Patents

Literature

67results about How to "Adjust running speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

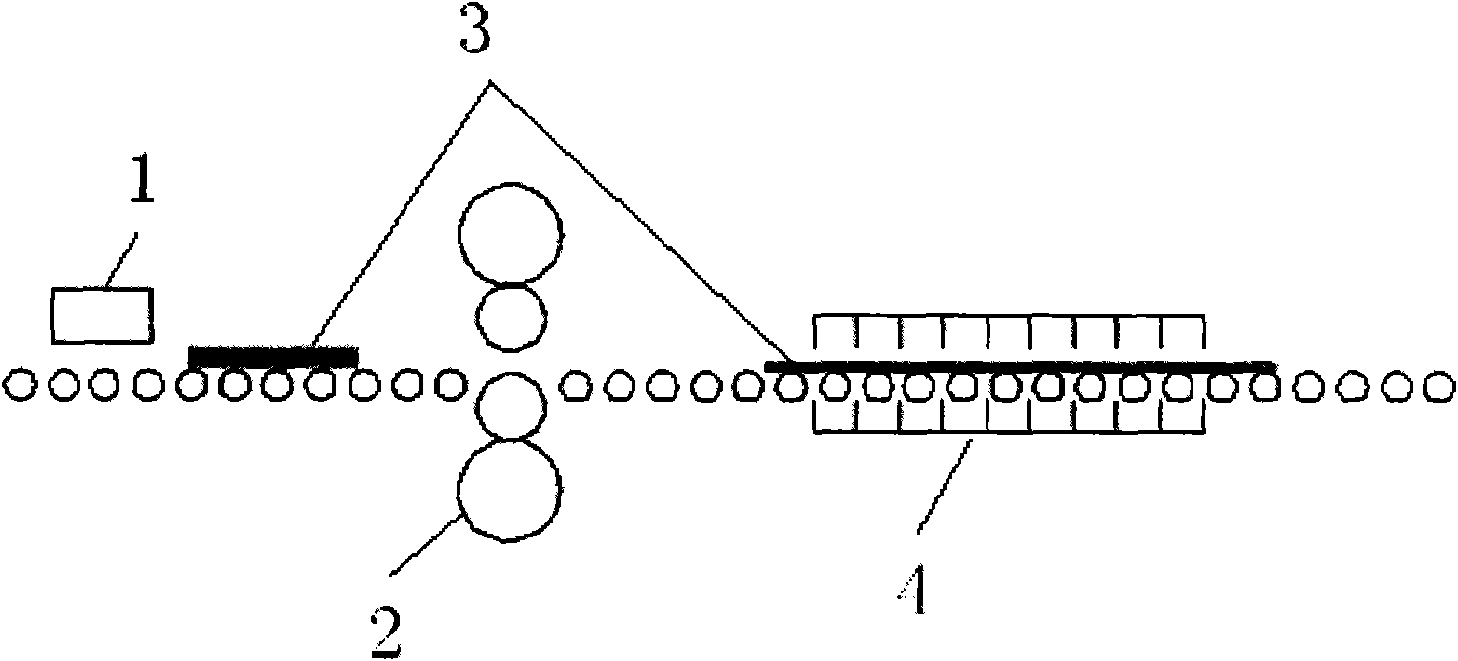

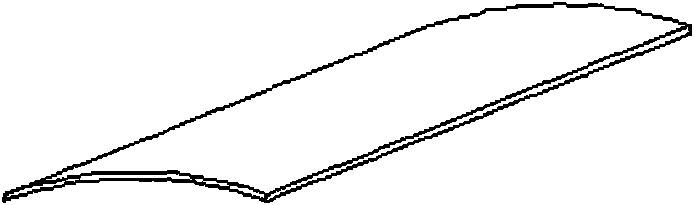

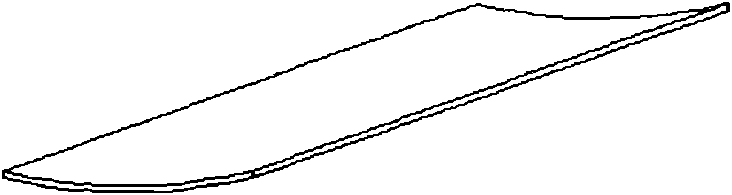

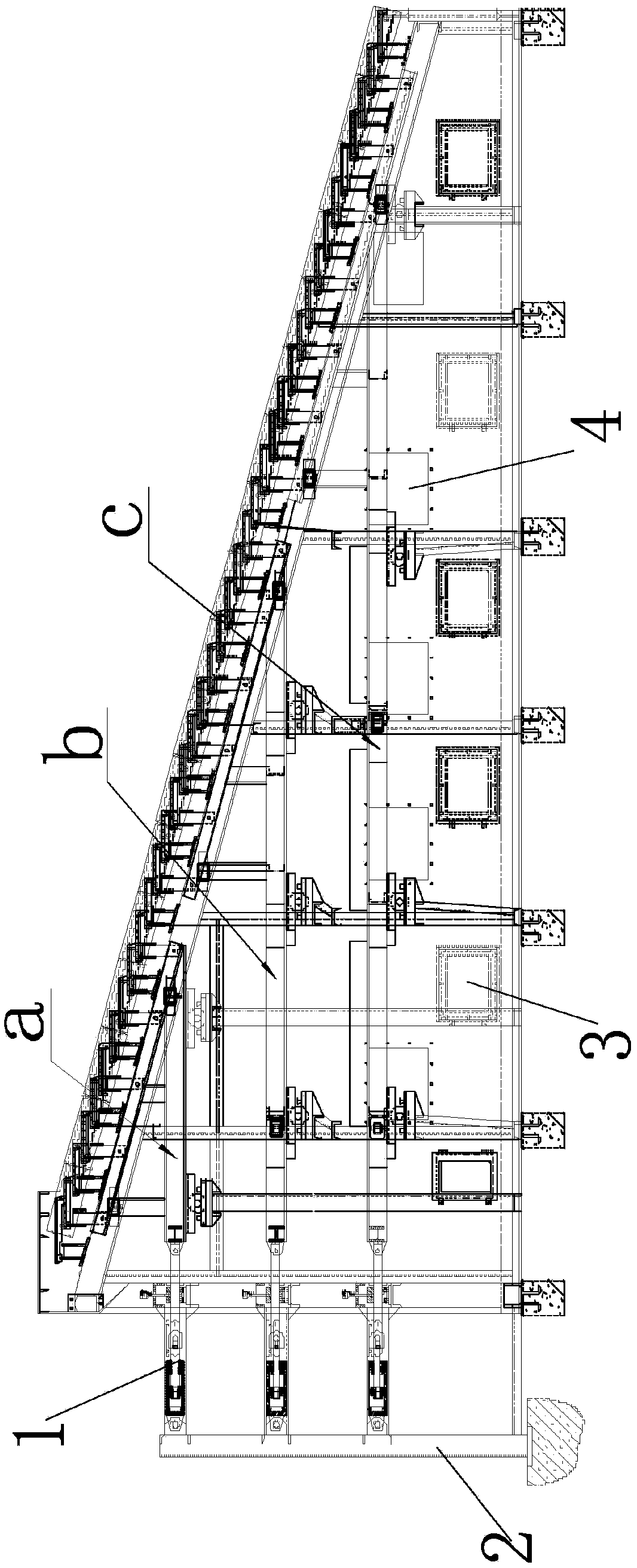

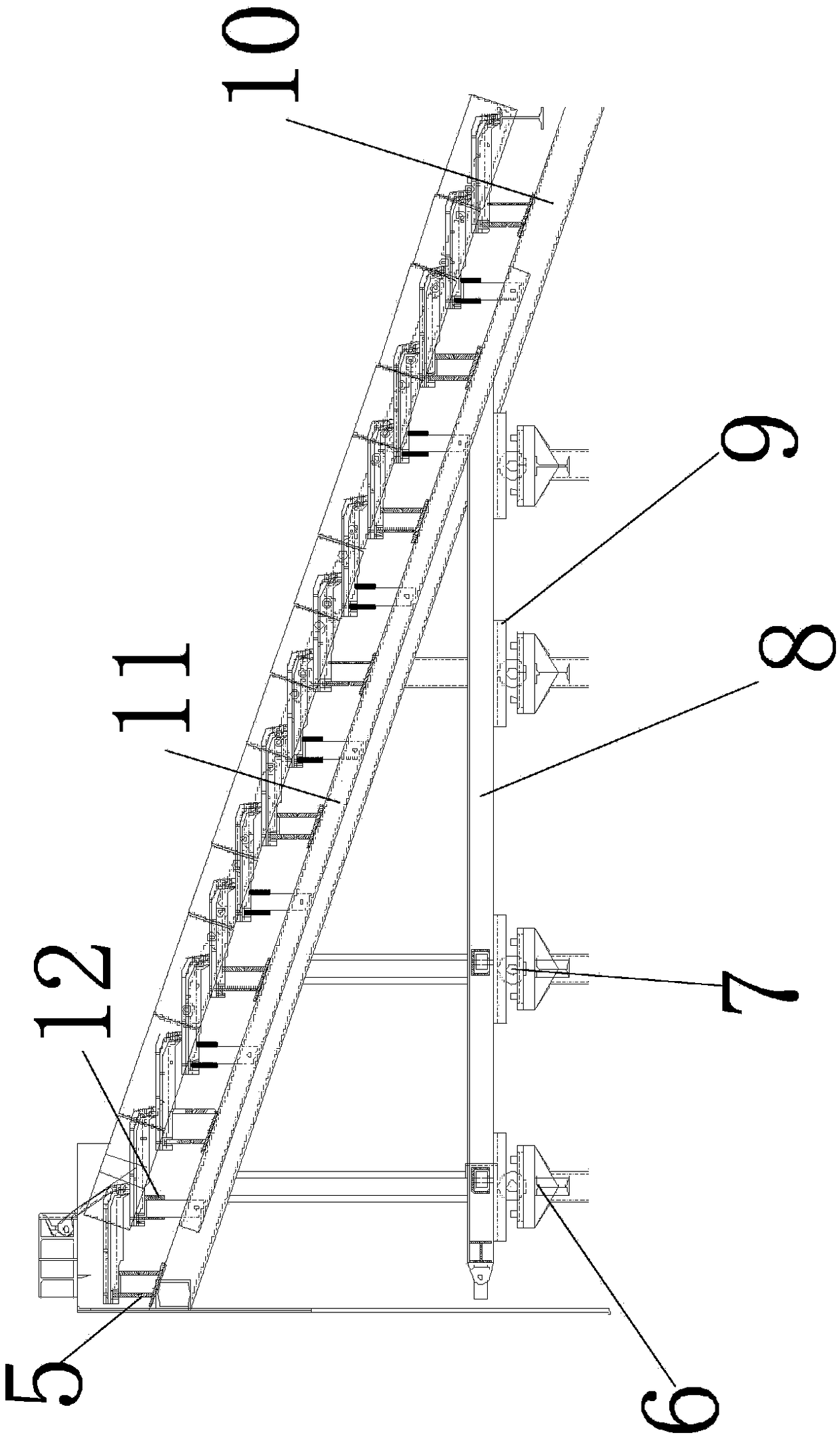

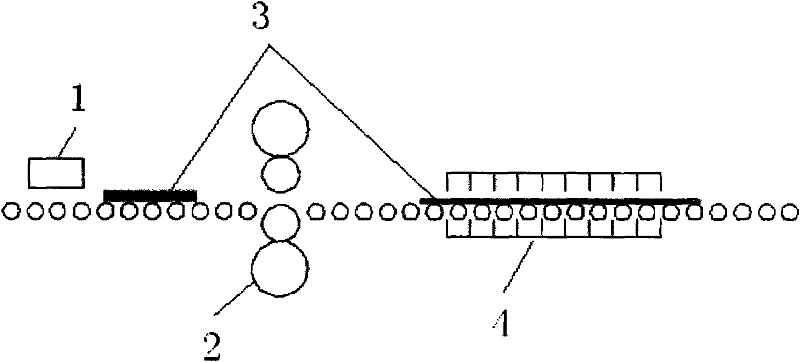

Method for controlling shape of low-alloy high-strength steel plate in controlled cooling phase

InactiveCN101885004ACooling temperatureMeet the plate typeTemperature control deviceMetal rolling arrangementsSteel platesSheet steel

The invention discloses a method for controlling the shape of a low-alloy high-strength steel plate in a controlled cooling stage. The method is used in a controlled rolling and cooling process for producing a steel plate; the shape of the steel plate after rolling is obtained by using a controlled cooling process, and the upper to lower water ratio of the steel plate, edge masking and the speed of the steel plate passing through a controlled cooling area in the cooling process are adjusted according to the shape of the steel plate after rolling so as to control the shape of the steel plate after controlled cooling, and thus, a low-alloy high-strength steel plate capable of meeting requirements is obtained. The product produced by using the method can eliminate shape defects, such as concave upward, concave downward, edge waves, center waves and the like, of the steel plate in the process of controlled cooling, improves the accuracy of the controlled cooling process, ensures that the texture and the performance of the steel plate are more uniform, and further enhances the yield rate of the product.

Owner:NANJING IRON & STEEL CO LTD

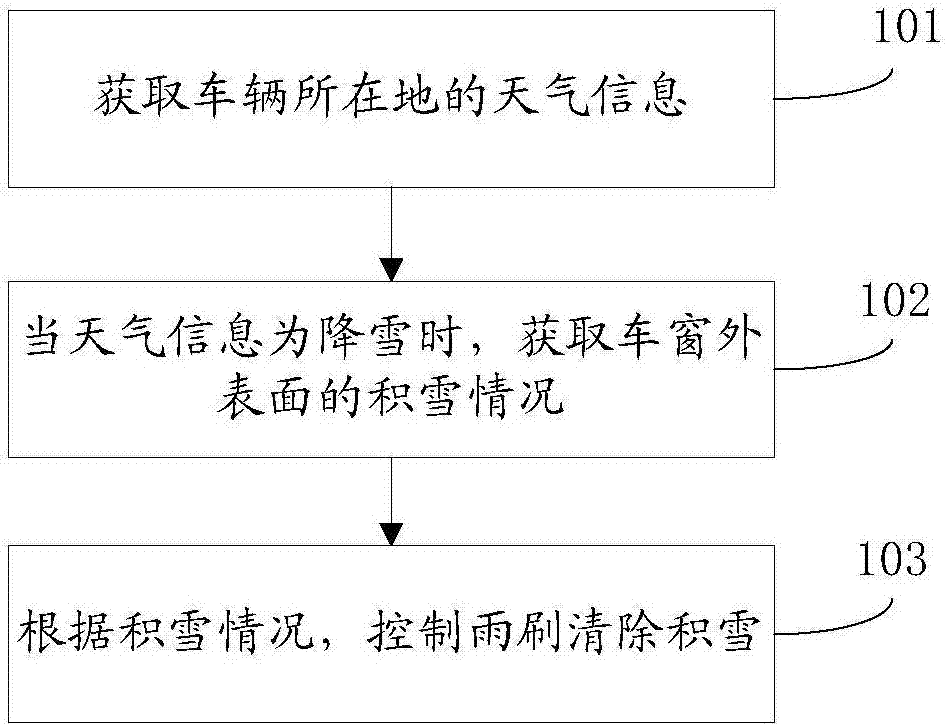

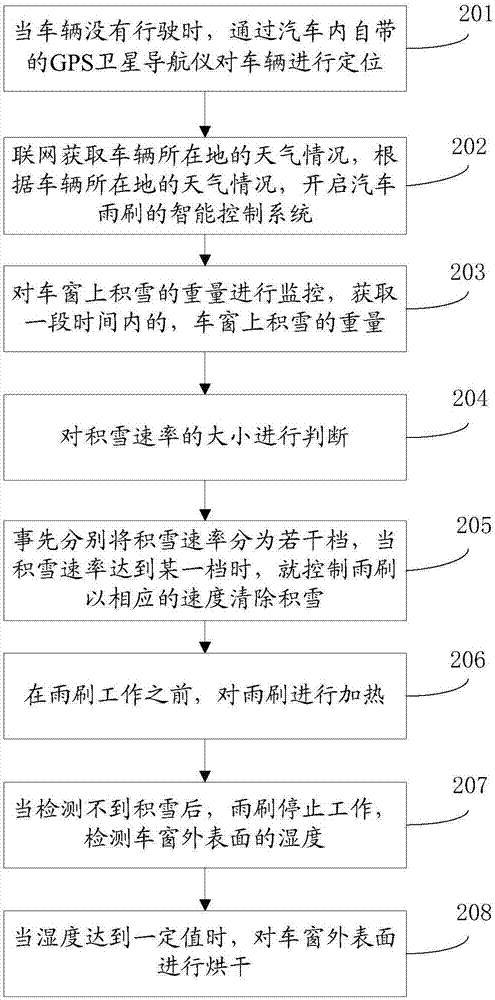

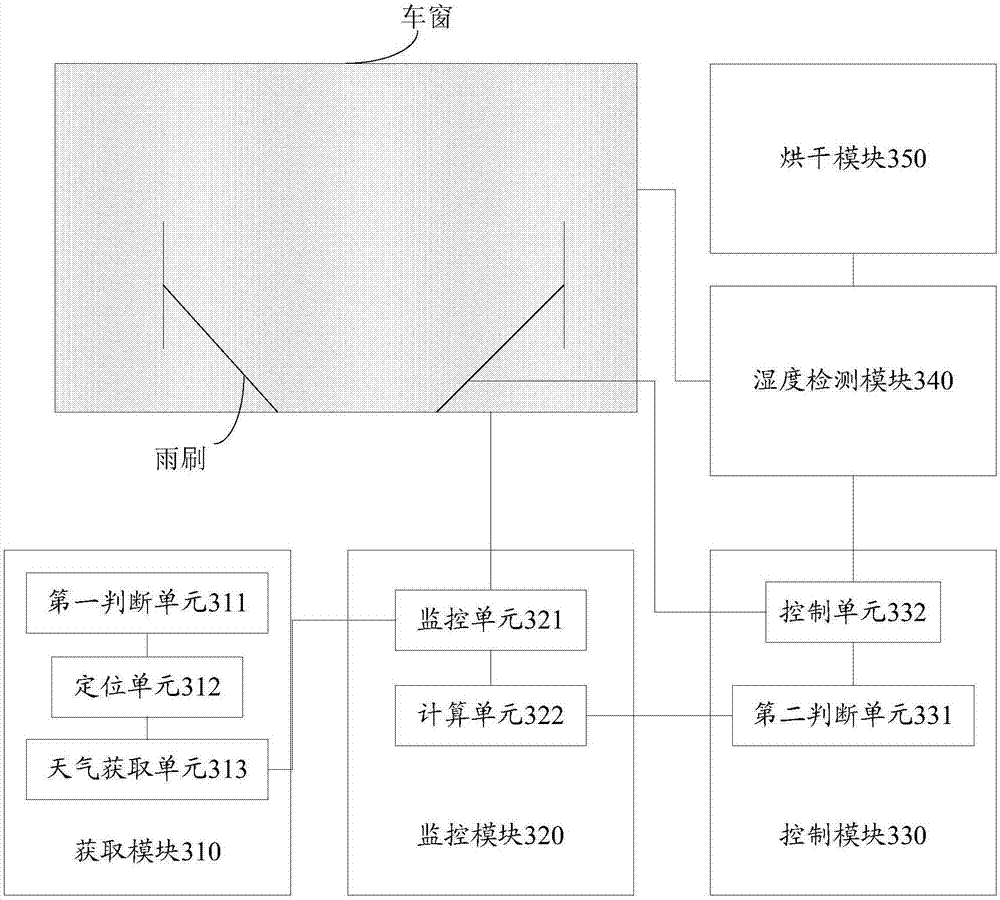

Intelligent control method and system for wiper

The invention relates to an intelligent control method and system for a wiper. The method comprises the following steps that weather information of the location of a vehicle is acquired; when the weather information is snowfall, snow accumulation condition of the outer surface of a vehicle window is acquired; according to the snow accumulation condition, the wiper is controlled to clean away accumulated snow. According to the intelligent control method and system for the wiper, the accumulated snow on the vehicle window can be cleaned away in time, and freezing of the vehicle window is avoided; furthermore, combing with the weather condition of the location of the vehicle, it can be judged whether to conduct monitoring of the snow accumulation condition on the vehicle window or not, the condition is avoided that the vehicle window is also subjected to monitoring of the snow accumulation condition when no accumulated snow exists, resources can be saved effectively, and the judgment on when to monitor the accumulated snow on the vehicle window can be more accurate.

Owner:郭泽华

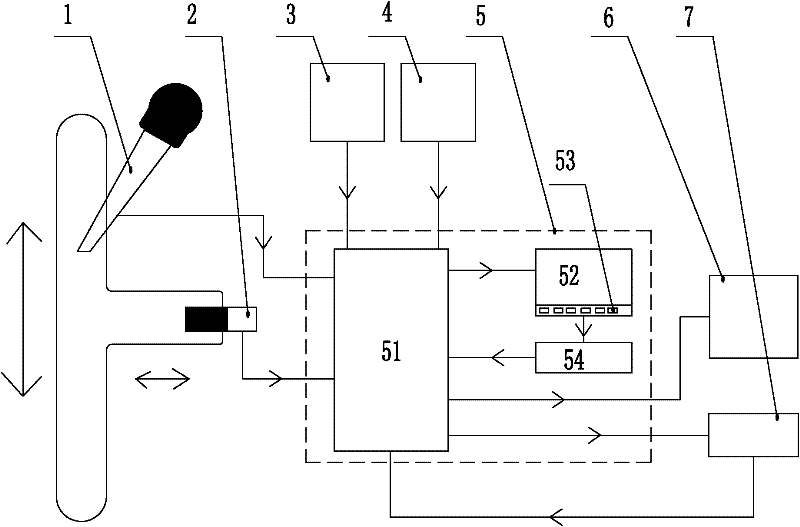

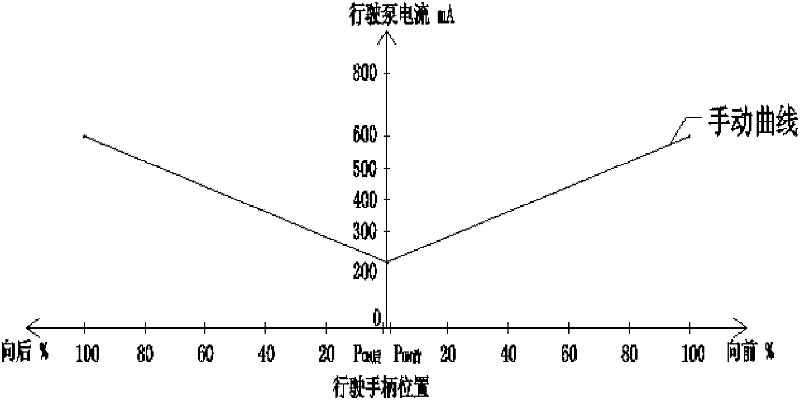

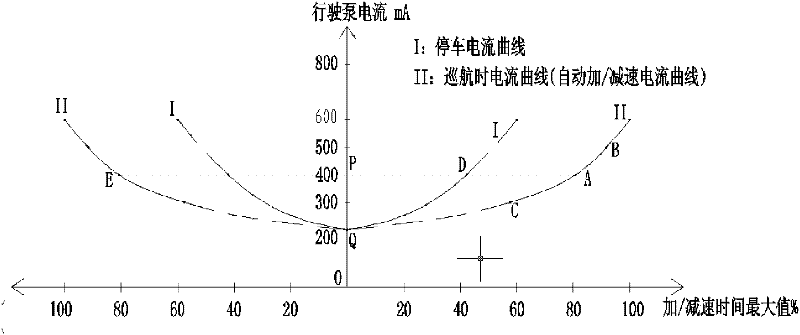

Road roller and motion control device and method thereof

The invention provides a road roller and a motion control device and method thereof. The motion control device comprises a position sensing device for sensing position information of an operation lever, and a controller connected with the position sensing device, wherein the controller is used for automatically adjusting driving current output to a travel pump according to the preset current-time relation curve which is in one-to-one correspondence with each motion indication range when the position sensor senses that the operation lever is positioned in each motion indication range; and each motion indication range comprises at least one of a forward indication position range, a backward indication position range or a stopping indication position range. According to the invention, the driving current output to the travel pump can be automatically adjusted, thereby the automatic adjustment on the operation speed of the road roller can be realized.

Owner:SANY HEAVY IND CO LTD (CN)

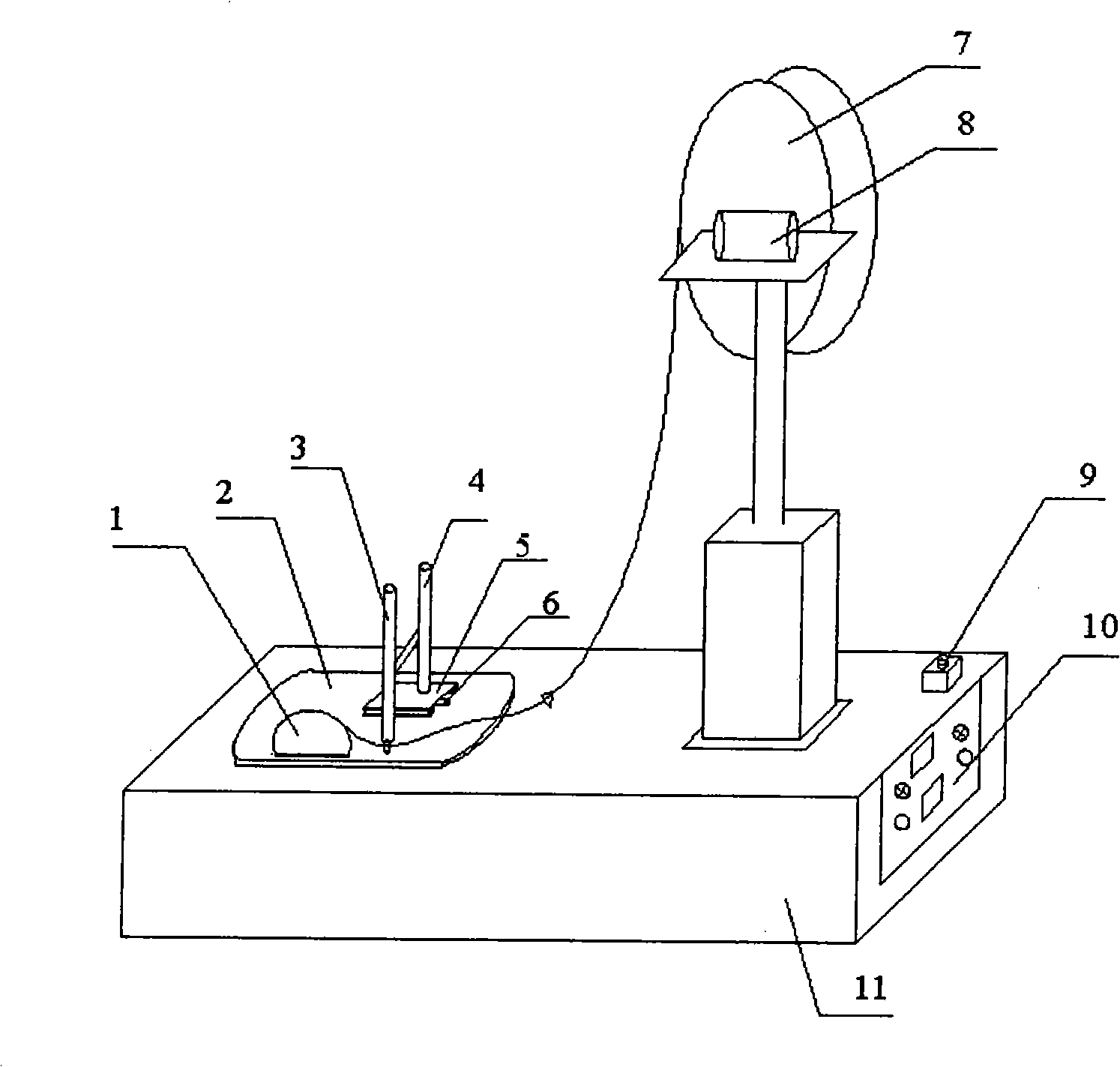

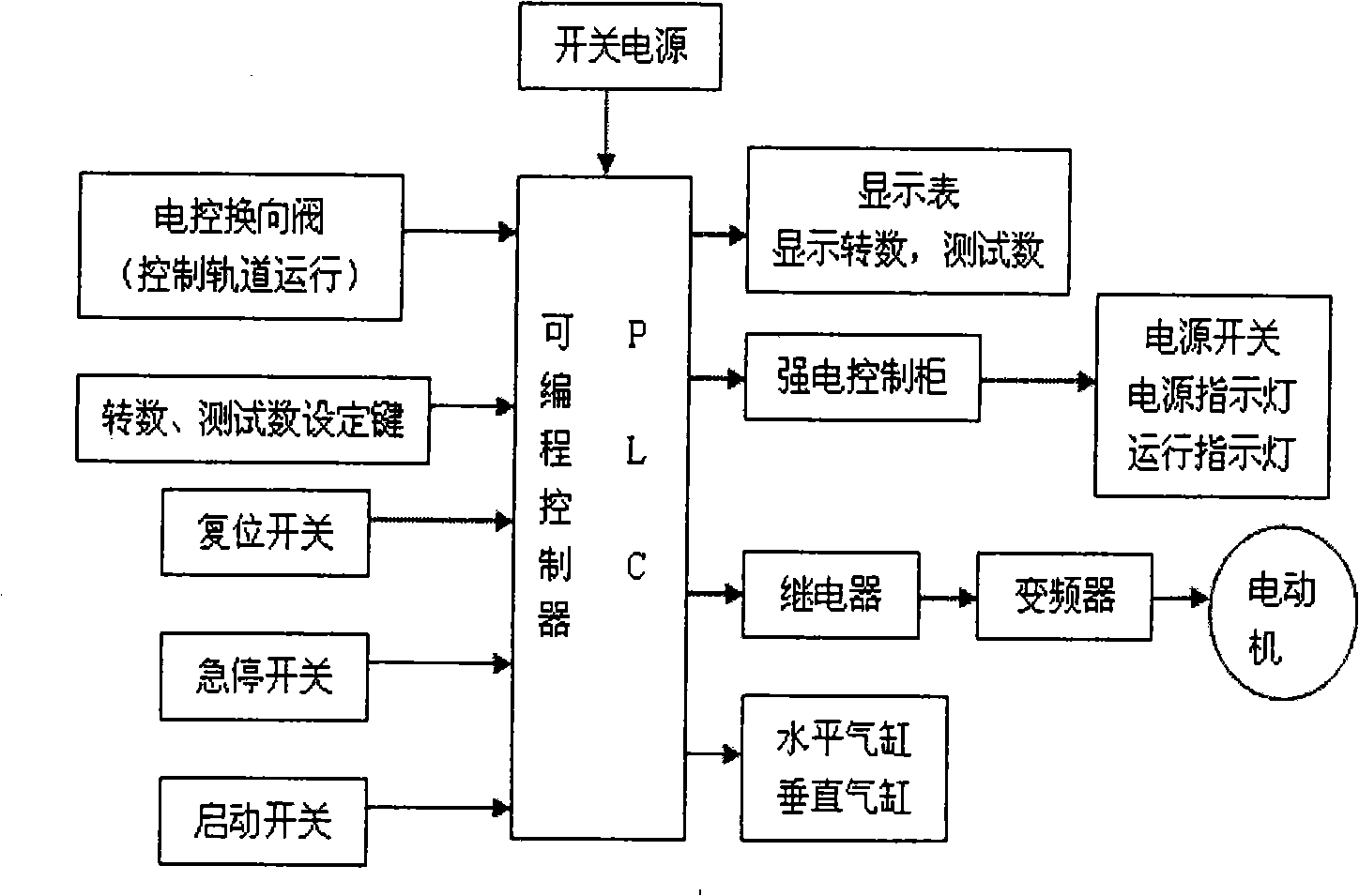

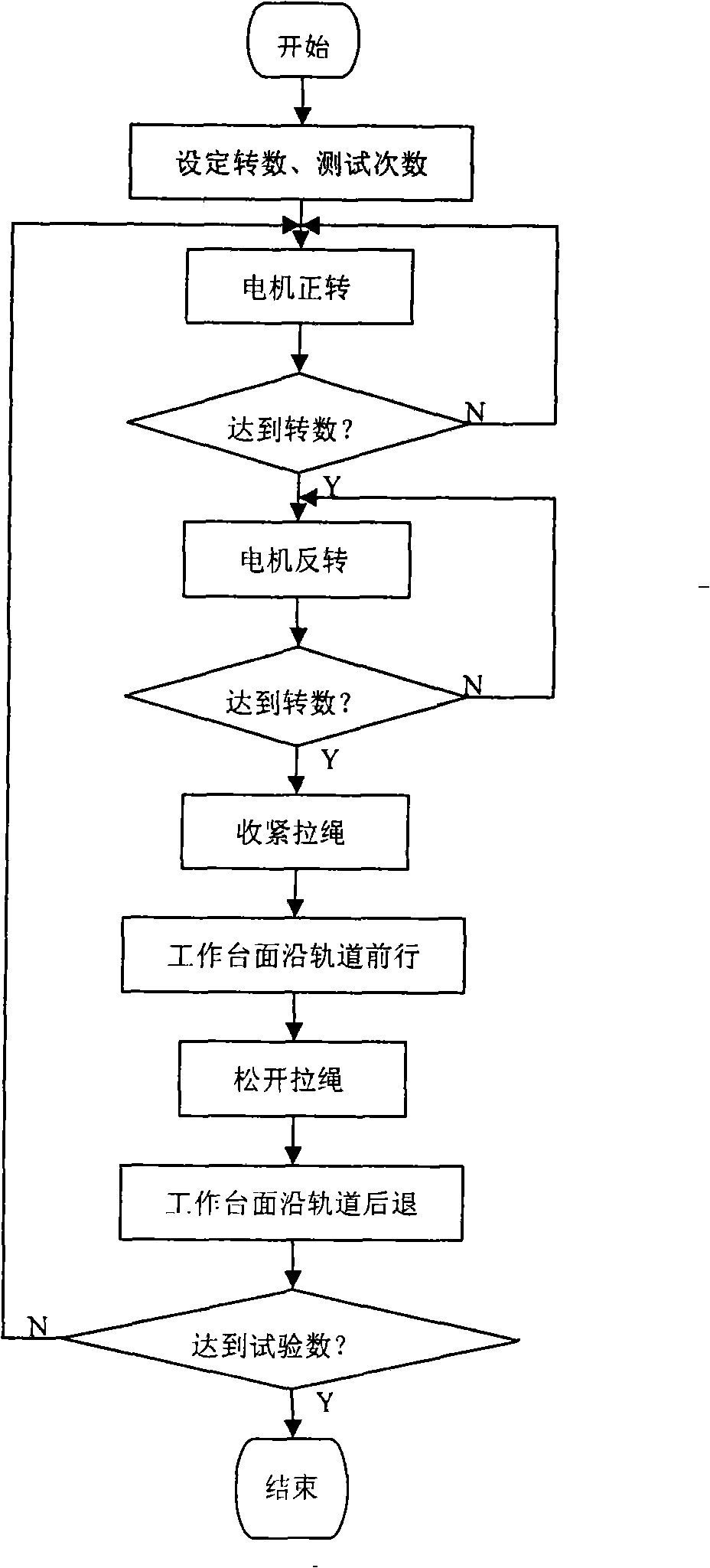

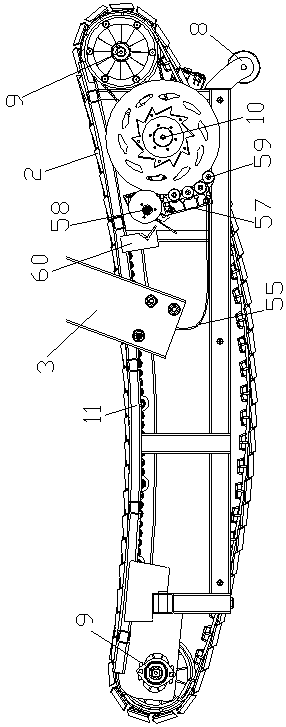

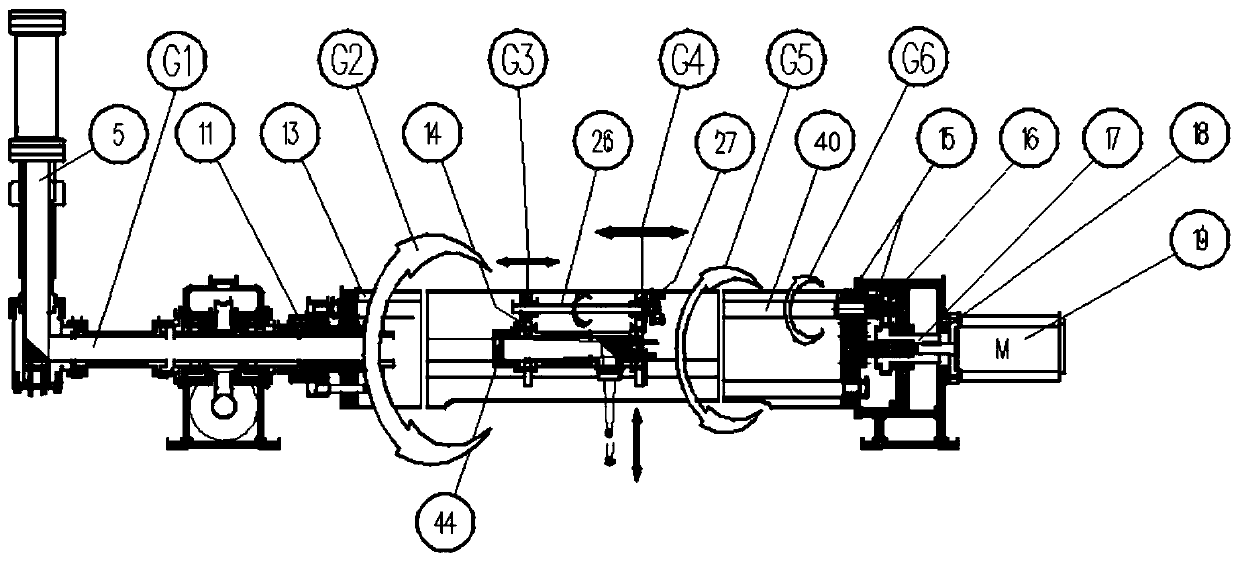

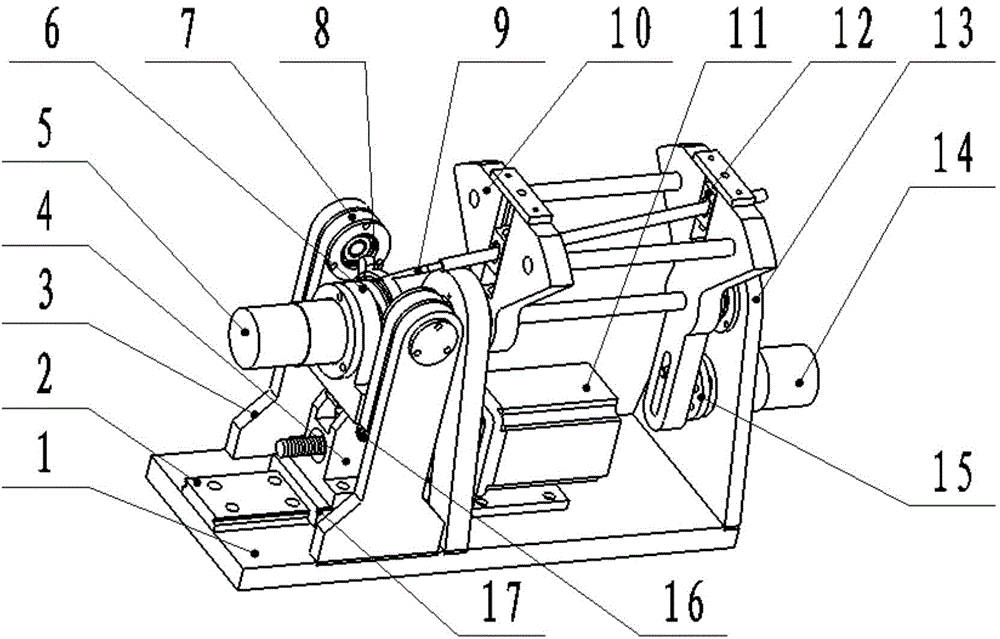

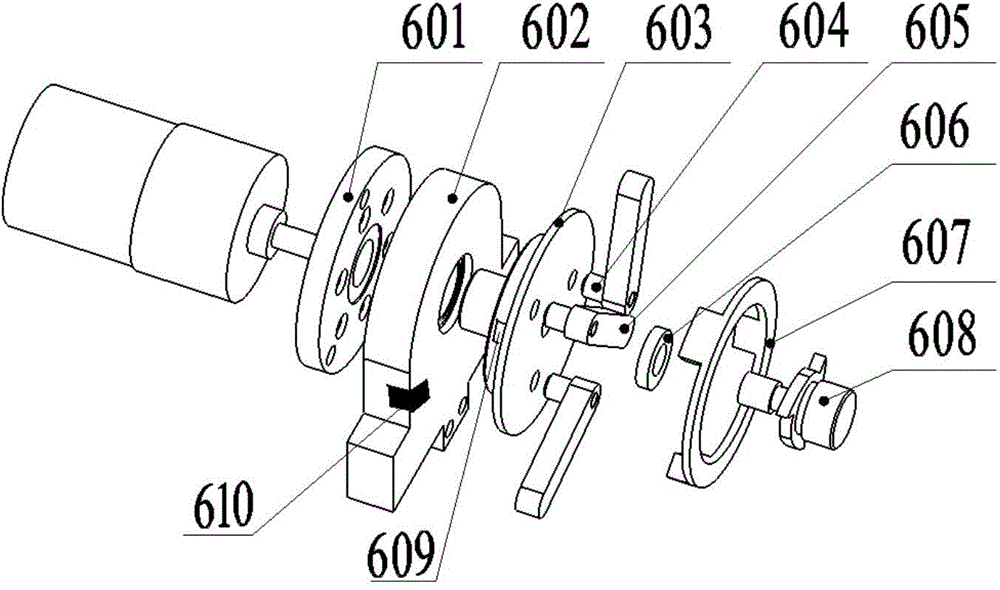

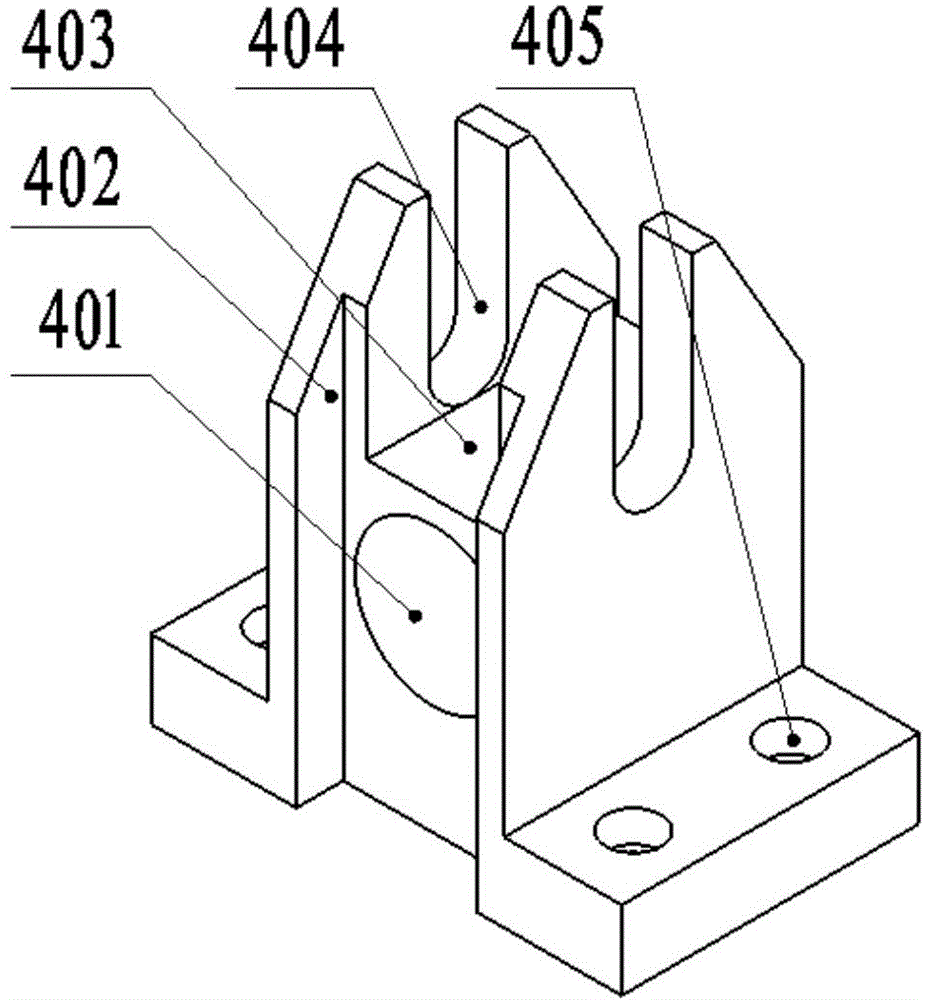

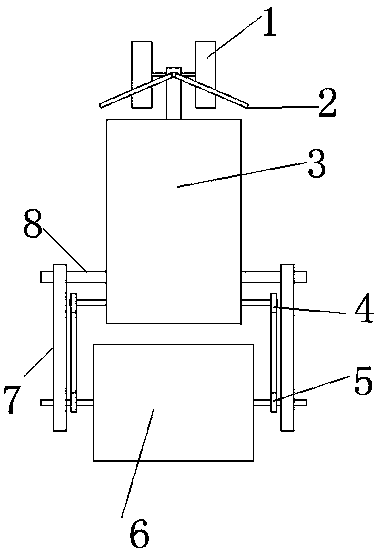

Intelligent pull rope fatigue tester

InactiveCN101358914AAdjustable speedAdjust running speedStrength propertiesElectric machineryEngineering

The invention relates to an intelligent stay-cord fatigue testing machine, comprising a control cabinet (11), an electric motor (8) and a wheel (7). The electric motor (8) and the wheel (7) are fixedly mounted on the control cabinet (11) in a rotatable manner, and the wheel (7) is driven by the electric motor (8). A test desk (2) for holding the product (1) under test is mounted on the control cabinet (11); a guide rail (5) is mounted on the test desk (2), and the guide rail (5) is connected with a cylinder which drives the guide rail to move; a first bracket (3) and a second bracket (4) which can make in-step movements are mounted on the guide rail (5), the first bracket (3) is connected with the second bracket (4) by a connecting rod, and a vertical cylinder which can make upward and downward movements and tension the product under test is mounted on the first bracket (3). The intelligent stay-cord fatigue testing machine has the advantages of high intelligent degree, high safety and reliability, easy operation, brief and clear display, compact structure, easy installation and operation and as well as relatively strong versatility.

Owner:南京电子计量有限公司 +2

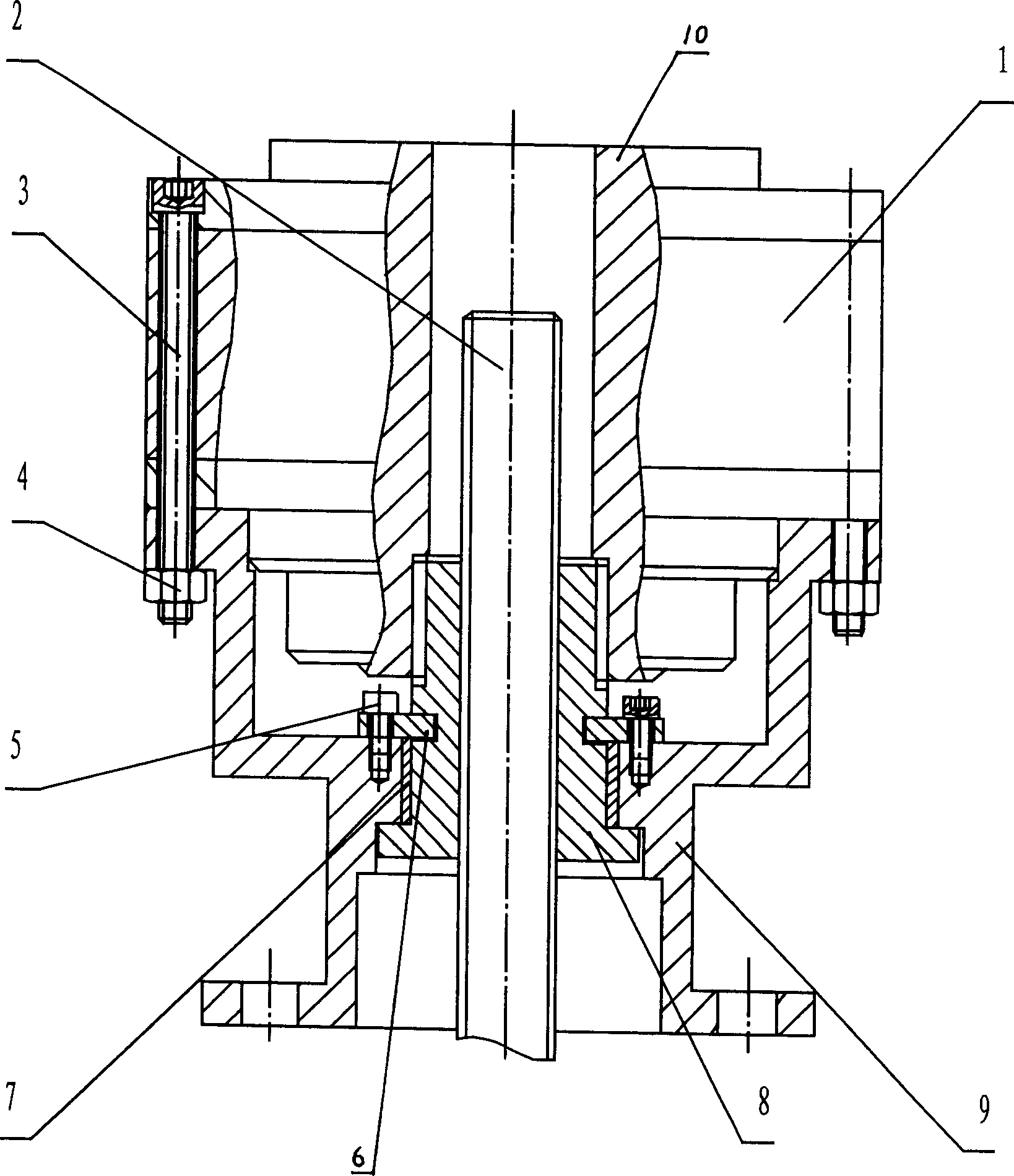

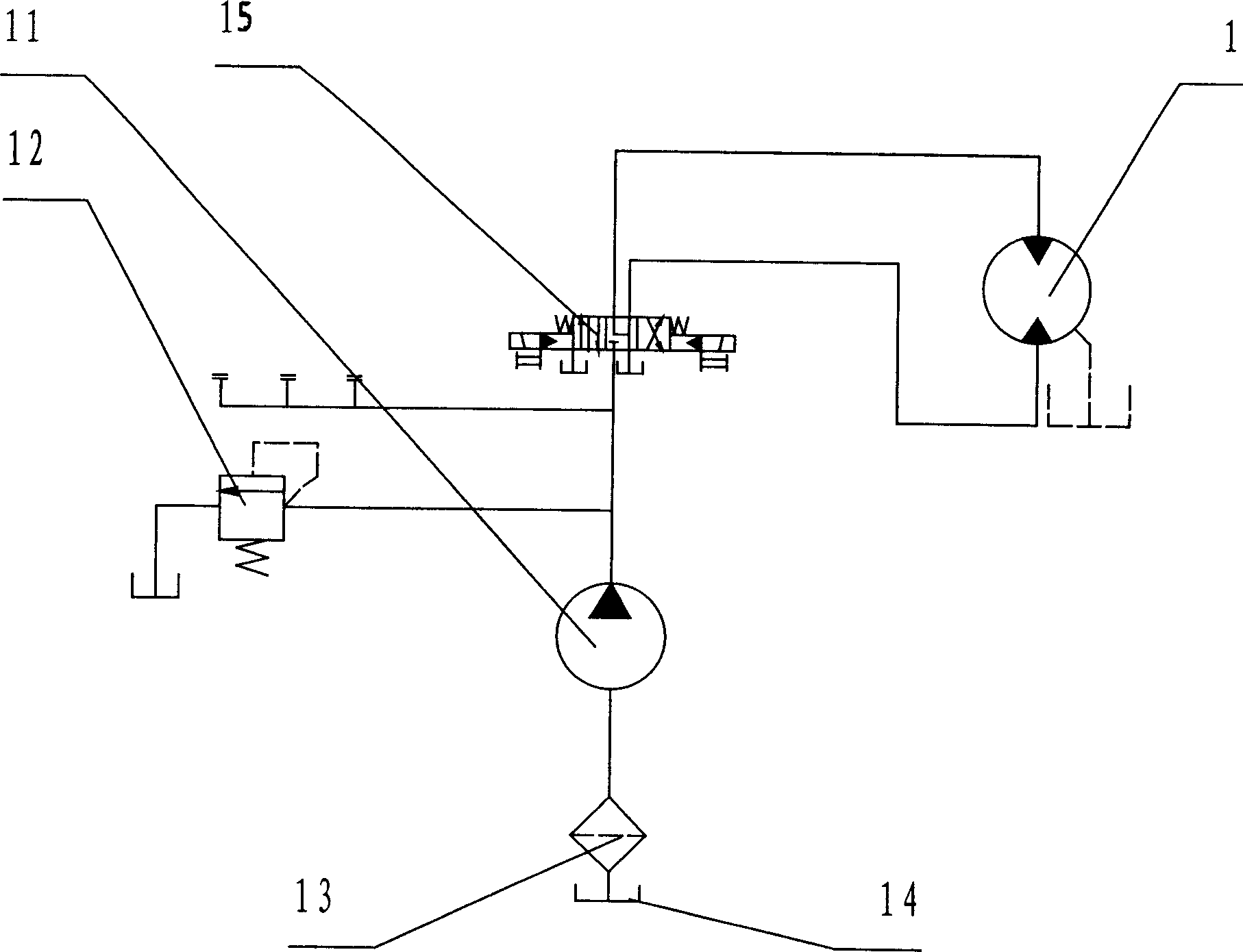

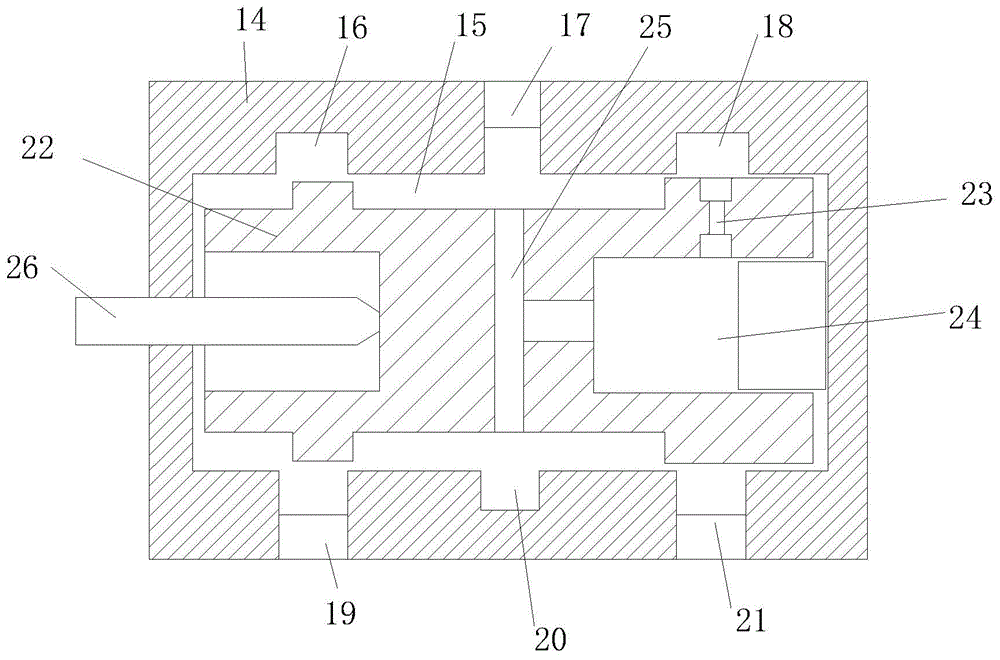

Hydraulic controllable sluice valve

InactiveCN1793707AAdjust running speedSmooth connectionOperating means/releasing devices for valvesSlide valveHydraulic motorFuel tank

The invention is a hydraulic controllable gate valve, belonging to a hydraulic driven gate valve, applied to water feeding and discharging engineering and comprising a main body and an auxiliary hydraulic pumping station; the main body comprises valve body, hydraulic motor, connection frame, drive nut, screw rod, clamp ring and copper cover; the hydraulic motor is connected with the drive nut through spline, the drive nut is axially located through the clamp ring and connection frame, and the hydraulic motor and the clamp ring are both fixed on the connection frame; the screw rod is connected with the drive nut through spiral auxiliary; the auxiliary hydraulic pump station comprises oil tank, hydraulic pump, electromagnetic directional valve and overflow valve; the inlet of the hydraulic pump is connected with the oil tank and its outlet is connected with the mouth P of the electromagnetic directional valve, the hydraulic motor is connected with mouths A and B of the electromagnetic directional valve, and the overflow valve is connected with the outlet end of the hydraulic pump.

Owner:TAIYUAN UNIV OF TECH

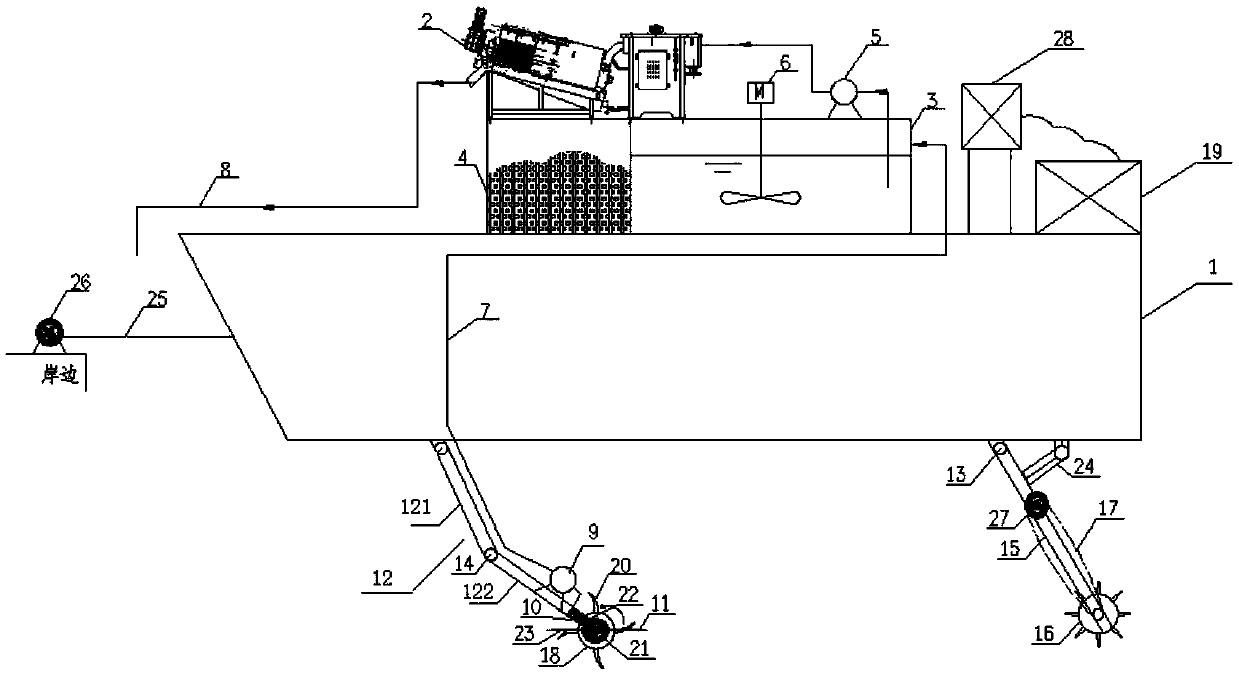

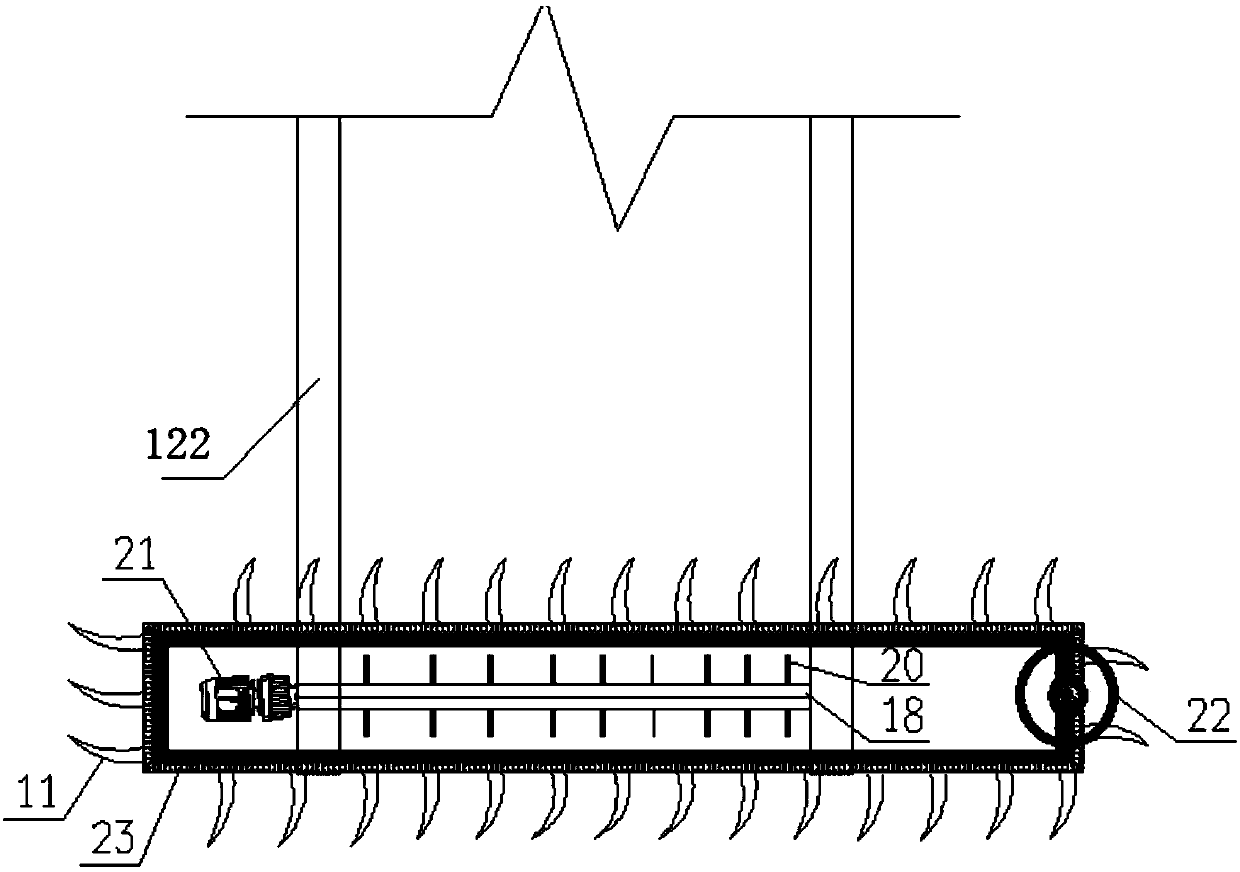

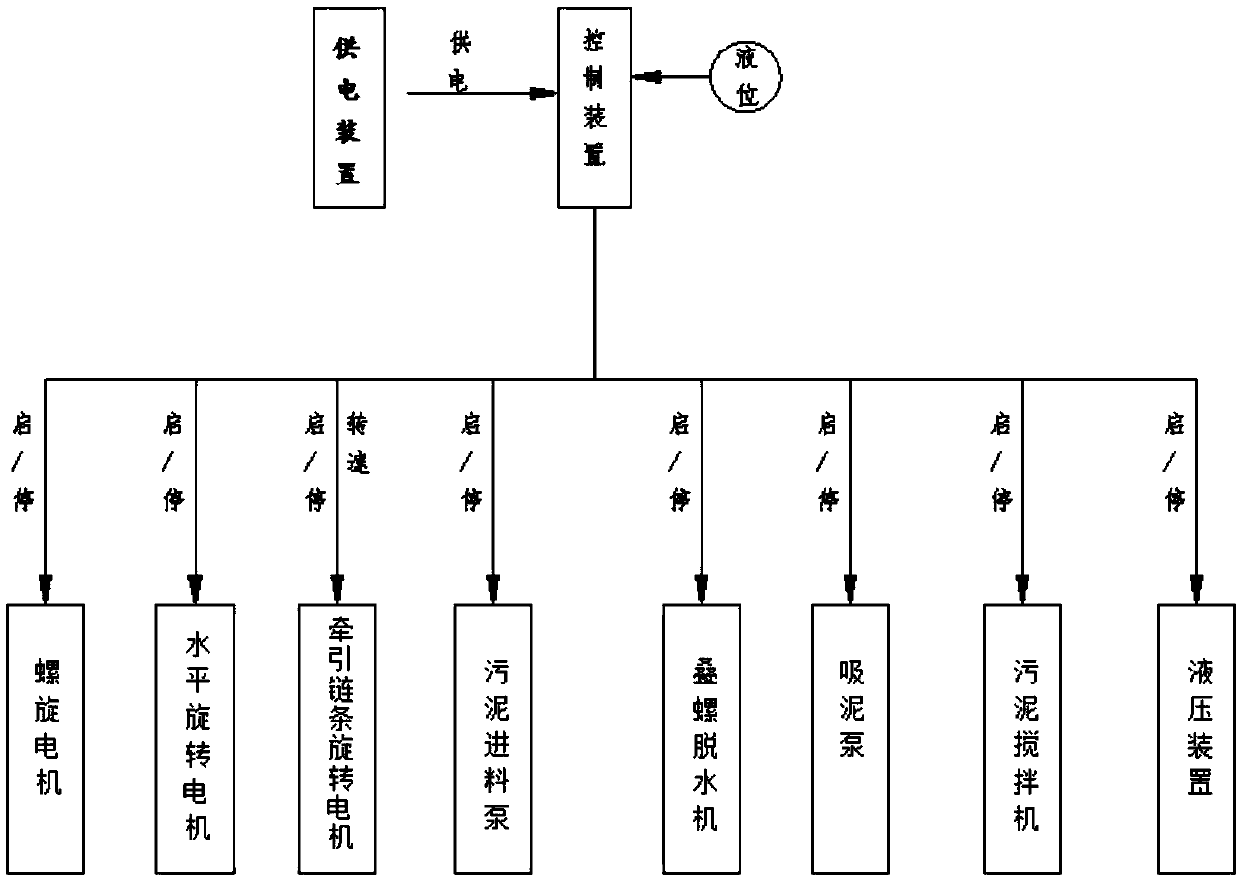

Automatic desilting ship

ActiveCN109680749AAffect the running effectFast forwardMechanical machines/dredgersMarine engineeringSilt

The invention discloses an automatic desilting ship which comprises a ship body, a sludge overturning mechanism, a barrier removing mechanism, a sludge conveying mechanism, a travelling mechanism, a dewatering device, a control device and a power supply device, wherein the sludge overturning mechanism is arranged at the front end of the bottom of the ship body and is used for overturning the sludge and conveying the overturned sludge to the dewatering device through the sludge conveying mechanism; the barrier removing mechanism is arranged at the front end of the bottom of the ship body and isused for barriers around the sludge overturning mechanism; the travelling mechanism is arranged at the rear end of the bottom of the ship body and is used for driving the ship body to run; the dewatering device is arranged on the ship body and is used for dewatering the sludge conveyed by the sludge conveying mechanism; the control device is arranged on the ship body and is used for controlling all mechanisms or devices to run; and the power supply device is arranged on the ship body and is used for supplying power for the mechanisms or devices. The automatic desilting ship can carry out desilting operation on riverway lakes with more entanglements including underwater aquatic plants and bottom mud with higher water content and is simple in structure and convenient to operate.

Owner:CEEP CO LTD

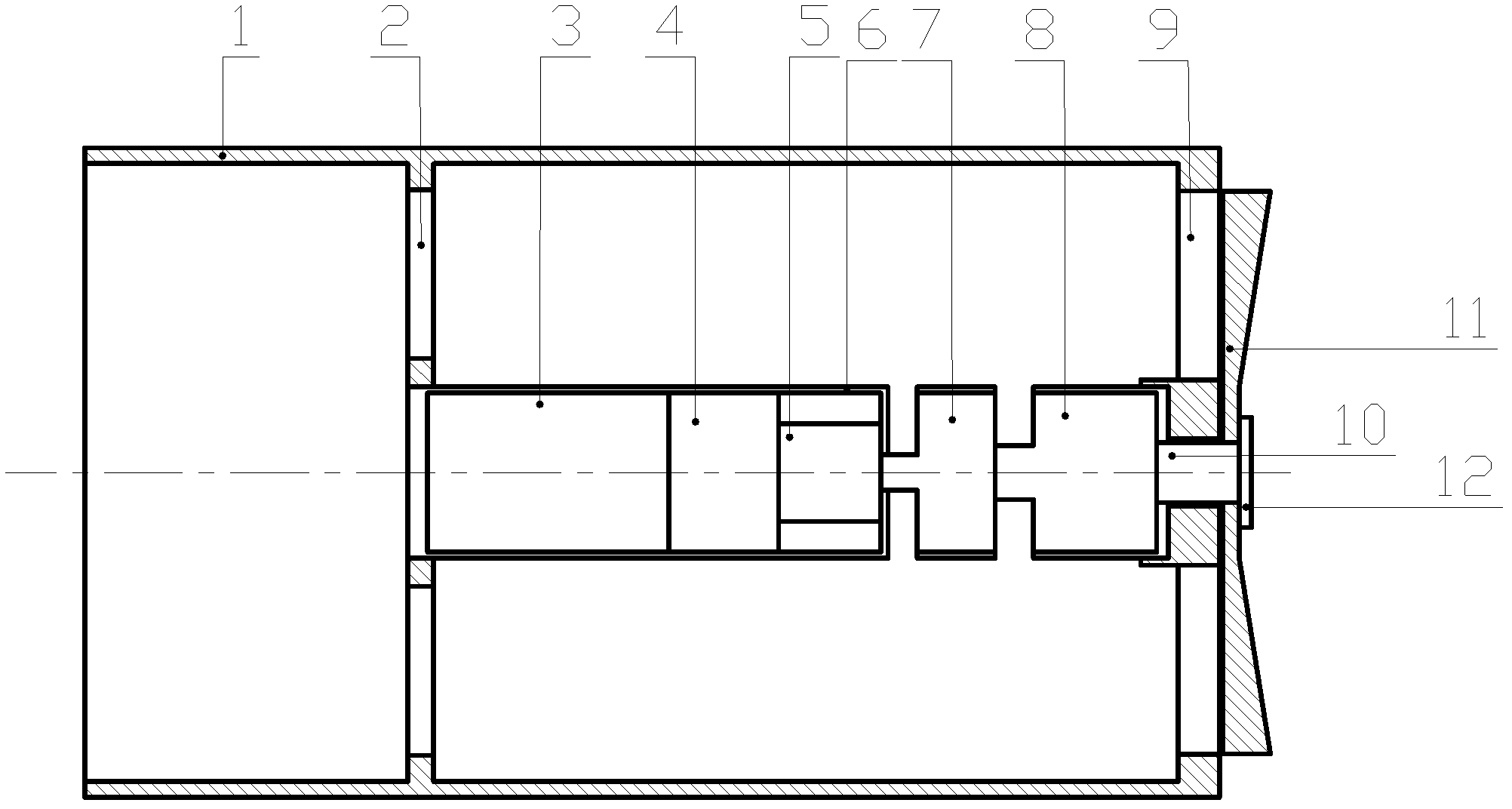

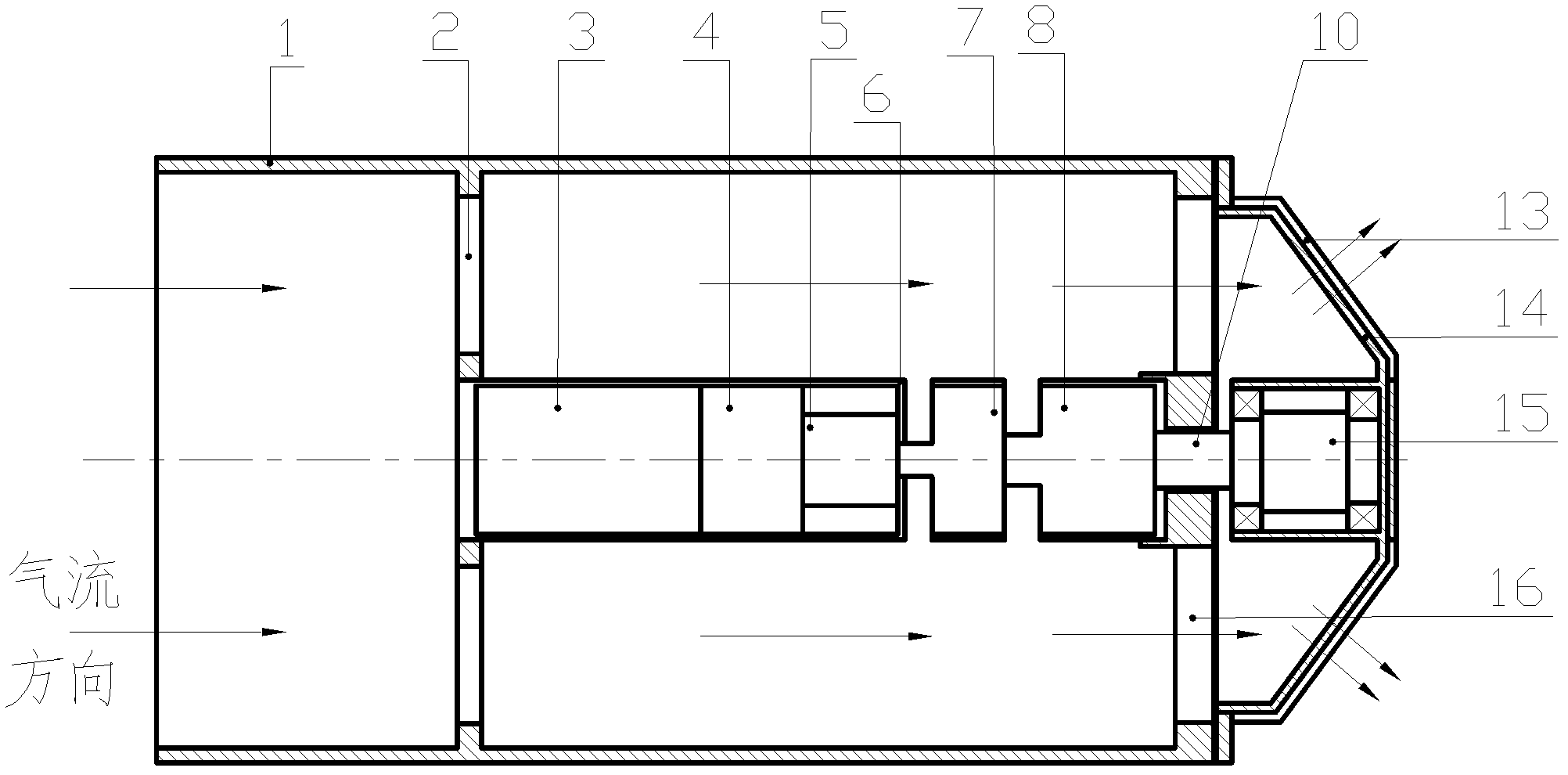

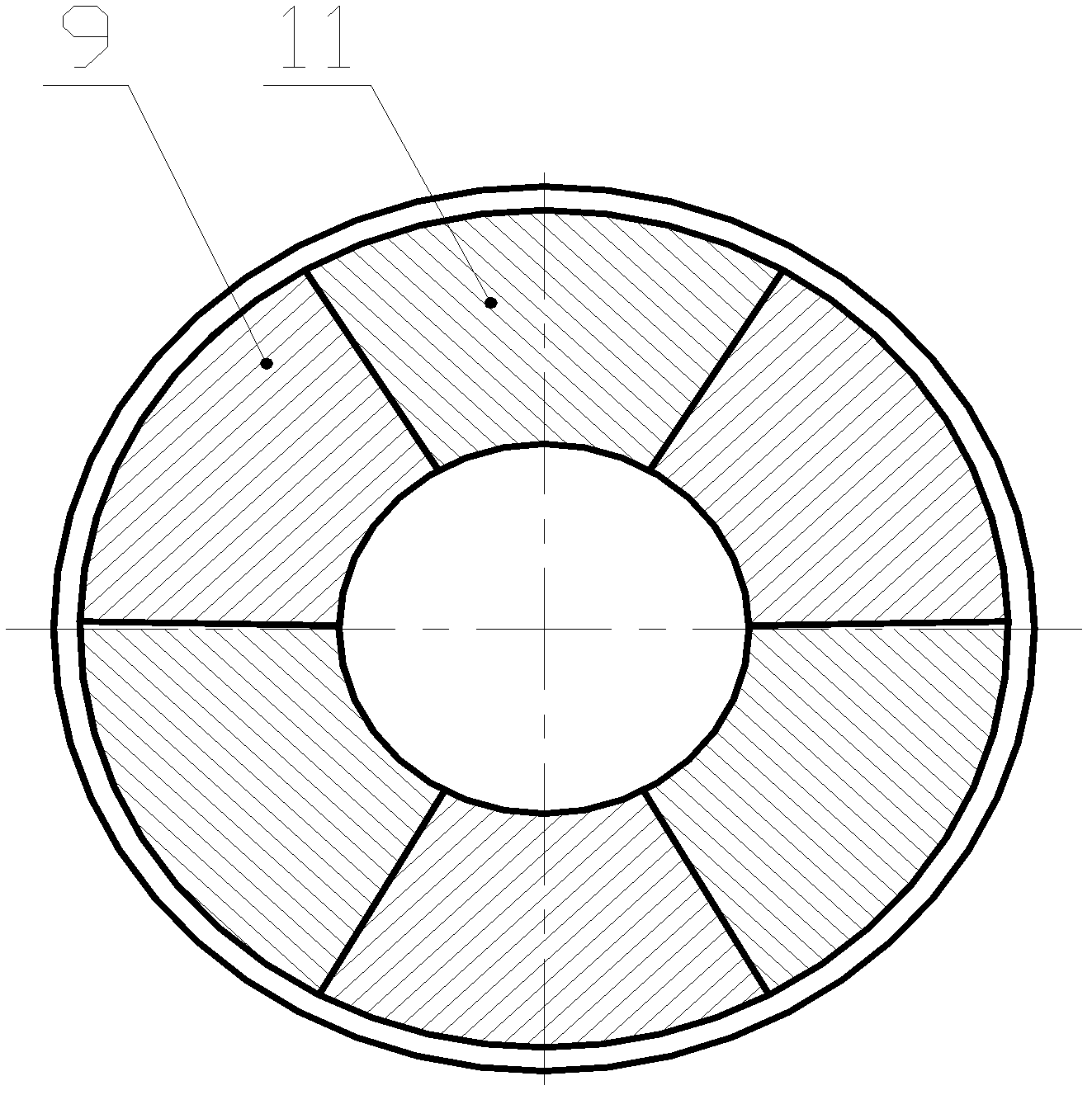

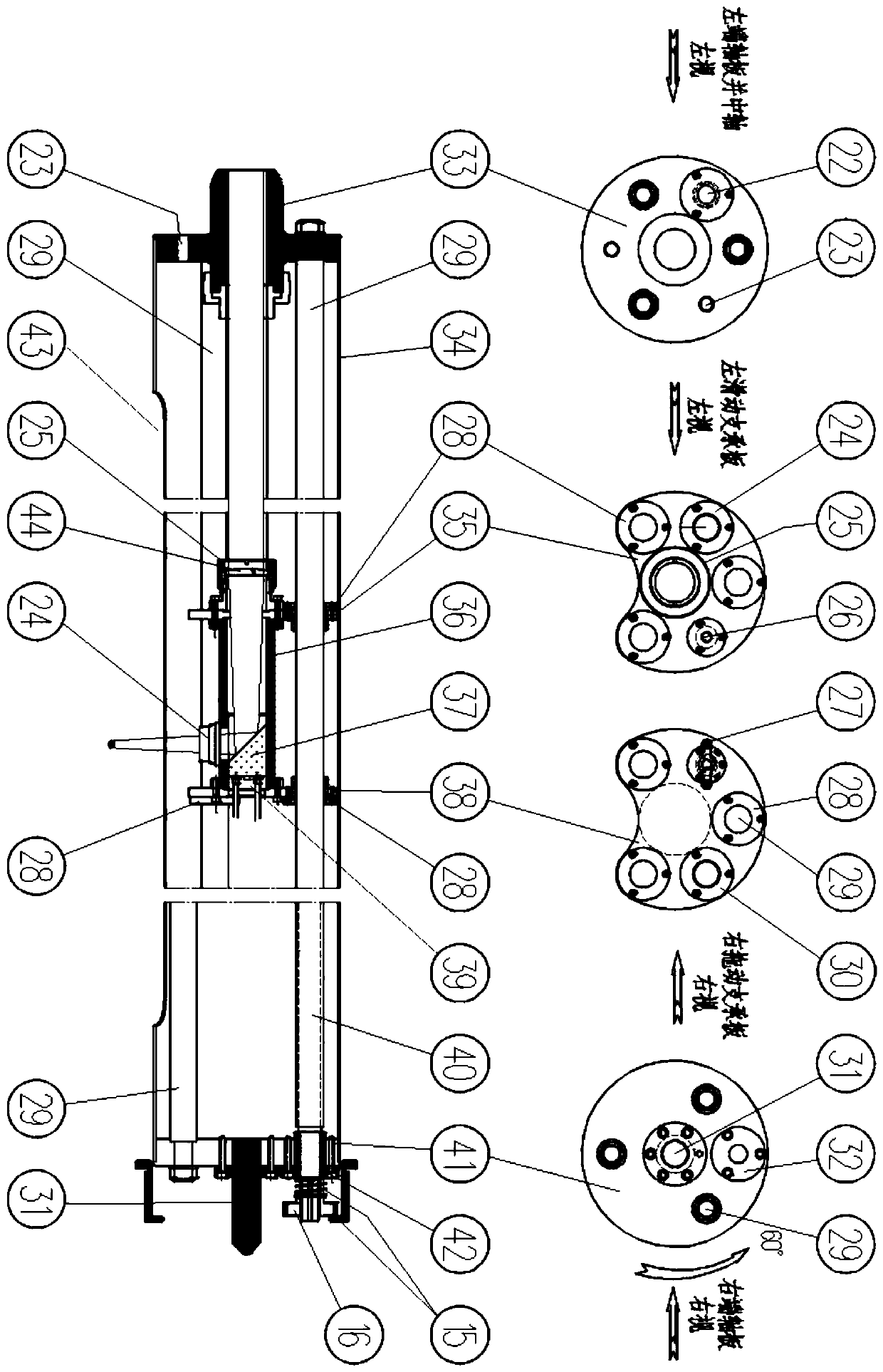

Speed control system actuator for pipeline cleaning and detection device

ActiveCN103042017AAdjust running speedCleaning processes and apparatusSpeed control systemDrive shaft

The invention relates to a speed control system actuator for a pipeline cleaning and detection device, and relates to the technical field of non-electric variable system control, gas flow affecting devices, flow measurement, linear speed measurement and pipeline systems. A battery pack (3), a control module (4) and a motor are mounted successively from back to front in a seal cabin (6) at the center of a back support (2) fixedly connected to the rear portion of a drainage cylinder (1), wherein the direction in which gas flows enter serves as front. A shaft of the motor (5) penetrates through a hole of the seal cabin (6) to be connected with a coupling (7) which is connected with a transmission shaft (10) through a reduction gearbox (8), the transmission shaft (10) stretches out of fixed blades (9) at the front end of the drainage cylinder (1) to be connected with movable blades (11), and the head of the transmission shaft (10) is further connected with a gland (12). According to the speed control system actuator, on the premise of normal delivery, the medium flow flowing through the pipeline cleaning and detection device is adjusted, and accordingly, the running speed of the pipeline cleaning and detection device in pipelines can be adjusted.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

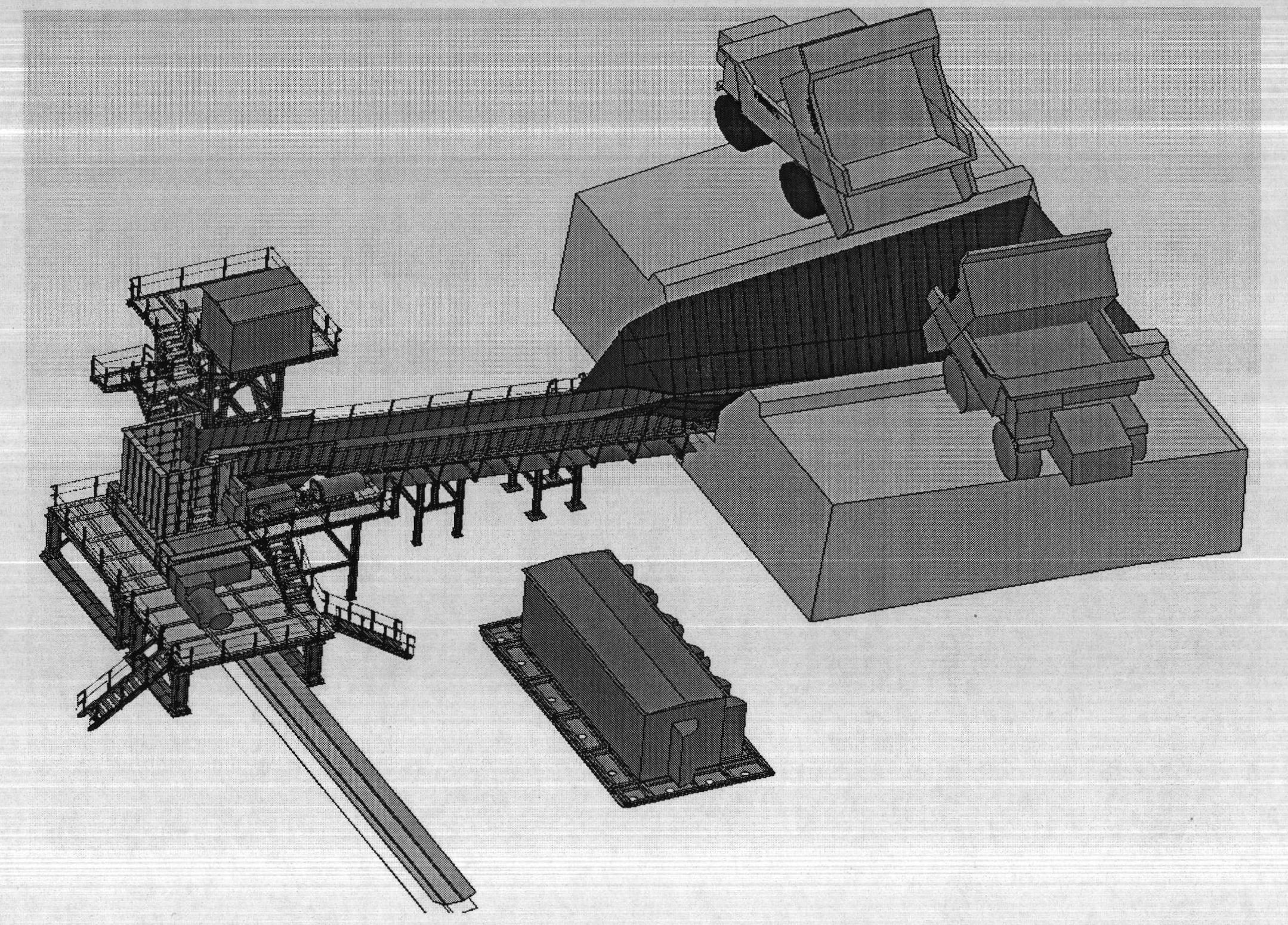

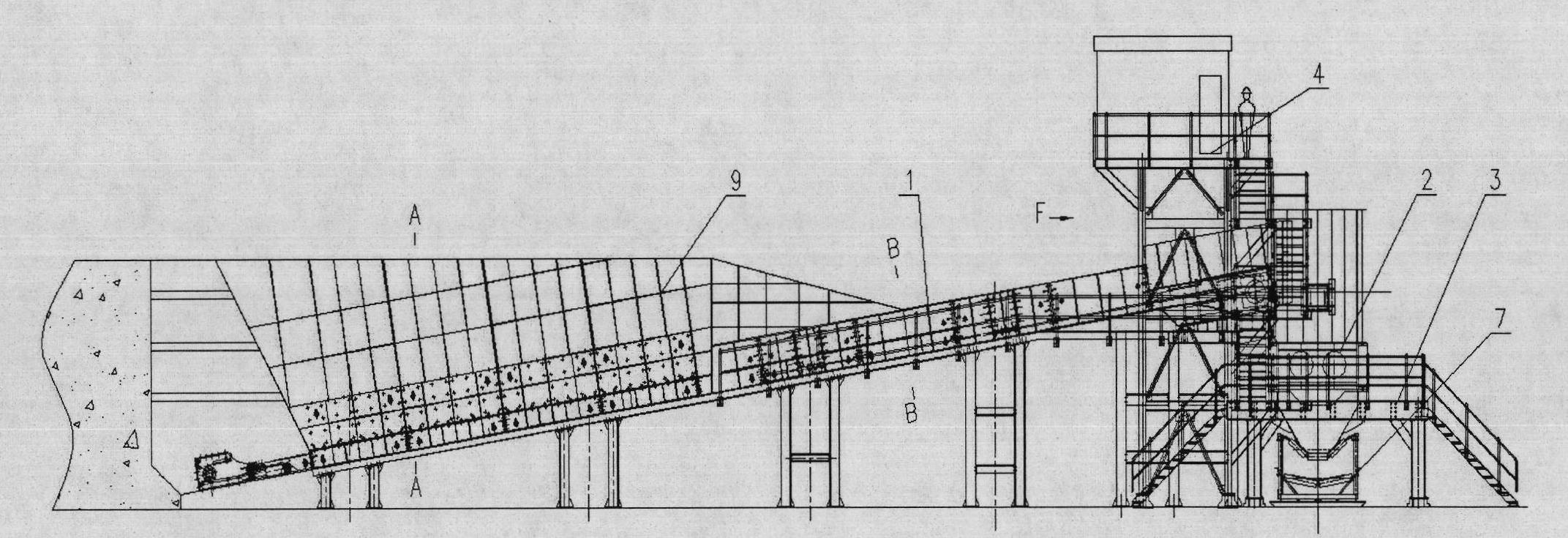

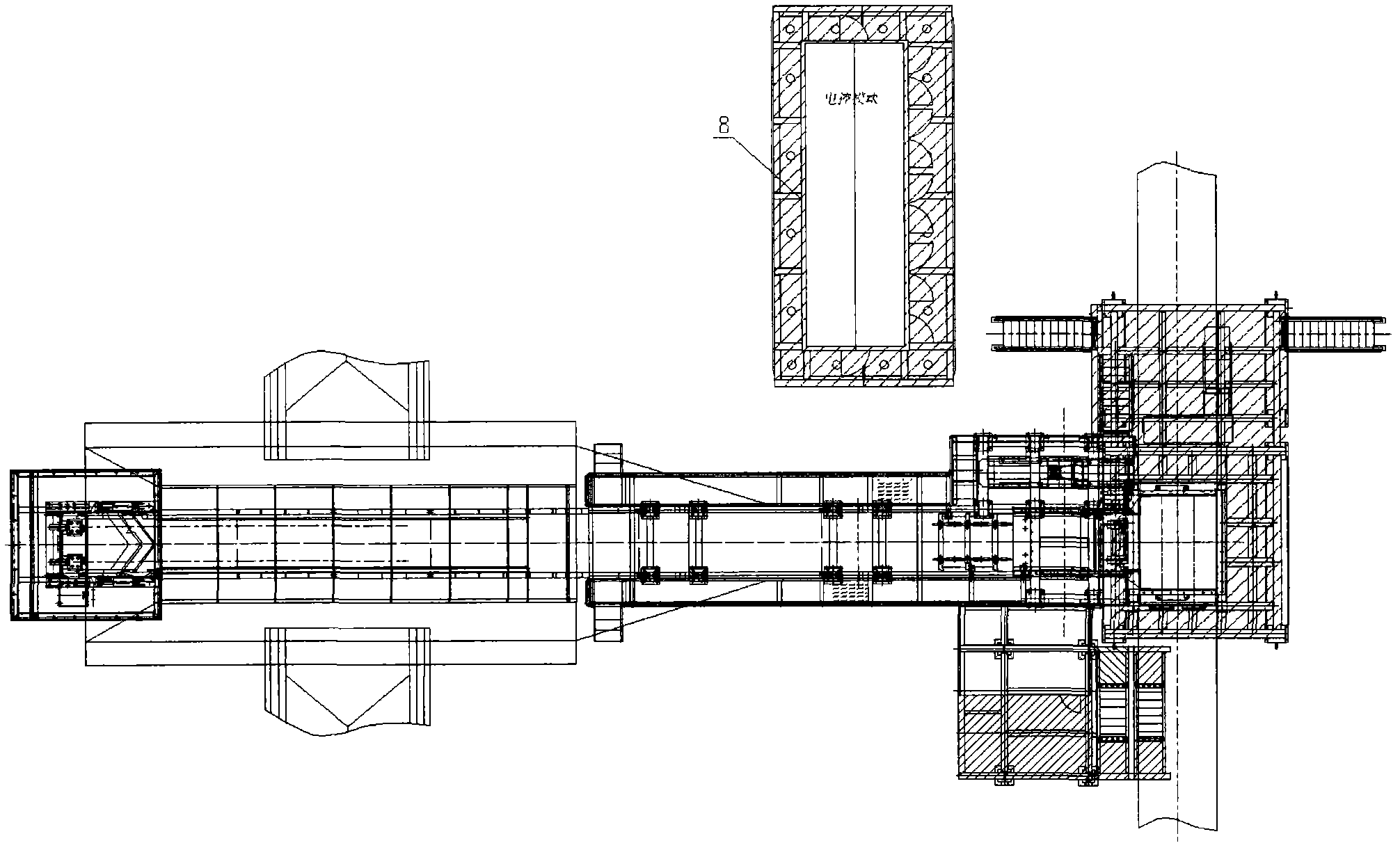

Semi-fixed crushing station

The invention relates to a novel semi-fixed crushing station for raw coal processing in an open pit coal mine, wherein the crushing station mainly consists of a scraper machine, a scraper machine material receiving section coal flow height limiter, a double-tooth-roller crushing machine, a crushing machine support platform, an operation room, a phase change distribution chamber and the like, wherein the scraper machine is in inclined arrangement, the inclined angle is 5 degrees to 11 degrees, the height of a machine head of the scraper machine can be regulated through regulating the length of a hoisting conveying section tank body of the scraper machine or through regulating the inclined angle of the scraper machine, scraper machine material receiving section is provided with a coal flow height limiter, the requirement that the height of the coal layer in the scraper machine is 400 to 700mm is met, the scraper machine adopts the variable-frequency driving, the speed of the scraper machine is regulated according to the height of the coal layer of the scraper machine, all modules are mutually independent, the moving and the installation are convenient, an operation room adopts an independent basis, and the influence on the body and mental health of operators as well as electric control equipment, which is caused by vibration, is reduced. The novel semi-fixed crushing station has the advantages that the starting of the scraper machine is stable, the operation is reliable, the instantaneous overload of the system can be effectively prevented, and the popularization and application values are realized.

Owner:WUHAN DESIGN & RES INST OF CHINA COALTECH & ENG GROUP

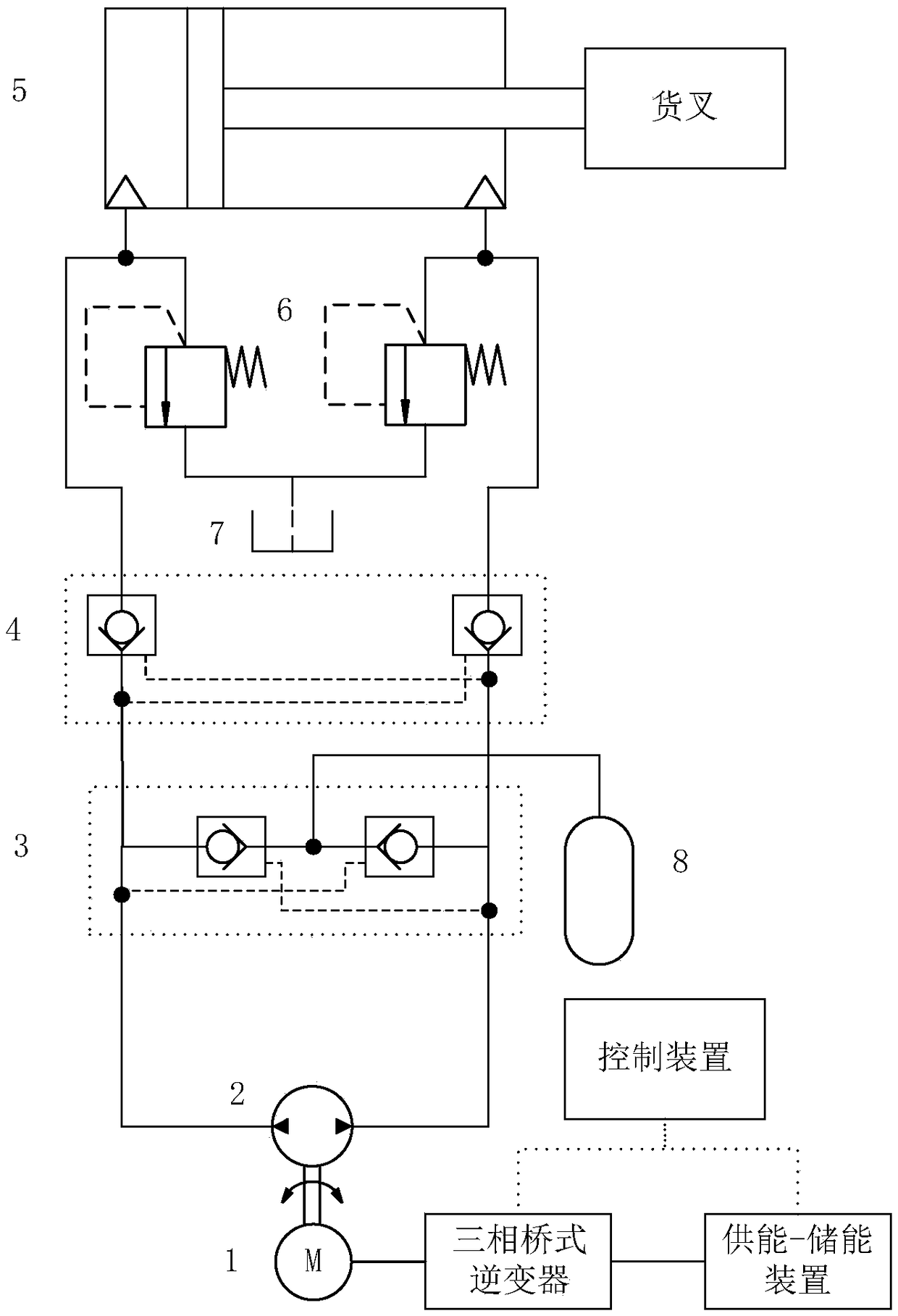

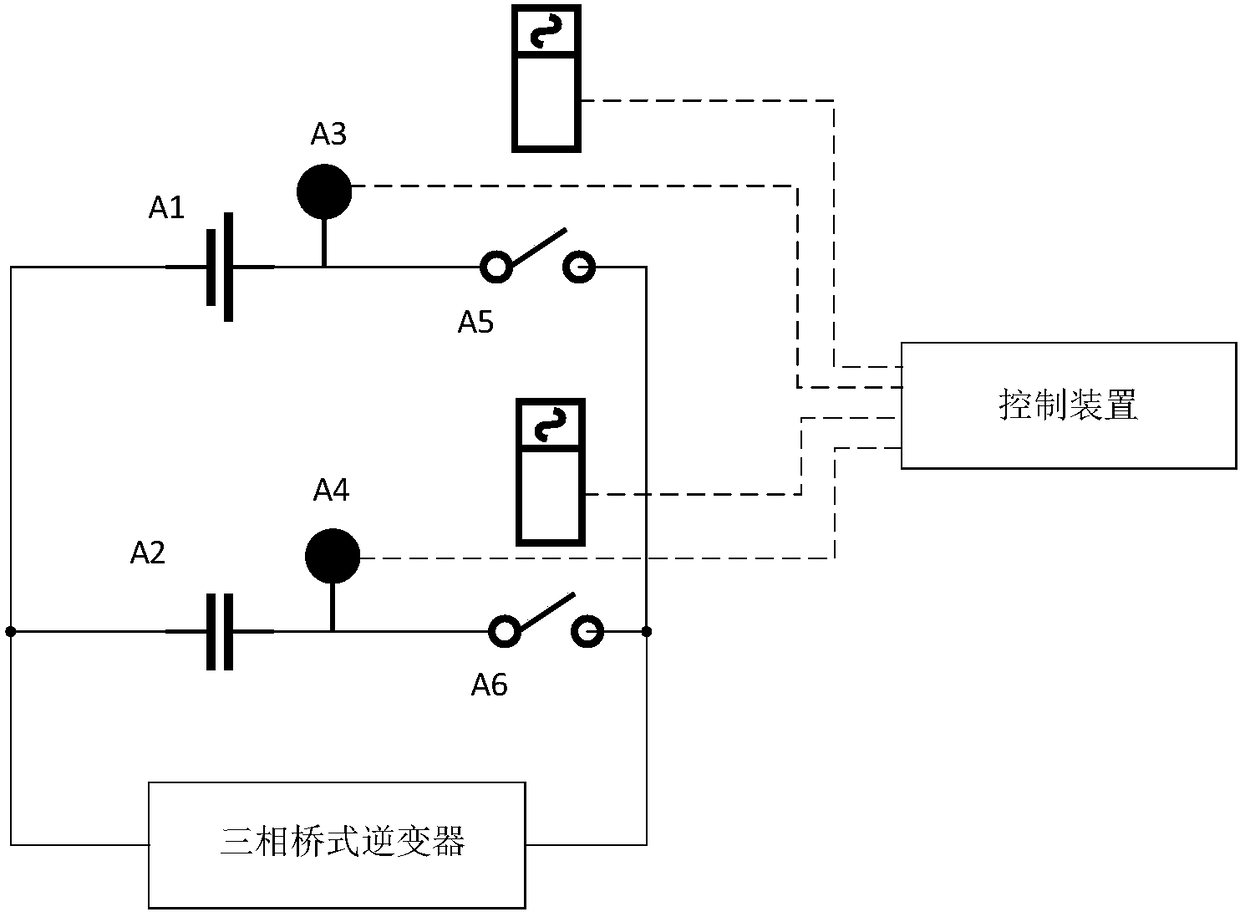

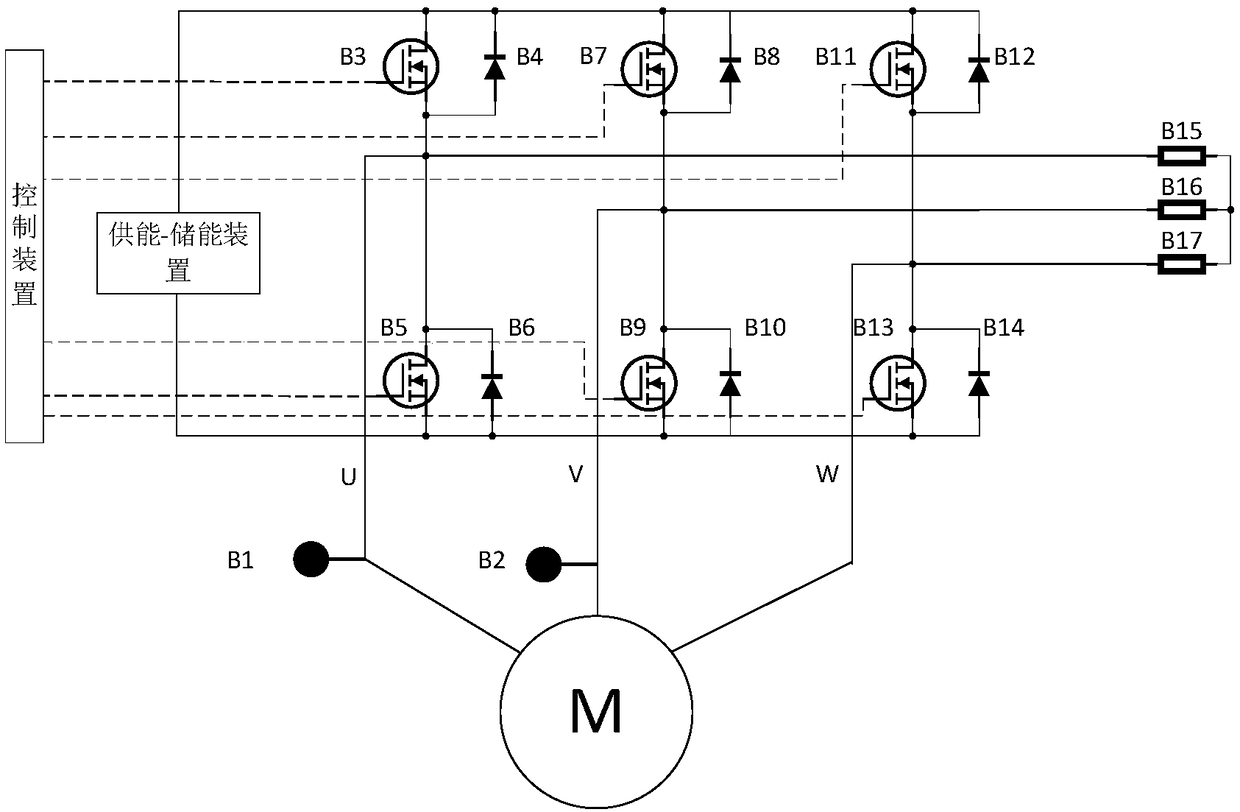

Forklift efficient energy-saving system with speed regulating function

PendingCN108298474AAvoid complex speed adjustment processSimple controlsServomotor componentsServomotorsSupply energySystem hardware

The invention provides a forklift efficient energy-saving system with a speed regulating function. The forklift efficient energy-saving system comprises a double-acting motor-power generator, a double-acting pump-motor, a sealing pressure oil tank, a liquid-control oil supplementing valve, a two-way hydraulic lock valve, a jacking oil cylinder, a safety valve, a three-phase bridge type inverter, an energy supply-energy storage device, a control device, and an oil tank, wherein the double-acting pump is connected with the double-acting motor-power generator; the double-acting motor-power generator is connected with the three-phase bridge type inverter; the three-phase bridge type inverter is connected with the energy supply-energy storage device; the control device controls a workings stateof the three-phase bridge type inverter and the energy supply-energy storage device; an oil outlet and an oil sucking hole of the double-acting pump-motor are connected with the liquid-control oil supplementing valve; the liquid-control oil supplementing valve is connected with the two-way hydraulic lock valve; the two-way hydraulic lock valve is connected with a rod cavity and a rodless cavity of the jacking oil cylinder; and the rod cavity and the rodless cavity of the jacking oil cylinder are connected with the safety valve. A potential energy recycling system regulates forklift descendingspeed by controlling rotation speed of the double-acting motor-power generator, eliminates throttling loss of a hydraulic loop, reduces heating of hydraulic oil, improves potential energy recycling efficiency; and moreover, system hardware and software are simple and reliable, and realizable degree is high.

Owner:ZHEJIANG UNIV

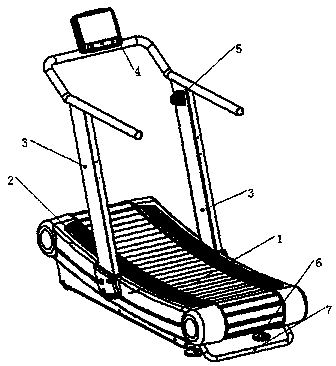

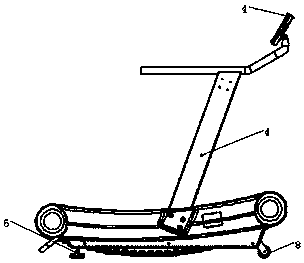

Self-operated running machine

PendingCN108126307AAdjustable speedSpeed, flexibility and convenienceMovement coordination devicesMuscle exercising devicesMagnetFitness effects

The invention discloses a self-operated running machine. The self-operated running machine mainly comprises a running platform, two vertical columns and a display screen, wherein the running platformconsists of a plurality of pedals, two synchronous belts, a rotary shaft, a linking aluminium disc and sliding rails; the linking aluminium disc is connected with a rotary shaft at the front end of the running platform; a resistance adjusting rod is arranged on one vertical column and consists of a handle, a rotary plate, a bottom plate and a pulling rope; the handle is arranged on the rotary plate; the bottom plate is fixed on the vertical column; the rotary plate is connected on the bottom plate by a plurality of rolling balls; the top end of the pulling rope is connected into a clamping groove on the bottom plate, and the bottom end of the pulling rope is connected onto the rotary plate; the rotary plate is arranged at one side of the pedals by an adjusting rotary shaft; a plurality ofpermanent magnets are respectively arranged at the two sides in the rotary plate. The self-operated running machine disclosed by the invention has the beneficial effects that a proper reverse rotationforce is generated for the rotary speed of the rotary shaft of the running platform by the resistance adjusting mechanism generated by cutting a magnetic field, so that the speed adjustment for the running machine is realized. The self-operated running machine disclosed by the invention has the advantages that the use is flexible and convenient, the application range is wide, the energy can be saved and the fitness effect is good.

Owner:山东蓝德健身科技股份有限公司

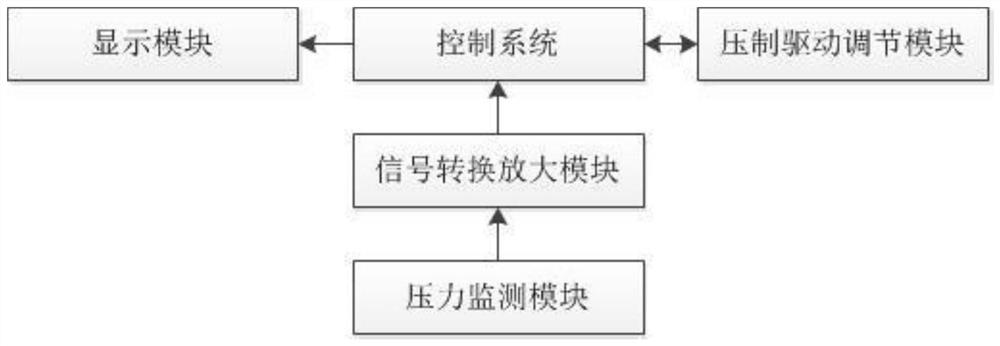

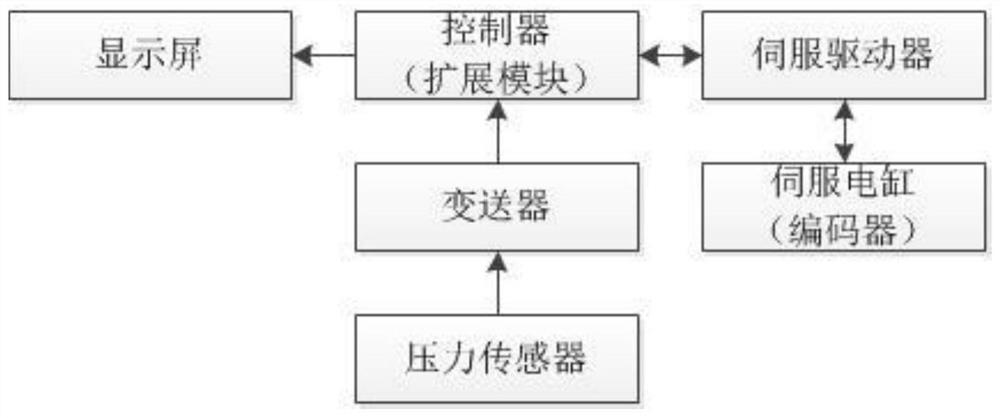

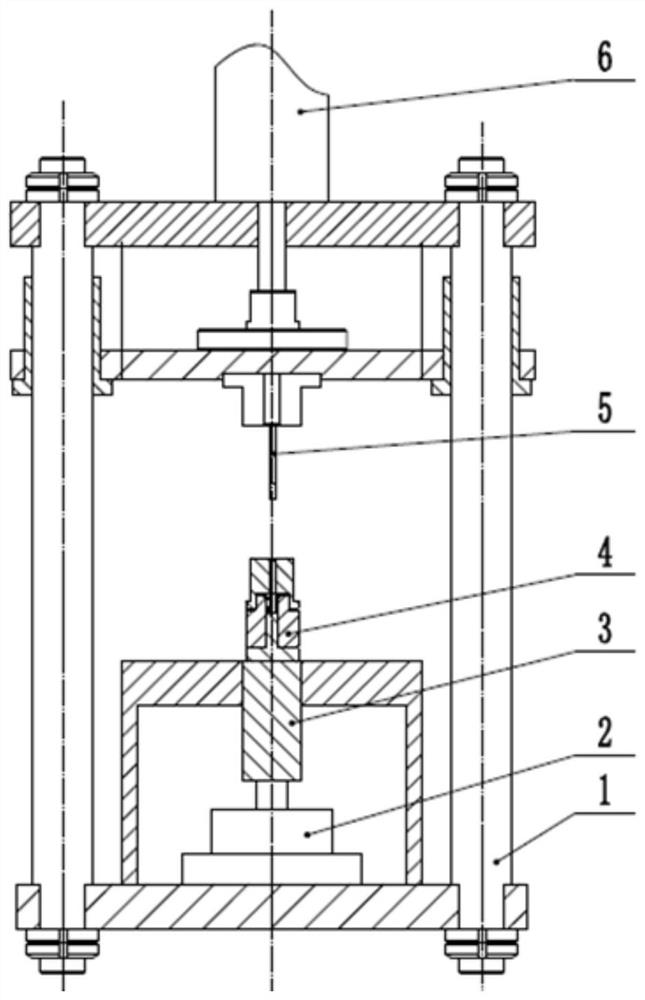

Initiating explosive device pressing system and method

The invention discloses an initiating explosive device pressing system and method, and the system comprises a punch which is used for pressing an initiating explosive device; a pressing driving adjusting mechanism which is connected with the punch; a pressure monitoring module which is used for measuring pressure information of pressing of the initiating explosive device; and a control system which receives the pressure information and controls the operation speed of the pressure driving adjusting mechanism according to the pressure information. The pressure monitoring module is arranged below the initiating explosive device, so that the magnitude of pressing force borne by the initiating explosive device can be obtained in real time and fed back to the control system; the control system controls the servo electric cylinder executing pressing according to pressure information, the operation speed of the servo electric cylinder is adjusted, and different pressing forces are applied to the initiating explosive device, so that the pressing force borne by the initiating explosive device reaches the target pressing force, and accurate pressure control in the pressing process is achieved; and the pressure adjusting process is simple, and automatic integration can be achieved.

Owner:中国兵器装备集团自动化研究所有限公司

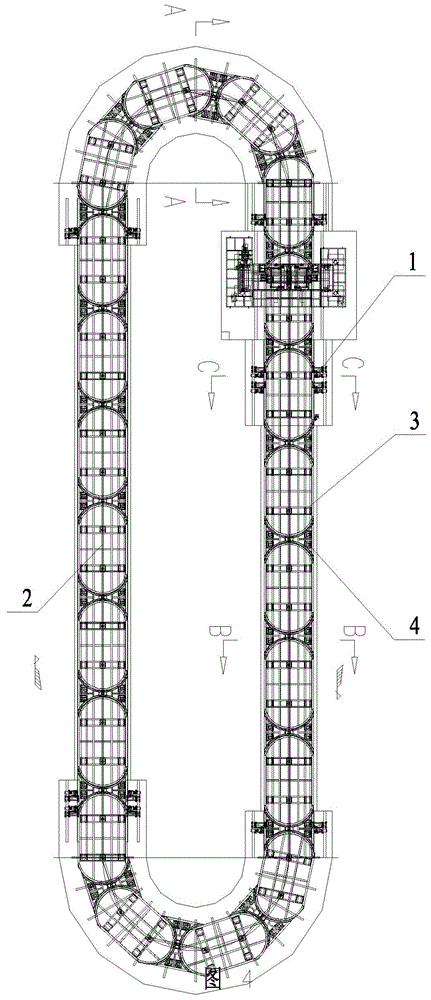

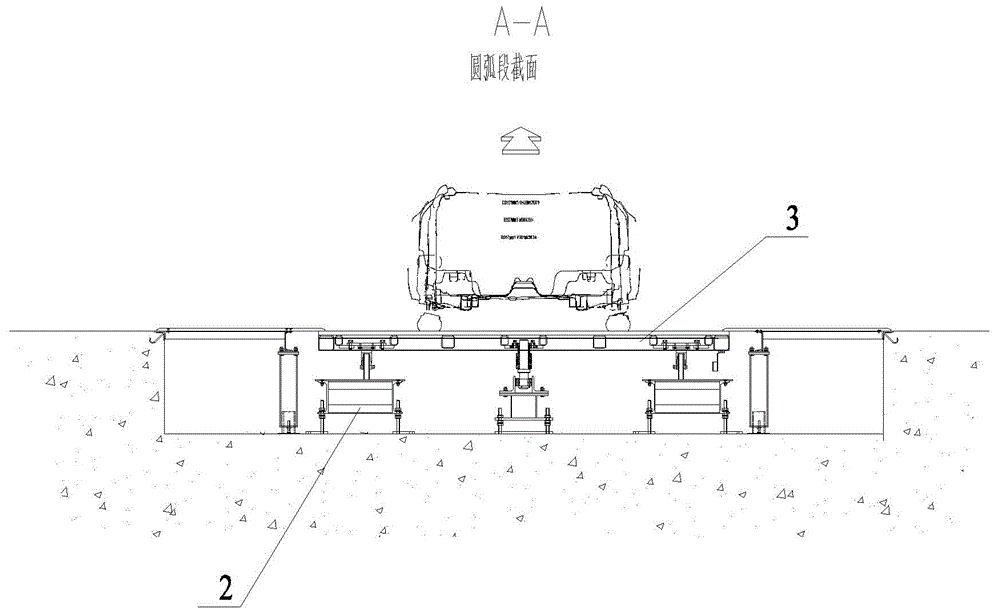

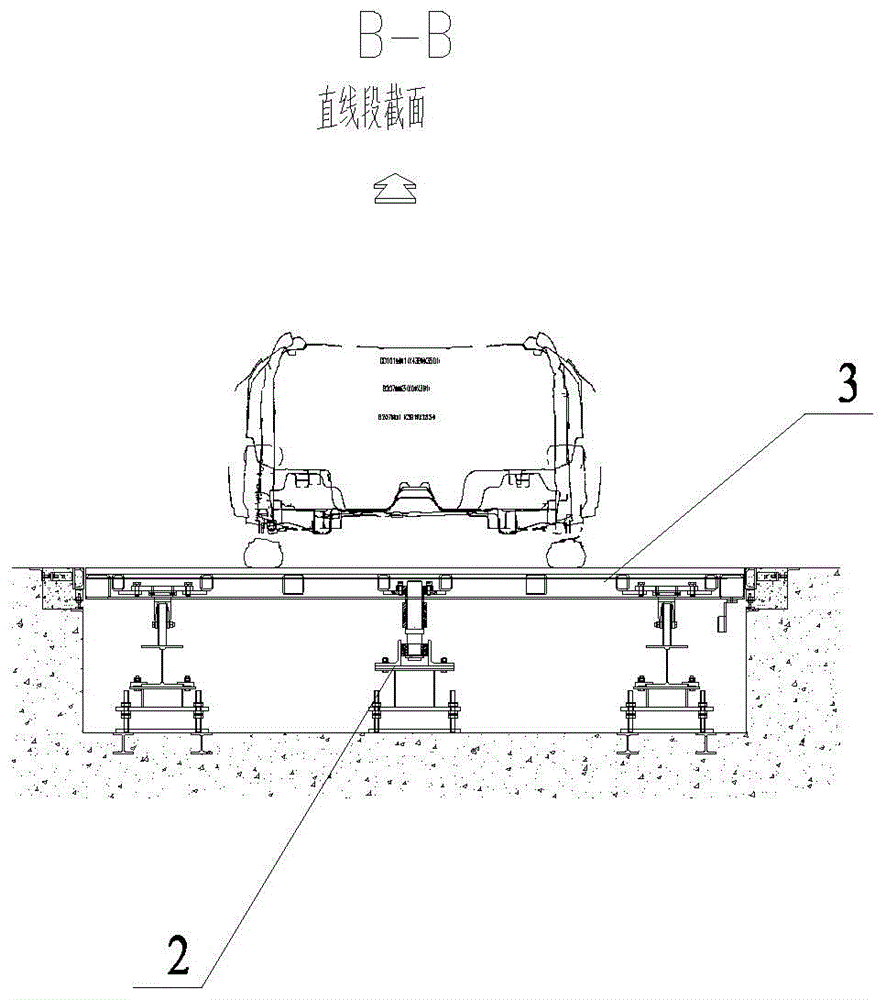

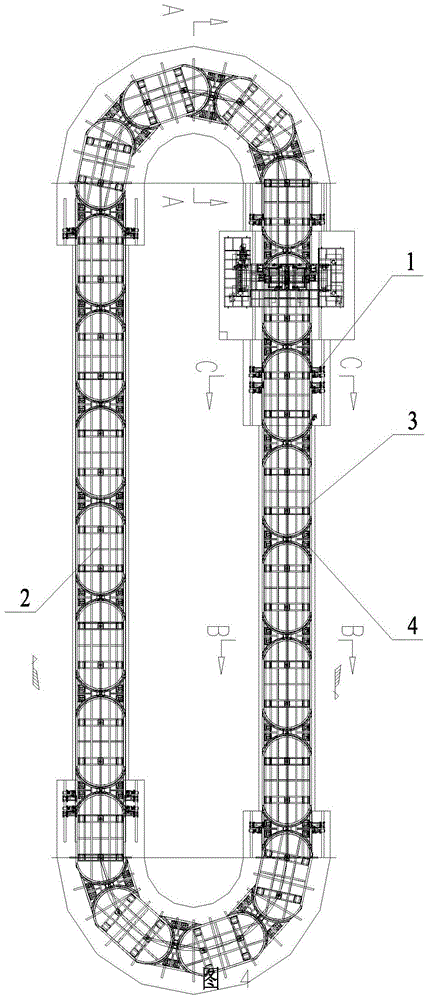

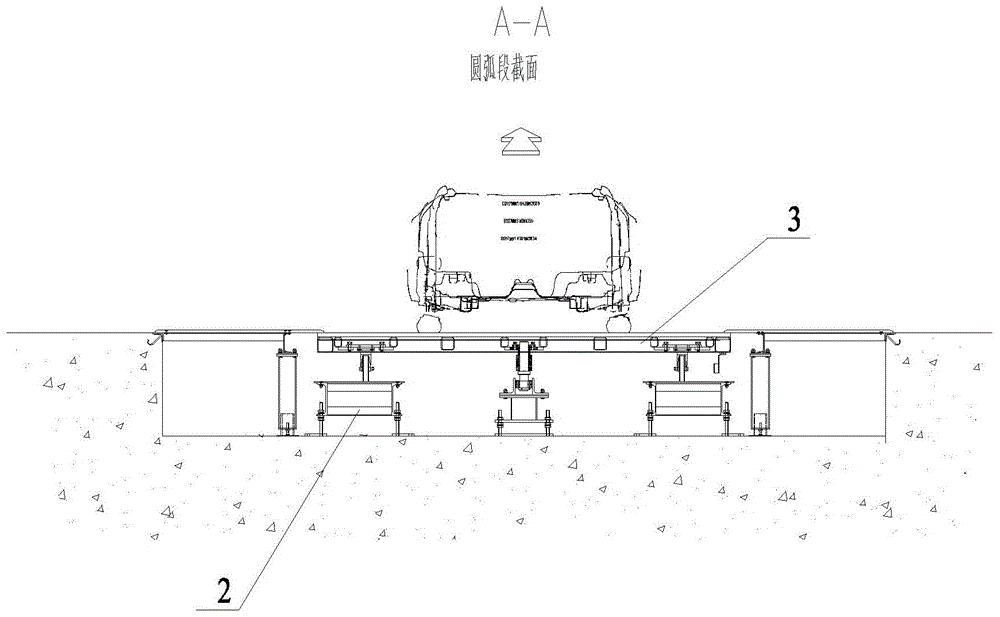

Arc-shaped slide plate conveyor line

ActiveCN104444174AChanging the way ground transportation is doneAdjust running speedMechanical conveyorsEngineeringSlide plate

The invention relates to an arc-shaped slide plate conveyor line. An annular bearing track and an annular guide track are fixed to a machine frame, the bearing track is matched with the guide track, a friction drive device is fixed to the machine frame, a plurality of arc-shaped slide plates are connected to the bearing track in a sliding mode, every two adjacent arc-shaped slide plates are connected through a slide plate connecting device, and the arc-shaped slide plates are matched with the friction drive device. When the arc-shaped slide plate conveyor line works, the friction drive device drives the arc-shaped slide plates to run along the bearing track under the guiding effect of the guide rack. Friction-form drive units of the arc-shaped slide plate conveyor line form a conveying system, and the arc-shaped slide plate conveyor line is stable in transmission, low in noise and high in programmable degree. The system is high in whole arrangement flexibility and low in investment cost, does not need lubrication and is an environment-friendly conveying device system.

Owner:MIRACLE AUTOMATION ENG CO LTD

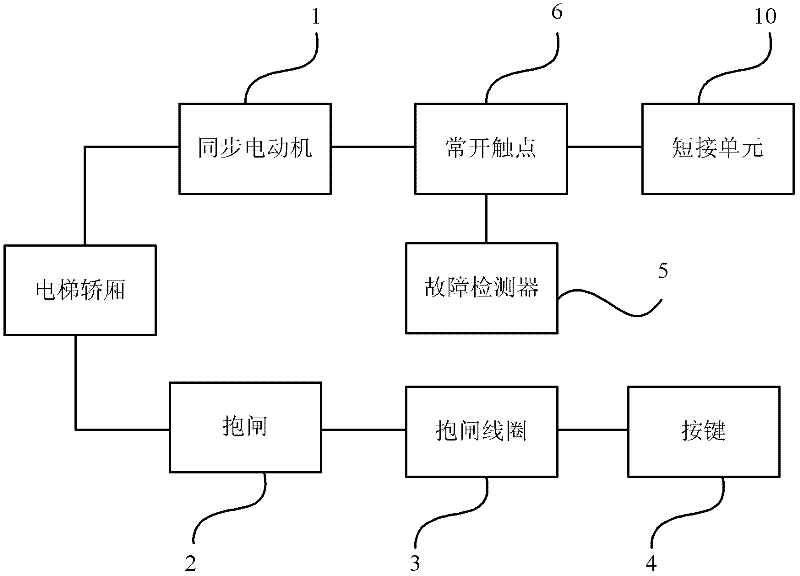

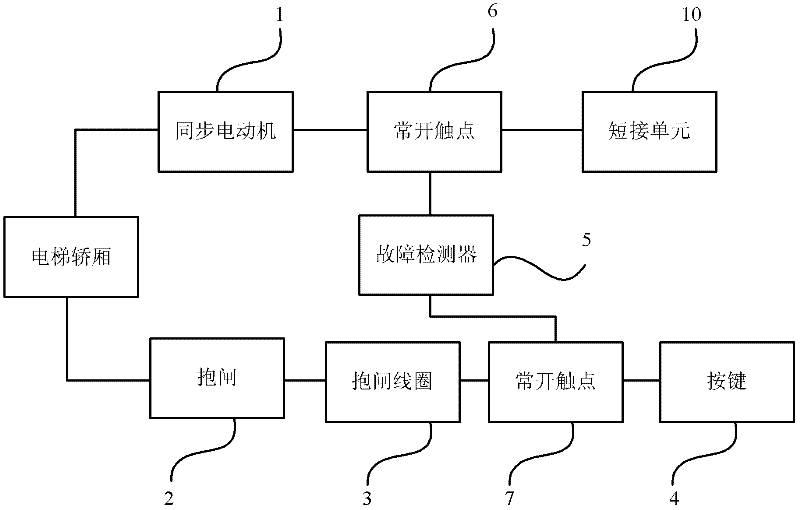

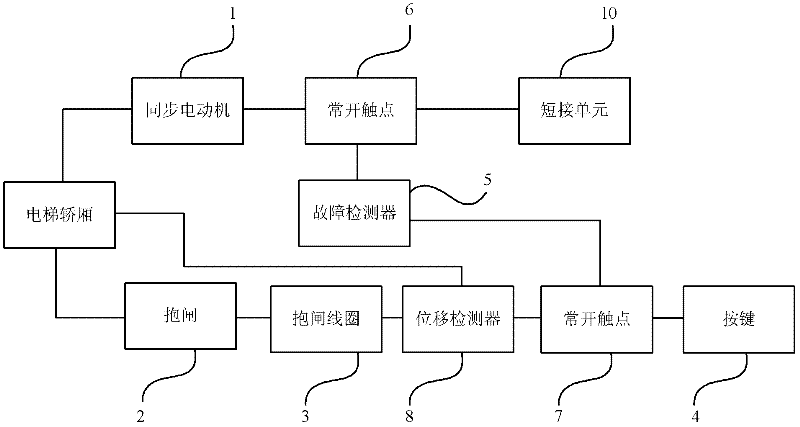

Elevator self-help system

The invention discloses an elevator self-help system which comprises a motor and a band-type brake used for an elevator system, wherein the motor is used for driving a lift car; the band-type brake is used for braking the lift car; the elevator self-help system also comprises a short circuit unit, a band-type brake releasing unit, a band-type brake controlling unit, a first normally open contact unit and a fault detection unit, wherein the motor is electrically connected with the short circuit unit through the first normally open contact unit; the short circuit unit is used for connecting the motor in short circuit; the band-type brake controlling unit is electrically connected with the band-type brake releasing unit and is used for controlling the band-type brake releasing unit to release the band-type brake; and the fault detection unit is used for controlling the closing and opening of the first normally open contact unit through detecting whether the elevator system breaks down or not. The elevator system in the invention enables a user to control the elevator to descend to the bottom of an elevator shaft leveling zone, thereby enabling the user to rapidly escape from predicament.

Owner:SHANGHAI WEIPINLAI ELECTROMECHANICAL TECH

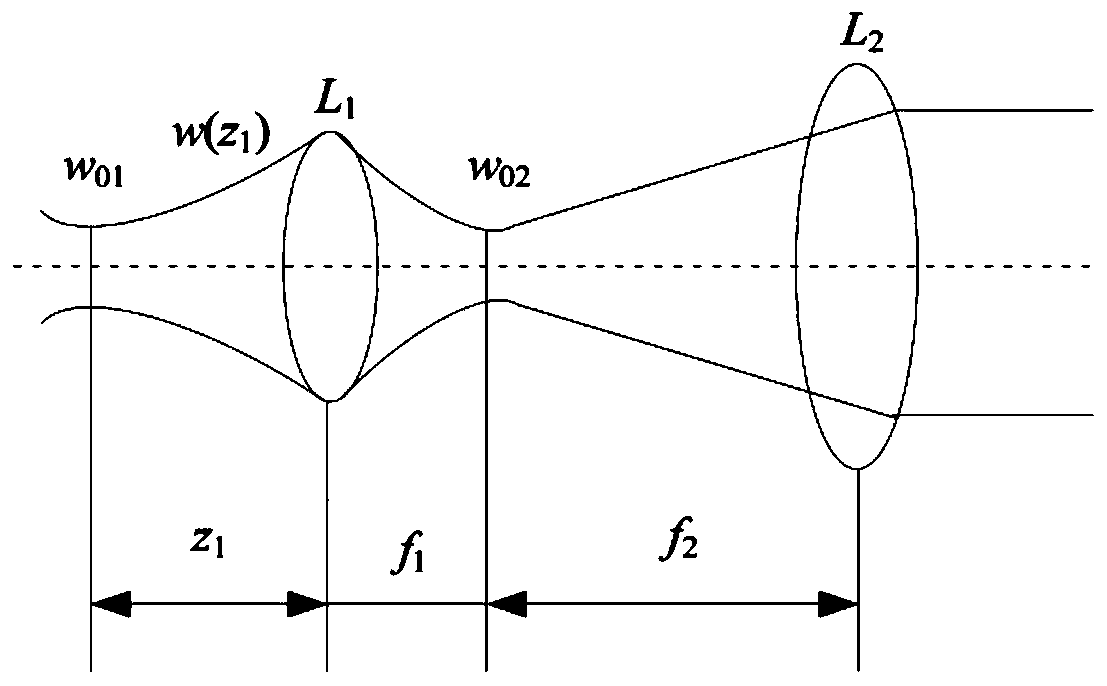

High-power semiconductor laser surface treatment device for inner walls of large long barrels

InactiveCN109739023ASolve the key problem of being too heavy to achieve rotationSimple surface treatmentMetallic material coating processesMountingsLaser processingPipe fitting

The invention discloses a high-power semiconductor laser surface treatment device for the inner walls of large long barrels. The device comprises a laser generation assembly, a laser beam expander anda laser processing beam type central rotating shaft, wherein the laser processing beam type central rotating shaft is arranged in a to-be-processed pipe fitting during use, and is provided with a shaft internal light guide channel; laser is transmitted through the shaft internal light guide channel after being shaped by the laser beam expander; a translation machine frame is further arranged in the laser processing beam type central rotating shaft, can rotate along with the rotation of the laser processing beam type central rotating shaft, and is used for driving a focusing assembly and a laser turning mirror to horizontally move in the laser processing beam type central rotating shaft; and the length of the to-be-processed pipe fitting is more than 10 meters. For the inner walls of largelong barrel workpieces such as ocean equipment, oil transportation pipelines, chemical equipment, tunneling equipment, coal mining equipment and the like, a high-power semiconductor laser cladding technology is used for enhancing the performances such as the wear resistance, the corrosion resistance and the like of the surfaces of the inner walls of the selected workpieces, so that the service lives of the workpieces are greatly prolonged.

Owner:HUAZHONG UNIV OF SCI & TECH

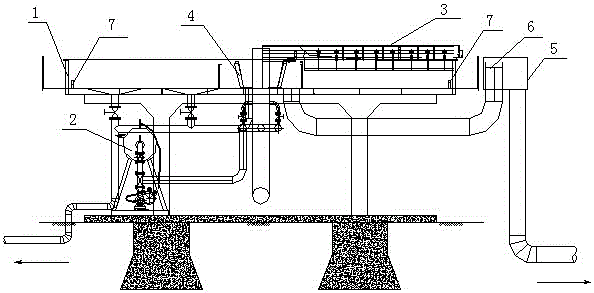

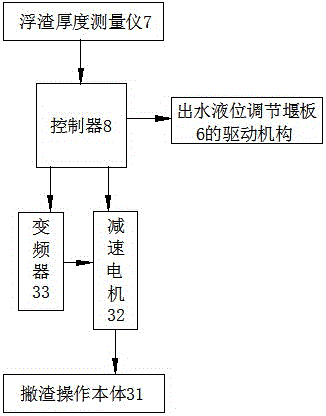

Automatic gelatin waste water drossing device applied to gas floatation clarifier

InactiveCN105905970APrevent overflowReduce cleanupWater/sewage treatment by flotationWastewaterGelatin

The invention discloses an automatic gelatin waste water drossing device applied to a gas floatation clarifier. The automatic gelatin waste water drossing device comprises the drossing device and an effluent liquid level adjusting weir plate of the gas floatation clarifier, a dross thickness measuring instrument arranged in a gas floatation pond, and an external controller. The dross thickness measuring instrument, an effluent liquid level adjusting weir plate adjusting mechanism of the gas floatation clarifier and a drossing device driving mechanism of the gas floatation clarifier are all connected with the external controller. The dross thickness measuring instrument is adopted for measuring the thickness of dross in the gas floatation clarifier, then the controller automatically adjusts the height of the effluent liquid level adjusting weir plate and the running speed, starting and stopping of a drossing machine according to thickness information, and it is avoided that the dross overflows out through the weir plate. When the thickness of the dross is reduced to a certain degree, the height of the weir plate is reduced through the controller, the running speed of the drossing device is decreased, or the drossing device is intermittently started, therefore, the dross is reasonably removed, the running efficiency of the drossing device is improved, the drossing device runs more effectively and reasonably, it is avoided that the drossing device runs in an idle mode, and the aim of energy saving and consumption reducing during daily running of a system is achieved.

Owner:ANHUI ZHONGHUAN ENVIRONMENTAL PROTECTION TECH CO LTD

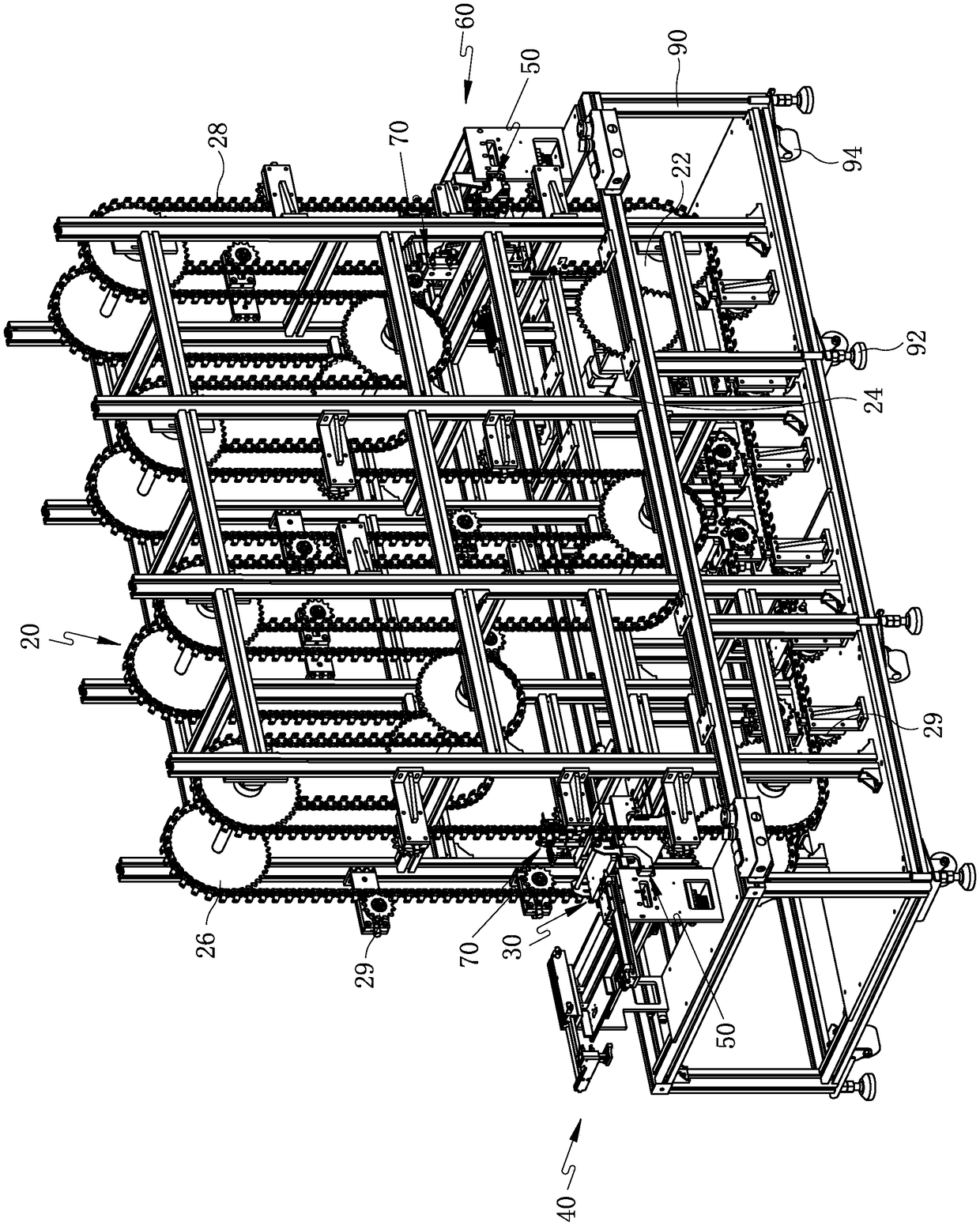

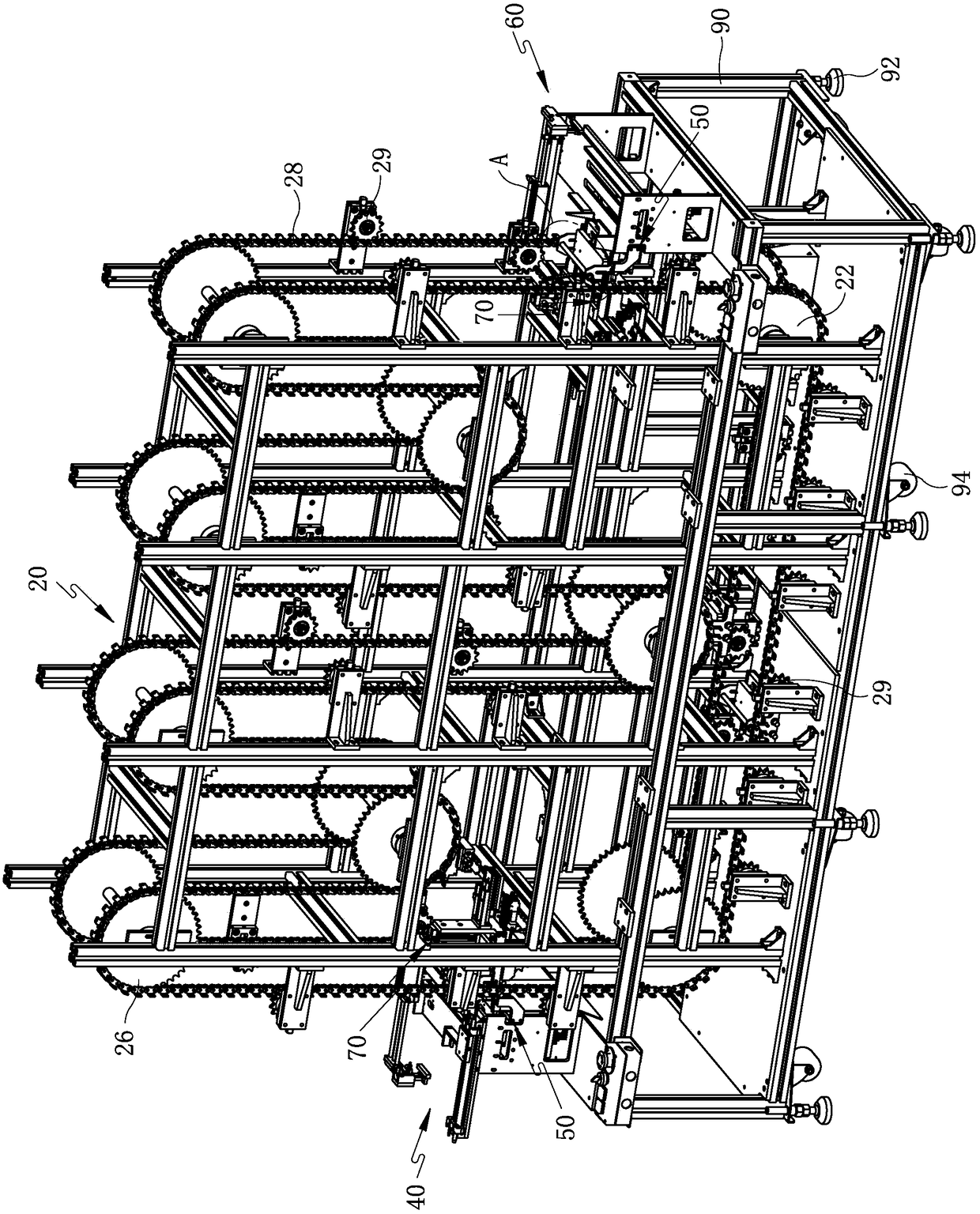

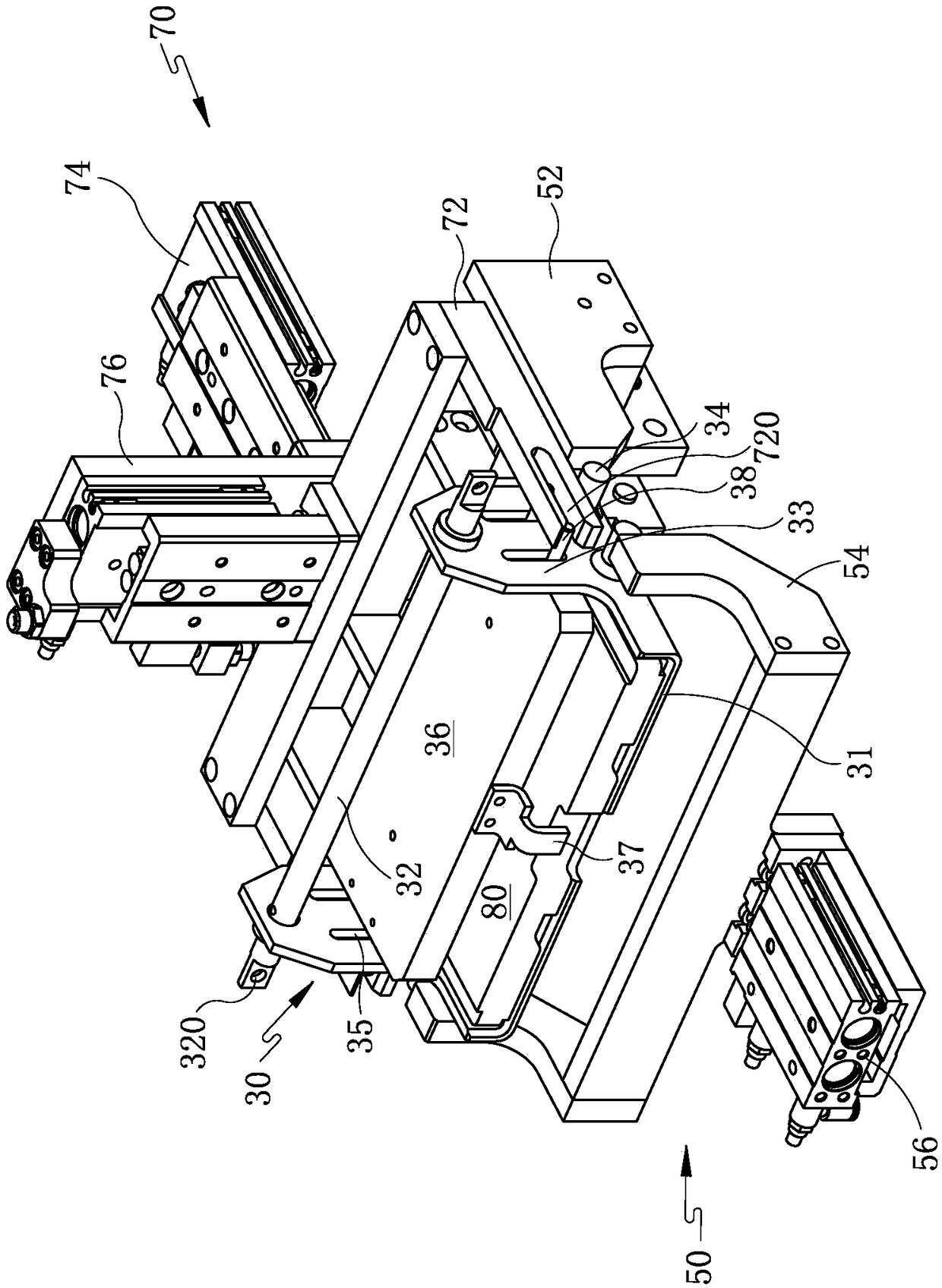

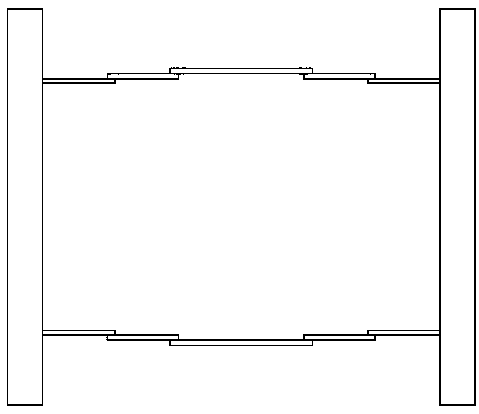

Tool pressure maintaining time-delay equipment

ActiveCN109230231AEasy to lift the counterweightRealization of holding pressure delayConveyorsSupporting framesTime delaysDelayed time

The invention discloses tool pressure maintaining time-delay equipment and relates to the technical field of electronic product production equipment. The tool pressure maintaining time-delay equipmentincludes a rack, multiple chain wheel groups are installed on the rack, each chain wheel group includes two chain wheels which are arranged coaxially, and all the chain wheels on the same side in each chain wheel group are surrounded by a chain; all the chain wheel groups are staggered vertically, and correspondingly the two chains form a structure which is folded several times; a hanging basketwhich is used for placing tools and moves along with the chains is hung between the two chains, and counter weights used for maintaining the pressure of the tools are arranged in the hanging basket; afeeding mechanism used for placing the tools into the hanging bracket and a discharge mechanism used for taking the tools out of the hanging basket are arranged at the two ends of the rack respectively; the two ends of the rack are both provided with a hanging basket positioning mechanism and a counter weight lifting mechanism, wherein each hanging basket positioning mechanism can position the hanging basket after the hanging basket moves in place, and each counter weight lifting mechanism is used for lifting up the counter weights after positioning in order to provide convenience for feedingby the feeding mechanism and discharge by the discharge mechanism. The tool pressure maintaining time-delay equipment in a small size meets the requirement for long pressure maintaining delay time.

Owner:WEIFANG LOKOMO PRECISION IND

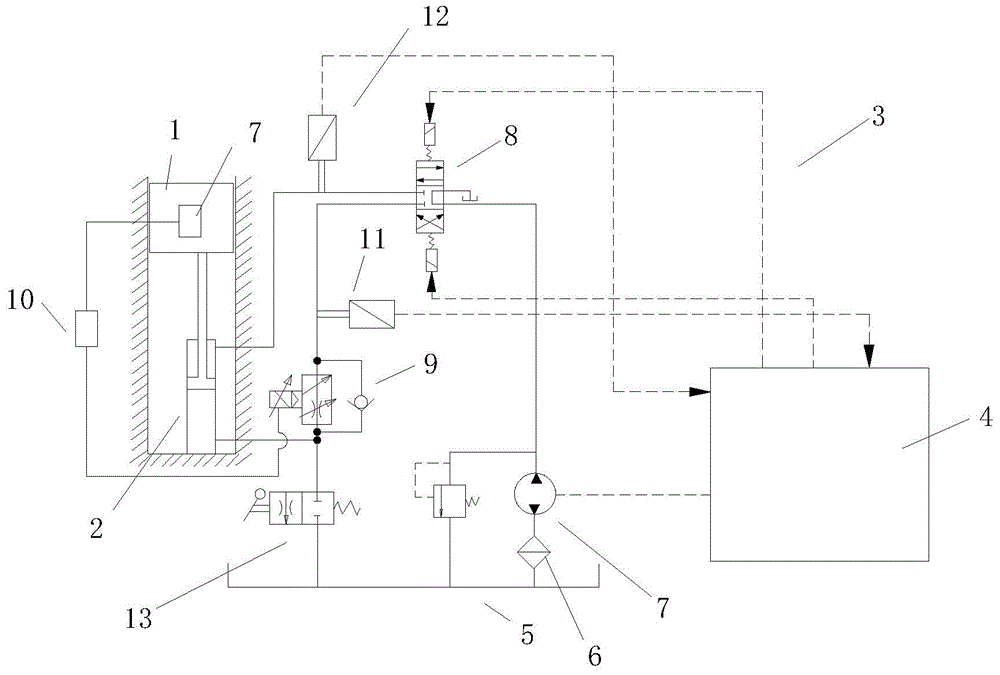

Hydraulic elevator system with ultra-low noise and stable operation

ActiveCN104401849AGuaranteed uptimeCorrect running speed deviationBuilding liftsHydraulic cylinderLow noise

The invention discloses a hydraulic elevator system with ultra low noise and stable operation. The hydraulic elevator system comprises a car, wherein a hydraulic cylinder is fixed at the bottom of the car and is connected with an oil way system; the oil way system is connected with a control system and comprises an oil cylinder; the oil cylinder is connected with a filter; the filter is connected with an oil pump; the oil pump is connected with a three-position four-way valve and is connected with a port A of the three-position four-way valve; a port B of the three-position four-way valve is connected with the oil cylinder; a port C of the three-position four-way valve is connected with an electric-hydraulic proportional velocity regulating valve; the electric-hydraulic proportional velocity regulating valve is connected with the bottom of the hydraulic cylinder; a port D of the three-position four-way vale is connected with the extension end of the hydraulic cylinder; and a speed detecting module is arranged on the car and is connected with the electric-hydraulic proportional velocity regulating valve via an amplifier. The hydraulic elevator system can correct the operation speed deviation of the car in real time, and can largely improve the car stability and reduce the elevator operation noise.

Owner:WEIBO ELEVATOR

Automatic press-polishing machine for gold bracelet

The invention discloses an automatic press-polishing machine for a gold bracelet, and belongs to the field of automatic jewelry machining devices. The automatic press-polishing machine is composed of a base, a guide rail, lateral supporting plates, a swinging shifting fork, a first direct-current motor, a bracelet supporting body, a press-polishing needle, swinging pieces, a lead screw stepping motor, middle clamps, a second direct-current motor, a flywheel, a transmission shifting shaft and the like. The guide rail, the lateral supporting plates, the first direct-current motor, the lead screw stepping motor and vertical plates are installed on the upper portion of the base, the swinging shifting fork is installed on a sliding block, the upper portion of the swinging shifting fork is connected with the bracelet supporting body through the transmission shifting shaft, and the press-polishing needle is fixed to the swinging pieces through the middle clamps. The up-and-down positions of the middle clamps in the swinging pieces are adjusted to enable the press-polishing needle to be in contact with the bracelet, and the second direct-current motor drives the swinging pieces to perform swinging movement through the flywheel. Front-and-back movement is converted into arc-shaped movement of the bracelet through a swinging shifting-fork structure, front-and-back swinging of the bracelet is achieved, and the cambered surface of the bracelet is completely machined; the bracelet supporting body is of a handle cam structure, the bracelet can be effectively prevented from loosening, and the bracelet can be assembled and disassembled in real time.

Owner:赣州市七里香珠宝礼品有限公司

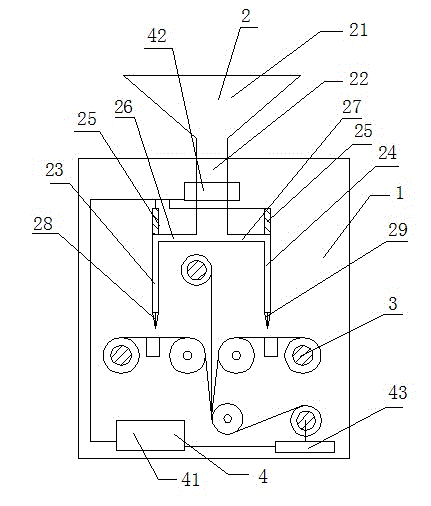

Nano fiber net forming device

ActiveCN104313799AEfficient and fast collectionSimple structureSpinnerette packsArtificial thread manufacturing machinesFiberNanofiber

The invention relates to a nano fiber net forming device. The nano fiber net forming device comprises a rack, a spinning mechanism, a tightening mechanism and a control mechanism, wherein the spinning mechanism comprises a hopper, a metering channel, a first spinning channel, a second spinning channel and high-pressure nozzles; the metering channel is fixed on the rack; one end of the metering channel is communicated with the hopper and the other end of the metering channel is horizontally provided with a first branch opening and a second branch opening; the first branch opening is communicated with the first spinning channel and the second branch opening is communicated with the second spinning channel; a first fiber nozzle is arranged at the bottom of the first spinning channel and a second fiber nozzle is arranged at the bottom of the second spinning channel; the two high-pressure nozzles are communicated with the first spinning channel and the second spinning channel respectively. The nano fiber net forming device is simple in structure and convenient to operate; nano fibers can be rapidly and effectively collected to form a net and can be laminated into a multilayered structure in one step; the cost is low and the air permeability is good; meanwhile, the filtering performance is very good and the applicable range is wide; the nano fiber net forming device can be applied to all fields of the modern society.

Owner:海南中美达纳米技术股份有限公司

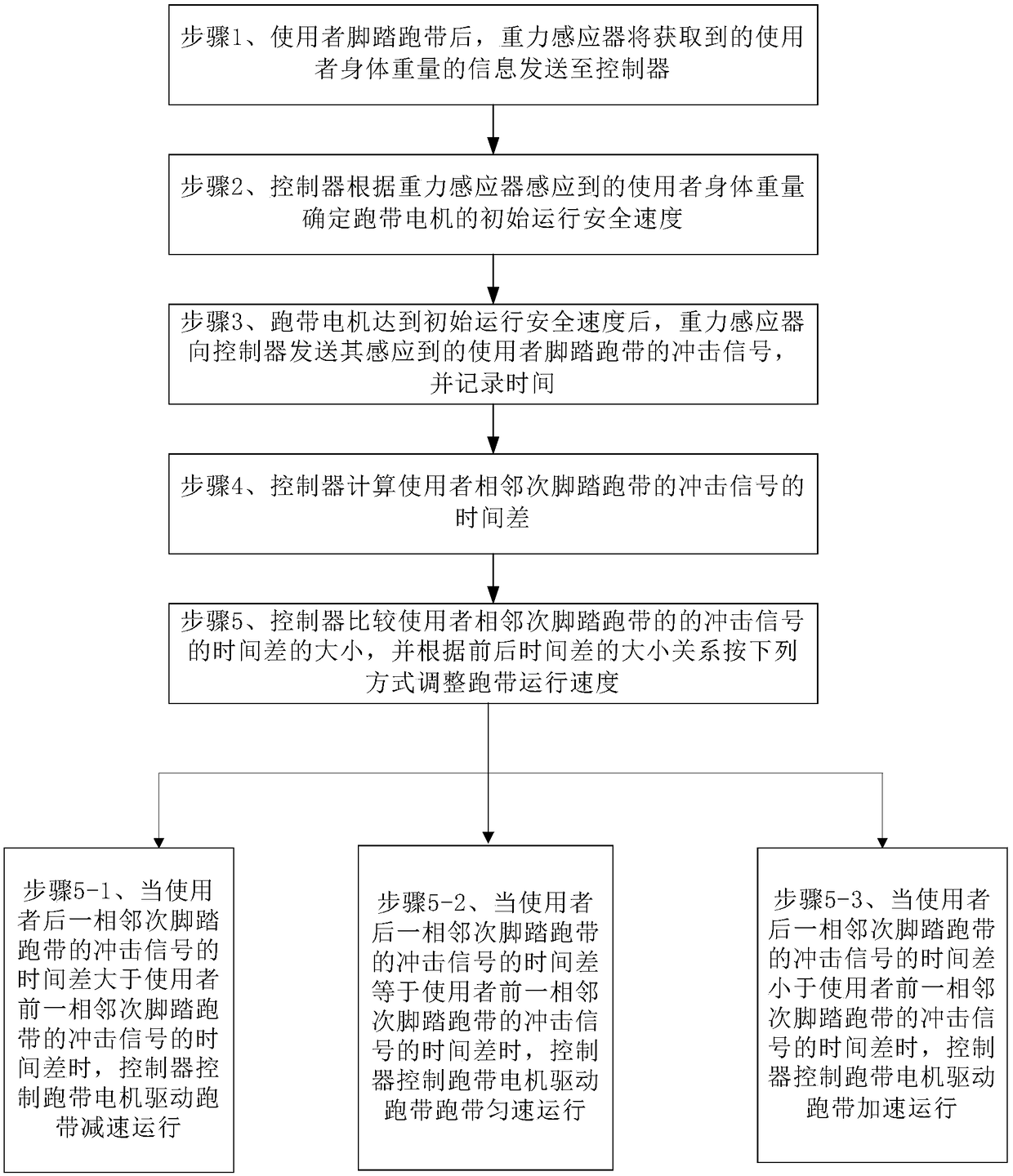

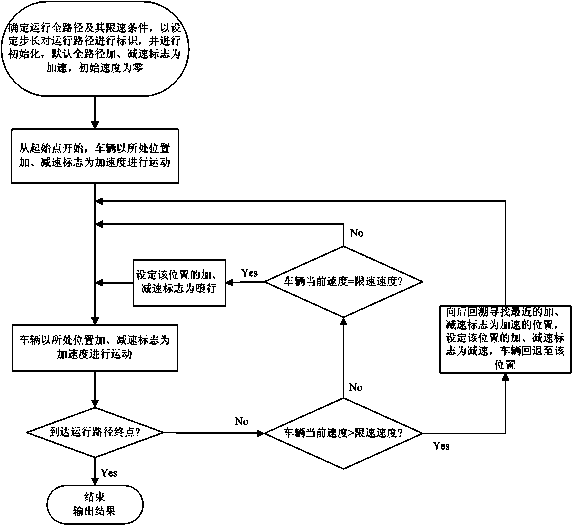

Method and system for control over speed of treadmill

InactiveCN109045627AAdjust running speedImprove experienceMovement coordination devicesCardiovascular exercising devicesEngineeringBody weight

The invention provides a method and system for control over the speed of a treadmill. The method involves a gravity sensor, a running belt motor and a controller, wherein the gravity sensor is used for sensing the body weight of a user, the running belt motor is used for driving a running belt to operate, and the controller controls the rotating speed of the running belt motor according to a signal of the gravity sensor; the method includes the steps that 1, after the user treads on the running belt, the gravity sensor sends obtained information of the body weight of the user to the controller; 2, the controller determines the initial operation safe speed of the running belt motor according to the body weight, sensed by the gravity sensor, of the user; 3, after the running belt motor reaches the initial operation safe speed, the gravity sensor sends an impact signal, sensed by the gravity sensor, generated by treading of the user on the running belt and records time; 4, the controllercalculates the time difference of an impact signal generated by next-time treading of the user on the running belt; 5, the controller compares the time difference of the impact signal generated by next-time treading of the user on the running belt, and adjusts the operation speed of the running belt.

Owner:永康市浩道健身器材有限公司

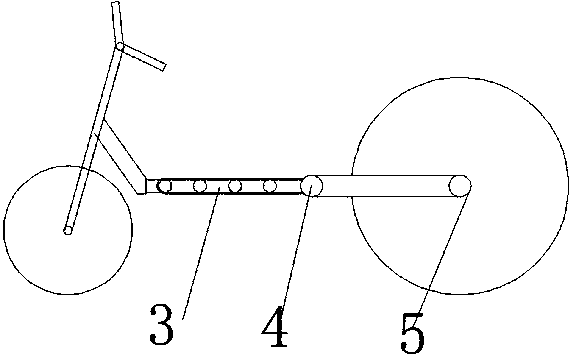

Bicycle with functions of exercising body and taking dog for walk

InactiveCN107757810AAvoid running aroundAdjustable sizeCycle equipmentsRider propulsionEngineeringCanis lupus familiaris

The invention discloses a bicycle with functions of exercising body and taking a dog for a walk. The bicycle comprises front moving wheels arranged at the front end of a running board, and a rear moving wheel arranged at the rear end of the running board; the front moving wheels are installed at the lower end of a steering lever, and a steering handlebar is arranged at the upper end of the steering lever; the steering lever is connected with the running board and is rotatably arranged at the front end of the running board; the rear moving wheel is arranged at the rear end of the running boardby means of a rear moving wheel support frame; the running board is provided with a front roller and a rear roller, and a running belt sleeve the front roller and the rear roller; a transmission wheelsleeves a roller shaft of the rear roller; the transmission wheel drives the rear moving wheel to rotate by means of belt driving and chain driving; the rear moving wheel is a barrel, and a circularcavity used for containing the pet dog to make motion is arranged in the barrel. The bicycle provided by the invention can enable an owner to take exercise while the safety of the dog during walking is guaranteed.

Owner:CHENGDU WENDA MAOYUAN TECH

Curved slide conveyor line

ActiveCN104444174BChanging the way ground transportation is doneAdjust running speedMechanical conveyorsEngineeringSlide plate

Owner:MIRACLE AUTOMATION ENG CO LTD

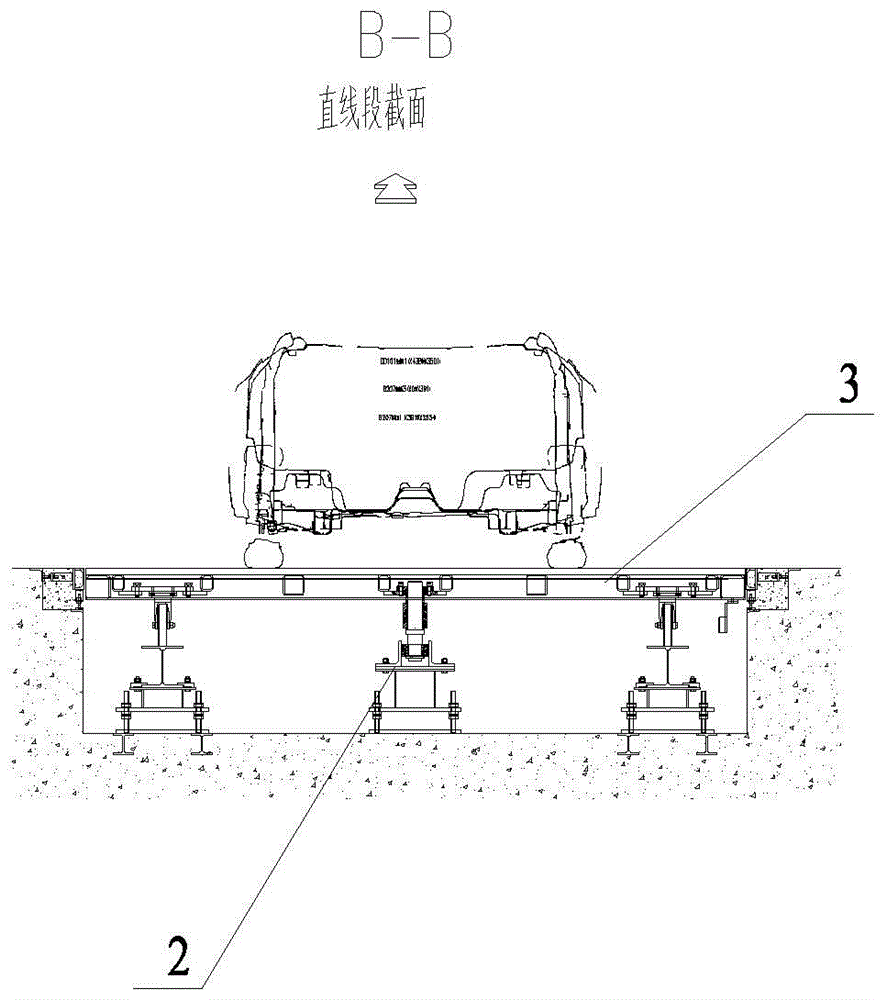

Control method for operation speed of urban rail transit vehicle

ActiveCN103963803AAvoid separate calculationsAvoid exceeding the speed limitRailway signalling and safetyLocomotivesSpeed limitVehicle control

The invention discloses a control method for the operation speed of an urban rail transit vehicle. According to the method, the vehicle is set to perform accelerated movement from the initial point, and speed marks of positions where the vehicle pass are all set as acceleration marks; in the operation process of the vehicle, if the operation speed of the vehicle is higher than limited speed of the position P where the vehicle is located, a vehicle control center controls the vehicle to back at a distance S and then perform decelerated movement, and meanwhile the speed mark of the position where the vehicle is located is set as a deceleration mark after the vehicle backs at the distance S; if speed of the vehicle still does not satisfy a speed limiting condition when the vehicle performs decelerated movement and then operates to the position P, the vehicle control center controls the vehicle to back at the distance S again and then perform deceleration movement, and the rest can be done in the same manner until the vehicle operates to the end point. It is avoided that in the operation process, the vehicle exceeds the limited speed, so that driving safety is effectively guaranteed.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

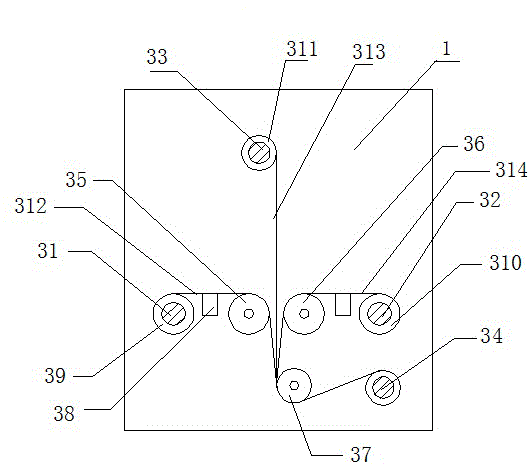

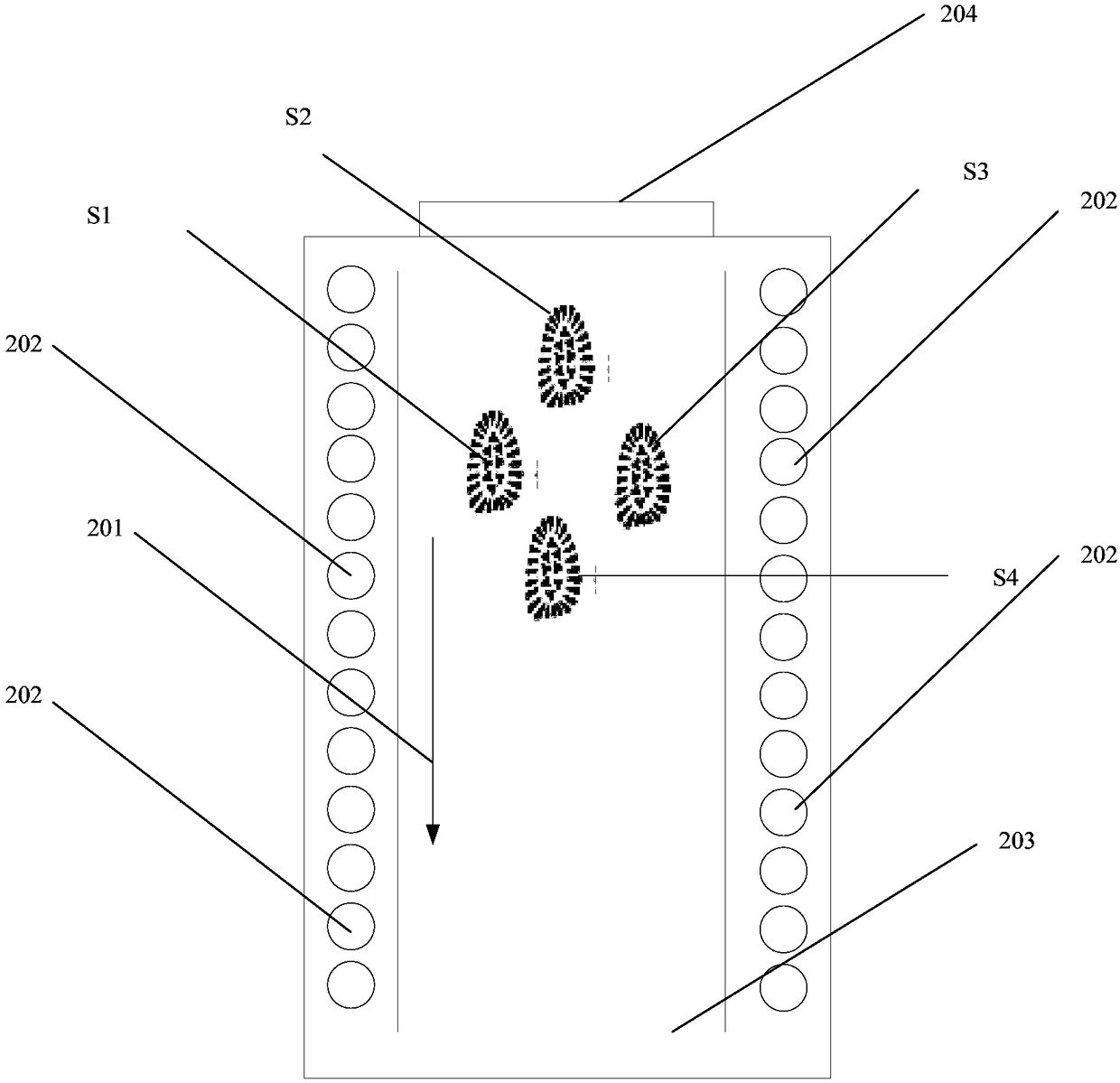

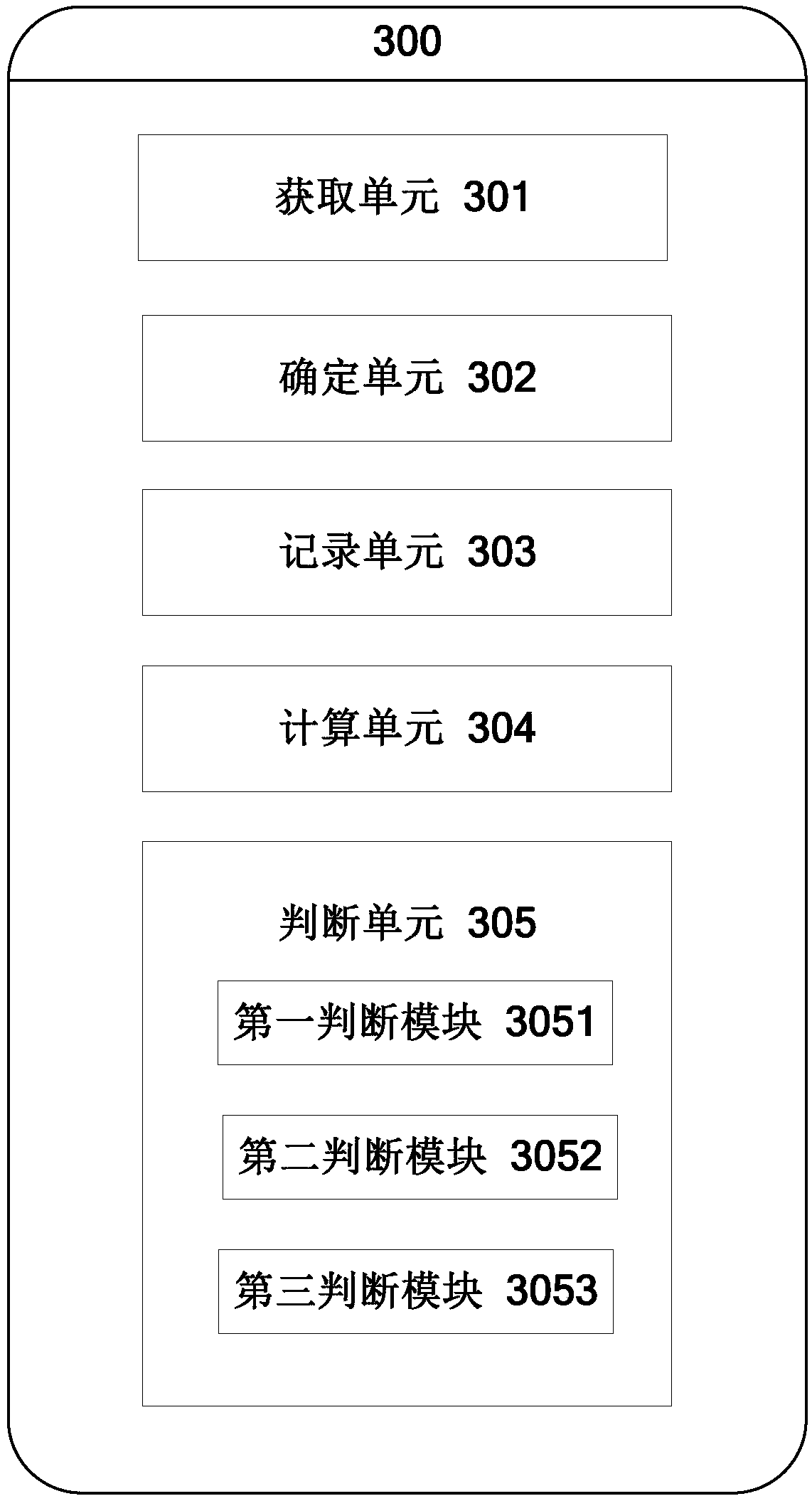

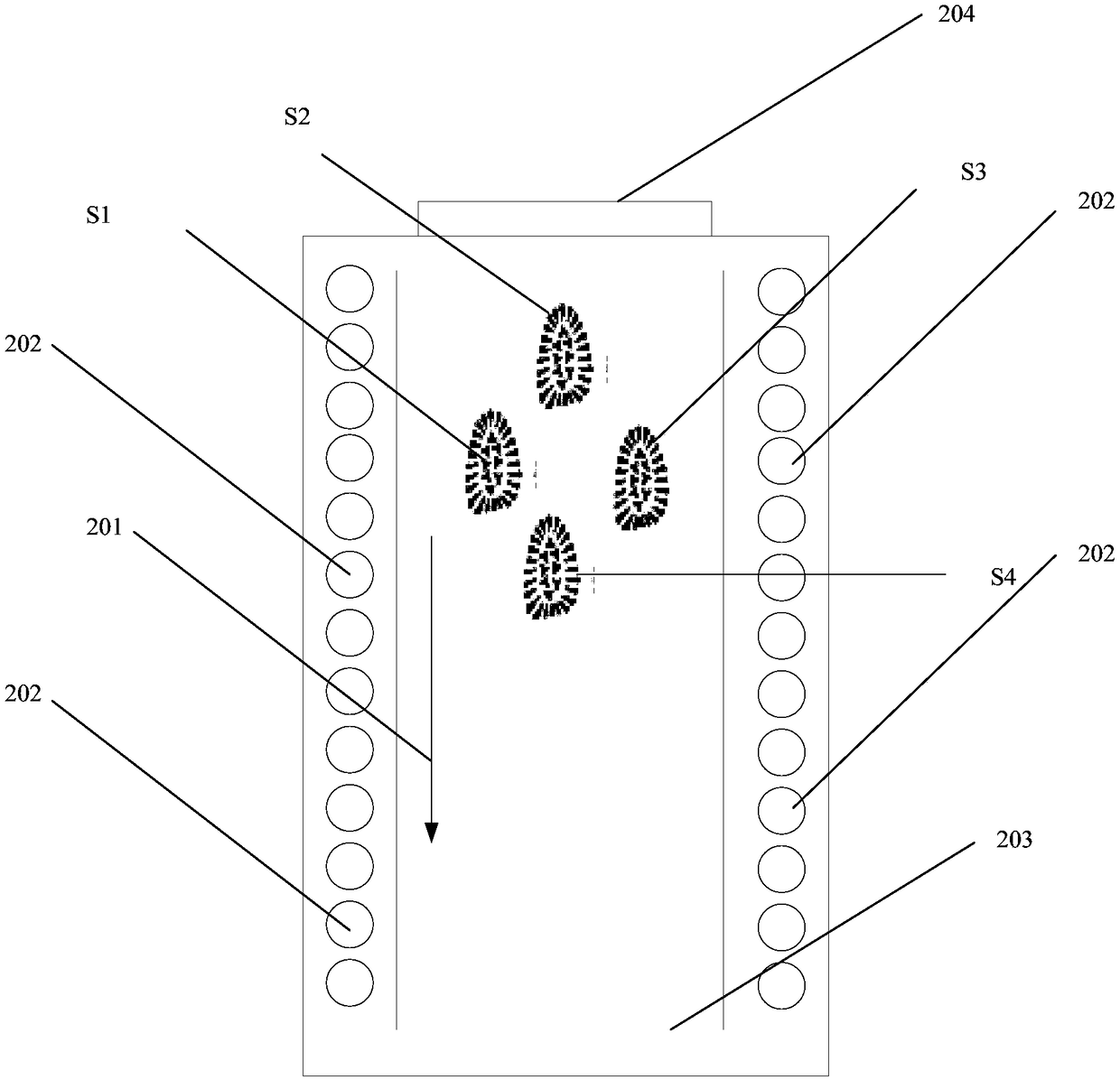

Running machine speed control method and system

ActiveCN109011353AAdjust running speedImprove accuracyMovement coordination devicesCardiovascular exercising devicesInductorTime difference

The present invention provides a running machine speed control method and system. The running machine comprises an inductor unit arranged on a treadmill and configured to induct a user's foothold, a running belt motor driving operation of a running belt and a controller configured to control the rotation speed of the running belt motor according to the signals of the inductor unit, wherein the inductor unit comprises a plurality of inductors. The method comprises the following steps that: the step 1, the controller receives signals of a user pedaling the running belt obtained by the inductor unit and records time; the step 2, the controller calculates time difference of the user's adjacent twice pedaling the running belt; and the step 3, the controller compares the time difference of the user's adjacent twice pedaling the running belt and regulates the operation speed of the running belt according to the relation of the time difference.

Owner:永康市浩道健身器材有限公司

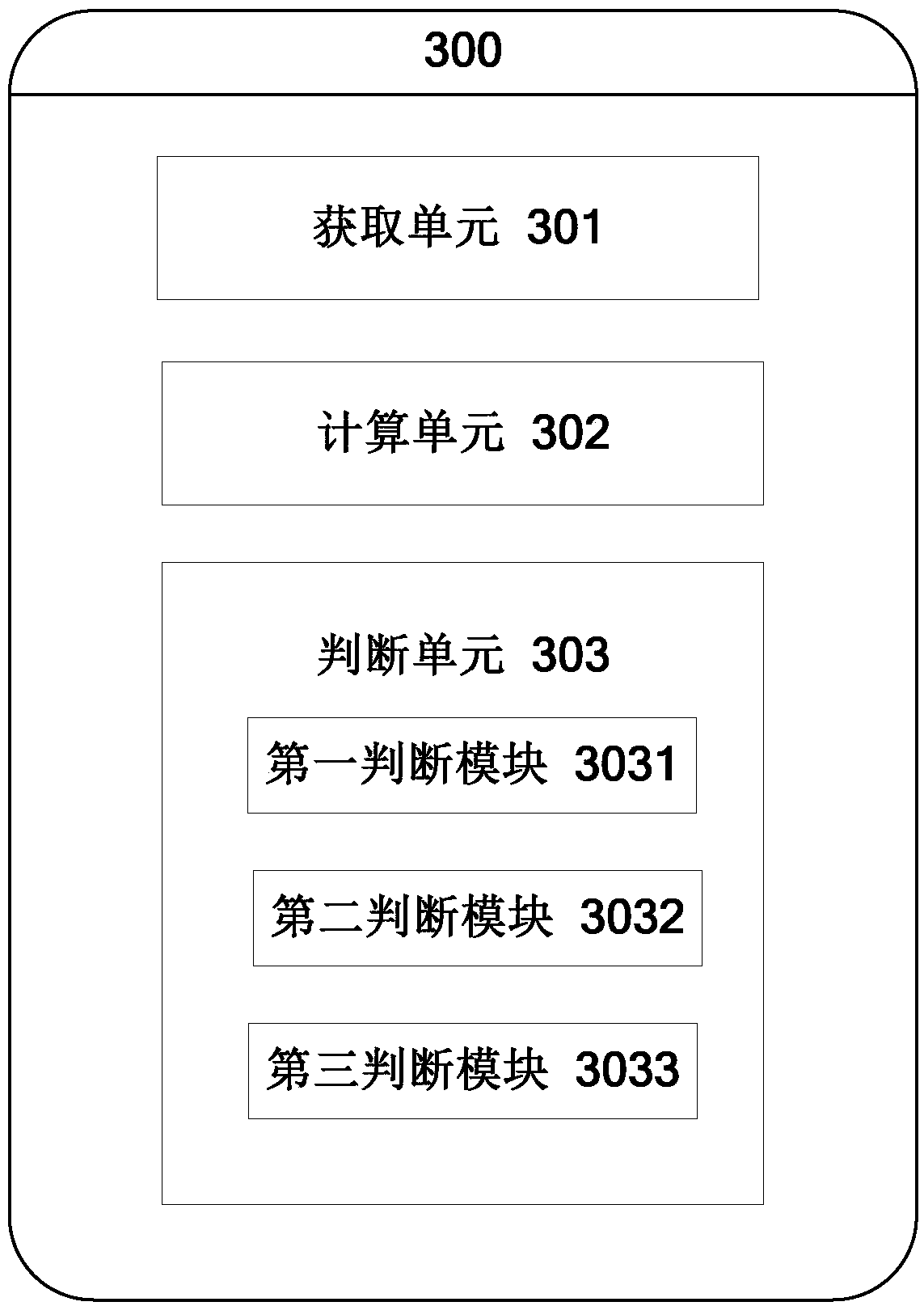

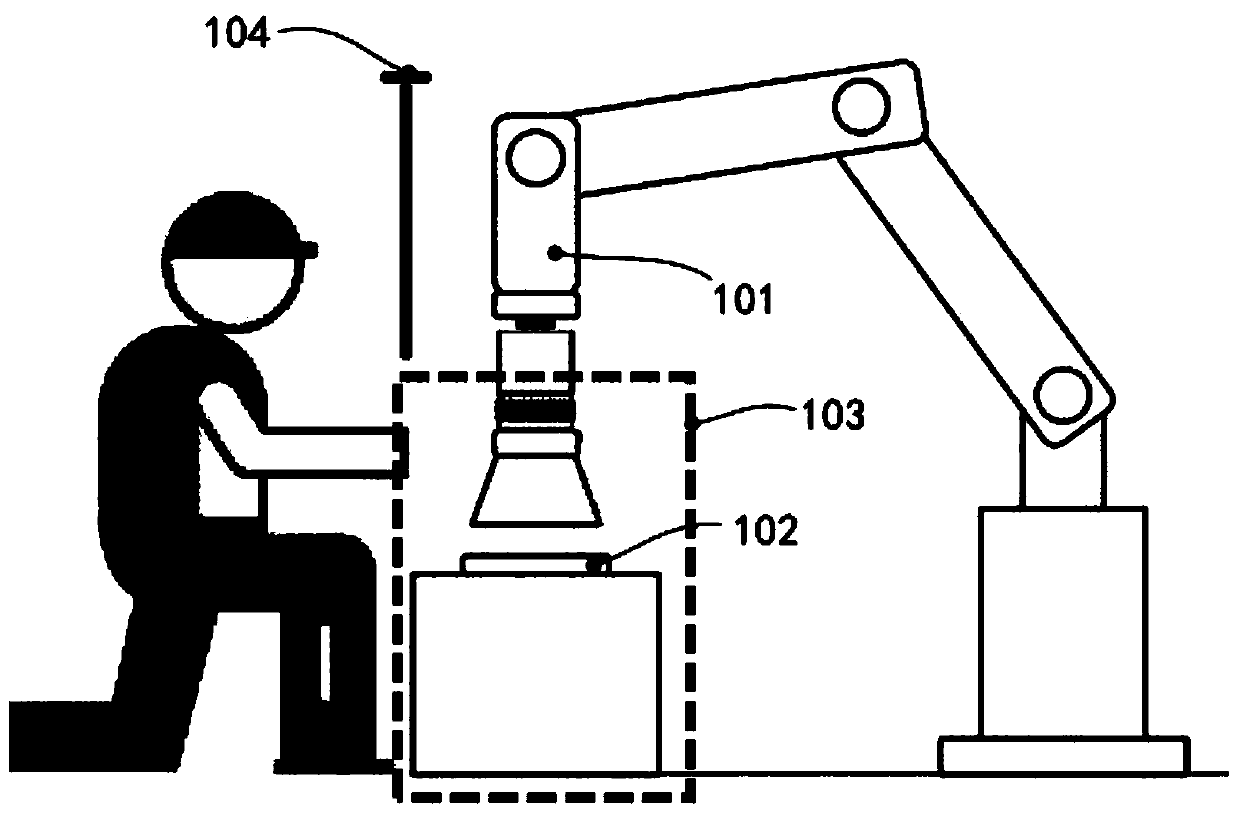

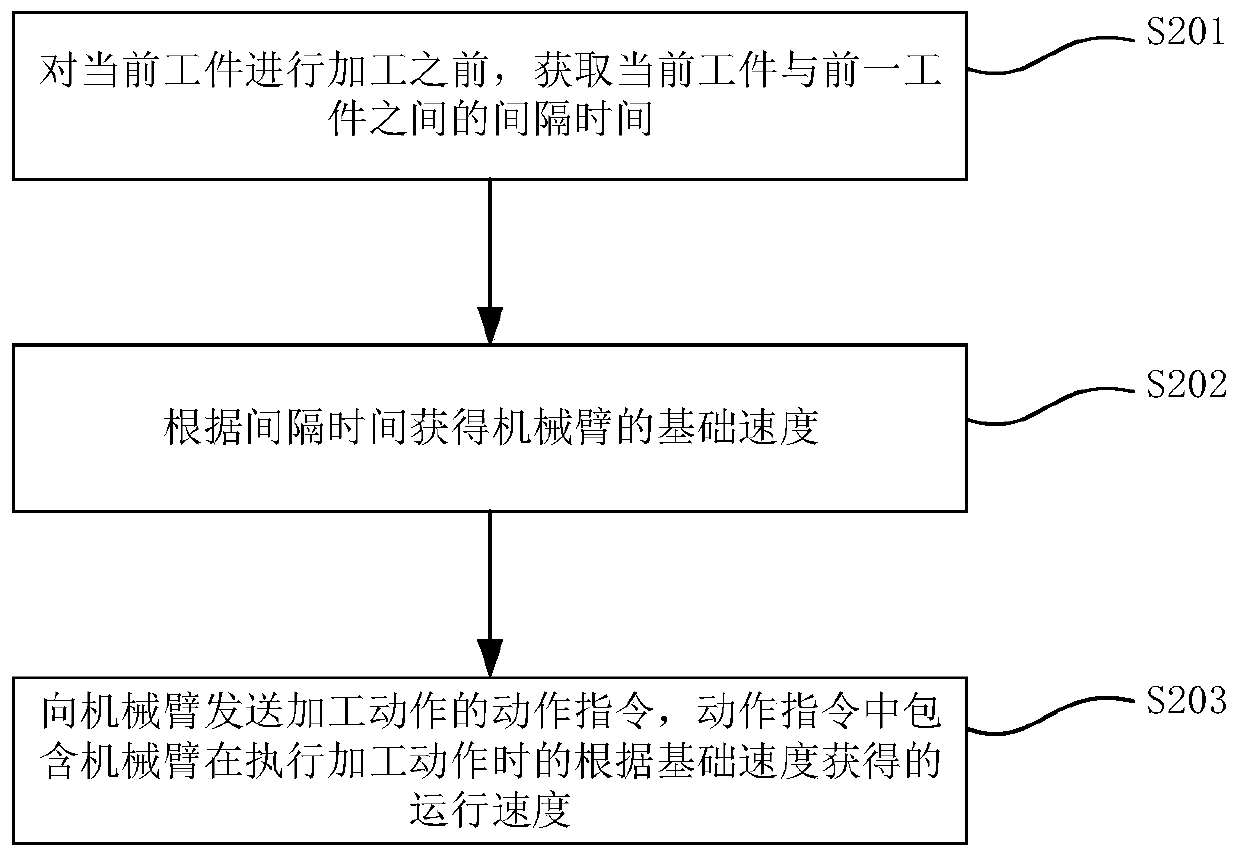

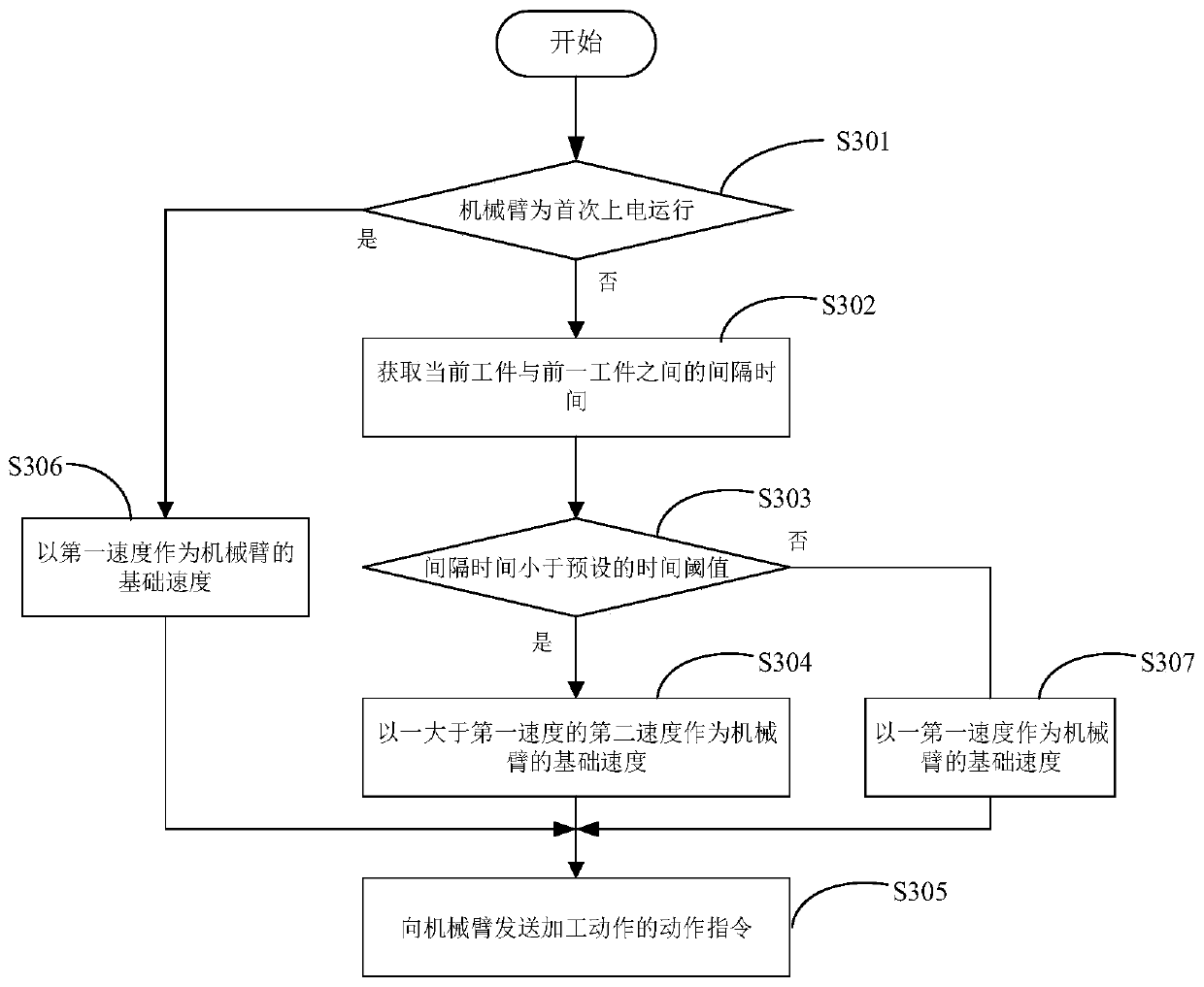

Mechanical arm speed regulation method, system and device and medium

ActiveCN109732602ASlow downReduce information pressureProgramme-controlled manipulatorControl theoryOverall efficiency

The invention discloses a mechanical arm speed regulation method, system and device and a medium. The mechanical arm speed regulation method comprises the steps that interval time of a current workpiece and a previous workpiece is obtained before machining of the current workpiece; according to the interval time, a base speed of a mechanical arm is obtained; and a motion command of machining motions is transmitted to the mechanical arm, and the motion command comprises an operation speed obtained according to the base speed of the mechanical arm during machining motions. The flexible regulation of the operation speed of the mechanical arm is achieved, and the overall efficiency of a production system is improved.

Owner:上海英医达医疗器械用品有限公司

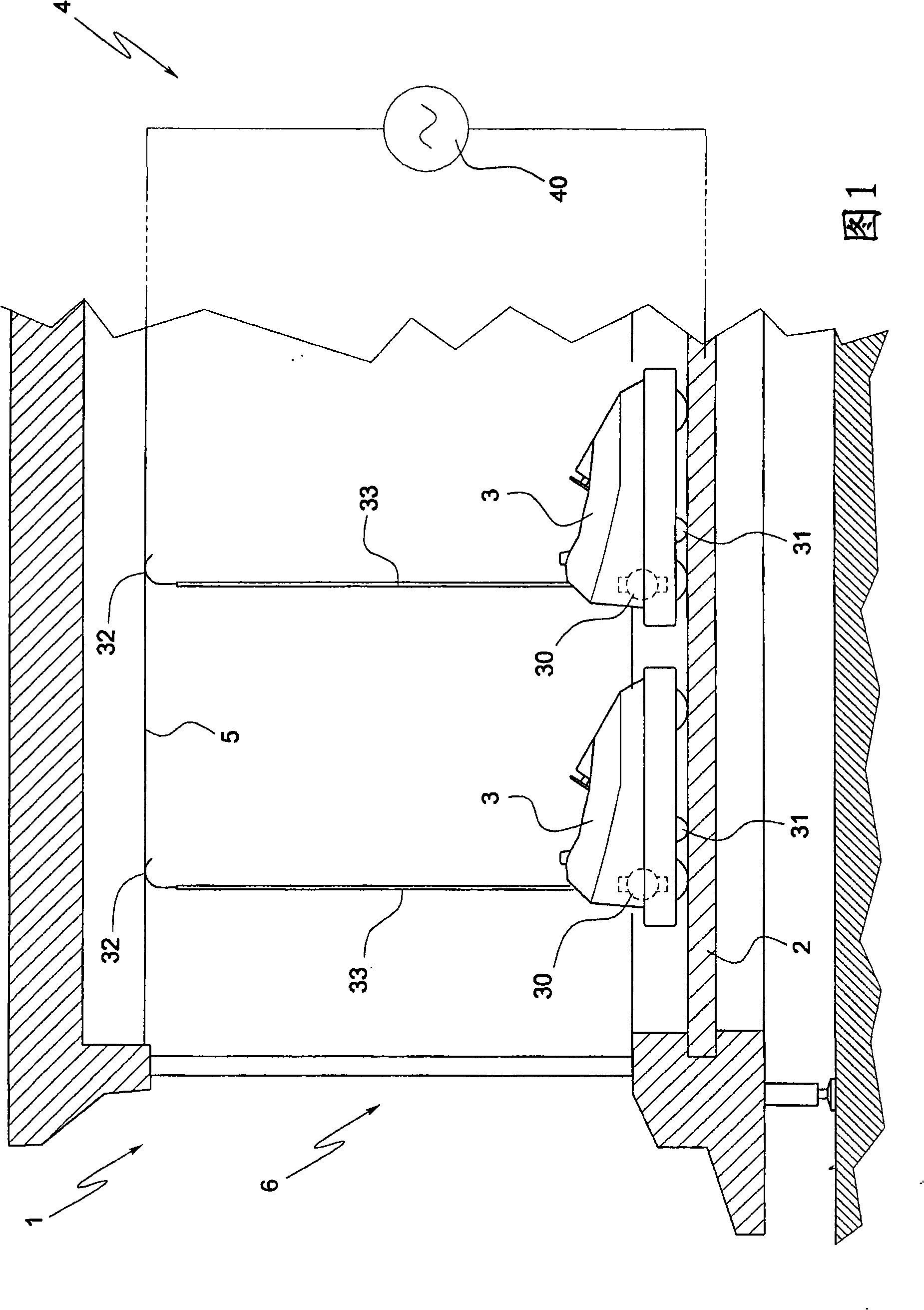

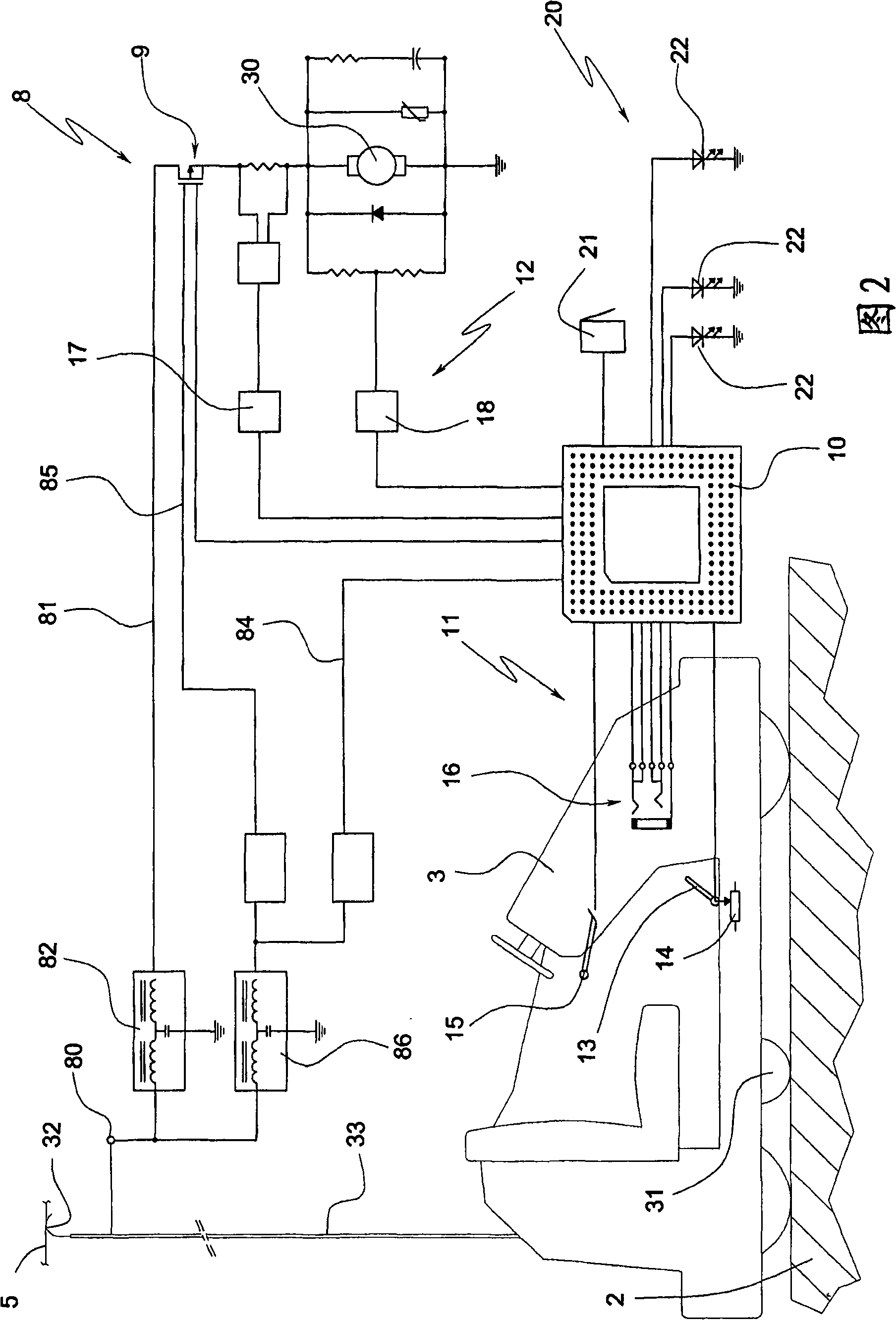

Rail of electric vehicle

The invention discloses an orbit of electric vehicle. A vehicle riding device comprises an orbit (2) and a plurality of vehicles (3) which move on the orbit (2), supplied with power by a relevant motor (30) mounted on the vehicle (3) and are in parallel connection to a single power device (4) associated with the orbit (2). Each vehicle (3) comprises an adjusting device (9) for adjusting the rotating speed of the relevant motor (30) by the manner of basically independent to the motor (30) of other vehicles (3) of the vehicle riding device.

Owner:PRESTON & BARBIERI

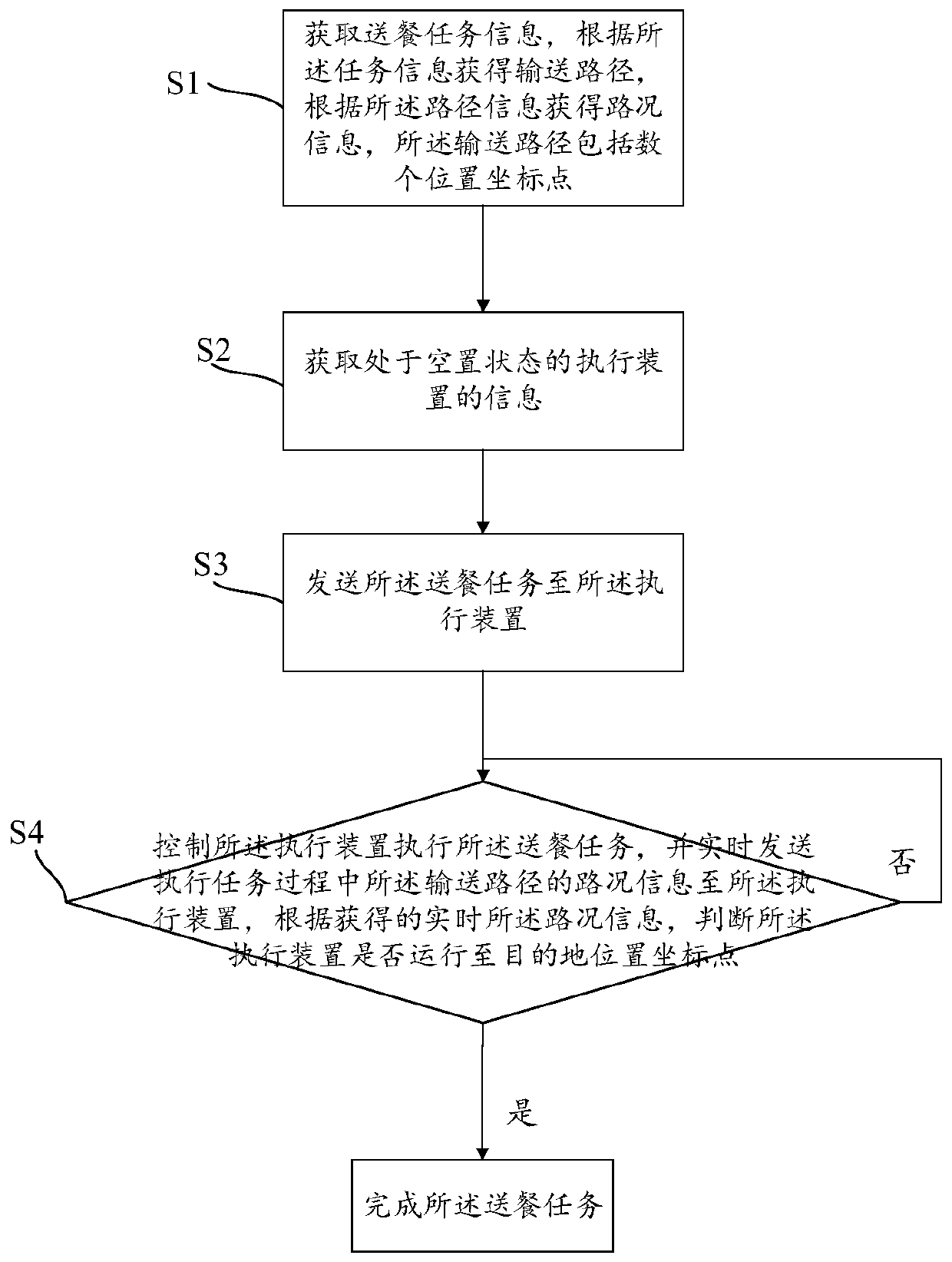

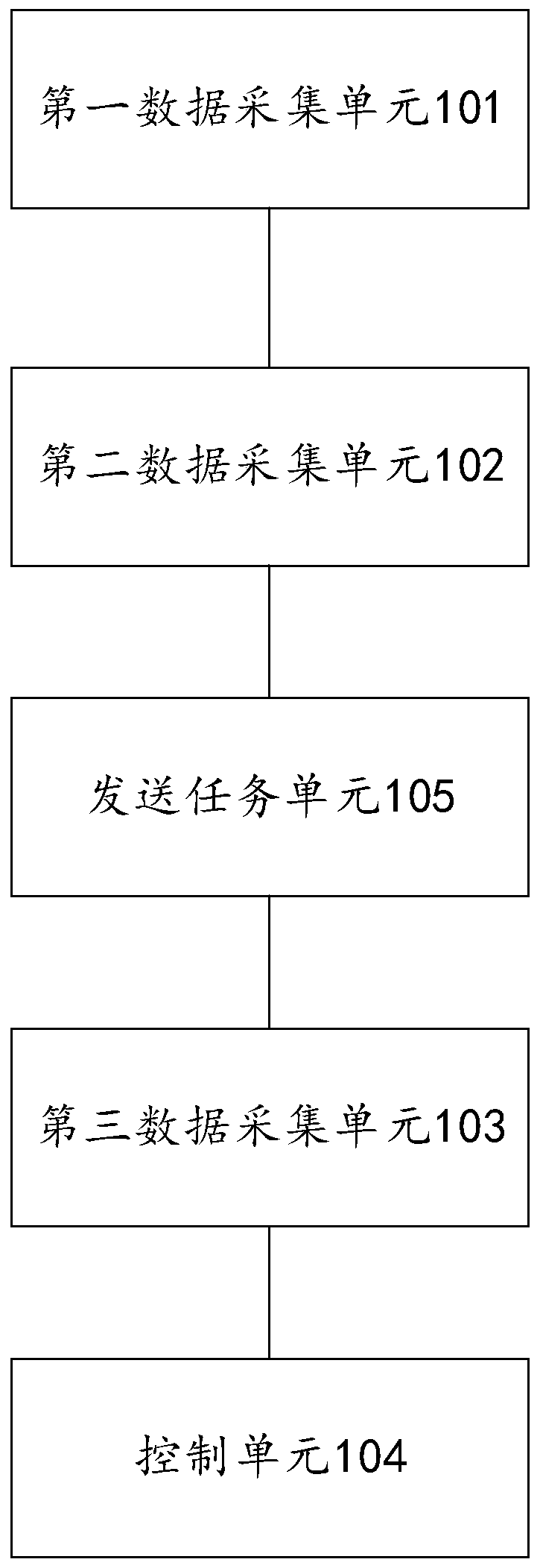

Method and system for meal delivery system to control execution device to operate and computer equipment

InactiveCN110928308AImprove performanceFlexible Control OperationPosition/course control in two dimensionsVehiclesOperating systemDelivery system

The embodiment of the invention relates to a method and a system for a meal delivery system to control an execution device to operate and computer equipment, and the method comprises the steps: S1, obtaining meal delivery task information, and obtaining a conveying path according to the task information; S2, acquiring information of an execution device in a vacant state; S3, sending the meal delivery task to an execution device; S4, controlling the execution device to execute the meal delivery task, sending road condition information of the conveying path in the task execution process to the execution device in real time, judging whether the execution device runs to the destination position coordinate point or not according to the obtained real-time road condition information, and if yes,completing the meal delivery task; if not, executing the step S4 again; wherein the road condition information comprises a plurality of position coordinate points, and the road condition information is the information of all the position coordinate points between the current position of the execution device and the end point of the conveying path in the task execution process. Operation of an execution device is flexibly controlled in the meal delivery system, the situation that the meal delivery task cannot be completed due to accidents is avoided, and the performance of the meal delivery system is improved.

Owner:GUANGDONG ATHENE ROBOTIC TECH CO LTD

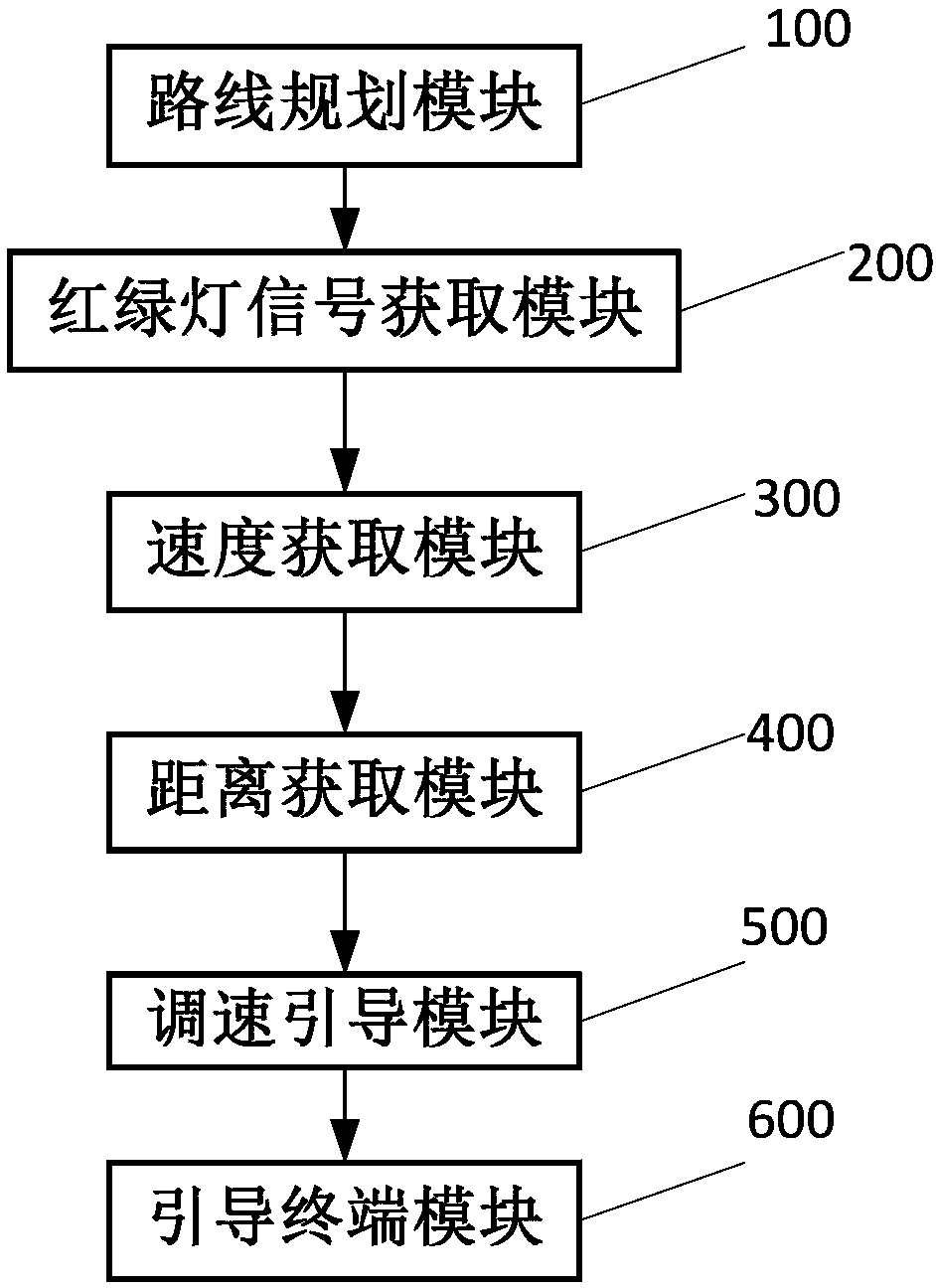

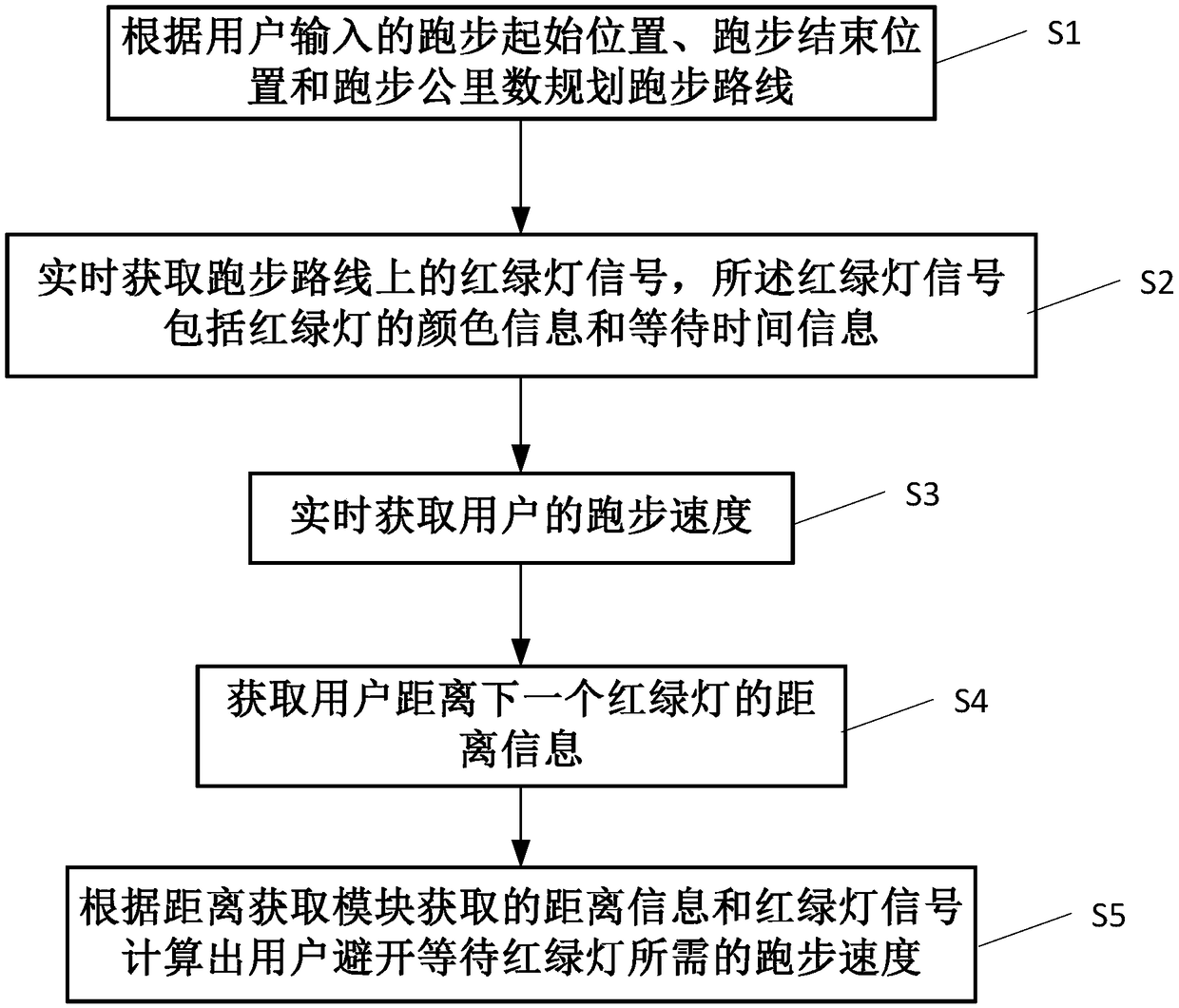

Real-time running speed adjustment instruction system and method thereof

InactiveCN108716921ADisrupt the running rhythmAdjust running speedInstruments for road network navigationSatellite radio beaconingUser inputLight signal

The invention discloses a real-time running speed adjustment instruction system and relates to the technical field of navigation. The system comprises a route planning module, a traffic light signal acquisition module, a speed acquisition module, a distance acquisition module and a speed adjustment instruction module, wherein the route planning module is used for planning a running route accordingto a running start position, a running ending position and a running mileage input by a user; the traffic light signal acquisition module is used for acquiring traffic light signals on the running route in real time; the traffic light signals comprise traffic light color information and waiting time information; the speed acquisition module is used for acquiring a running speed of the user in real time; the distance acquisition module is used for acquiring distance information of the user and a next traffic light; the speed adjustment instruction module is used for calculating the running speed of the user according to the distance information and the traffic light signal to prevent the user from waiting for the traffic light in a running process. The invention further provides a corresponding method to avoid traffic light waiting.

Owner:佛山市洁宇信息科技有限公司

Three-stage type hydraulic driving biomass reciprocating fire grate

The invention discloses a three-stage type hydraulic driving biomass reciprocating fire grate, which comprises a fixing column, three hydraulic driving devices, and a frame, a first segment fire grate, a second segment fire grate and a third segment fire grate are successively arranged in the frame from top to bottom, each segment of the fire grate includes a movable frame, a connecting shaft, fire grate pieces, movable beams, fixed beams, steel plates, idler wheels and supporting frames; each movable framecomprises a bottom beam and a movable inclined beam which are connected,a plurality of reinforcing beams are arranged between the bottom beams and the movable inclined beams, the movable inclined beams are installed on the frame, a plurality of steel plates are arranged on the lower faces of the bottom beams, the idler wheels are arranged between the steel plates and the supporting frames, the bottom beam in each segment of the fire grate is connected to one end of the correspondinghydraulic driving device, and the other ends of the hydraulic driving devices are connected to the fixing column. According to design, combustion of biomass in a hopper is effectively prevented, hydraulic pushing is stable, operation is stable, the use effect is good, and the operation speed is adjusted according to the combustion condition.

Owner:瓦房店市永宁机械厂

Method for controlling shape of low-alloy high-strength steel plate in controlled cooling phase

InactiveCN101885004BAdjust running speedIncrease the number of open groupsTemperature control deviceMetal rolling arrangementsSheet steelAlloy

The invention discloses a method for controlling the shape of a low-alloy high-strength steel plate in a controlled cooling stage. The method is used in a controlled rolling and cooling process for producing a steel plate; the shape of the steel plate after rolling is obtained by using a controlled cooling process, and the upper to lower water ratio of the steel plate, edge masking and the speed of the steel plate passing through a controlled cooling area in the cooling process are adjusted according to the shape of the steel plate after rolling so as to control the shape of the steel plate after controlled cooling, and thus, a low-alloy high-strength steel plate capable of meeting requirements is obtained. The product produced by using the method can eliminate shape defects, such as concave upward, concave downward, edge waves, center waves and the like, of the steel plate in the process of controlled cooling, improves the accuracy of the controlled cooling process, ensures that the texture and the performance of the steel plate are more uniform, and further enhances the yield rate of the product.

Owner:NANJING IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com