Tooling pressure holding delay equipment

A technology of tooling and equipment, which is applied in the field of tooling pressure holding and delay equipment, can solve the problems of bulky equipment, inability to meet the production requirements of pressure holding and delay time, and short pressure holding and delay time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

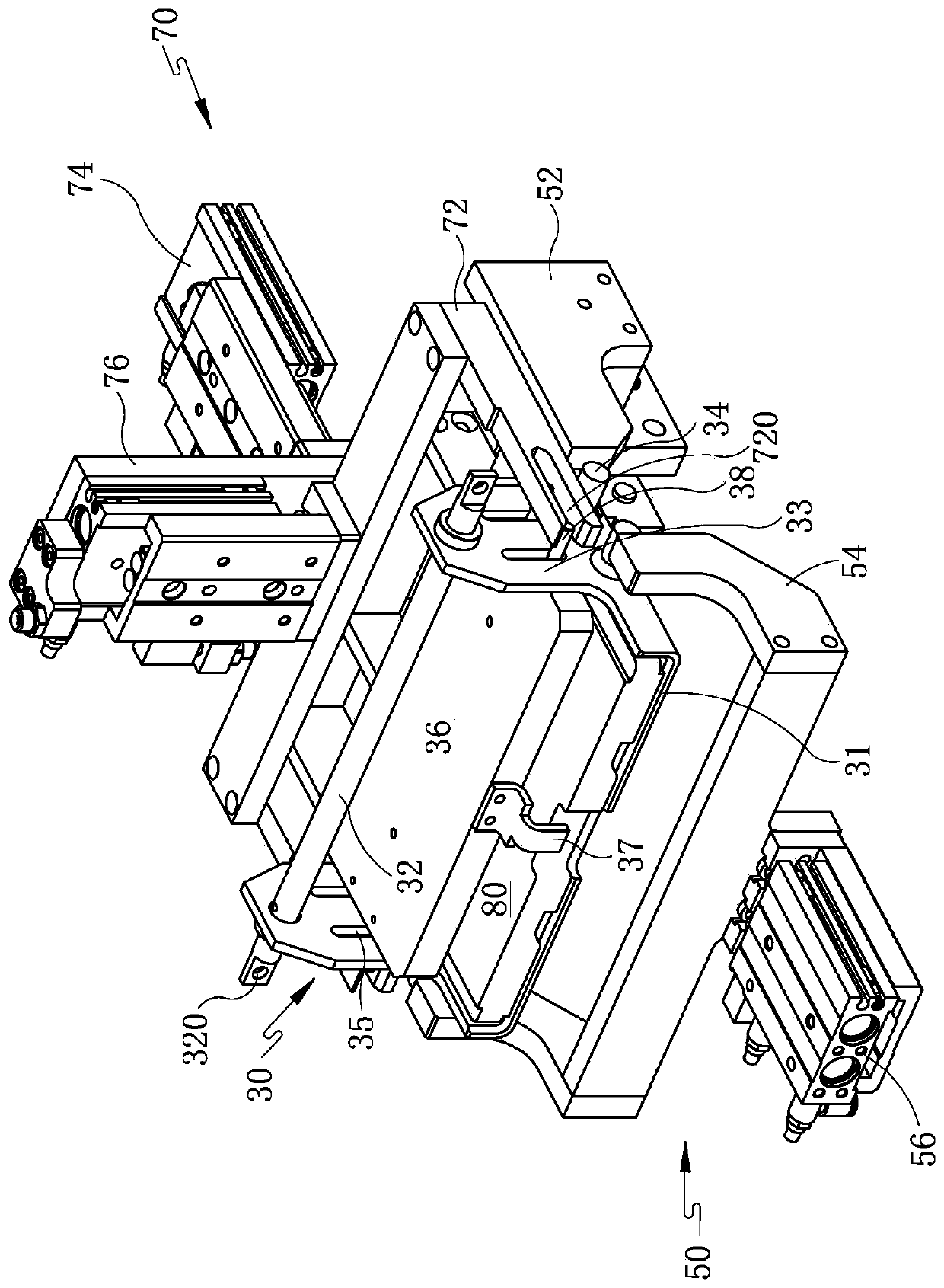

[0030] Below in conjunction with accompanying drawing and embodiment, further elaborate the present invention.

[0031] The orientations involved in this specification are all subject to the orientations shown in the drawings, which only represent relative positional relationships, not absolute positional relationships.

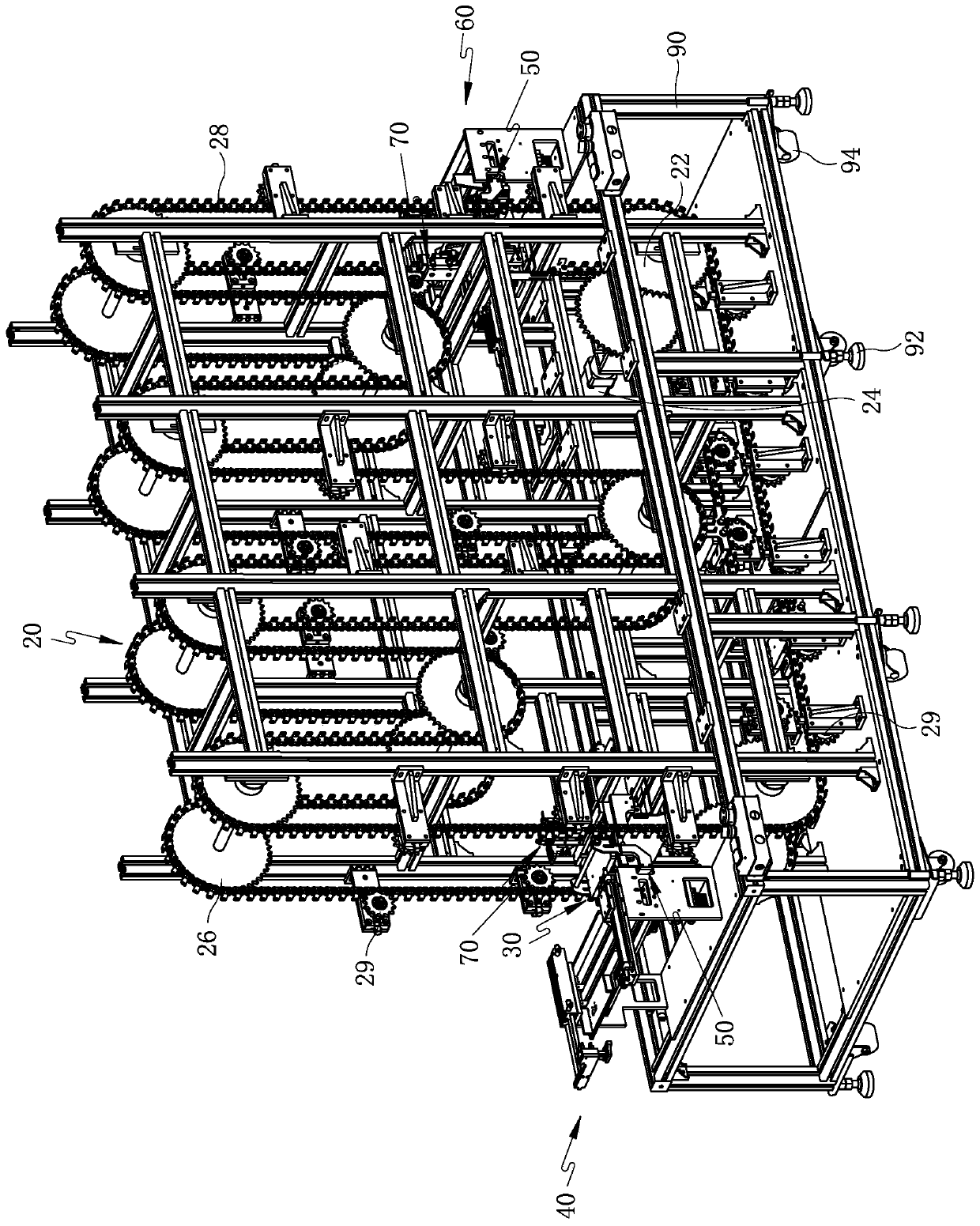

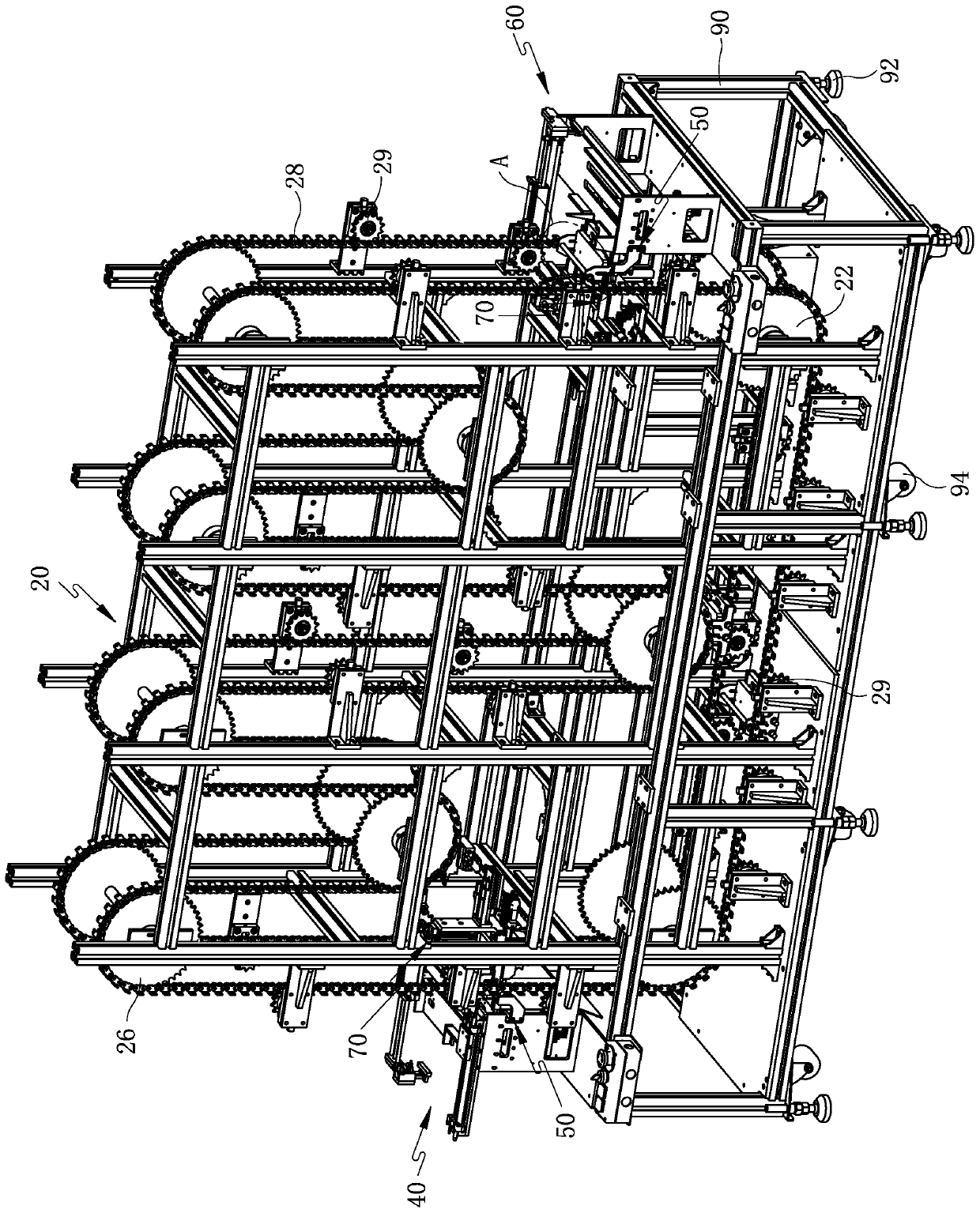

[0032] Such as figure 1 and figure 2 Commonly shown, a tooling pressure maintaining and delaying device includes a frame 90, the frame 90 is a frame structure composed of multiple vertical beams and multiple cross beams, and its cross section is rectangular. A suspension conveying mechanism 20 is installed on the frame 90, and the suspension conveying mechanism 20 comprises a plurality of chain wheel groups installed on the frame 90, and each chain wheel group comprises two sprockets arranged coaxially, and the two sprockets are respectively installed on The two ends of the sprocket shaft, the sprocket shaft is installed on the frame 90 by bearing rotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com