Nano fiber net forming device

A nanofiber and web forming technology, applied in the field of nanofiber web forming devices, can solve the problems of air permeability, unattainable filterability, high cost, complex structure, etc., and achieve the effects of low cost, simple structure and good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

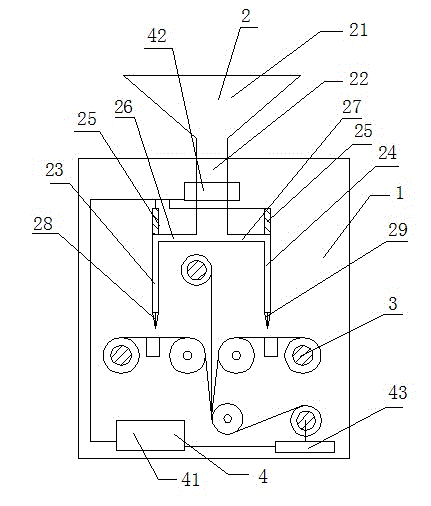

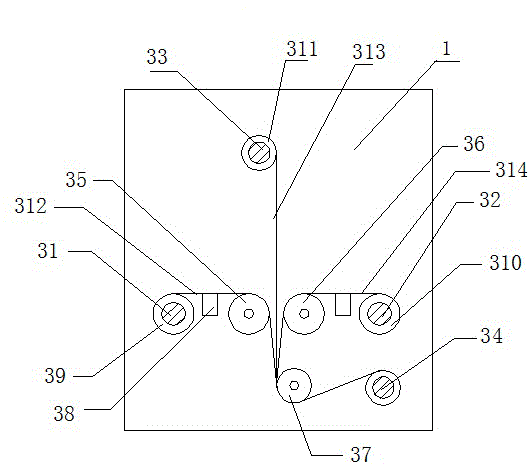

[0016] As shown in the figure, a nanofiber web forming device includes a frame 1, a spinning mechanism 2, a tightening mechanism 3 and a control mechanism 4, and the spinning mechanism 2 includes a hopper 21, a metering channel 22, and the first spinning channel 23, the second spinneret channel 24, the high-pressure nozzle 25, the metering channel 22 is fixed on the frame 1, one end of the metering channel 22 communicates with the hopper 21, and the other end is horizontally provided with a first branch port 26 and a second branch port 27, the first branch port 26 communicates with the first spinneret channel 23, the second branch port 27 communicates with the second spinneret channel 24, and the bottom end of the first spinneret channel 23 is provided with a first fiber nozzle 28 , the bottom end of the second spinning channel 24 is provided with a second fiber nozzle 29, the number of the high-pressure nozzles 25 is two, and the two high-pressure nozzles 25 communicate with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com