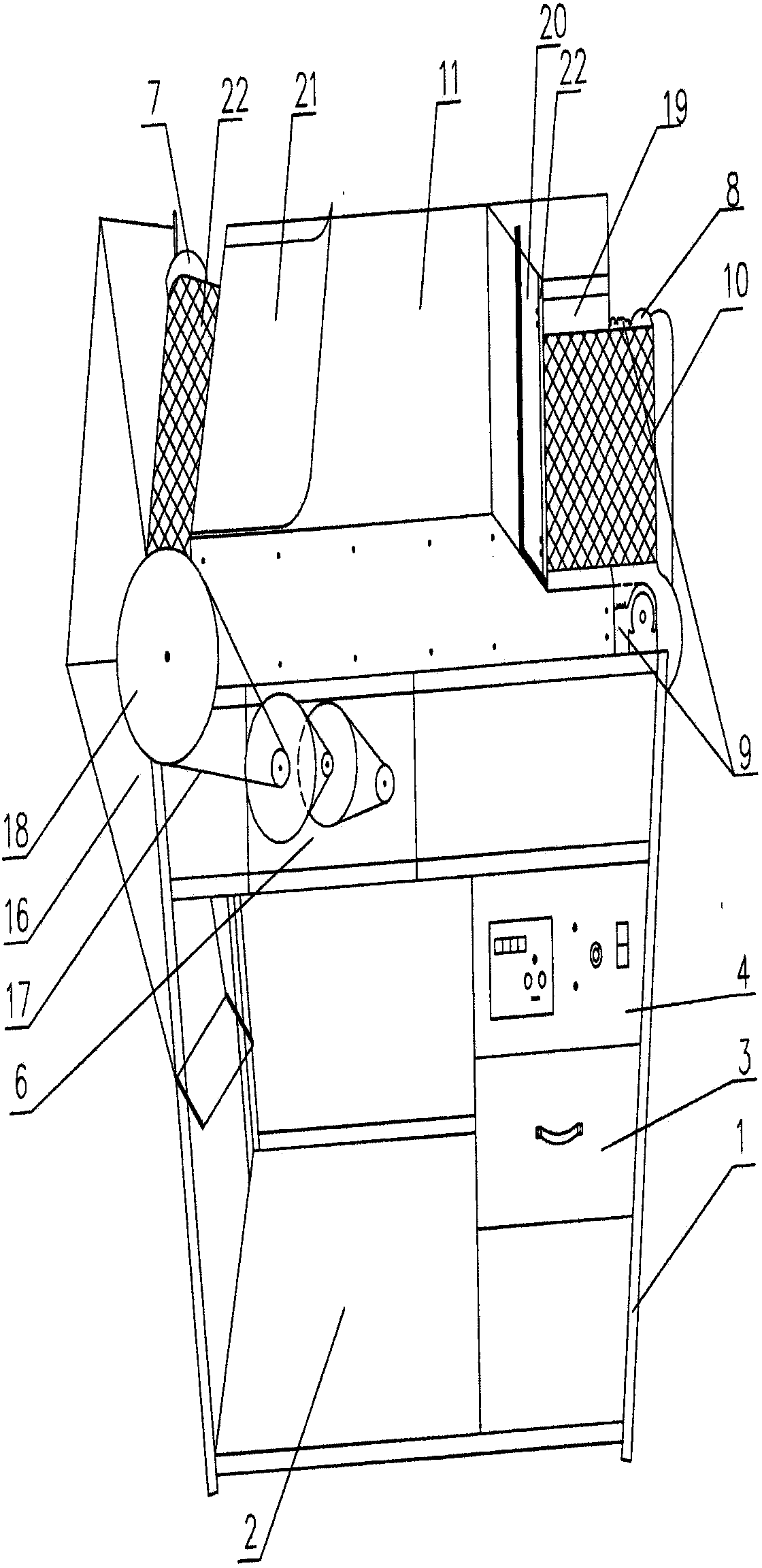

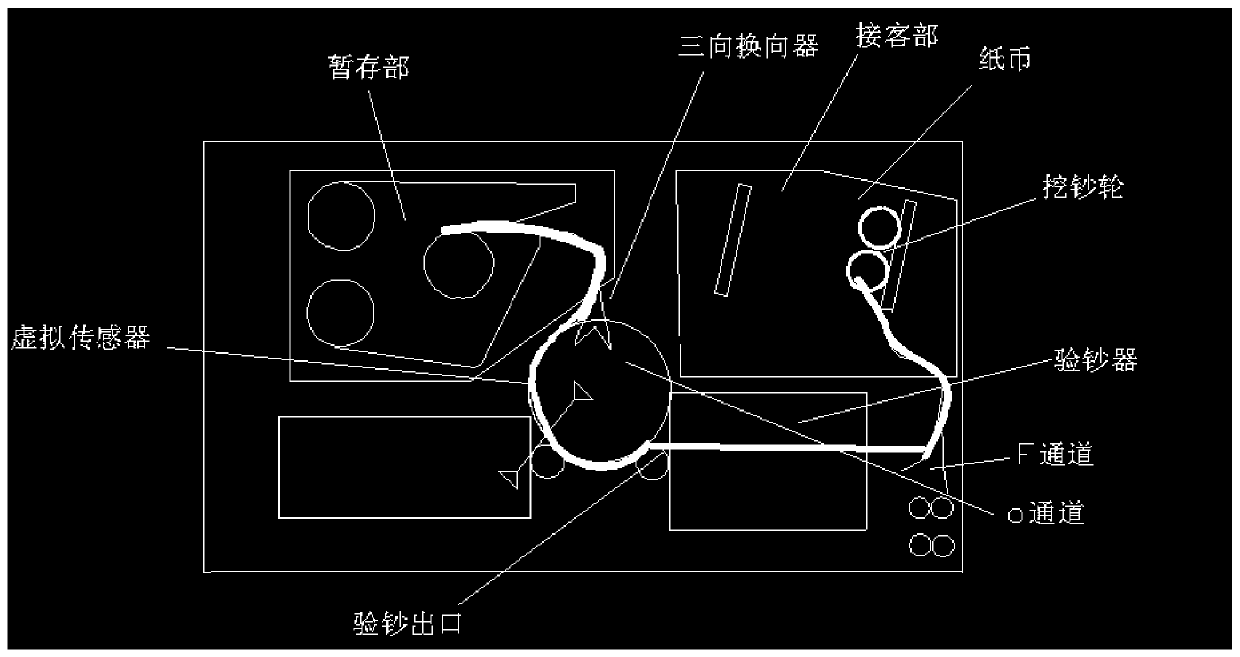

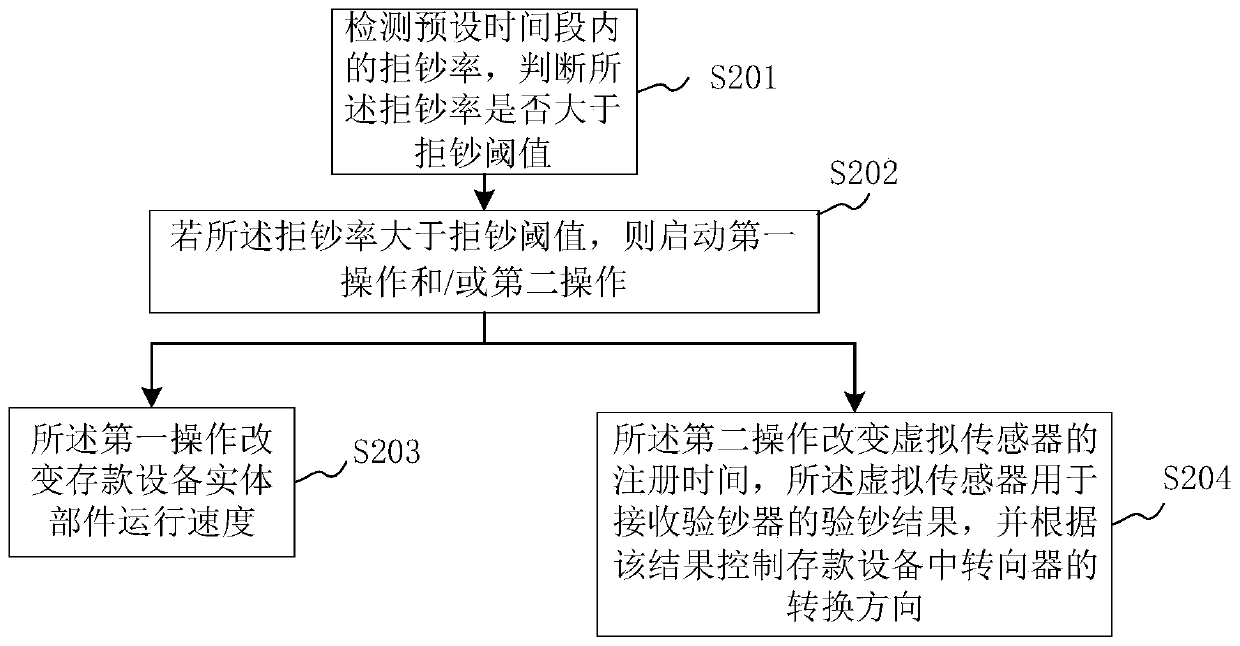

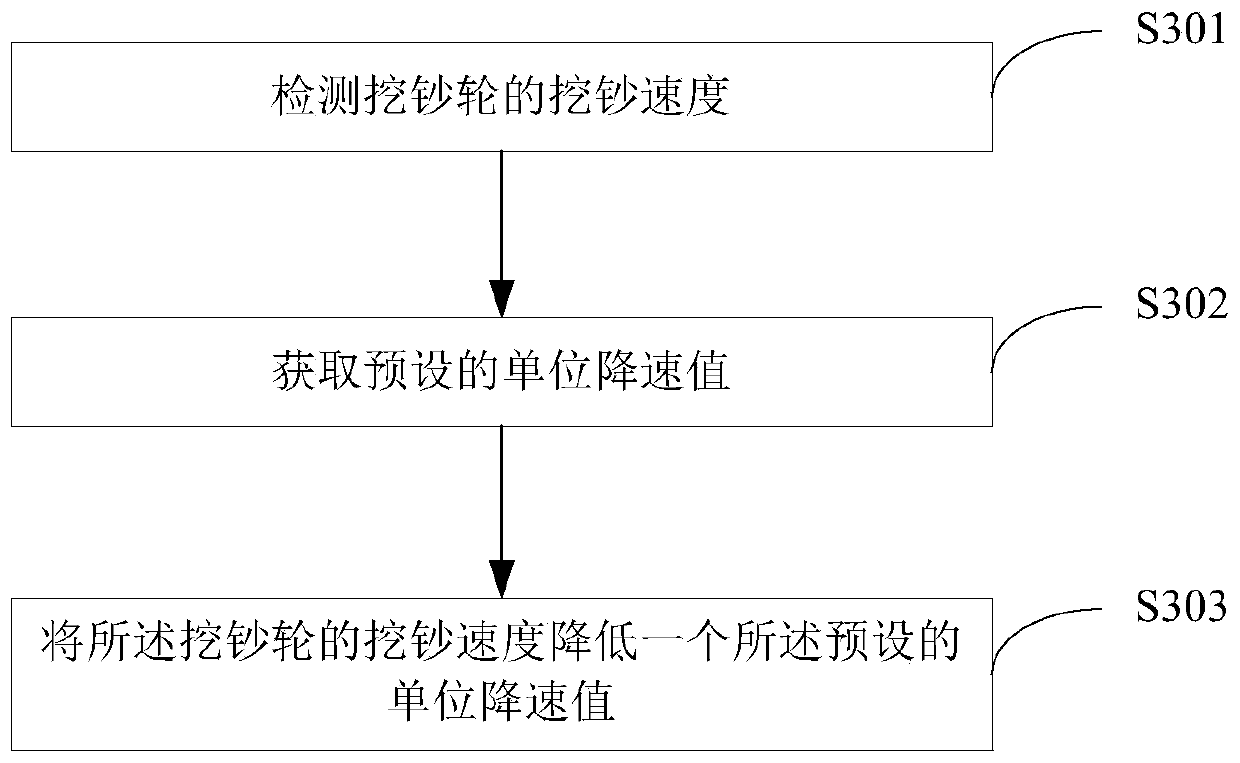

Control method and system for deposit facility

ActiveCN107301742BChange running speedChange registration timeComplete banking machinesCoin/currency accepting devicesVirtual sensorsComputer science

The invention is applicable to the field of financial devices, in particular to a control method and system for a deposit device. The control method for the deposit device comprises the steps of judging whether or not a currency note rejecting rate is greater than a preset threshold through detecting the currency note rejecting rate in a preset period, and enabling the system to determine whether or not a current financial device is running normally; if the currency note rejecting rate is greater than the preset threshold, changing the running speed of the physical component of the deposit device, and / or changing the registration time of a virtual sensor so as to make the system have adequate time to judge and allocate currency notes and improve the accuracy of currency note detection.

Owner:SHENZHEN YIHUA COMP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com