Patents

Literature

109results about How to "Control running speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

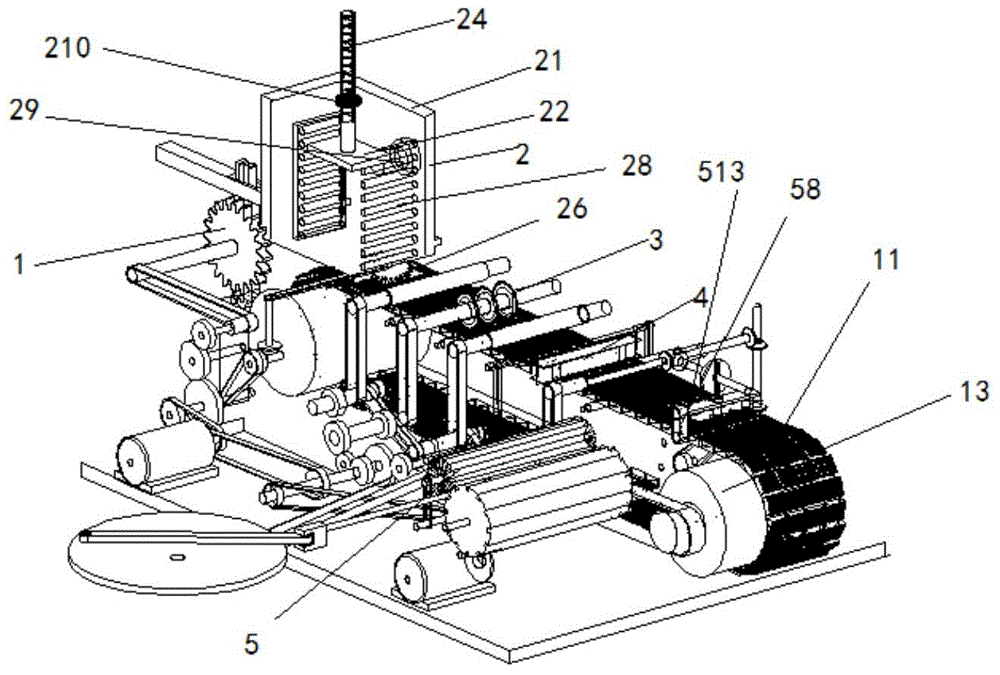

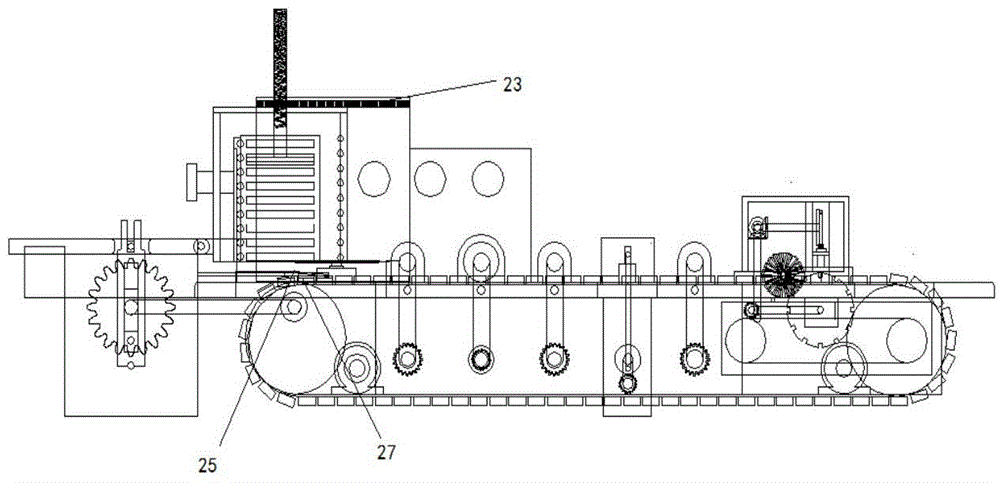

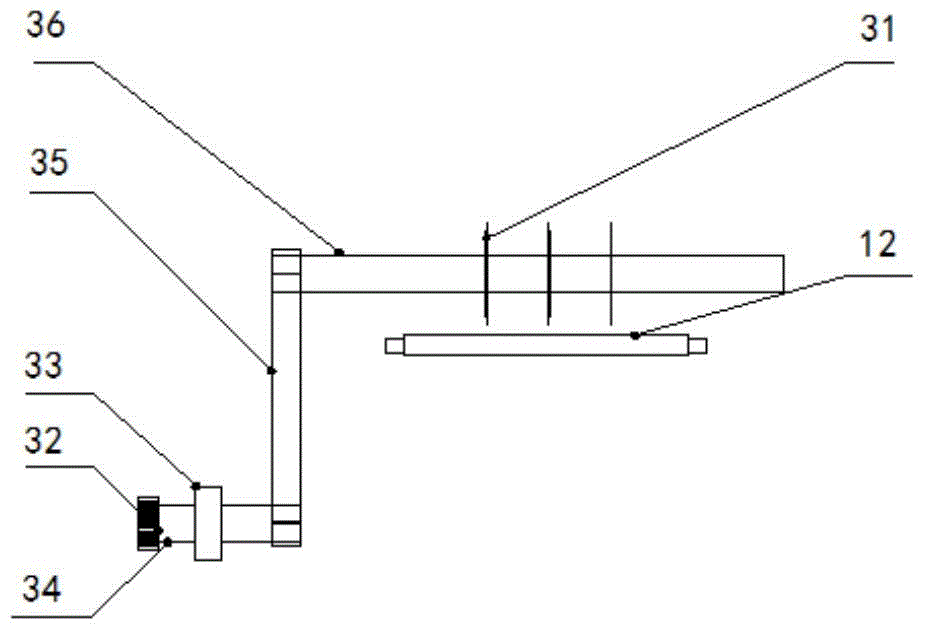

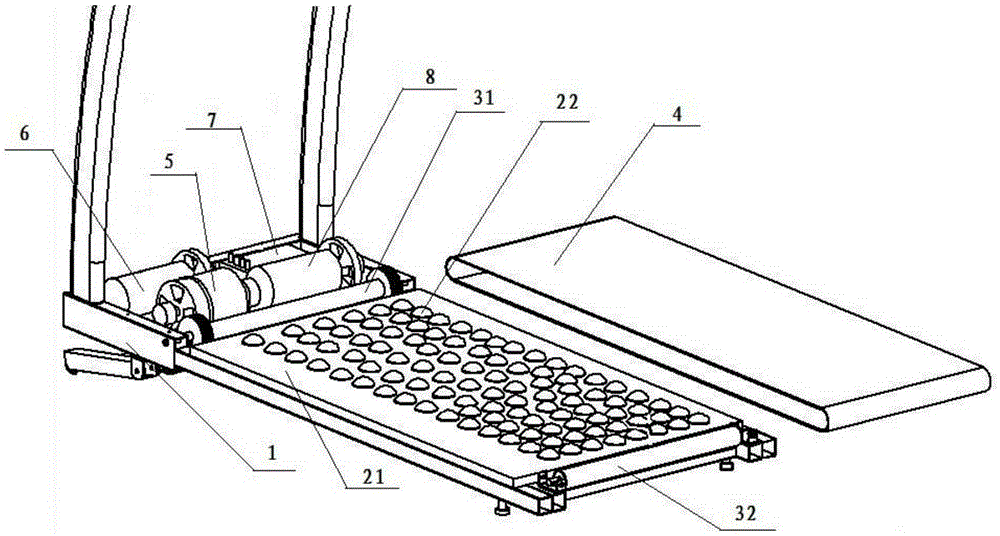

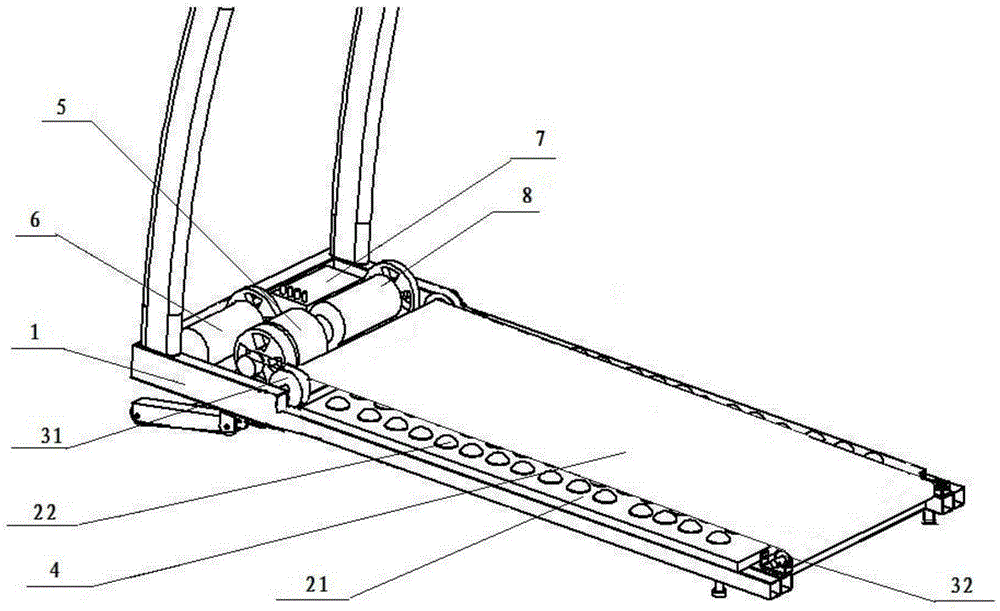

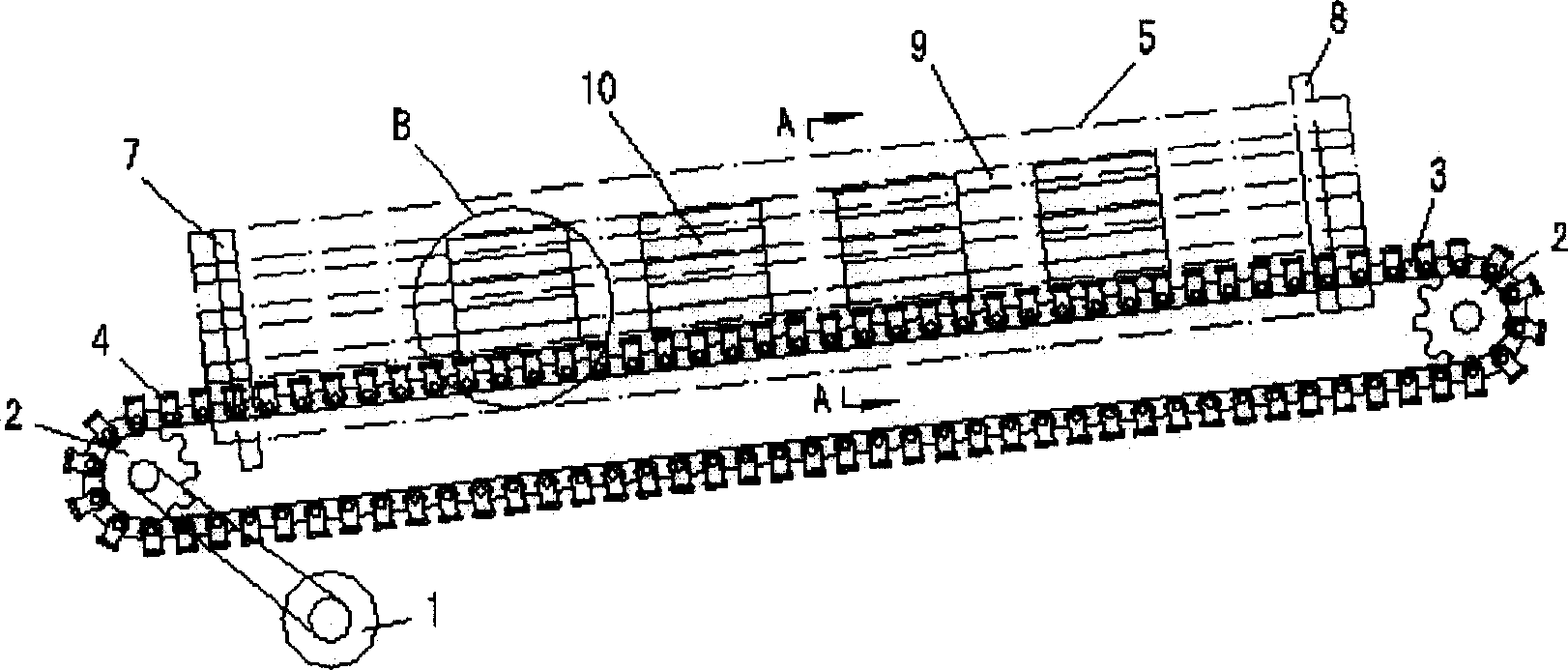

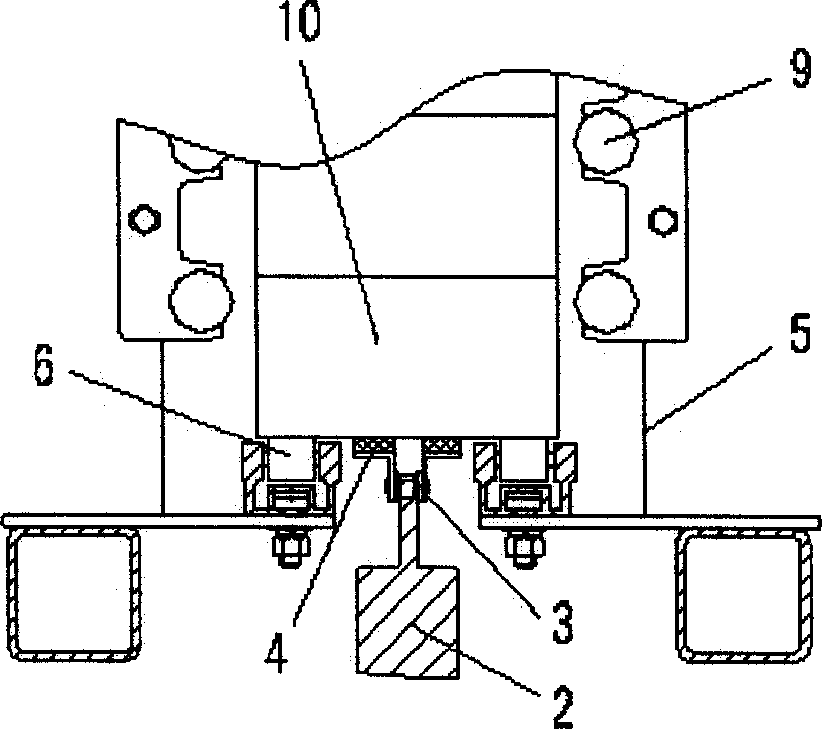

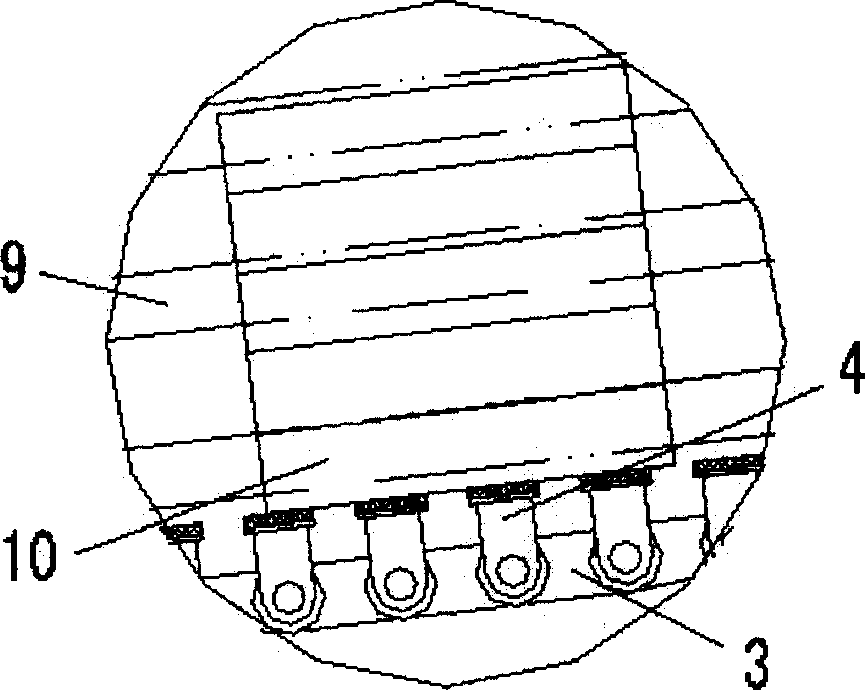

Automatic stringer

InactiveCN104920572AReduce in quantityControl running speedMeat/sausage hanging-upPutting meat on skewersPunchingKnurling

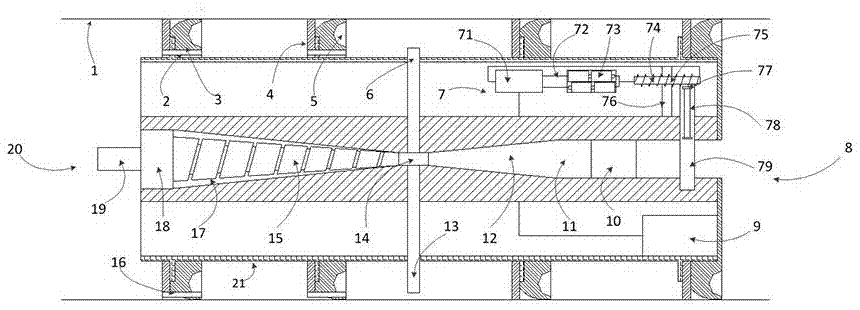

The invention relates to an automatic stringer which comprises a power transmission device, an automatic meat slicing device with a propelling automatic meat locking box, a knurling tool meat cutting device, a shearing and feeding device and an automatic prod punching device, wherein the device integrates slicing, slitting, bar-cutting and prod-stringing, so that the production efficiency is improved, automation and multi-functionalization can be further realized, the automatic stringer is multipurpose, and the consumption of manpower and material resources as well as financial resources is greatly reduced. The automatic stringer not only can string meat, but also can string various foods such as balls and the like. Moreover, meat in different thicknesses and different sizes can be stringed. The mechanical degree and the production efficiency are improved, and the automatic stringer is easy to operate and maintain, low in cost, small in size and high in degree of automation.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

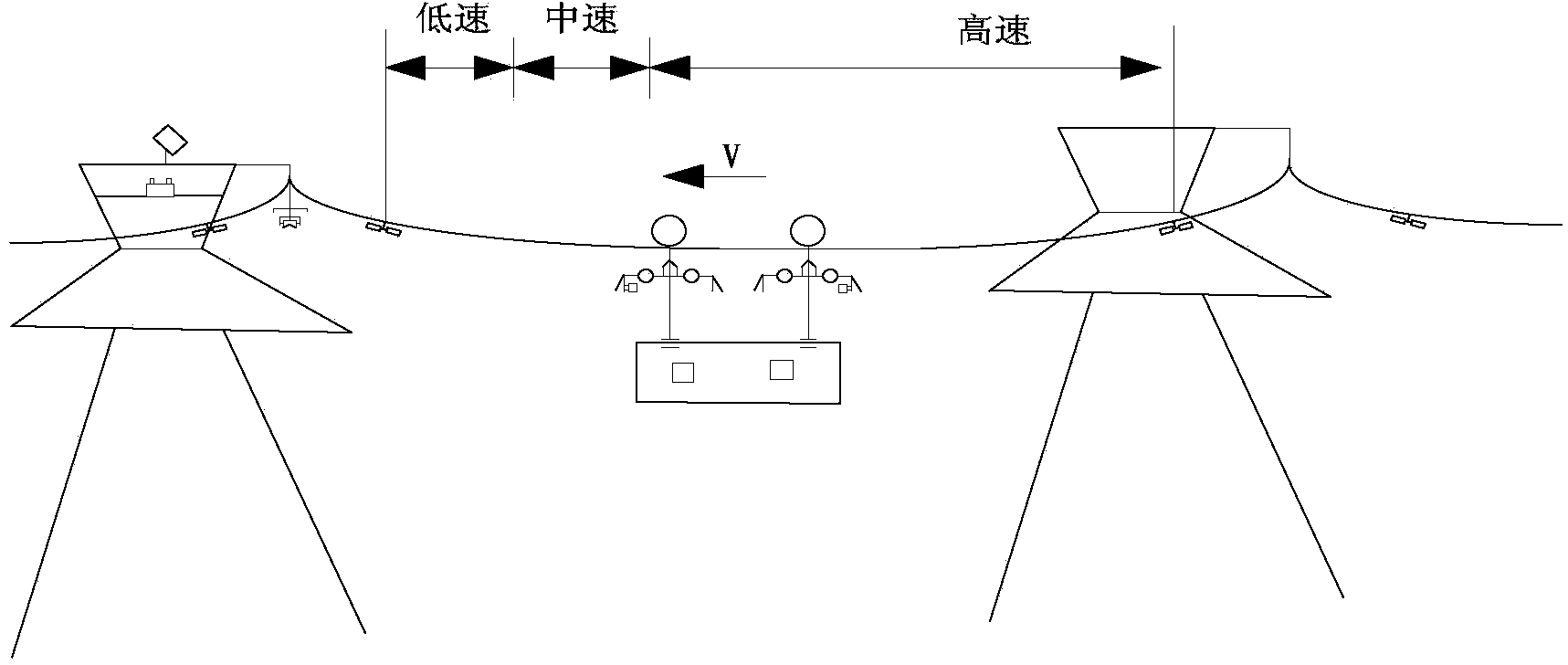

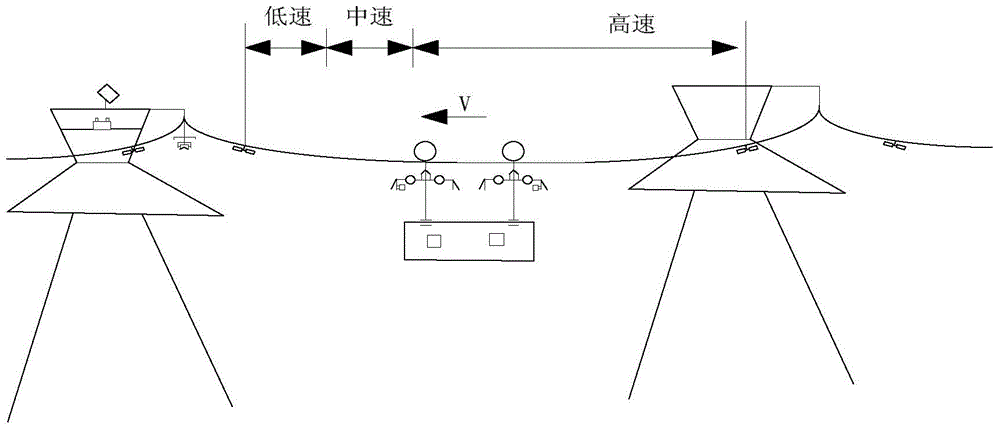

Device and method for controlling self-localization, butting and charging of high-voltage line inspection robot

InactiveCN103825338AControl running speedImprove the efficiency of autonomous charging and dockingBatteries circuit arrangementsElectric powerProximity sensorHigh pressure

The invention discloses a device and a method for controlling self-localization, butting and charging of a high-voltage line inspection robot. According to the device and the method, the specific position of the robot in a high-voltage power transmission line is located through a GPS-GIC (Global Position System-Geographic Information System) technology according to a self line structure of the high-voltage power transmission line and a self obstacle crossing function of the robot, and a moving speed of the robot in the high-voltage power transmission line is controlled by combining an ultrasonic wave sensor and a hall proximity sensor, so that the efficiency of an automatic butting process is improved; joints of the robot are controlled by using a speed mode, a moment mode and a position mode, so that the charging and butting process is accurately controlled; finally, the charging and butting process is accurately adjusted according to signal feedback of a strain gage of a charging plug and the hall proximity sensor, so that the tangential internal stress between the charging plug and a charging socket is reduced and the safe and reliable processing of the charging process is ensured.

Owner:WUHAN UNIV

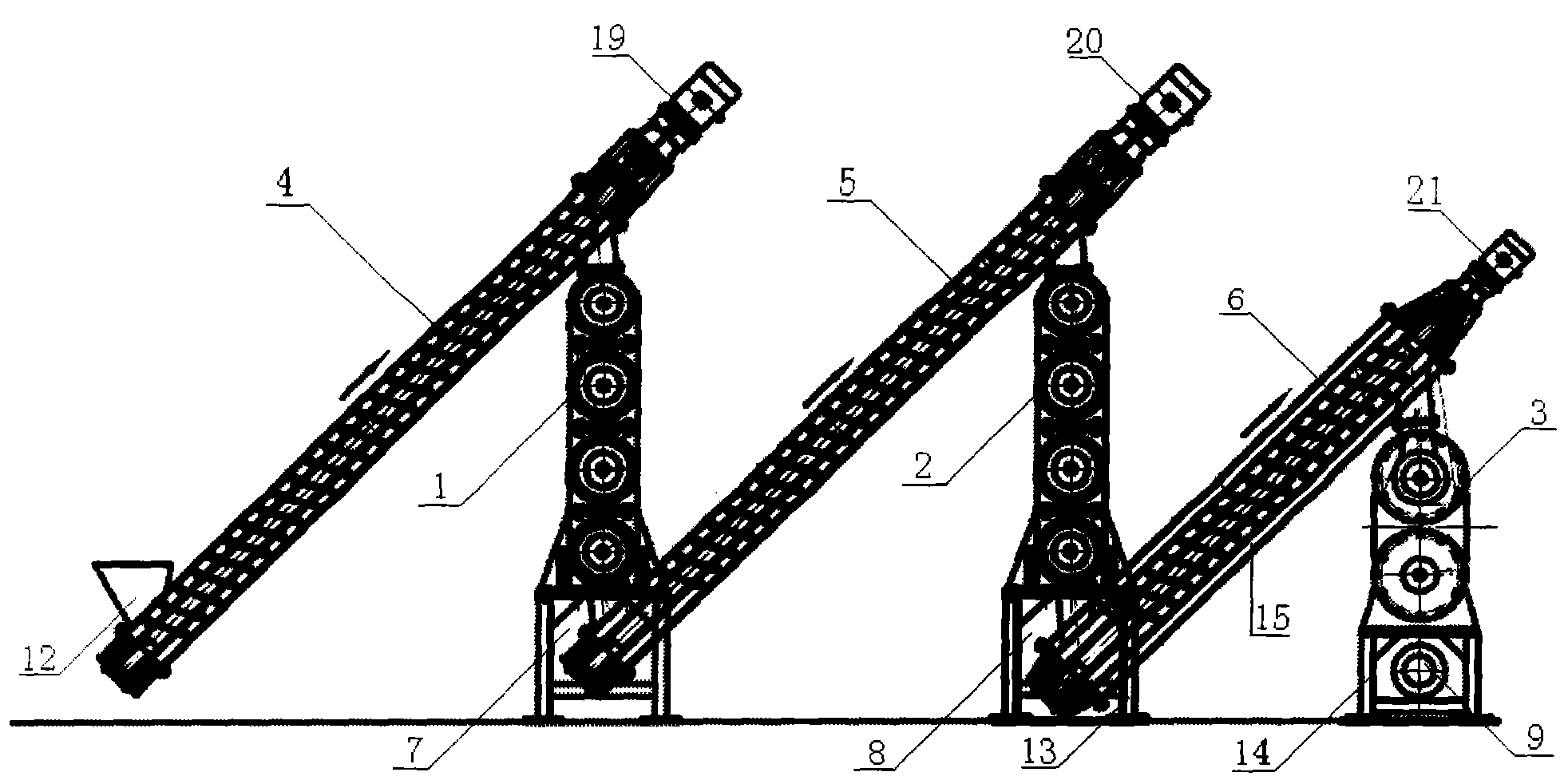

Automatic brick making production line

The invention discloses an automatic brick making production line, which comprises a feeding machine, a jaw breaker, a crushing machine, a roller screen, a storage bin, a stirring machine, a brick making machine, a slitter, a base cutter, a base grasping machine, a base transport machine, a setting platform and a rotary kiln, wherein the rotary kiln and the setting platform are arranged on an annular track, the feeding machine, the jaw breaker, the crushing machine and the roller screen, which are connected through a conveyer belt in sequence, are arranged at the outer side of the annular track, the storage bin, the stirring machine, the brick making machine, the slitter and the blank cutter, which are connected through the conveyer belt in sequence, are arranged at the inner side of the annular track, the roller screen is connected to an inlet of the storage bin through an overhead conveyer belt, the blank transport machine is concentric to the annular track, is annular and is arranged at the inner side of the annular track, a blank distribution table is connected to the inner side of the blank transport machine through the blank cutter, the blank grasping machine is arranged on the blank distribution table, the blank grasping machine and a setting robot are arranged on the setting platform, and a sintering process is completed by the rotary kiln after brick base are piled by the setting robot, so that automatic production of brick is realized.

Owner:SICHUAN PROVINCE PINXIN MACHINERY +1

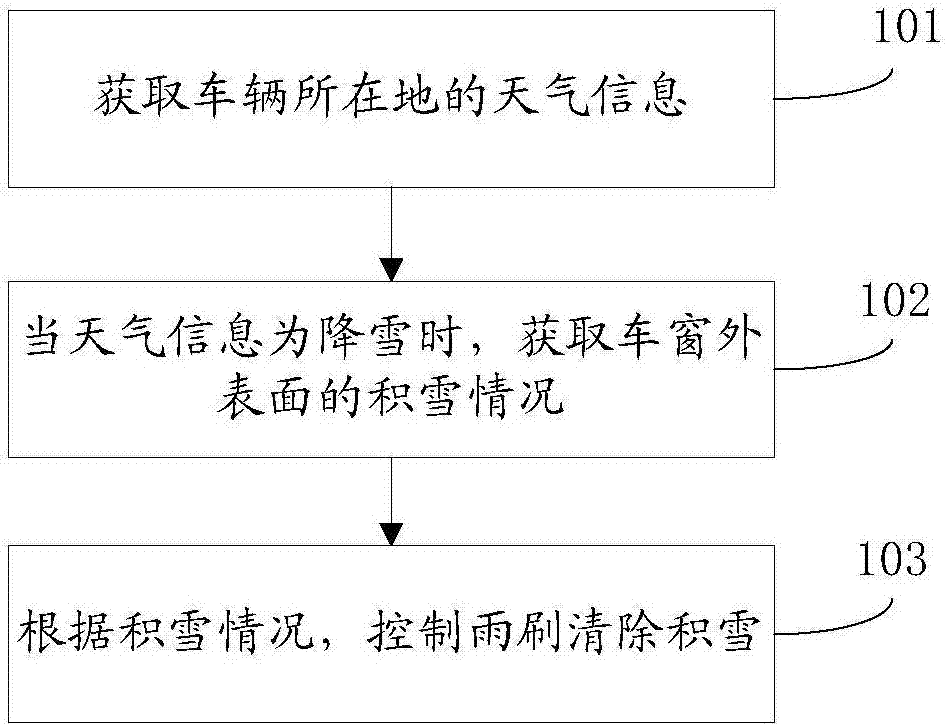

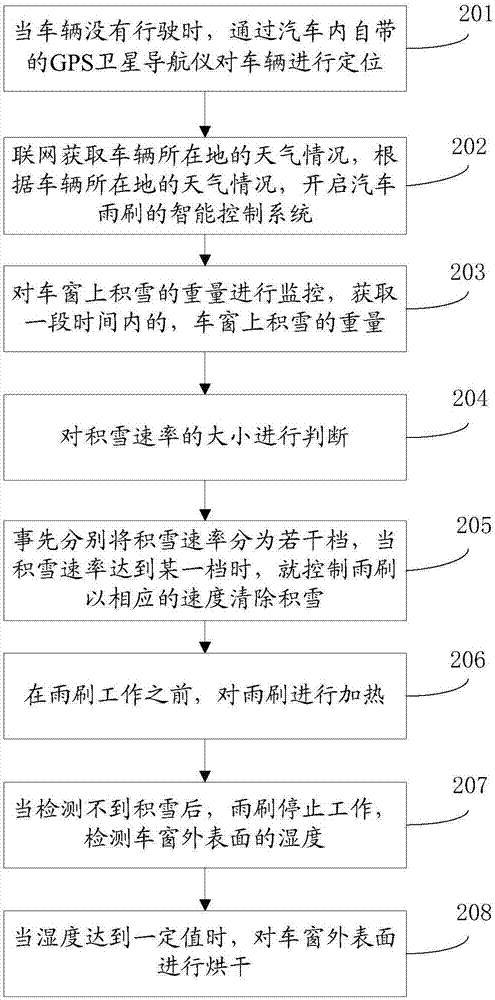

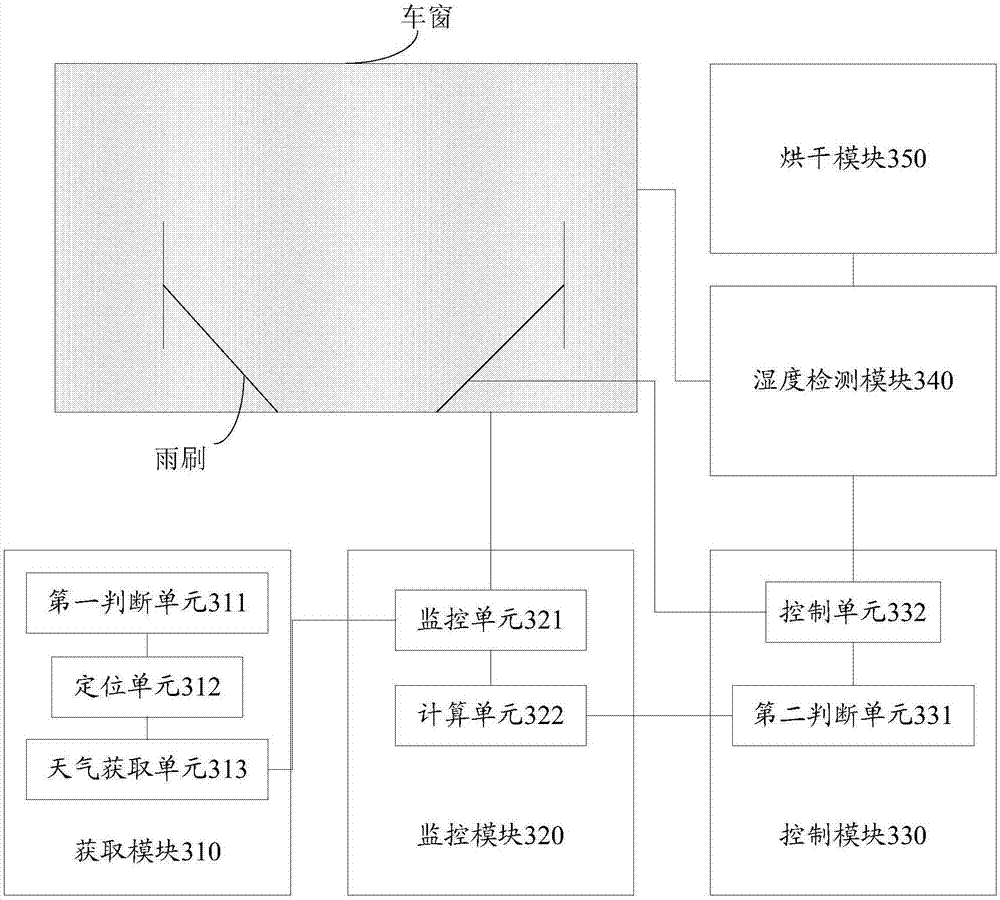

Intelligent control method and system for wiper

The invention relates to an intelligent control method and system for a wiper. The method comprises the following steps that weather information of the location of a vehicle is acquired; when the weather information is snowfall, snow accumulation condition of the outer surface of a vehicle window is acquired; according to the snow accumulation condition, the wiper is controlled to clean away accumulated snow. According to the intelligent control method and system for the wiper, the accumulated snow on the vehicle window can be cleaned away in time, and freezing of the vehicle window is avoided; furthermore, combing with the weather condition of the location of the vehicle, it can be judged whether to conduct monitoring of the snow accumulation condition on the vehicle window or not, the condition is avoided that the vehicle window is also subjected to monitoring of the snow accumulation condition when no accumulated snow exists, resources can be saved effectively, and the judgment on when to monitor the accumulated snow on the vehicle window can be more accurate.

Owner:郭泽华

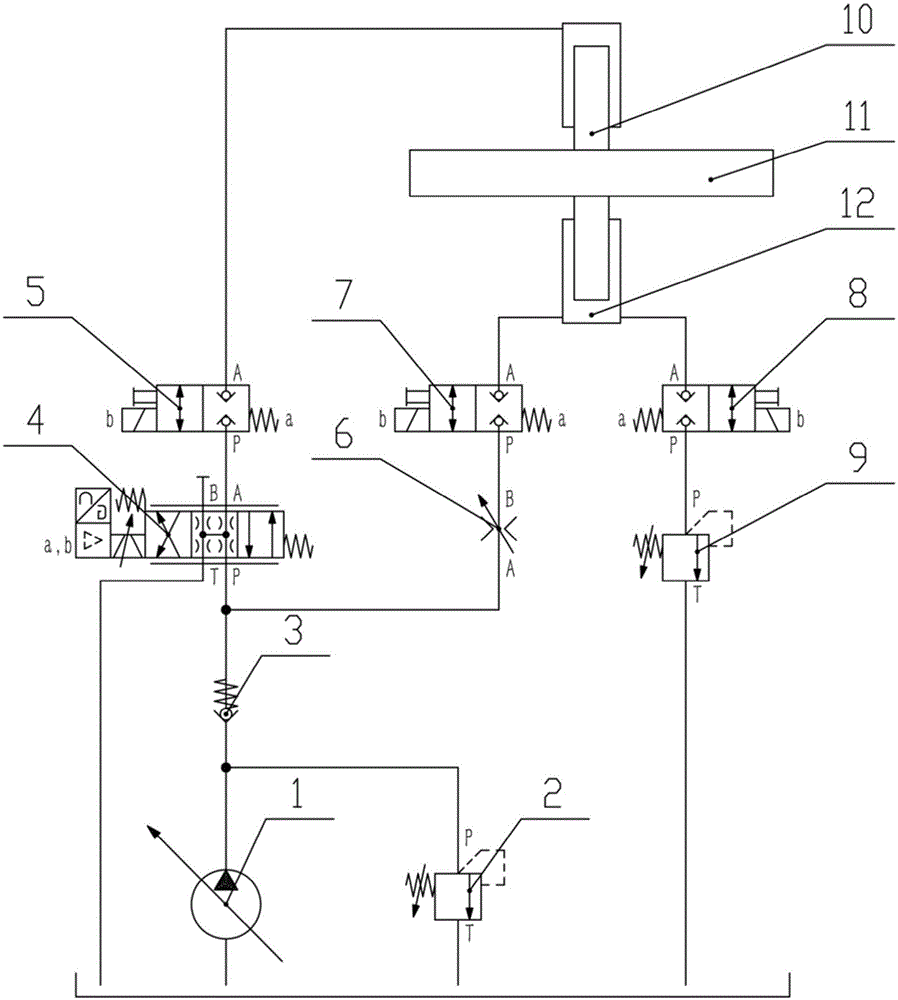

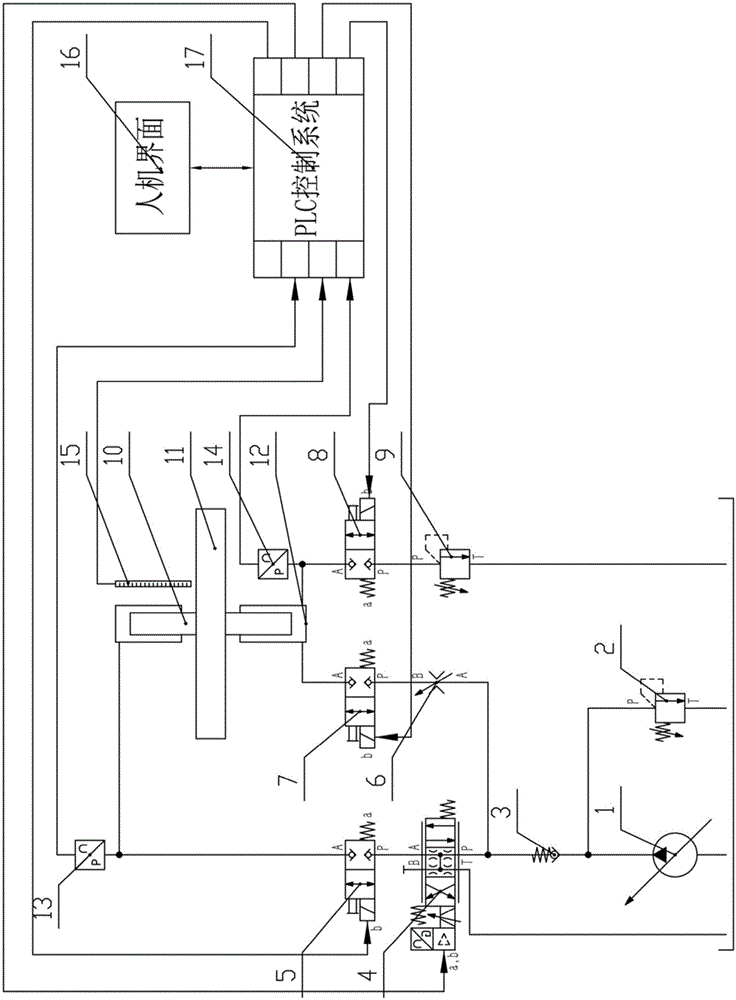

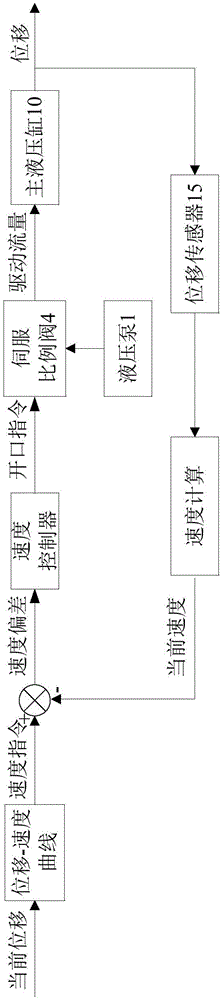

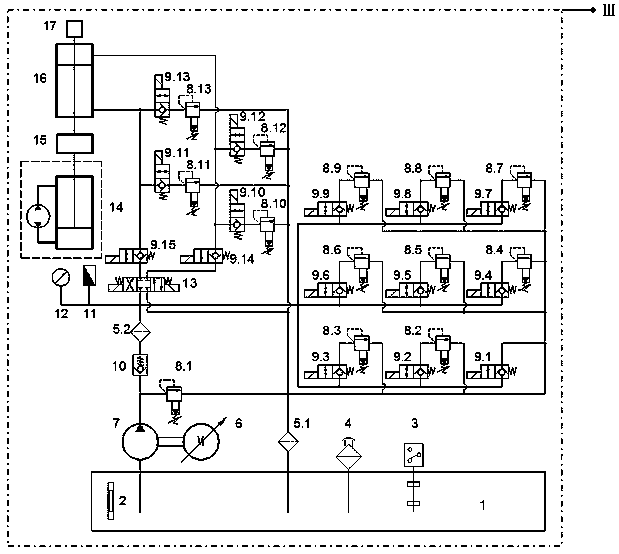

Electro-hydraulic control system capable of achieving ultralow-speed stable running of hydraulic machine

The invention discloses an electro-hydraulic control system capable of achieving ultralow-speed stable running of a hydraulic machine. The electro-hydraulic control system mainly comprises a hydraulic pump, an overflow valve, a check valve, a three-way flow control valve, a first two-way ball valve, an adjustable fluidic resistor, a second two-way ball valve, a third two-way ball valve, a supporting valve, a main hydraulic cylinder and a return cylinder. At the ultralow-speed feeding stage of the hydraulic machine, the electro-hydraulic control system has a route of hydraulic oil entering the return cylinder through the hydraulic pump, the check valve, the adjustable fluidic resistor and the second two-way ball valve all the time, and therefore a certain opening can still be kept at the ultralow-speed feeding stage of the hydraulic machine, the unstable phenomenon that the hydraulic oil is intermittent when the flow is too small is avoided, and stability of the ultralow-speed running of the hydraulic machine is ensured. The three-way flow control valve is arranged on an oil inlet route of the main hydraulic cylinder, and therefore the oil inlet flow of the main hydraulic cylinder can be effectively controlled at the ultralow-speed feeding stage, and it is ensured that the hydraulic machine can run according to a preset displacement-speed curve or a displacement-pressing force curve.

Owner:ZHEJIANG UNIV

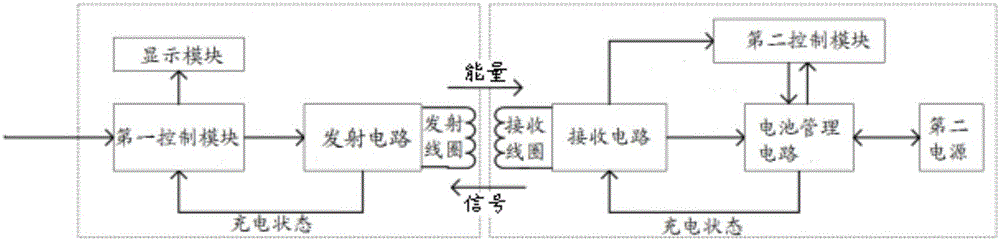

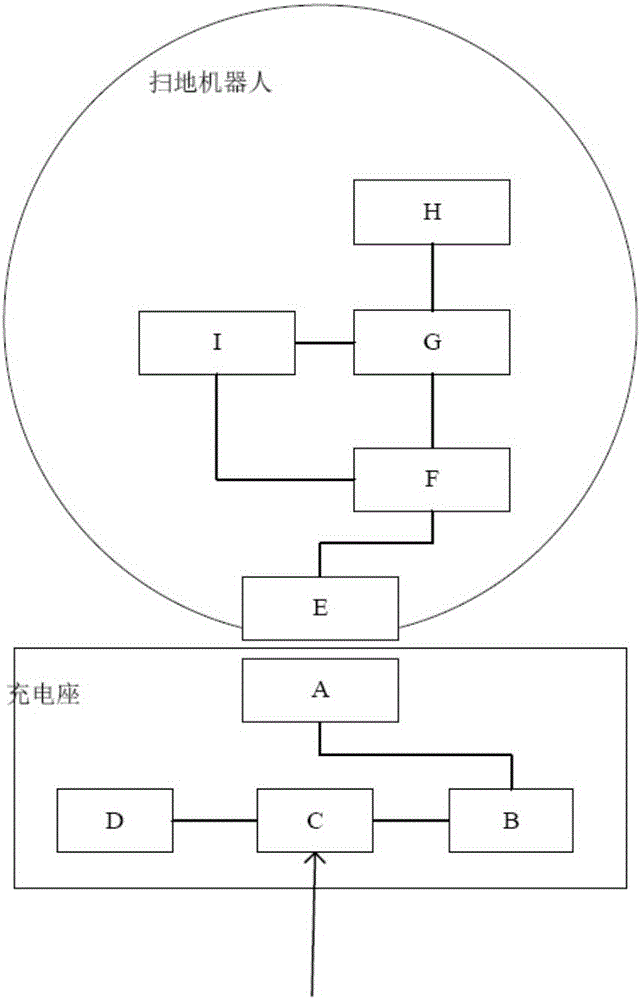

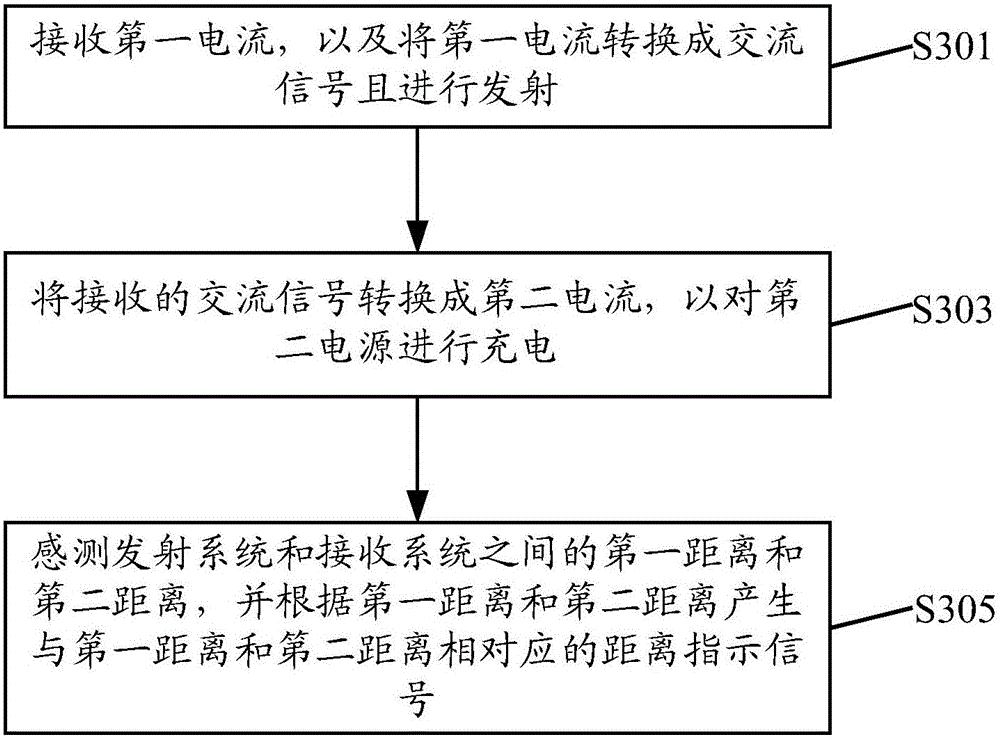

Wireless charging system, method and sweeping robot

InactiveCN105978114ARealize contactless chargingSolve the disadvantages of exposed charging contactsBatteries circuit arrangementsElectric powerPower flowControl system

The present invention proposes a wireless charging system, method, and sweeping robot. The wireless charging system includes: a transmitting system, including a first control module, used to control a first power supply, and provide a first current; a transmitting module, used to receive The first current, and convert the first current into an AC signal and transmit it; the receiving system, including a receiving module, is used to receive the AC signal, and convert the AC signal into a second current, and according to the distance between the transmitting system and the receiving system Generate an indication signal corresponding to the distance; the second control system is used to receive the second current and the indication signal to charge the second power supply. Through the wireless charging system, the non-contact charging of the sweeping robot can be realized.

Owner:青岛众海汇智能源科技有限责任公司

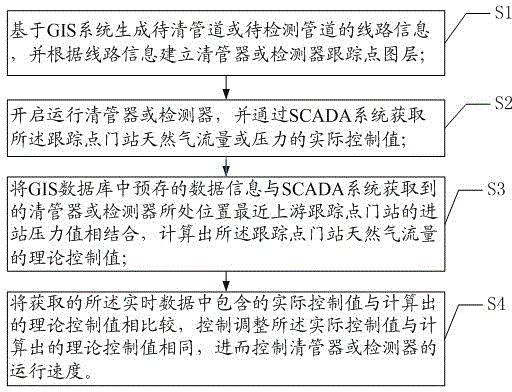

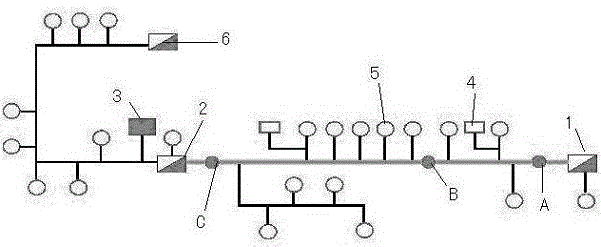

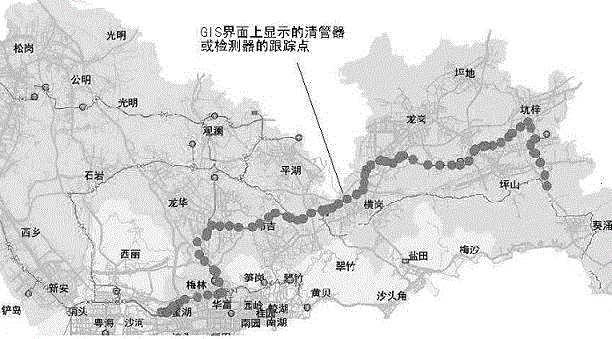

GIS (Geographic Information System)-based operational control method and system for pipeline cleaner or detector

InactiveCN104678856AEffective speed controlControl running speedProgramme controlComputer controlReal time acquisitionData value

The invention provides a GIS (Geographic Information System)-based operational control method and system for a pipeline cleaner or a detector. The operational control method comprises the following steps: acquiring a circuit graph layer of a natural gas pipeline by using a GIS; acquiring natural gas flow data in real time by establishing a pipeline model and using an SCADA (Supervisory Control and Data Acquisition) system; calculating a theoretic flow value of natural gas in the natural gas pipeline; controlling and adjusting the actual control flow value to be equal to the calculated theoretic value according to the actual natural gas flow data value acquired in real time; further controlling the operational speed of the pipeline cleaner or detector. The method and the system realize real-time control of natural gas flow of each trace point gate station of the natural gas pipeline, ensure that the flow data can be reasonably scheduled by detection personnel and further effectively control the operational speed of the pipeline cleaner or detector.

Owner:SHENZHEN GAS CORP

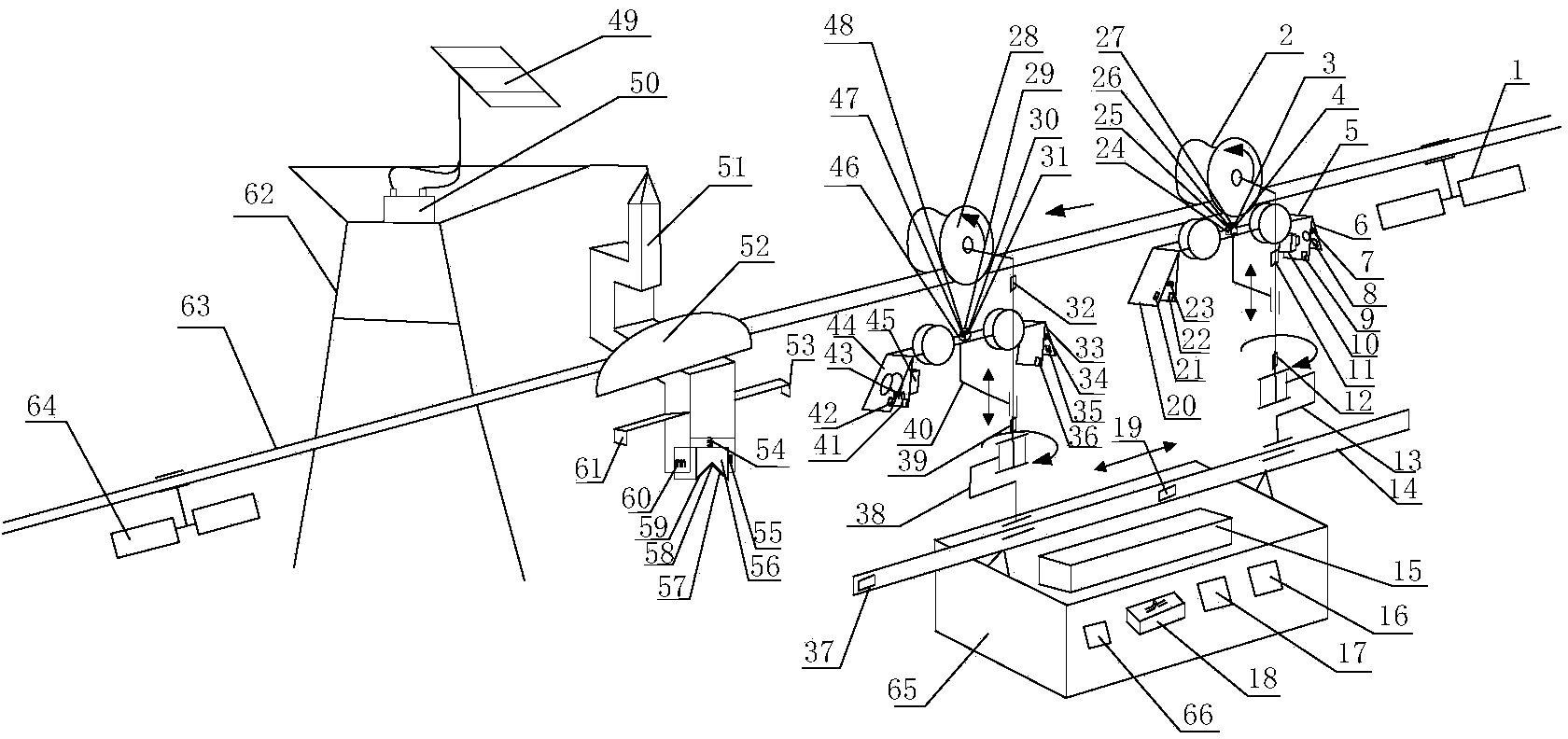

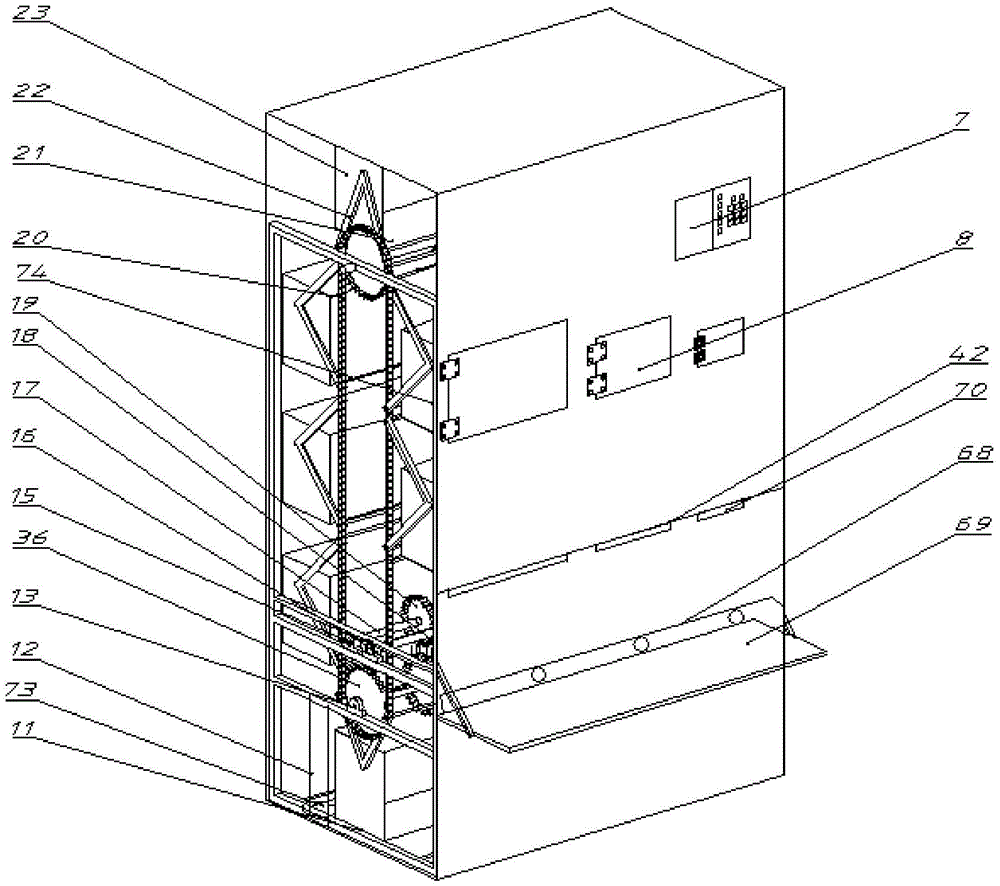

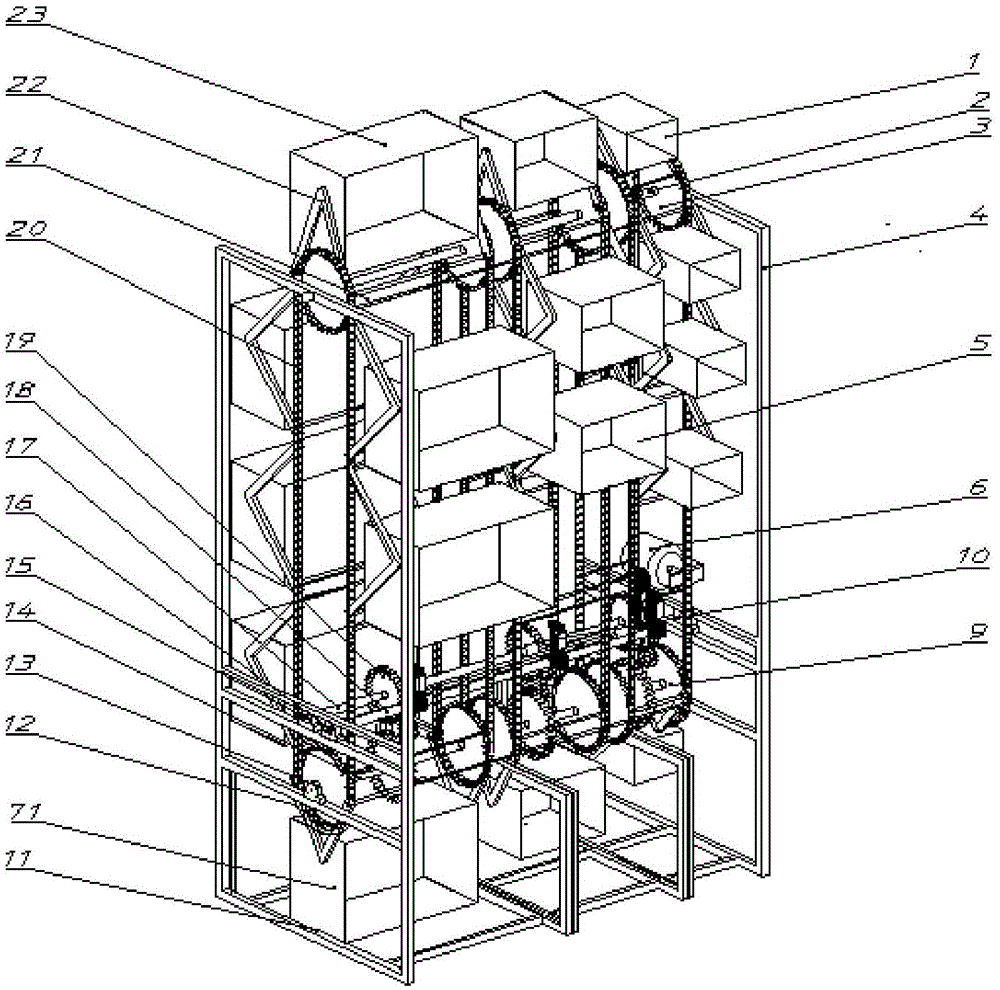

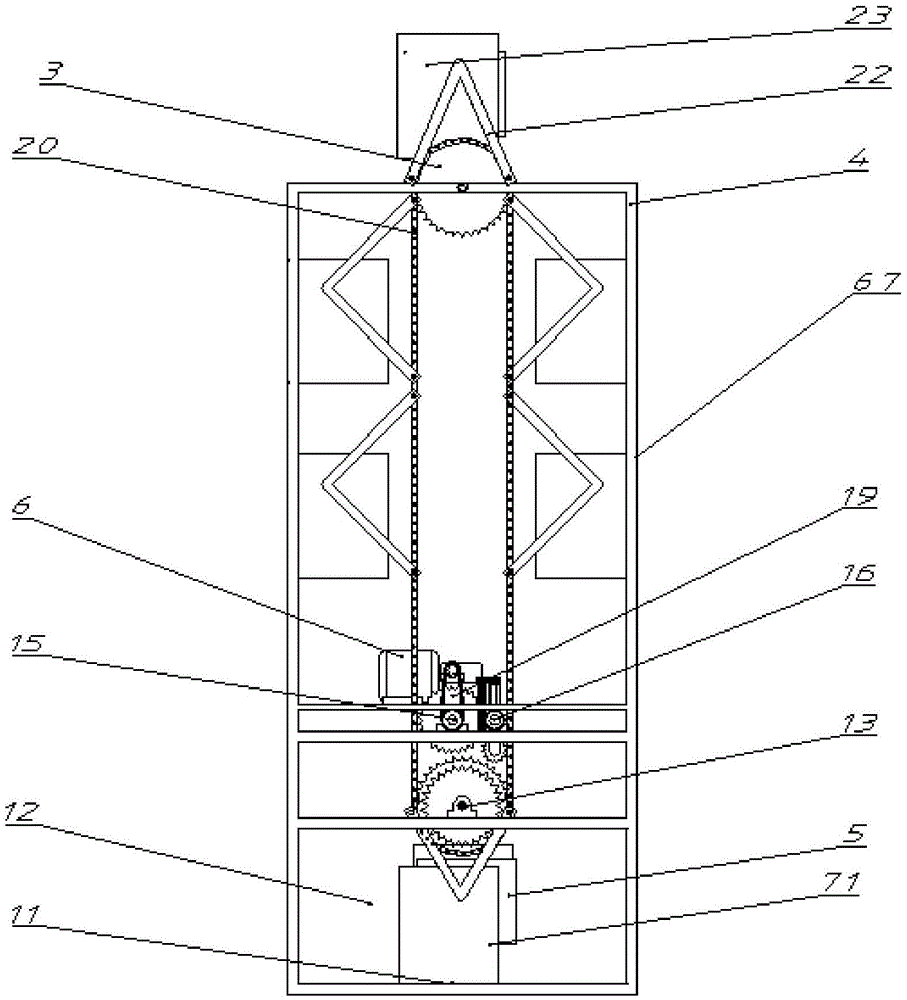

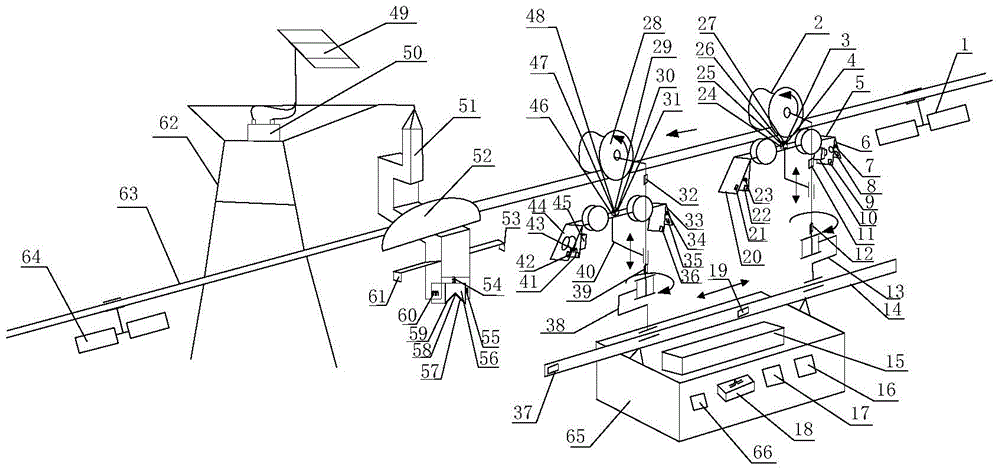

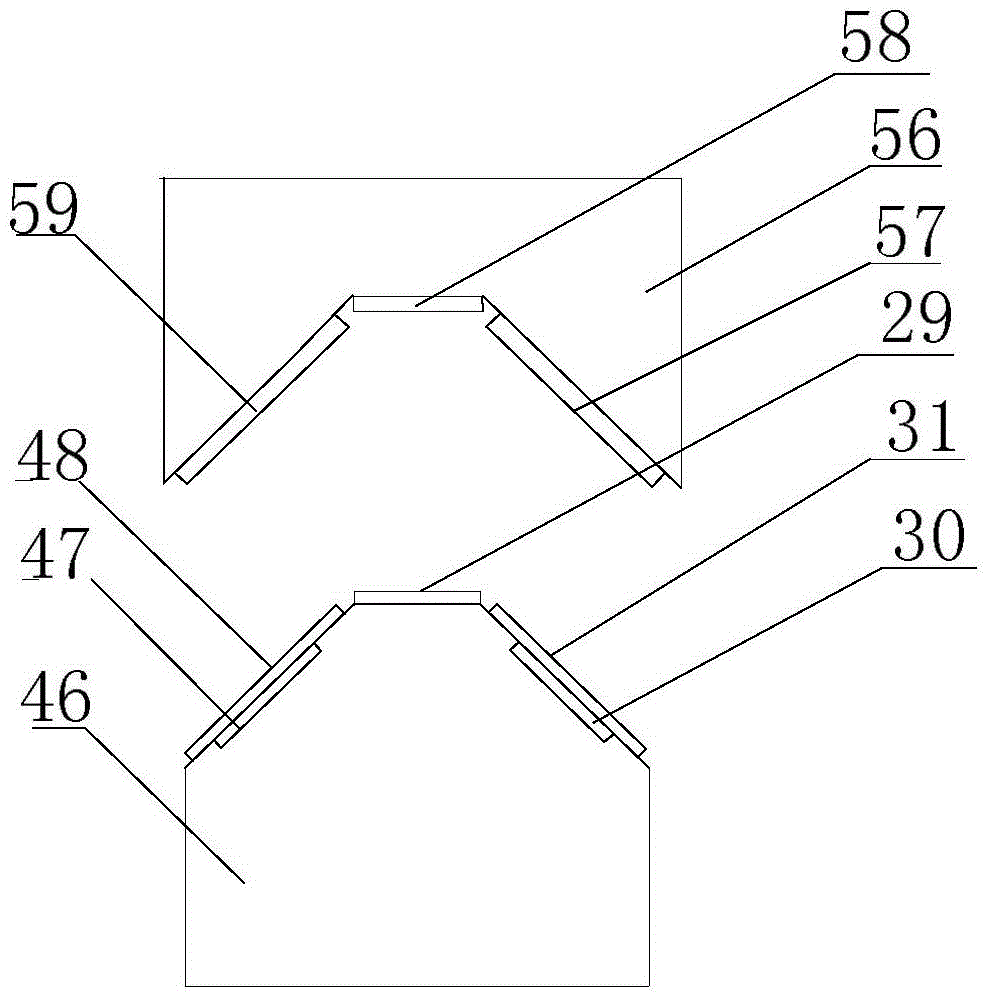

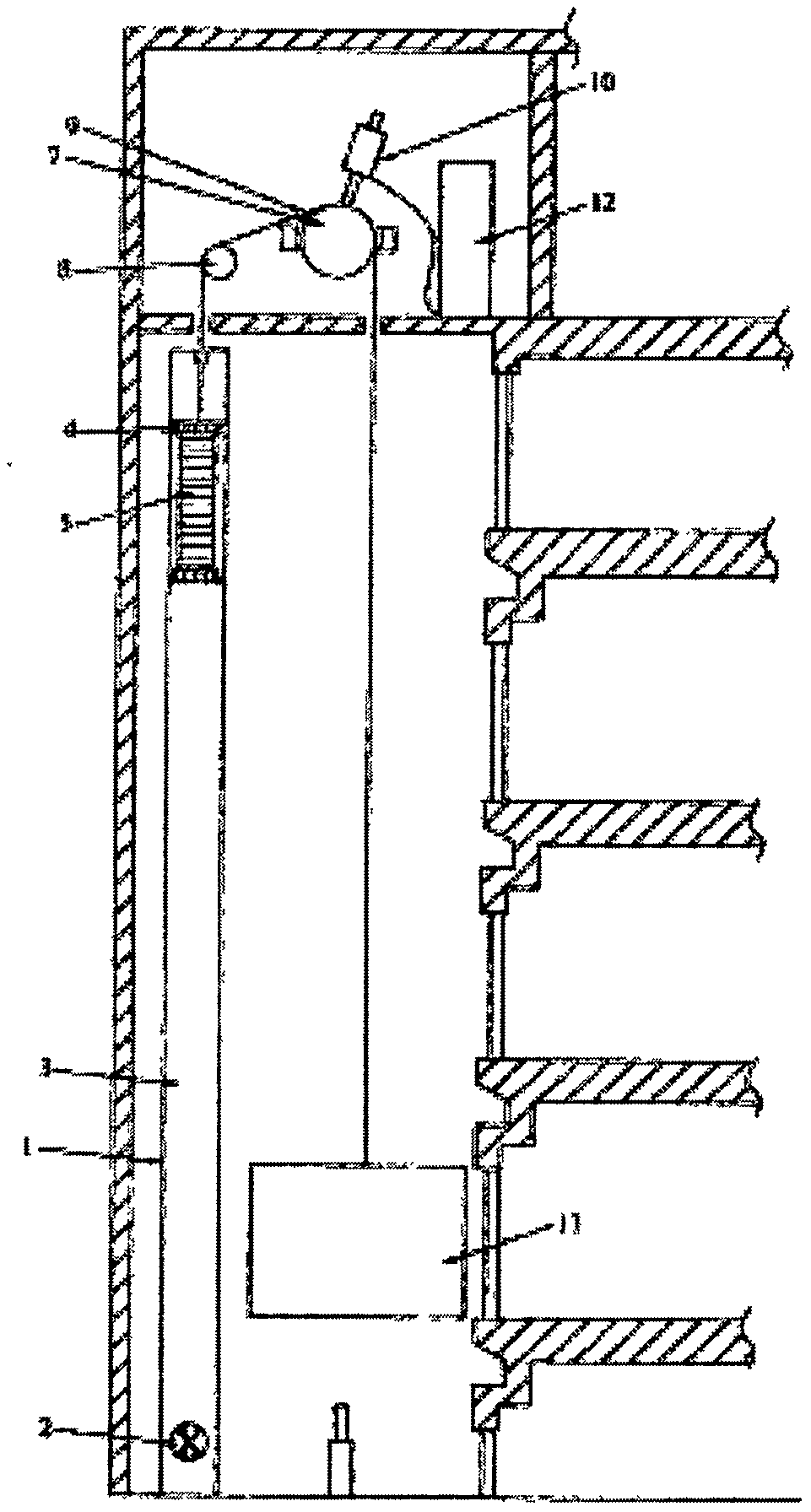

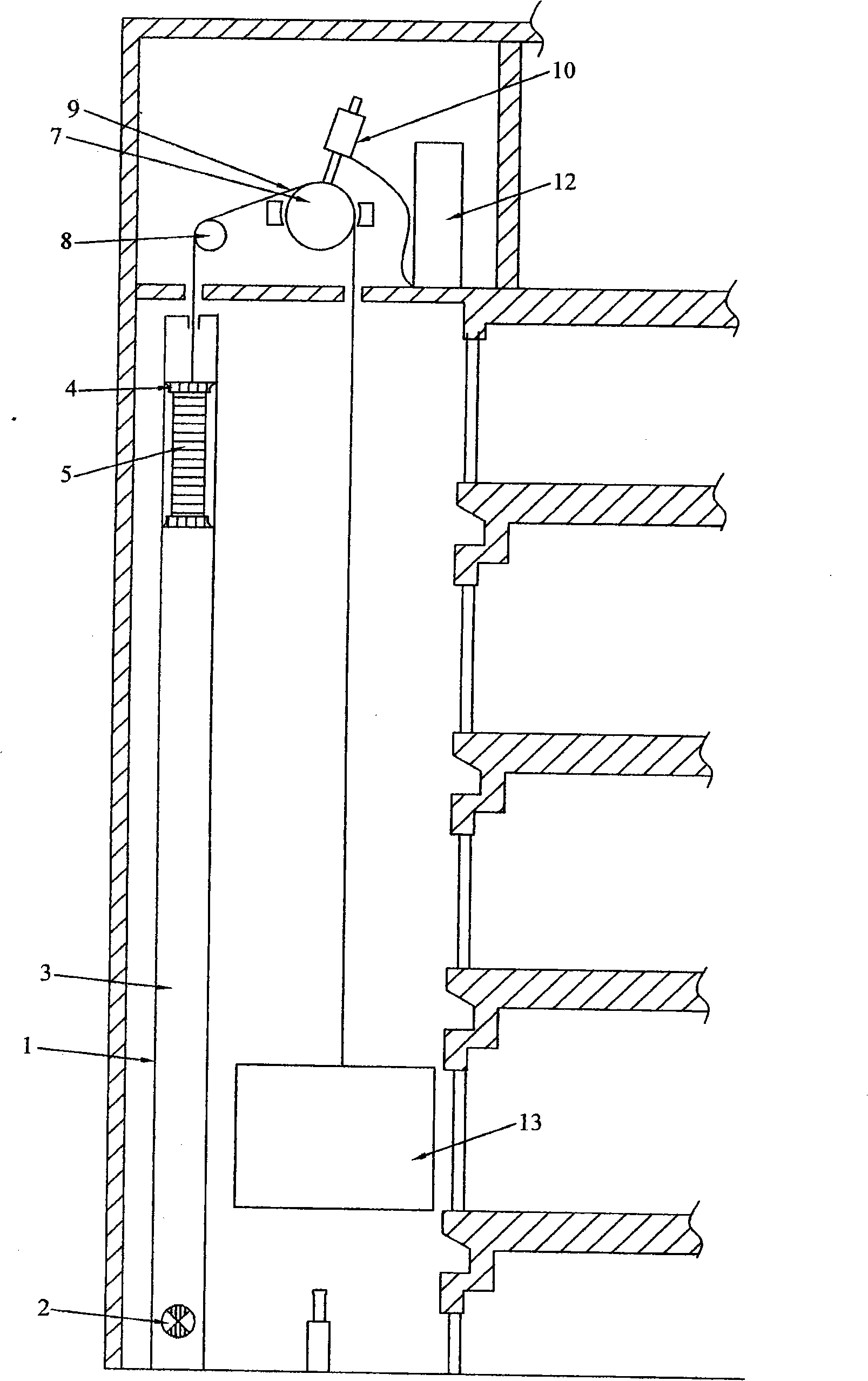

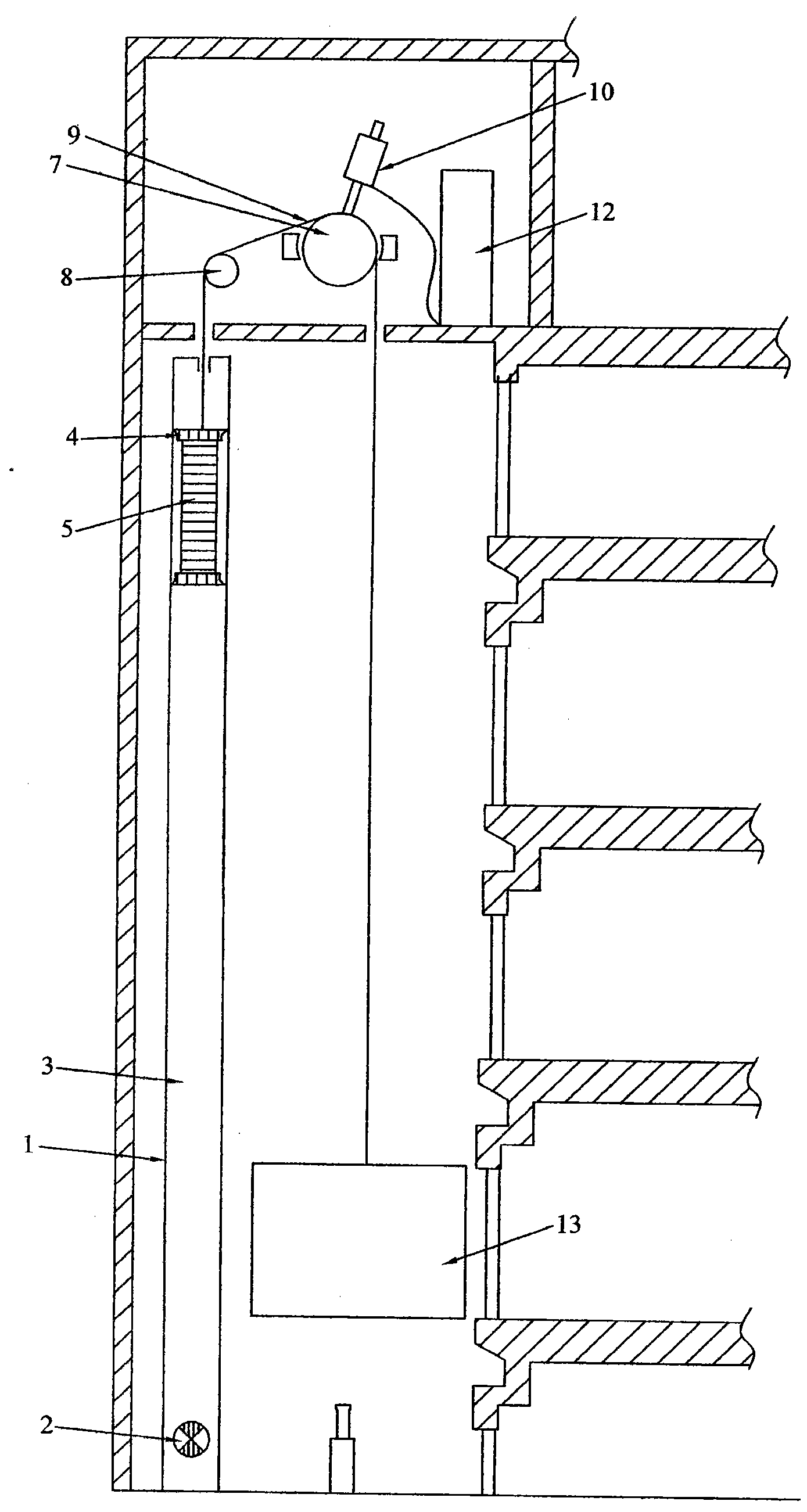

Vertical rotation type automatic filling, positioning and code scanning intelligent express system

ActiveCN105581530AReduce in quantityControl running speedCabinetsLogisticsEngineeringComputer terminal

The invention provides a vertical rotation type automatic filling, positioning and code scanning intelligent express system used for performing filling, code scanning and deposit operation on express items with different sizes through a portable assistant sorting and filling device, an automatic positioning and code scanning device, a power transmission device, a vertical rotation device, a gear meshing control device and an intelligent service terminal. The vertical rotation type automatic filling, positioning and code scanning intelligent express system comprises the power transmission device, the portable assistant sorting and filling device, the automatic positioning and code scanning device, the vertical rotation device, the gear meshing control device and the intelligent service terminal; the power transmission device is installed in the middle of a rack, the automatic positioning and code scanning device is installed at an item inlet, the portable assistant sorting and filling device can be detached and carried on the outer side of the item inlet, the gear meshing control device is located on one side of a motor, and the intelligent service terminal is installed on the left rear portion of the rack.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Rear axle steering valve group, axle steering centering hydraulic control system and vehicle

ActiveCN104564880AControl running speedServomotor componentsSteering controlsThrottle controlControl system

The invention provides a rear axle steering valve group, an axle steering centering hydraulic control system and a vehicle. The rear axle steering valve group comprises a hydraulic control proportional throttle valve, wherein the hydraulic control proportional throttle valve is arranged between an oil source and a first executing mechanism, the hydraulic control proportional throttle valve is provided with a throttle control port which is used for controlling the opening of the hydraulic control proportional throttle valve, the throttle control port is connected with the control oil source, the flow of the control oil source increases along with the increase of the wheel speed, and the opening of the hydraulic control proportional throttle valve is reduced along with the increase of the flow of the control oil source. By adopting the rear axle steering valve group, the running speed of the first executing mechanism can be controlled.

Owner:ZOOMLION HEAVY IND CO LTD

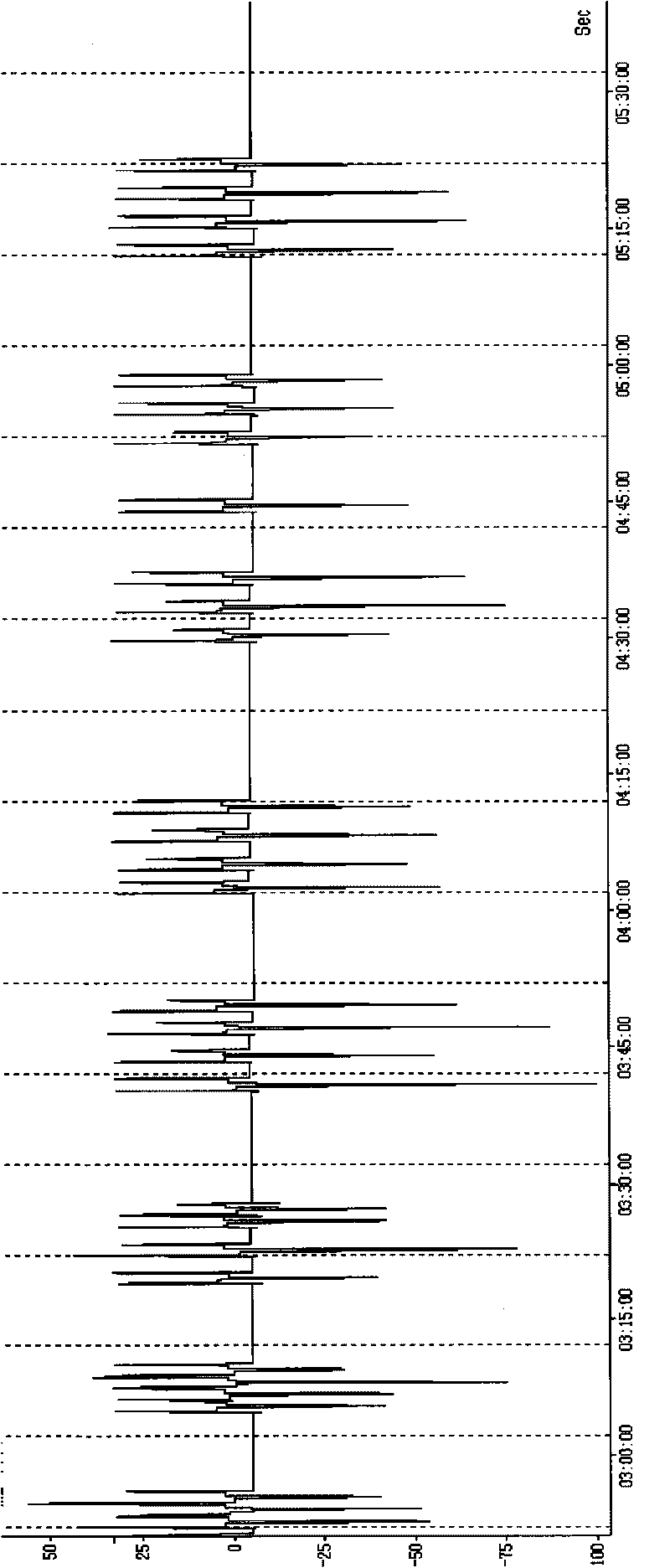

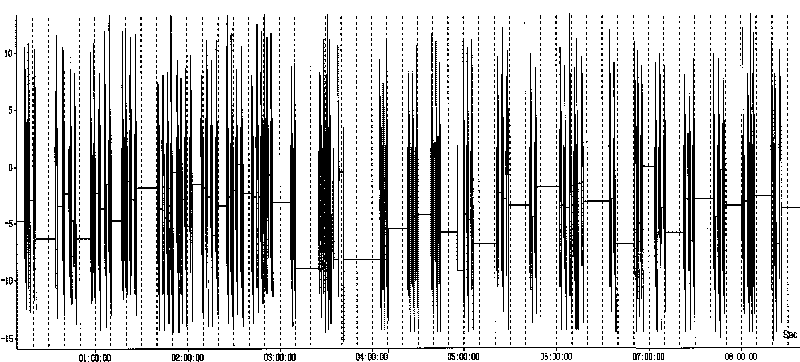

Stepping beam lifting synchronous control method of stepping plate blank heating furnace

InactiveCN101726189AControl running speedReal-time adjustment of lifting speedCharge manipulationControllers with particular characteristicsFailure rateSynchronous control

The invention discloses a stepping beam lifting synchronous control method of a stepping plate blank heating furnace, comprising the following steps of: adjusting the set value of a speed by mainly using a molten steel side beam to ensure that the molten steel side beam completes the corresponding stroke with the set time according to the set speed; using the molten steel side beam as the reference datum for the lifting of a finished steel side beam, obtaining the position differential of the two beams according to the measuring valve of a displacement sensor, and then calculating the speed compensating value of the finished steel side beam; using the speed compensating value outputted by a PID controller as the output of a PLC and correcting the lifting speed of the finished steel side beam in real time so that the finished steel side beam follows the molten steel side beam in real time, and then realizing the synchronous running of the lifting. In the invention, the position differential of the two beams is controlled within 10 millimeters so that the heating quality of the plate blank is ensured, and then the stepping beam is protected. Meanwhile, the invention reduces the failure rate, reduces the maintenance time of equipment, enhances the heating efficiency, lowers the cost and increases the benefits.

Owner:NANJING IRON & STEEL CO LTD

Magnetic suspension electric automobile

InactiveCN102152745AImprove powerControl running speedElectric propulsionControl devicesClutchVehicle frame

The invention discloses a magnetic suspension electric automobile which comprises a rear wheel magnetic suspension bearing driving system, a front wheel magnetic suspension bearing system and a detection control system, wherein the rear wheel magnetic suspension bearing driving system comprises an axial magnetic suspension rear differential (1), a power magnetic suspension bearing (2), a rear speed governing clutch, a rear semiaxis and a rear wheel; the front wheel magnetic suspension bearing system comprises an axial magnetic suspension front differential (6), a radical magnetic suspension bearing (7), a front speed governing clutch, a front semiaxis and a front wheel; the detection control system comprises a controller (8) and a sensor. The magnetic suspension electric automobile realizes no friction and no abrasion bearing between the semiaxis and the frame, and directly drives the semiaxis to rotate so as to drive the wheels through an electromagnetic torque, shortens a transmission chain, and improves the drive efficiency; therefore, the energy consumption is obviously reduced, and the power property of the electric automobile is improved.

Owner:YANGZHOU UNIV

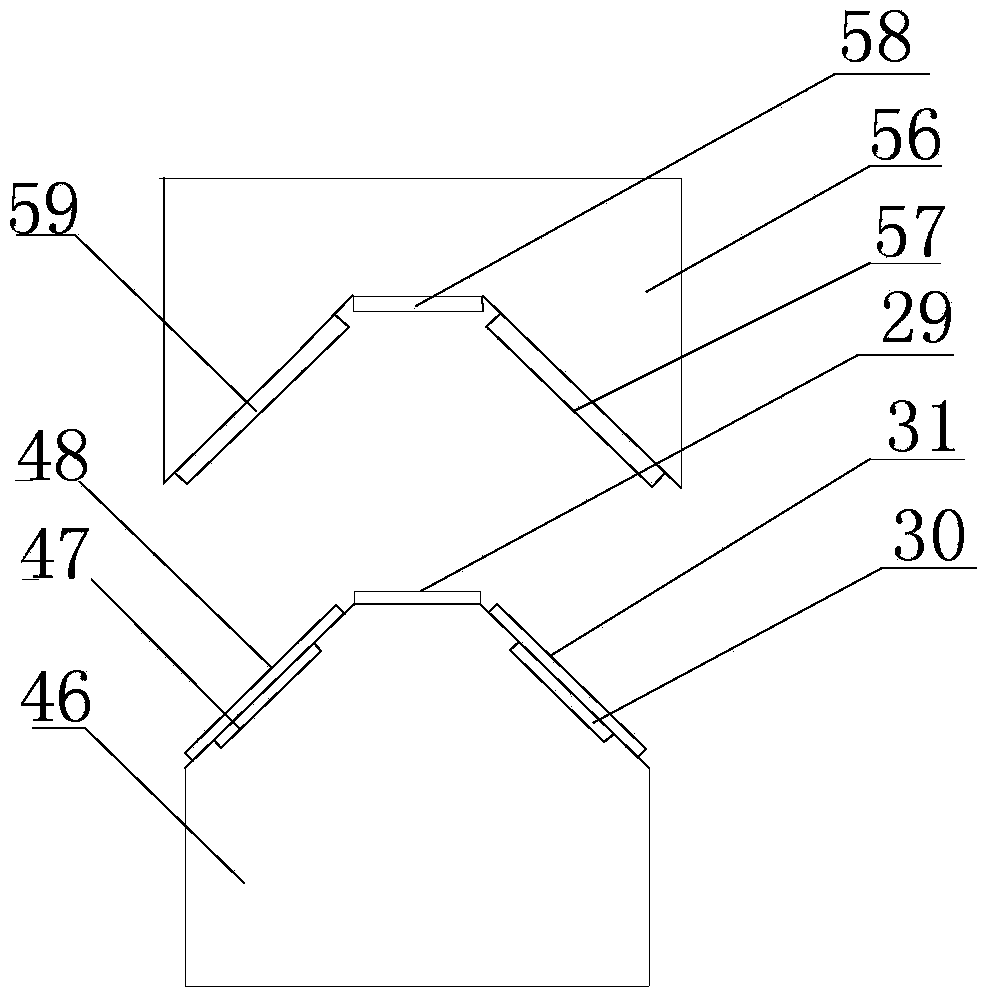

Film-coating pipe cleaner with emergency start-up system

ActiveCN106890748AGuaranteed quantityGuaranteed thicknessFluid pressure control using electric meansLiquid spraying apparatusThermodynamicsProcess engineering

The invention discloses a film-coating pipe cleaner with an emergency start-up system, and relates to the technical field of pipeline operation. The emergency start-up system is designed, so that the pipe cleaner can be guaranteed to restore operation under a working condition that a speed control device loses efficacy; three sets of speed control devices are arranged, so that operation speed of the pipe cleaner is controlled by regulating a bypass area; a corrosion inhibitor collecting spraying system is designed, so that the system is used for collecting a corrosion inhibitor settled on the bottom of the pipe cleaner and performing secondary spraying, and therefore, amount of the corrosion inhibitor on the top of a pipeline is increased; a pressure induction device is designed for judging whether the pipe cleaner is blocked or not as a result of a too great bypass area in the pipeline; a spray head is designed, so that the molecular particle size of the corrosion inhibitor sprayed out from the spray head is small, and a film is easily formed on the top of the pipeline. The film-coating pipe cleaner with the emergency start-up system disclosed by the invention can control the speed of the pipe cleaner, can prevent the pipe cleaner from being blocked due to the fact that the speed control device loses efficacy, and can be used for collecting the corrosion inhibitor settled on the bottom of the pipeline, and spraying the corrosion inhibitor for a second time in a comparatively ideal mode.

Owner:SOUTHWEST PETROLEUM UNIV

FPC feeding robot

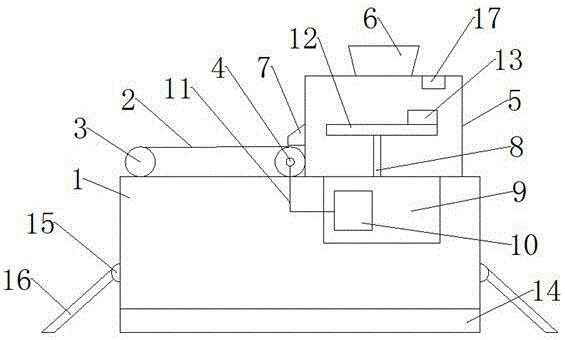

ActiveCN105775665AThe device is compactSimple design principleConveyorsControl devices for conveyorsDrive motorManufacturing efficiency

The invention discloses an FPC feeding robot. The FPC feeding robot comprises a rack and a conveying belt. The conveying belt is arranged on the rack. Conveying wheels are arranged in the conveying belt. A rotating speed sensor is arranged on one conveying wheel. A bin is arranged at the right ends of the conveying wheels. A feeding hopper is arranged at the upper end of the bin, and a discharging hopper is arranged at the lower end of the bin. A push rod is arranged in the bin. A drive motor is connected to the lower end of the push rod. The drive motor is provided with a frequency modulation speed changer connected with the rotating speed sensor through a wireless network. A material supply tray is arranged at the upper end of the push rod. A material pushing device is arranged on the material supply tray. The whole device is compact in structure, the design principle is simple, very high using value is achieved, and FPC feeding can be well finished. The FPC manufacturing efficiency is greatly improved, the FPC feeding robot can well adapt to different feeding speeds for material supply, a very high automation degree and a very high intelligent degree are achieved, and the FPC feeding robot is worthy of popularization.

Owner:华粹智能装备有限公司

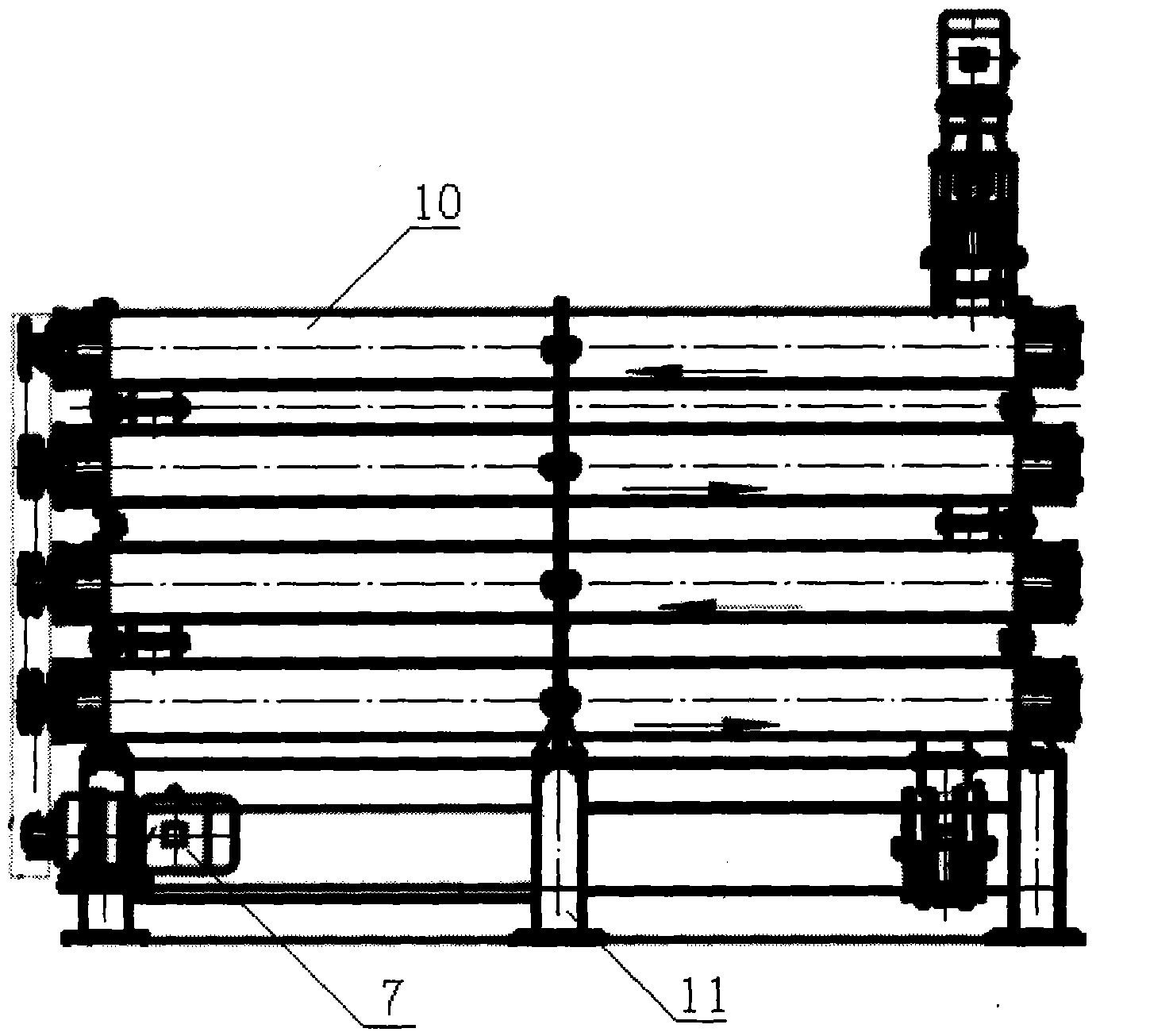

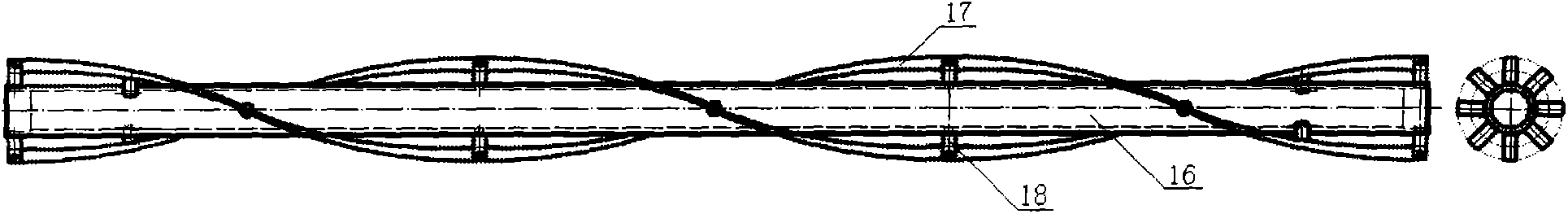

Continuous plasticizing production device and method

The invention relates to a continuous plasticizing production device. The continuous plasticizing production device is characterized in that a heat preserving and maintenance stranding cage set is arranged between a heating plasticizing stranding cage set and a cooling stranding cage set and communicated with the two sets; rubber powder conveying parts arranged in the heating plasticizing stranding cage set, the heat preserving and maintenance stranding cage set and the cooling stranding cage set are composed of rotating shafts and screw blades, wherein the screw blades are connected to the rotating shafts; and the screw blades and the rotating shafts are arranged at a certain spacing. According to the method, the plasticizing of the rubber powder is carried out in three process steps of heating, heat preserving and maintenance, and cooling. The method is characterized in that the rubber powder is uniformly heated, and the heated rubber powder is subjected to heat preserving and maintenance, thus the performance of reclaimed rubber can be recovered, and the plasticizing effect is greatly improved; the designed screw blades of the stranding cage enables sufficient agitating and conveying of the rubber powder in the heating, heat preserving, cooling and other working areas; and particularly the rubber powder is difficulty adhered to the rubber conveying parts.

Owner:张兴和

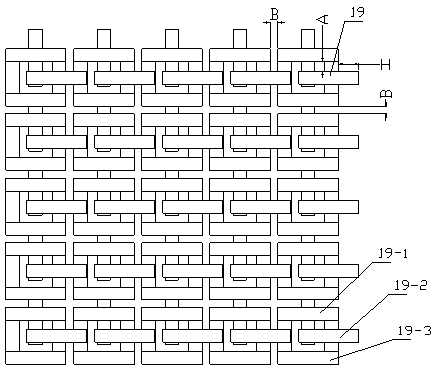

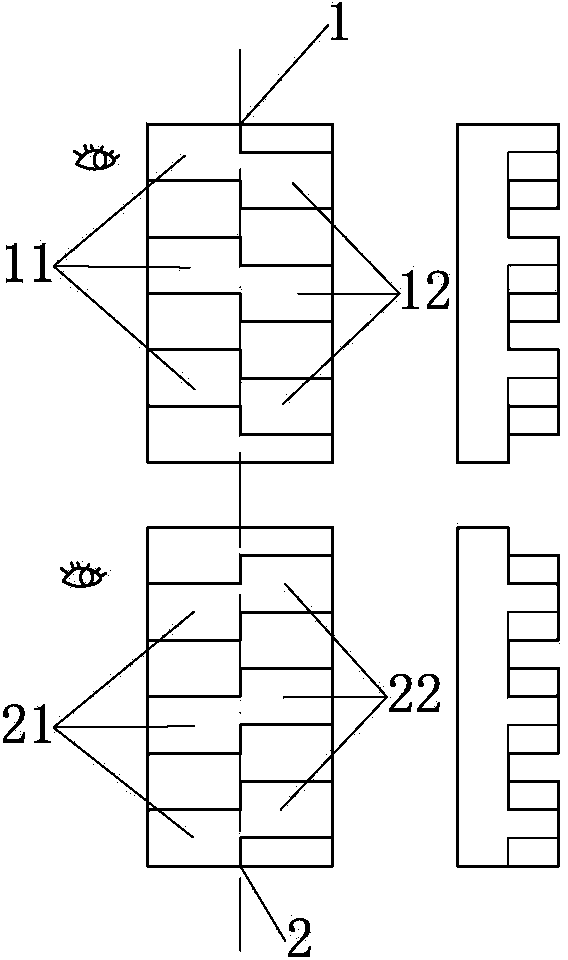

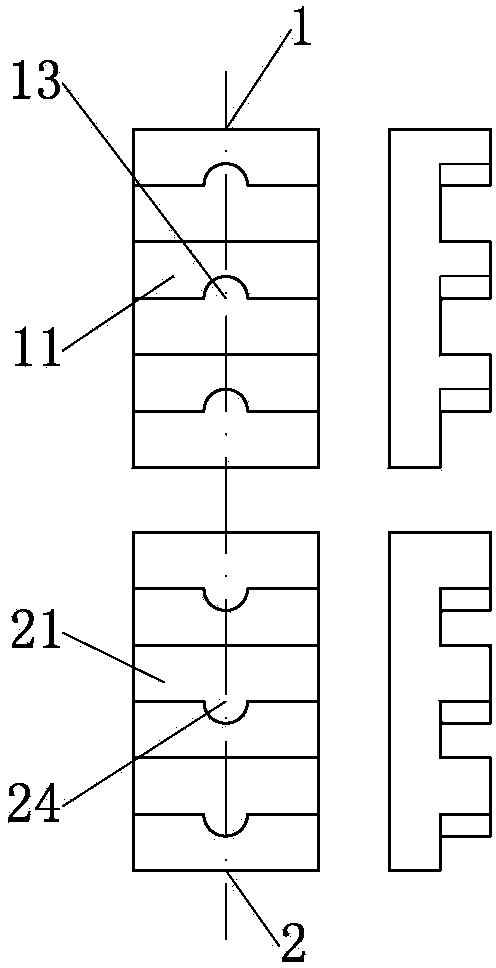

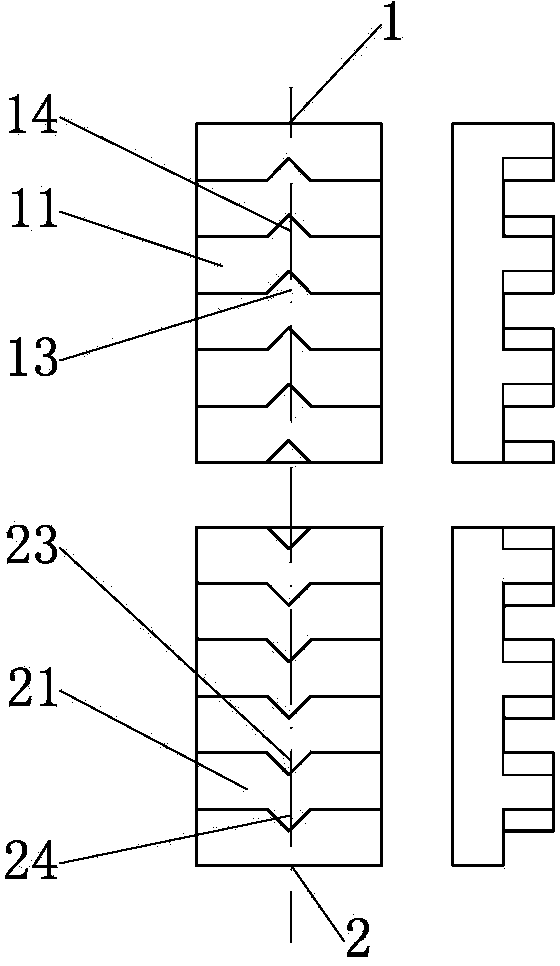

Gear tooth structure of gear, gear pump with gear tooth structure and fluid transmission device with gear pump

InactiveCN103742626AReduce wearPrevent axial relative slidingPortable liftingRotary piston pumpsIsosceles trapezoidGear pump

The invention discloses a gear tooth structure of a gear, gear pump with the gear tooth structure and a fluid transmission device with the gear pump. The gear tooth structure of the gear is characterized in that an anti-slipping structure which prevents gears meshed with each other from slipping relatively along the axial direction is arranged on a gear tooth side surface of a spur gear or a gear tooth side surface of a one-way bevel gear. By using the anti-slipping structure, gear teeth of the gears meshed with each other can be prevented from slipping relatively along the axial direction, and abrasion on the gear teeth of the gears is greatly reduced. The gear pump is provided with at least one double-face gear with inner teeth and outer teeth. The flow of each rotating cycle of the gear pump can be greatly increased under the condition that the size of a pump body of the gear pump is slightly increased. The cross section of each blade of a blade type fluid motor in the fluid transmission device is in the shape of an isosceles triangle or an isosceles trapezoid. The blades are not easy to break, the radial elasticity of the blades can be improved, the airtightness of space between the top of each blade and a shell is improved, and the revolving speed of the fluid motor can be increased.

Owner:谭奇万

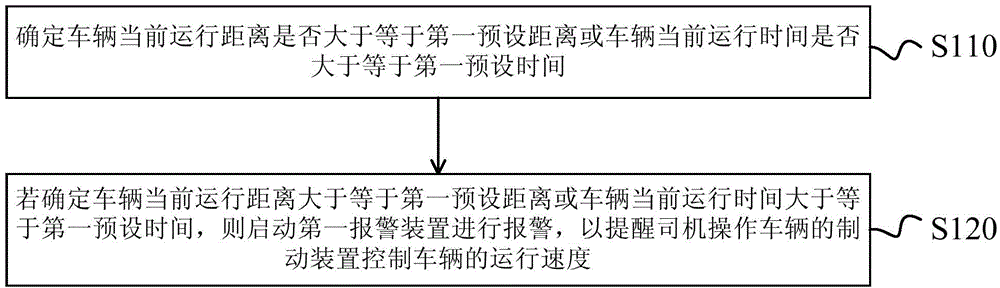

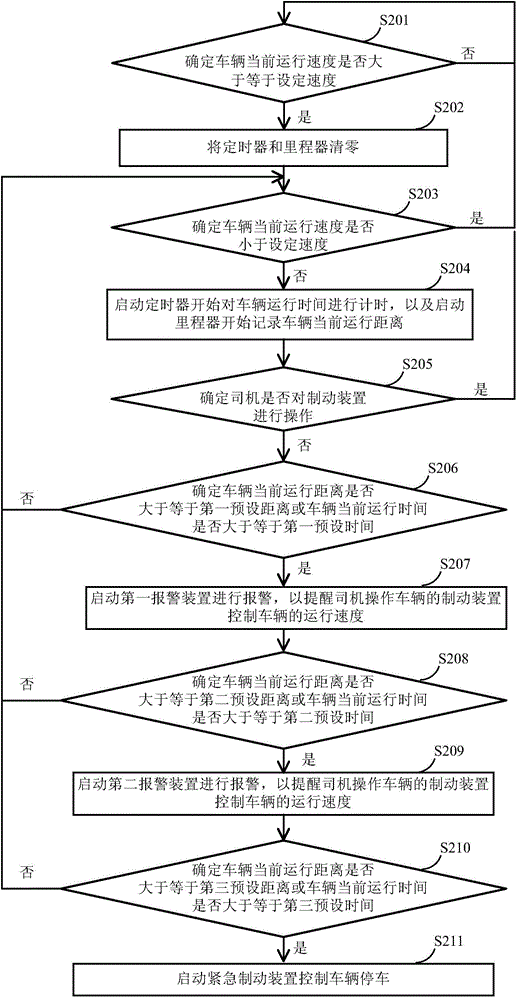

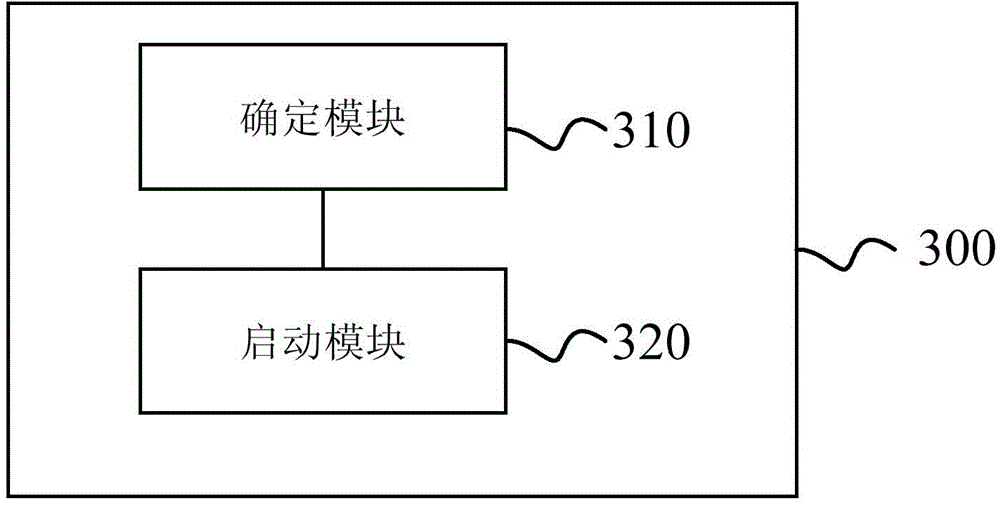

Fool-proof control method and device

The invention provides a fool-proof control method and device. The fool-proof control method includes the steps that whether the current running distance of a vehicle is longer than or equal to a first preset distance or not is confirmed or whether the current running time of the vehicle is longer than or equal to first preset time or not is confirmed; andif it is confirmed that the current running distance of the vehicle is longer than or equal to the first preset distance or the current running time of the vehicle is longer than or equal to the first preset time, a first alarm device is started to give an alarm to remind a driver to operate a brake device of the vehicle to control the running speed of the vehicle. Therefore, the problem that the driver cannot be effectively reminded in the prior art is solved, the driver is reminded through the alarm device, and the situation of negative action of the driver is prevented.

Owner:CRRC DALIAN R & D CO LTD

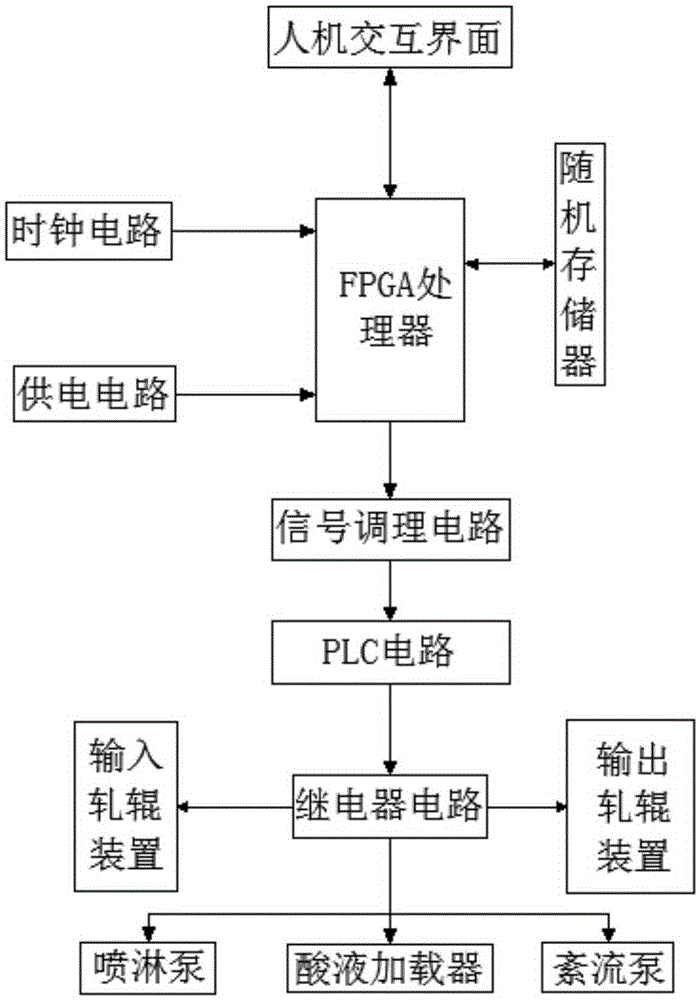

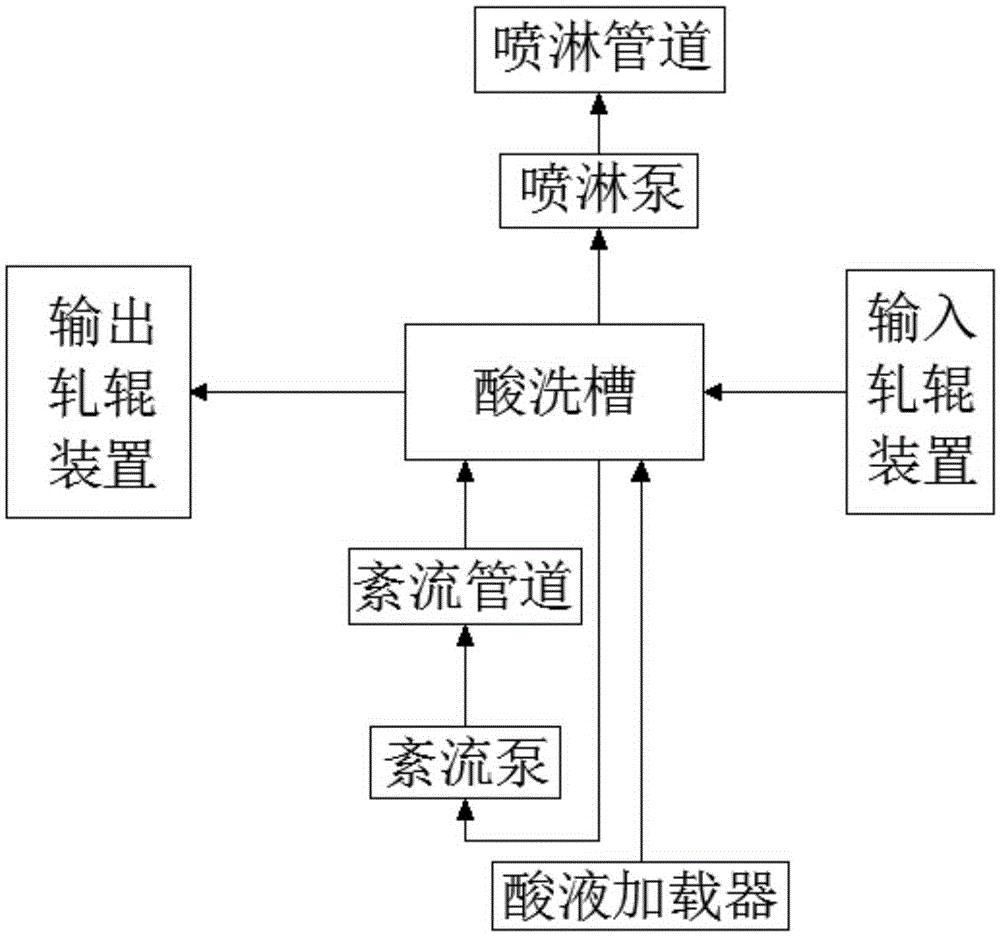

Strip steel pickling system with spraying system

The invention discloses a strip steel pickling system with a spraying system. The strip steel pickling system with the spraying system comprises a strip steel pickling device and a control system connected with the strip steel pickling device. A field programmable gate array (FPGA) processor, a power supply circuit, a storage circuit and a signal processing circuit are arranged in the control system. The FPGA processor is connected with the power supply circuit, the storage circuit and the signal processing circuit. The signal processing circuit is connected with the strip steel pickling device. Strip steel is pickled by combining the spraying system with a turbulent flow system so that the surface state of the surface, in an acid tank, of a steel plate can be improved, iron oxide skin on the surface of the steel plate can be fully pickled, no iron oxide skin exists on the surface of the pickled steel plate, the surface of the plate is bright, and the quality is stable; in addition, the intelligent control system is used for controlling the pickling process and the fluidity of acid liquor in the pickling tank, the pickling process and the operation of the strip steel are managed synchronously, and the strip steel is pickled optimally.

Owner:CHONGQING GUANGJI IND

Running machine

InactiveCN105288948AReduce frictionEasy running fitnessMovement coordination devicesCardiovascular exercising devicesEngineeringFriction force

The invention discloses a running machine which comprises a rack. The running machine further comprises a universal running plate, rollers and a running belt. The universal running plate comprises a plate body and a plurality of universal balls arranged on the plate body. The rollers comprise the front roller arranged in front of the front end face of the universal running plate and the rear roller arranged in front of the rear end face of the universal running plate. The running belt wraps the universal running plate and the rollers. Due to the fact that the universal balls are adopted in the universal running plate, friction force between the running belt and the universal running plate is greatly reduced; the universal balls are spherical, and borne pressure can be evenly distributed to all the balls; the multiple universal balls are arranged on the plate body, the distance between the running belt and the universal running plate cannot change along with movement of the running belt, and therefore a runner can do running exercises easily and freely, the running speed of the runner can be controlled, the runner can stop and walk at will, and the safety of the running machine is greatly improved.

Owner:四川工业科技学院

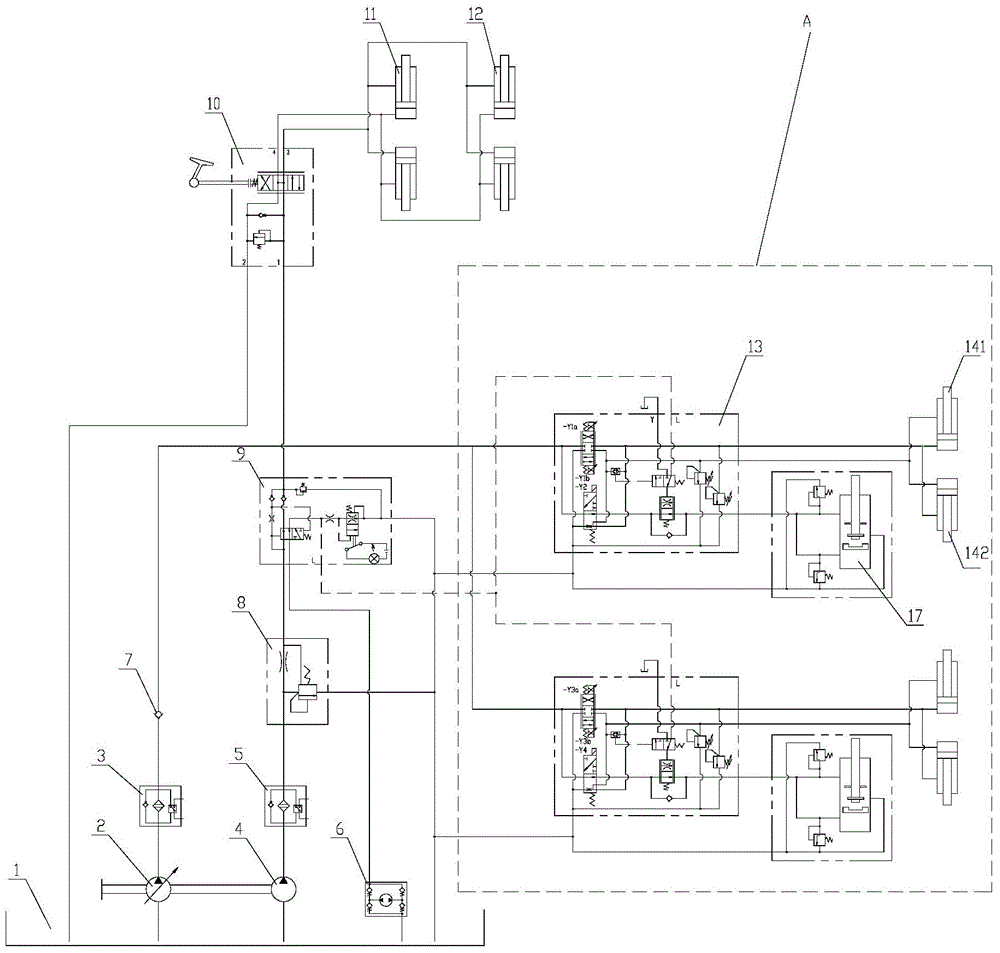

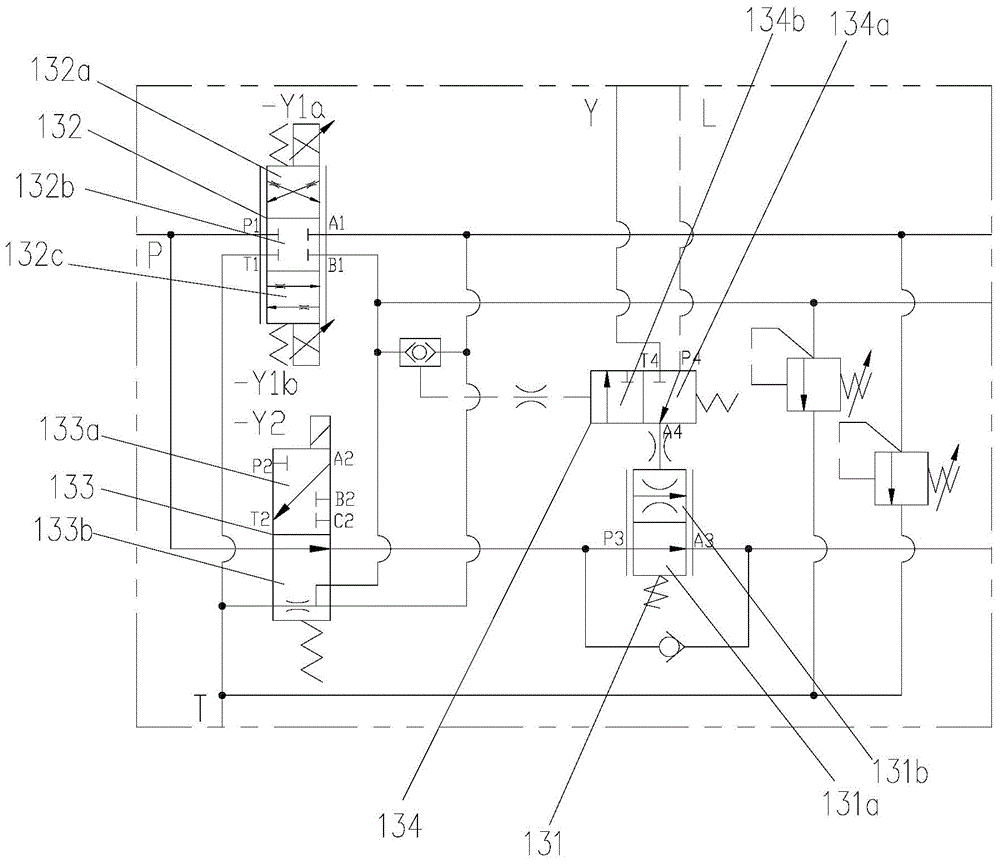

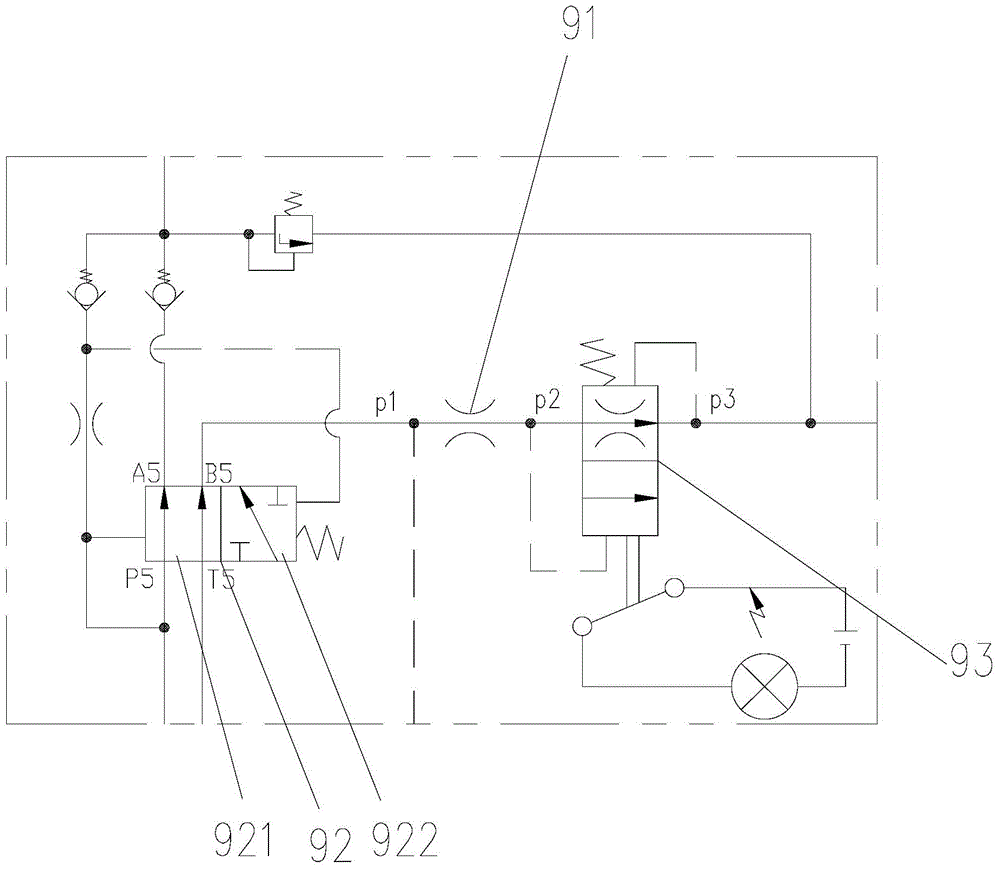

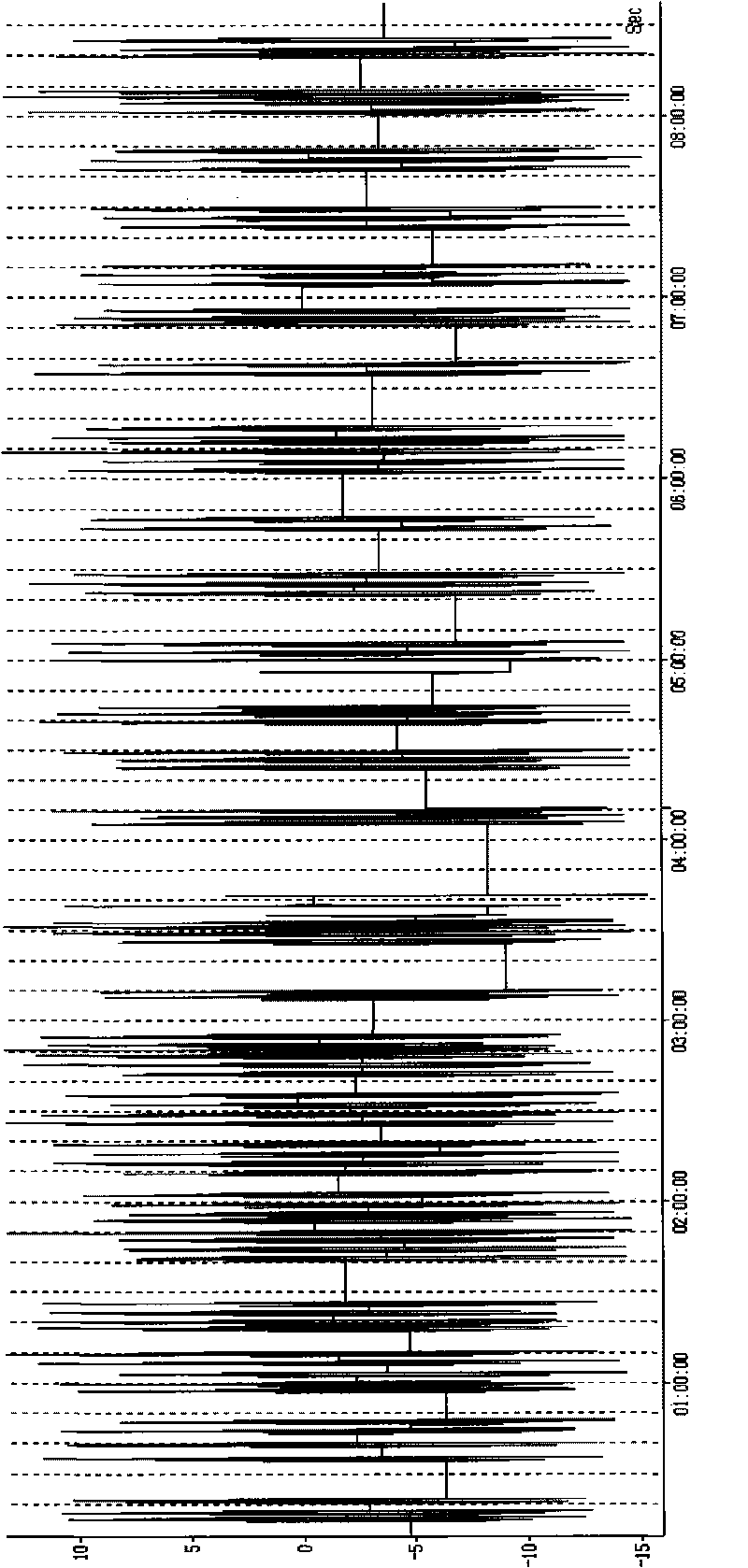

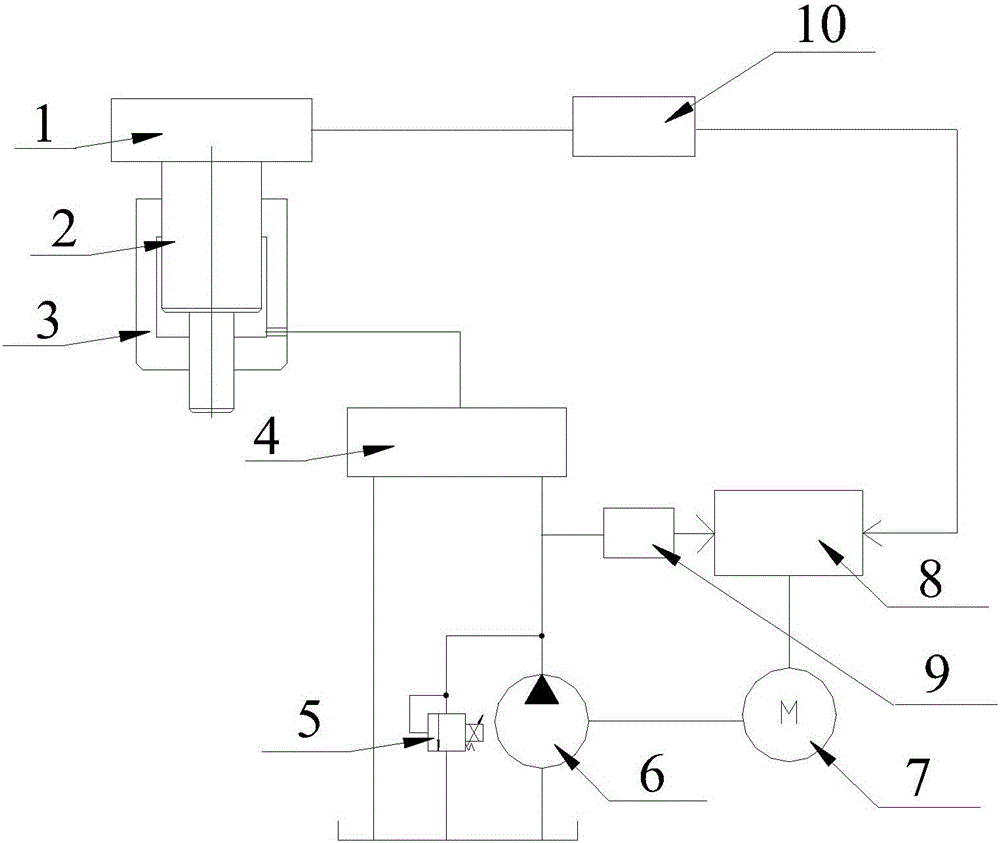

Hydraulic test table of electro-hydrostic actuator

PendingCN110259764AHighlight substantiveSignificant technological progressFluid-pressure actuator testingServometer circuitsHydraulic testEngineering

The invention relates to a hydraulic test table of an electro-hydrostic actuator. The table comprises a test base, a test tool, a hydraulic system, an electric control system and a detection system. Through the test tool, mounting and dismounting of the tested electro-hydrostic actuator can be rapidly finished on the test base, the hydraulic system is used for testing the tested electro-hydrostic actuator, through the electric control system, the hydraulic system and the test process are controlled, through the detection system, test data in the test process can be collected and fed back to the electric control system to be analyzed and treated, the full-automatic test device is provided for the property test of the electro-hydrostic actuator, and the advantages of being high in test precision, high in test efficiency and high in practicability are achieved.

Owner:SHANGHAI UNIV

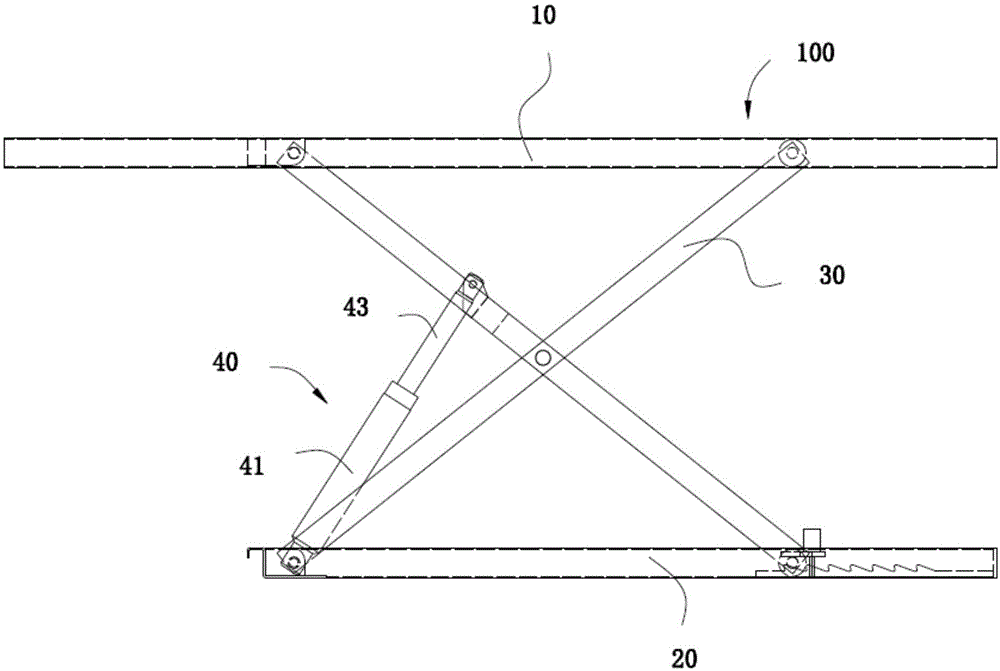

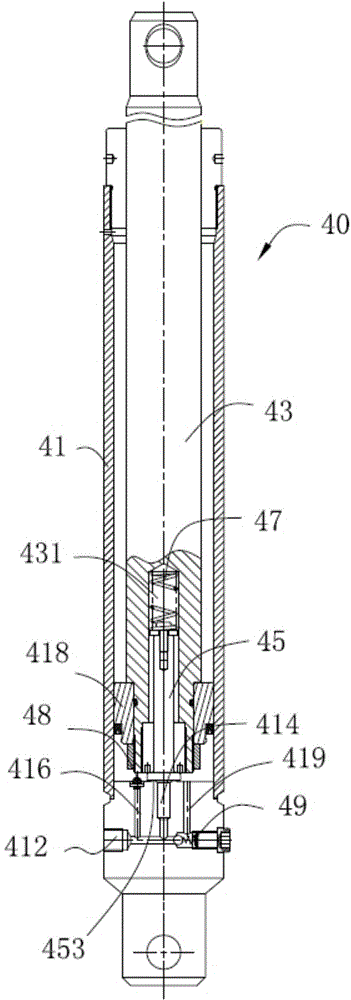

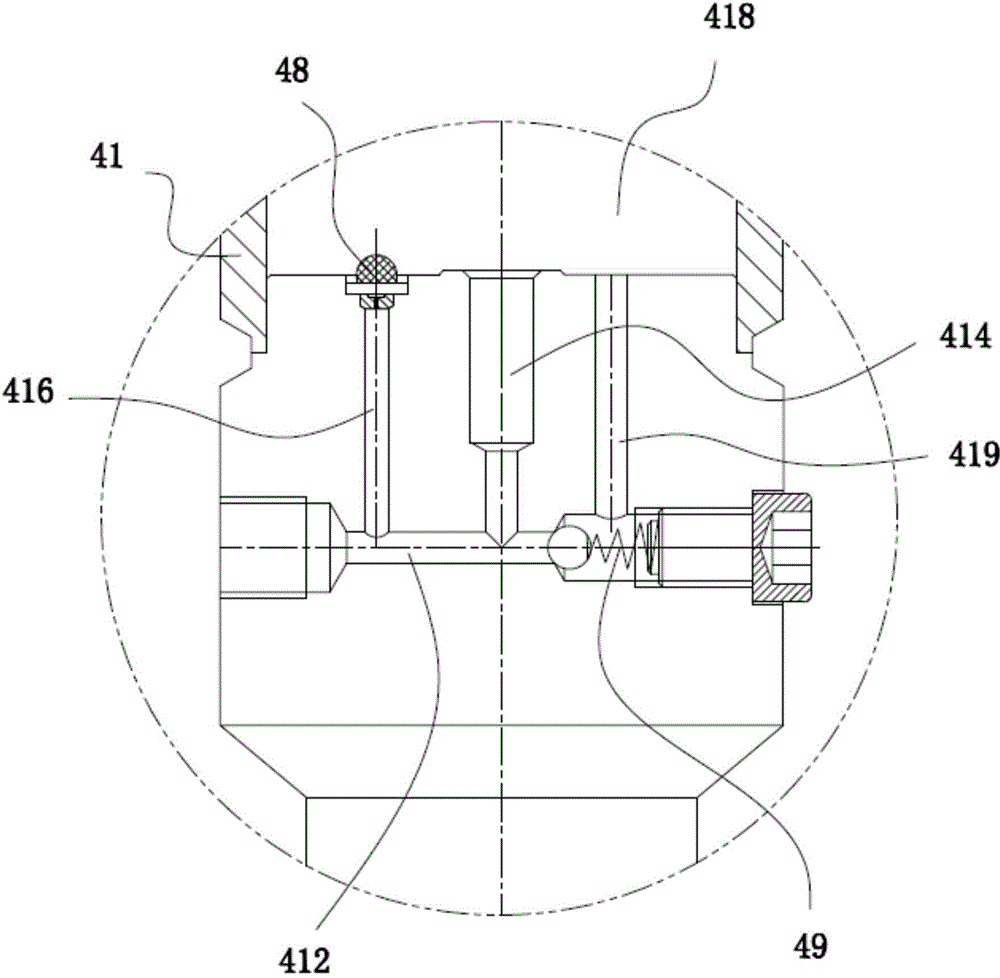

Two-speed hydraulic cylinder and lifting mechanism applying same

ActiveCN104405715AReduce shockExtended service lifeLifting framesFluid-pressure actuatorsCylinder blockEngineering

The invention provides a two-speed hydraulic cylinder and a lifting mechanism applying the same. The invention relates to the two-speed hydraulic cylinder and the lifting mechanism, wherein the hydraulic cylinder comprises a cylinder body and a piston movably arranged in the cylinder body; an oil channel, a fast hole and a damping hole are arranged at the bottom of the cylinder body; the oil channel is used for being communicated with an external oil way; the cylinder body comprises a motion chamber for allowing the piston to do piston motion; the two ends of the fast hole and the two ends of the damping hole are communicated with the oil channel and the motion chamber respectively; the end of the fast hole, which has a large diameter, is communicated with the motion chamber; the hydraulic cylinder further comprises a limit valve rod and an elastic piece, and the limit valve rod is opposite to the fast hole; the end, accommodated in the motion chamber, of the limit valve rod is provided with a blind hole; the elastic piece and part of the limit valve rod are accommodated in the blind hole; and the other part of the limit valve rod extends out of the blind hole under the elastic action of the elastic piece. During the oil return process of the hydraulic cylinder, when the limit valve rod is not propped against the fast hole, the hydraulic cylinder returns oil simultaneously through a fast channel and a slow channel, and when the limit valve rod is propped against and seal the fast hole, the hydraulic cylinder returns oil only through the slow channel.

Owner:江苏海力达机电制造有限公司

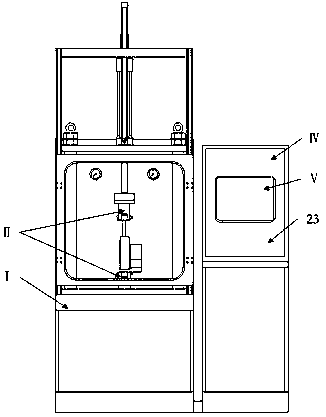

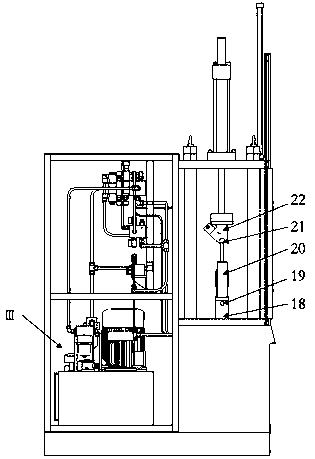

Alternating current servo drive fine blanking machine

InactiveCN105057434AImprove machining accuracyIncrease productivityMetal working apparatusThick plateMaster cylinder

The invention discloses an alternating current servo drive fine blanking machine. The alternating current servo drive fine blanking machine comprises a master cylinder, a workbench, a directional valve control system and a pump control system. A piston rod on the master cylinder is connected with the workbench. The directional valve control system and the pump control system are connected with the master cylinder. A position sensor used for detecting the position of the workbench in the perpendicular direction is arranged on the workbench. Position signals detected by the position sensor are transmitted to a servo motor controller in the pump control system. The servo motor controller transmits fine blanking speed signals corresponding to the position signals to an alternating current servo motor in the pump control system, and finally the operation speed of the piston rod on the master cylinder is controlled. With the alternating current servo drive fine blanking machine, the current situation that because the fine blanking speed of a traditional fine blanking machine is constant, the request for fine blanking machining on thick plates and composite materials cannot be met is changed, the speed of fine blanking is controlled in real time according to the position changes of the workbench, and therefore production efficiency and machining accuracy are improved.

Owner:WUHAN RIVET MACHINERY

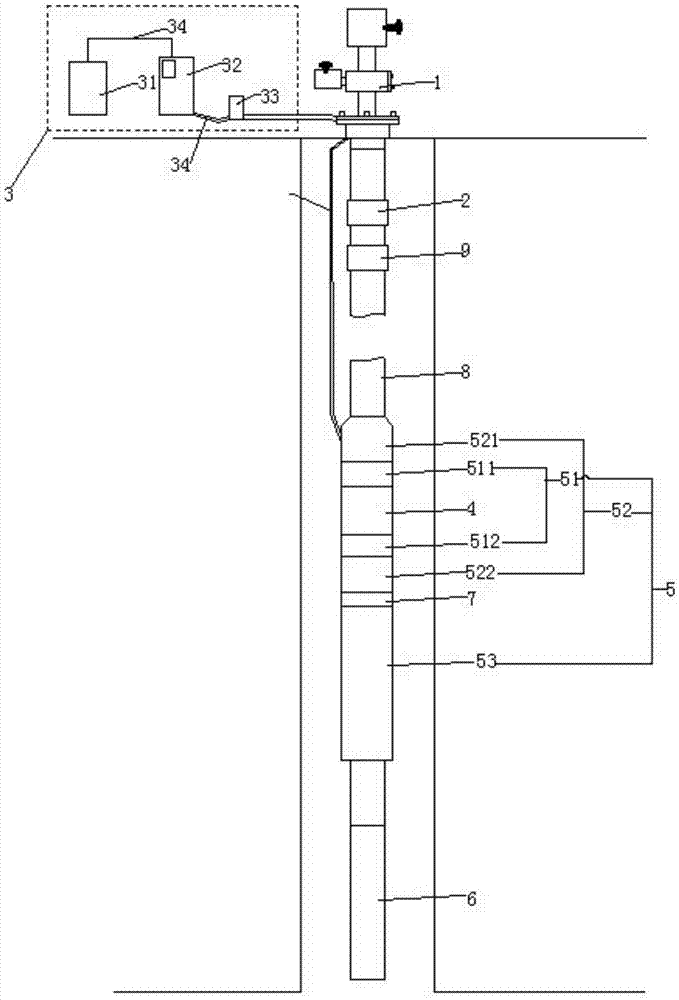

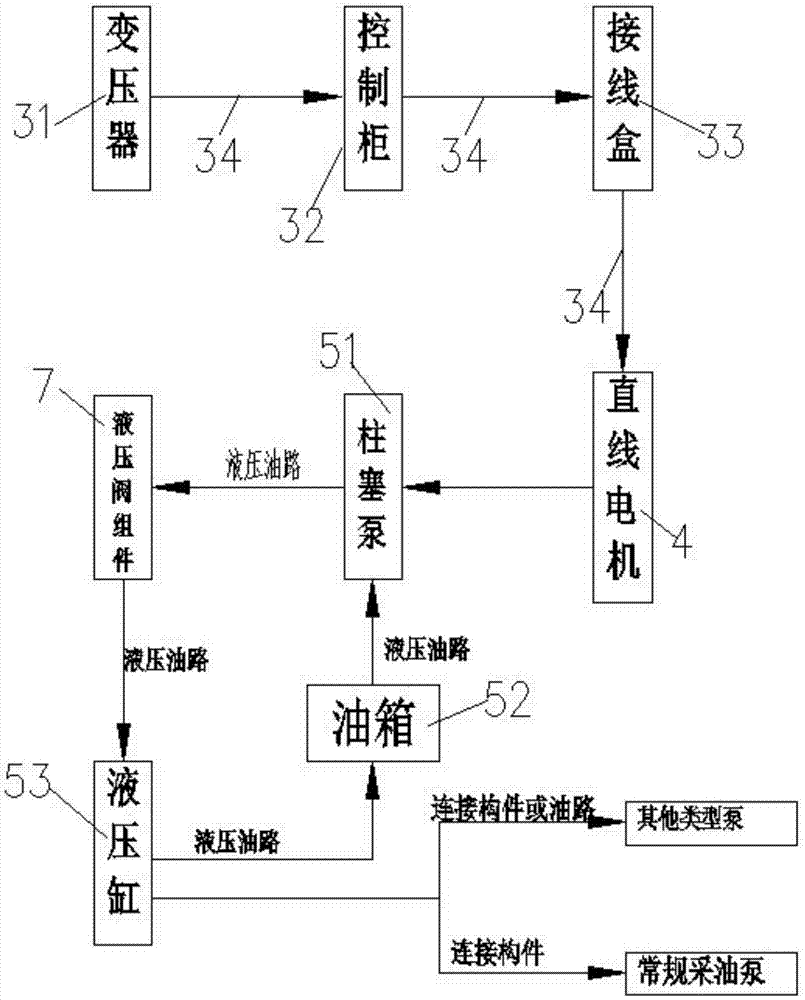

Linear motor drive and hydraulic driven oil pumping unit for oil extraction

ActiveCN105443082AReduce usageSolve the heavy load of rod-type oil recoveryFluid removalElectric machineReciprocating motion

The invention relates to a linear motor drive and hydraulic driven oil pumping unit for oil extraction, which comprises well head equipment, an oil pipe, electric control equipment, a linear motor, a hydraulic power system and an oil extraction pump, wherein the well head equipment is connected with the linear motor through the oil pipe; the electric control equipment is used for controlling the linear motor and supplying power to the linear motor; the linear motor is arranged in a well and provides power for the hydraulic power system; the hydraulic power system can provide power for the oil extraction pump to do up-down reciprocating motion. The linear motor drive and hydraulic driven oil pumping unit for oil extraction has the beneficial effects of overcoming the technical defects of complex ground equipment, high one-time investment maintenance cost and poor adaptability.

Owner:韩祥林

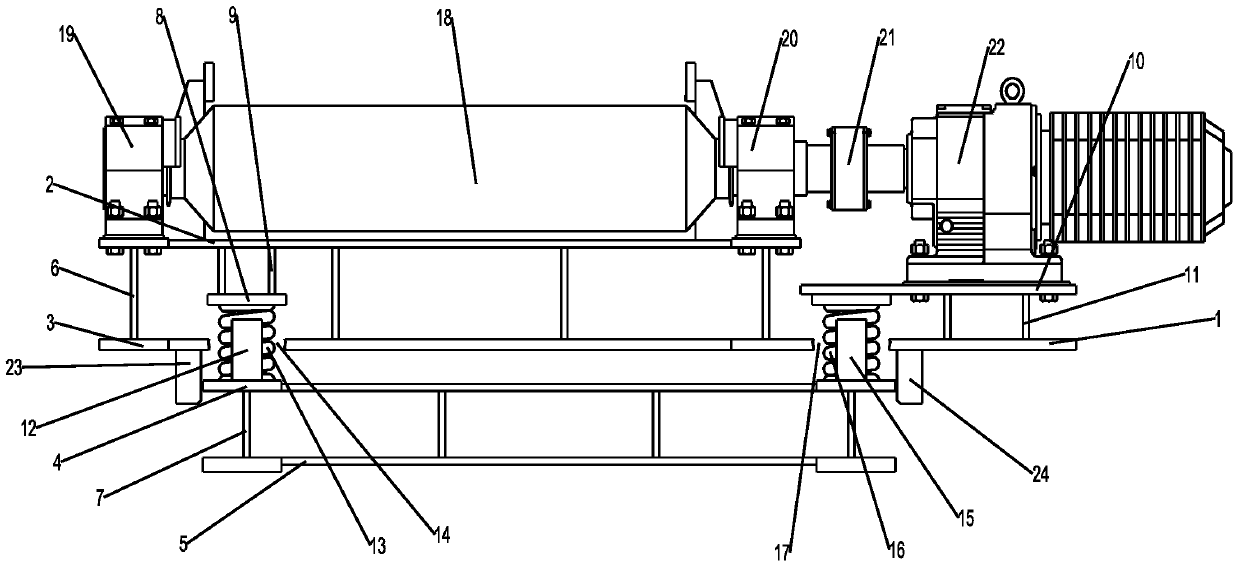

Loading roller way with buffer device

InactiveCN105509482AReduce shockExtended service lifeCharge manipulationMechanical equipmentEngineering

The invention belongs to the technical field of mechanical equipment, and in particular, relates to a loading roller way with a buffer device. The loading roller way comprises a bearing base; the bearing base includes a first layer of support plates, a second layer of support plates, a third layer of support plates and a fourth layer of support plates arranged from top to bottom; the first layer of support plates and the second layer of support plates are connected through connecting plates A; the third layer of support plates and the fourth layer of support plates are connected through connecting plates B; middle support plates A and middle support plates B are arranged between the first layer of support plates and the second layer of support plates; the middle support plates A are connected with the first layer of support plates through connecting plates C; the middle support plates B and the second layer of support plates are connected through connecting plates D; limiting columns A and limiting columns B are arranged on the third layer of support plates; the limiting columns A are coated with springs A; and the limiting columns are coated with springs B.

Owner:TIANJIN TIANZHONG ZHONGZHI TECH ENG CO LTD

Method of carrying cigarette assisted by slight friction force and apparatus thereof

Owner:GUIYANG PUTIAN LOGISTICS TECH

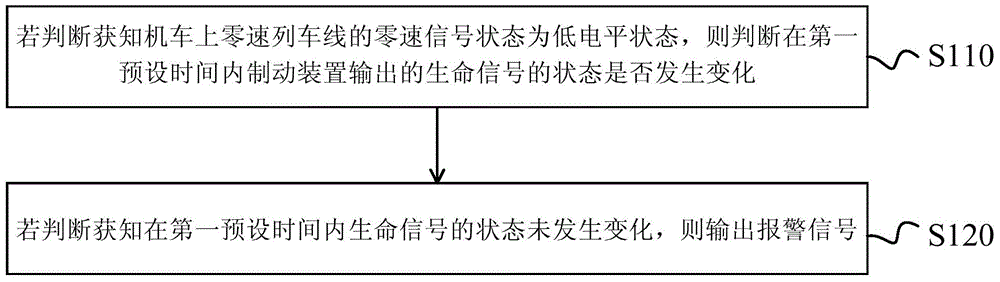

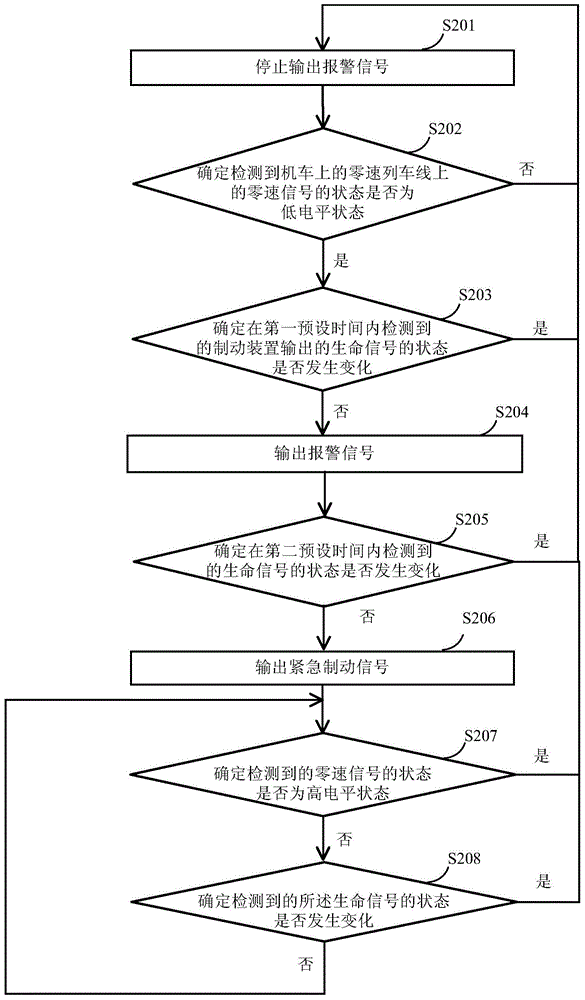

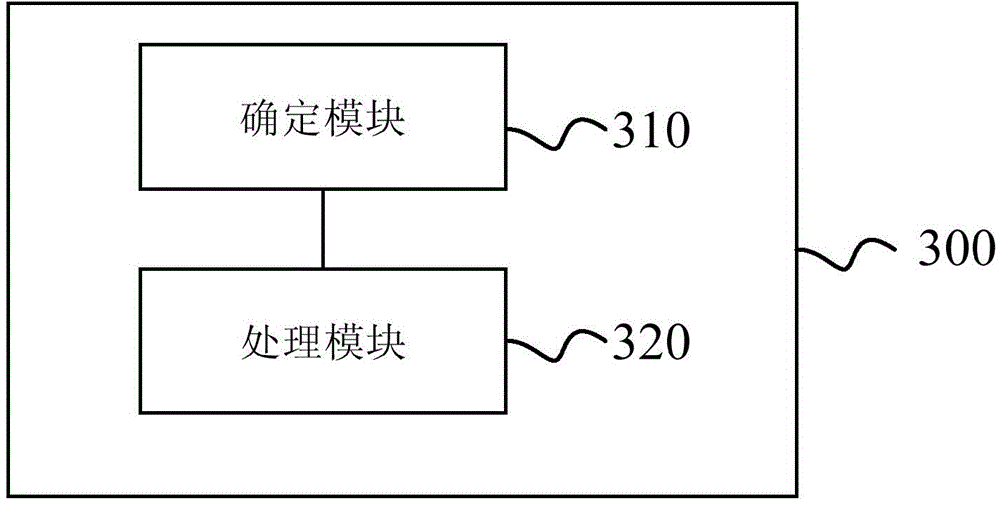

Fool-proof control method and fool-proof control device

The invention provides a fool-proof control method and a fool-proof control device. The fool-proof control method comprises the following steps: if the zero-speed signal state of a zero-speed train line on a locomotive is judged to be in a low-level state, judging whether the state of a life signal output by a brake device changes within the first preset time, and if the state of the life signal is judged to be unchanged within the first preset time, outputting an alarm signal. By the fool-proof control method, the problem that in the prior art, drivers cannot be effectively reminded is solved.

Owner:CRRC DALIAN R & D CO LTD

Control device and method for autonomous positioning docking charging of high-voltage line inspection robot

InactiveCN103825338BControl running speedImprove the efficiency of autonomous charging and dockingBatteries circuit arrangementsElectric powerProximity sensorHigh pressure

The invention discloses a device and a method for controlling self-localization, butting and charging of a high-voltage line inspection robot. According to the device and the method, the specific position of the robot in a high-voltage power transmission line is located through a GPS-GIC (Global Position System-Geographic Information System) technology according to a self line structure of the high-voltage power transmission line and a self obstacle crossing function of the robot, and a moving speed of the robot in the high-voltage power transmission line is controlled by combining an ultrasonic wave sensor and a hall proximity sensor, so that the efficiency of an automatic butting process is improved; joints of the robot are controlled by using a speed mode, a moment mode and a position mode, so that the charging and butting process is accurately controlled; finally, the charging and butting process is accurately adjusted according to signal feedback of a strain gage of a charging plug and the hall proximity sensor, so that the tangential internal stress between the charging plug and a charging socket is reduced and the safe and reliable processing of the charging process is ensured.

Owner:WUHAN UNIV

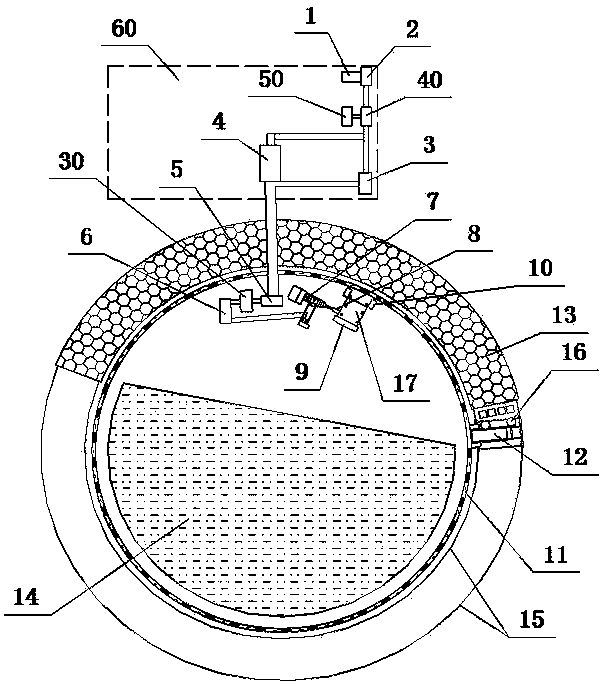

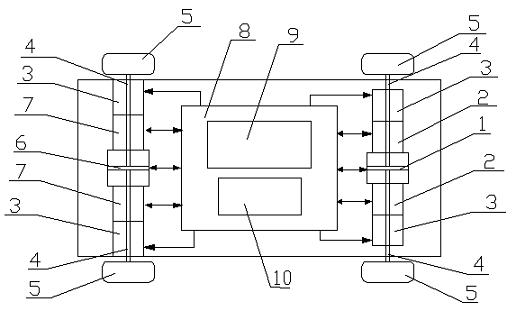

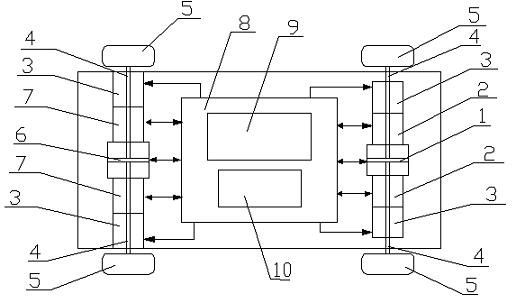

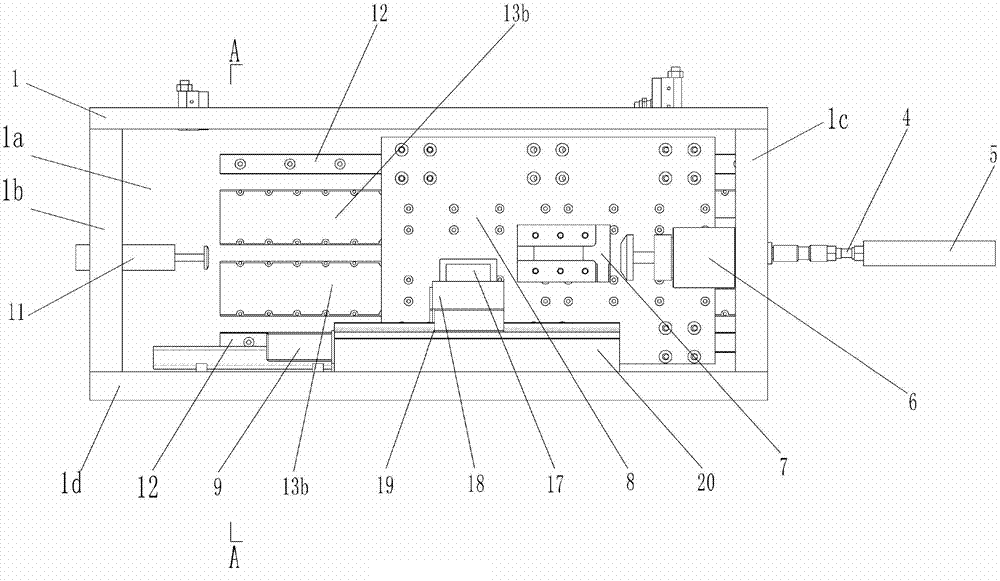

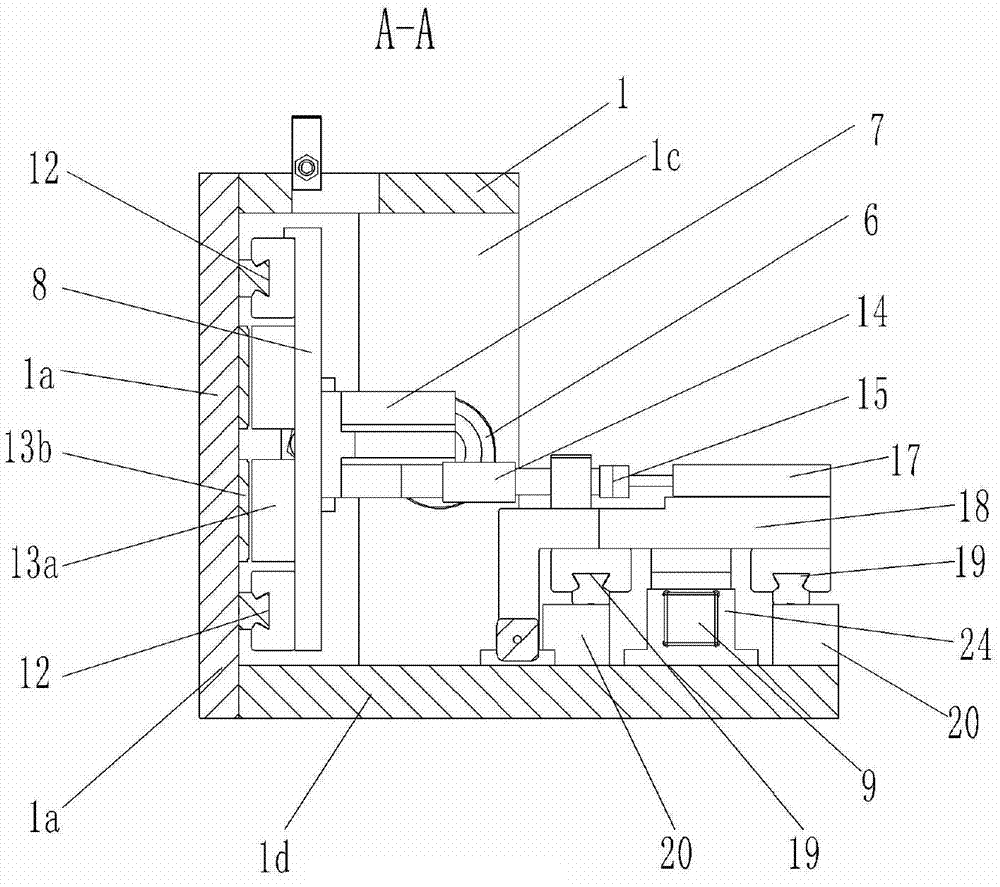

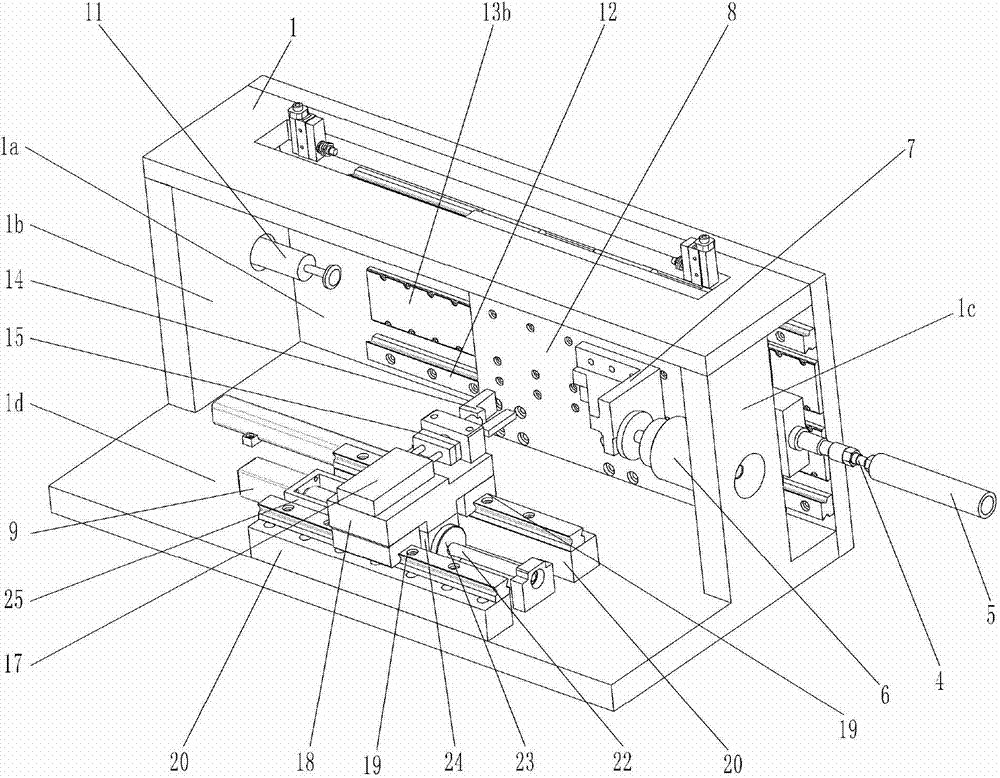

Pulse stick driving mechanism

InactiveCN104217771APrecisely control the running speedControl running speedNuclear energy generationNuclear reaction controlElectric machineryLinear motor

A pulse stick driving mechanism includes a connecting rod (4) which connects a pulse stick (5) and is connected to a power mechanism. The power mechanism is composed in a following manner: a rotor (13a) of a linear motor is fixed to a vertically-arranged sliding bench (8); the sliding bench (8) is connected to a side plate (1a) of a rack (1) through a guide rail pair (12); a stator (13b) of the linear motor is fixed to the side plate (1a); a front plate (1c) and a back plate (1b) of the rack (1) are respectively provided with a front buffer (6) and a back buffer (11); the sliding bench (8) is provided with an impacting block (7); and the front buffer (6) is aligned with a front part of the impacting block (7) and the back buffer (11) is aligned with a back part of the impacting block (7). By means of the driving mechanism, a launching speed can be increased. In addition, the pulse stick driving mechanism is less in impact and oscillation at an operating end and can achieve continuous and accurate control of the speed of a pulse stick.

Owner:SOUTHWEST JIAOTONG UNIV

Traction type elevator

InactiveCN109775520AControl running speedAchieve movementElevatorsBuilding liftsElectricityElectric machinery

The invention relates to a traction type elevator. The traction type elevator comprises a traction guide device as well as a counterweight device and an elevator car which are connected to the two sides of the traction guide device, wherein the traction guide device is electrically connected with a motor and a control device; the counterweight device adopts a sealed piston type structure which comprises a longitudinal piston barrel, wherein a counterweight is arranged in the piston barrel, a piston motion space for allowing the counterweight to move up and down is arranged in the piston barrel, a gas-sealing device which can be tightly in contact with the inner wall of the piston barrel to reach the sealing effect is arranged on the counterweight, and the position, close to the lower end,of the piston barrel is equipped with a movable air door capable of controlling the size of an air door through the control device. The traction type elevator can process extra energy generated when the traction type elevator is under a power generation state, and is better in safety performance.

Owner:郭媛媛

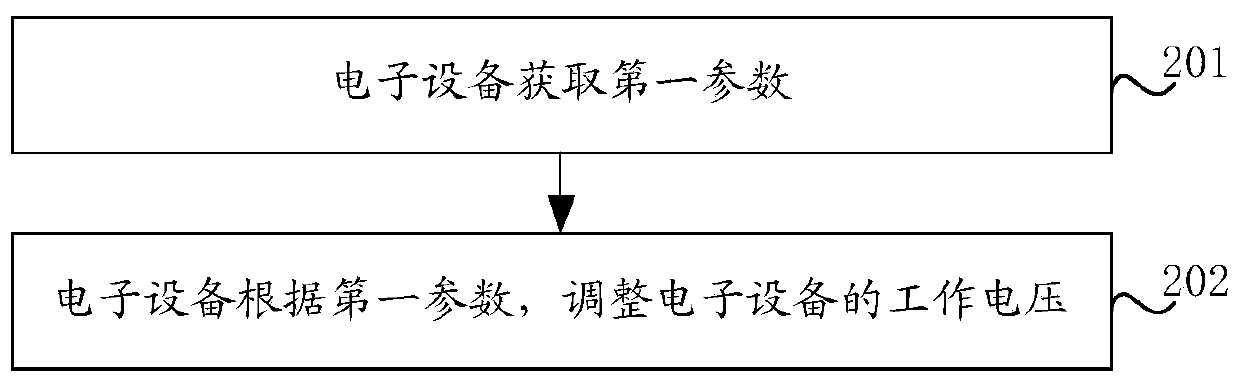

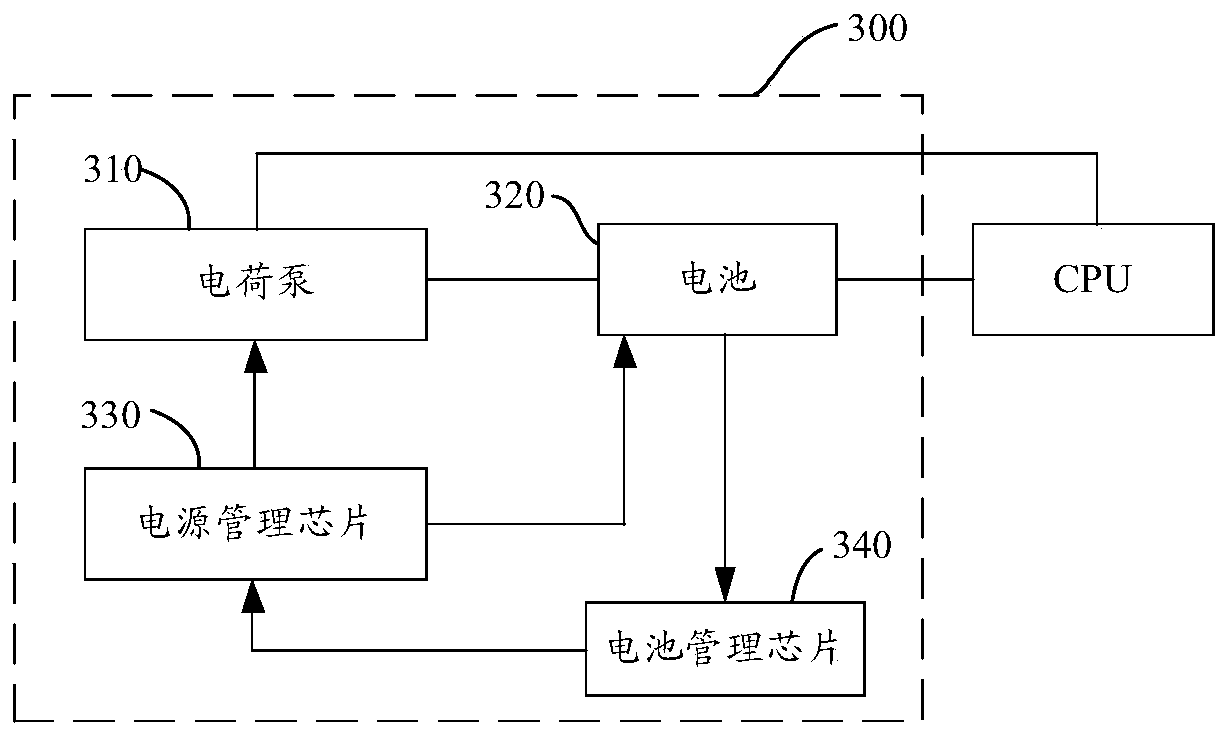

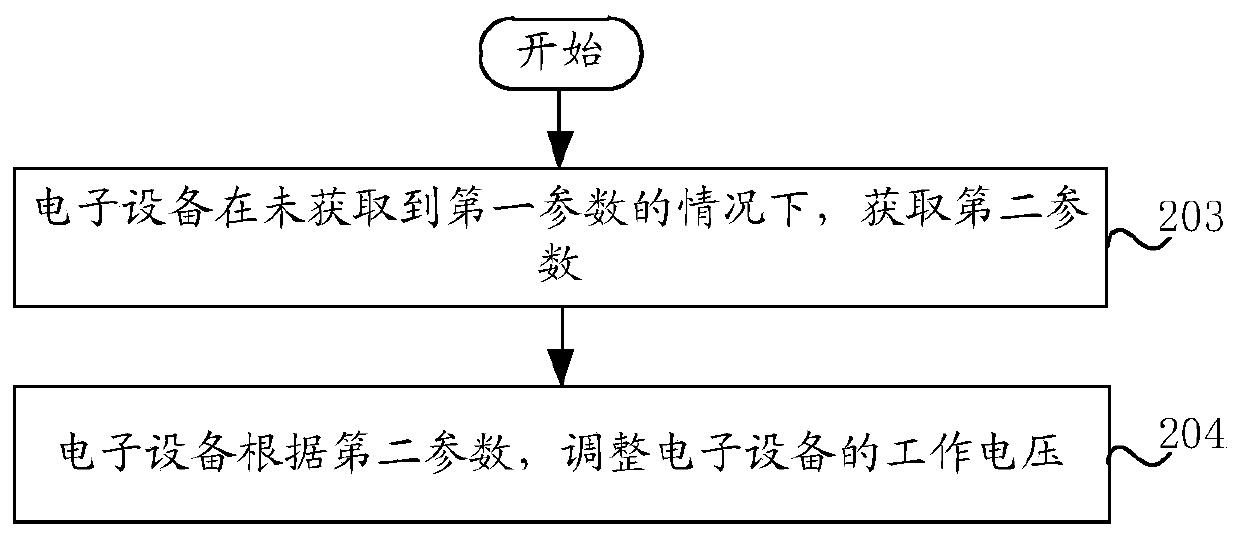

Voltage control method and electronic equipment

ActiveCN110941326AControl running speedPrevent overheatingDigital data processing detailsHigh electronControl theory

The embodiment of the invention provides a voltage control method and electronic equipment, relates to the technical field of communication, and aims to solve the problems that the operating stabilityof the electronic equipment is reduced and the service life of the electronic equipment is shortened due to the fact that the temperature of the electronic equipment is increased by increasing the working voltage of the electronic equipment. The method comprises the steps of obtaining a first parameter; according to the first parameter, the working voltage of the electronic equipment is adjusted,and the first parameter comprises at least one of the following items: the heart rate of the target user and the operation frequency of the target user for operating the electronic equipment. The method is applied to a scene that a user uses the electronic equipment.

Owner:VIVO MOBILE COMM CO LTD

Traction type elevator

InactiveCN101966951AControl running resistanceControl running speedElevatorsBuilding liftsElectricityTraction system

The invention relates to a traction type elevator which comprises a traction guiding device, a counterweight device and an elevator car, wherein the counterweight device and the elevator car are connected with the two sides of the traction guiding device; the traction guiding device is electrically connected with a motor and a control device; a sealed piston type structure is adopted by the counterweight device; the sealed piston type structure comprises a longitudinal piston barrel; a counterweight is arranged in the piston barrel; a piston motion space for the counterweight to move up and down is formed in the piston barrel; a hermetic sealing device which can be in close contact with the inner wall of the piston barrel to achieve the sealing effect is arranged on the counterweight; and a movable throttle of which the magnitude can be controlled by the control device is arranged in the position near the lower end of the piston barrel. The invention can better consume the extra energy generated by an elevator traction system in a generating state, and the safety performance is better.

Owner:GUANGDONG HUANYU ELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com